Patents

Literature

126results about How to "Make sure it fits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remote personal identity verification method in vehicle sharing process and vehicle sharing method based on remote personal identity verification method

InactiveCN106056430AMake sure it fitsEnabling remote face-to-face driving qualificationBuying/selling/leasing transactionsIn vehicleRecognition algorithm

The invention relates to a remote personal identity verification method in a vehicle sharing process and a vehicle sharing method based on the remote personal identity verification method and belongs to the vehicle sharing field. The objective of the invention is to solve problems in automatic and convenient identity authentication in vehicle sharing. According to the technical schemes of the invention, the fifth step of the invention includes the following operations that: a face recognition algorithm is utilized to compare an image captured in the fourth step with a certificate photo image of an identity card and a driving license uploaded by an applicant; if a comparison result satisfies requirements, video authentication is successful, an authentication video connection is closed; and if the comparison result does not satisfy the requirements, the method returns to the fourth step, if the results of a plurality of times of comparison do not satisfy the requirements, video authentication fails, authentication is terminated. With the method and device of the invention adopted, certificates uploaded by the applicant such as the identity card and the driving license can satisfy the requirements, and on-site business handling can be avoided, and remote face-to-face driving qualification examination can be achieved.

Owner:DALIAN ROILAND SCI & TECH CO LTD

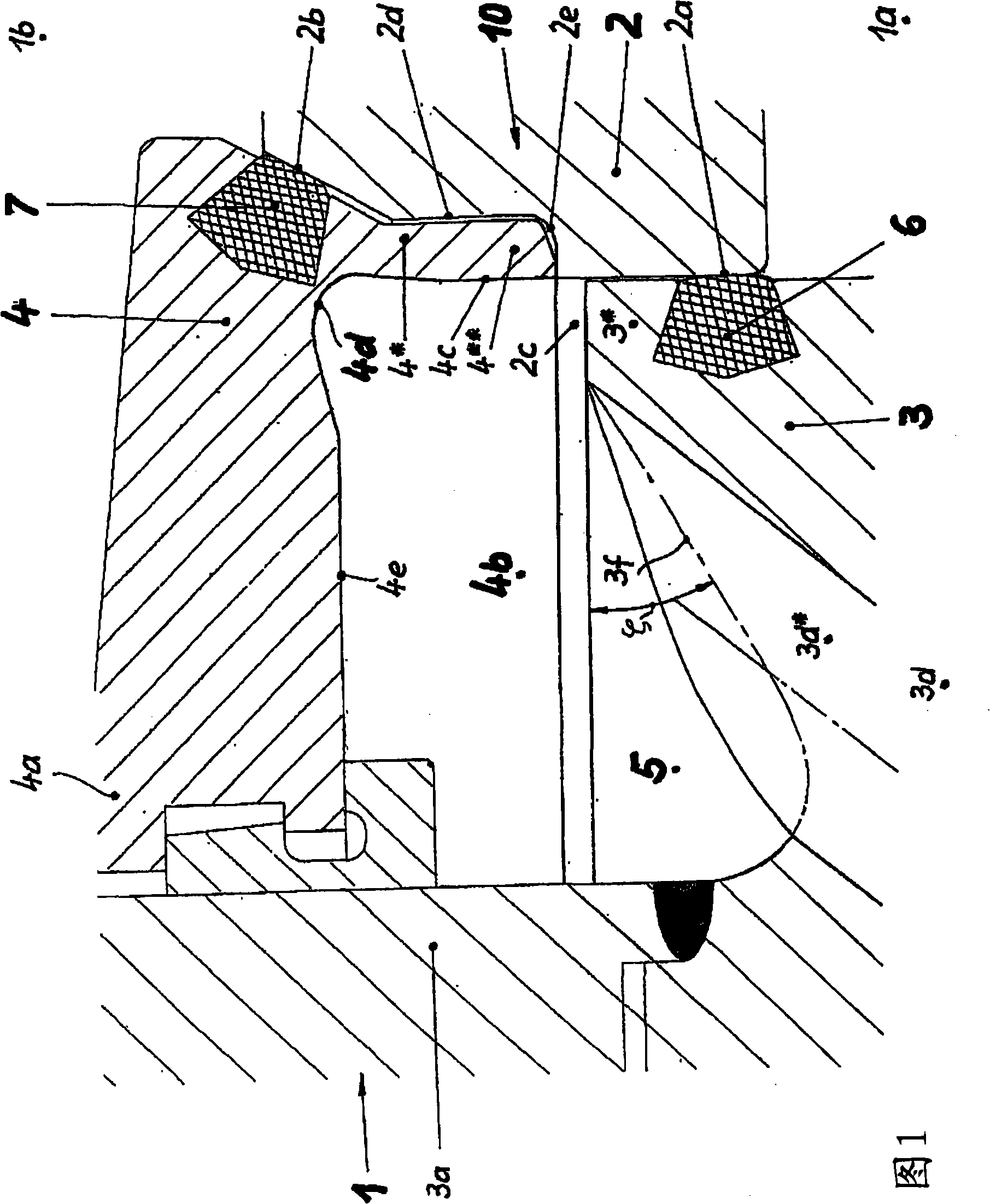

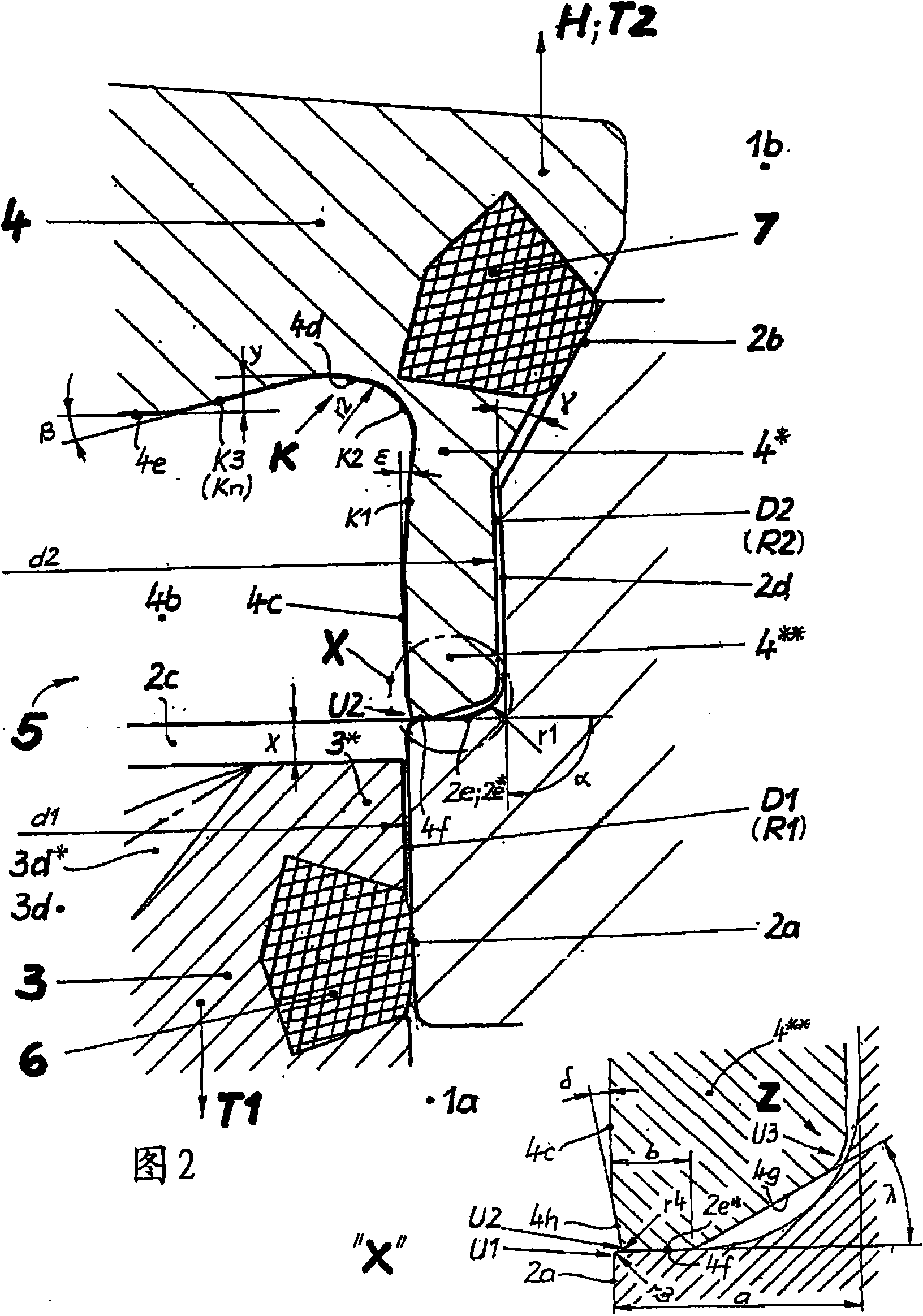

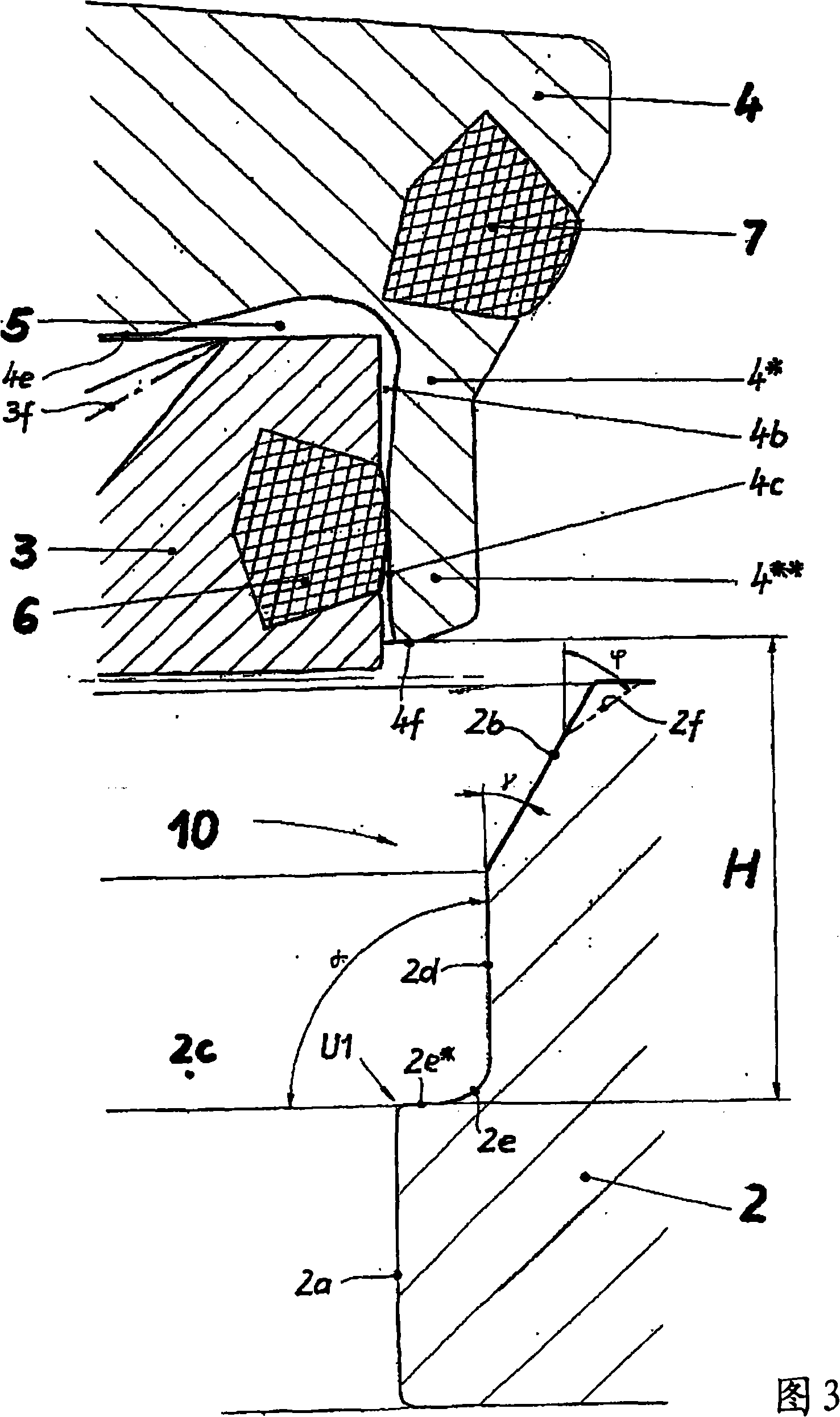

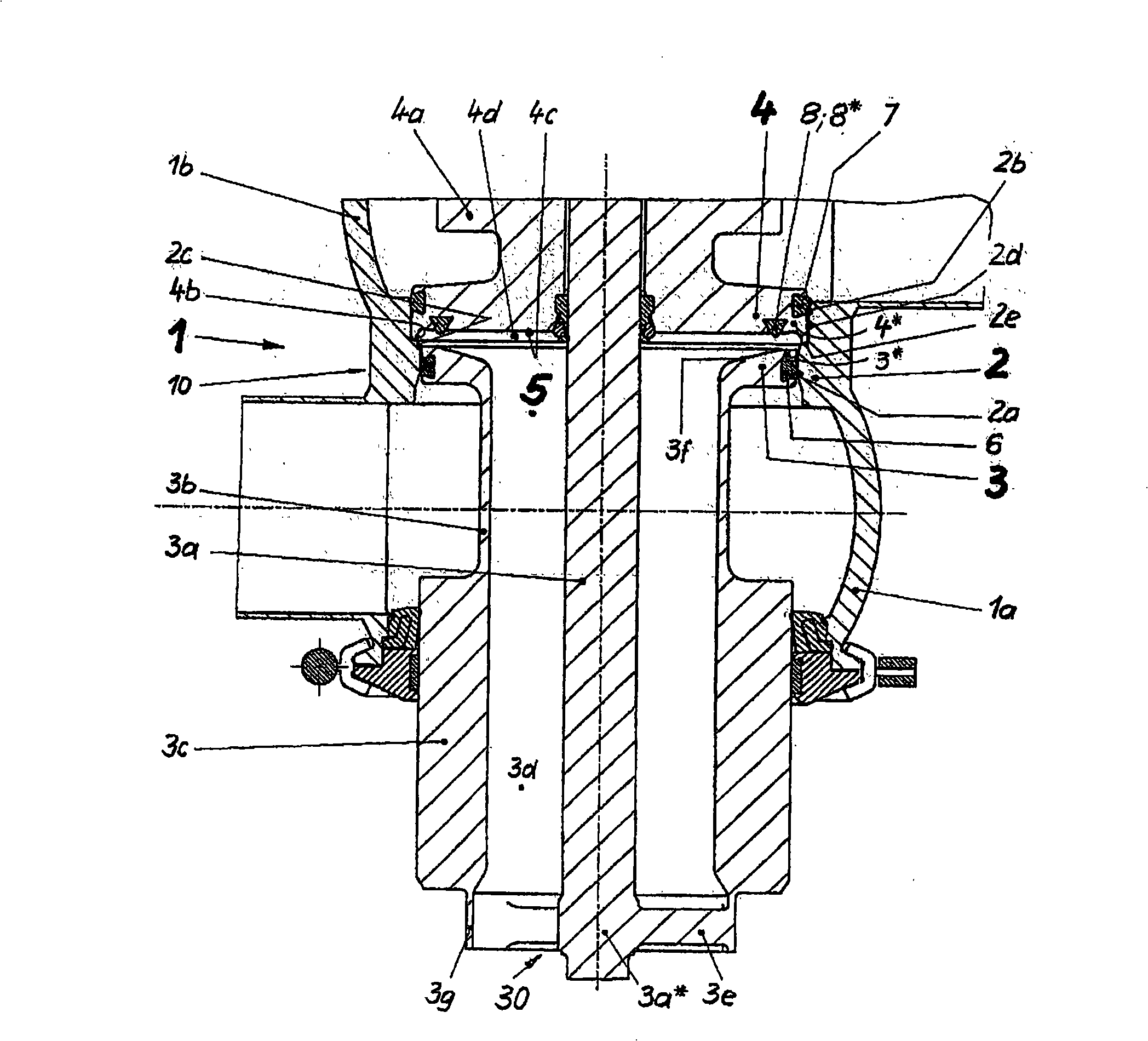

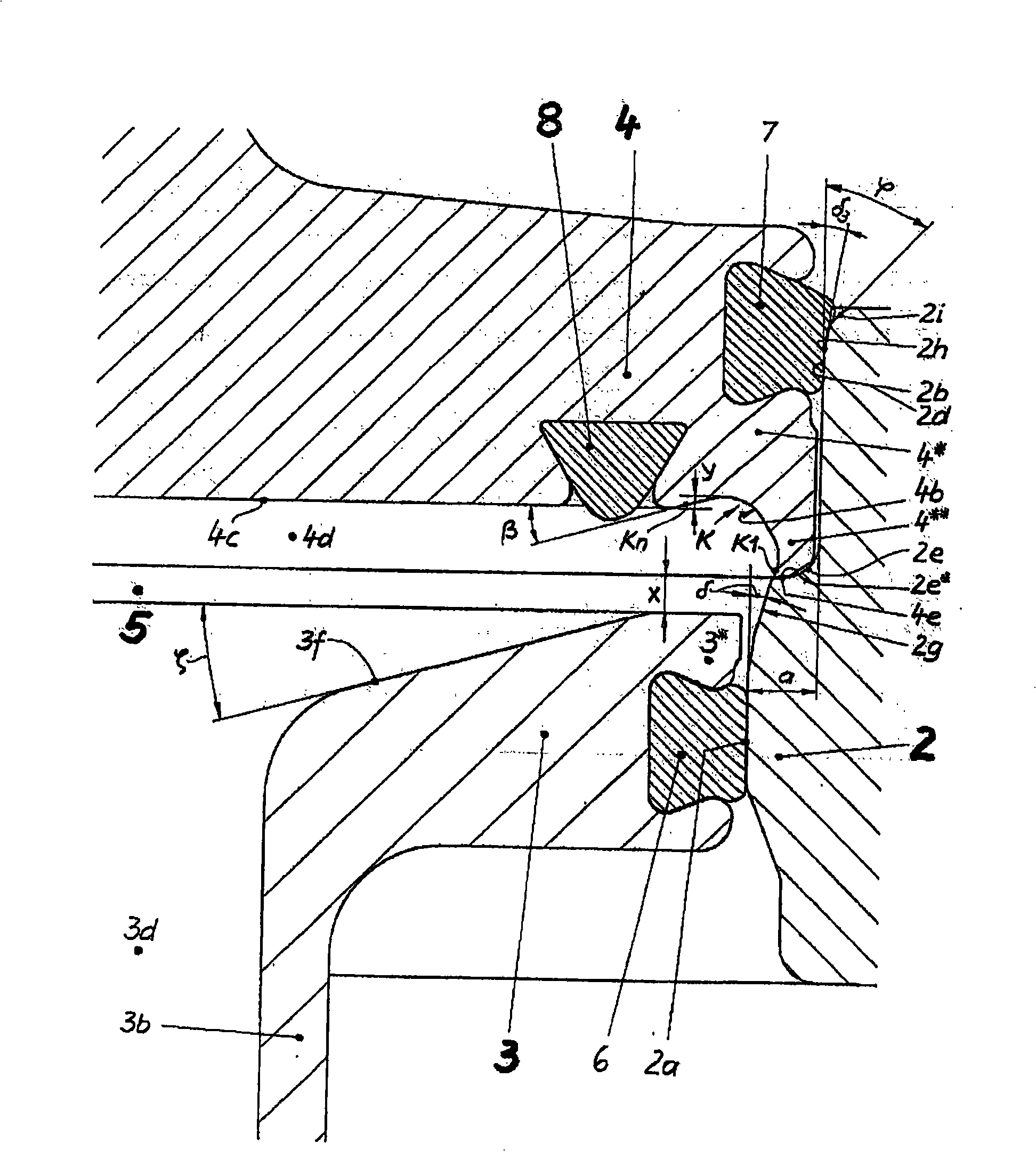

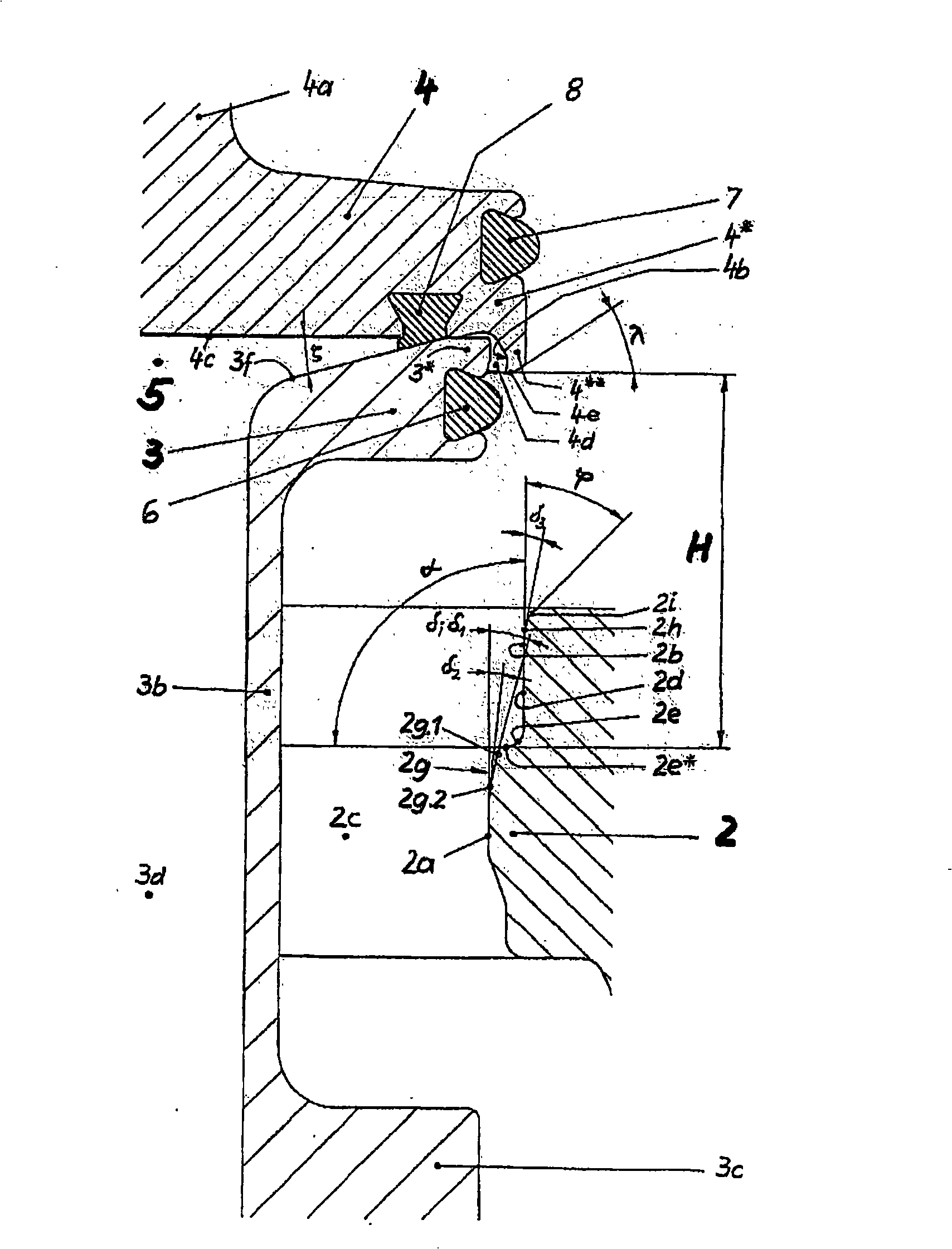

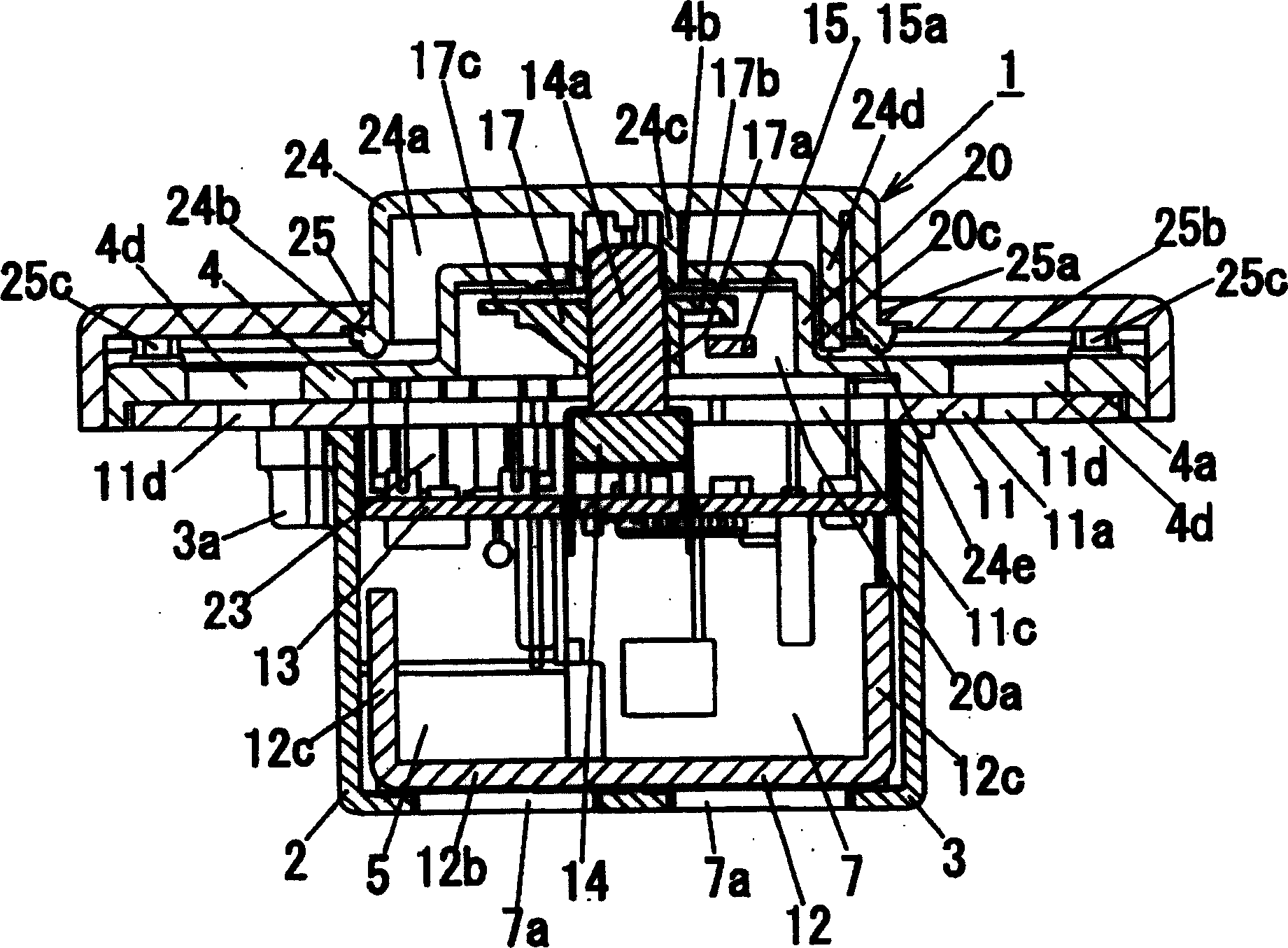

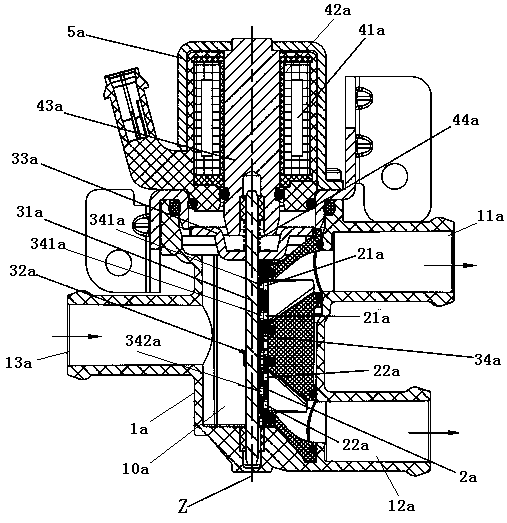

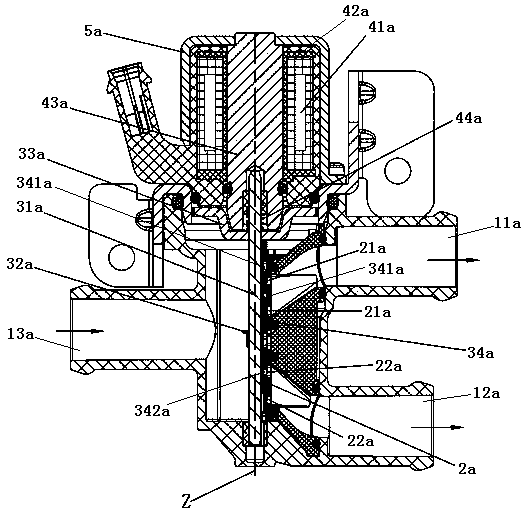

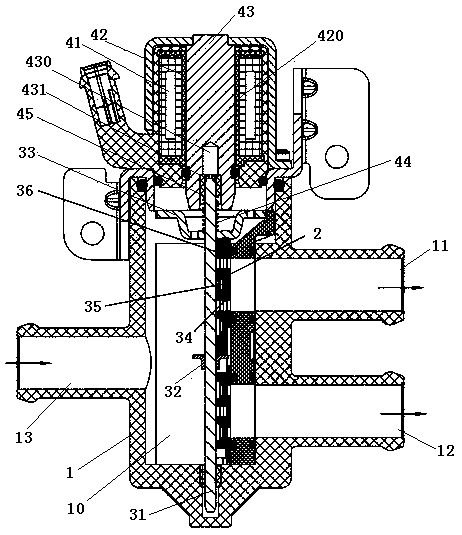

Double seat valve

The invention relates to a double seat valve, which is capable of cleaning the seat and which is improved compared to that of the prior art, whereby a delivery as free from turbulence as possible of the seat cleaning flow into and out of the leakage cavity is ensured, and a pressure-increasing direct action upon the seat areas is reliably prevented.; This is achieved in that: the second closing element (4), when in its closed position, rests with a stopping surface (4f), which is placed on a face of its cylindrical projection (4*) and which, together with the peripheral wall (4c, 4h), forms a second wraparound edge (U2), upon the interface (2e, 2e*), and to be