Control valve for an air spring and motor vehicle seat having a control valve

A technology for pneumatic springs and vehicle seats, which is applied to vehicle seats, vehicle components, seat suspensions, etc., and can solve the problems of height adjustment devices, such as the fineness of static height adjustment and the response performance of sensitivity and speed are not optimal. , to achieve the effect of reducing tolerance, avoiding empty travel and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

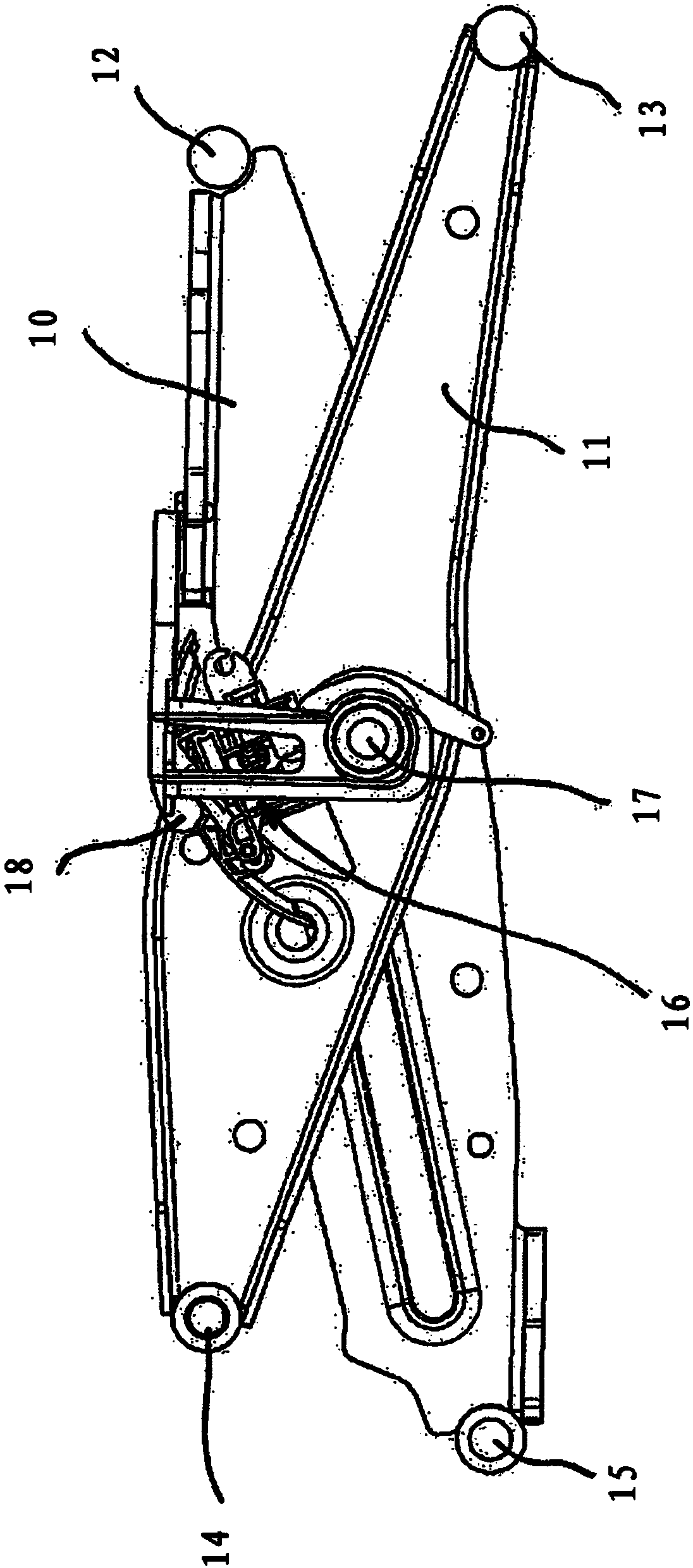

[0026] exist figure 1 A side view of part of the swing system of a vehicle seat showing a pneumatic spring. Furthermore, the theoretical design of such a pivoting system with a height adjustment device of a seat surface of a vehicle seat or a height adjustment device is known in principle. Therefore, only the components that are relevant to the design of the invention will be considered below.

[0027] figure 1 Two scissor link pairs arranged parallel to one another are shown with an inner scissor link 10 and an outer scissor link 11 . The two scissor links 10 , 11 are rotatably connected to each other via a shaft 17 . The scissor guide rod in its figure 1 On the right-hand ends shown in , there are respectively fixed bearings 12 , 13 , which are fixed in position on the upper frame (not shown) or the lower frame (likewise not shown). Horizontal displacement bearings 14 , 15 are formed at the respective left-hand ends of the scissor links 10 , 11 . It is possible to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com