Patents

Literature

41results about How to "Avoid empty trips" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

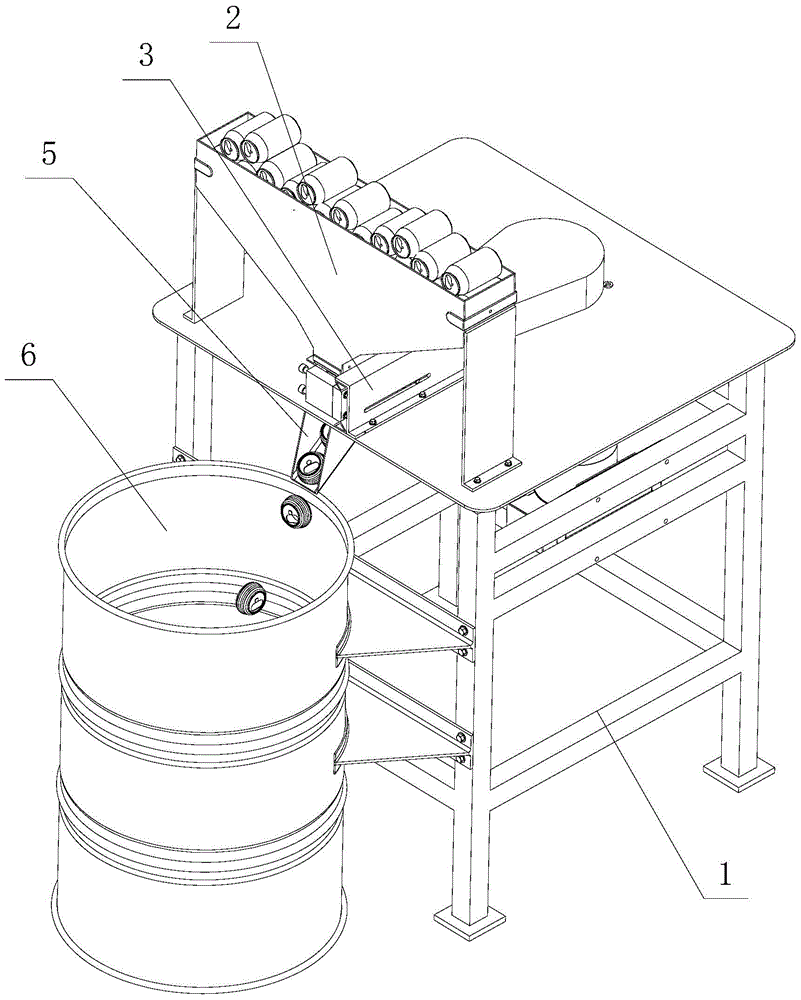

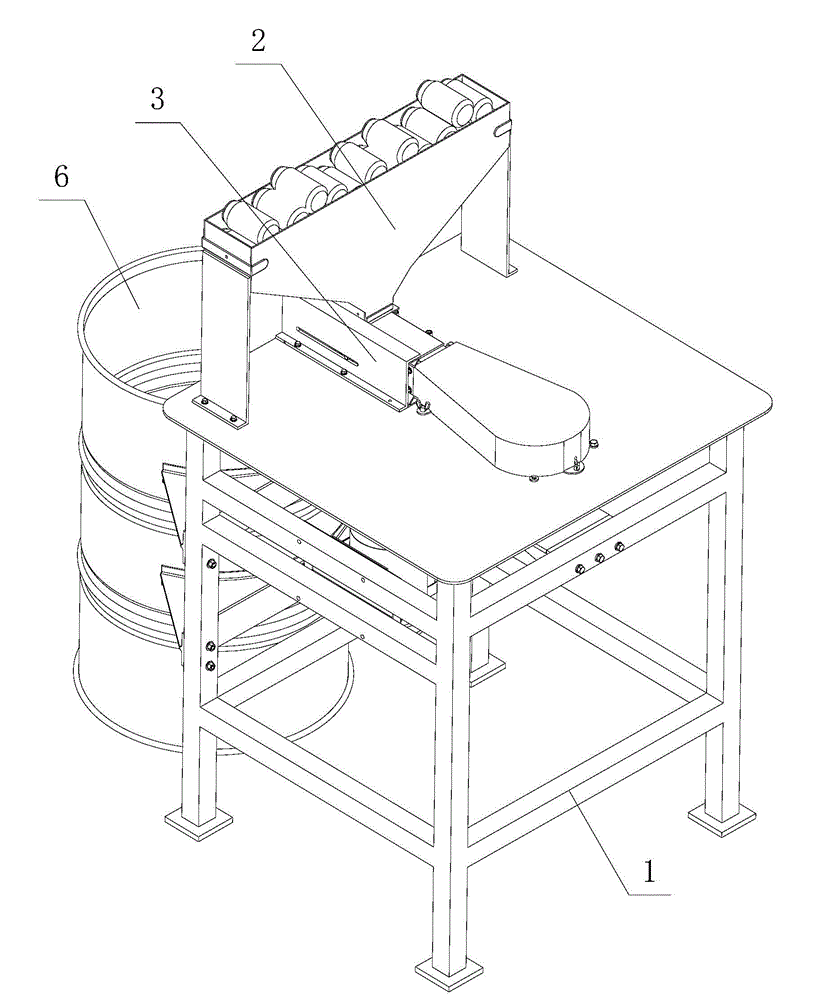

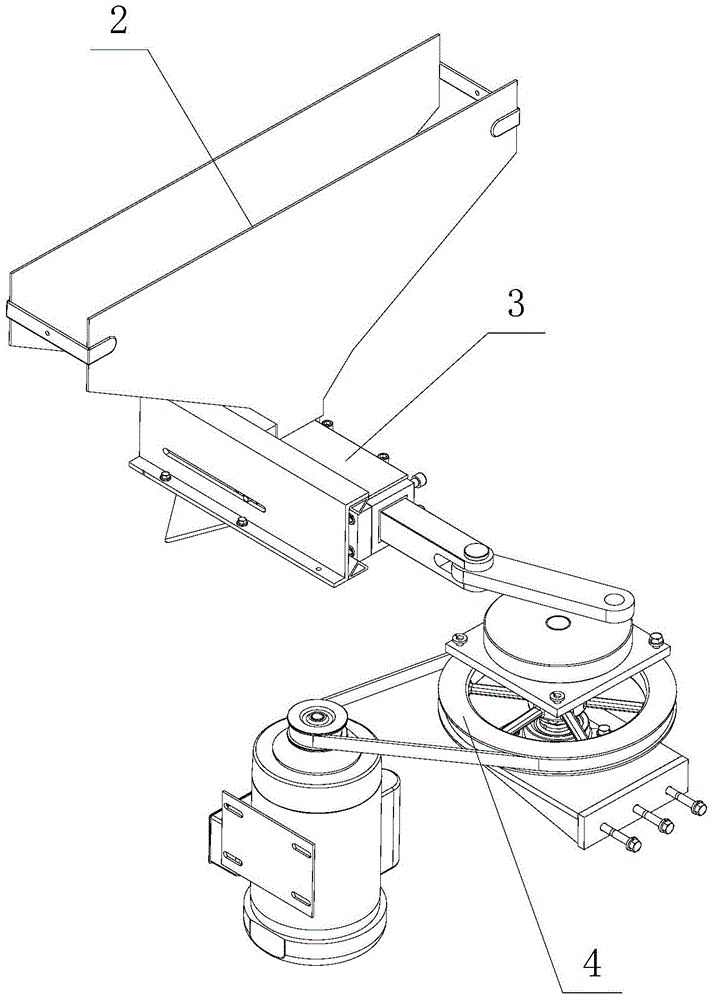

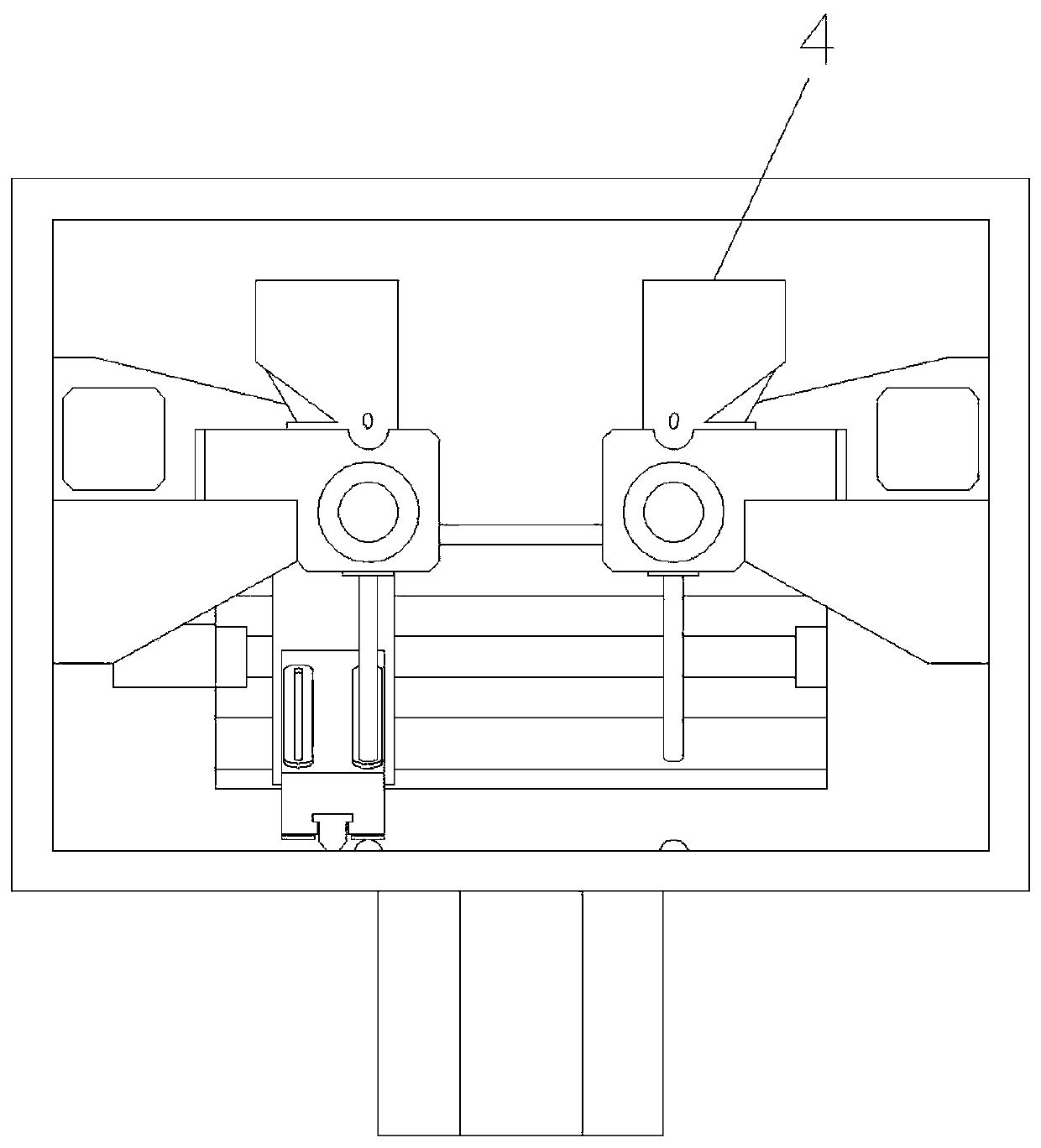

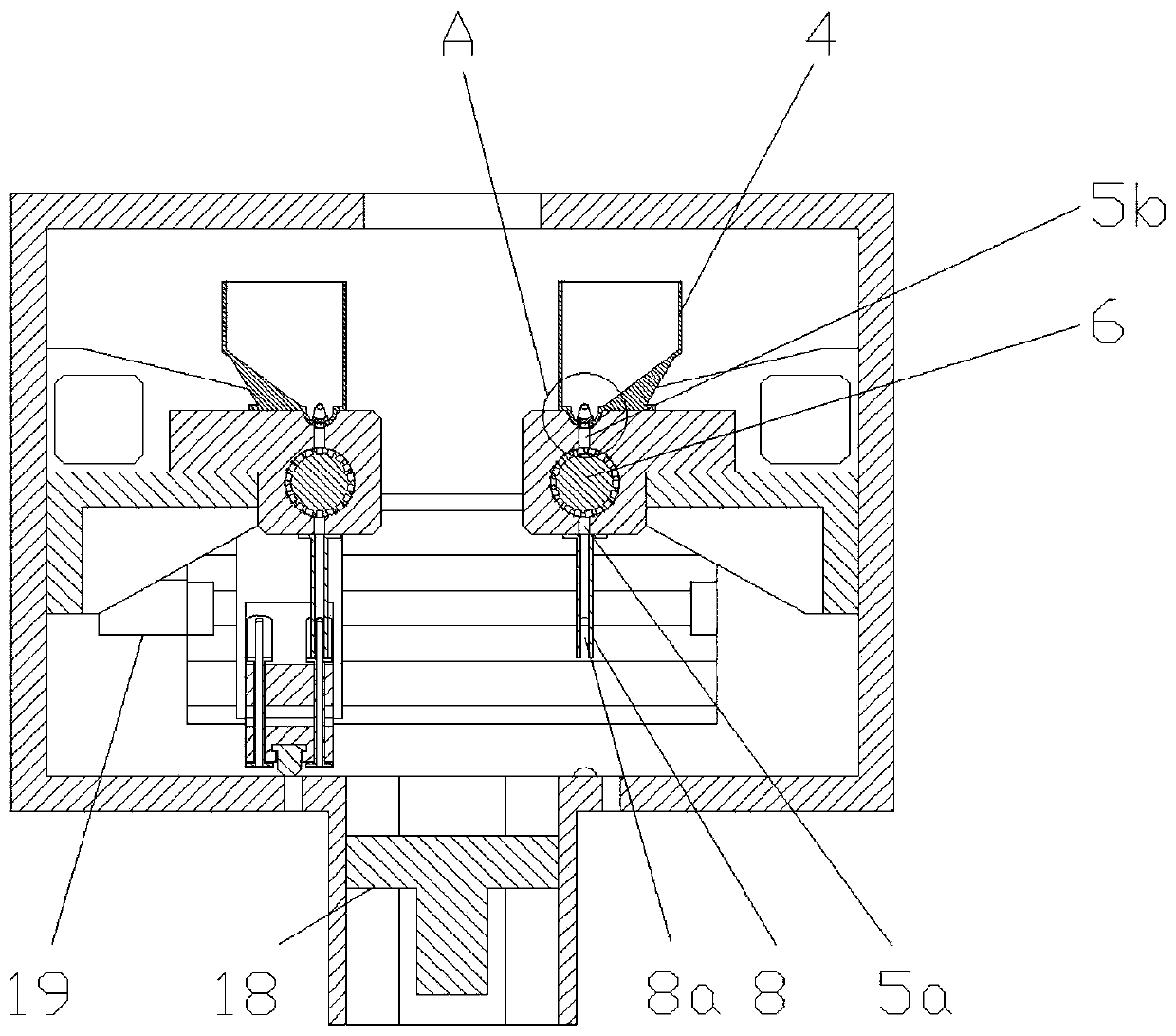

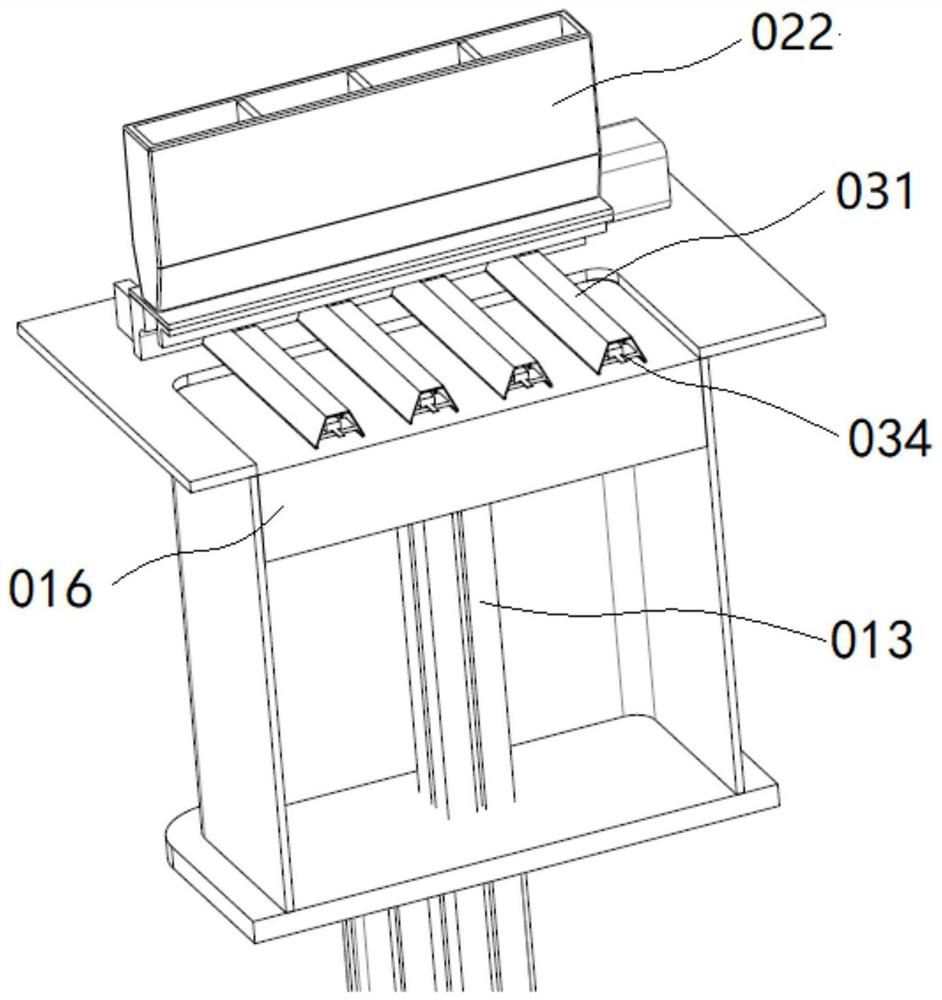

Pop can flatting machine

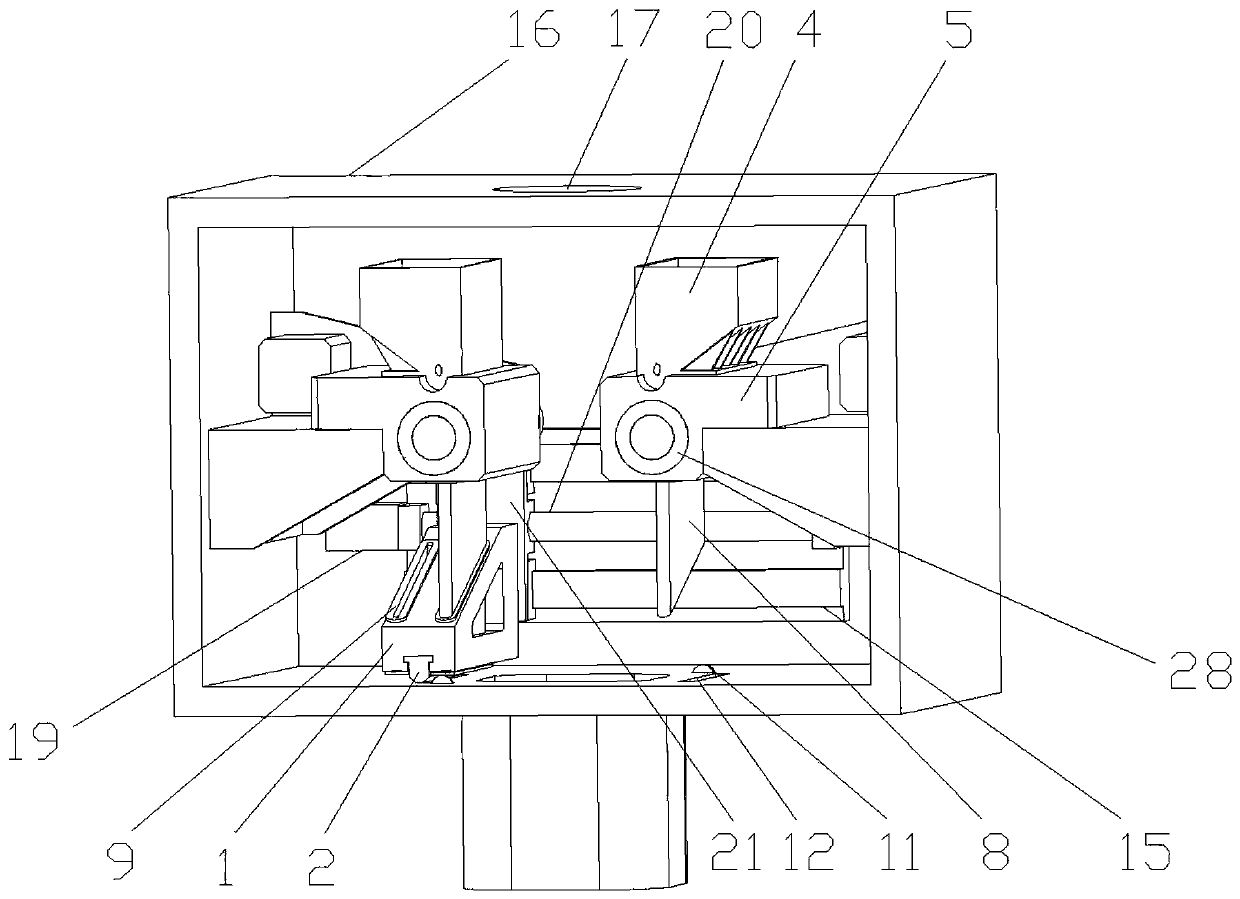

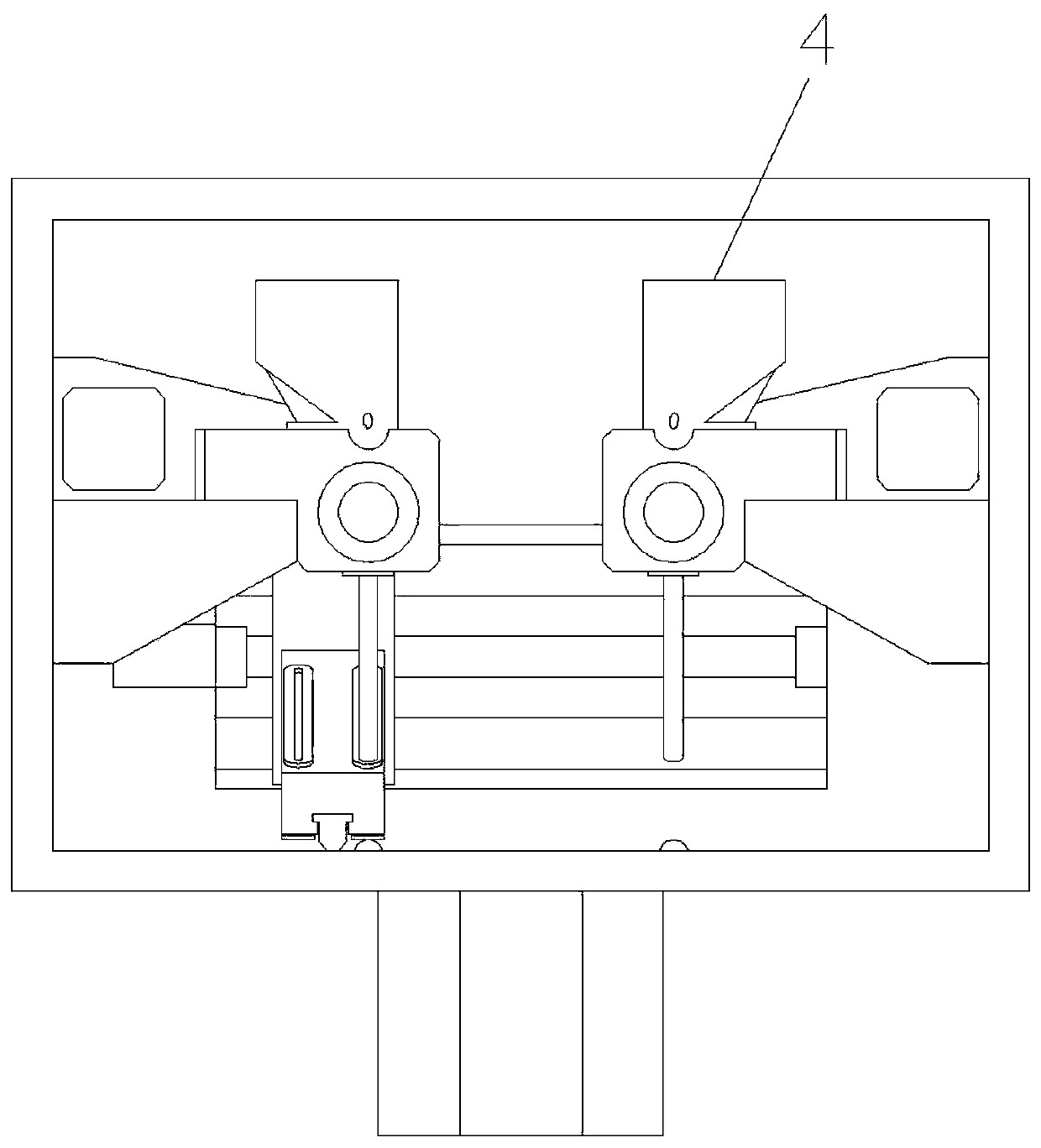

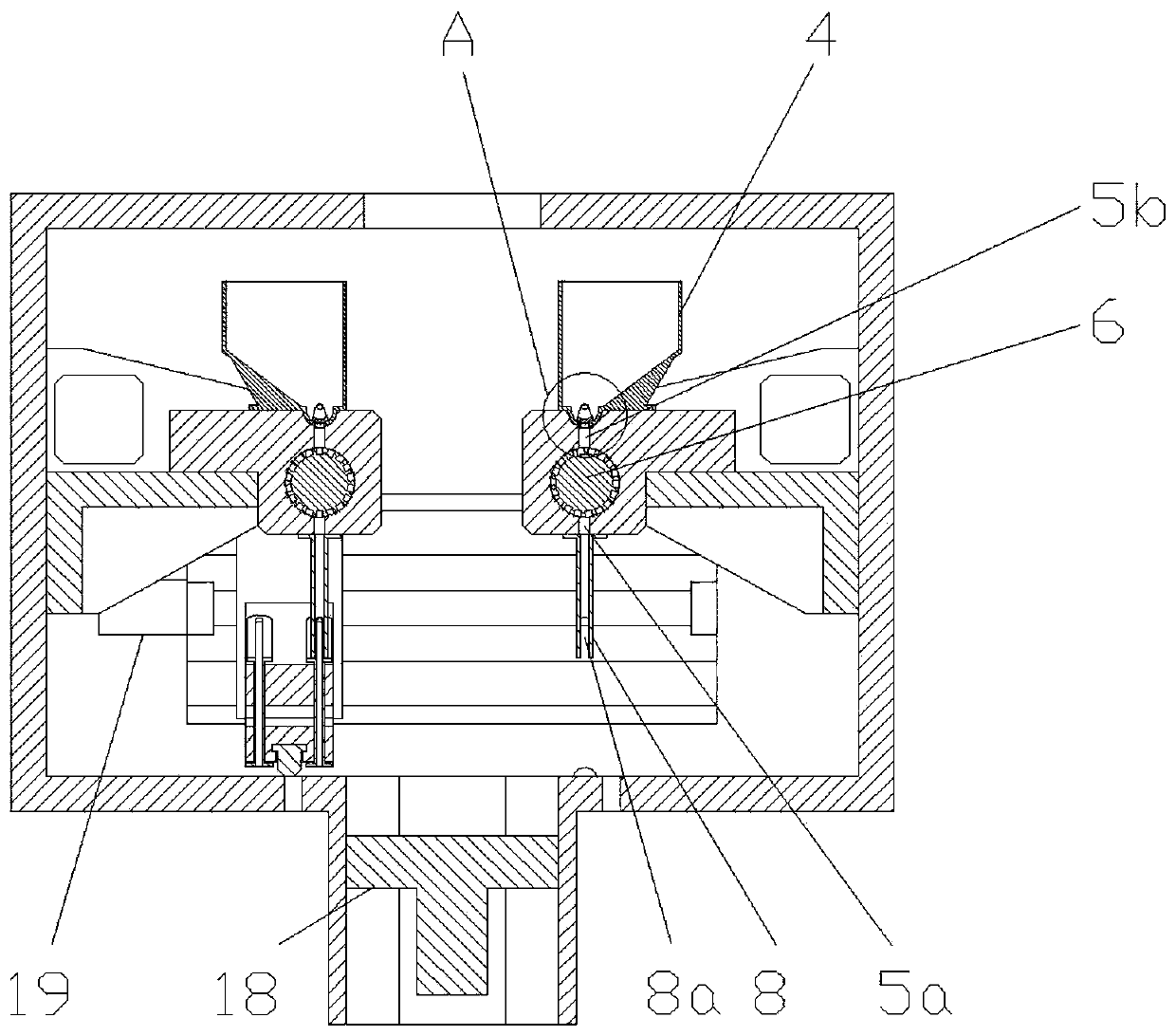

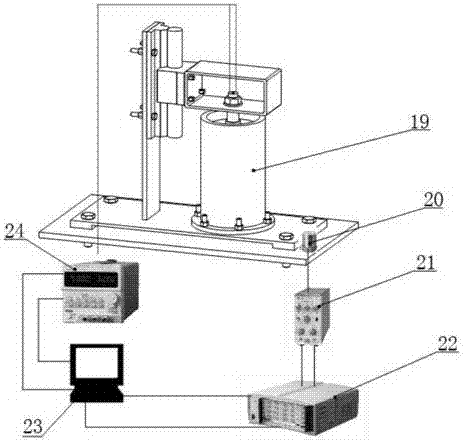

The invention provides a pop can flatting machine which comprises a rack, a hopper, a pressing mechanism and a driving mechanism, wherein the rack is used for supporting and mounting other components; the hopper is fixedly arranged on the rack and used for accommodating pop cans; the bottom of the hopper is provided with a discharge hole, and the pop cans are discharged through the discharge hole; a pressing cavity is formed in the pressing mechanism and is positioned under the discharge hole of the hopper; the pressing mechanism is internally provided with a pressure lever capable of changing the volume of the pressing cavity; the bottom of the pressing cavity is provided with a discharge opening, and the flatted pop cans are discharged through the discharge opening; the driving mechanism is connected with the pressure lever and used for driving the pressure lever to reciprocate. The pop can flatting machine is simple in structure, convenient to operate, high in pressing efficiency, good in pressing effect and stable in operation.