precise, directly upon the first seating (2a) in an adjoining manner; the peripheral wall (4c), at its end facing away from the first closing element (3), merges into a rotationally symmetric reversing surface (4d) (starting point of contour K)), and this reversing surface (4d) leads in a face (4e) of the recess (4b) oriented, in essence, perpendicular to the longitudinal axis of the second closing element (4) (leading point of contour K)), and; ; when viewing the meridian section, the reversing surface (4b) has a contour (K) with a bend-free curve, a direction vector in the leading point of the reversing surface (4d) points into a discharge borehole (3d, 3d*) centrally provided in the first closing element (3) without colliding with the first closing element (3) in the vicinity of its areas bordering the leakage cavity (5) and forming dynamic pressure.

Owner:TUCHENHAGEN GMBH

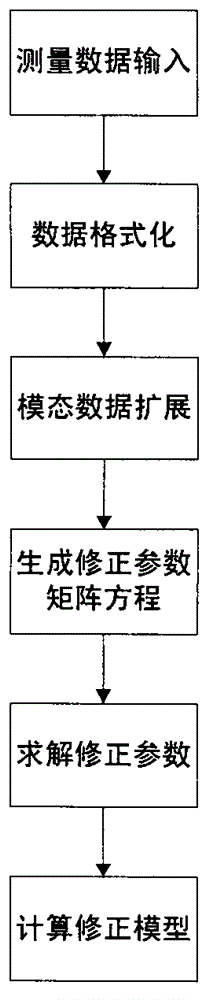

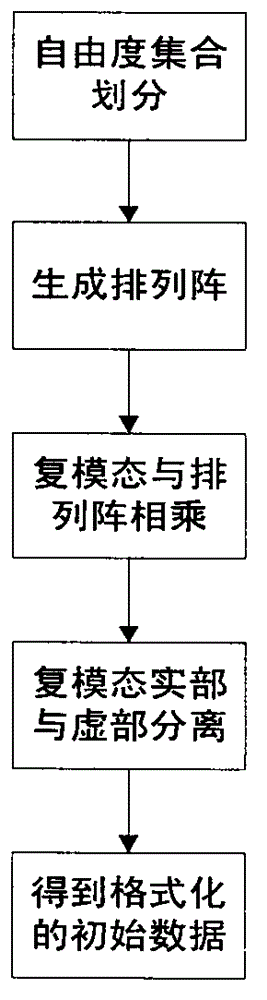

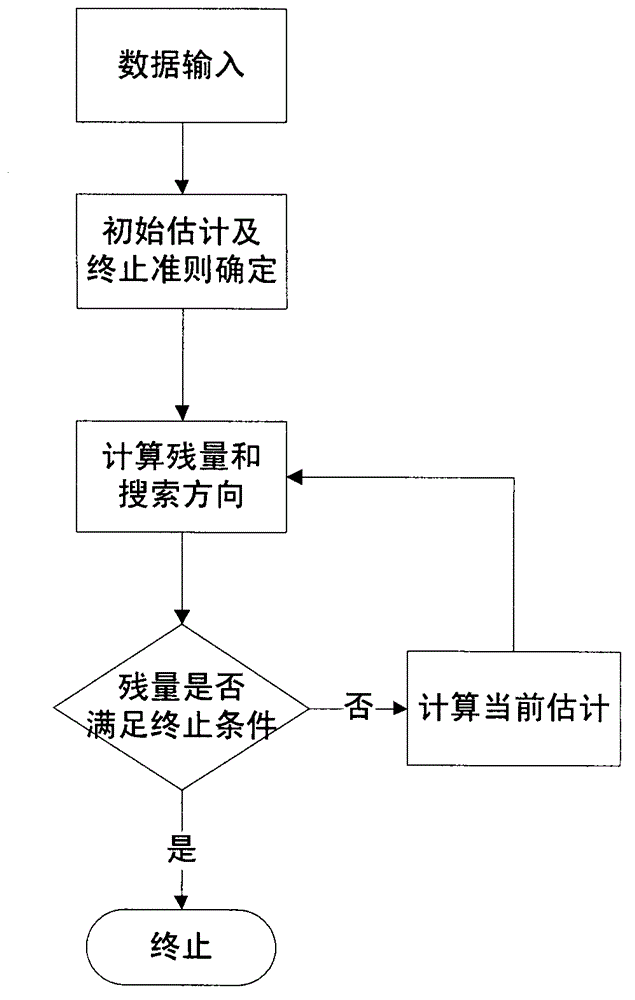

Model correcting method based on defective modal structure

ActiveCN102982202AHigh precisionMake sure it fitsSpecial data processing applicationsLeast squaresAlgorithm

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

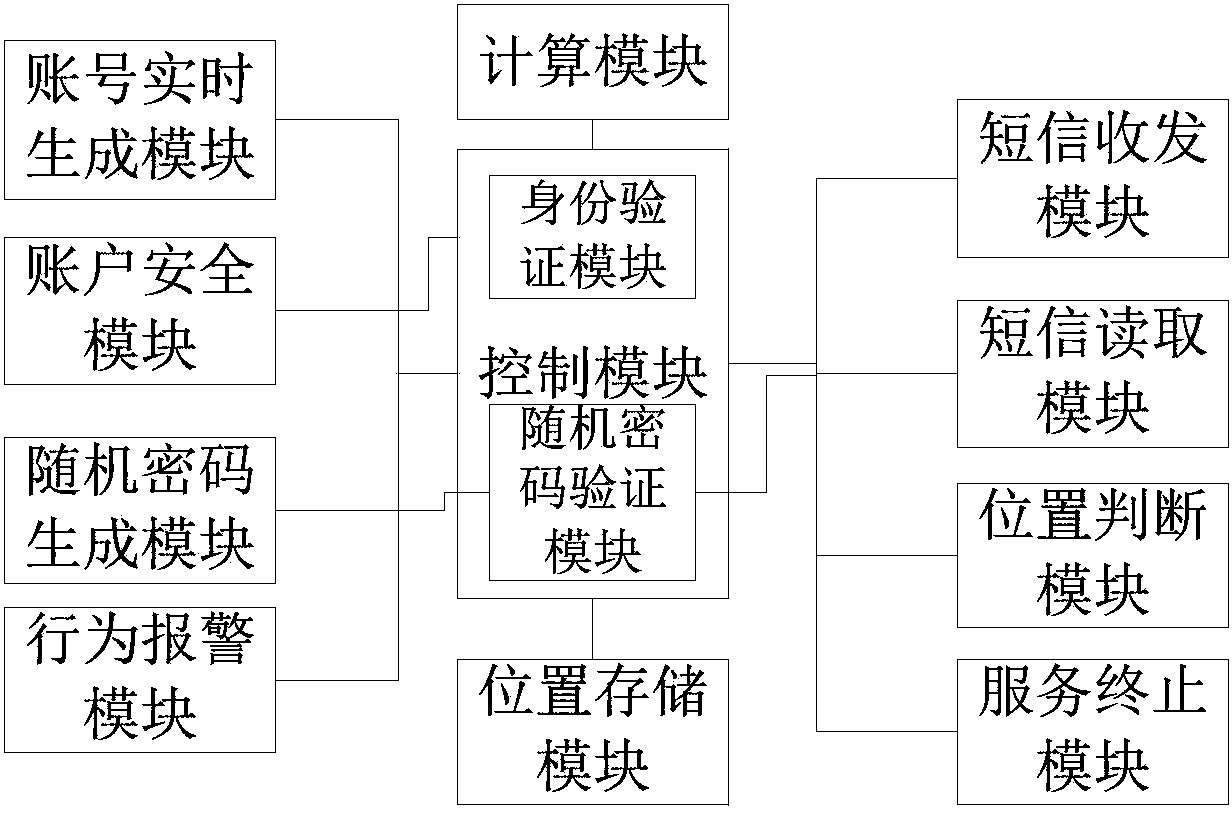

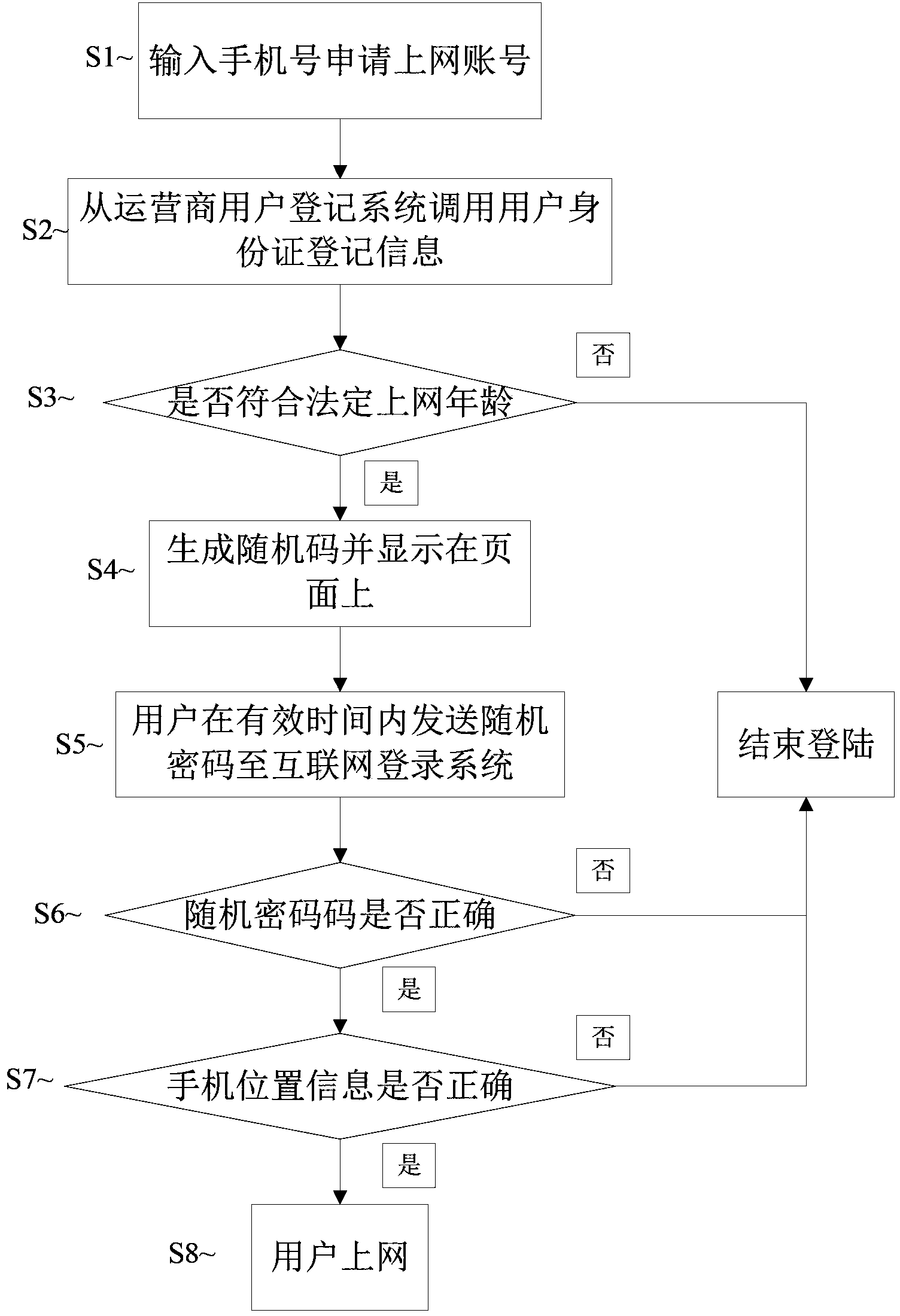

Internet account number login management system and method based on short message

ActiveCN103458407AEasy to rememberEasy to useMessaging/mailboxes/announcementsTransmissionThe InternetMobile phone operator

The invention discloses an internet account number login management system based on a short message. The internet account number login management system comprises an account number real-time generating module, an account safety module, a random cipher generating module, a computing module, a short message receiving-sending module, a short message reading module, a position storage module, a position judging module, a service stop module and a behavior alarm module, wherein the account number real-time generating module, the account safety module, the random cipher generating module, the computing module, the short message receiving-sending module, the short message reading module, the position storage module, the position judging module, the service stop module and the behavior alarm module are connected with a control module. Therefore, the internet account number login management system is complete in function, specific information of a user can be inquired, and the aim that the user is supervised to safely use the internet can be achieved. The invention further provides an internet account number login management method based on the short message, the internet account number login management system and method combine the mobile phone short message and mobile phone operator networks, and convenient and rapid management on the account from login to use is achieved.

Owner:BEIJING SAFESOFT GREATMAKER CO LTD

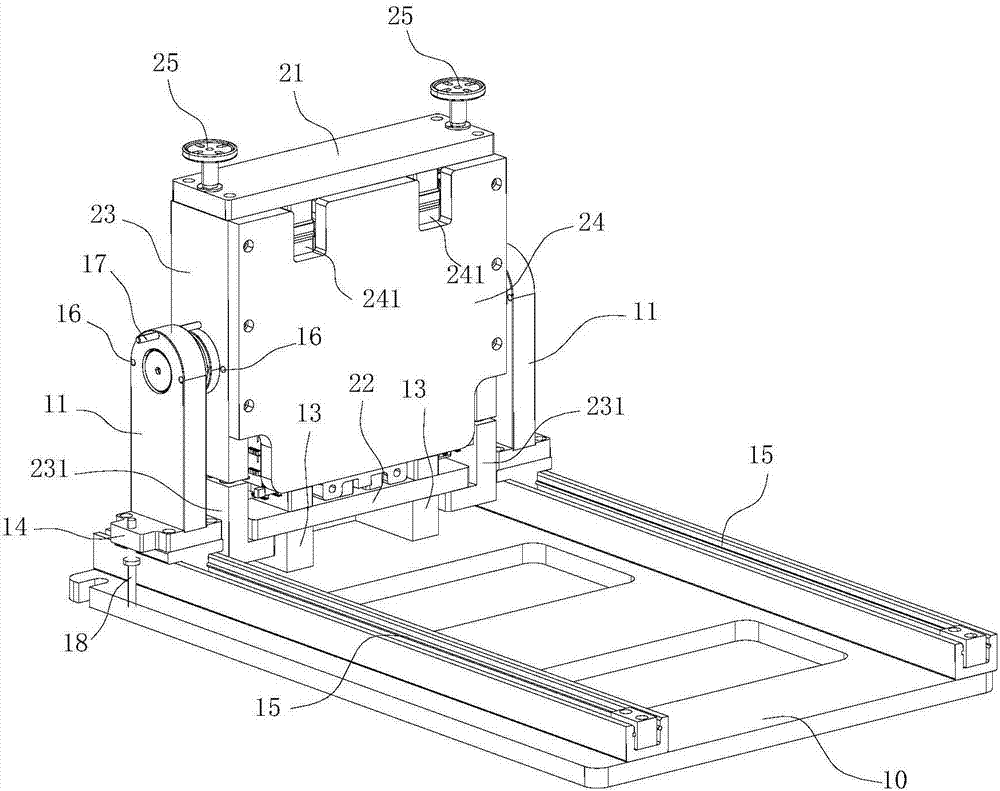

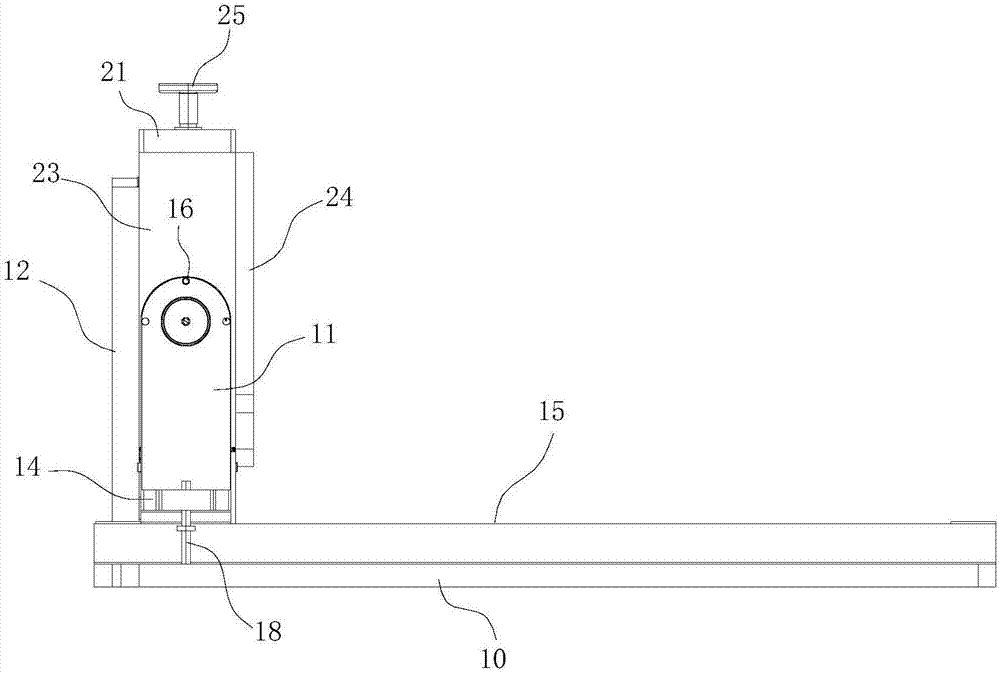

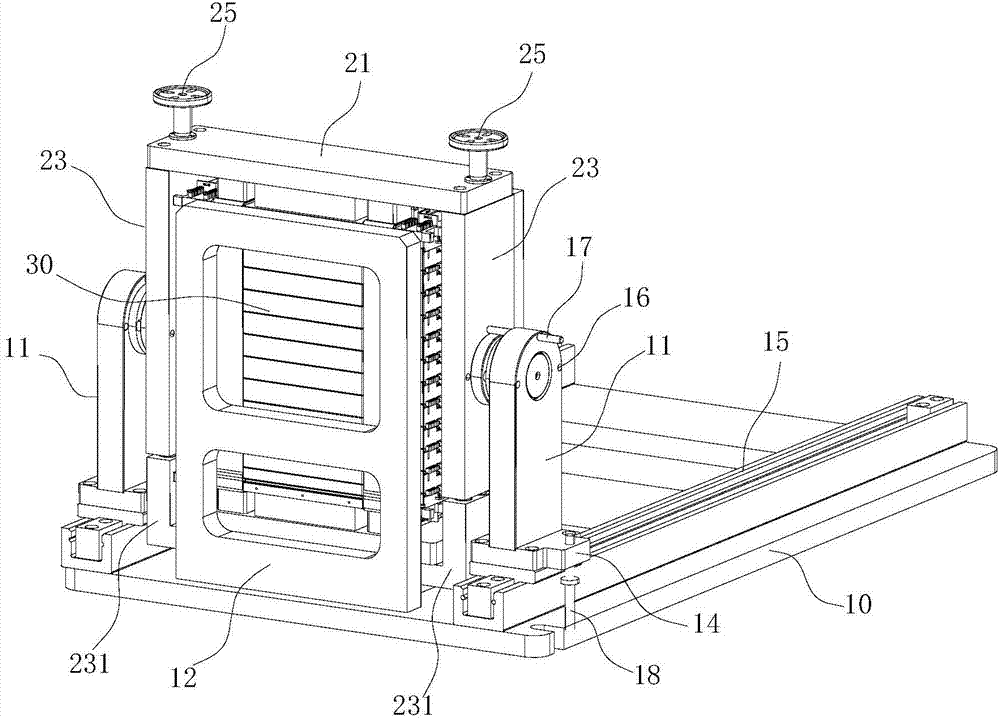

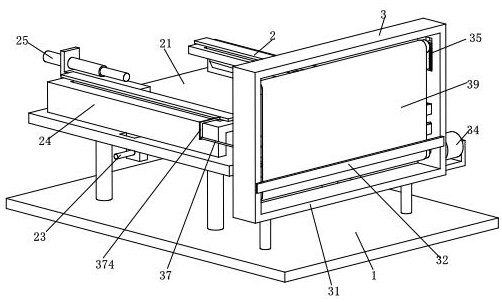

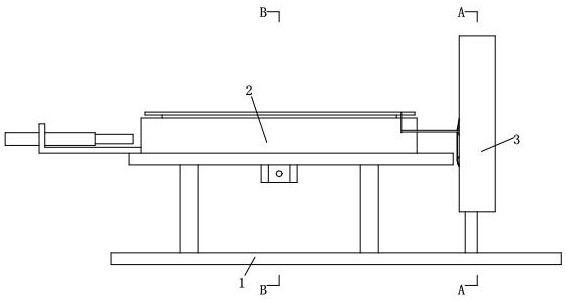

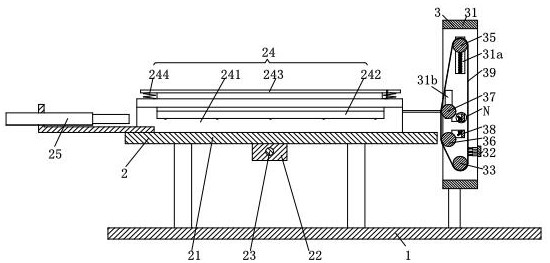

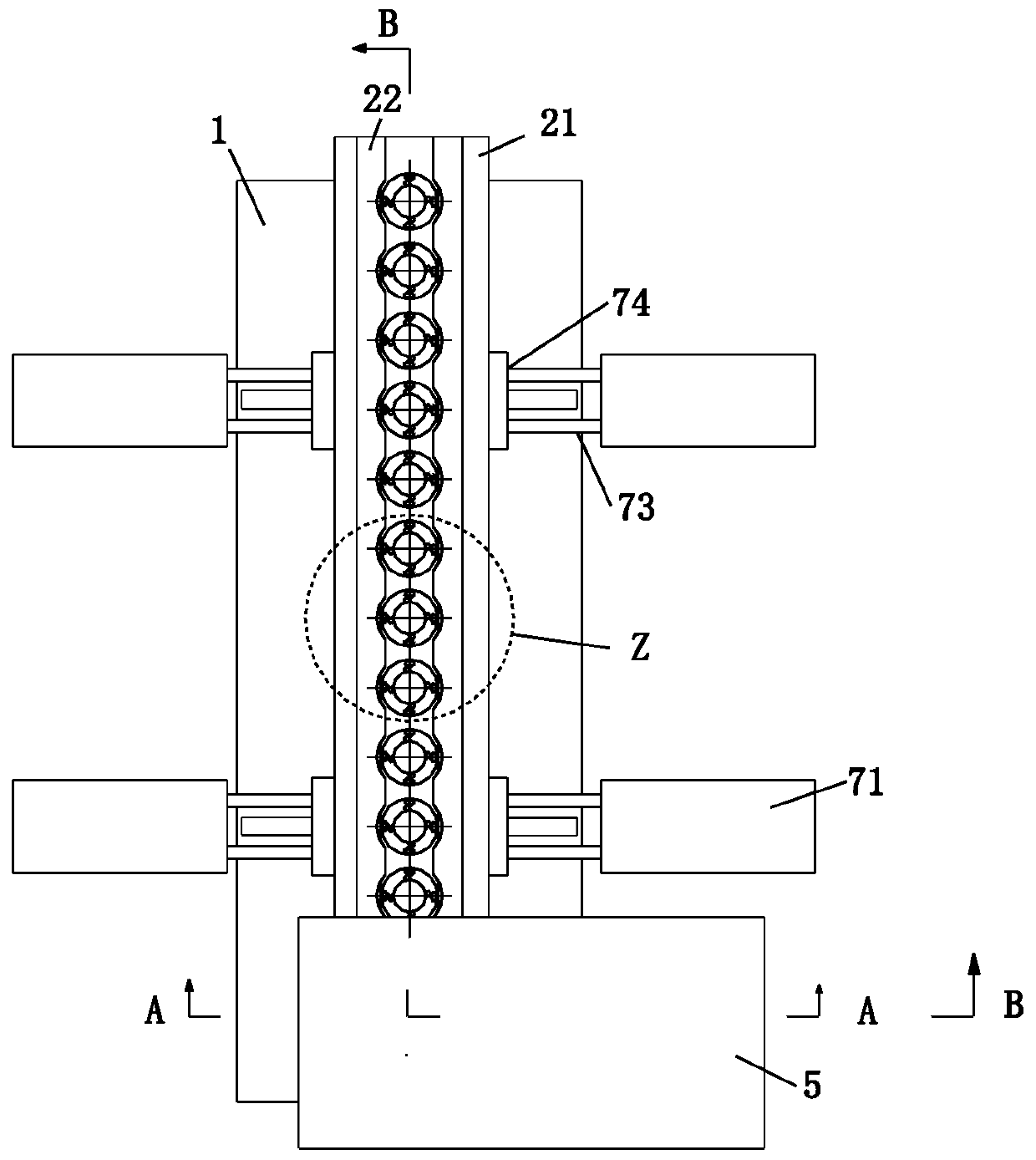

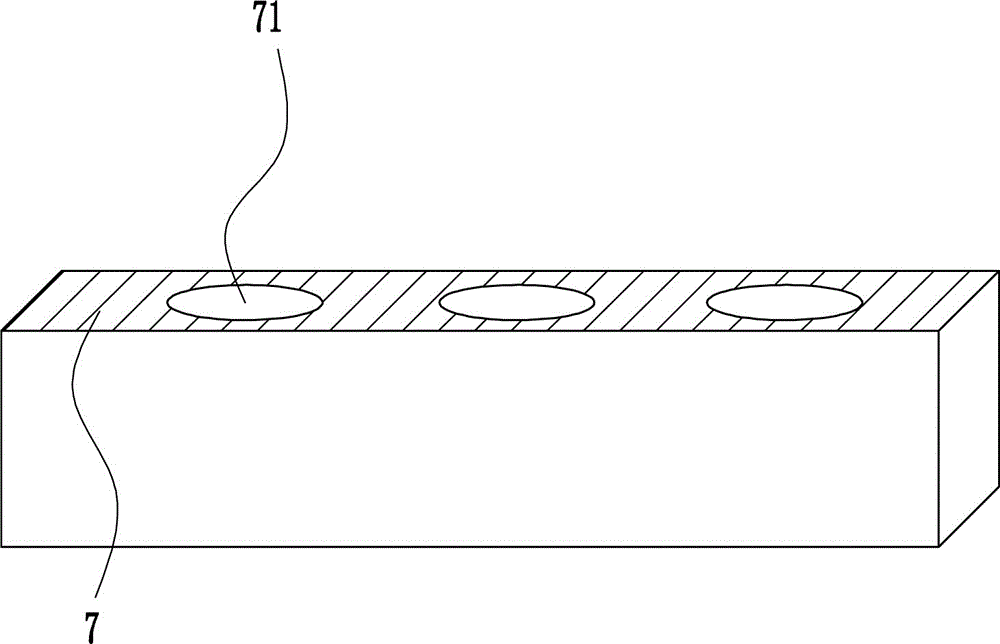

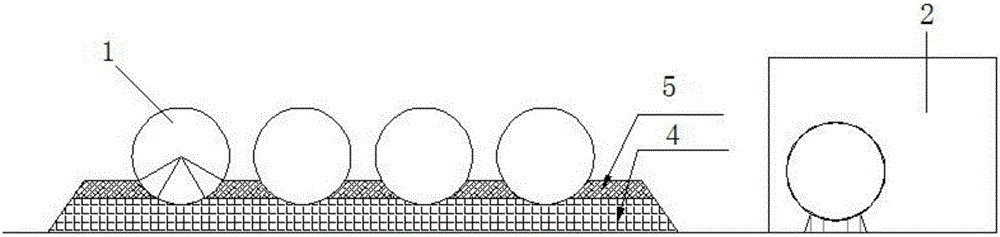

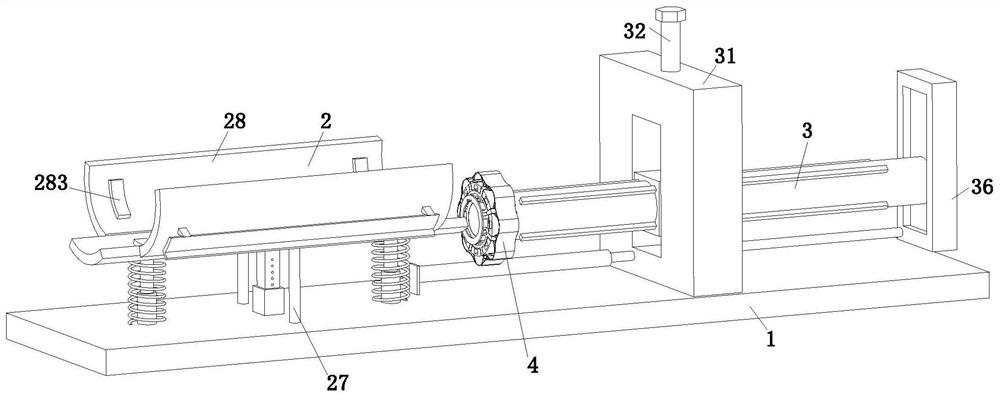

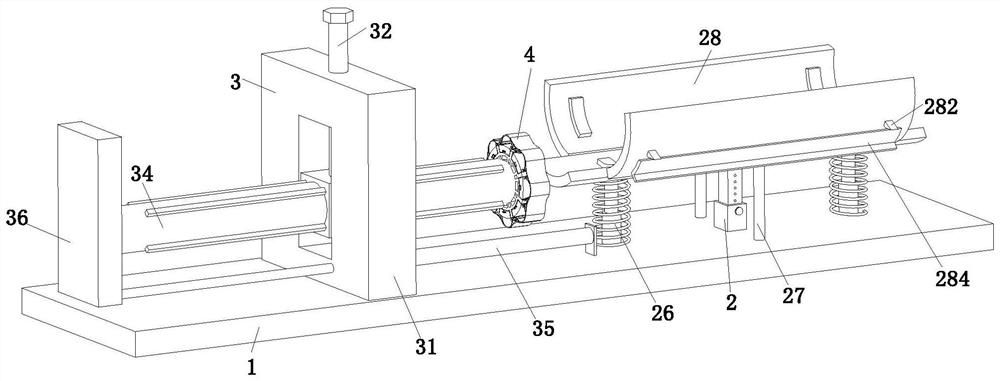

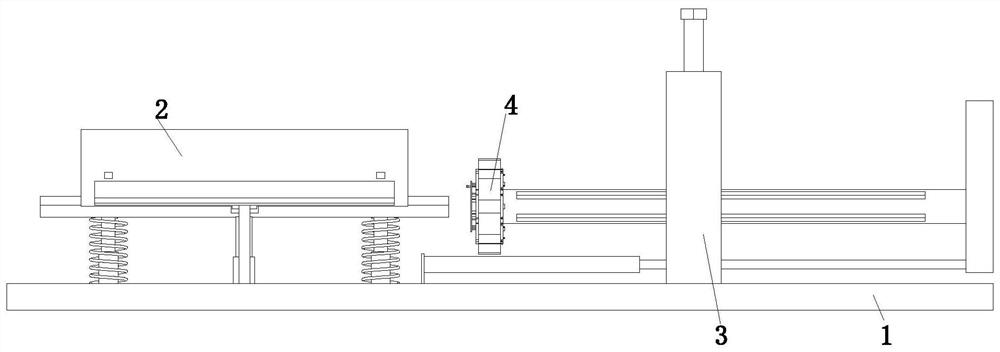

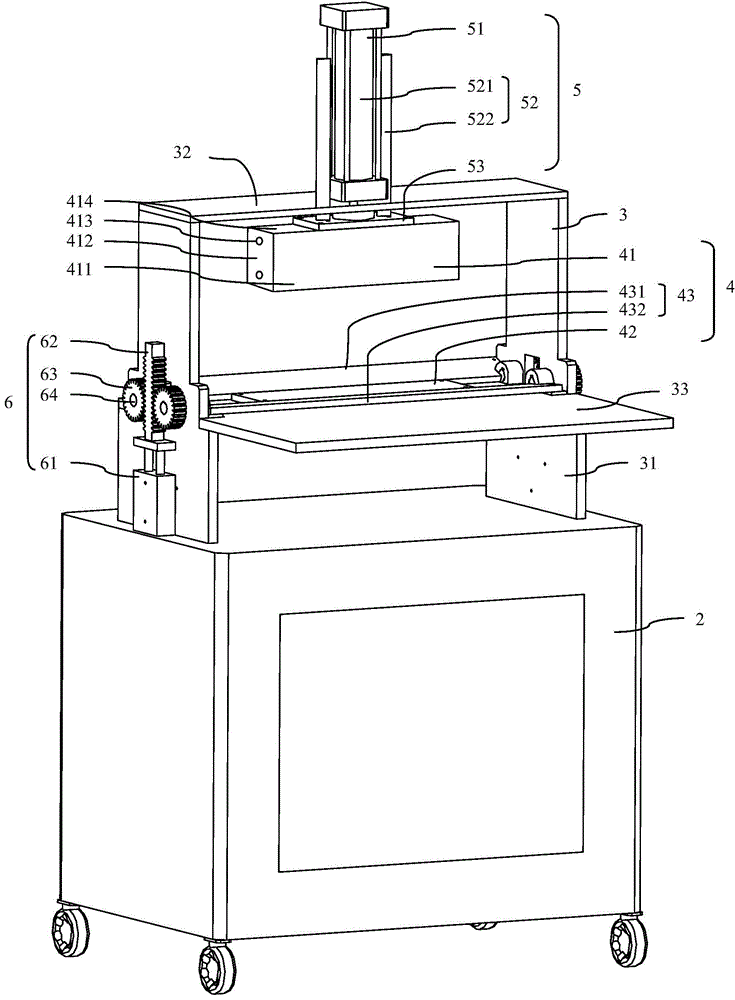

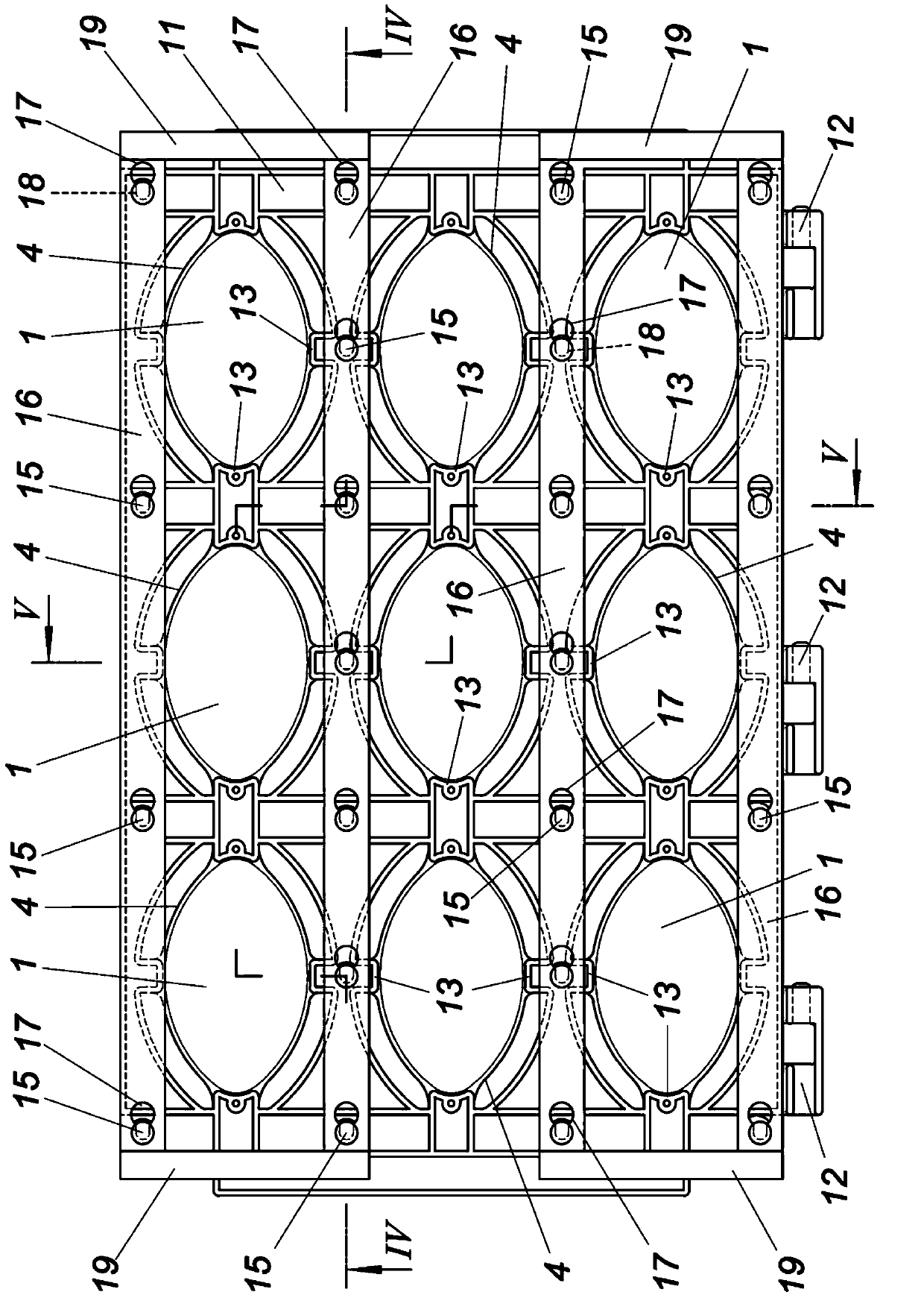

Erecting welding tool for soft package battery module

InactiveCN107030429AMake sure it fitsAssembly precisionWelding/cutting auxillary devicesAuxillary welding devicesHorizontal axisEngineering

The invention belongs to the technical field of electric car battery production and processing, and particularly relates to an erecting welding tool for a soft package battery module. The erecting welding tool for a soft package battery module comprises an overturn frame, a support and a base, wherein the overturn frame is rotationally arranged on the support along the horizontal axis, the support is installed on the base, a limiting device is arranged on the support, and the overturn frame can be locked to stay in the horizontal state or the vertical state by the limiting device. The overturn frame comprises a rectangular frame body and two end plates, wherein the rectangular frame body is formed by a bottom plate, two side plates and a top plate in an enclosure manner, each end plate is arranged at one end of the rectangular frame body, the distance between the top plate and the bottom plate is set to be adjustable, at least the end plate on one side is detachably connected with the rectangular frame body, a chamber for containing a battery module is formed inside the overturn frame, and notches for exposing the welding positions of the battery module are formed in each of the two end plates. With the erecting welding tool for a soft package battery module, the position of the battery module can be fixed, it is guaranteed that all the soft package batteries are aligned accurately, and meanwhile, the shell of the battery module can be tightly clamped, it is guaranteed the batteries inside the shell of the battery module are pressed tightly, and the accuracy of welding is guaranteed.

Owner:ANHUI OFFNENBACH NEW ENERGY TECH CO LTD

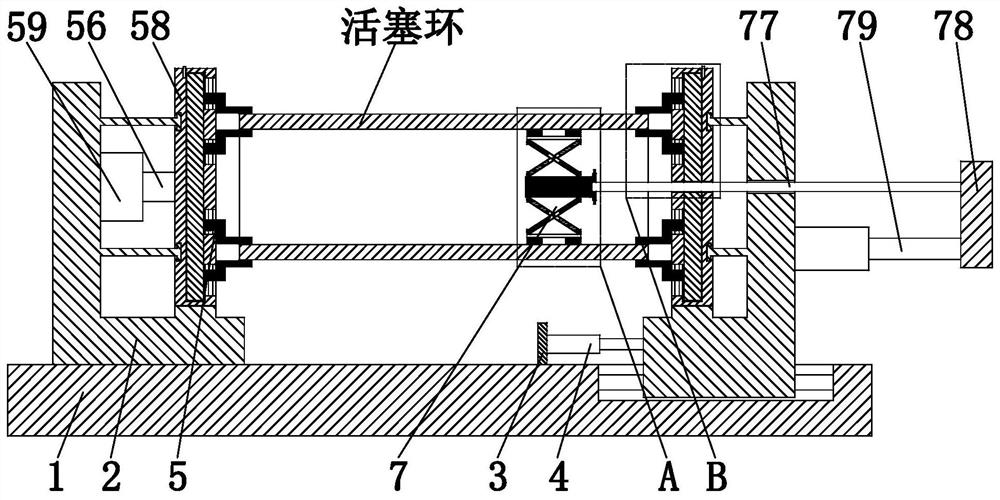

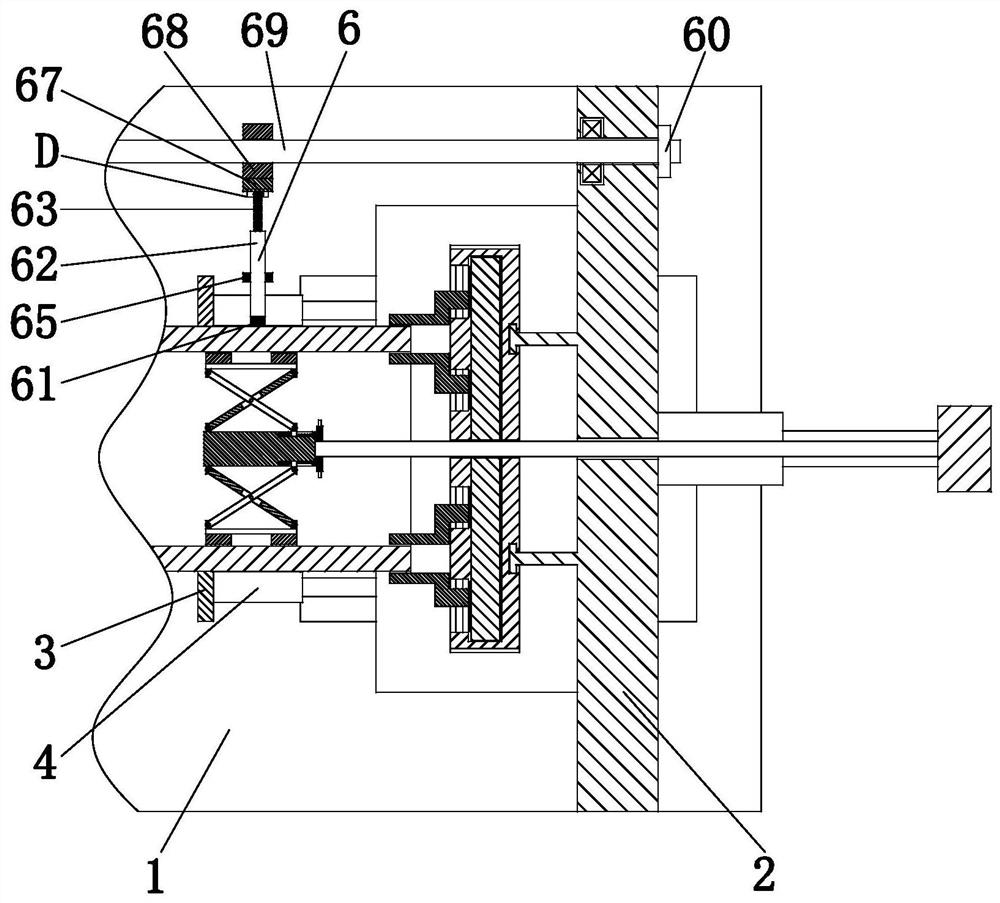

Sealing assembly piston ring casting molding machining machine and molding machining process

InactiveCN112059735ALow efficiencyAvoid scrubbingEdge grinding machinesRevolution surface grinding machinesMolding machinePiston ring

The invention provides a sealing assembly piston ring casting molding machining machine and a molding machining process. The sealing assembly piston ring casting molding machining machine comprises abase, a mounting plate, a baffle plate, a movable air cylinder, a clamping and rotating mechanism, an outer knock-out mechanism and an inner knock-out mechanism. The invention provides the sealing assembly piston ring casting molding machining machine which can solve the following problems existing in the piston ring casting molding process: a, when a piston ring is cast into a cylinder with a certain length, a plurality of sand grains can be generated on the inner and outer surfaces of the piston ring, the sand grains on the surfaces of the piston ring need to be removed, the sand grains on the surfaces of the piston ring are removed through grinding of abrasive paper according to a traditional manual mode, and the mode is time-consuming, labor-consuming and low in efficiency so as to beundesirable; and b, a traditional piston ring grinding device is single in function, generally can only grind piston rings of one specification and cannot be suitable for piston rings of different specifications, and the equipment is high in price, so that the price and the function effect cannot be equivalent.