Owner:WENZHOU POLYTECHNIC

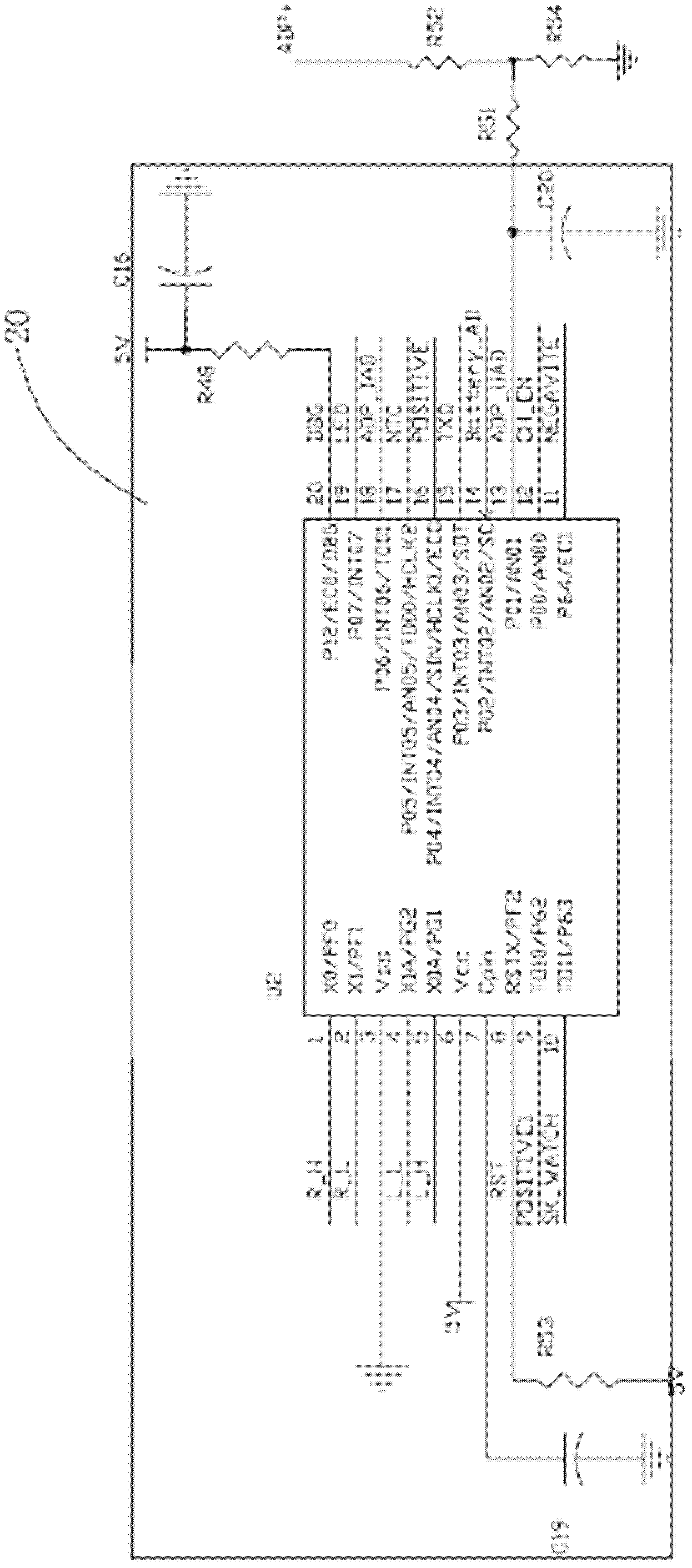

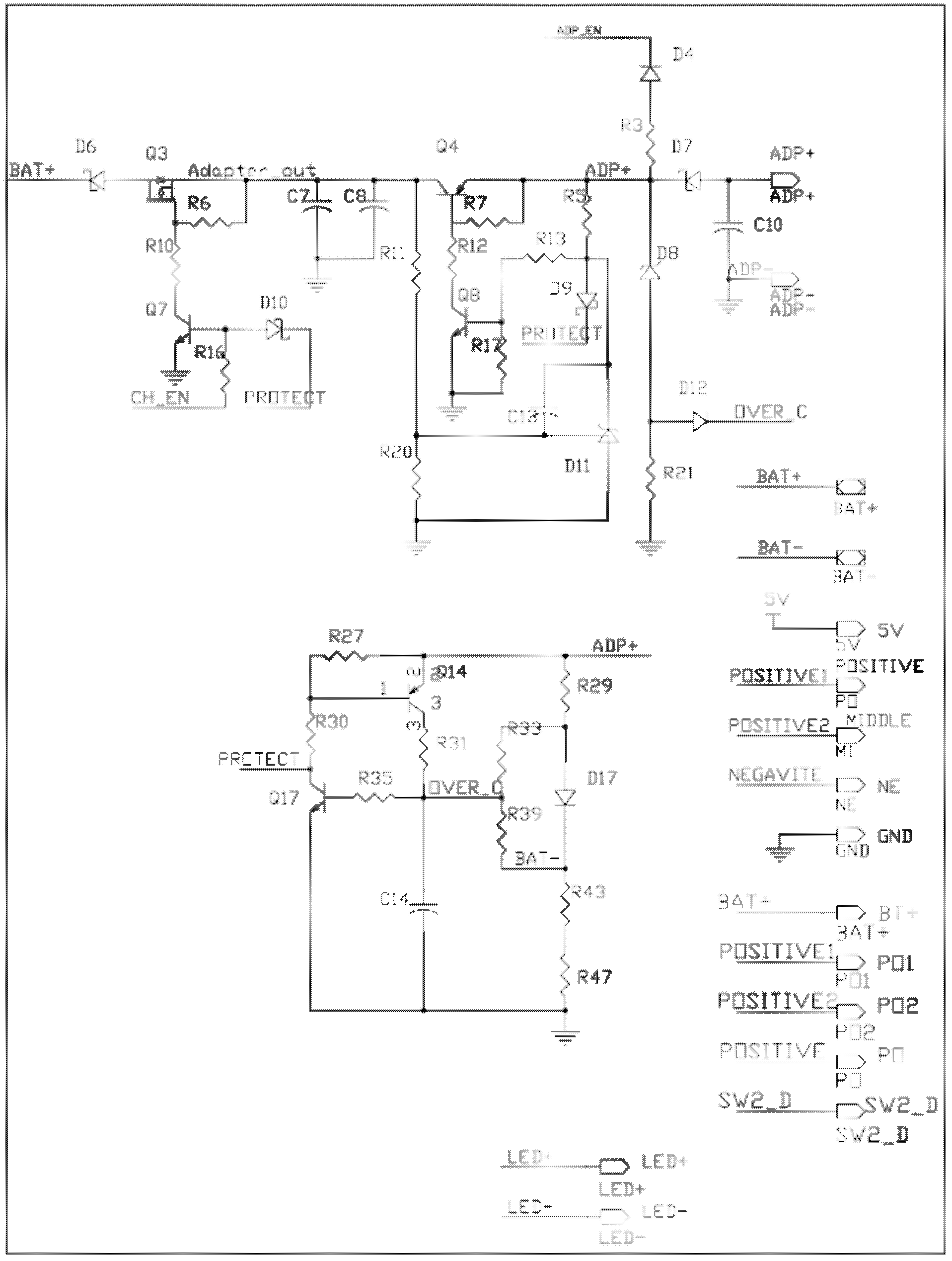

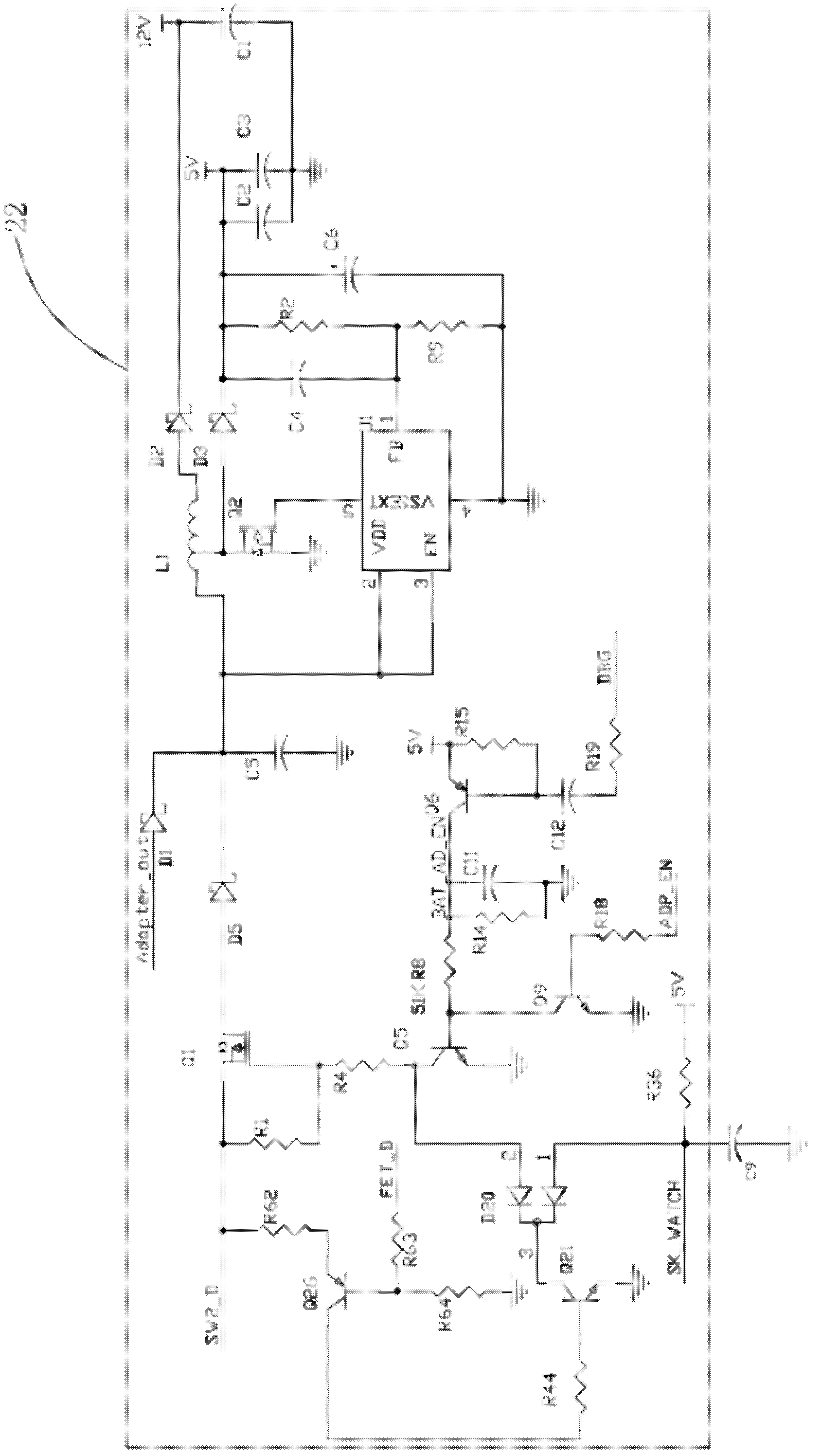

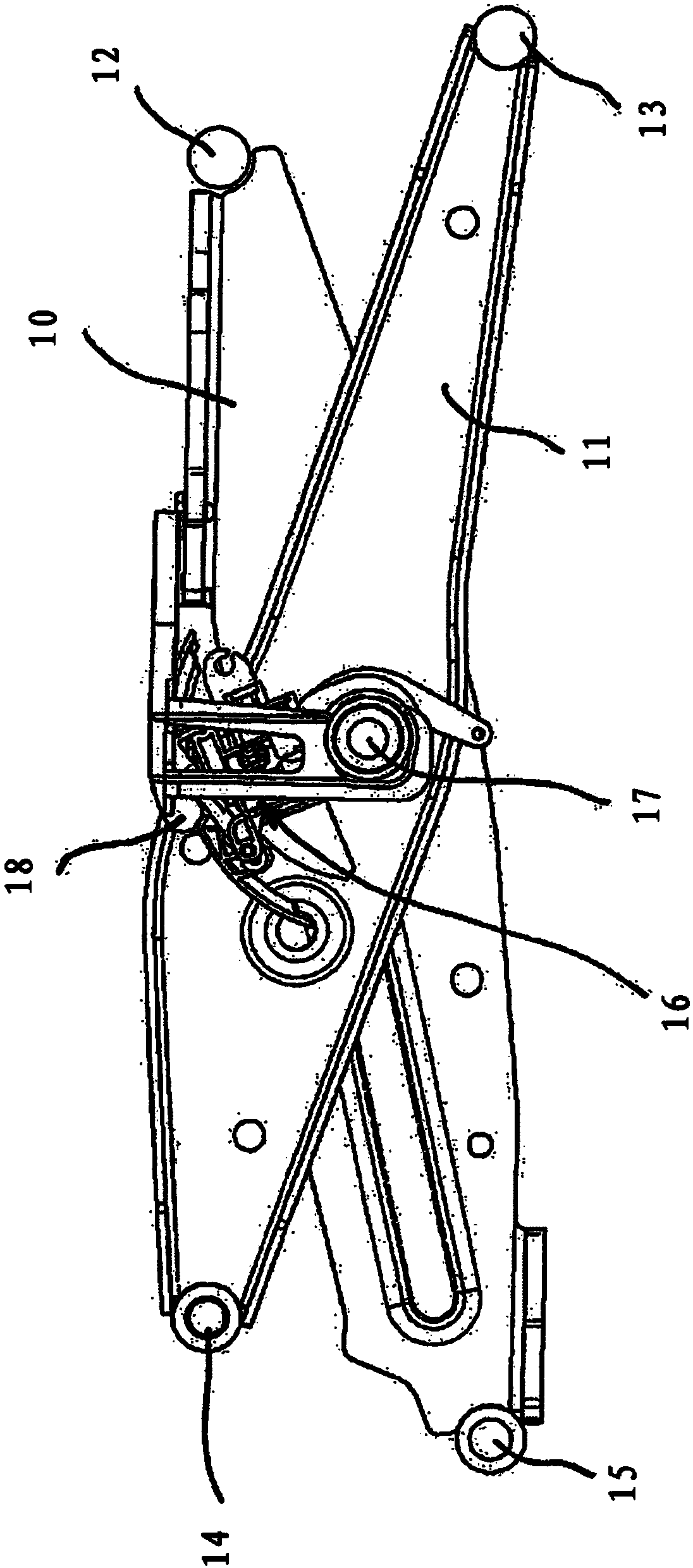

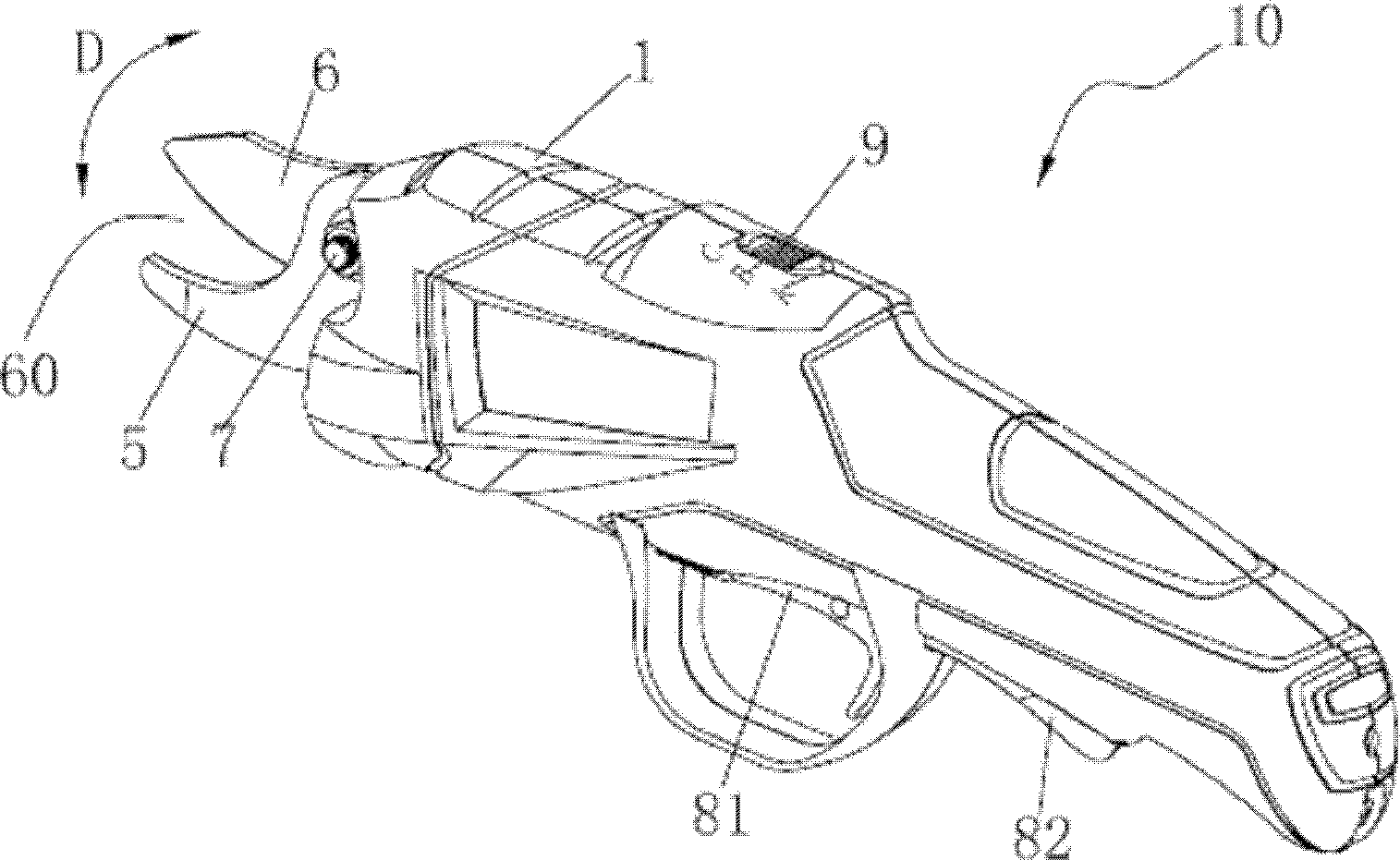

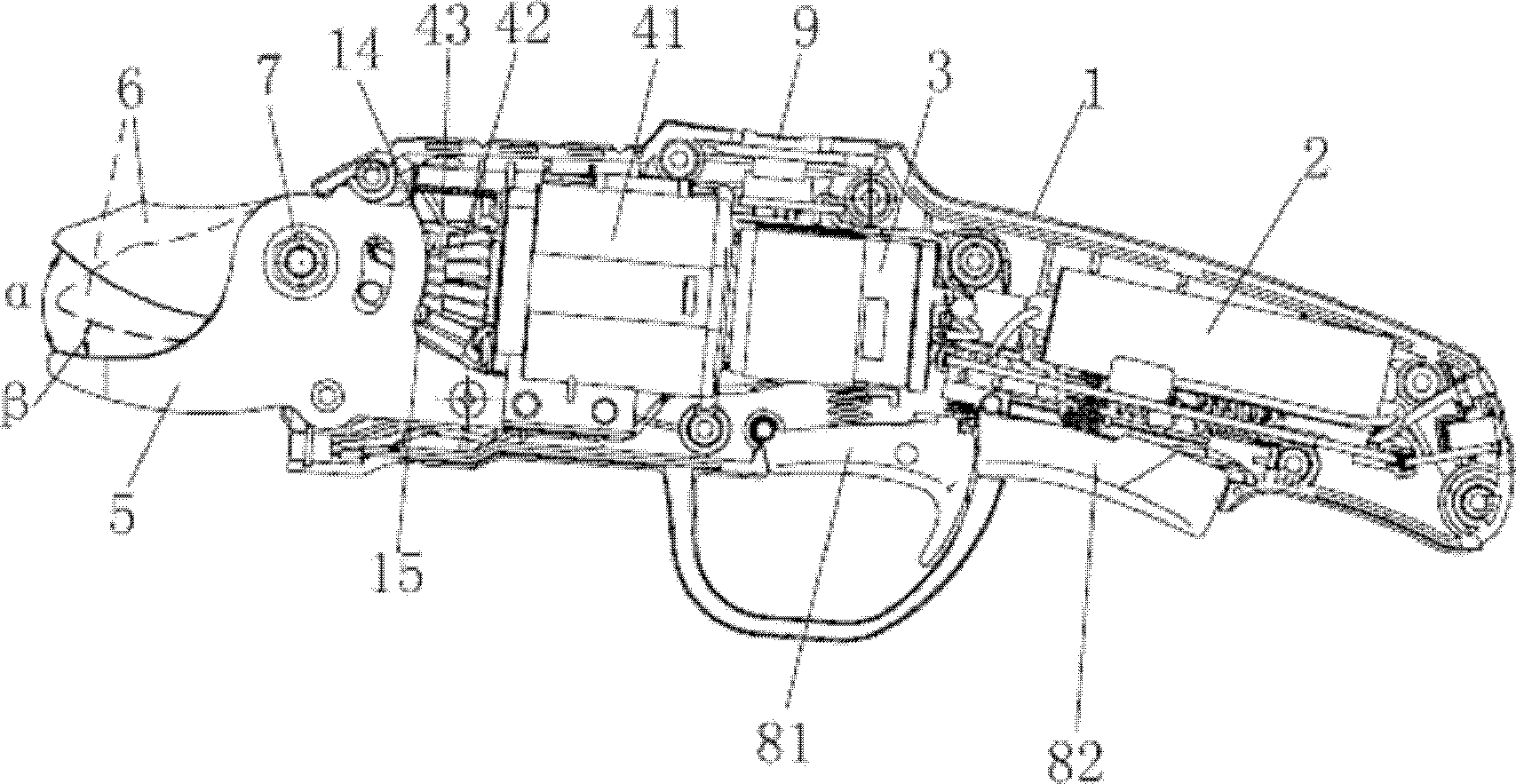

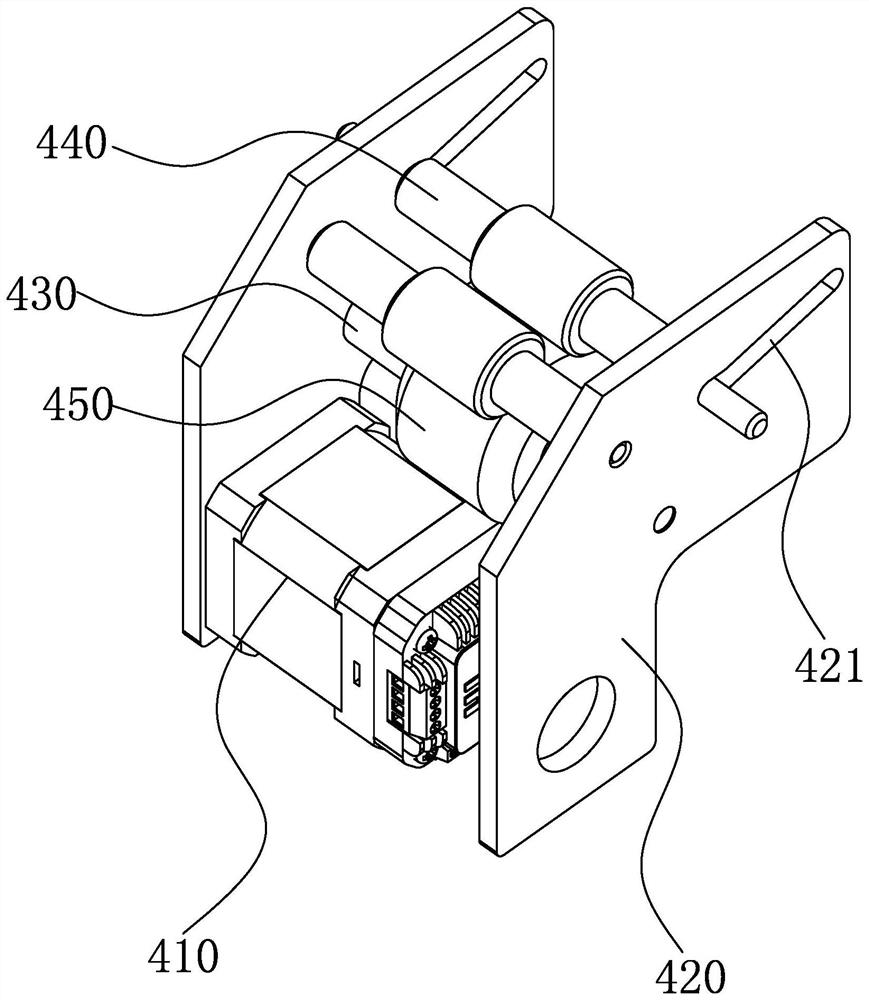

Electric pruning shears

The invention discloses a pair of electric pruning shears which comprises an enclosure, a motor positioned in the enclosure, a transmission gear connected with the motor, a pair of blade groups, and a trigger arranged on the enclosure and used for controlling the motor, wherein the pair of blades comprise a fixed blade and a movable blade, and the movable blade is driven by the motor to conduct reciprocating swing. The pair of electric pruning shears is characterized by also comprising a stroke switch arranged on the enclosure, wherein the stroke switch at least comprises two states, when the stroke switch is in the first state, the movable blade has a first stroke, and when the stroke switch is in the second state, the movable blade has a second stroke which is different from the first stroke. The pair of electric pruning shears effectively overcomes the defects of waste of time and power when a pair of conventional pruning shears is used for shearing twigs.

Owner:NANJING CHERVON IND

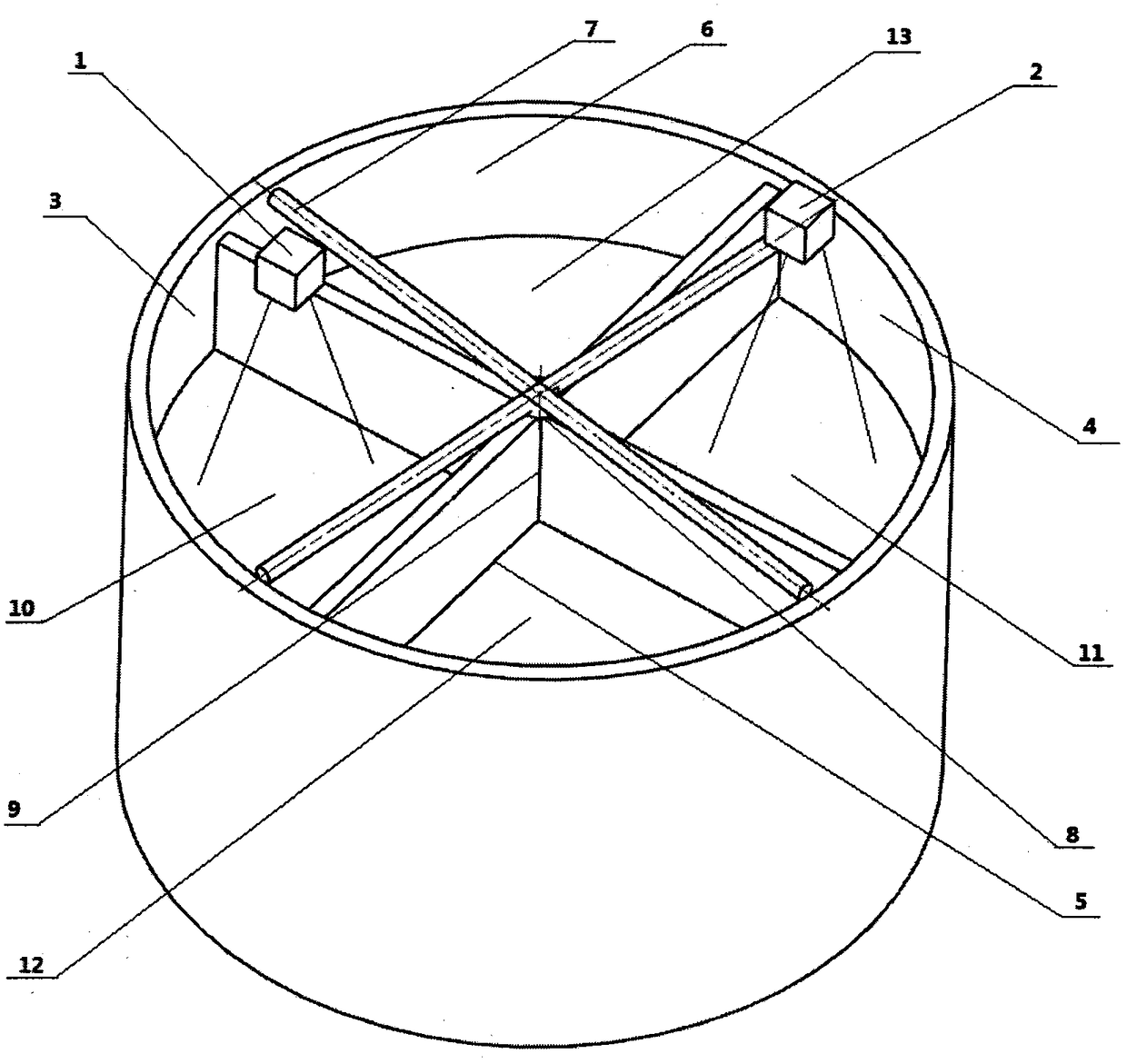

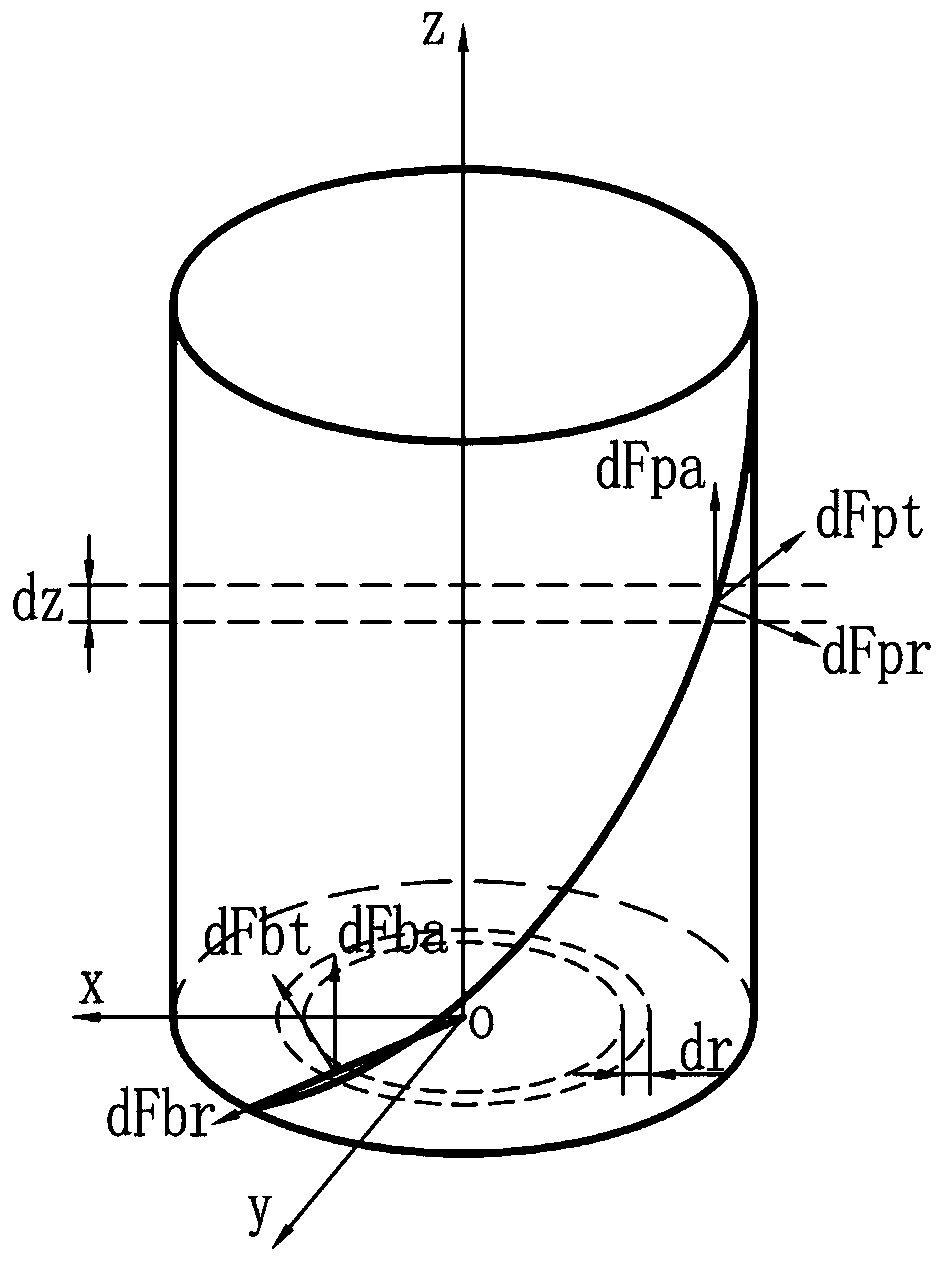

Annular four-cylinder efficient rapid prototyping device and method

InactiveCN108500260AImprove processing efficiencyAvoid empty tripsAdditive manufacturing apparatusIncreasing energy efficiencyLight sourceRapid prototyping

The invention discloses an annular four-cylinder efficient rapid prototyping device and method. The device comprises two laser sources, two prototyping cylinders, two transition cylinders, a powder laying roller, a rotating base, a cross partition board, two prototyping cylinder lifting supporting plates and two transition cylinder lifting supporting plates; the two prototyping cylinders and the two transition cylinders jointly form an annular four-cylinder body, the four cylinders are the same in size, the four cylinders are isolated to be independent through the cross partition board, the prototyping cylinders are used for loading prototyping parts and the powder supporting material, the prototyping cylinder lifting supporting plates are arranged inside, a prototyping part does the lifting motion, the laser sources are arranged over the two prototyping cylinders, the powder in the prototyping cylinders is scanned, irradiated and sintered, the two transition cylinders are used for recycling and supplying powder materials at the same time, the rotating base is located on the crossing position of the cross partition board, the powder laying roller mounted on the rotating base is driven to rotate, and the powder material is supplemented and recycled. The machining efficiency can be improved, the manual labor amount is reduced, and automatic manufacturing is achieved.