Owner:王德忠

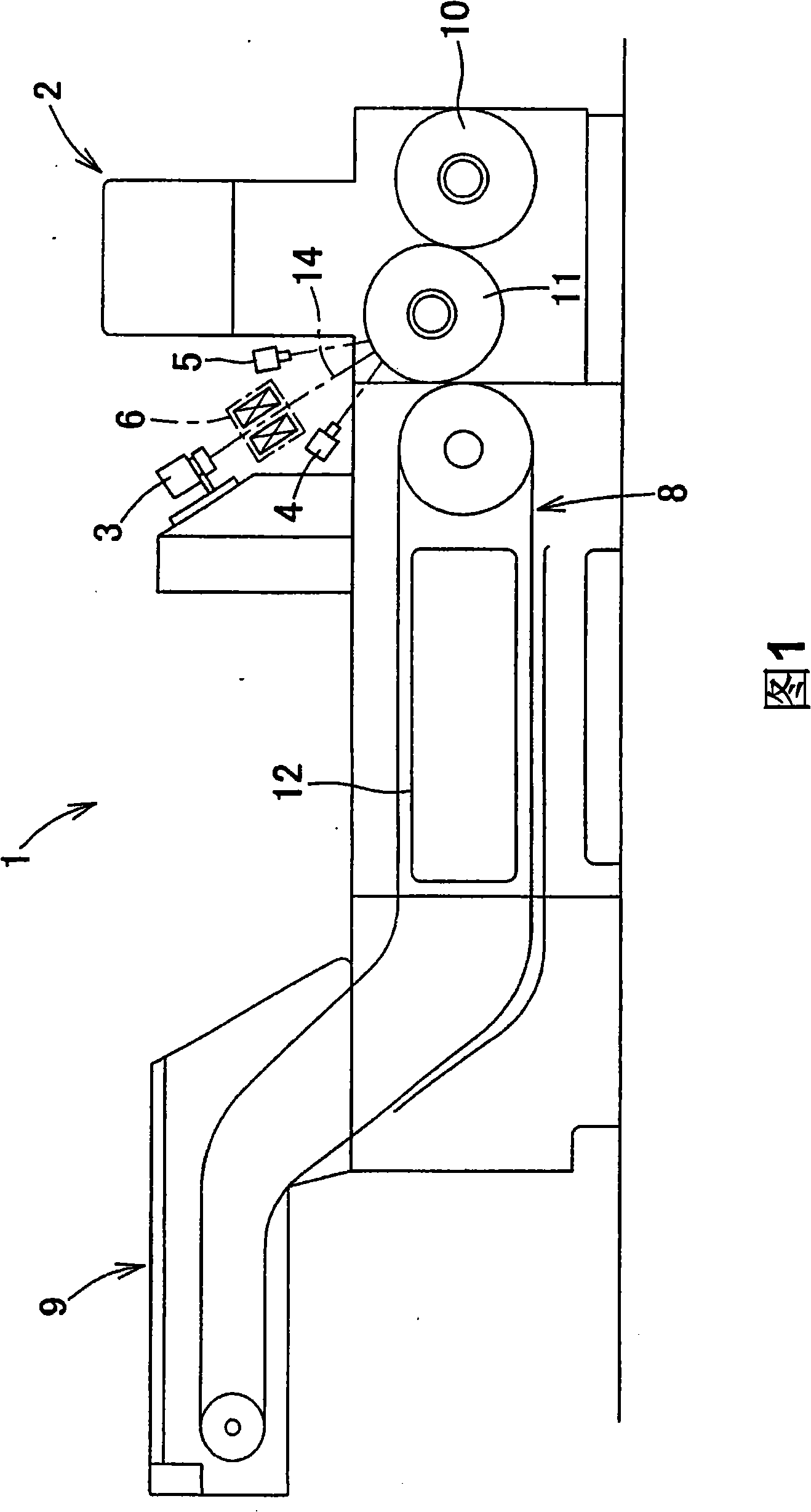

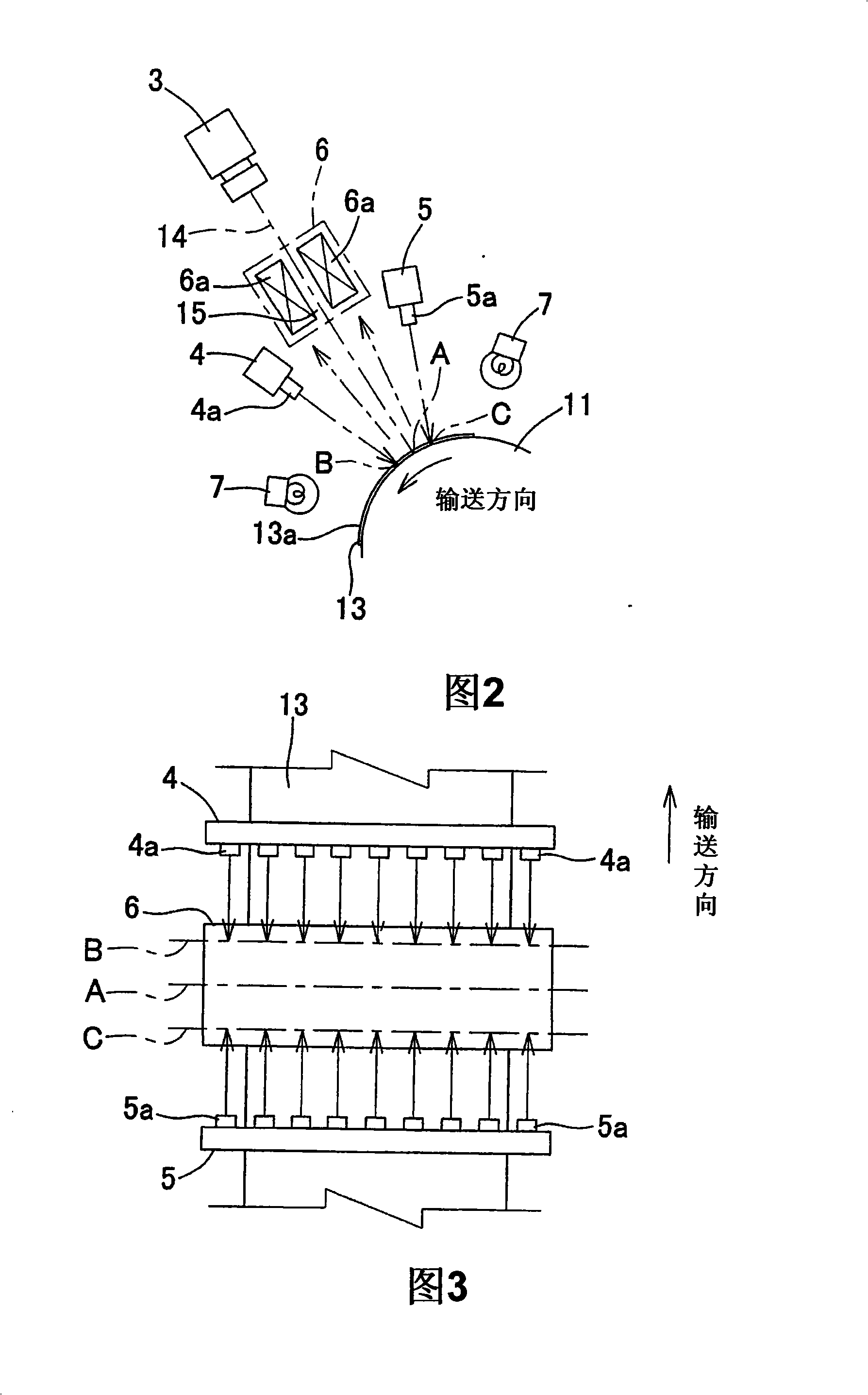

Printed matter examination apparatus

Owner:DAC ENG

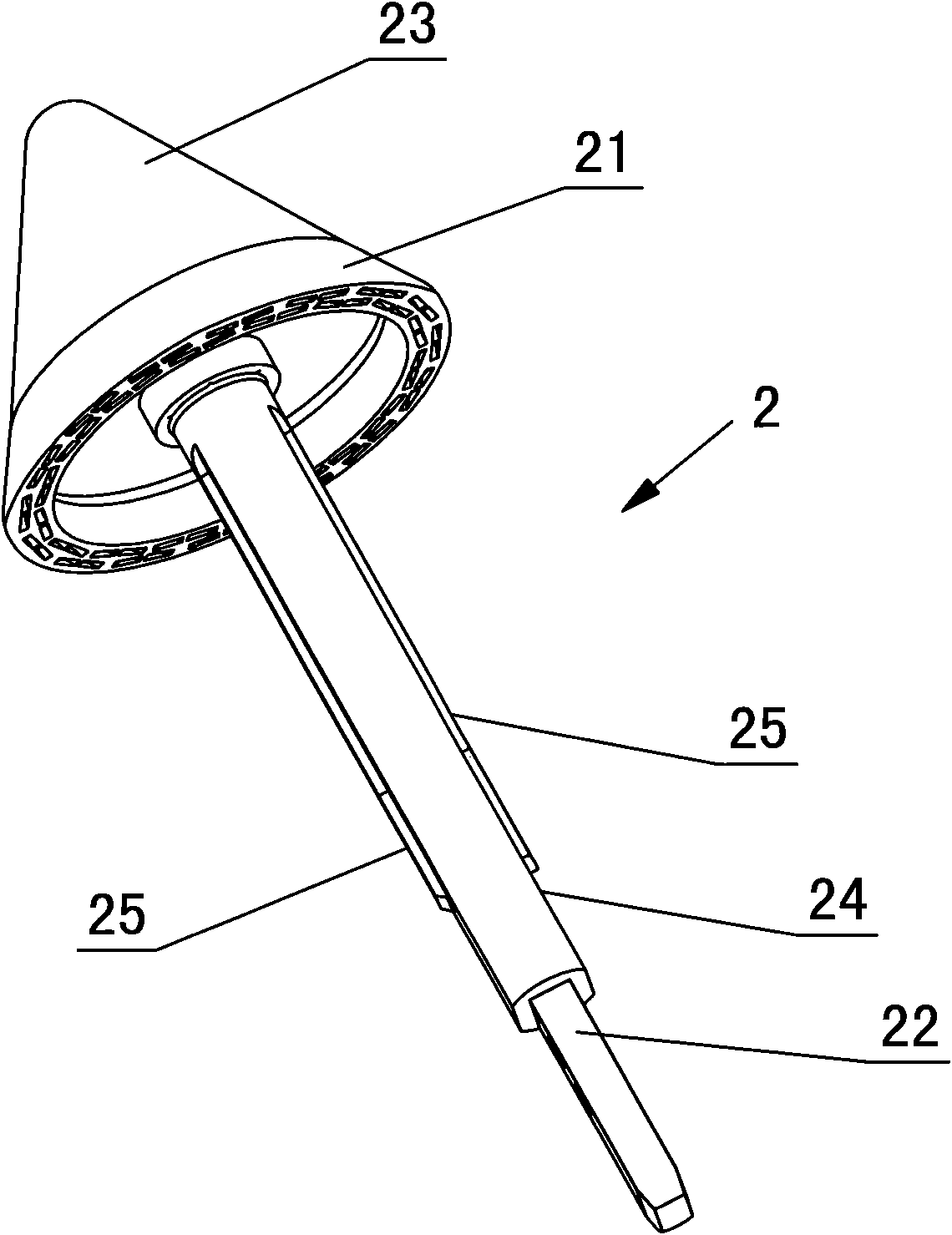

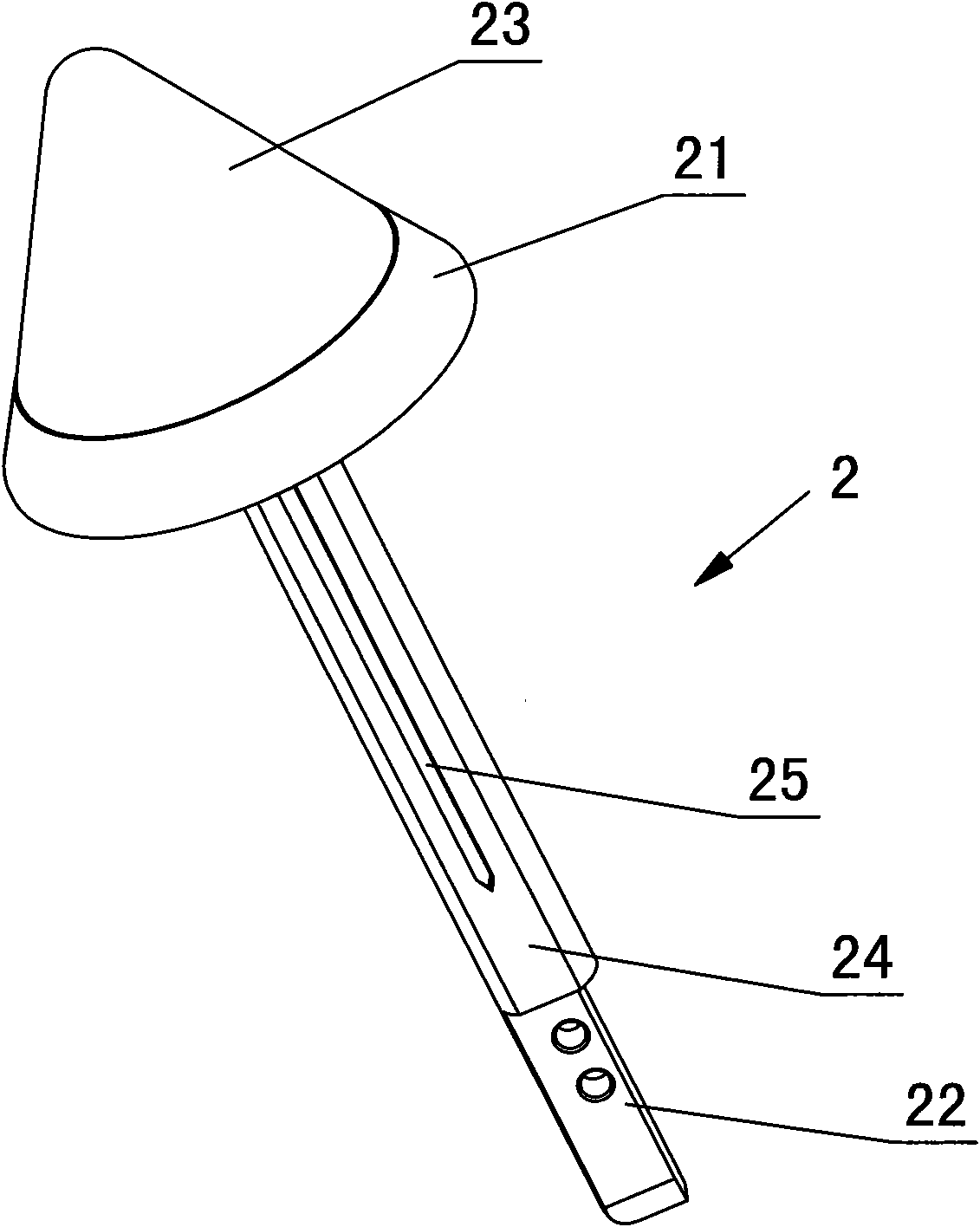

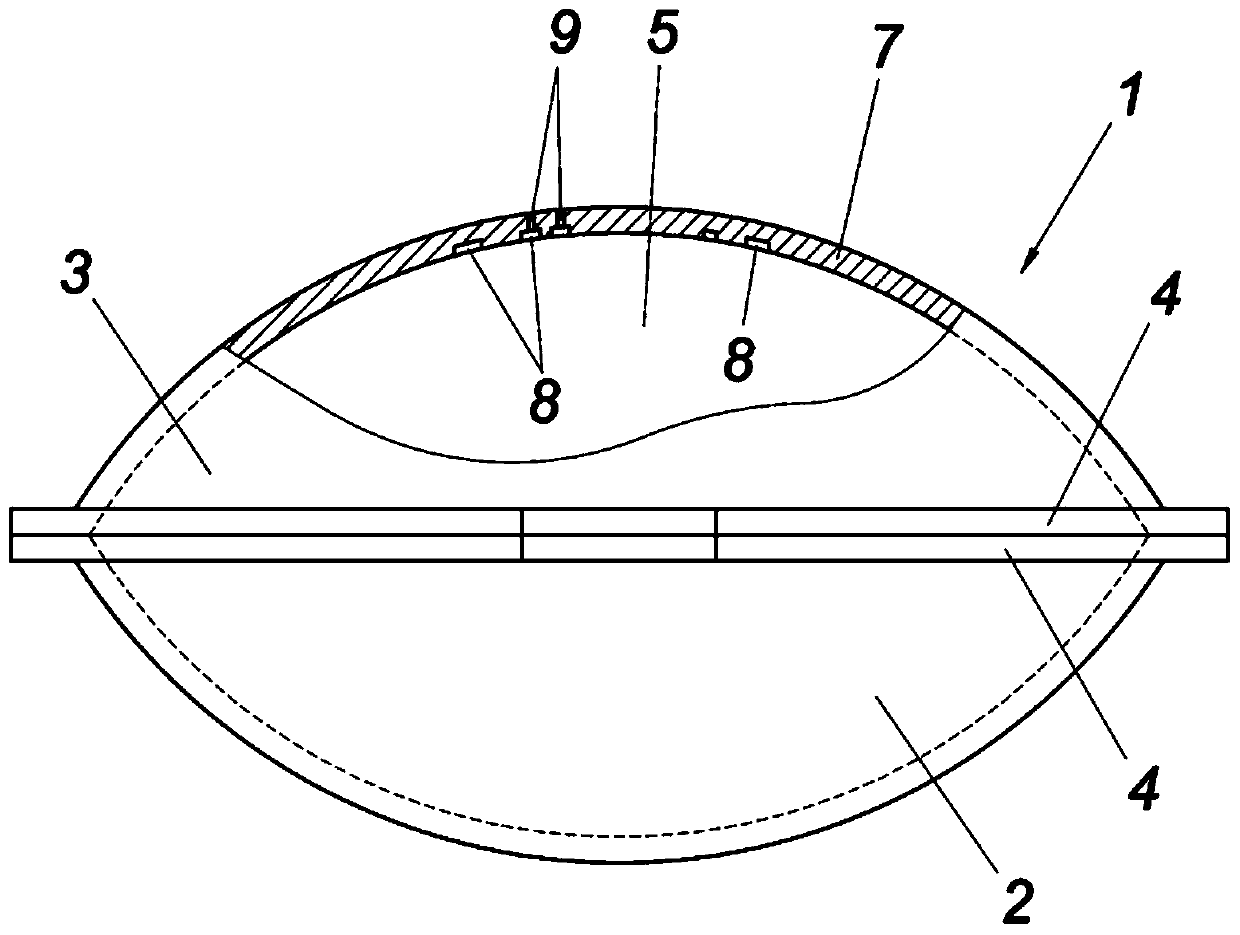

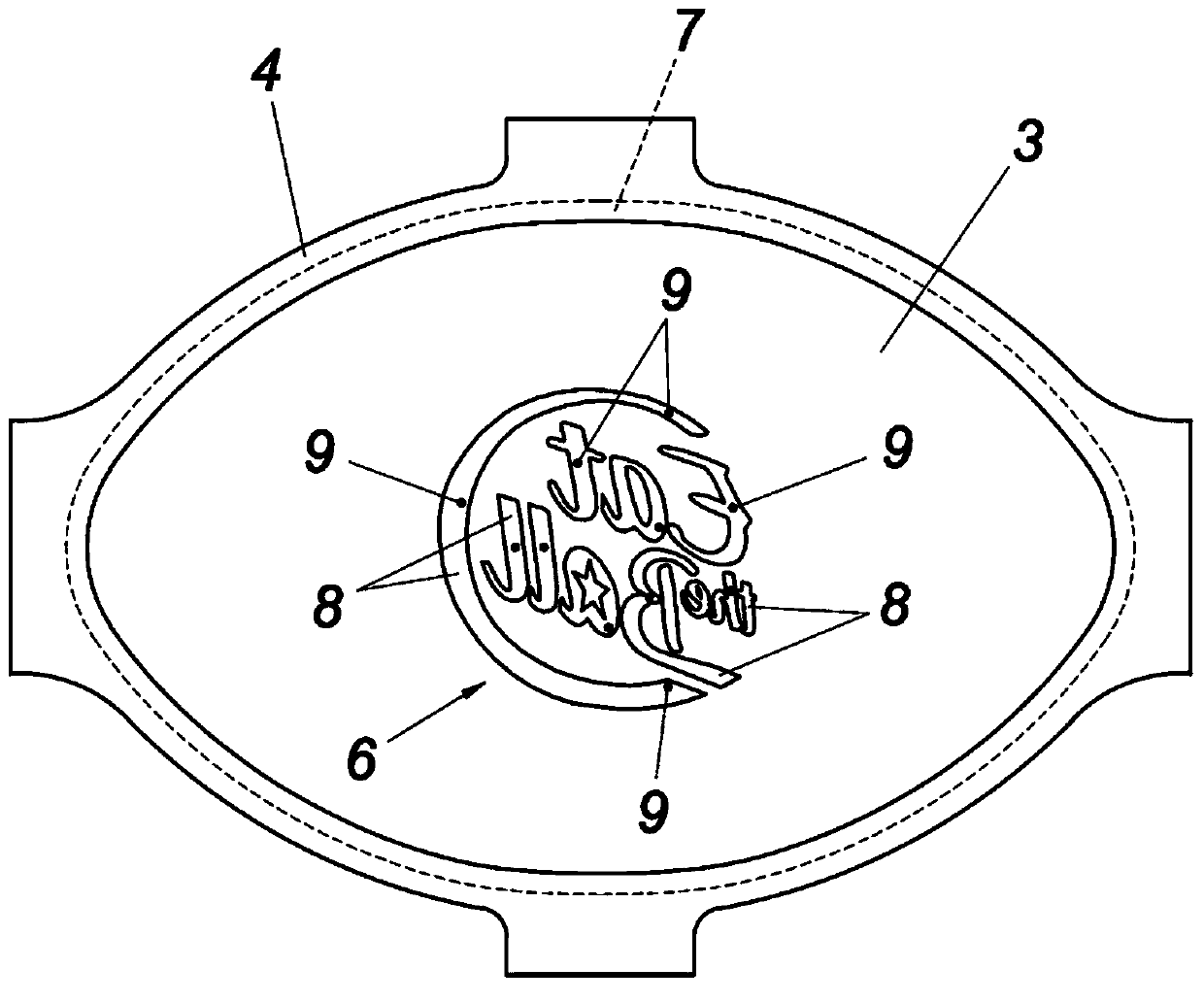

Nail-head component of a hemorrhoid anastomat

The invention provides a nail-head component of a hemorrhoid anastomat, which at least comprises a nail tube and a nail anvil, wherein the nail tube comprises a housing; the rear end of the housing is used for connecting a hemorrhoid anastomat body; a rise stopping tube is arranged in the housing; the nail anvil comprises a nail anvil ring and a nail anvil shaft which are fixed and connected to each other; the through-hole of the rise stopping tube comprises at least two planes arranged along the axis of the rise stopping tube; guide grooves are respectively arranged on the planes; and at least two planes are correspondingly arranged on the nail anvil shaft, and guide ribs are respectively arranged on the planes in a way that the guide ribs can slide in the guide groove. The invention has the following beneficial effects that: by arranging two symmetrical guide ribs, the nail anvil shaft and the rise stopping tube are in finer fit, thereby ensuring the fit of the nail tube and the nail anvil and further ensuring the effect of anastomosis.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