Owner:XIAN UNIV OF SCI & TECH

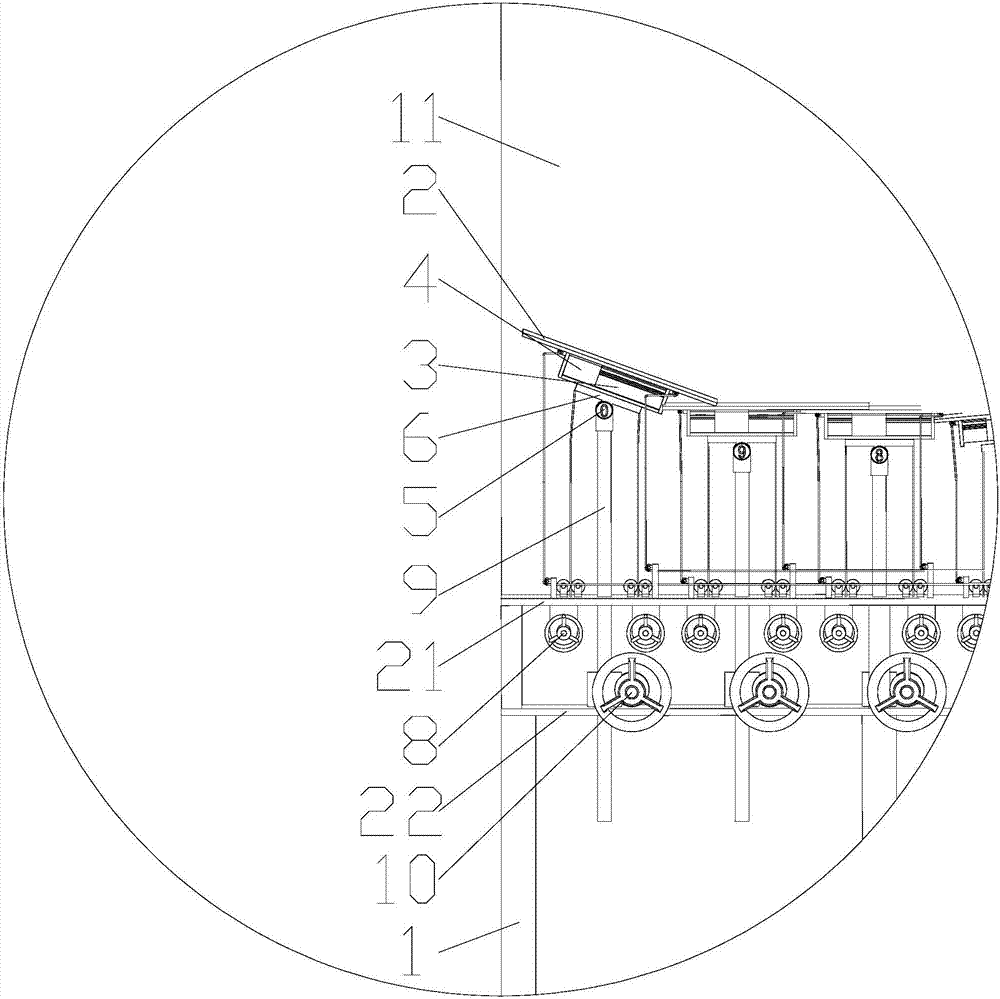

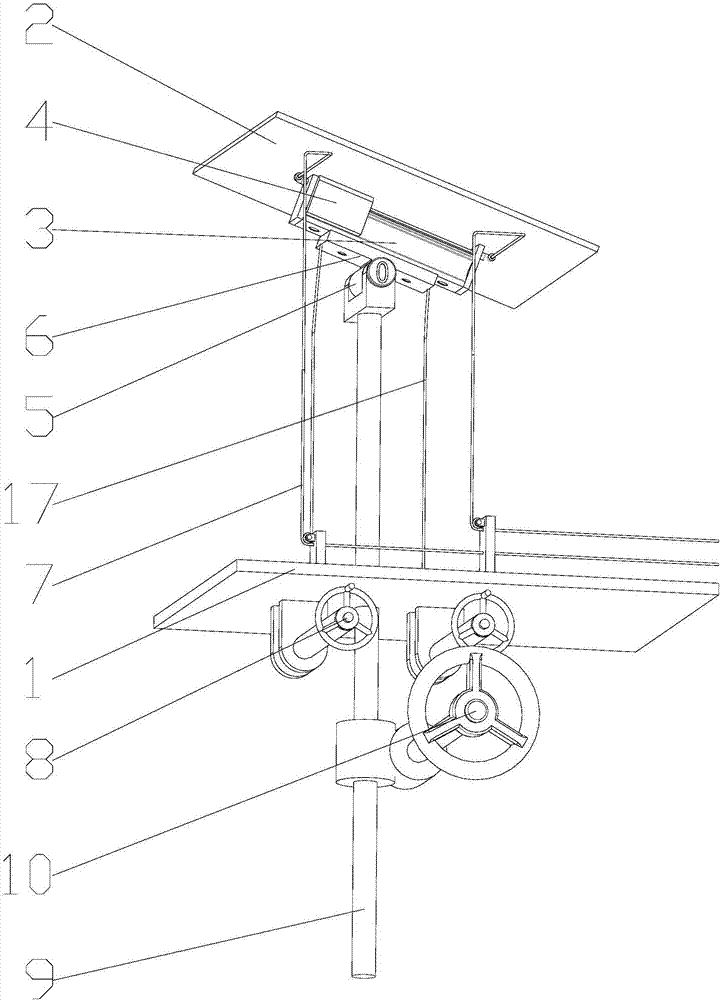

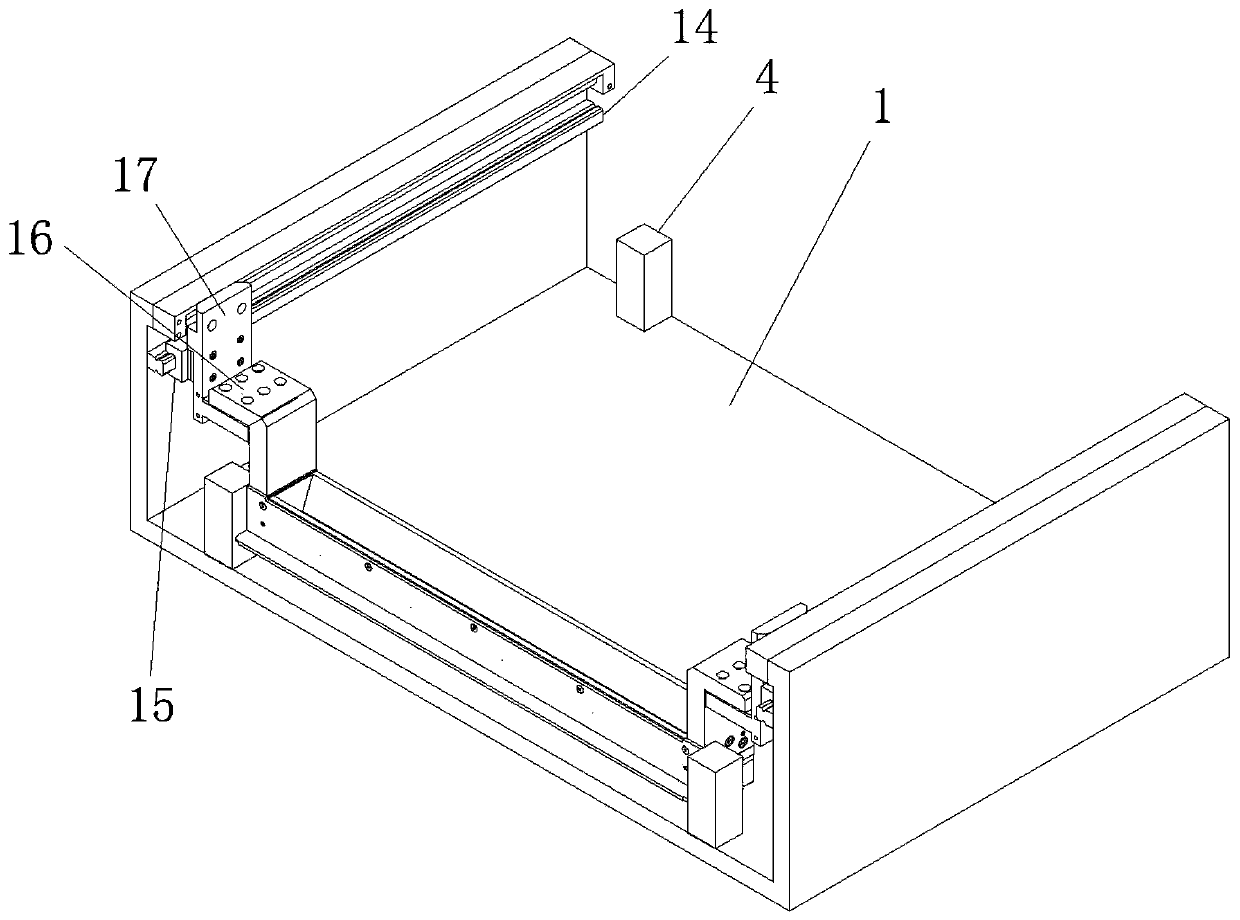

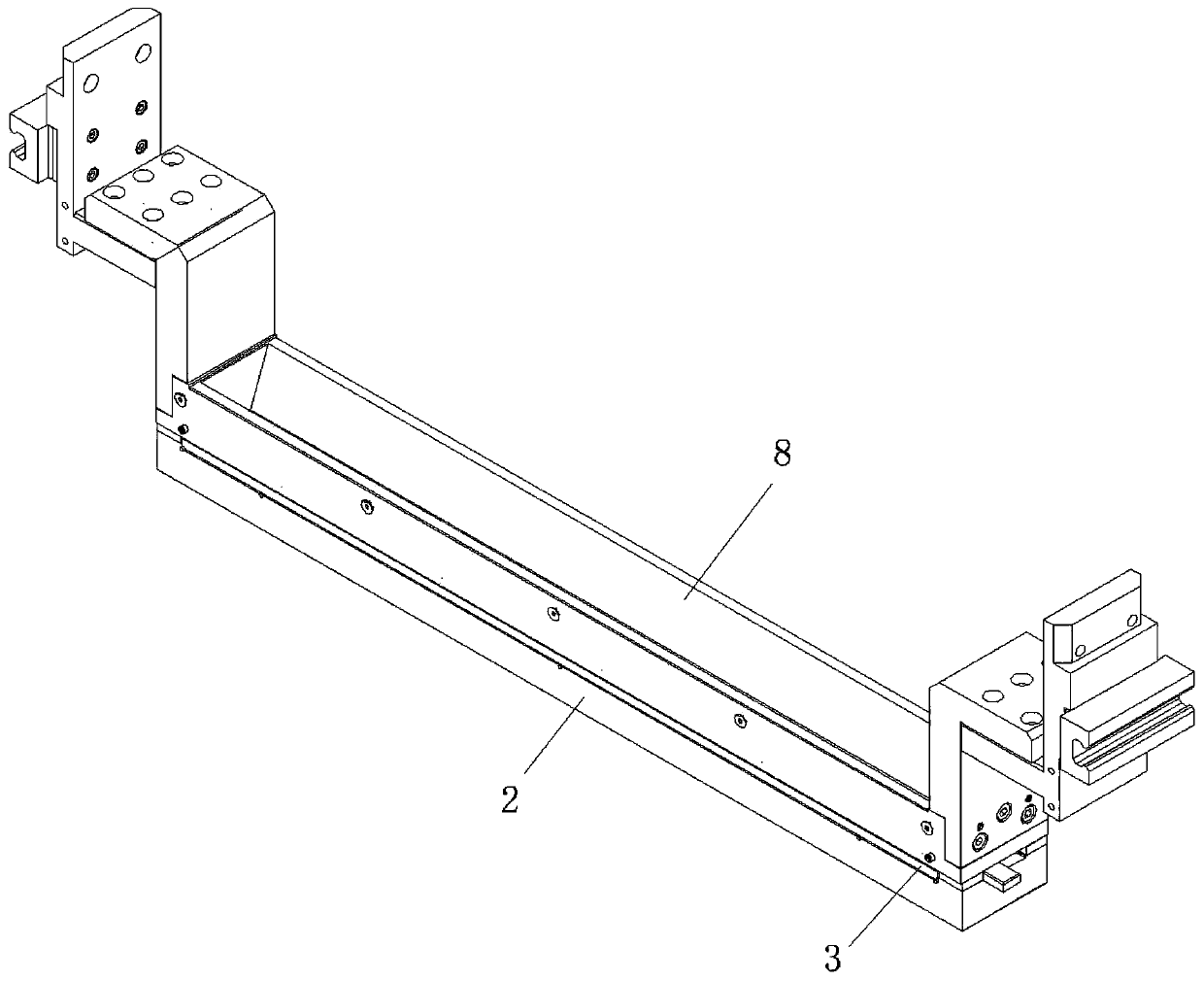

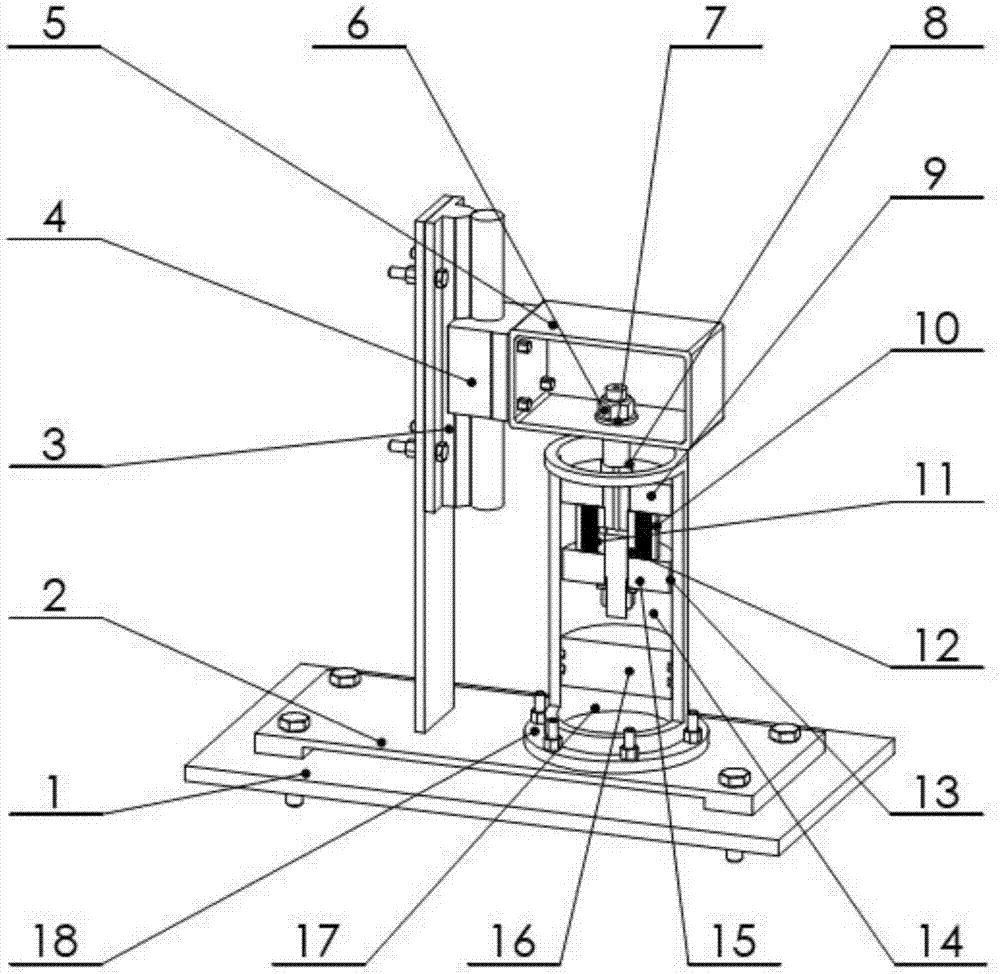

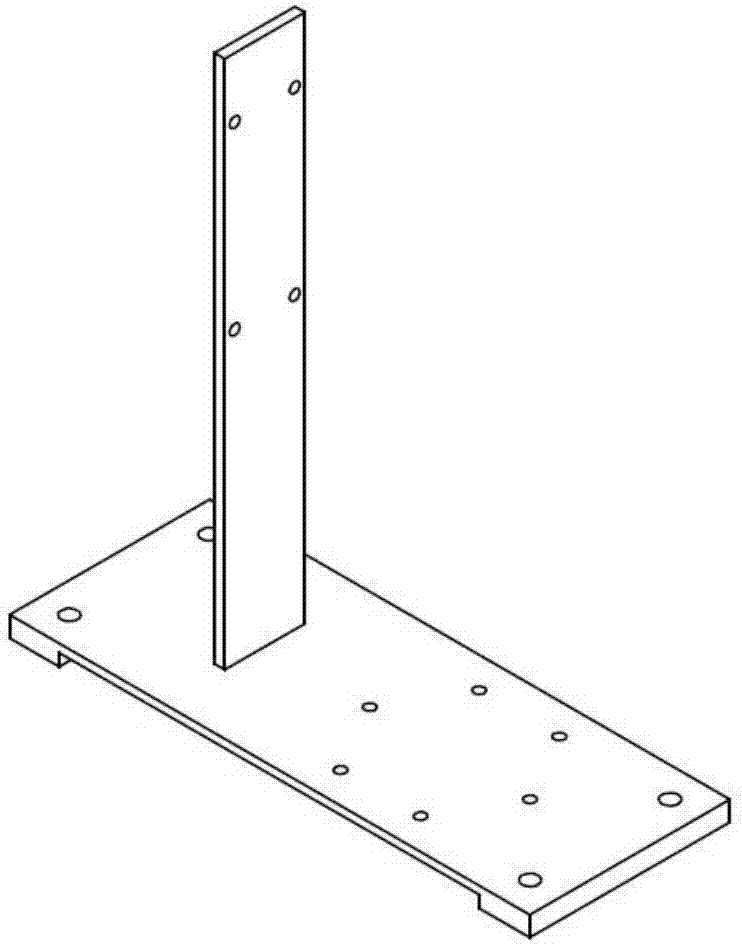

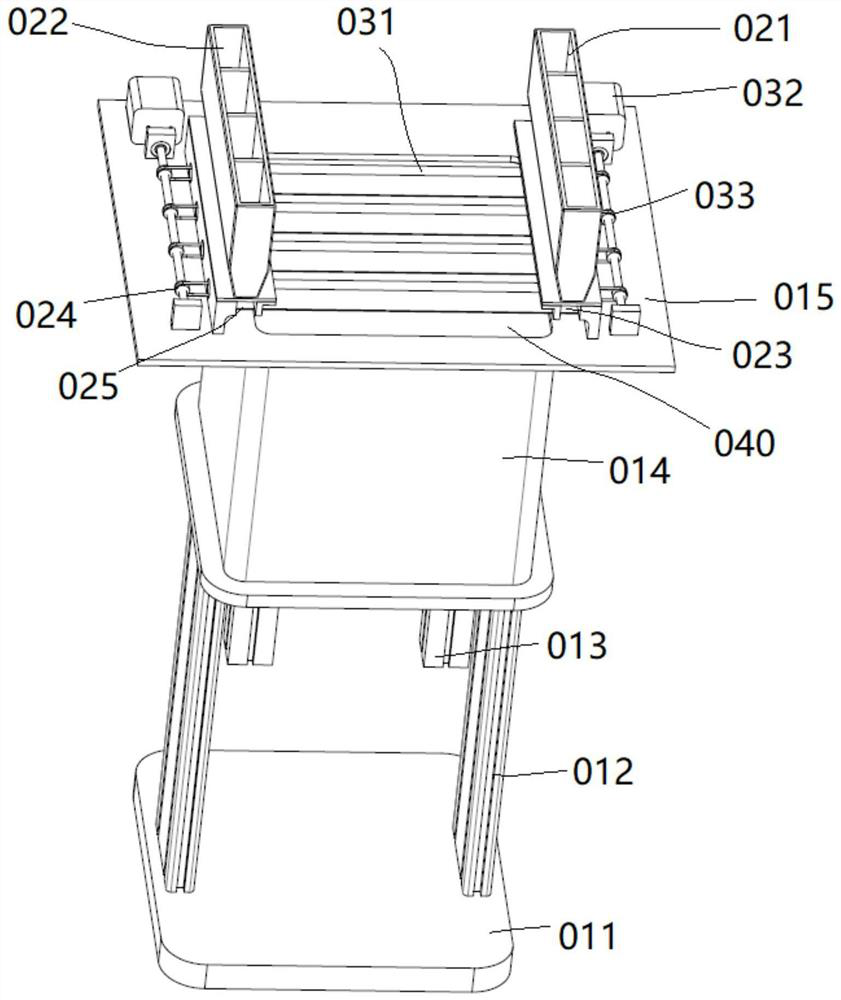

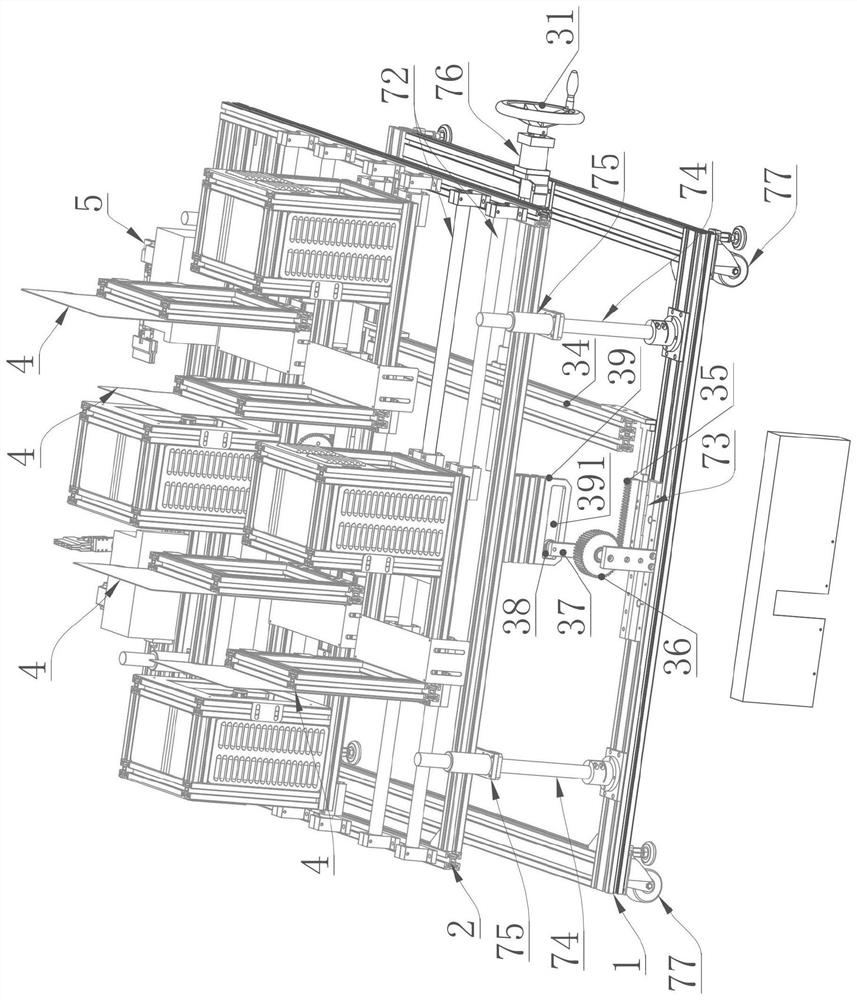

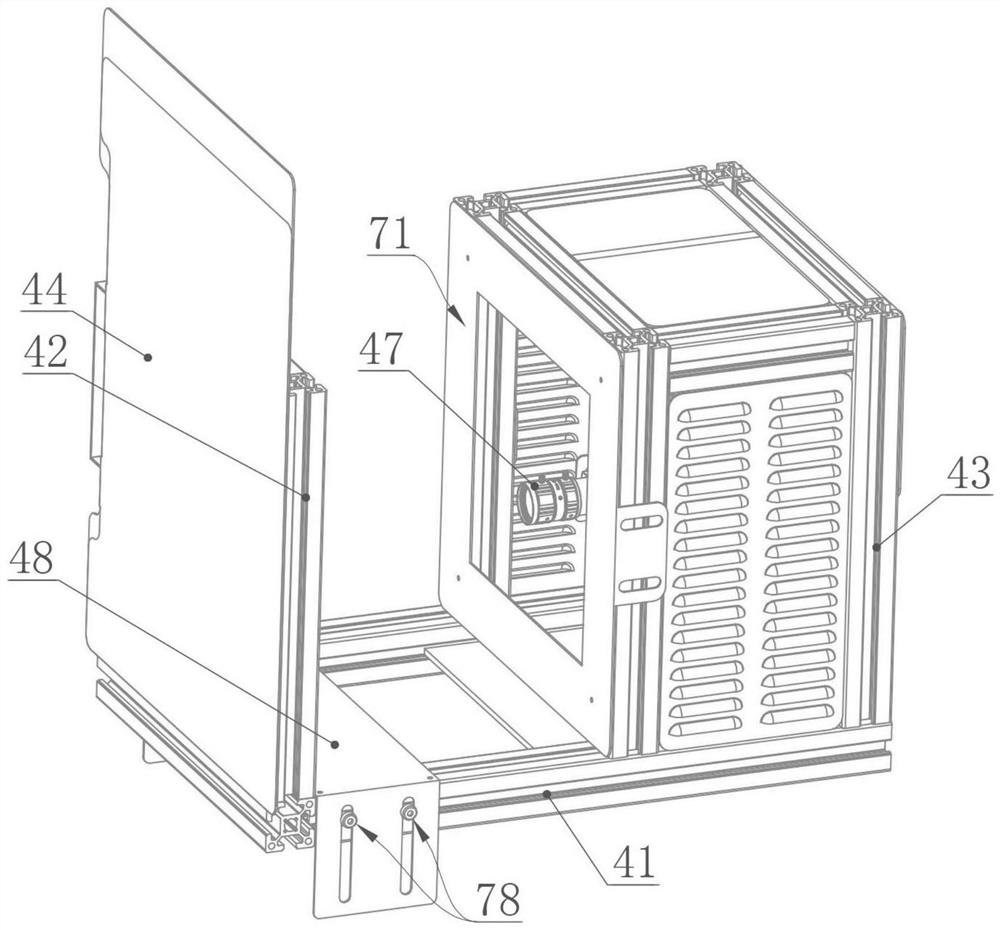

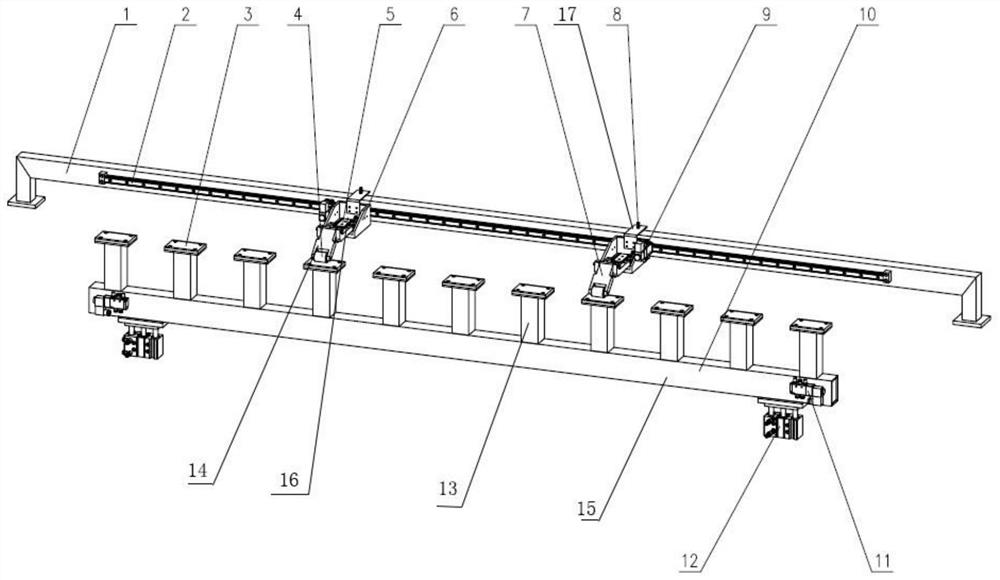

Sliding surface pull-type landslide model test device

ActiveCN107389903AAdjust the angular positionAdjust the horizontal positionClimate change adaptationEarth material testingPull forceLine tubing

The invention discloses a sliding surface pull-type landslide model test device. The sliding surface pull-type landslide model test device comprises an outer frame, a lifting unit and a power module, wherein the lifting unit and the power module are arranged on the outer frame. The lifting unit comprises a sliding plate, a guide rail sliding block, a rotary support, an adjusting mechanism and a lifting mechanism. The guide rail sliding block comprises a guide rail and a sliding block. The rotary support comprises a hinge rod and a connecting plate arranged on the hinge rod. The adjusting mechanism comprises pipes arranged in two sides of the hinge rod, movable pulleys are connected to the lower parts of the pipes and the movable pulleys are connected to adjusting hand wheels. The lifting mechanism comprises a worm gear and a worm fitting to and connected to the worm gear. The worm gear is provided with a lifting hand wheel. The power module comprises a servo motor, a slide rail and a speed reduction gear set which are arranged on the outer frame. The servo motor is connected to a screw guide rail through the speed reduction gear set. The screw guide rail is connected to a power distribution plate through threads. The two ends of the sliding plate are provided with pull ropes. The pull ropes pass through a pipe joint mounting plate. The pull ropes are provided with pull force sensors. The sliding surface pull-type landslide model test device realizes a model test in various directions and improves safety.

Owner:SOUTHWEST JIAOTONG UNIV

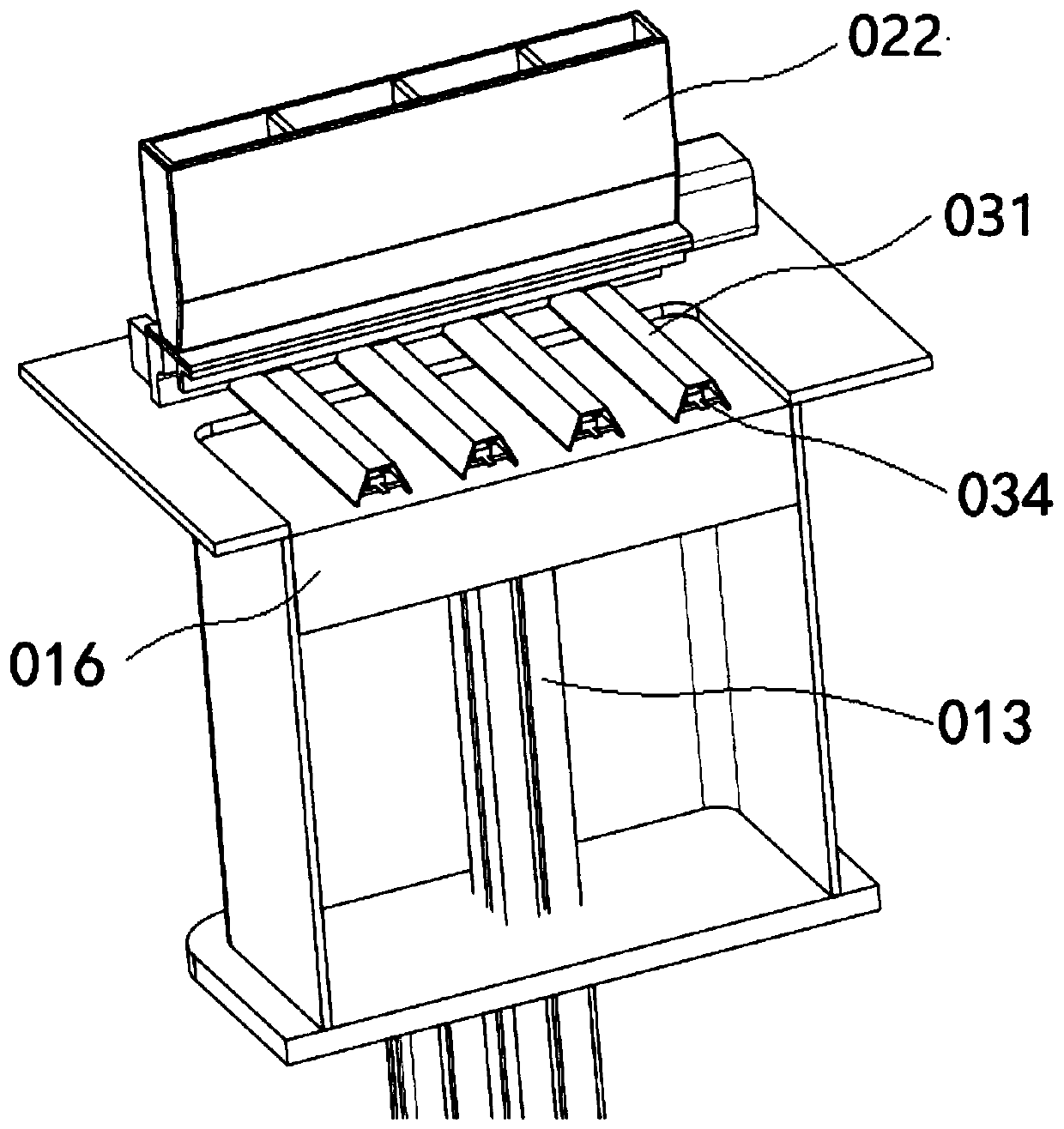

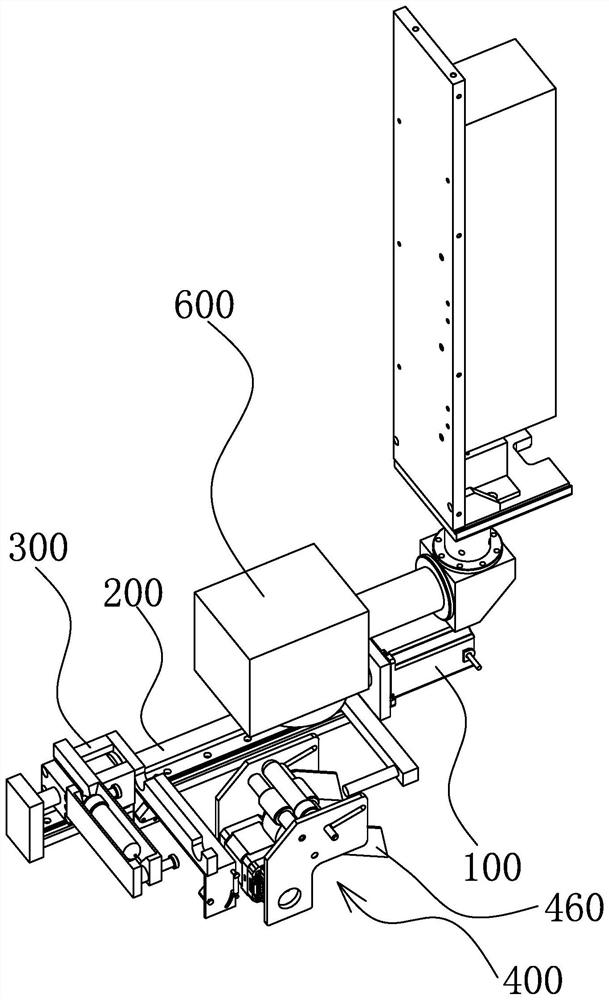

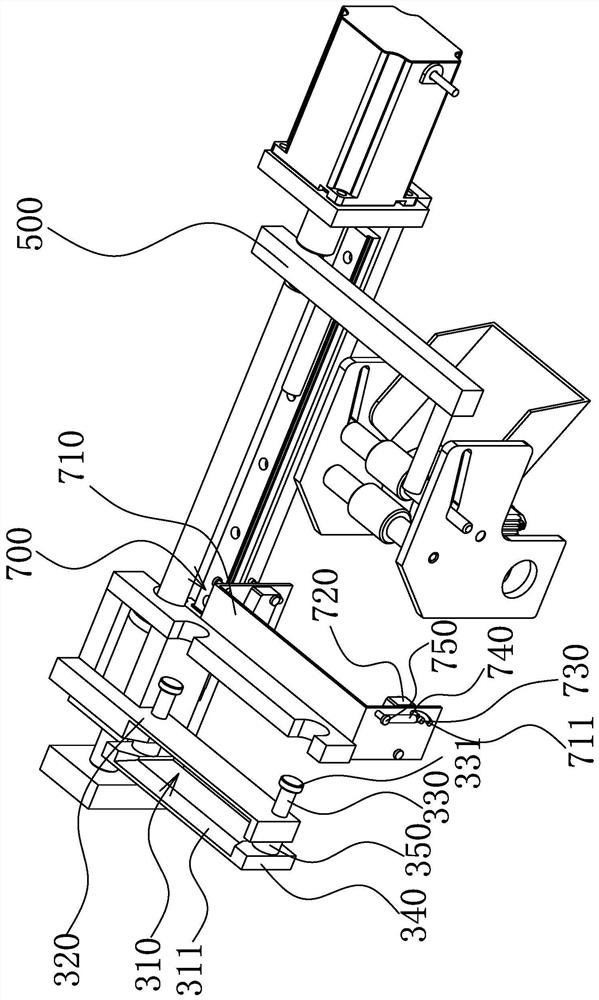

Powder falling and powder spreading device for additive manufacturing equipment

ActiveCN109760313ASimple structureImprove uniformityApplying layer meansIncreasing energy efficiencyControl systemSingle degree of freedom

The invention discloses a powder falling and powder spreading device for additive manufacturing equipment. The powder falling and powder spreading device comprises a powder spreading operation table,a powder spreading assembly and a driving assembly. The powder spreading assembly is installed on the powder spreading operation table in a front-back single degree-of-freedom sliding mode. The driving assembly drives the powder spreading assembly to slide. The powder spreading assembly comprises a flow guide block, a powder falling opening switching plate and hitting blocks. The flow guide blockis connected to the powder spreading operation table in a front-back sliding mode and is used for powder falling. The powder falling opening switching plate is arranged above the flow guide block andcan slide front and back. The hitting blocks are installed on the powder spreading operation table, are located on the front and rear sides of the powder spreading assembly and are used for hitting the powder falling opening switching plate. The powder falling opening switching plate is provided with a powder falling switching groove extending left and right. The flow guide block is provided withtwo powder falling grooves formed front and back and extending left and right. According to the powder spreading assembly, automatic switching of the powder falling grooves is achieved through hittingin the sliding process, no special driving device needs to be arranged for switching the powder falling grooves in the structure, the structure of the powder spreading assembly is simplified, a control system is simplified, and cost of the additive manufacturing equipment is lowered.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD

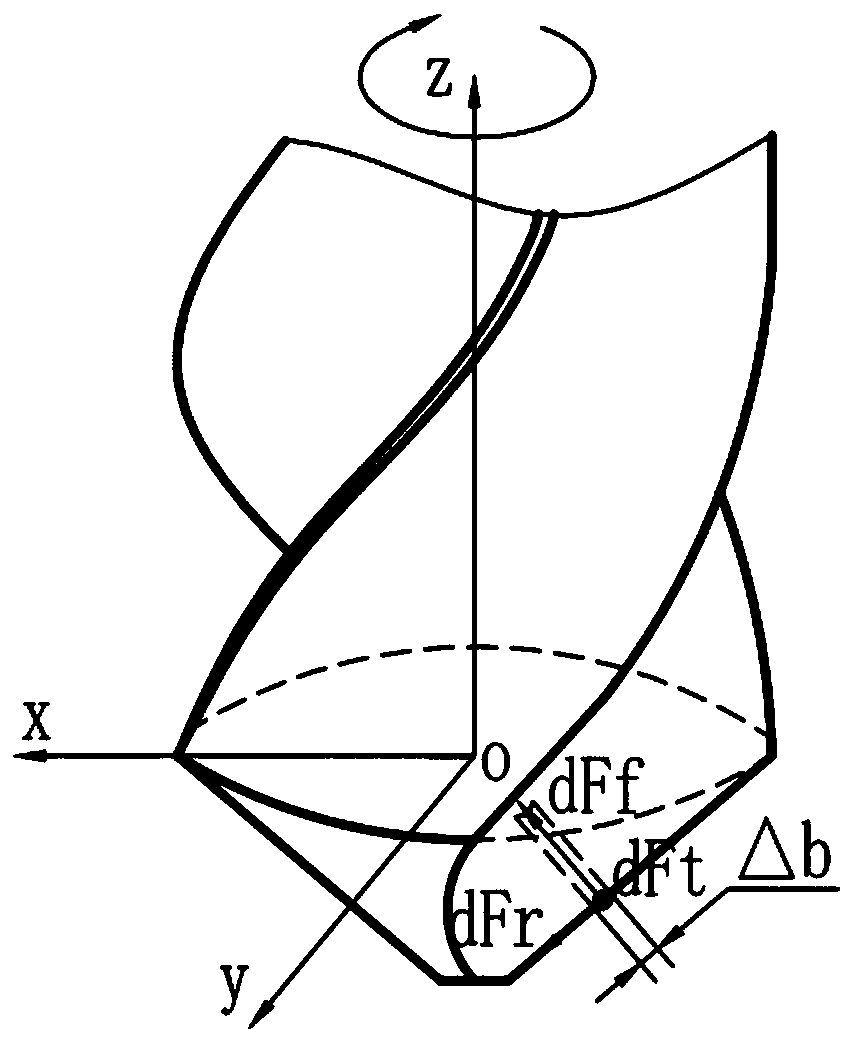

Machining method for spindle hole oil groove of large diesel engine body

ActiveCN105583449AProtectImprove rigidityWorkpiecesMilling equipment detailsMilling cutterDiesel engine

The invention relates to a machining method for a spindle hole oil groove of a large diesel engine body. The method comprises the following implementation steps that most margins are removed with a short ball milling cutter with the good rigidity; margins of the interference portion are removed with a long ball milling cutter; remaining margins are removed for one time with a three-edge milling cutter, and the groove is finally obtained. The machining method has the advantages that the machining time is short, the machining efficiency is high, the cutters are not prone to be tipped, the using effect is good, and the life is long.

Owner:WEICHAI HEAVY MACHINERY

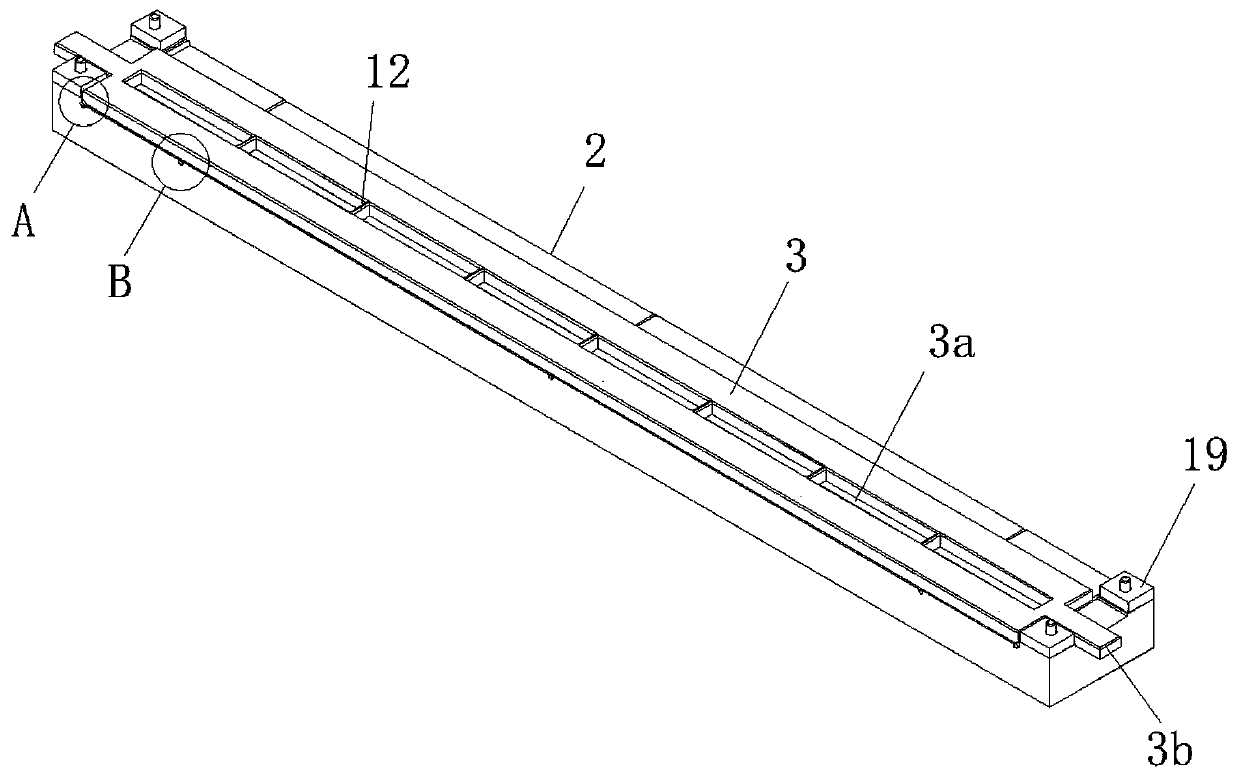

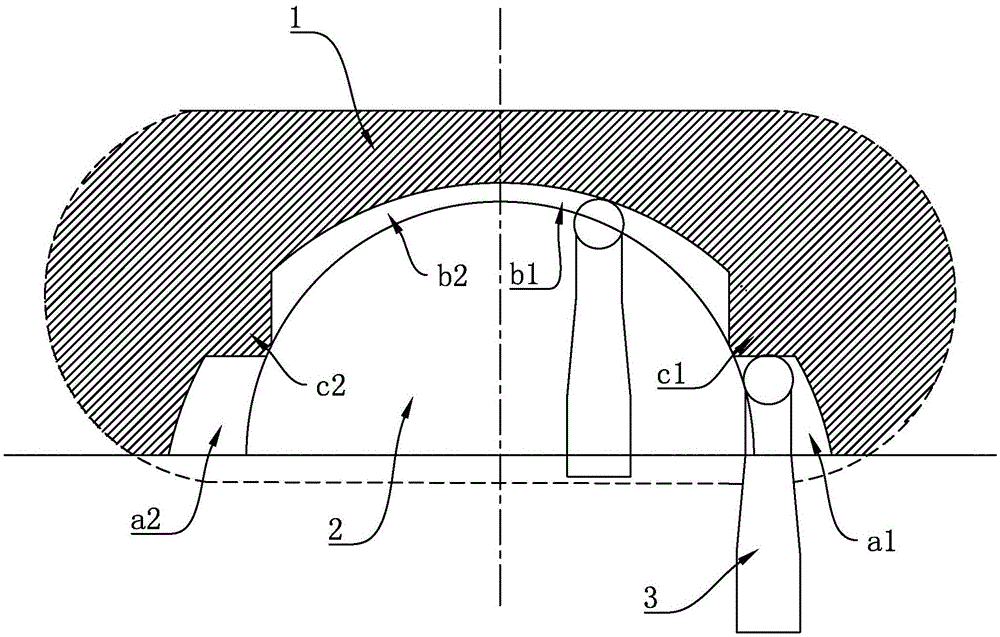

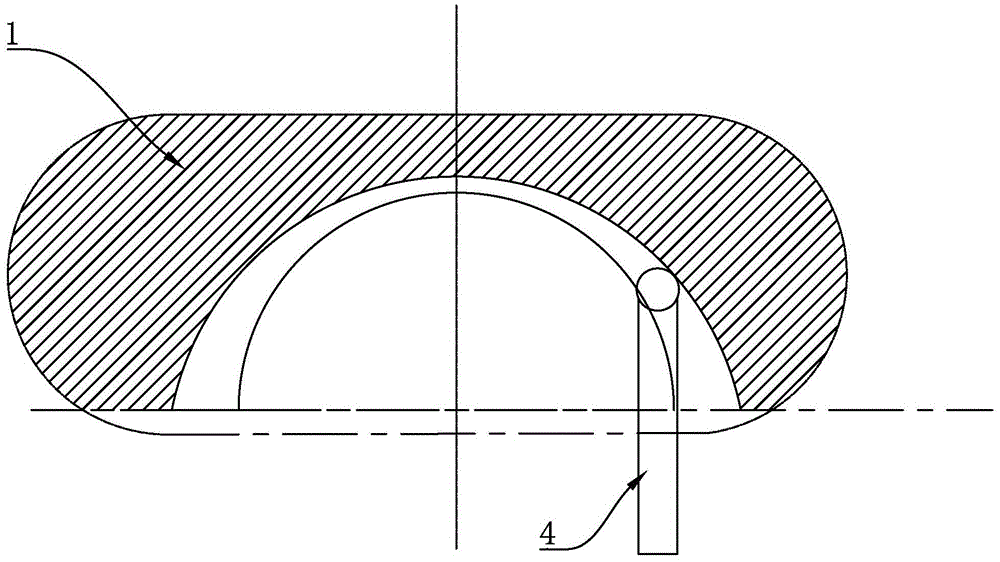

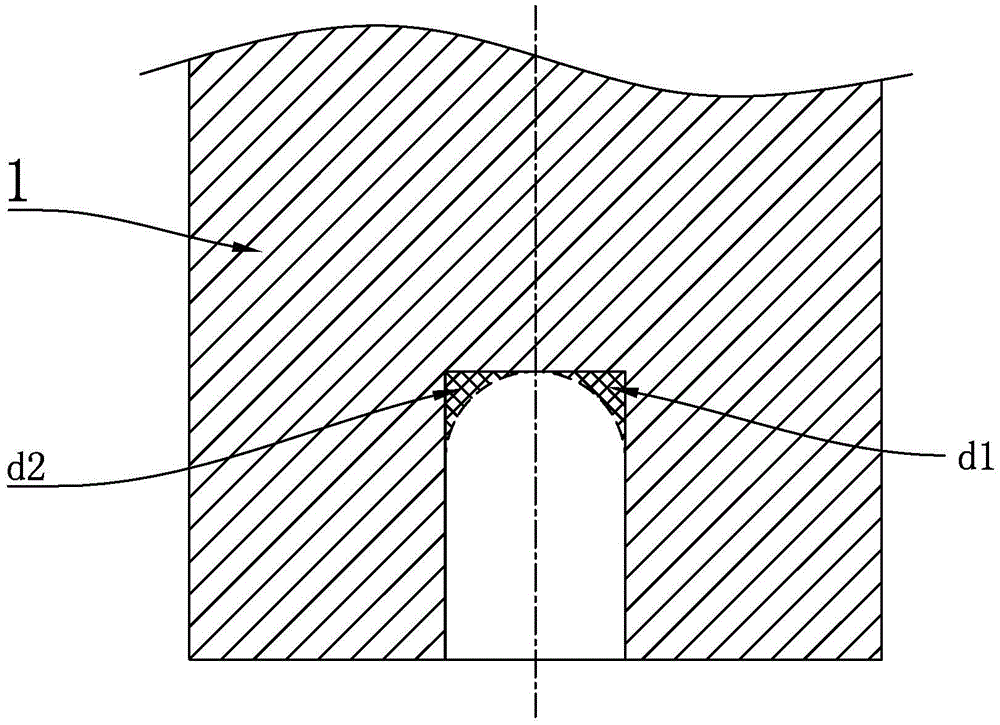

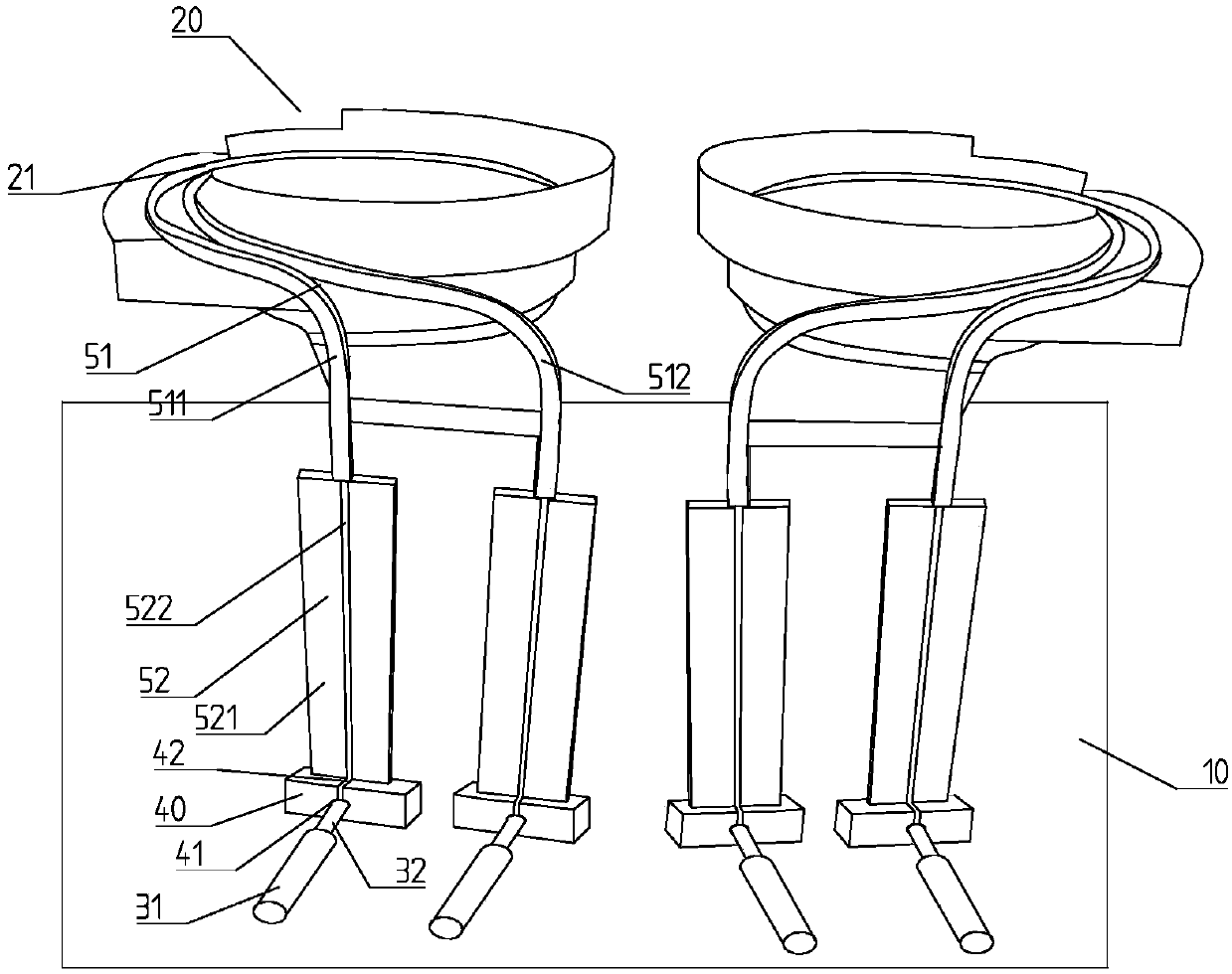

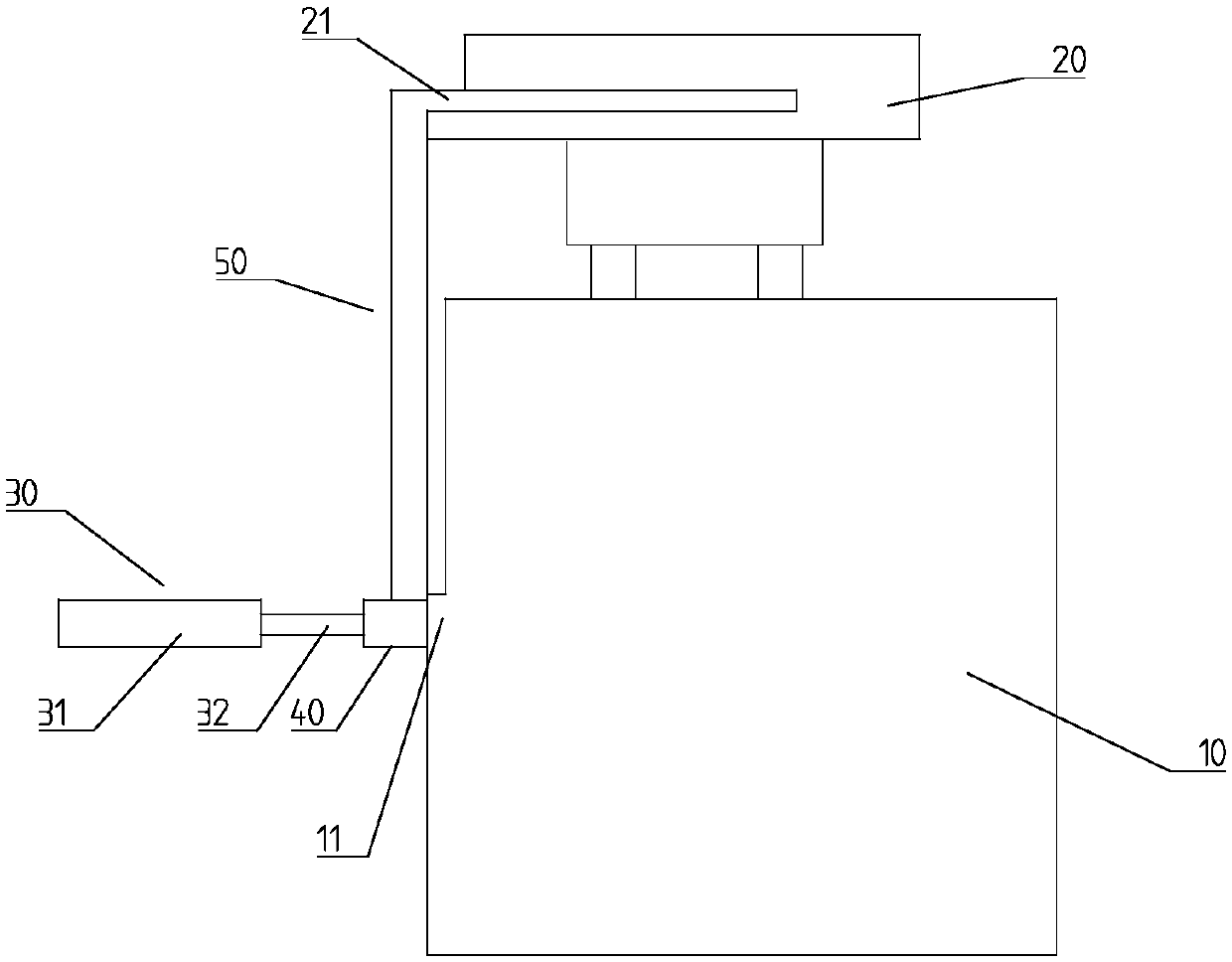

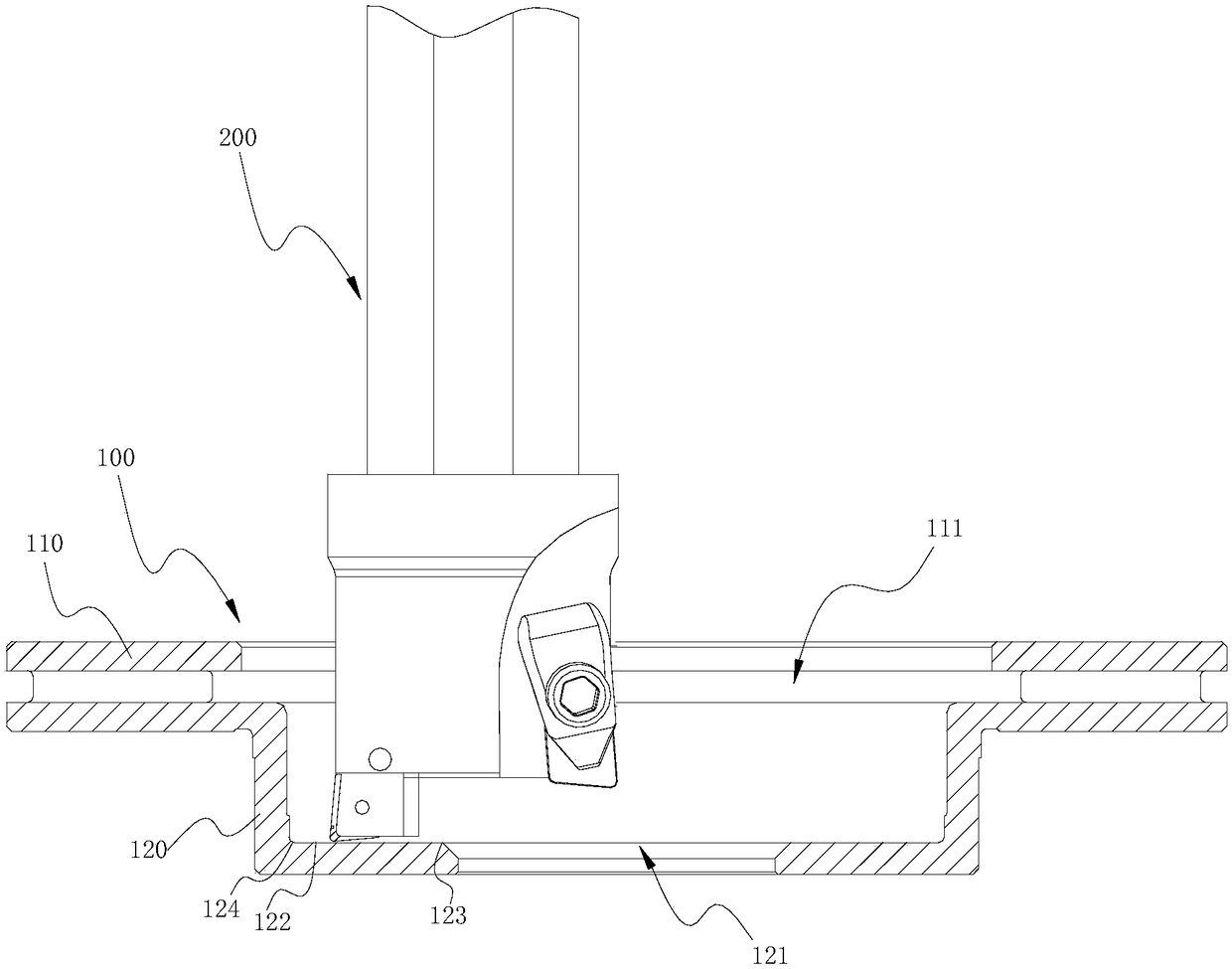

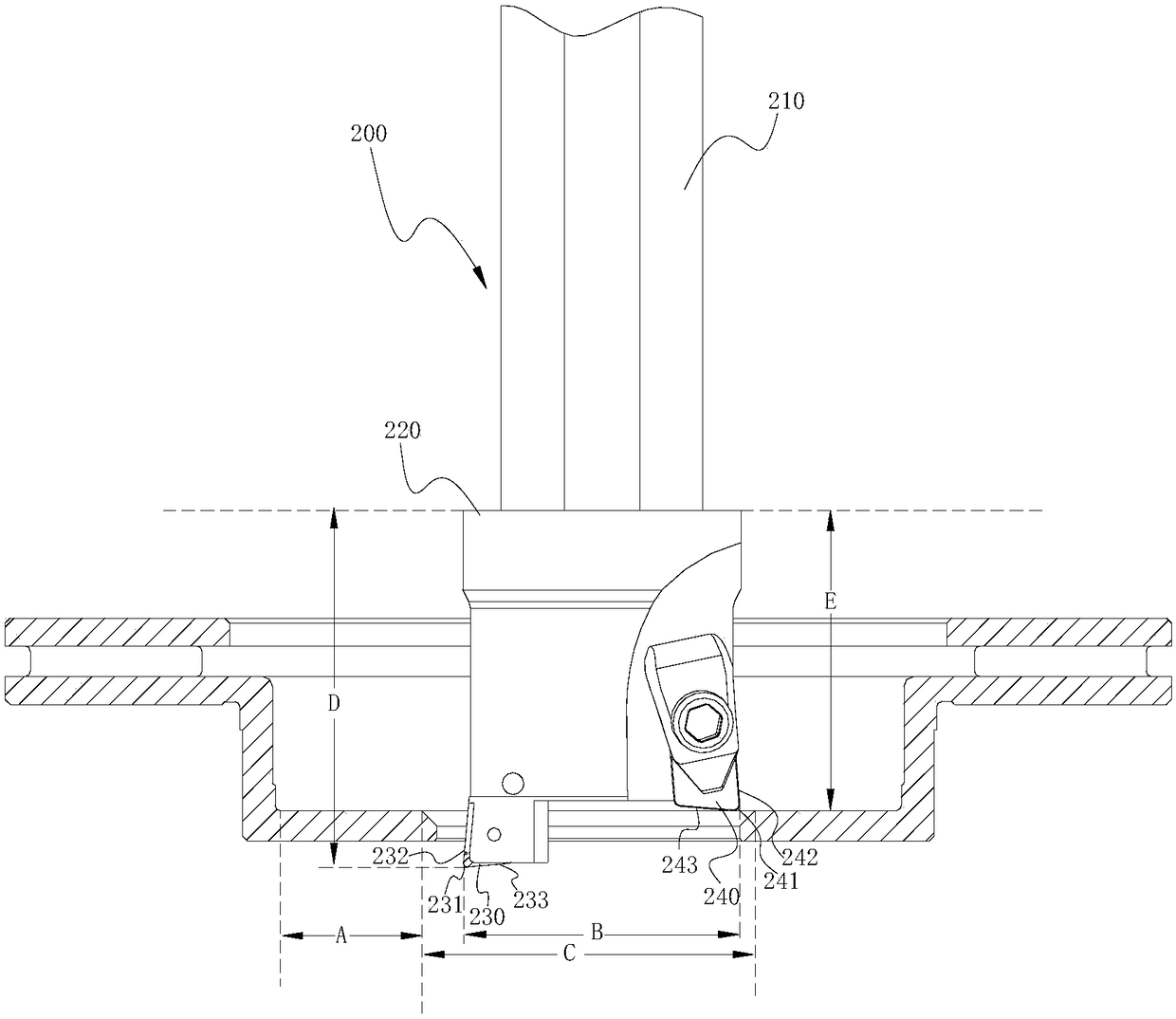

Two-way powder laying device for additive manufacturing

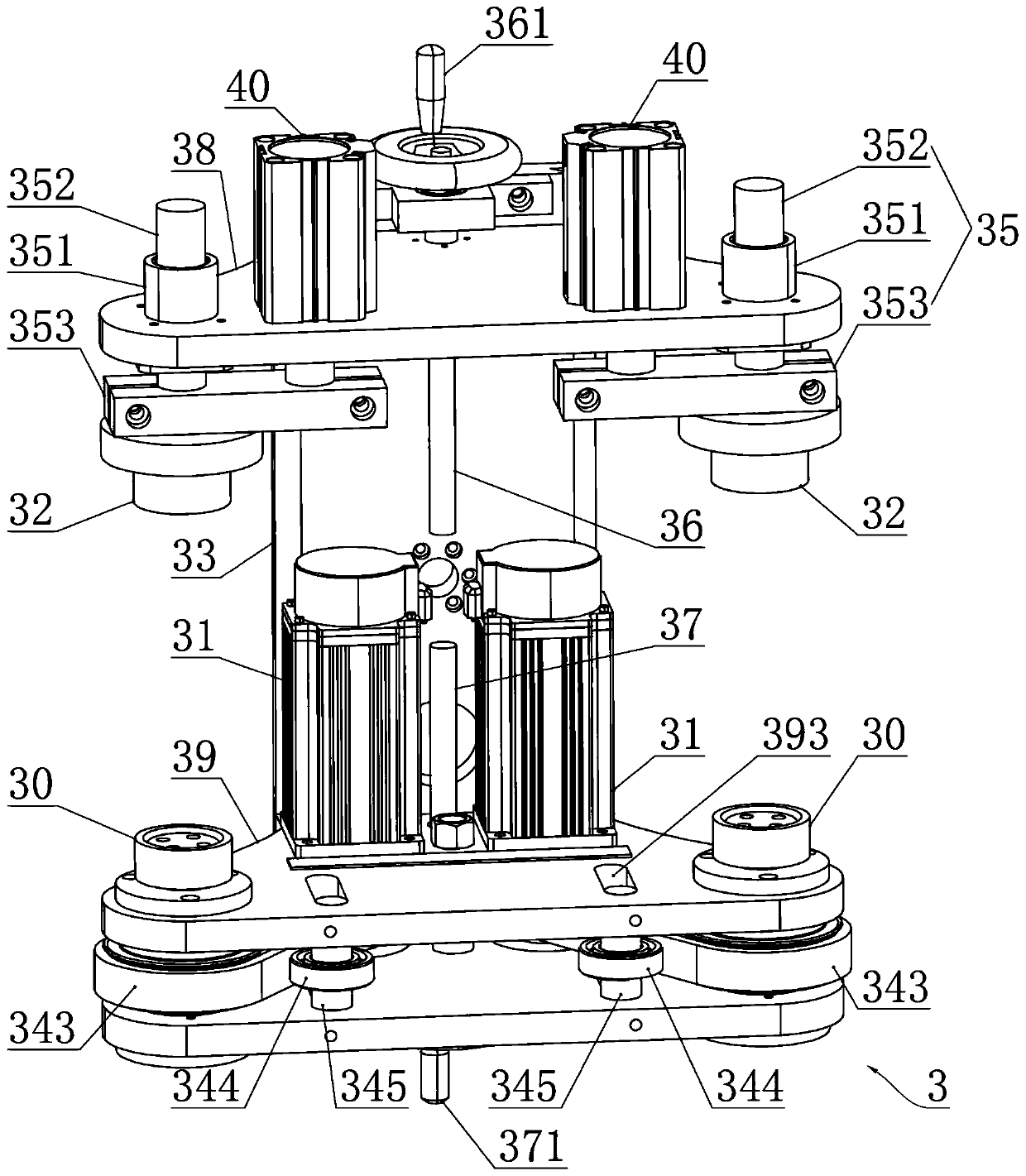

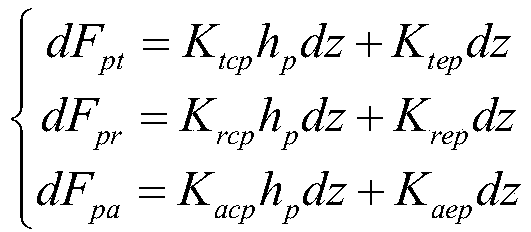

PendingCN109693376AAvoid empty tripsImprove spreading efficiencyAdditive manufacturing apparatus3D object support structuresEngineeringMechanical engineering

The invention discloses a two-way powder laying device for additive manufacturing. The two-way powder laying device for additive manufacturing comprises a working table, a powder laying mechanism anda first driving device, wherein the powder laying mechanism is slidably installed on the working table in a linear reciprocating left and right mode, and the first driving device is installed on the working table and used for driving the powder laying mechanism to slide. The powder laying mechanism comprises a scraper installation seat, a scraper and two powder laying channels, the reciprocating sliding scraper installation seat is driven by the first driving device, the scraper is installed at the bottom of the scraper installation seat, and the two powder laying channels are arranged on thescraper installation seat and located on the left side and the right side of the scraper. The two-way powder laying device for additive manufacturing can lay powder in both directions, empty stroke isavoided, two-way stroke is effectively used for performing the powder laying operation, and the efficiency of powder laying is improved.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD

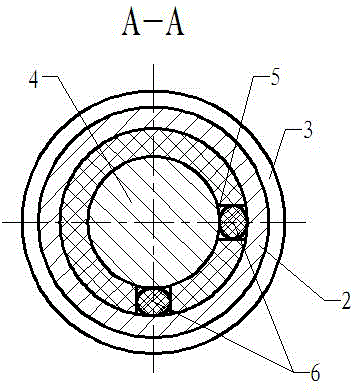

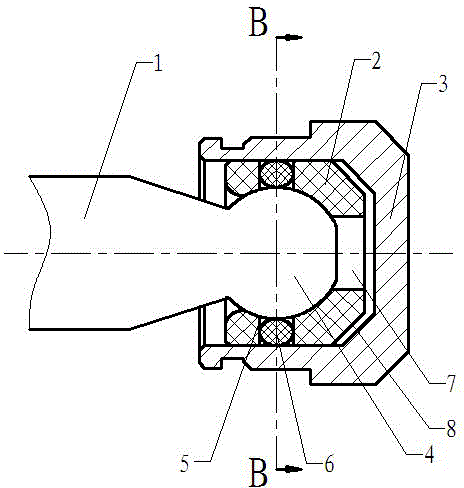

Direct-acting rigidity-controllable magneto-rheological fluid damper

InactiveCN107269757AAdjust stiffnessVibration reduction frequency bandwidthSpringsNon-rotating vibration suppressionPower flowVibration control

The invention relates to a direct-acting magneto-rheological fluid shock absorber with controllable stiffness, which belongs to the technical field of vibration control. The shock absorber includes the controlled object and the magnetorheological fluid shock absorber, wherein the controlled object is the vibration control object, and the magnetorheological fluid shock absorber is composed of a support plate, a slide rail, a slider, a connecting plate, a lock nut, Gasket, piston rod, upper piston, outer sleeve, excitation coil, inner sleeve, damping channel, magnetorheological fluid, lower piston, floating piston, nitrogen chamber and working cylinder. The stiffness of the magnetorheological fluid in the magnetorheological fluid damper can be controlled by changing the current of the excitation coil, so as to meet the internal resonance requirements between the controlled object and the magnetorheological fluid damper in the system. The damping consumes vibration energy to achieve the purpose of vibration reduction. The invention utilizes the internal resonance phenomenon for vibration reduction, has obvious vibration reduction effect, strong robustness and less energy consumption, and has good practical value in the vibration reduction of vehicle engines, flexible mechanical arms and other fields.