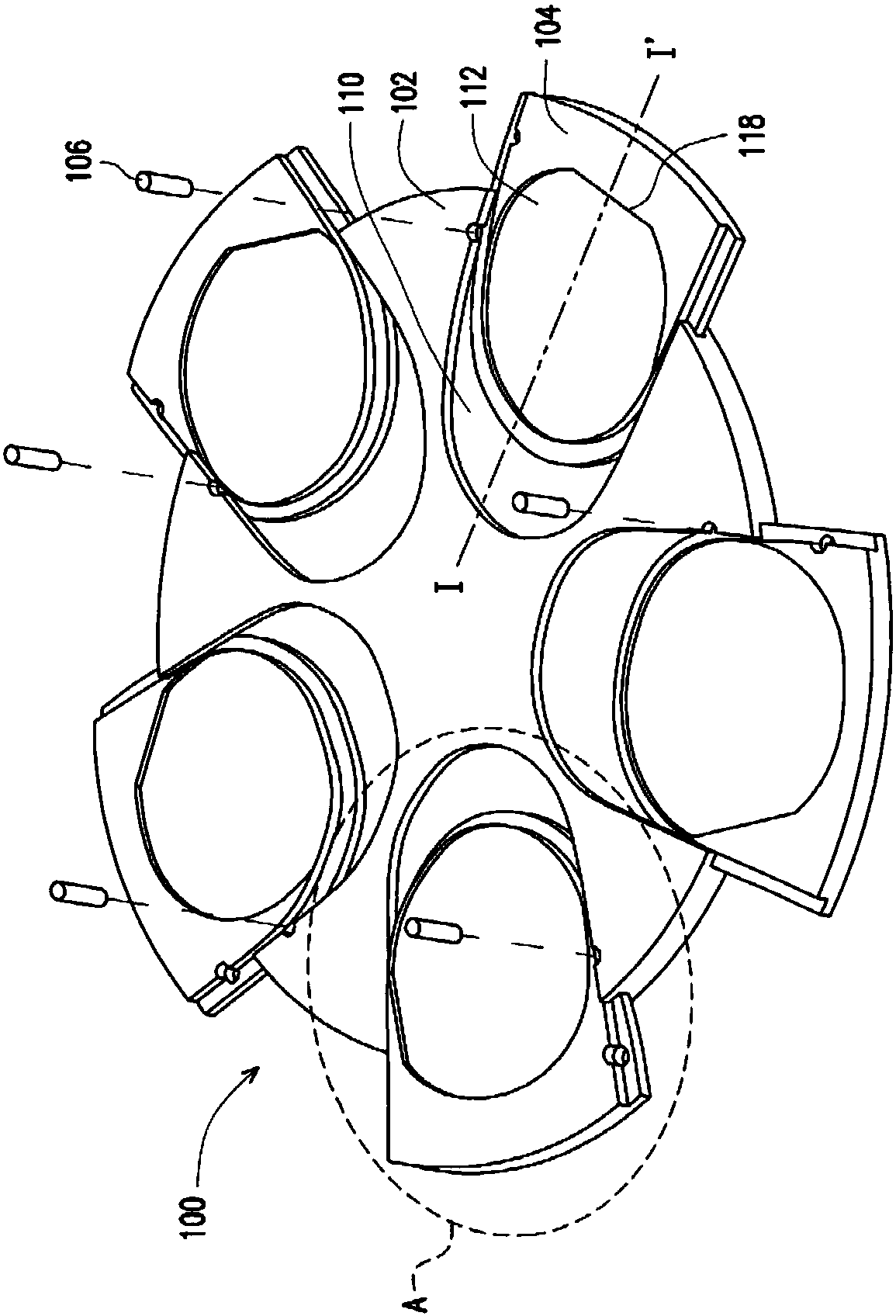

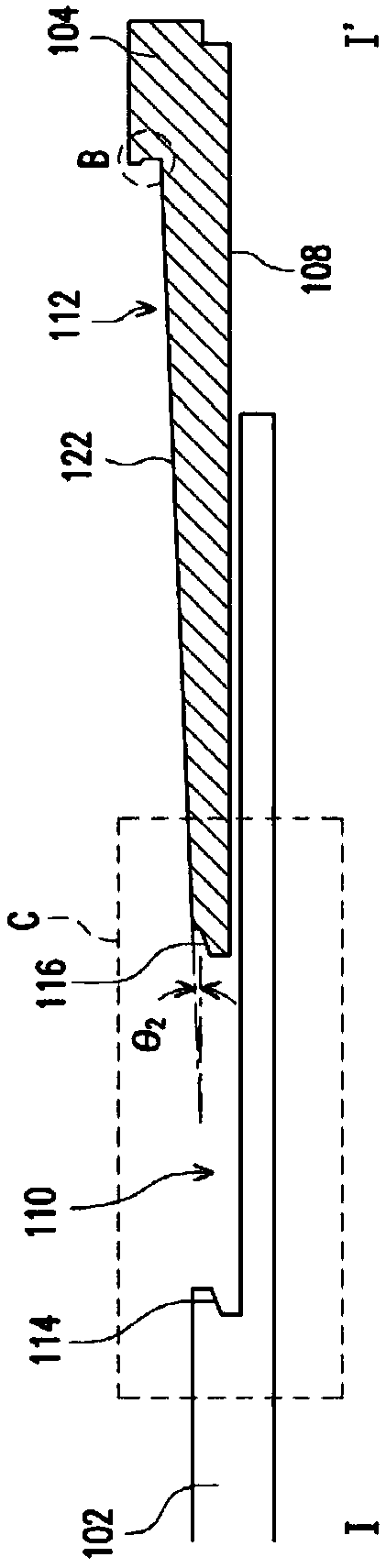

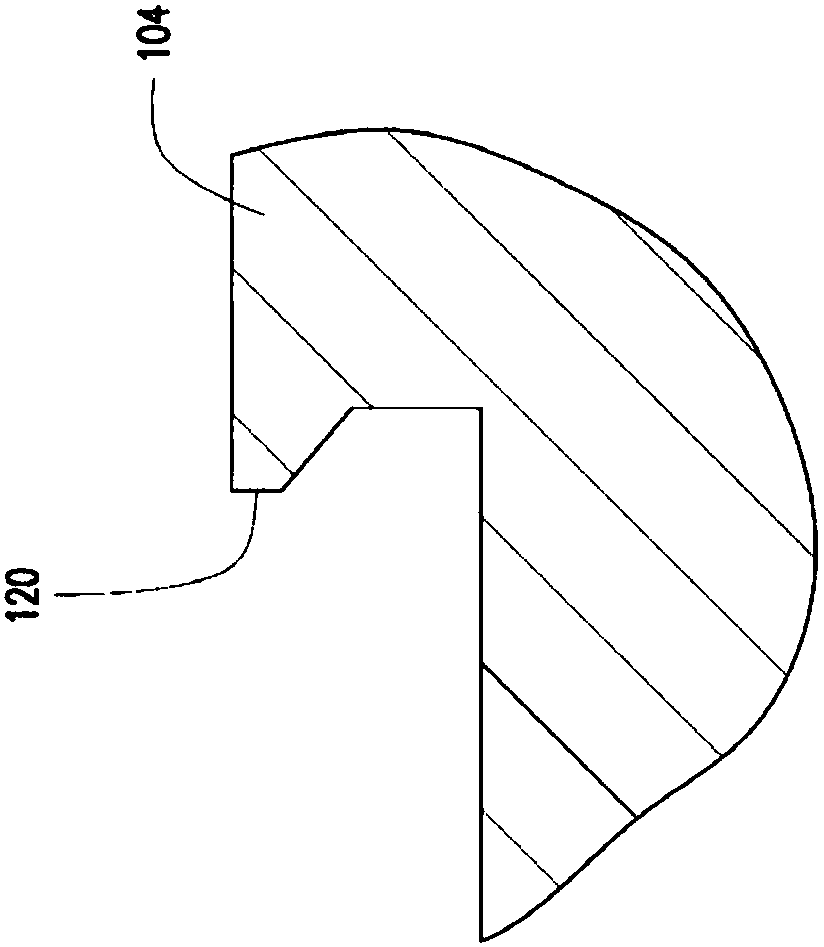

Wafer susceptor

ActiveCN108085659AMake sure it fitsEvenly heatedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEaves

The invention provides a wafer susceptor which includes a main plate, minor plates, and plugs. The main plate has first notches. The minor plates are disposed in the first notches, respectively. Eachof the minor plates has a second notch for carrying a wafer and an engaging surface of inclination engages with a side surface of the first notch. A first angle of 20-45 degrees is provided between the engaging surface and a horizontal plane. The second notch has a flat side corresponding to a flat of the wafer. The flat side has an eave portion. The plugs are disposed between the main and minor plates to fix the minor plate, respectively. The wafer susceptor can solve the problem of drafting of inner edges of a wafer due to centrifugal force during rotation, so that the wafer is heated uniformly and a film can form uniformly effectively.