Owner:BEIHANG UNIV

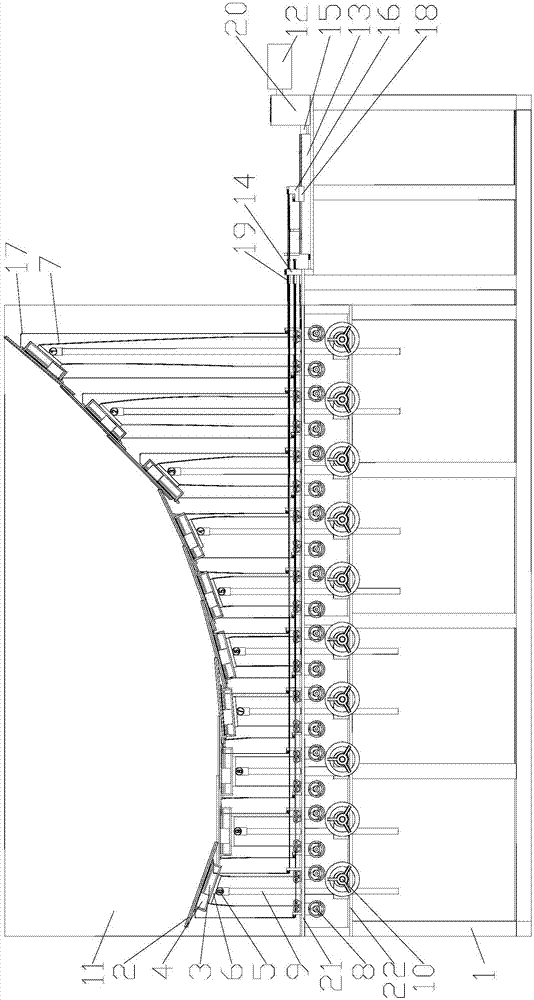

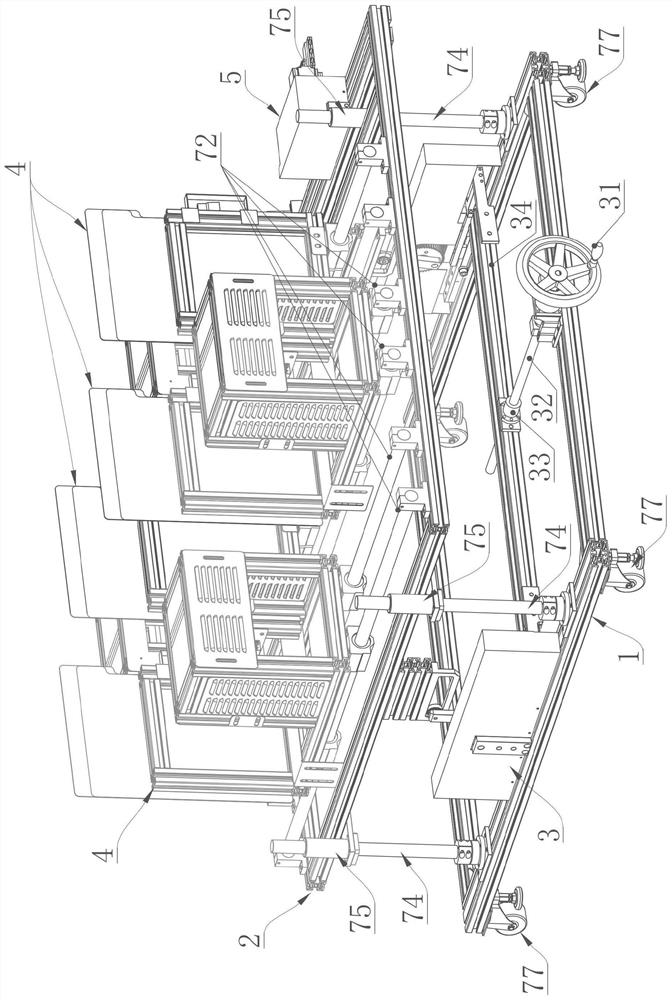

Multi-partition array type selective melting manufacturing equipment and process

ActiveCN111267344AReduce waiting time for spreading powderImprove processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyElectric machineryEngineering

The invention relates to multi-partition array type selective melting manufacturing equipment and a process. The equipment is characterized in that a forming bin is internally connected with a formingbottom plate through a lifting guide rail, a forming platform is arranged at the upper end of the forming bin, a plurality of powder laying grids which are distributed in parallel are arranged on theforming platform, a powder forming area on the forming platform is divided into a plurality of array type powder selecting areas, a powder bin is arranged at each of the two ends of each powder laying grid, the two ends of each powder laying grid and the powder bins on the corresponding powder laying grid are connected with the forming platform through bin sliding bases, the bin sliding bases drive the powder laying grids and the powder bins to perpendicularly reciprocate on the forming platform in the powder laying direction, multi-partition powder laying is formed, and high-energy beams canbe used for printing in the middles of the powder laying grids, so that powder laying and printing are relatively isolated; and a plurality of small scrapers are arranged in each powder laying grid,the small scrapers are connected with scraper driving motors through scraper driving mechanisms, and the scraper driving motors drive the small scrapers to reciprocate in the powder laying grids through the scraper driving mechanisms to evenly lay powder in the powder laying grids.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

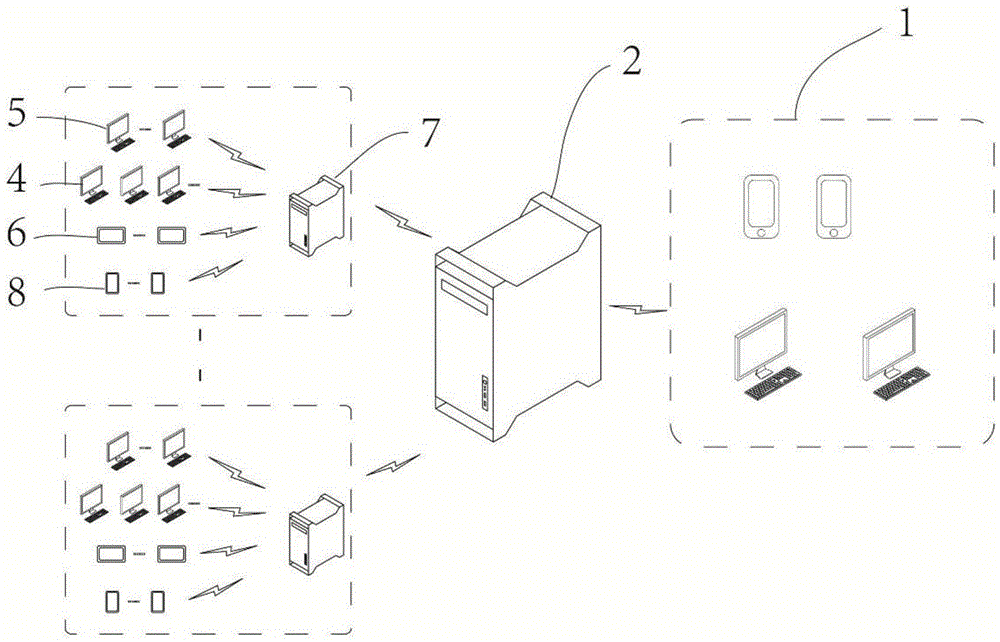

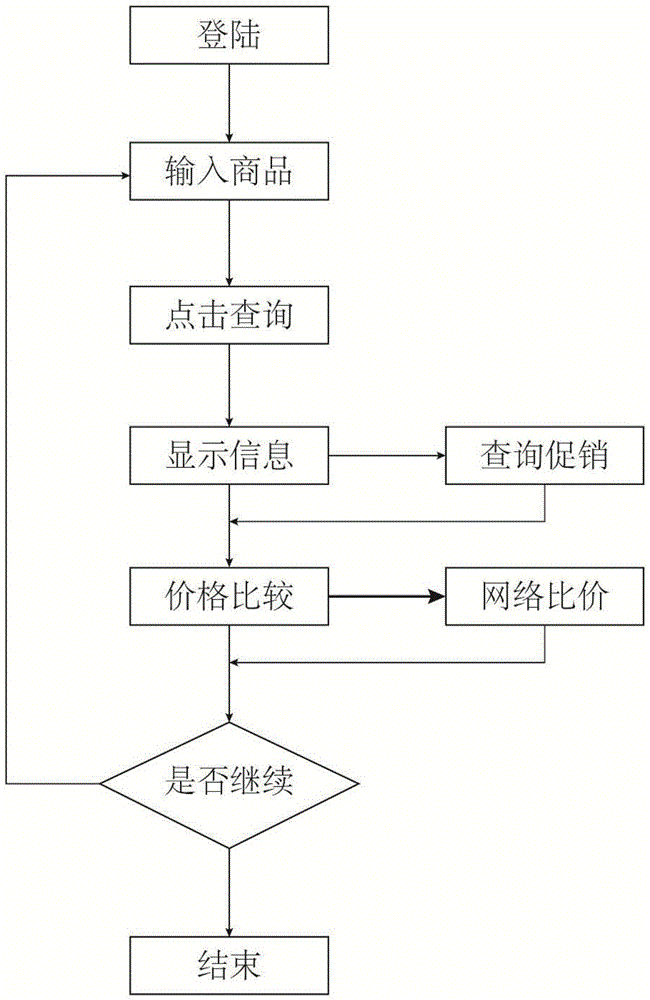

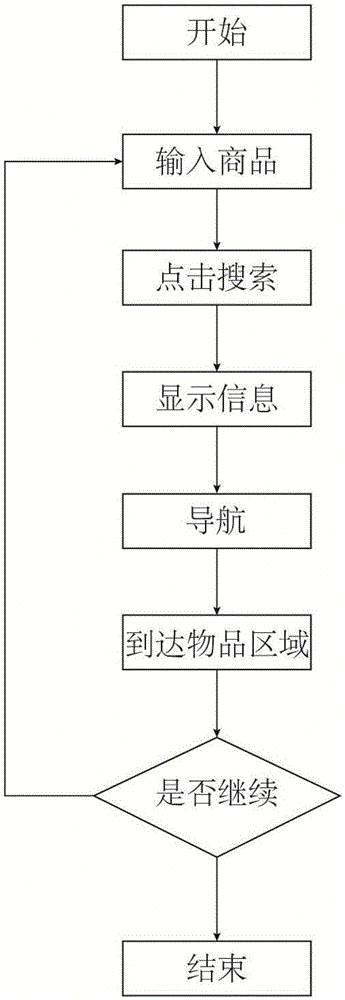

Intelligent city shopping inquiry system

InactiveCN105631726AGuaranteed uniformityGuaranteed unityBuying/selling/leasing transactionsMarketingInternet networkIntelligent city

The invention discloses an intelligent city shopping inquiry system, which is characterized by comprising a personal user terminal, a city server and a plurality of shopping terminals, wherein the personal user terminal and the server are connected via an Internet network or a wireless network; the shopping terminals comprise a plurality of checkout terminals, a plurality of management terminals, a plurality of inquiry terminals and a shopping server; the shopping server and the city server are connected via the Internet network; and the plurality of checkout terminals, the plurality of management terminals and the plurality of inquiry terminals are connected with the shopping server via a local area network. The intelligent city shopping inquiry system has the advantages that the system is firstly queried before shopping, preferential information can be queried conveniently in real time, and physical shopping becomes convenient; and as a comparison module is set, the shopping traffic cost is checked, and the user can select a consumer channel and a shopping site more intuitively and more rationally.

Owner:TIANJIN ANJIAXIN TECH DEV CO LTD

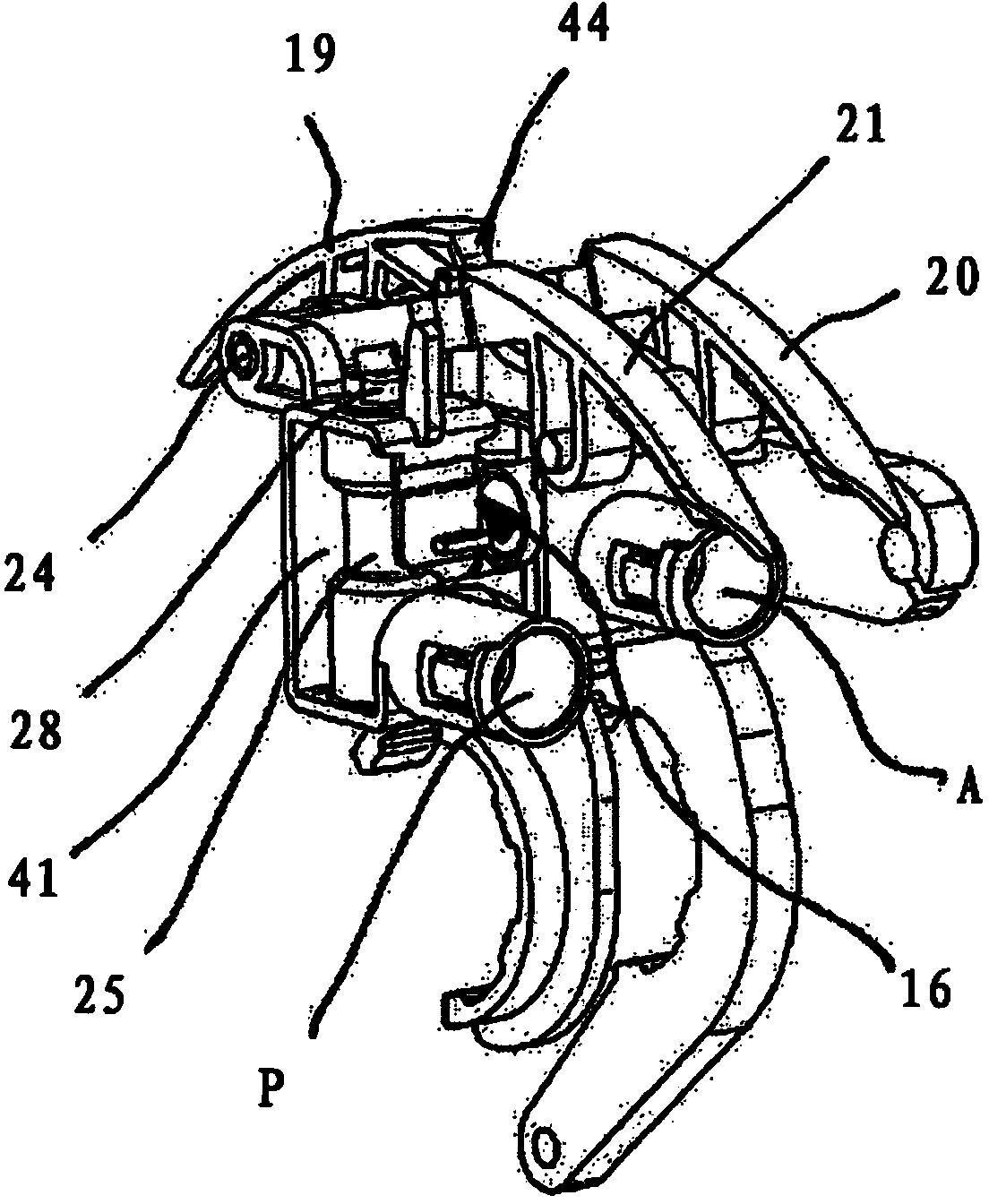

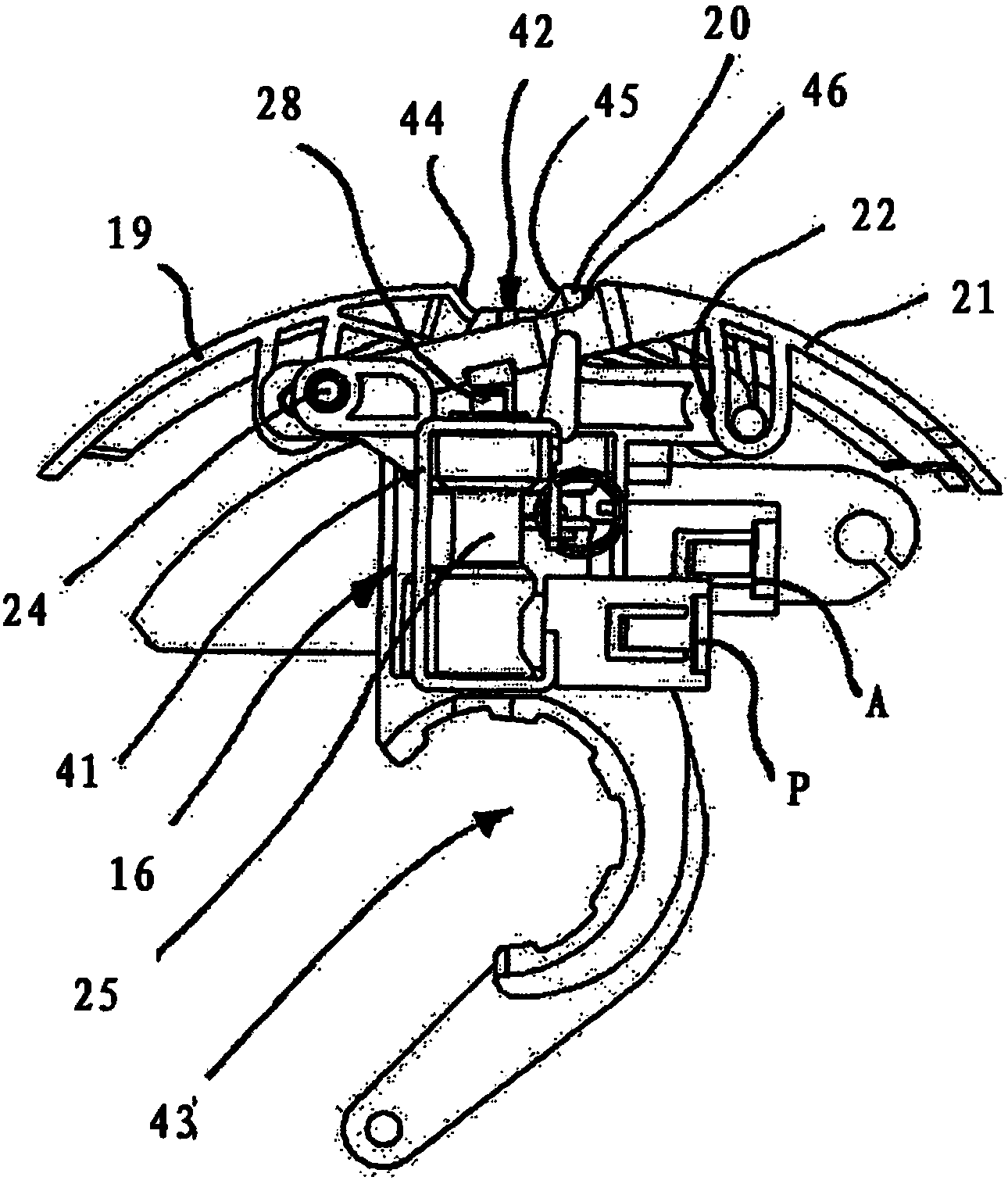

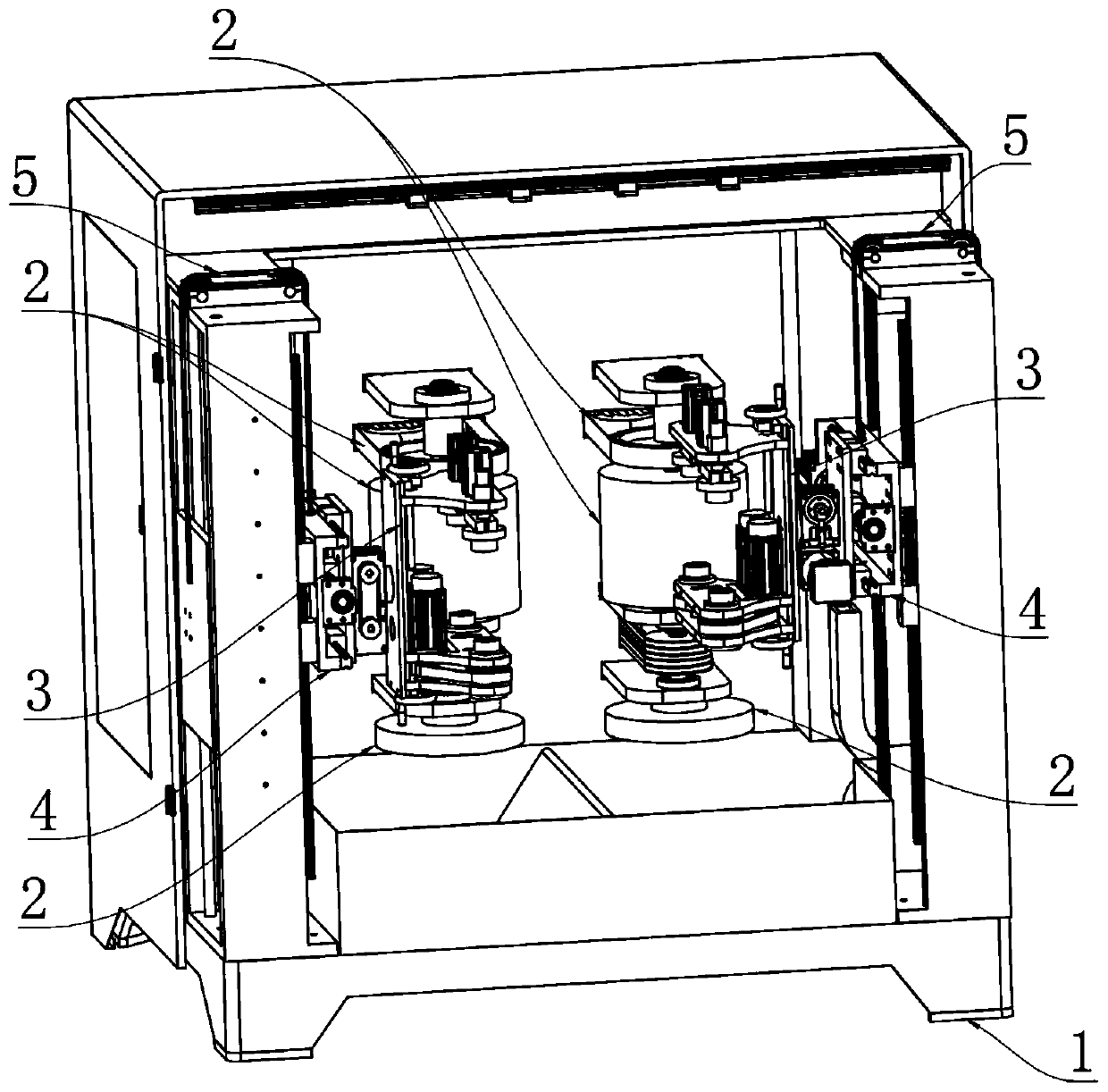

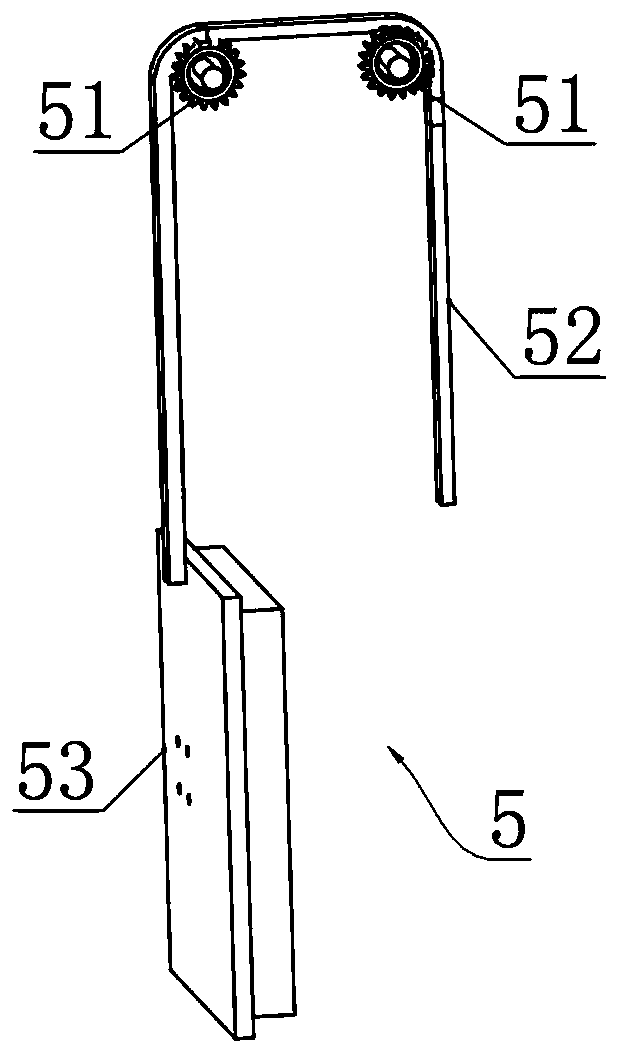

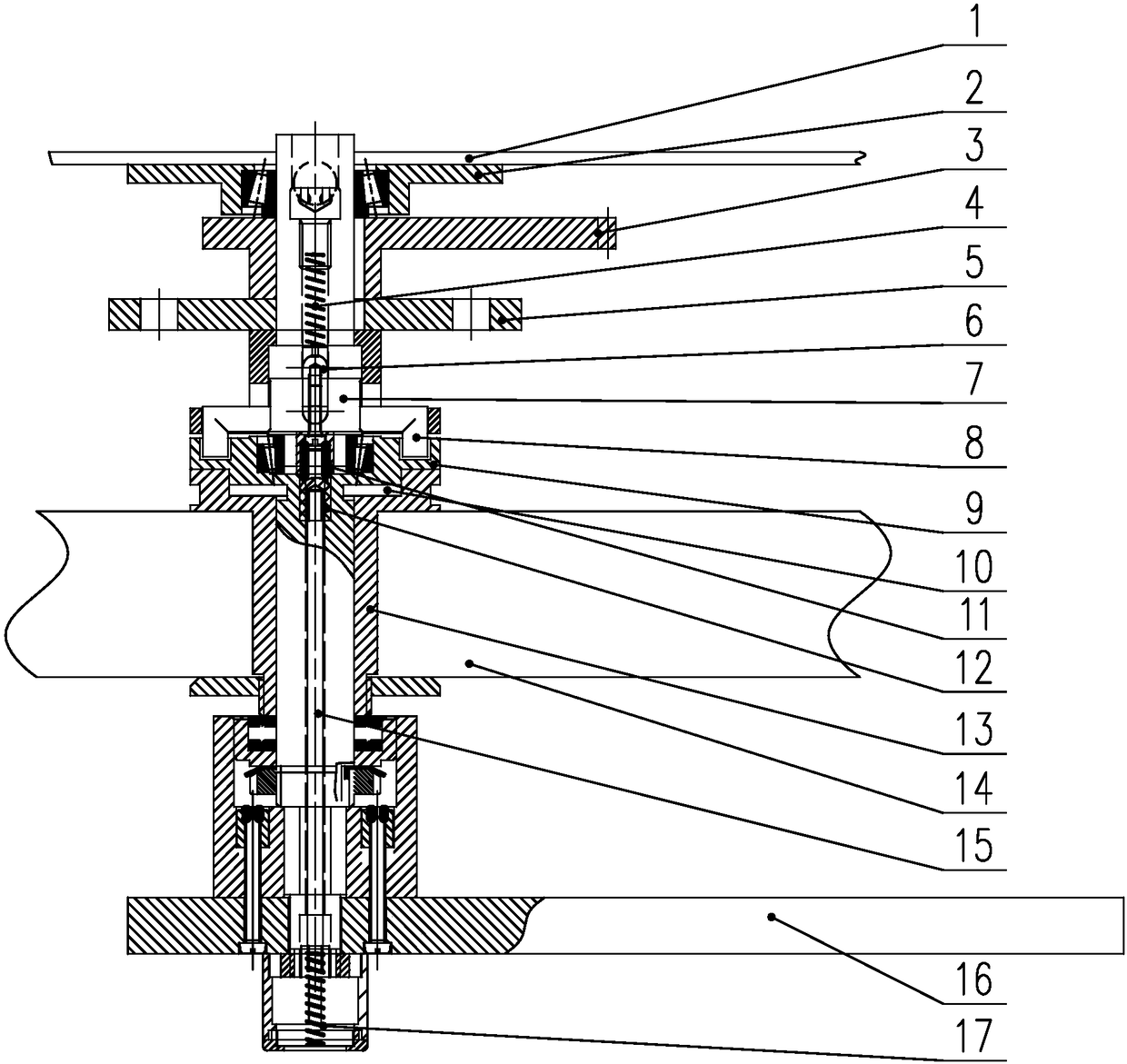

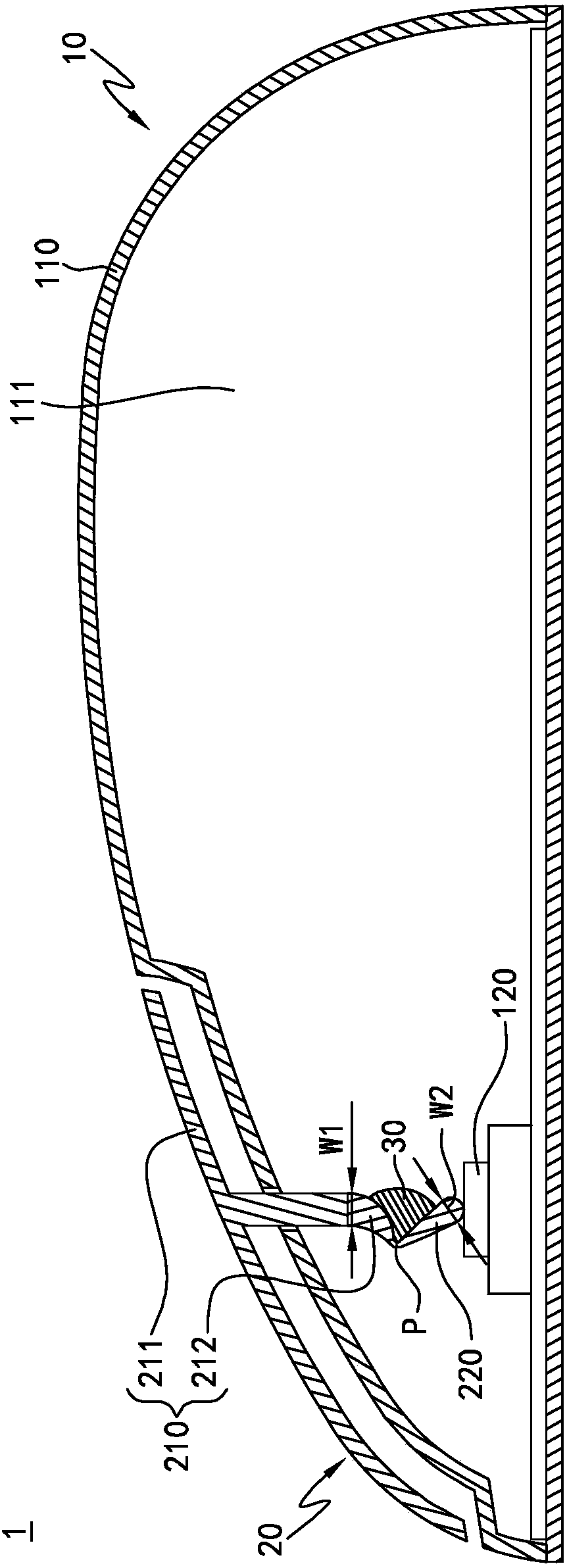

Control valve for an air spring and motor vehicle seat having a control valve

ActiveCN104144821AEasy to controlSmall toleranceOperating means/releasing devices for valvesEqualizing valvesAir springEngineering

The invention relates to a control valve (16) for an air spring, comprising a housing (41), an exhaust duct that has an exhaust tappet (26) for opening of closing the exhaust duct, which exhaust tappet interacts with a first control means (19), a ventilation duct that has a ventilation tappet (27) for opening or closing the ventilation duct, which ventilation tappet interacts with a second control means (20), and a supplemental duct having a supplemental tappet (28) for opening or closing the supplemental duct, which supplemental tappet interacts with a third control means (21), wherein a first air connection A connects to the exhaust duct and a second air connection P connects to the exhaust duct together with the supplemental duct, wherein a first control means (19) and a second control means (20) are arranged to one another in such a manner that said control means cannot be actuated at the same time by an control element (18), and wherein the second control means (20) and the third control means (21) are arranged to one another in such a manner that the supplemental duct can only be opened when the ventilation duct is opened. The invention further relates to a motor vehicle seat comprising a mechanical swing system and an air spring, which motor vehicle seat has such a control valve.

Owner:GEBR ISRINGHAUSEN GMBH & CO KG

Polishing machine

PendingCN110315413AHigh degree of automationReduce labor inputPolishing machinesGrinding drivesEngineeringCam

The invention discloses a polishing machine. The polishing machine aims to solve the problem of simultaneously performing feeding, discharging and polishing machining of workpieces in the prior art. The polishing machine comprises a machine frame, clamping mechanisms, polishing mechanisms and feeding mechanisms, wherein each feeding mechanism comprises a first sliding table, a second sliding tableand a cam divider, each clamping mechanism comprise a support, rotatable lower pressing discs are arranged on each support, first motors are in transmission connection with the lower pressing discs,first air cylinders are arranged on the supports, the output ends of the first air cylinders are provided with rotatable upper pressing discs, the first motors can drive the workpieces clamped betweenthe upper pressing discs and the lower pressing discs to rotate, the output ends of the cam dividers are fixedly arranged on the supports, each clamping mechanism is provided with at least two lowerpressing discs and at least two upper pressing discs, the cam dividers can drive the workpieces clamped between the upper pressing discs and the lower pressing discs to rotate in the circumferential direction so that the workpieces at different positions can simultaneously undergo feeding, discharging and polishing.

Owner:永康市沪邦机械科技有限公司

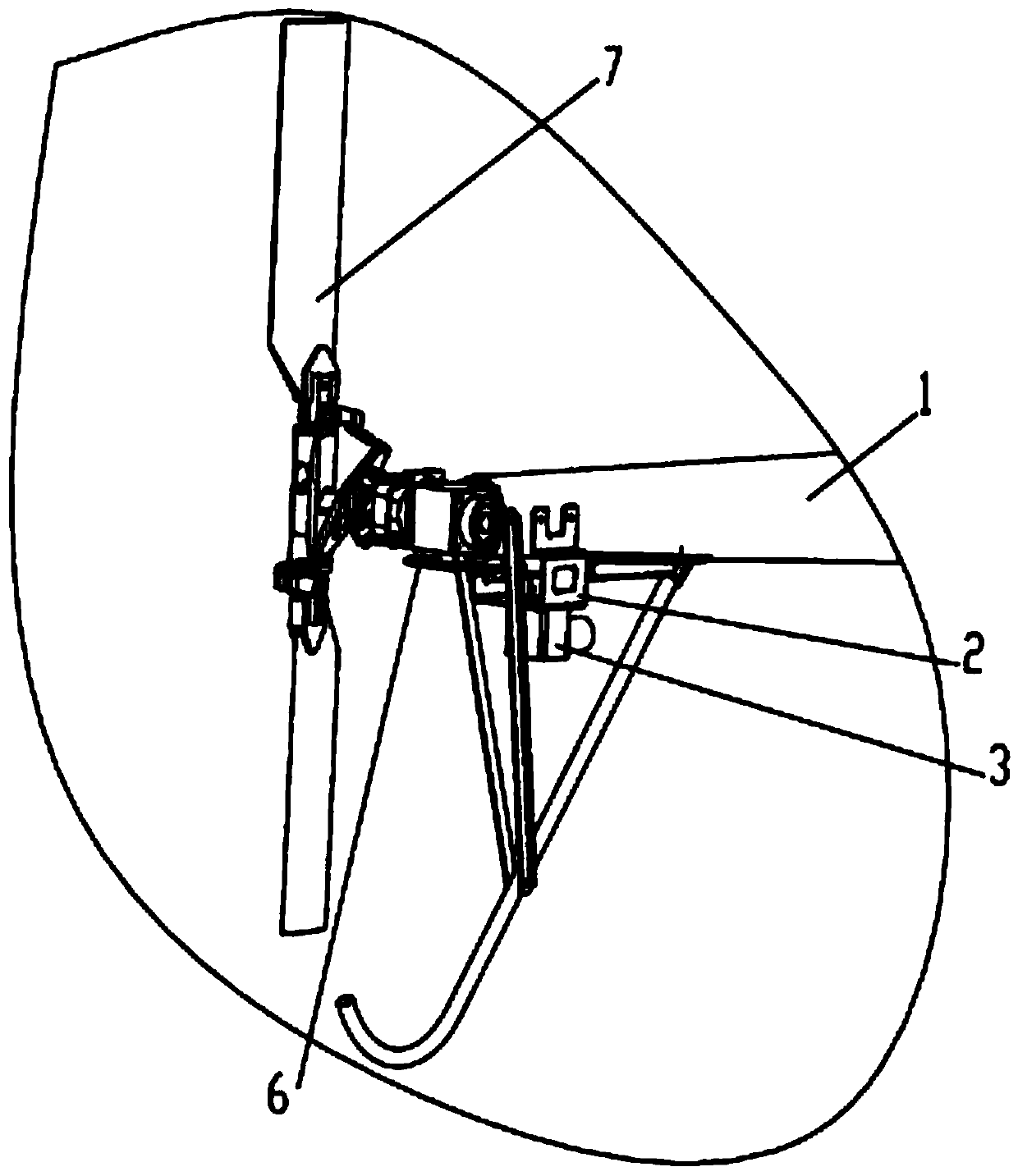

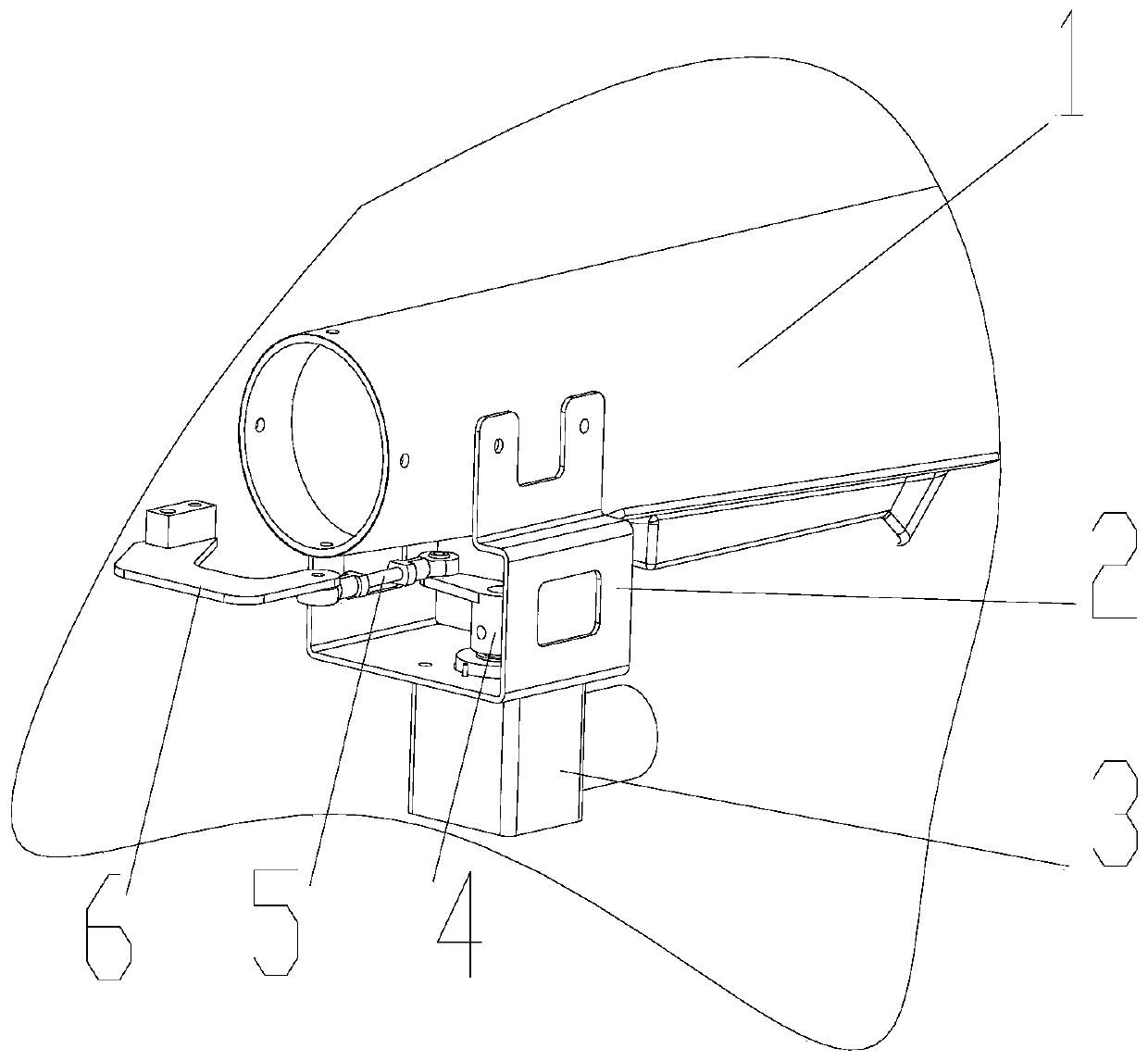

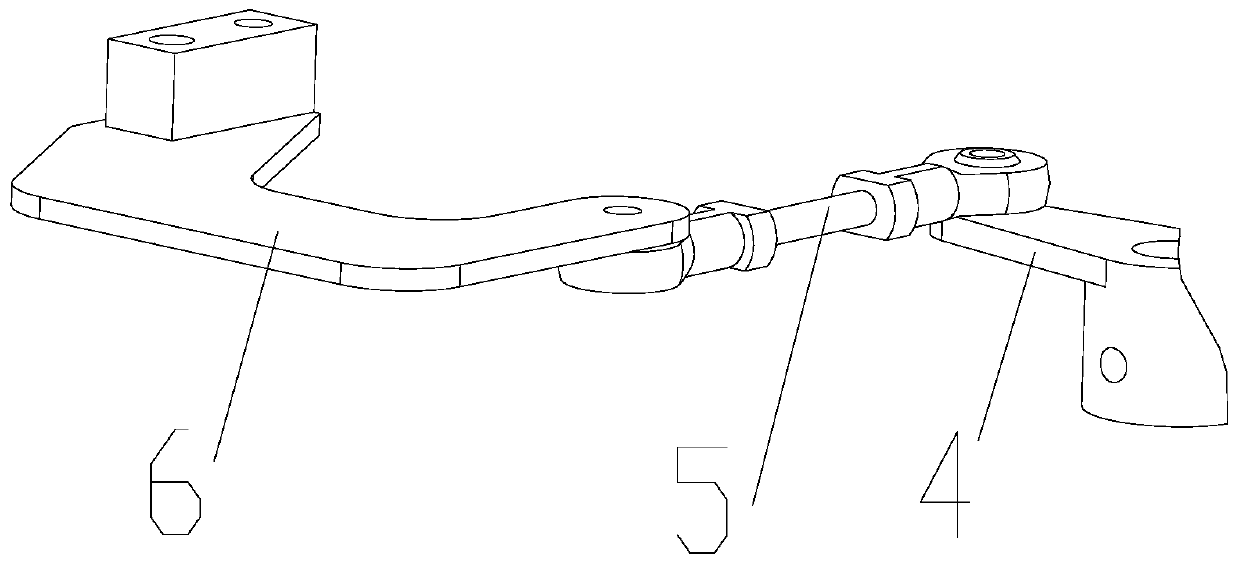

Tail vane refitting structure for refitting manned helicopter into aviation fire extinguishing device

Owner:STATE GRID HUNAN ELECTRIC POWER +2

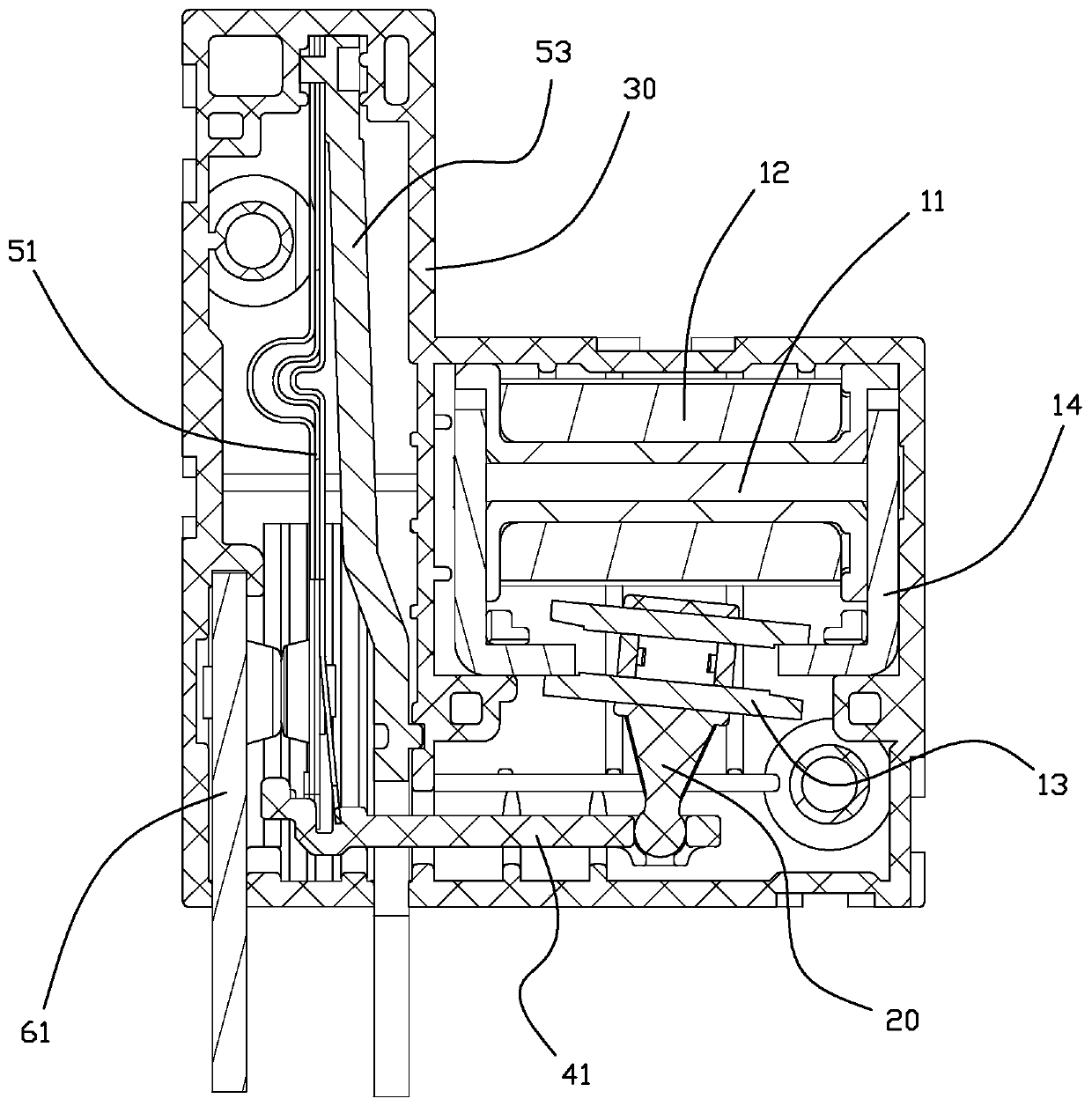

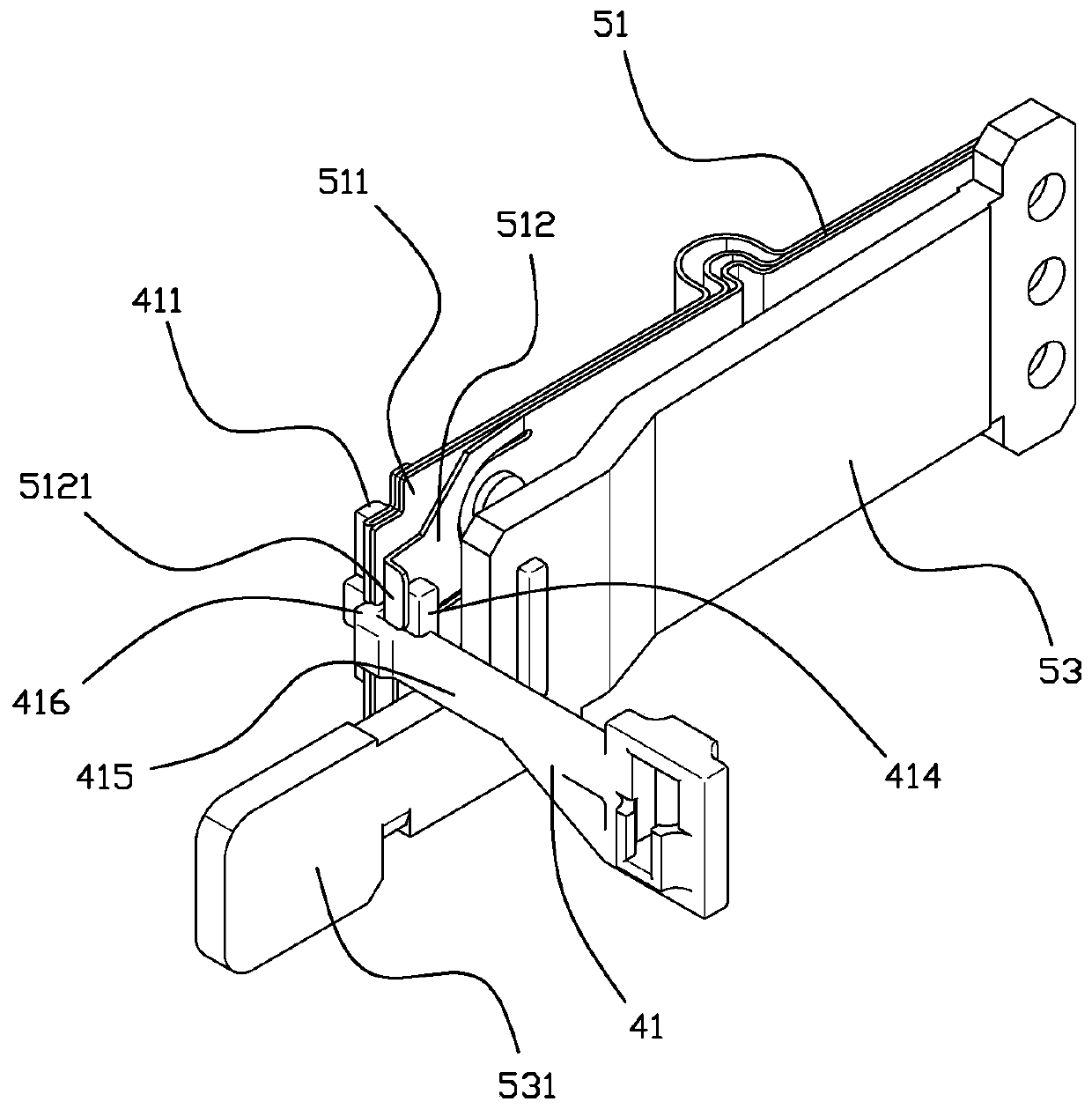

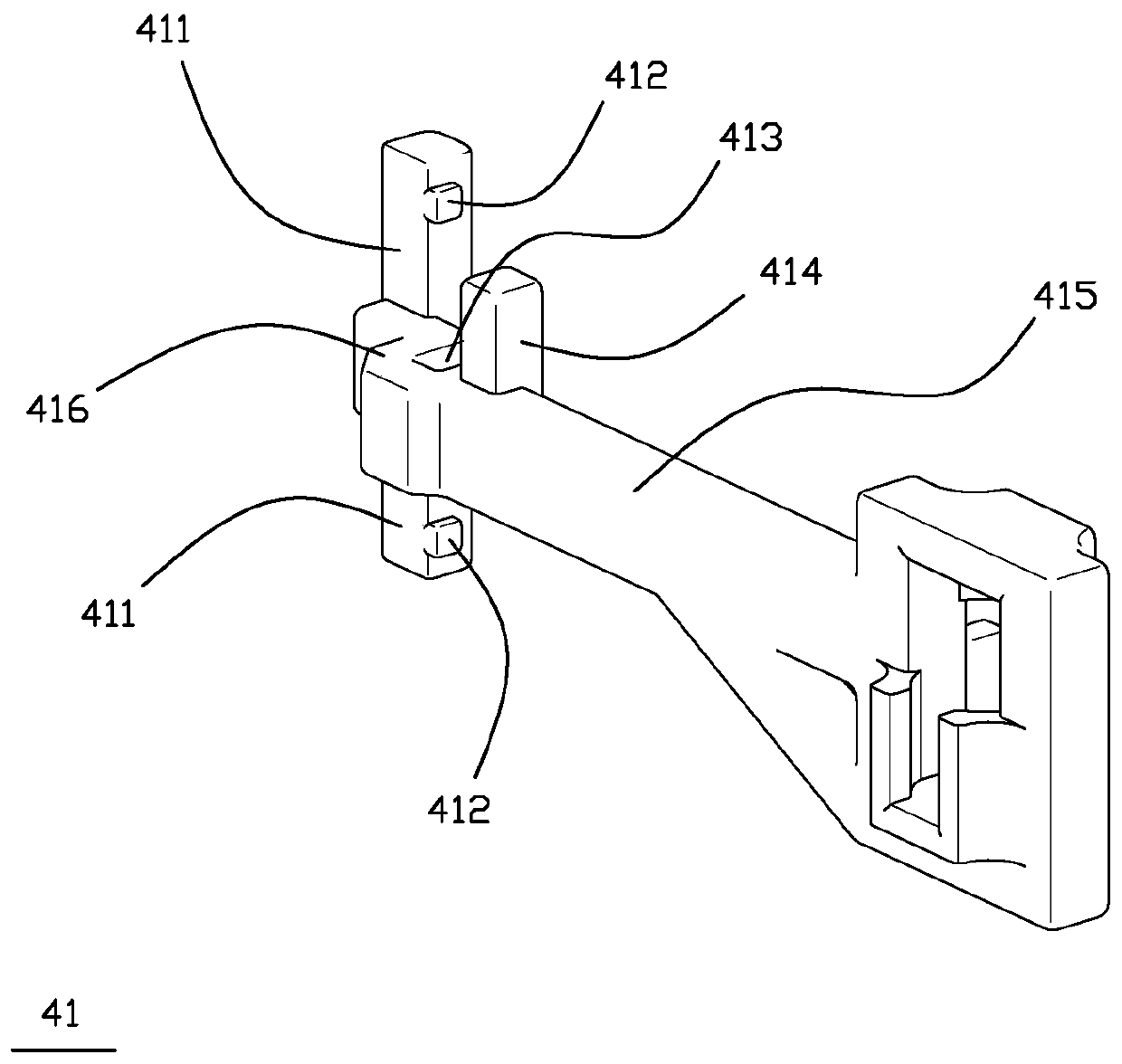

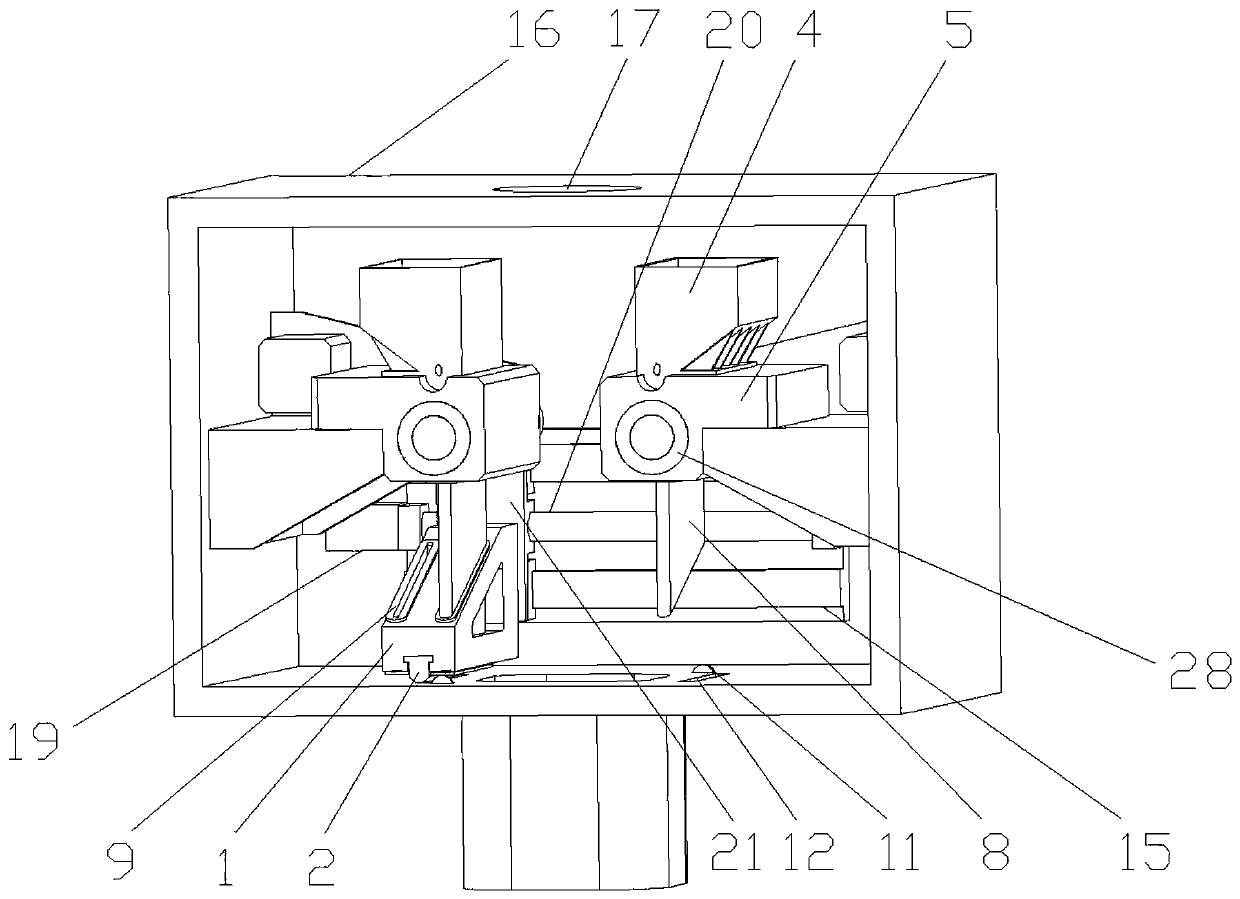

Relay capable of reducing contact jitter

PendingCN110544604AReduce arcingReduce the probability of stickingElectromagnetic relay detailsPush pullMiniaturization

The invention relates to a relay capable of reducing contact jitter. A pulling block cooperates with a clamping groove, so as to respectively locate a main body movable reed and a counter-force reed;especially, the clamping groove effectively limits the jitter stroke of the counter-force reed, thereby avoiding the idle stroke caused by kinetic energy in the action process, reducing the jitter ofthe movable reed part in the contact closing process, reducing the springback, avoiding the electric arcs generated between contacts due to springback, and reducing the bonding probability of the contacts. In the breaking process of the contact, the vibration phenomenon of the movable contact is reduced, and the situation of electric arc reignition is avoided. A push-pull rod effectively fixes themovable reed part through the combination of the pull block and the clamping groove, and solves the interference problem at one side close to a movable reed leading-out piece, so that the design of the movable reed leading-out piece is simpler, and the miniaturization design of the relay is facilitated. The pulling block is contacted with the main body movable reed through a convex bract, so thatthe stressed position of the main body movable reed can be fixed, and furthermore, the contact disconnection positions are consistent.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

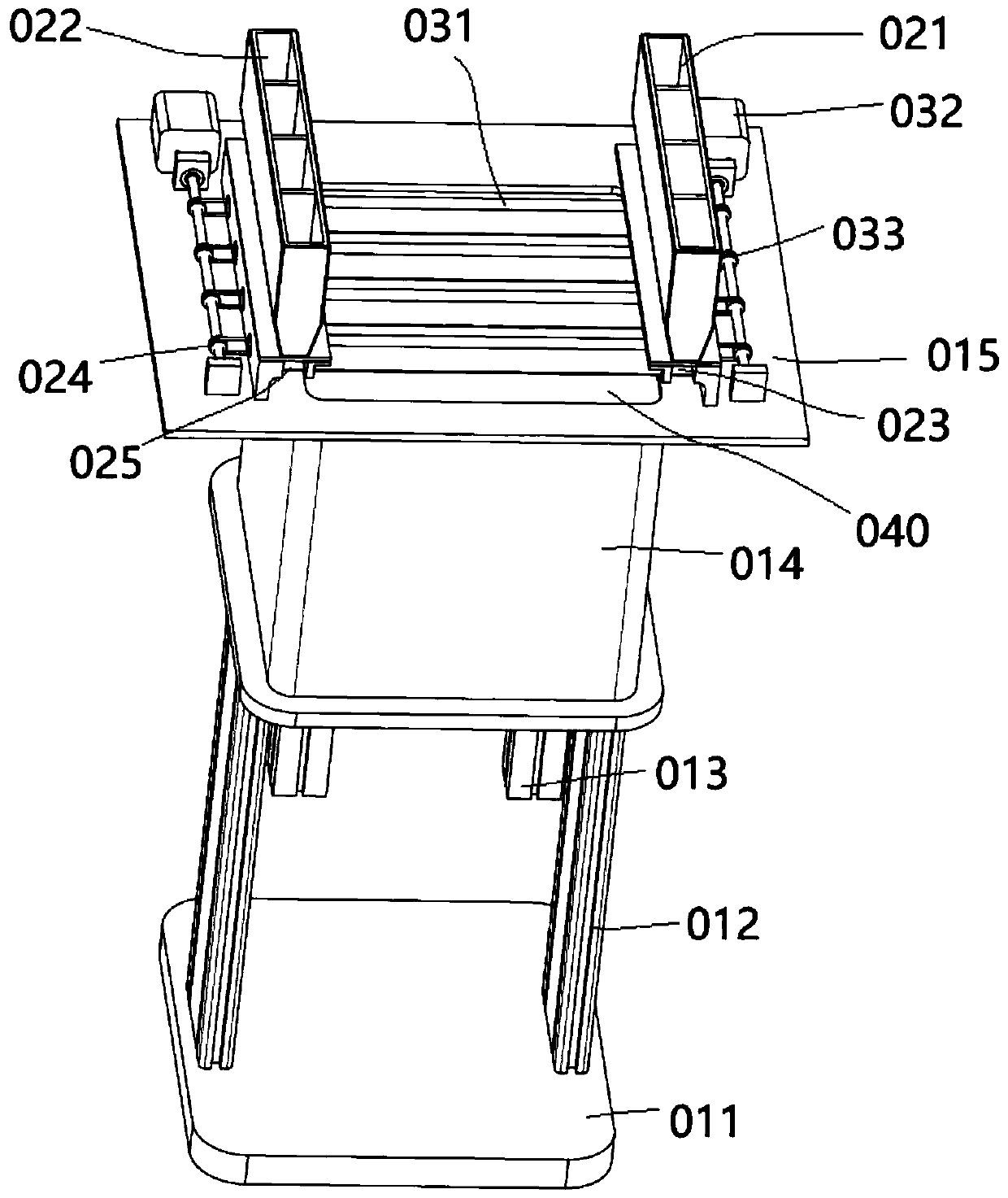

Bidirectional quantitative powder supplying and spreading device for additive manufacturing

PendingCN109795110AAvoid empty tripsImprove spreading efficiencyManufacturing driving means3D object support structuresEngineeringElectrical and Electronics engineering

The invention discloses a bidirectional quantitative powder supplying and spreading device for additive manufacturing. The bidirectional quantitative powder supplying and spreading device comprises aworktable, a powder spreading mechanism capable of linearly and slidably mounted on the worktable in a reciprocating mode in the left-right direction, a first driving device mounted on the worktable and used for driving the powder spreading mechanism to slide, and two power supplying devices mounted on the worktable, located on a sliding path of the powder spreading mechanism and used for supplying powder to the powder spreading mechanism; the powder spreading mechanism comprises a scraper mounting seat driven by the first driving device to slide in a reciprocating mode, a scraper mounted at the bottom of the scraper mounting seat, and two powder spreading flow passes formed in the scraper mounting seat and located in the left side and the right side of the scraper; and powder supplying grooves are formed in the bottoms of the power supplying devices, and the two powder spreading flow passes are used for bearing the powder falling from the two powder supplying grooves to achieve bidirectional powder spreading of the powder spreading mechanism. Bidirectional powder spreading can be achieved, the idle stroke is avoided, the bidirectional stroke is effectively utilized for powder spreading operation, and thus the powder spreading efficiency is improved.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD

Electric pruning shears

The electric pruning shears disclosed by the present invention comprise: a casing, a motor inside the casing, a transmission device connected to the motor, a pair of blade sets, and a trigger mounted on the casing for controlling the motor. The blade includes a fixed blade and a movable blade, and the movable blade reciprocates under the drive of the motor. It is characterized in that the electric pruning shears also include a travel switch installed on the casing, and the travel switch is It includes two states. When the travel switch is in the first state, the movable blade has a first stroke; when the travel switch is in the second state, the movable blade has a second stroke different from the first stroke. The pruning shears effectively overcome the defects of wasting time and electric power when the existing pruning shears cut thin branches.