Owner:GLOBALWAFERS CO LTD

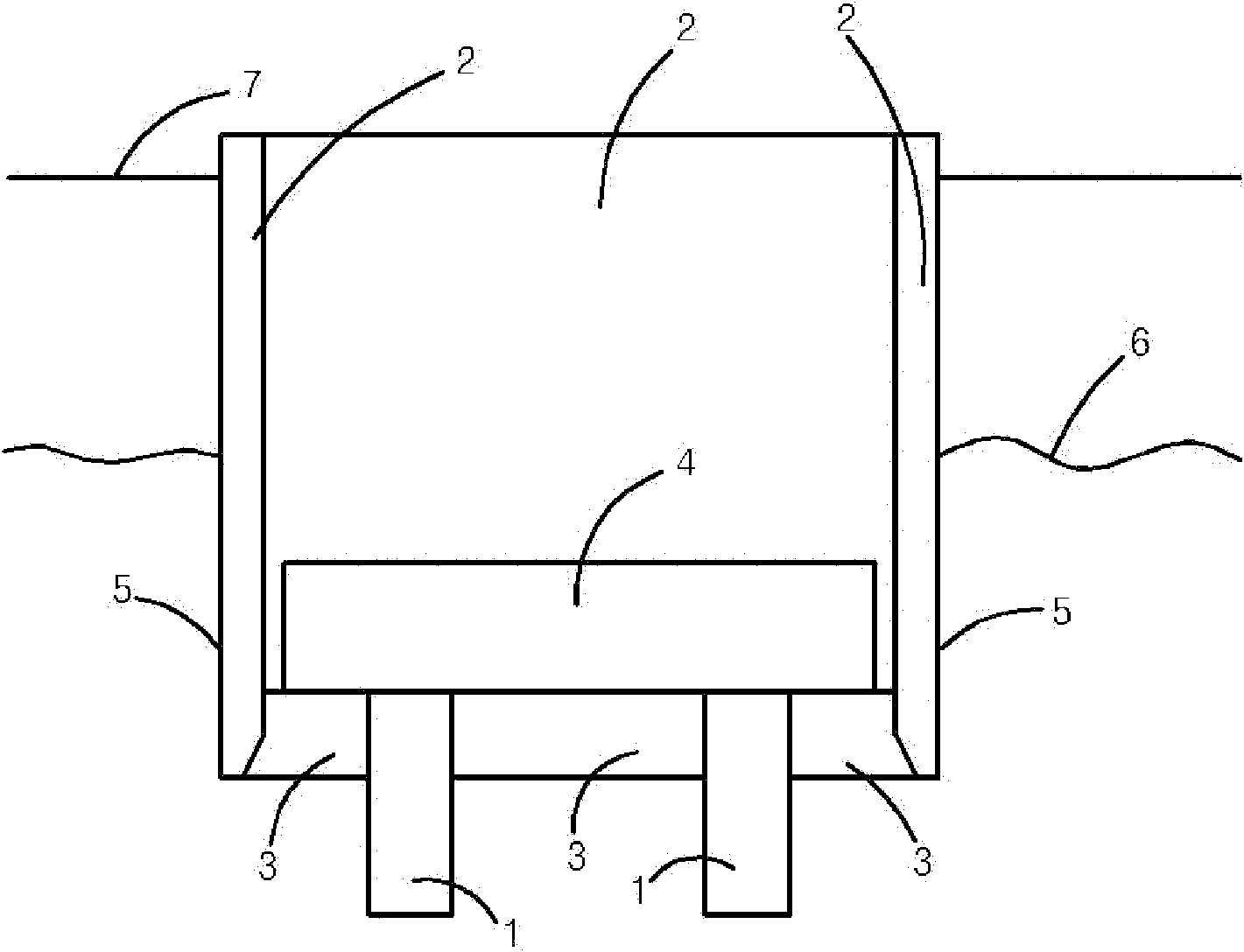

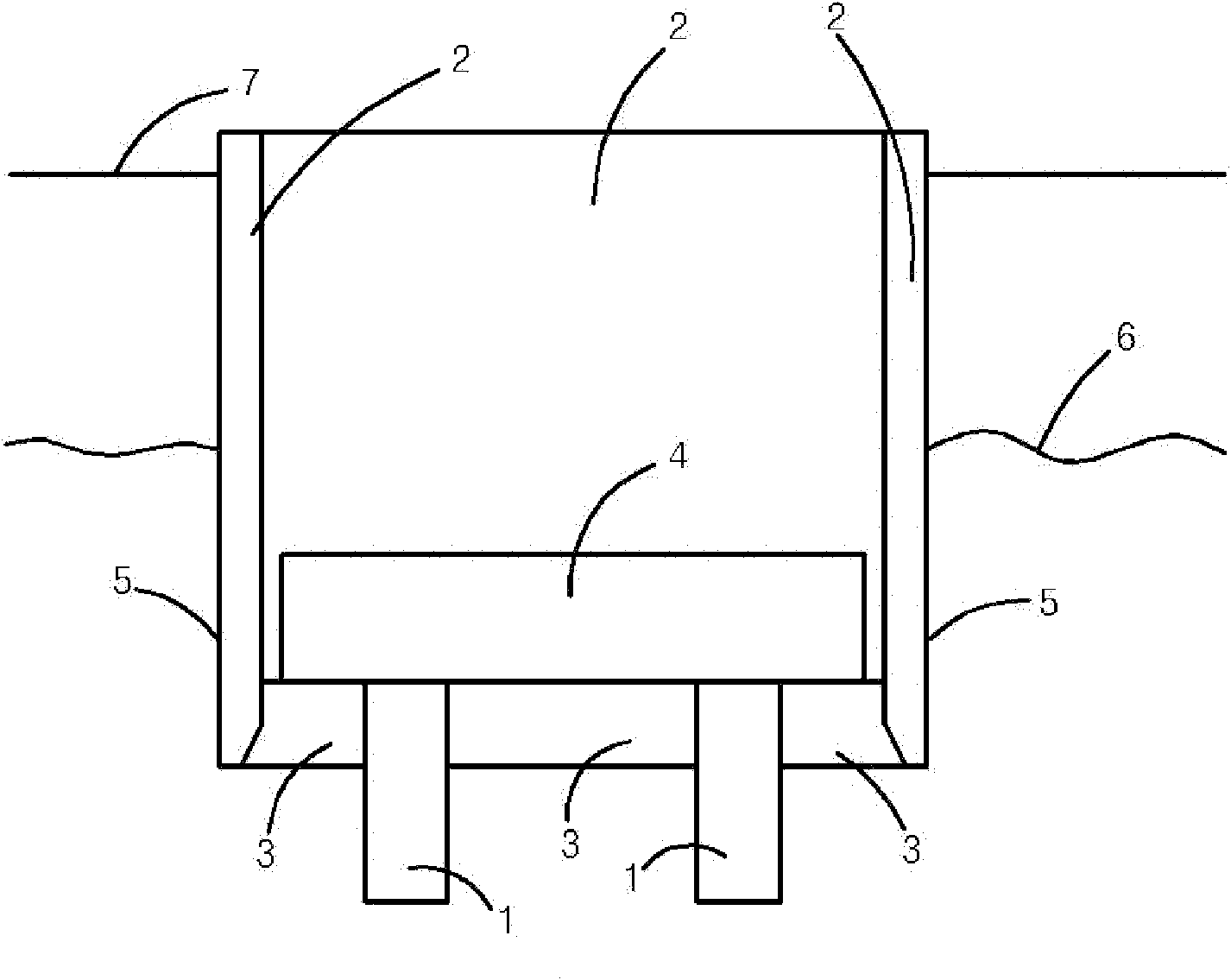

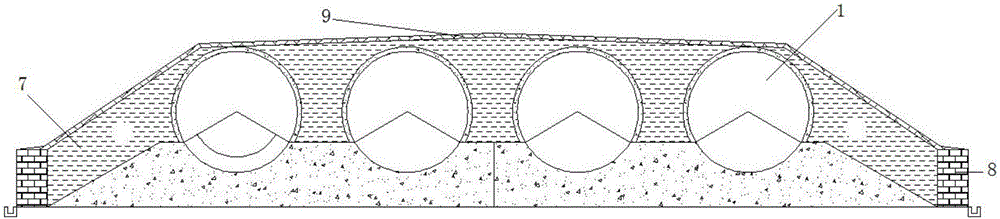

Deepwater cofferdam slot sinking construction method

The invention discloses a deepwater cofferdam slot sinking construction method, which is characterized by comprising the following processes in turn: before cofferdam wall sinking construction, forming a slot at the design position of the cofferdam wall on a riverbed by using slotting equipment; sinking the cofferdam wall into the formed slot; removing soil on the riverbed on the inner side of the cofferdam wall; and casting construction bottom sealing concrete, and forming a cofferdam after the bottom sealing concrete reaches a strength. The slotting operation is performed at the design position on the riverbed by using the slotting equipment and then the cofferdam can be smoothly put into the slot so as to prevent the over hard riverbed from blocking the sinking of the cofferdam and ensure that the position of the cofferdam is matched with the design position.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Wood board surface finish machining and polishing machine for furniture manufacturing

ActiveCN113231935AIncrease flexibilityImprove applicabilityGrinding carriagesBelt grinding machinesSurface finishPolishing

The invention relates to a wood board surface finish machining and polishing machine for furniture manufacturing. A bottom plate, a containing device and a polishing device are included, the containing device and the polishing device are sequentially installed at the upper end of the bottom plate from left to right, and the polishing device is in sliding fit with the containing device. The wood board surface finish machining and polishing machine can solve the problems that when an existing machine polishes round corners on wood boards, generally, only round corners of the same radian can be polished, corresponding adjustment cannot be conducted according to changes of the radians of the round corners, corresponding adjustment cannot be conducted according to the thicknesses and the widths of the wood boards, the use flexibility of a machine is reduced due to the phenomenon that the round corners of the wood boards are not completely polished, complete attaching of the machine and the round corners on the wood boards cannot be ensured, the phenomenon that the round corners are incompletely polished after the wood boards are polished, and consequently, the wood board round corner polishing effect is reduced.

Owner:联享家居(徐州)有限公司

Double seat valve

The invention relates to a double seat valve, which is capable of cleaning the seat and which is improved compared to that of the prior art, whereby a delivery as free from turbulence as possible of the seat cleaning flow into and out of the leakage cavity is ensured, and a pressure-increasing direct action upon the seat areas is reliably prevented. This is achieved in that: the second closing element (4), when in its closed position, rests with a stopping surface (4e), which is placed on a face of its cylindrical projection (4*), upon the interface (2e; 2e*) and, to be precise, directly upon the first seating (2a, 2g) in an adjoining manner; in the face of the second cylindrical projection (4*), a central recess (4d) is provided which, radially outside, starts (starting point of contour (K)) with a rotationally symmetric reversing surface (4b) and is delimited on the face by a face (4c) oriented, in essence, essentially perpendicular to the longitudinal axis of the second closing element (4), the reversing surface (4b) leading into the face (4c) (leading point of contour (K)) ; the reversing surface (4b) and the stopping surface (4e) form a second wraparound edge (U2) that, when the second closing element (4) is closed, directly abuts against a first end section (2g) of the first seating (2a); when viewing the meridian section, the reversing surface (4b) has a contour (K) with a bend-free curve, a direction vector in the leading point of the reversing surface (4b) points into a discharge borehole (3d) centrally provided in the first closing element (3) without colliding with the first closing element (3) in the vicinity of its areas bordering the leakage cavity (5) or of the middle seal (8; 8*) and forming dynamic pressure, and a front-side delimitation of the first closing element (3) facing the leakage cavity (5) is at an axial safe distance (x) from the direction vector on an outlet point of the interface (2e) into the first end section (2g).

Owner:TUCHENHAGEN GMBH

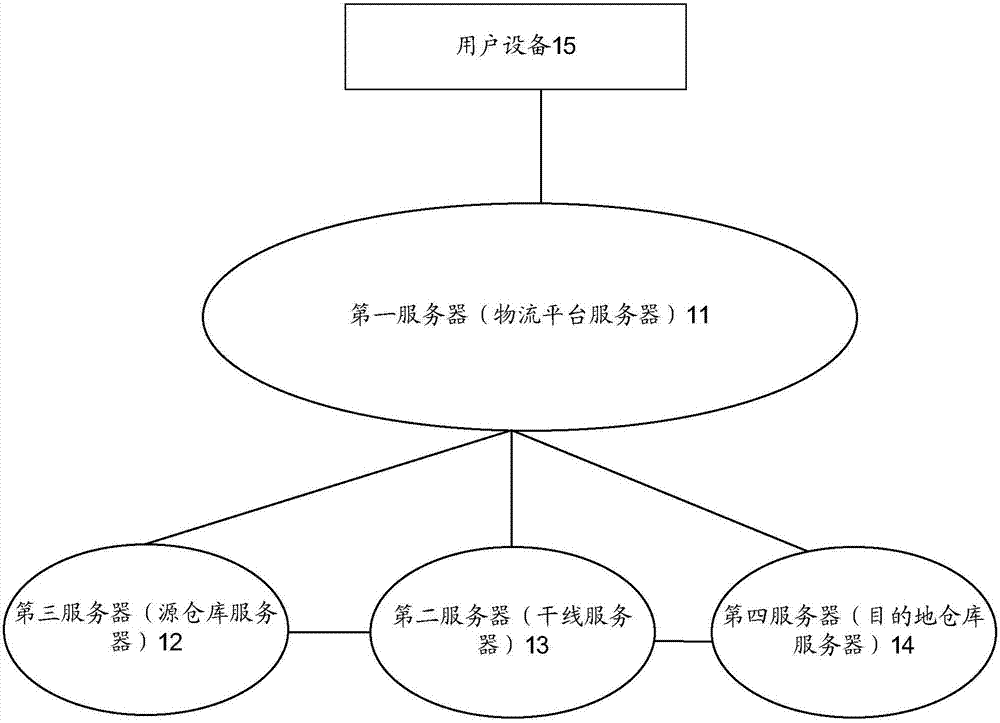

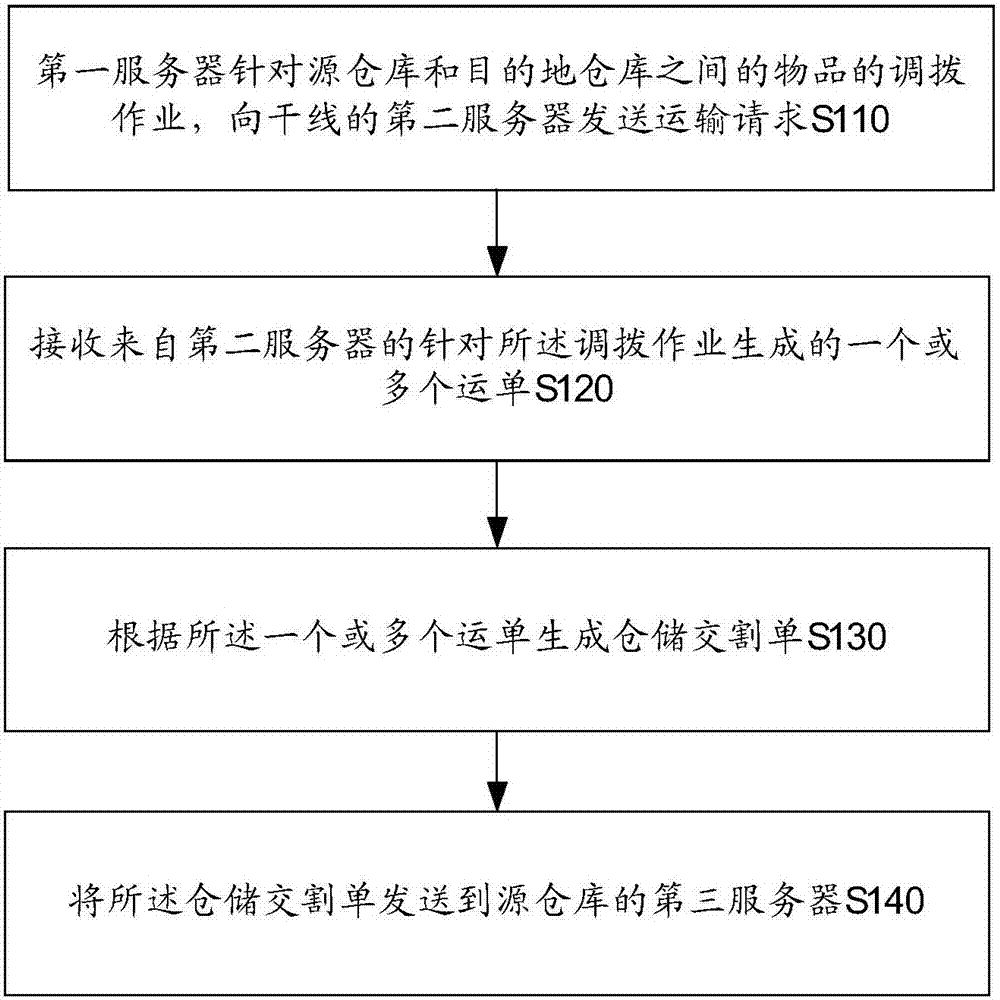

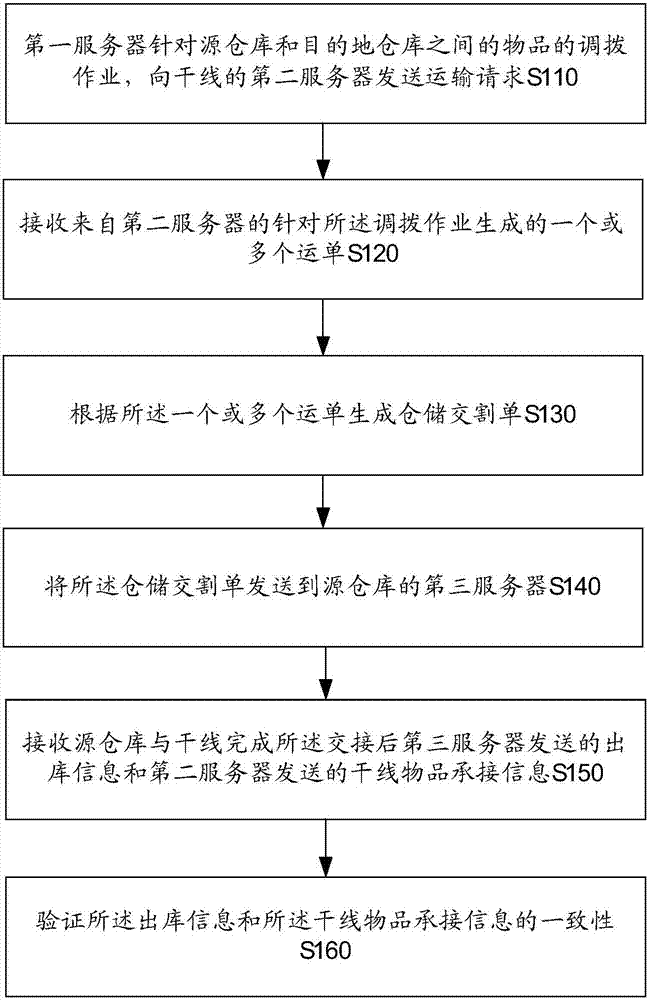

Information processing method and device for goods handover between warehouse and trunk line