Owner:NANJING CHERVON IND

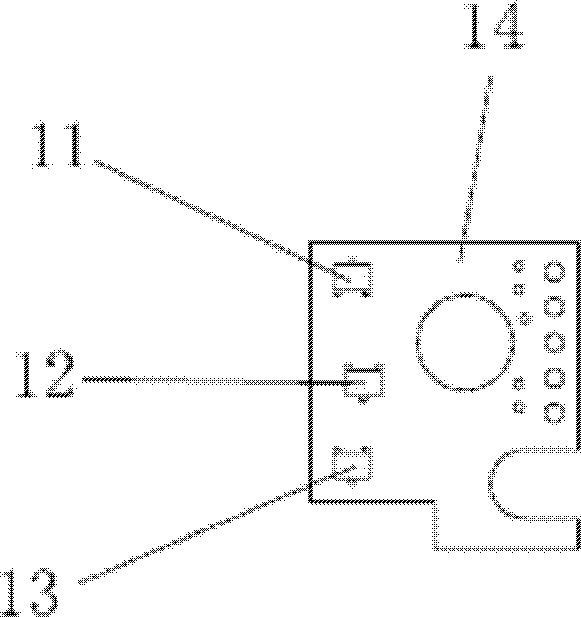

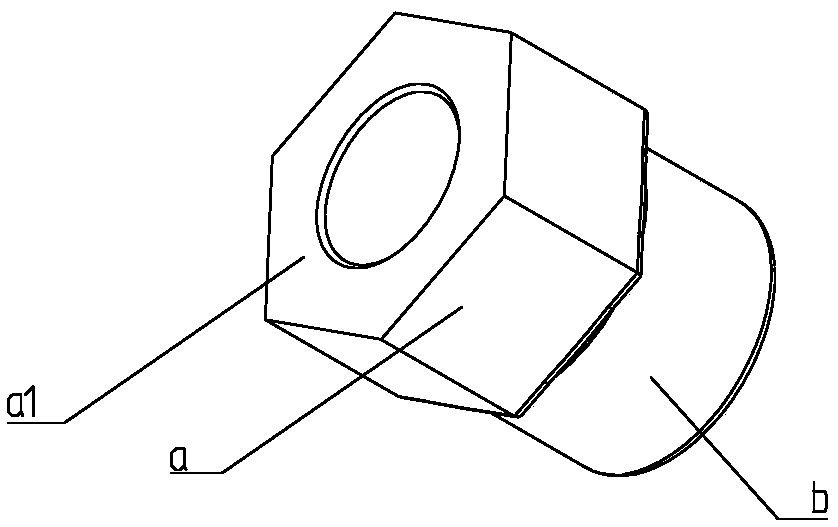

Thread processing device of high-consistency nuts

PendingCN109570654AImprove consistencyImprove coaxialityThread cutting feeding devicesEngineeringScrew thread

The invention discloses a thread processing device of high-consistency nuts. The thread processing device comprises screening nut vibrating disks and nut tapping machines, wherein a discharging opening of each screening nut vibrating disk communicates with a corresponding nut guiding path; an outlet of each nut guiding path is located at an inlet of the corresponding nut tapping machine; a material pushing mechanism is arranged at an inlet of each nut tapping machine, and comprises a driving mechanism and a push rod connected to the power output end of the driving mechanism; each push rod is used for pushing nuts at an outlet of the corresponding nut guiding path into the corresponding nut tapping machine; each nut guiding path is provided with two guiding pipelines; and each guiding pipeline corresponds to the corresponding nut tapping machine. According to the thread processing device disclosed by the invention, each guiding pipeline is twisted along the axis of the corresponding guiding pipeline; in the course of moving the guiding pipelines, directions of the nuts are changed, so that the axis of the nuts at an outlet of each guiding pipeline coincides with the axis of the corresponding push rod; and sieving and unifying are performed through screening of the screening nut vibrating disks, and then the nuts are pushed into nut tapping teeth through the material pushing mechanism, so that the processing consistency of the nuts is substantially improved.

Owner:海盐华胜紧固件有限公司

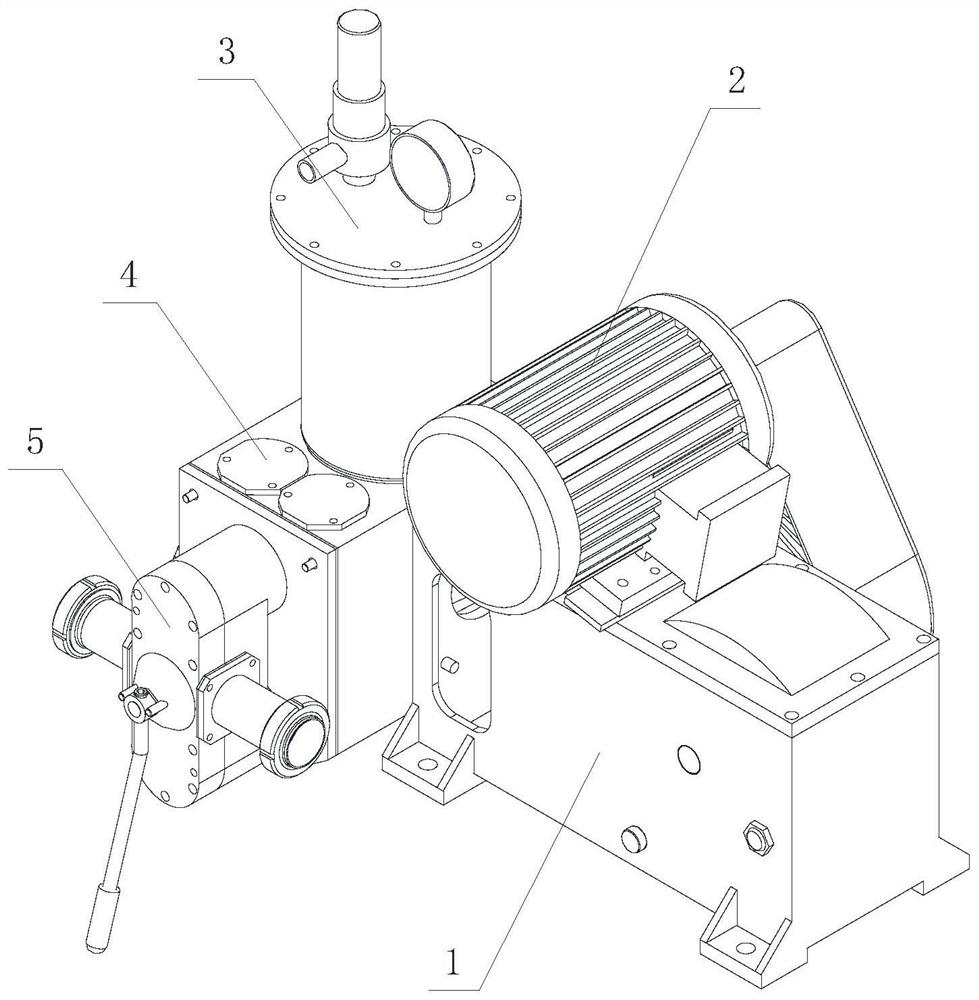

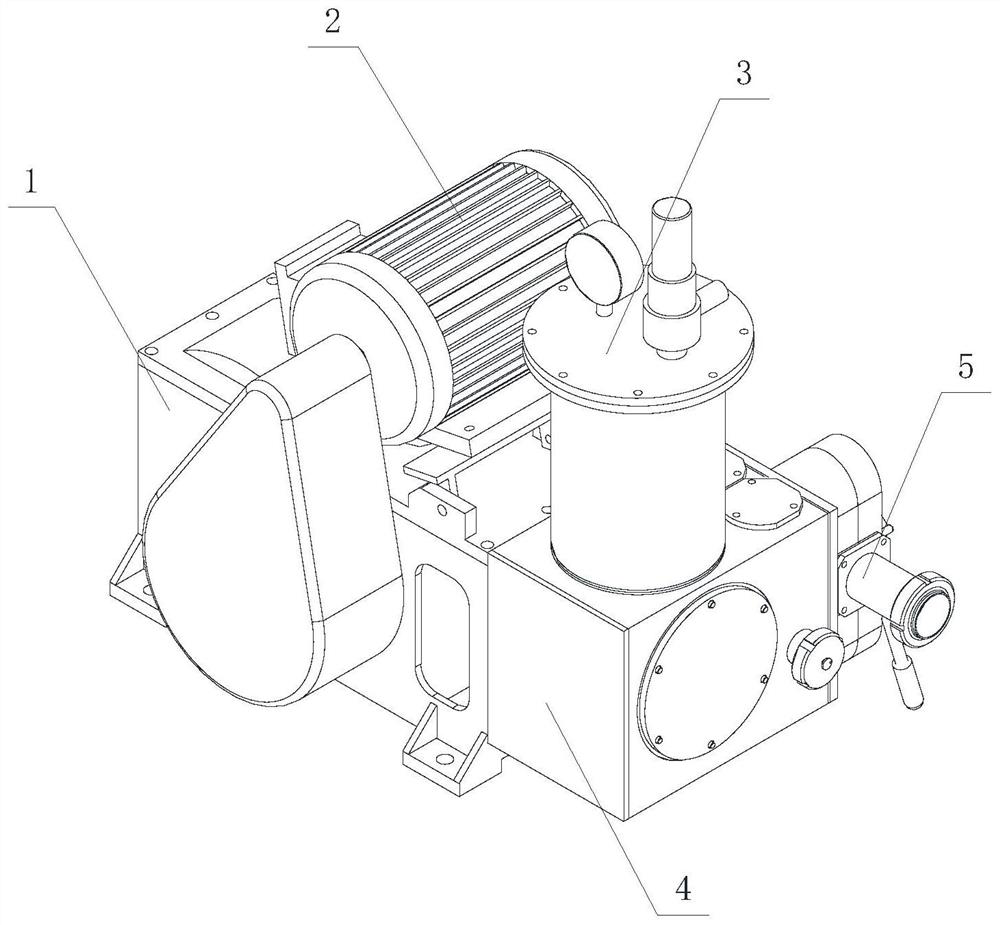

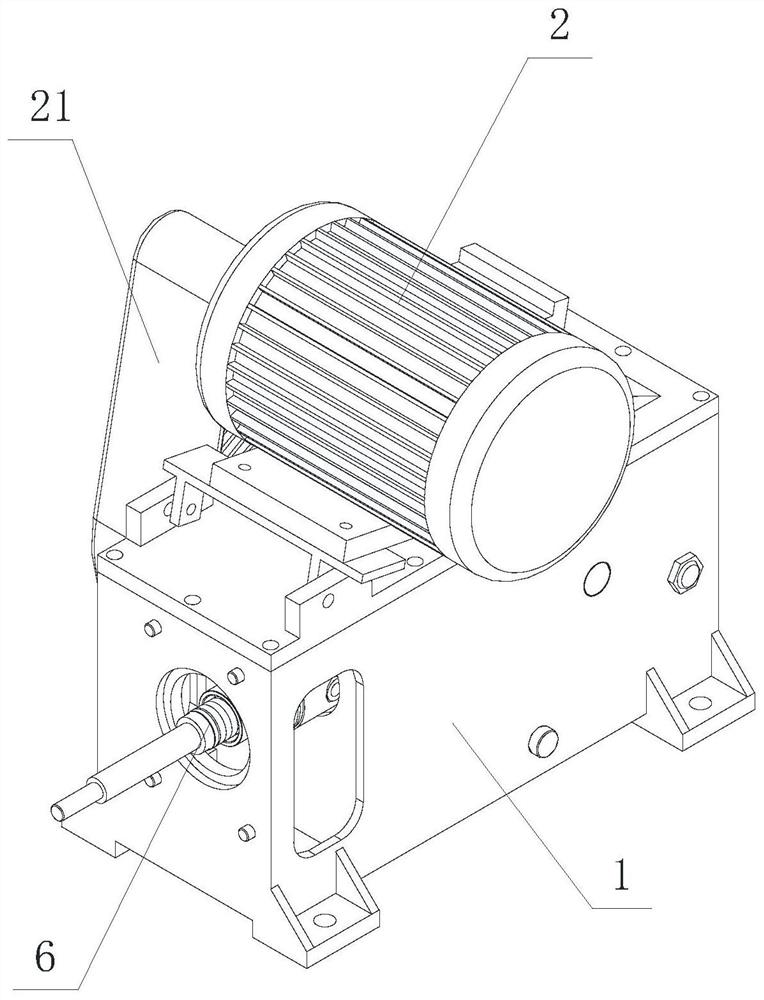

Uninterrupted water supply plunger pump system

PendingCN112855519ALarge and stable output forceStable and reliable output forcePositive displacement pump componentsPump installationsReciprocating motionWater flow

The invention provides an uninterrupted water supply plunger pump system. The uninterrupted water supply plunger pump system comprises a plunger pump device, a reciprocating driving mechanism and a valve body; a sliding plug cavity, a first sub water inlet cavity, a second sub water inlet cavity, a main water inlet cavity and a water outlet cavity are formed in the plunger pump device; one-way valves for realizing blockage or communication in the water flowing direction are respectively arranged between the first sub water inlet cavity and the main water inlet cavity, between the second sub water inlet cavity and the main water inlet cavity, between the water outlet cavity and the first sub water inlet cavity and between the water outlet cavity and the second sub water inlet cavity; the reciprocating driving mechanism is used for pushing a sliding plug to perform a reciprocating motion in the sliding plug cavity; and the valve body is provided with a water inlet pipe and a water outlet pipe. The uninterrupted water supply plunger pump system is compact in structure and convenient to assemble, can realize uninterrupted water supply, can realize fluid reversing through the valve body, and is wide in application range.

Owner:宁波贡承机械有限公司

Multi-zone array selective melting manufacturing equipment and process

ActiveCN111267344BReduce waiting time for spreading powderImprove processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyReciprocating motionElectric machinery

The invention relates to a multi-division array type selective melting manufacturing equipment and a process. A forming bin of the device is connected to a forming bottom plate through a lifting guide rail, a forming platform is arranged on the upper end of the forming bin, and a plurality of parallel powder spreading grids are arranged on the forming platform. The powder forming area on the forming platform is divided into a plurality of array powder selection areas, a powder silo is respectively provided on both ends of the powder spreading grid, and both ends of the powder spreading grid and the powder silos on it pass through respectively. The sliding base of the silo is connected with the forming platform, and the sliding base of the silo drives the powder spreading grid and the powder silo to reciprocate vertically along the powder spreading direction on the forming platform to form multi-zone powder spreading. Printing is carried out in the middle, so that powder spreading and printing are relatively isolated; there are several small scrapers in the powder spreading grid, and the small scrapers are connected to the scraper driving motor through the scraper driving mechanism, and the scraper driving motor drives the small scrapers on the powder spreading grid through the scraper driving mechanism. Internal reciprocating motion, spread the powder evenly in the powder grid.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

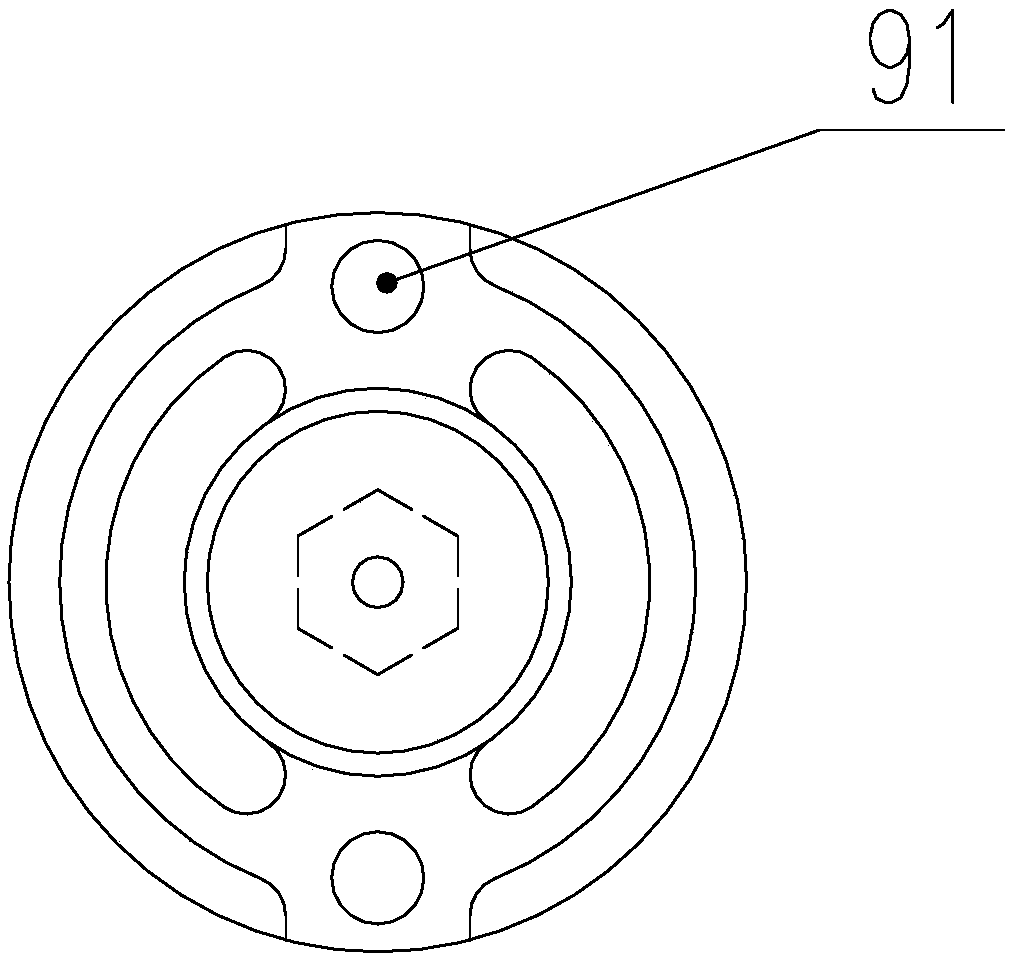

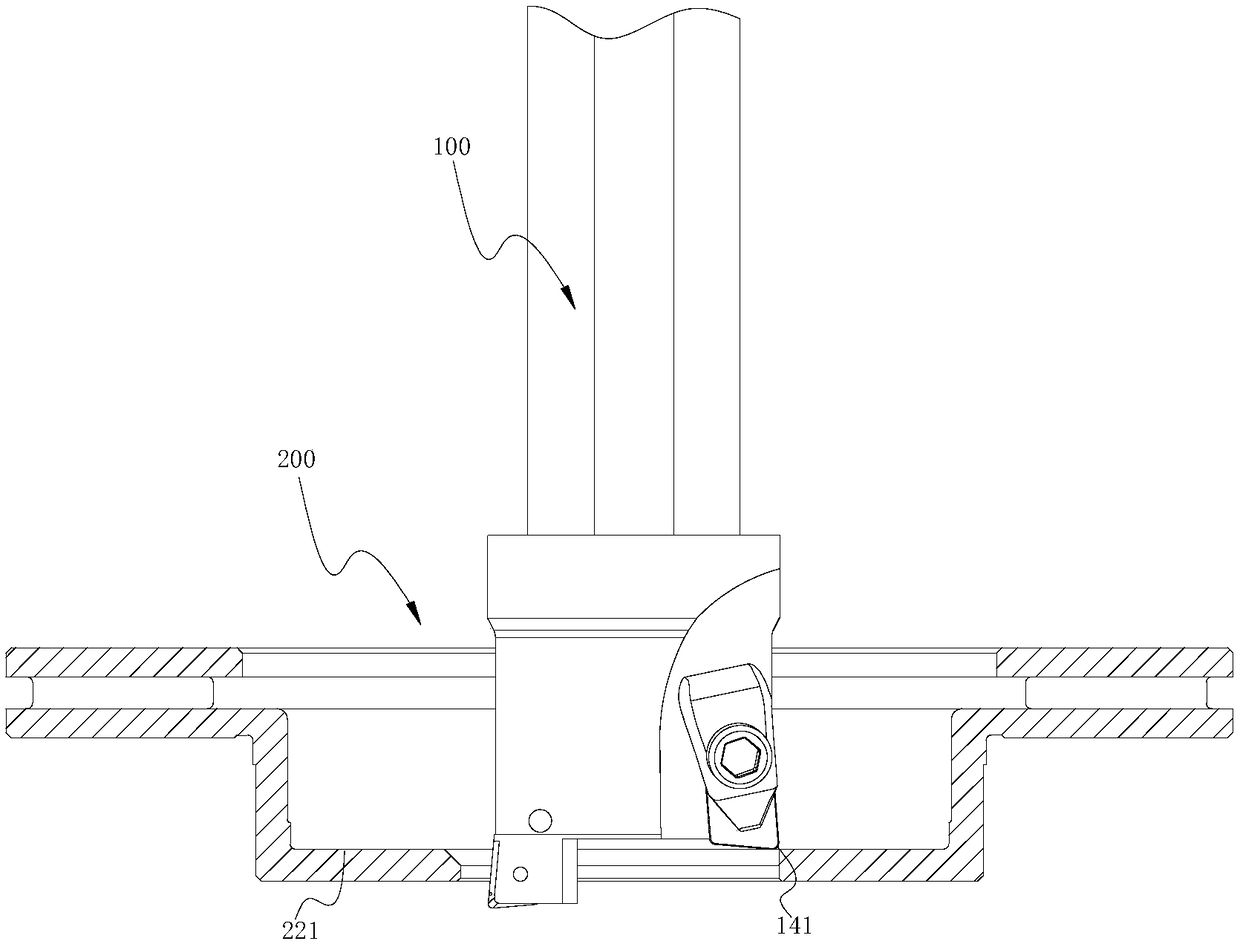

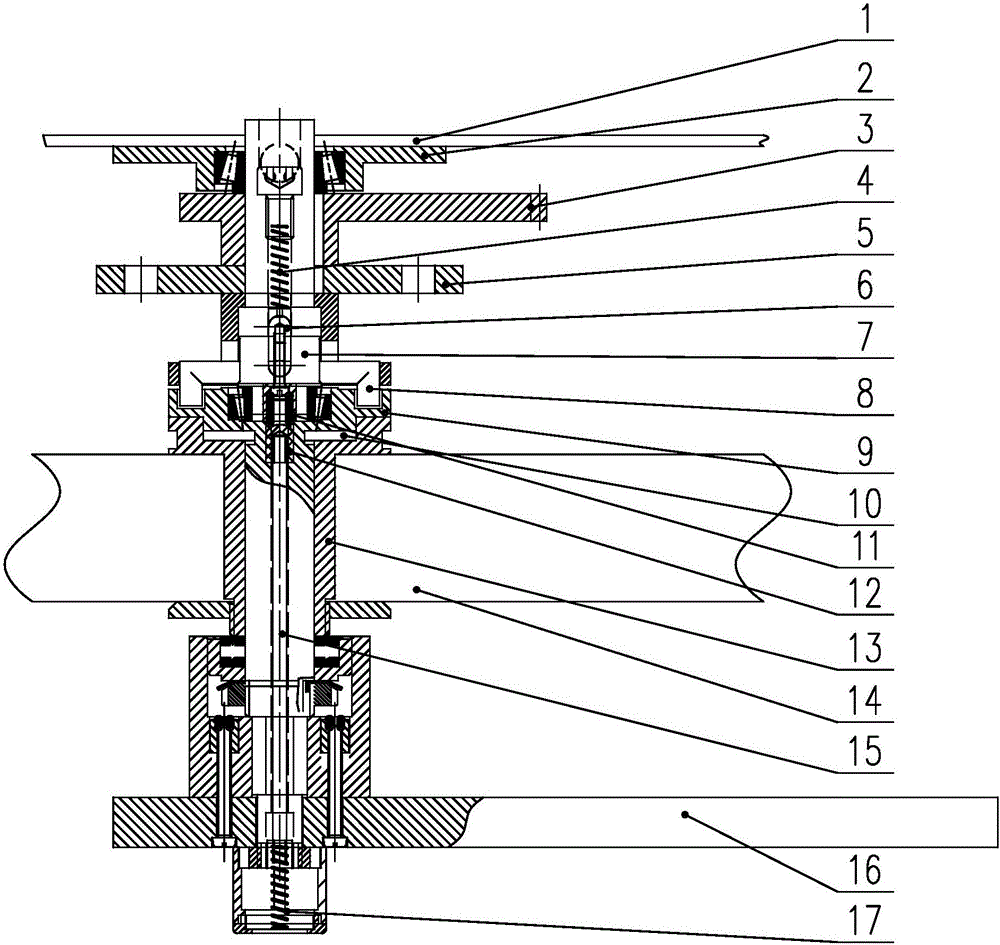

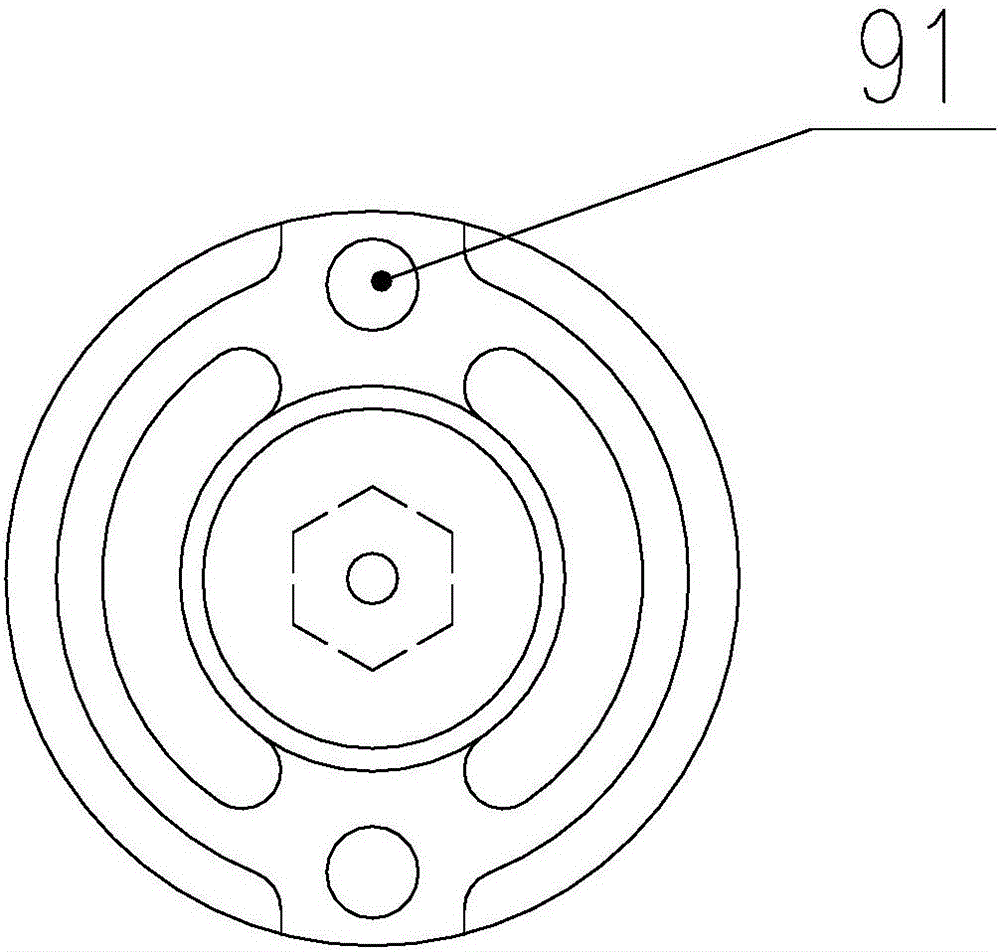

Screen door locking manual electric switching device

ActiveCN106522725BGuaranteed against wearMotion oriented smoothMan-operated mechanismPower-operated mechanismEngineeringElectric drive

The invention discloses a shielded gate locking manual-electric operation switching device. The switching device comprises an electric shaft, an electric driving part, a manual driving part and a connection shaft pushing component, wherein the electric shaft is provided with a movable connection shaft and rotatably supported on a shielded gate; the electric shaft is in transmission connection with a gate locking device of the shielded gate, so that the electric shaft drives the gate locking device to act when being driven to rotate, and opening and closing of the shielded gate are achieved; the manual driving part penetrates through a shield-sealing material layer of the shielded gate; the electric driving part is in transmission connection with the electric shaft; the connection shaft pushing component is connected with a connection shaft, so that the connection shaft pushing component acts to enable the connection shaft and the manual driving part to be separated or connected; and when the electric driving part does not act, the connection shaft pushing component acts so that the connection shaft and the manual driving part can be connected, and then the manual driving part drives the electric shaft to rotate. According to the shielded gate locking manual-electric operation switching device, not only can no-spare-stroke switching of manual gate opening and closing be ensured, but also convenient switching of manual operation and electric operation can be ensured.

Owner:常州雷宁电磁屏蔽设备有限公司

Defect detection equipment

PendingCN113804688AEasy to debugEasy to operateOptically investigating flaws/contaminationSortingEngineeringStructural engineering

The invention discloses defect detection equipment, which aims to overcome the problems of low working efficiency and missing detection in the prior art. The defect detection equipment comprises a base, wherein a working table capable of vertically sliding is arranged on the base, a height adjusting mechanism is arranged between the base and the working table, a discharging mechanism and a detection mechanism capable of transversely sliding are arranged on the working table, the height adjusting mechanism is used for adjusting the height of the working table on the base, the detection mechanism comprises a background plate, a light source and a CCD camera and can photograph passing gloves, the discharging mechanism comprises a third rack, the third rack is fixedly arranged on the working table, a driving device is arranged on the third rack, a rotating shaft is further rotationally arranged on the third rack, the driving device is in transmission connection with a rotating shaft, at least two pneumatic fingers are fixedly arranged in the circumferential direction of the rotating shaft, and the pneumatic fingers are used for detaching defective gloves, so that continuous discharging is supported.

Owner:杭州超凡自动化科技有限公司

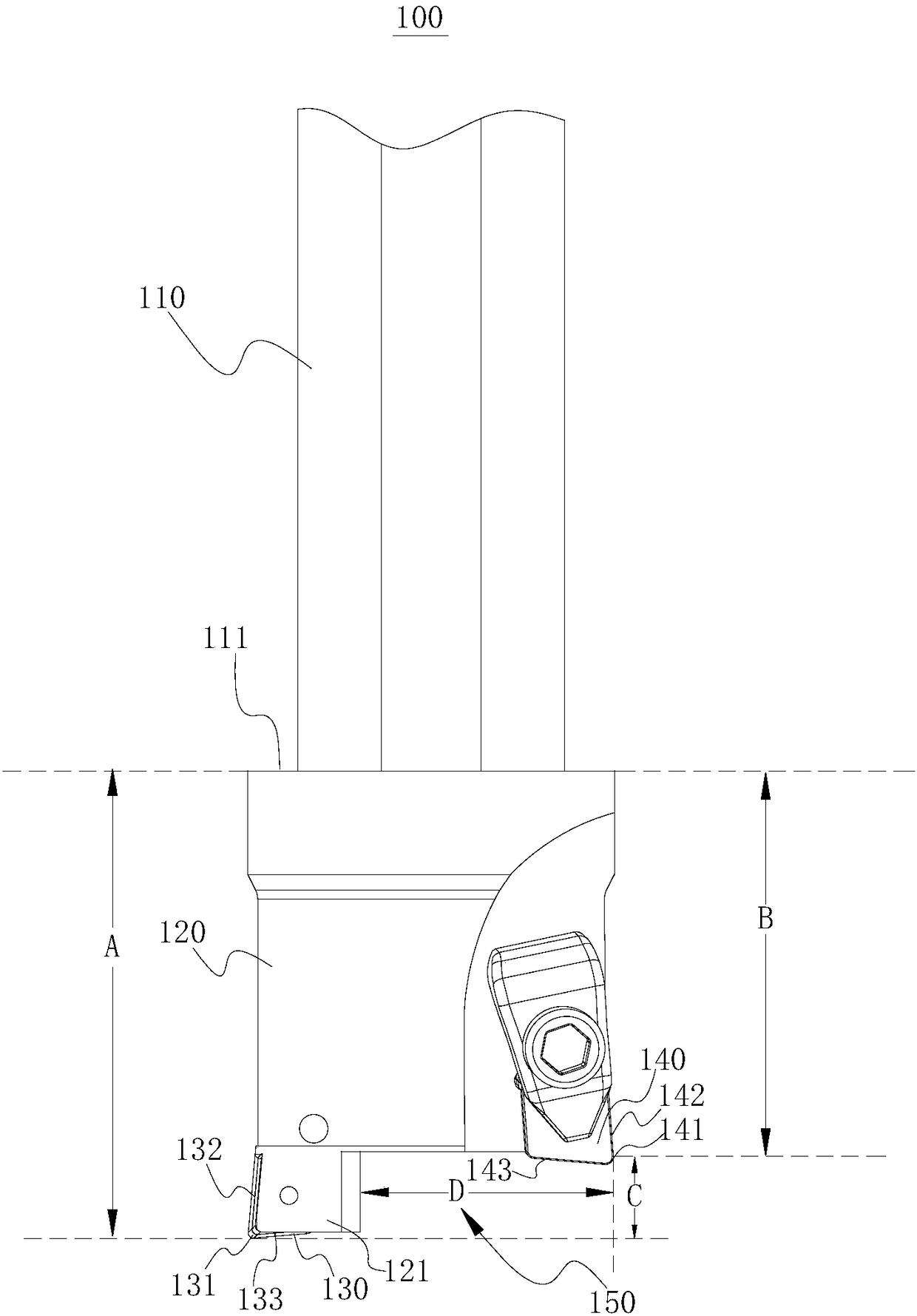

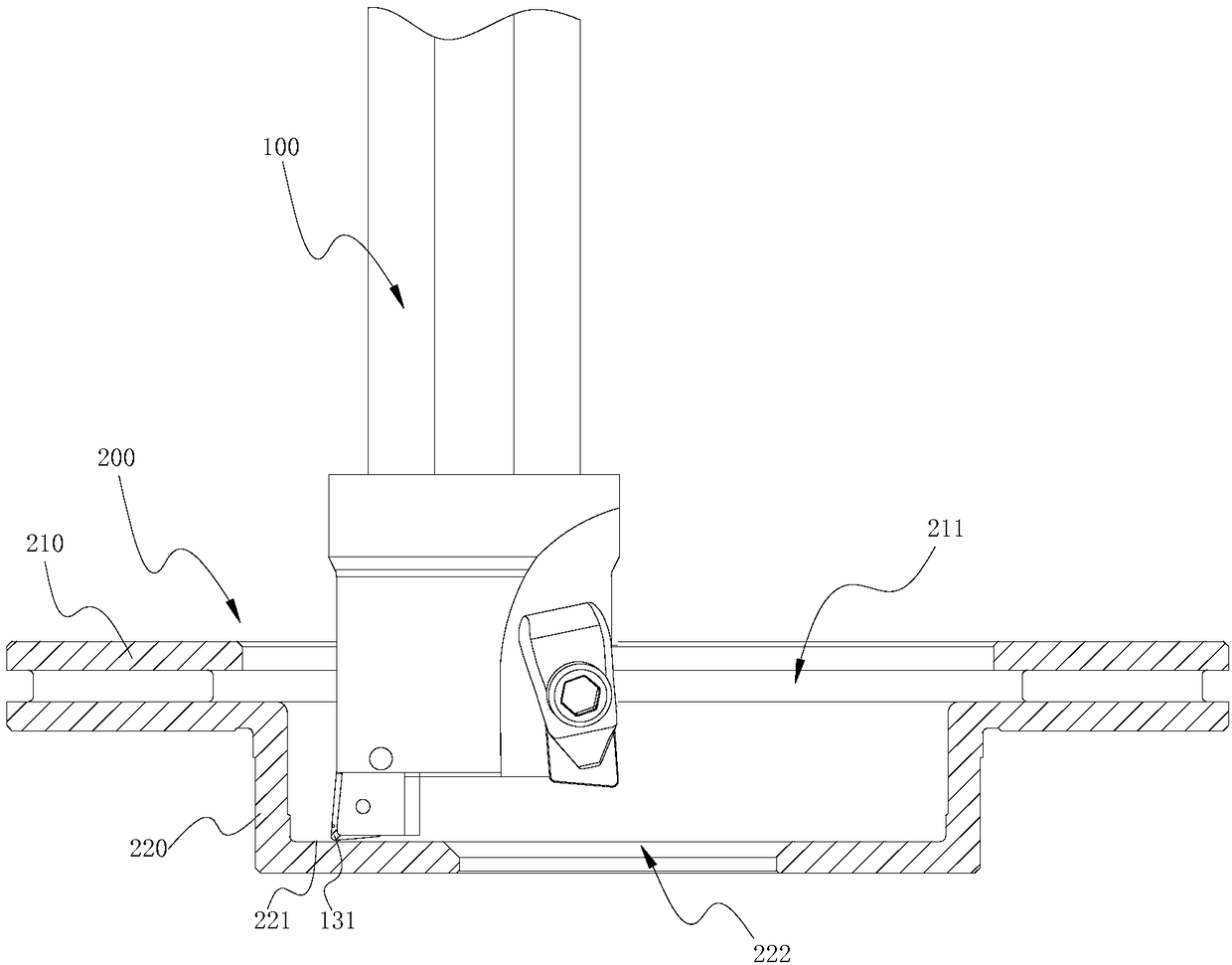

Multipurpose lathe tool with axial height difference

PendingCN108326329AAvoid Repeat Positioning AccuracyFast state switchingCutting insertsTurning toolsTool bitShortest distance

The invention belongs to the technical field of lathe tools and provides a multipurpose lathe tool with the axial height difference. The multipurpose lathe tool comprises a tool bar, a tool bit, a rough tool blade and a fine tool blade. The tool bit is convexly arranged on the tool bar, one edge of the tool bit is convexly provided with a first containing notch, and the oppositely-arranged other edge is convexly provided with a fixing part. A second containing notch is formed in the fixing part, and the tool bar is provided with a connecting face connected with the tool bit. The rough tool blade is provided with a first main tool nose, and the shortest distance between the first main tool nose and the plane where the connecting face is located is set to be a first distance. The fine tool blade is provided with a second main tool nose, and the shortest distance between the second main tool nose and the plane where the connecting face is located is set to be a second distance. The firstdistance is larger than the second distance. A cutting receding space exists between the rough tool blade and the fine tool blade. According to the multipurpose lathe tool, rough turning and finish turning are achieved through one tool, tool replacement is not needed, positioning is quick and accurate, the distances are short, the tool replacement time is greatly saved, and the tool replacement efficiency is improved.

Owner:成都曼德希新材料有限公司

Shielded gate locking manual-electric operation switching device

ActiveCN106522725AGuaranteed against wearMotion oriented smoothMan-operated mechanismPower-operated mechanismEngineeringElectric drive

The invention discloses a shielded gate locking manual-electric operation switching device. The switching device comprises an electric shaft, an electric driving part, a manual driving part and a connection shaft pushing component, wherein the electric shaft is provided with a movable connection shaft and rotatably supported on a shielded gate; the electric shaft is in transmission connection with a gate locking device of the shielded gate, so that the electric shaft drives the gate locking device to act when being driven to rotate, and opening and closing of the shielded gate are achieved; the manual driving part penetrates through a shield-sealing material layer of the shielded gate; the electric driving part is in transmission connection with the electric shaft; the connection shaft pushing component is connected with a connection shaft, so that the connection shaft pushing component acts to enable the connection shaft and the manual driving part to be separated or connected; and when the electric driving part does not act, the connection shaft pushing component acts so that the connection shaft and the manual driving part can be connected, and then the manual driving part drives the electric shaft to rotate. According to the shielded gate locking manual-electric operation switching device, not only can no-spare-stroke switching of manual gate opening and closing be ensured, but also convenient switching of manual operation and electric operation can be ensured.

Owner:常州雷宁电磁屏蔽设备有限公司

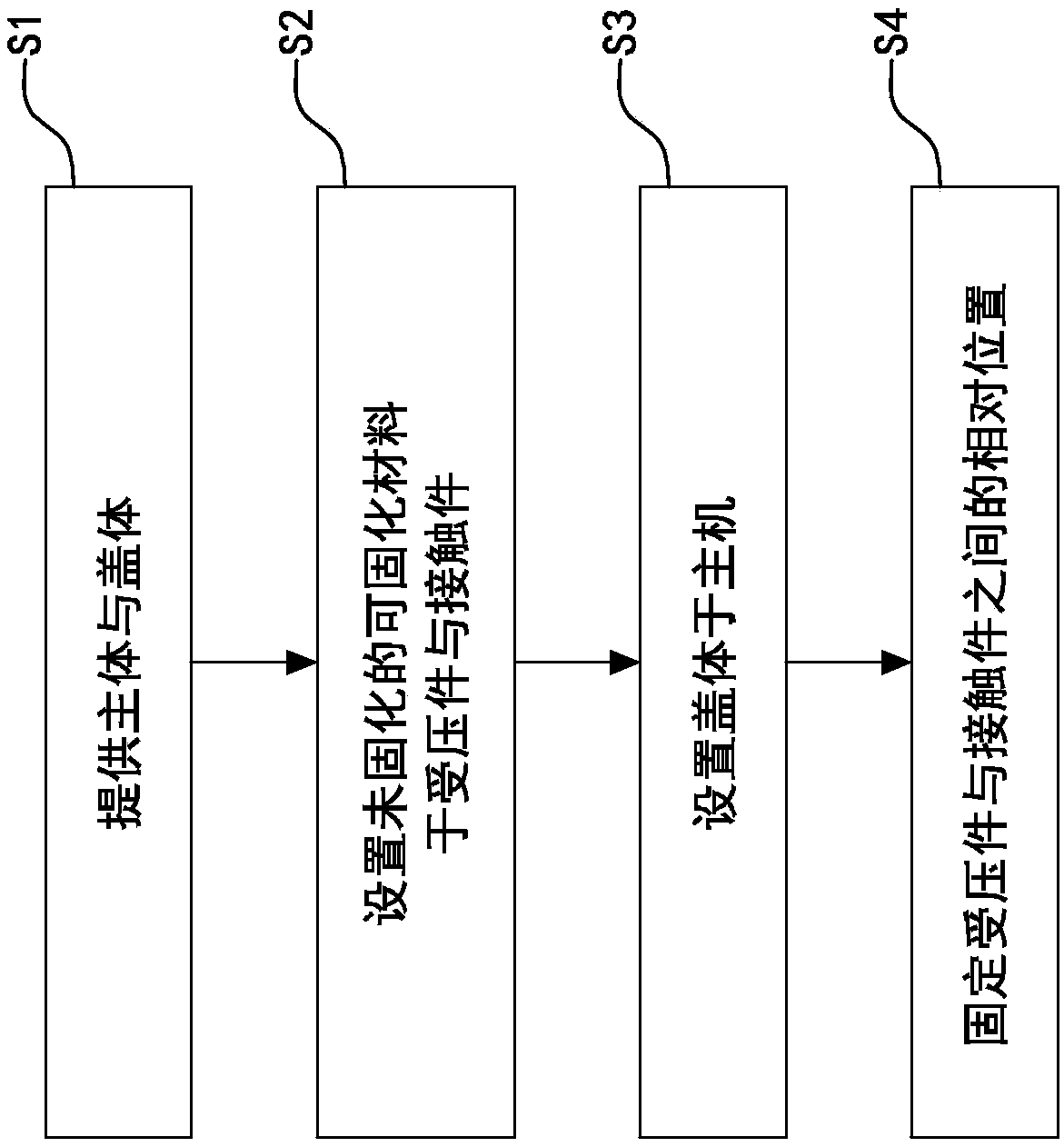

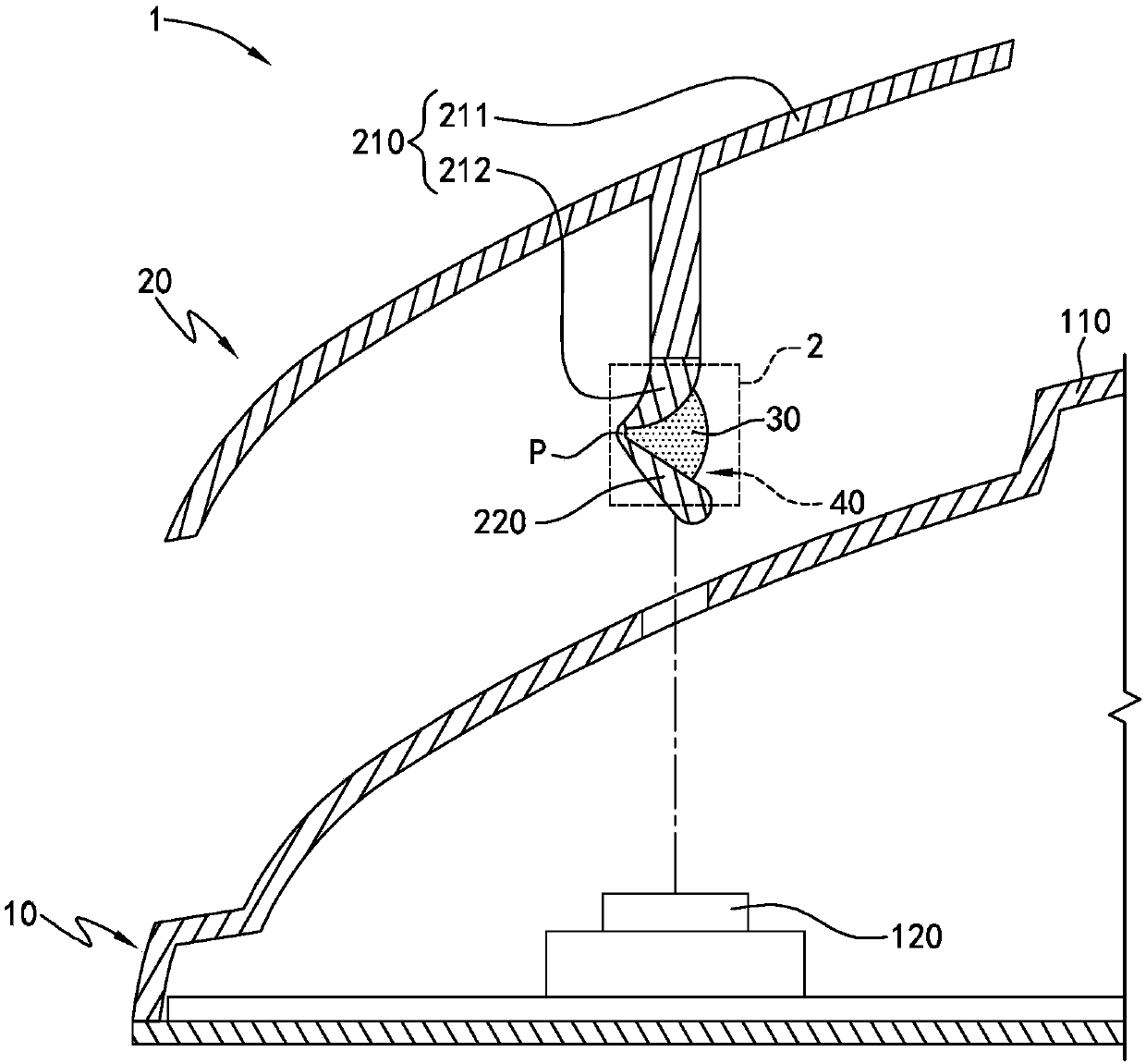

Input device and manufacturing method thereof

ActiveCN107665050ARuns smoothlyAvoid empty tripsInput/output processes for data processingBiomedical engineeringFastener

The invention discloses an input device and a manufacturing method thereof. The method comprises the following steps that a main body is provided, wherein the main body comprises a shell and a switchwhich is arranged in a cavity formed by the shell in an enclosing mode; a cover is provided, wherein the cover comprises a pressure part, a contact part and an elastic fastener. The contact part is directly connected with the pressure part, or the contact part is connected with the pressure part through the elastic fastener; the cover is arranged on the main body, one part of the pressure part isarranged on the shell, the other part of the pressure part is arranged in the cavity. The contact part is directly connected with the other part or connected with the other part through the elastic fastener; the relative position between the contact part and the pressure part is adjusted, so that the contact part just makes contact with the switch; the relative position between the pressure part and the contact part is fixed through the elastic fastener.

Owner:GIGA BYTE TECH CO LTD

Clamping device for glass plate laser drilling machine

InactiveCN112589293AImprove drilling efficiencyHighly consistentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a clamping device for a glass plate laser drilling machine, and belongs to the technical field of glass plate deep processing auxiliary equipment. The clamping device comprisesa supporting cross beam, a plurality of first clamping device bodies and a plurality of second clamping device bodies, one end of each first clamping device body is detachably and fixedly connected with the supporting cross beam, the other end of each first clamping device body abuts against one side of a glass plate, the second clamping device bodies are arranged on the other side of the glass plate, one side of each second clamping device body abuts against the other side of the glass plate, and the other end of the first clamping device body is matched with one side of the second clampingdevice body in a clamping manner to clamp the glass plate. During drilling, the glass plate is jacked up and clamped, the height of the lower surface of the glass plate is kept consistent, the positioning accuracy of a visual system can be guaranteed, and the drilling efficiency and the drilling precision are effectively improved.

Owner:CHINA TRIUMPH INT ENG

Printing mechanism for sample container

ActiveCN113002183AAchieve rotationReduce the number of passesTypewritersOther printing apparatusComputer printingEngineering

The invention provides a printing mechanism for a sample container, and belongs to the technical field of medical instruments. The printing mechanism comprises a material receiving end and a discharging end, wherein the material receiving end is provided with a material receiving frame, the material receiving frame is connected with a fixed material receiving plate and a movable material receiving plate, and the fixed material receiving plate and the movable material receiving plate are spliced and separated to form a material receiving groove and a material falling channel correspondingly; and the discharging end is provided with a rotating assembly, receives the sample containers falling from the discharging channel, drives the sample containers to rotate, and aligns unprinted blank areas on the sample containers to a printing assembly. The printing mechanism has the beneficial effects that through abutting cooperation between a blocking arm and an ejector rod, the sample container in the material receiving groove accurately falls onto the rotating assembly below, autorotation of the sample container is achieved, it is guaranteed that the blank area on the sample container corresponds to the printing assembly, doctor's advice information of a patient is printed, the number of times of transmission of the sample container between an inspector and the patient is reduced, the phenomenon of taking by mistake or cross contamination is avoided, and the subsequent detection precision and the detection efficiency are improved.

Owner:ZHEJIANG GONGDONG MEDICAL TECH

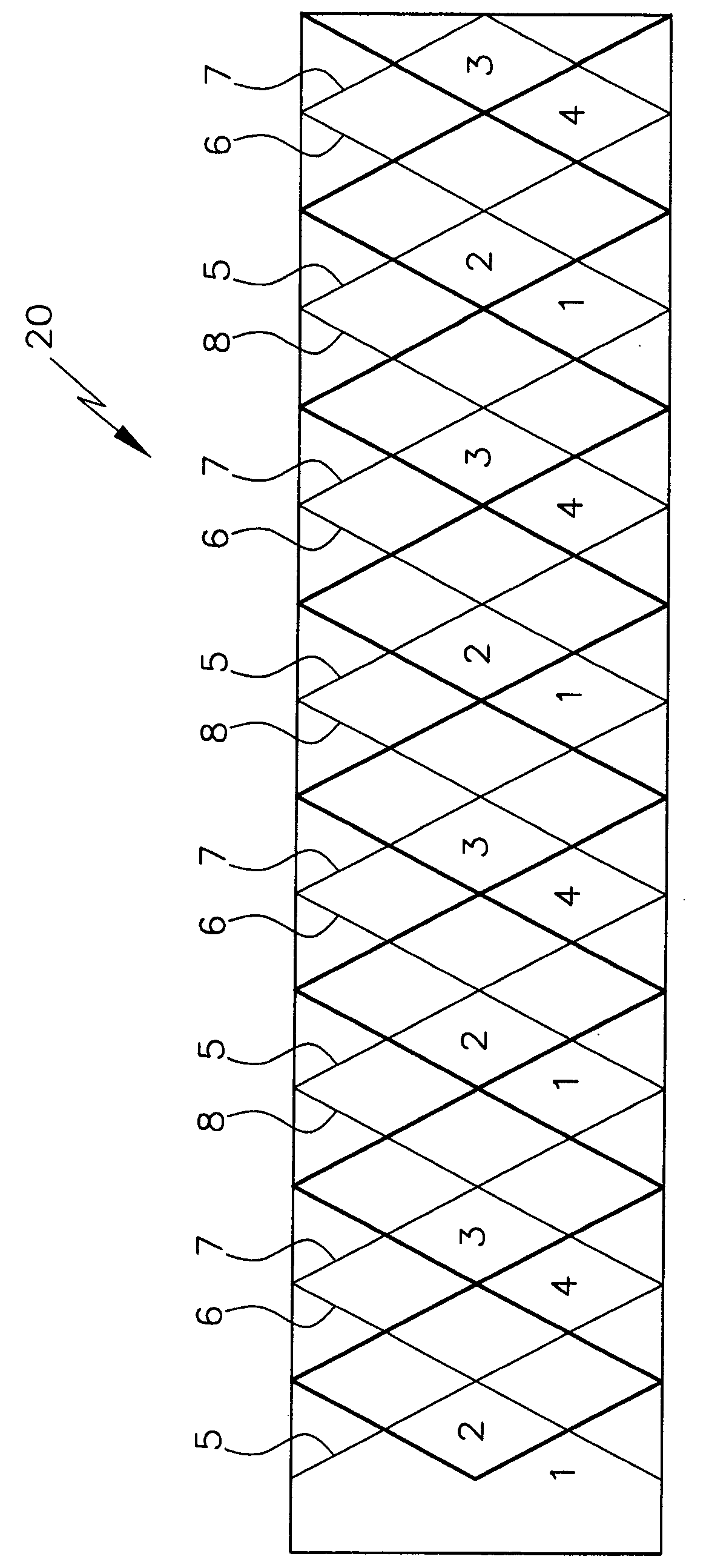

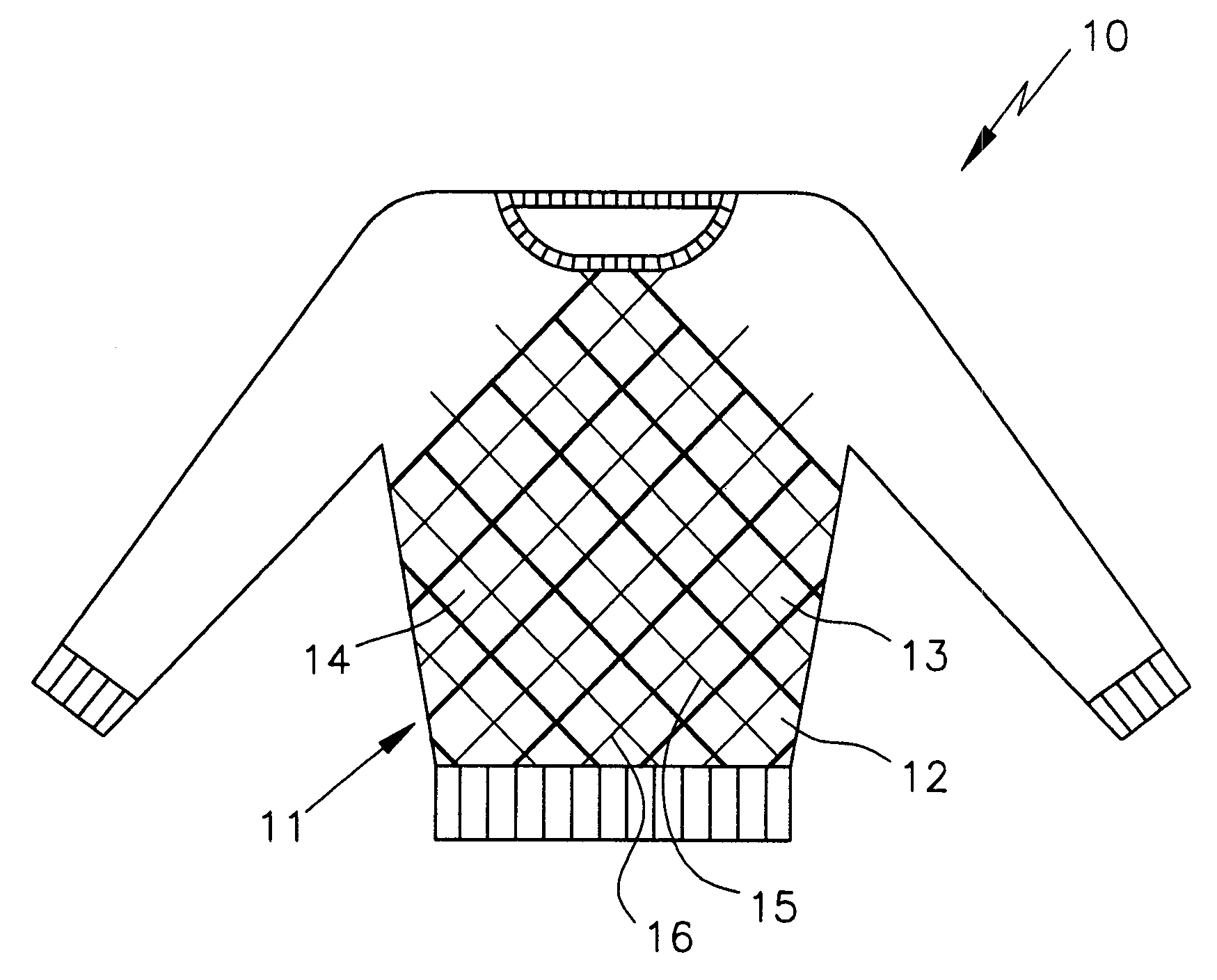

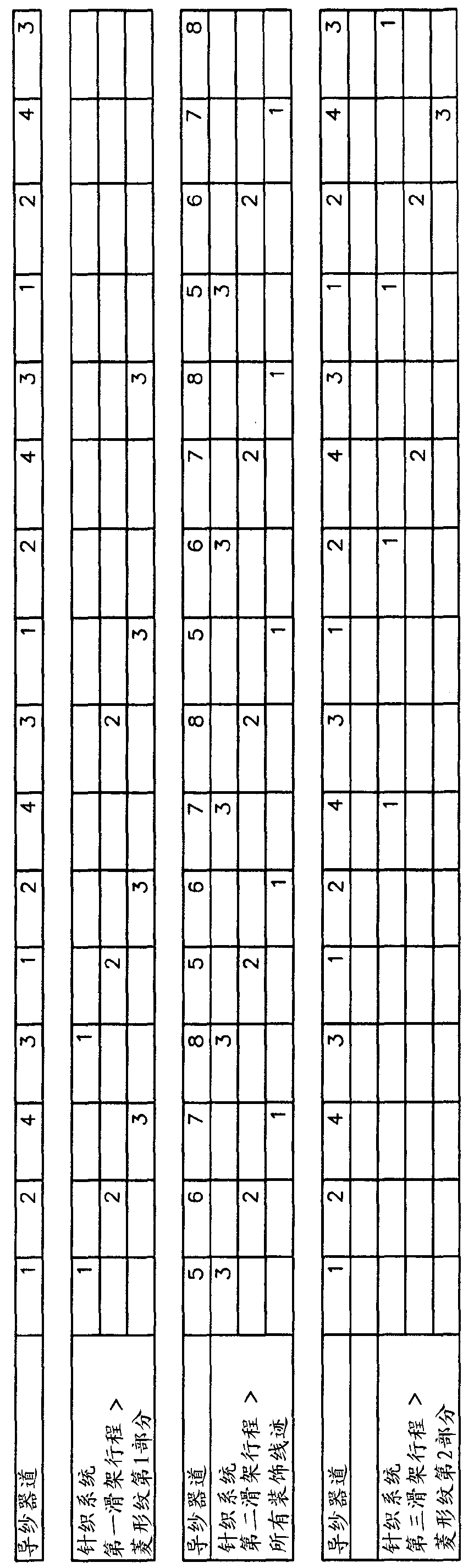

Method for the manufacture of knitted fabrics with intarsias and decorative stitches

ActiveCN102995262BAvoid empty tripsReduce knitting timeWarp knittingFlat-bed knitting machinesYarnEngineering

The method involves providing a flat knitting machine having separate yarn guide for intarsia pattern e.g. argyle pattern (20), and carriage with two knitting systems. All stitches for the intarsia pattern are formed along the carriage and all decorative stitch loops are formed in the opposite direction along the carriage.

Owner:KARL MAYER STOLL R&D GMBH

Brake disc production process using turning tool

InactiveCN108543954AEasy to solveAvoid Repeat Positioning AccuracyTurning machinesEngineeringKnife blades

The invention belongs to the technical field of lathe tools, and provides a brake disc production process using a turning tool. The process comprises the steps that the turning tool is provided with arough blade and a fine blade; in the direction perpendicular to the tool rod axis of the turning tool, the direction from the fine blade to the rough blade is set as the first preset direction, and the direction from the rough blade to the fine blade is set as the second preset direction; the turning tool is fed to a main blade tip of the rough blade to make contact with the inner edge in the axis direction parallel to a brake disc body through hole; at the moment, the brake disc is rotated, and meanwhile, the rough blade is fed in the first preset direction; the turning tool is fed to the main blade tip of the fine blade in the second preset direction, and the turning tool and the inner edge are located on the same straight line, and the turning tool is fed to the main blade tip of the fine blade to make contact with the inner edge along the straight line; at the moment, the brake disc is rotated, and meanwhile, the fine blade is continuously fed in the second preset direction. The production process is easy to operate, rough and fine turning can be achieved without tool changing, positioning of the turning tool on the brake disc is rapid and accurate, the tool changing time canbe greatly shortened, and machining efficiency is improved.

Owner:成都曼德希新材料有限公司

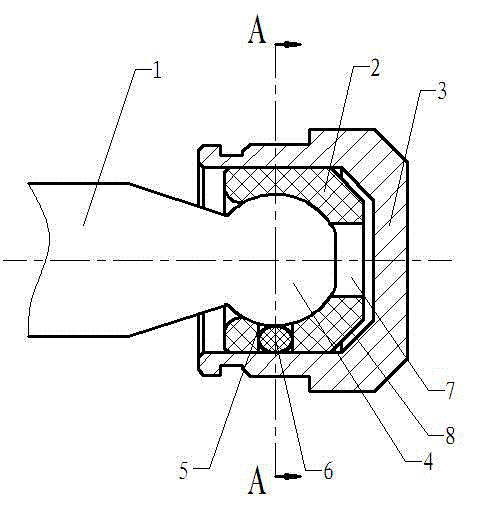

Spherical hinge structure with automatic gap compensation function

InactiveCN105275973AImprove comfortAvoid empty tripsGearing controlPivotal connectionsEngineeringHinge angle

The invention provides a spherical hinge structure with an automatic gap compensation function. The spherical hinge structure comprises a gear-shifting shaft, a spherical hinge lining and a spherical hinge base; a bulb is arranged at one end of the gear-shifting shaft and is contained in the spherical hinge lining; the bulb and an inner cavity of the spherical hinge lining form a spherical face pair; the spherical hinge lining is contained in the spherical hinge base and provided with at least two through holes I; a small elastic ball is arranged inside each through hole I; the ball centers of the small elastic balls and the center of the bulb are located on the same plane perpendicular to the axis of the gear-shifting shaft; the ligatures of the ball centers of at least two small elastic balls and the center of the bulb are mutually perpendicular; the small elastic balls make contact with the bulb and the spherical hinge base and are compressed and deformed in the axial direction of the through holes I. Compared with the prior art, the spherical hinge structure has the beneficial effects that a gap can be automatically compensated, the idle stroke of the gear selecting process is avoided, and comfort of driving is improved.

Owner:SINO TRUK JINAN POWER

A method for automatic identification of laminated interface when making holes in laminated structure

ActiveCN109226801BSimplify the drilling processReduce processing timeAutomatic control devicesFeeding apparatusEngineeringMachining time

The invention discloses an automatic identification method for a laminated interface during laminated structure drilling. The method has the advantages of measuring and recording an idle rotation speed n0 of a drilling equipment spindle; obtaining a function expression of Td=f(n) of an output torque Td of the drilling equipment spindle with respect to the rotation speed n of the drilling equipmentspindle by experiment and mathematical fitting; deriving a formula of Td=g(n,m,k) for calculating the torque by using the formula; combining two equations to obtain an equation of f(n)=g(n,m,k); determining the corresponding coefficient of mi(i=1,2,3...) for each material, determining other processing parameters except the rotation speed of the drilling equipment spindle, and obtaining the corresponding coefficient ka; solving the rotation speed ni (i = 1, 2, 3...) of the drilling equipment spindle corresponding to different materials; during drilling processing, measuring the real-time rotation speed na of the drilling equipment spindle, comparing na with n0 and ni one by one, and finding a value closest to na, wherein if the value is closest to n0, a cutter does not touch a workpiece orcuts through the workpiece, and if the velue is closest to ni, the drilling equipment processes the workpiece material corresponding to Ni. The method has the advantages of simplifying the drilling operation process, shortening the processing time and the like.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com