The invention provides an information processing method and device for goods handover between a warehouse and a trunk line. The method comprises the steps: enabling a first server to transmit a delivery request to a second server of the trunk line for the allocation of goods between a source warehouse and a destination warehouse; receiving one or more freight notes, generated for the allocation, from the second server; generating a storage delivery order according to one or more freight notes; transmitting the storage delivery order to a third server of the source warehouse, wherein the source warehouse carries out the handover of goods in one or more freight notes according to the storage delivery order and the trunk line. According to the invention, the information processing method can enable a storage service provider and a trunk line service provider to carry out the clear handover of goods, and improve the handover accuracy of goods.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

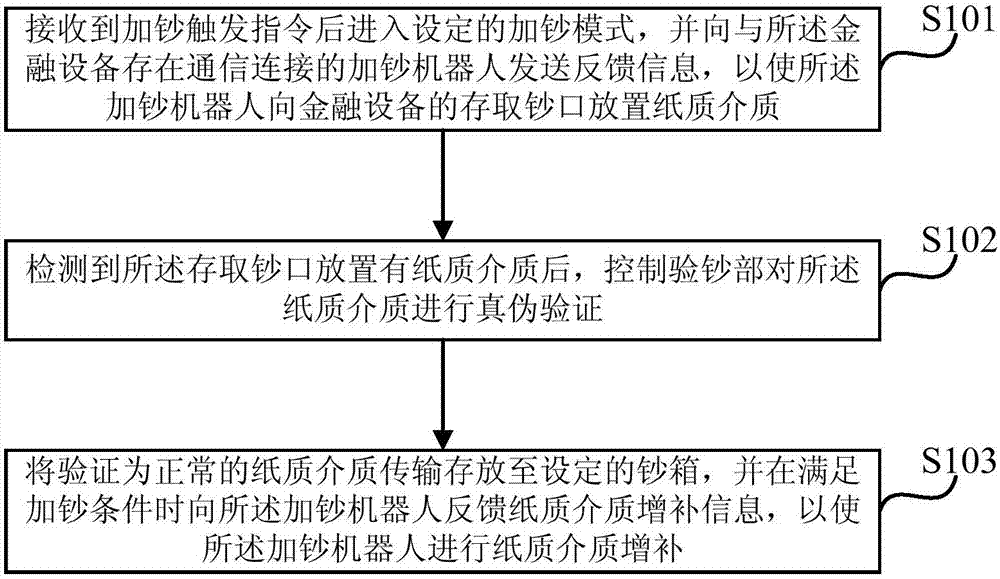

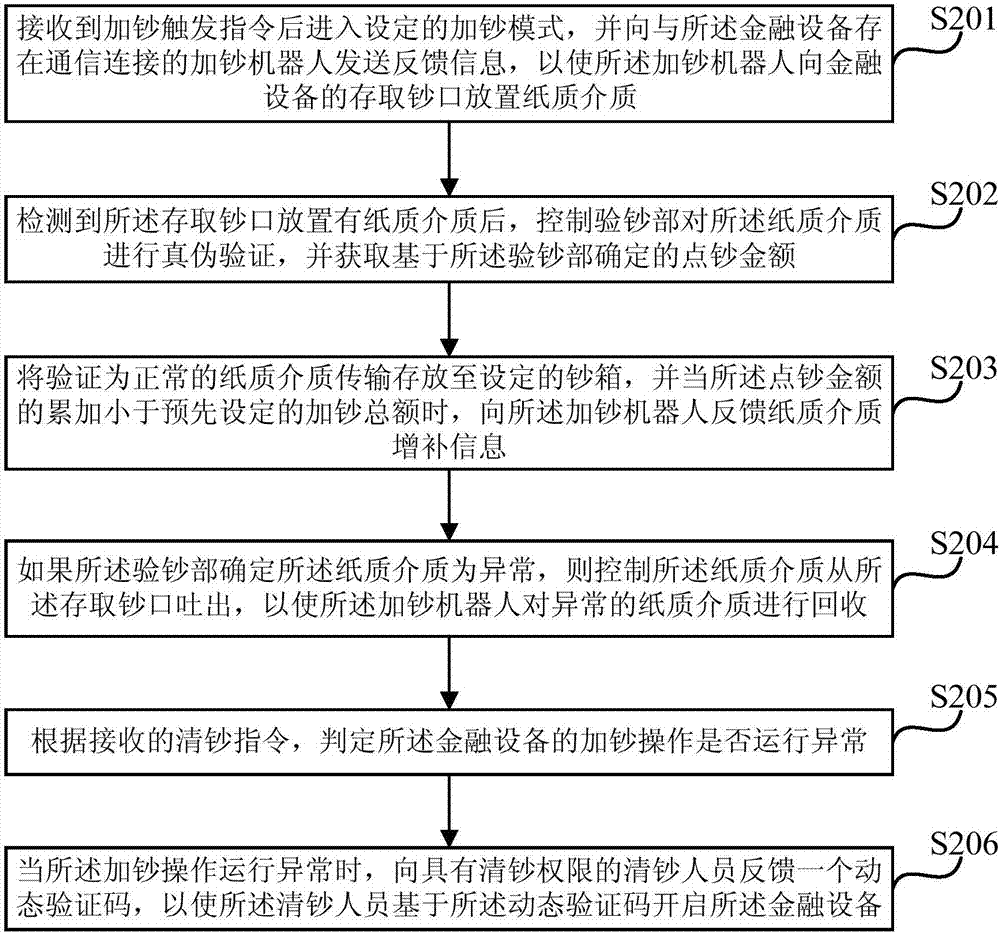

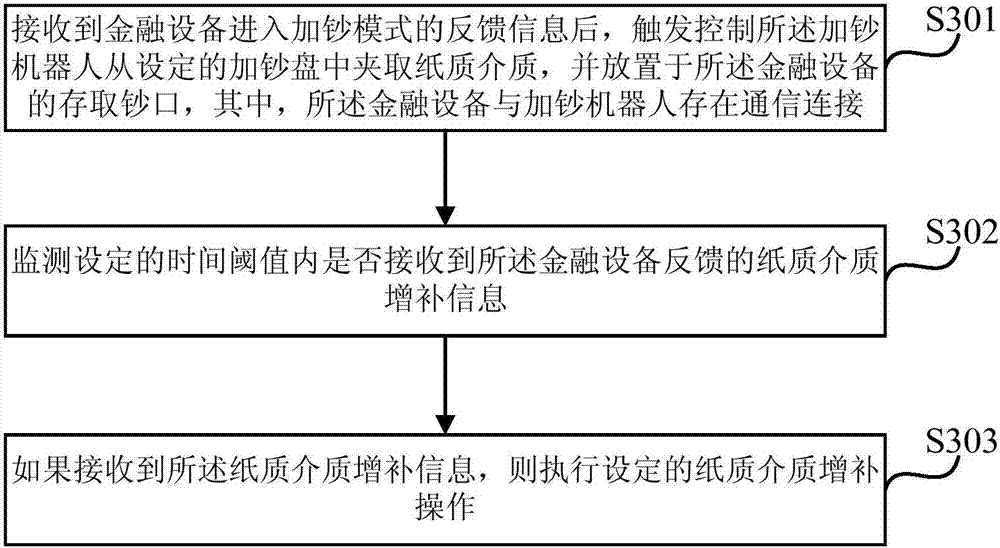

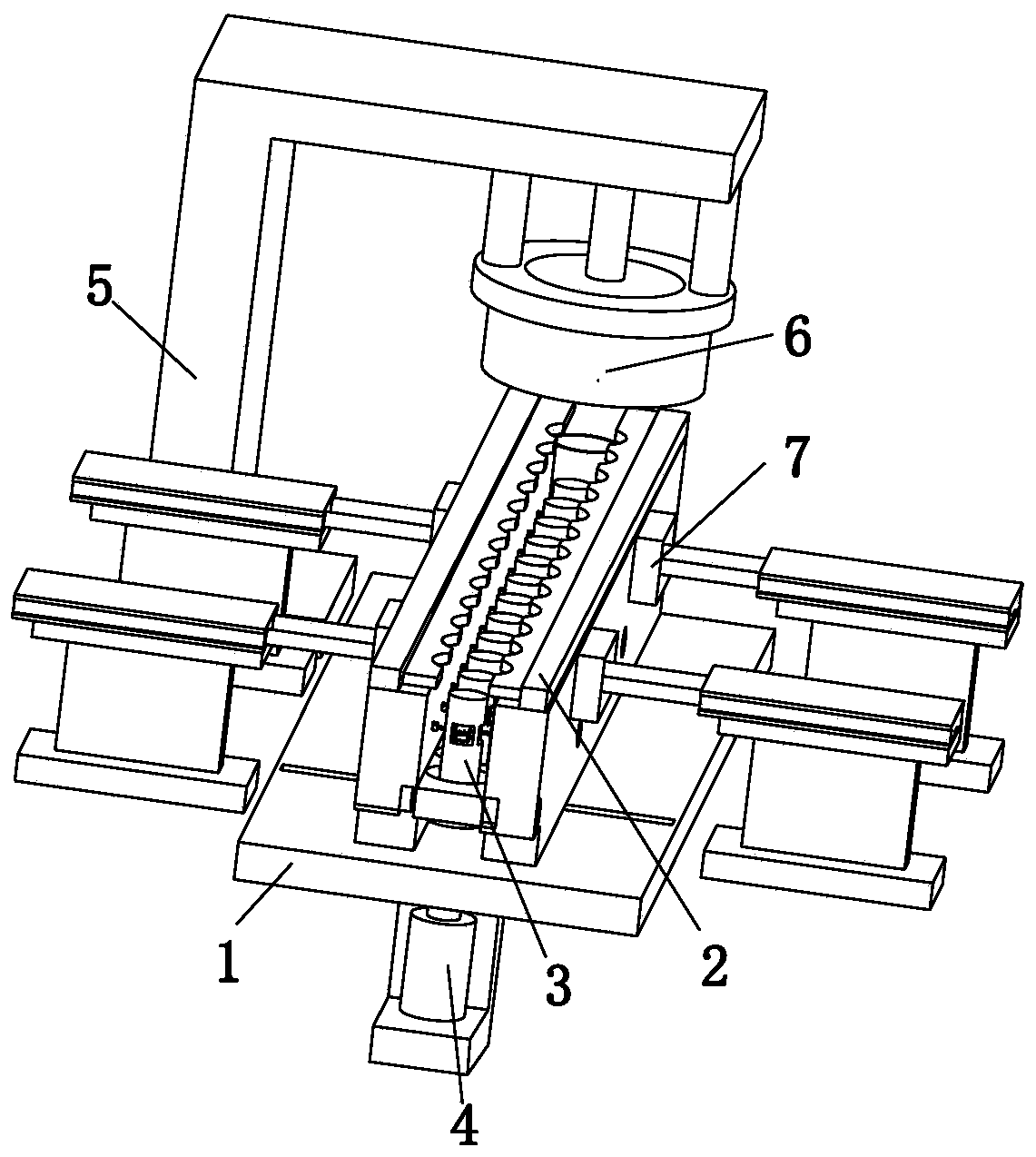

Money adding method of financial equipment, apparatus, system, corresponding equipment and storage medium thereof

InactiveCN107393128ARealize automatic banknote additionImprove the speed of adding banknotesCoin/currency accepting devicesPaper basedComputer science

The invention discloses a money adding method of financial equipment, an apparatus, a system, corresponding equipment and a storage medium thereof. The method comprises the following steps of after a money adding trigger instruction is received, entering into a set money adding mode and sending feedback information to a money adding robot so that the money adding robot places a paper-based medium at an access money port of the financial equipment; after the paper-based medium is detected to be placed at the access money port, making a currency detection portion carry out authenticity verification on the paper-based medium; and transmitting and storing the paper-based medium which is verified to be normal to a set money box, and when a money adding condition is satisfied, feeding back paper-based medium supplement information to the money adding robot so that the money adding robot carries out paper-based medium supplement. By using the method, automatic money adding of the financial equipment can be realized; each paper money which enters into the money box can be ensured to be real; a condition that a money adding person changes the money can be prevented; accuracy of a money adding amount is ensured so that a condition that the money amount does not accord with a preset amount during manual money adding is avoided; a money adding operation speed of the financial equipment is increased; and simultaneously safety of money adding operation is increased too.

Owner:SHENZHEN YIHUA COMP +2

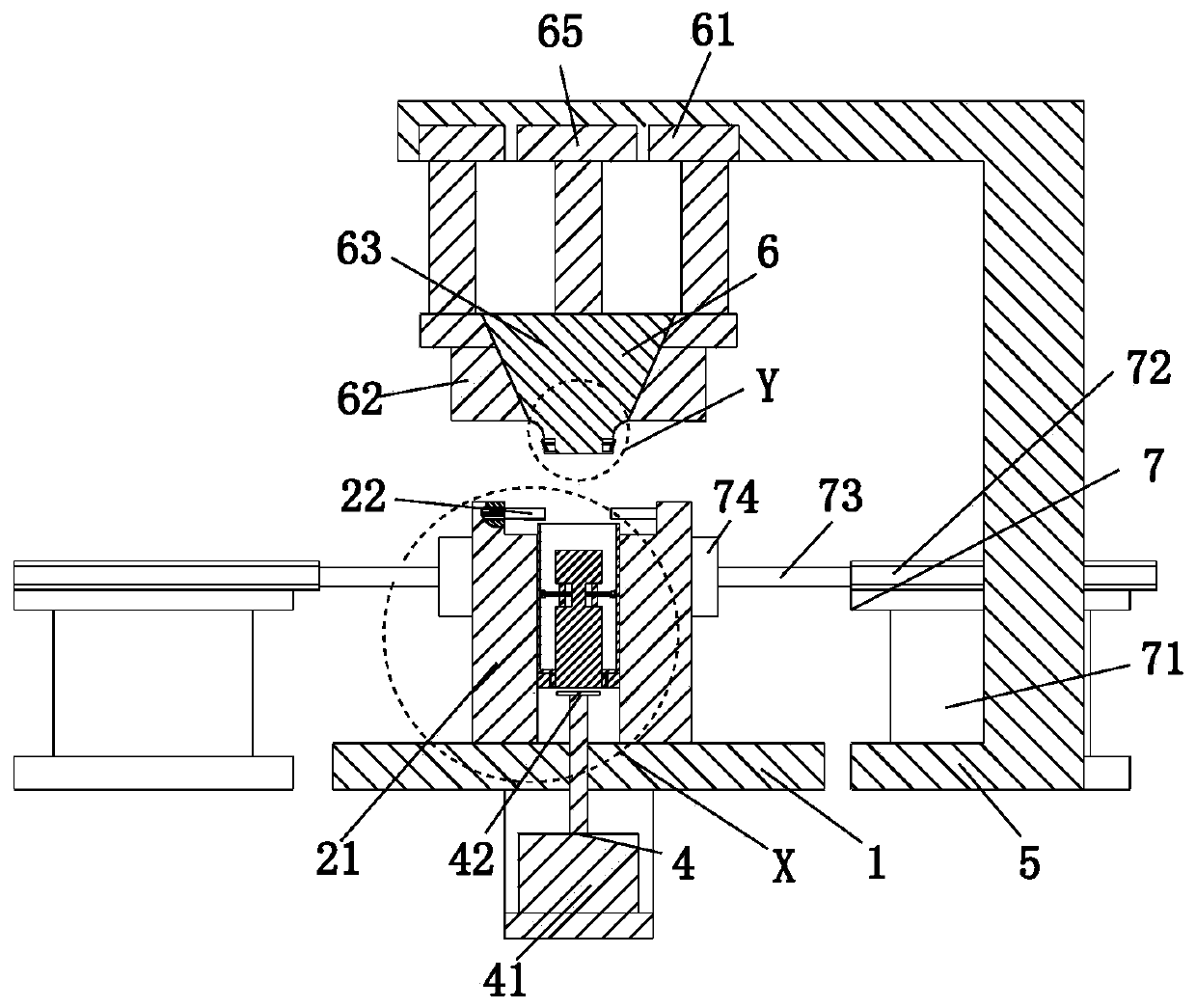

Hardware product hemming stamping die

ActiveCN110421089AReduce shakingReduce wrinklesShaping toolsMetal-working feeding devicesWrinkle skinPunching

The invention relates to a hardware product hemming stamping die. The hardware product hemming stamping die comprises a workbench, two attaching devices, a limiting device, an ejection device, a U-shaped frame, a stamping device and four clamping devices, wherein the attaching devices are symmetrically arranged on the upper end surface of the workbench in a bilateral symmetry mode, the two clamping devices are connected by the limiting device, the ejection device is arranged behind the lower end of the workbench, the clamping devices are symmetrically arranged on the left side and the right side of the workbench, the U-shaped frame is installed at the front end of the right side of the workbench, and the stamping device is installed on the lower end surface of the U-shaped frame. The hardware product hemming stamping die can solve the problems that when an existing iron sheet is punched, the iron sheet can be directly placed into a clamping groove, and a fixing device is not arranged in the clamping groove, and during stamping, wrinkles can be generated between the iron sheets in the punching process, the iron sheet can also shake, stamping deviation is avoided, and hemming is noteasy to form, and meanwhile, an existing external rigid clamping device and an iron sheet contact part are easy to deform.

Owner:武汉普泰金属制造技术有限公司

Novel feeder

ActiveCN106516721AEasy to removeSolve the blockageLarge containersConveyor partsEngineeringBolt connection

The invention relates to a feeder, particularly to a novel feeder, and provides the novel feeder which can accurately enable a working hopper to be right below a conical funnel, facilitates dredging of the conical funnel, and is aimed at solving the technical problem. The novel feeder provided to solve the technical problem comprises a hopper lifting feeding machine, a mounting plate, slide rails, sliding blocks, first springs, electric wheels, steel wire ropes, a movable plate, a connecting rod, travel switches, a placing bucket, and the like, wherein the mounting plate is in bolted connection with the bottom of the hopper lifting feeding machine; a through hole is formed in the mounting plate; the slide rails are in bolted connection with the front and back walls in the mounting plate; and the travel switches are in screw connection with the right sides of the inner walls of the slide rails. According to the novel feeder designed by the invention, the placing bucket and the hopper lifting feeding machine are combined, and the placing bucket can move left and right.

Owner:新昌县云大农业有限公司

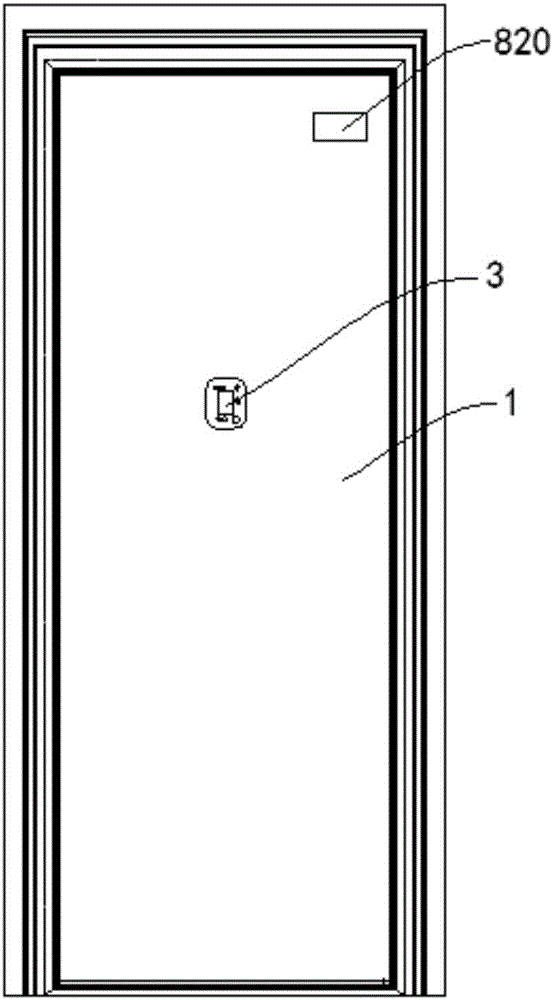

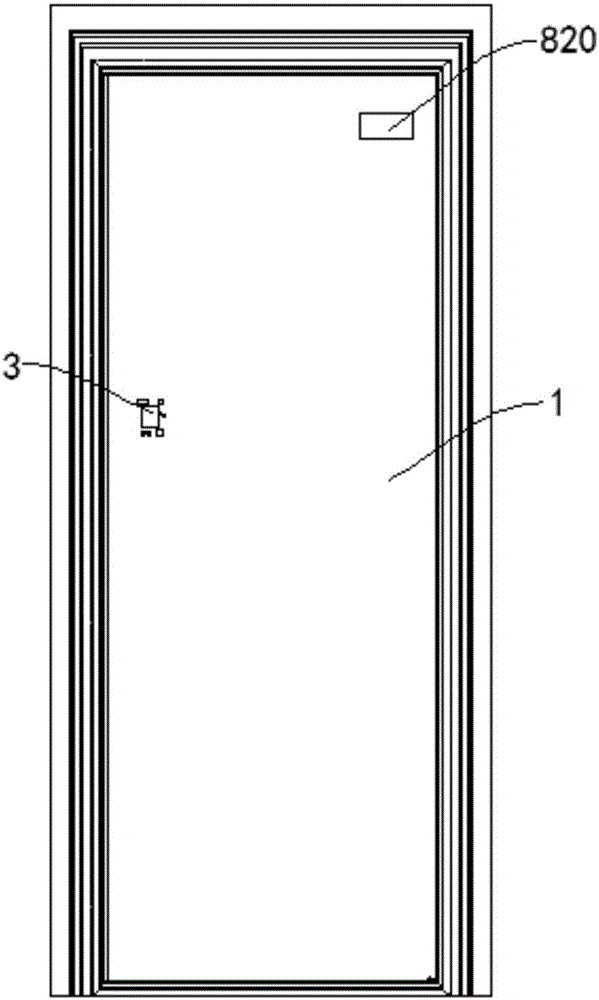

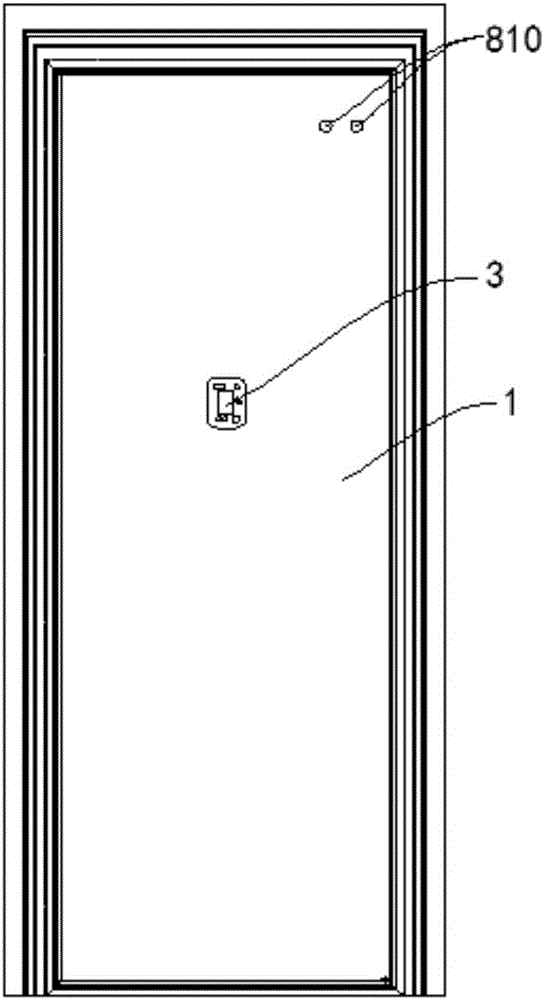

Lockhole-free full-automatic intelligent door

PendingCN106760967AImprove aestheticsMake sure it fitsBuilding locksIndividual entry/exit registersElectricityAutomatic control

The invention relates to a lockhole-free full-automatic intelligent door. The lockhole-free full-automatic intelligent door comprises a door body, an intelligent lock of which opening and closing are controlled electrically, an information collection device, an electric door closer and a control module. The information collection device and the intelligent lock are embedded into the door body. The control module is electrically connected with an electric control part of the electric closer and an electric control part of the intelligent lock. The lockhole-free full-automatic intelligent door further comprises a human body sensor and a door closing sensing device; the human body sensor is arranged on the door body and electrically connected with the control module; and the door closing sensing device is connected with the control module and used for sensing whether the door body and a door frame are well combined. The lockhole-free full-automatic intelligent door has the beneficial effects that the safety is effectively improved, the effect that the outside of the door is free of a lockhole can be achieved thoroughly, meanwhile, after the electric door closer is additionally arranged, opening and closing of the door are both controlled automatically and conveniently, and the intelligent degree is high.

Owner:JEWXON INTELLIGENT TECHWUHANCO LTD

Slide-to-position method for large earth-covering bullet pot

The invention provides a slide-to-position method for a large earth-covering bullet pot. The method comprises the following steps: S1, according to a planning design of a sand bed, calculating the fall between the elevation of a field installed and welded region and the elevation of the bullet pot in position on the sand bed, and designing the height, to which the bullet pot needs to be jacked; S2, performing a jacking operation: jacking the earth-covering bullet pot to the field installed and welded region to the designed height by using a jacking bracket; S3, sliding the bracket to position: after the earth-covering bullet pot is jacked to the designed height, transferring the bullet pot to a slide bracket on a slide rail, and jacking the slide bracket till the elevation of the bullet pot exceed the minimum passage height of the sand bed; S4, horizontally pushing and sliding: pushing the bullet pot to the corresponding designed position on the sand bed by using a pushing device; and S5, enabling earth-covering bullet pot to be in position: moving the slide bracket in the bottom of the bullet pot out, wherein the bullet pot fully falls to the corresponding position of the sand bed. The method provided by the invention can mount the large earth-covering bullet pot in position, and is relatively low in cost and high in using efficiency.

Owner:WUHAN YIYE STEEL STRUCTURE

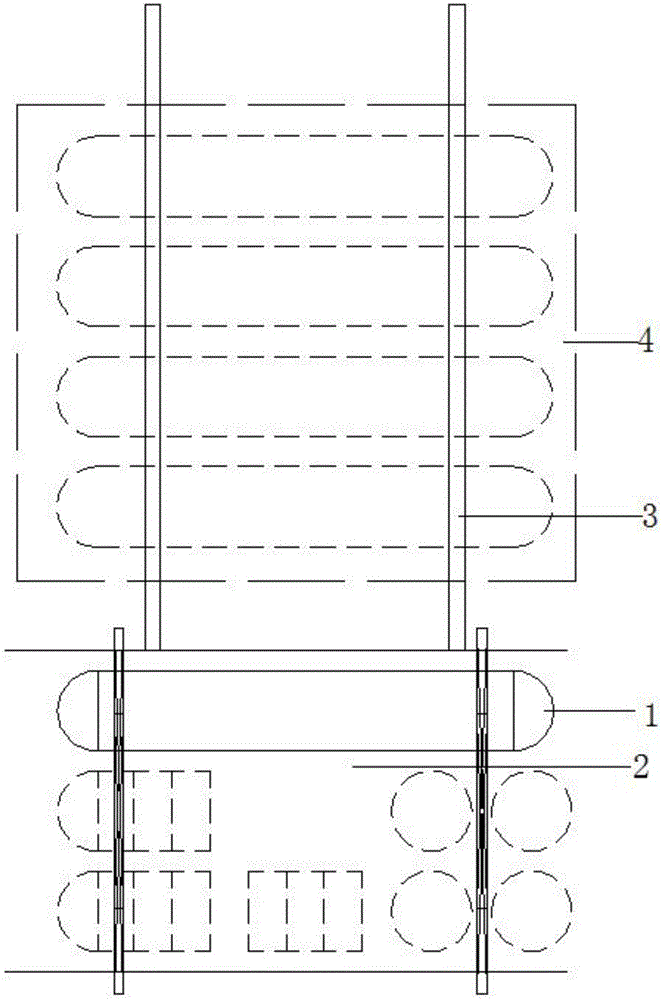

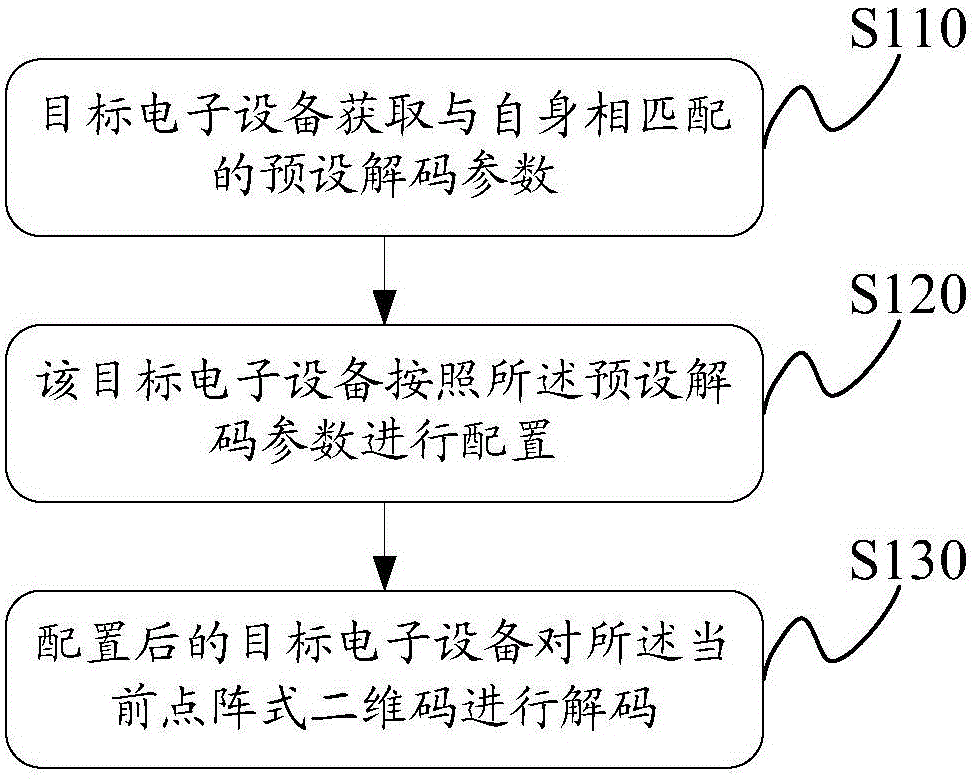

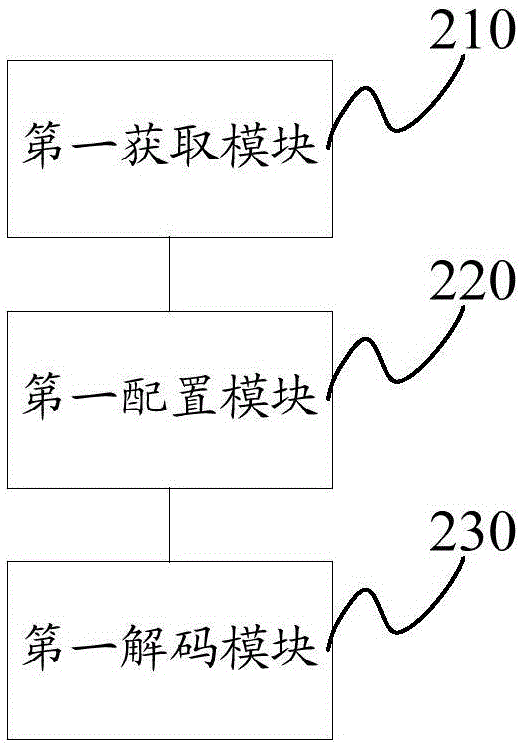

Image reading method used for dynamically configuring decoding parameter and device

InactiveCN105138941AGuaranteed success rateMake sure it fitsSensing by electromagnetic radiationComputer hardwareDot matrix

The invention provides an image reading method used for dynamically configuring a decoding parameter and a device. The method and the device are applied to an electronic device. The electronic device comprises a camera and a display. When the target electronic device is used to decode a current dot-matrix two-dimensional code, a preset decoding parameter which matches the target electronic device is acquired to configure the target electronic device. The decoding parameter is suitable for the target electronic device. When the configured target electronic device decodes the current dot-matrix two-dimensional code, the code point of the dot-matrix two-dimensional code in an acquired preview image is appropriate. The success rate of the target electronic device for current dot-matrix two-dimensional code decoding is ensured.

Owner:BEIJING VISION BRILLIANCE TECH CO LTD

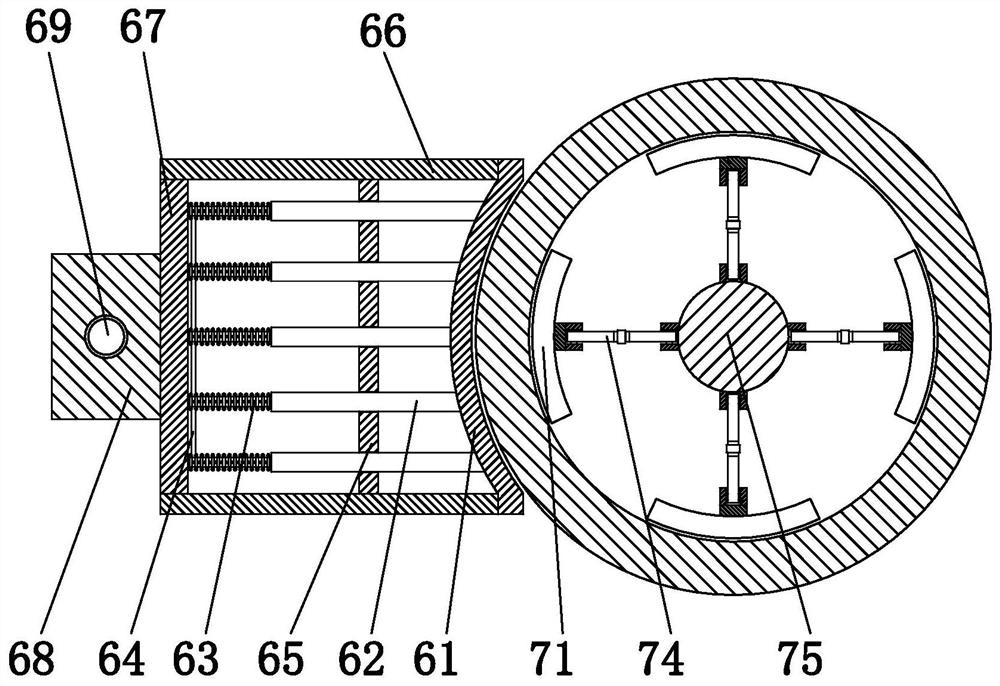

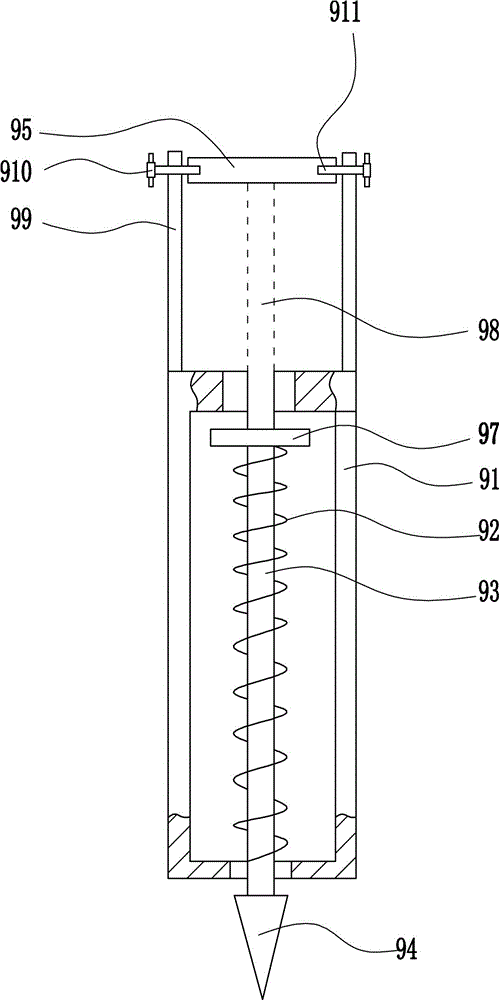

Screw drill motor stator manufacturing and forming machining machine and machining method

ActiveCN113386026AIncrease flexibilityGuaranteed validityBelt grinding machinesManufacturing stator/rotor bodiesEngineeringMachine

The invention relates to a screw drill motor stator manufacturing and forming machining machine and machining method. The screw drill motor stator manufacturing and forming machining machine comprises a bottom plate, a placing device, a driving device and a grinding device, wherein the placing device and the driving device are sequentially installed at the upper end of the bottom plate from left to right, and the portion, close to the left end, of the outer surface of the driving device is rotatably connected with the grinding device through a bearing. By means of the screw drill motor stator manufacturing and forming machining machine and machining method, the problems that when an existing machine conducts surface grinding on the inner walls of screw drill motor stators, inner wall grinding can only be conducted on the stators of the same specification generally, corresponding adjustment cannot be conducted within a certain range according to the diameters of the inner walls of the stators, thus the inner walls of the stators of different sizes cannot be ground, the mechanical use flexibility is reduced, corresponding adjustment cannot be conducted according to the radians of arc-shaped protrusions on the inner walls of the stators, thus grinding effects are reduced, moreover, a grinding mechanism cannot be replaced, thus the grinding effects of the grinding machine after long-term use are reduced, and the like can be solved.

Owner:YANCHENG XINYONGJIA PETROLEUM MACHINERY MFG

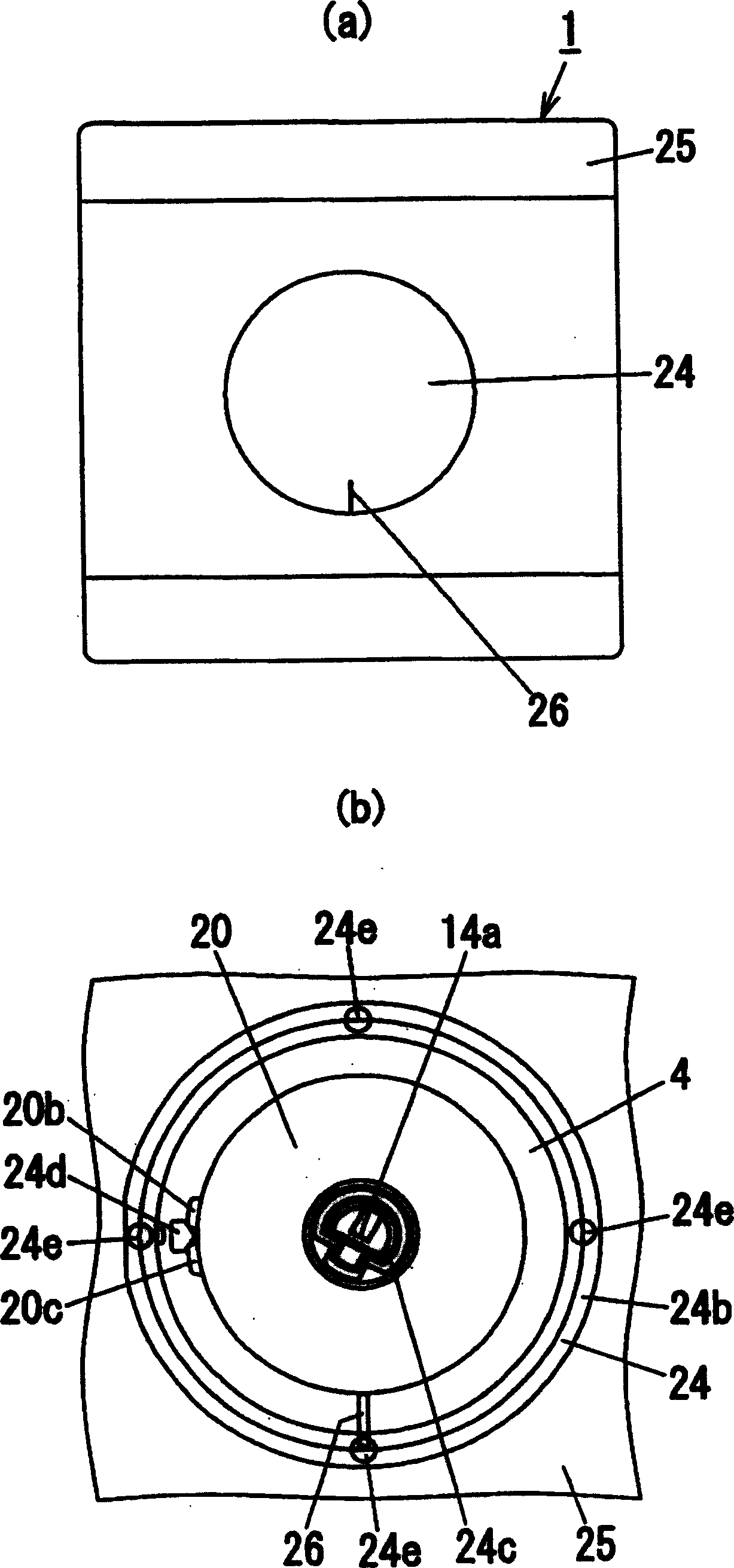

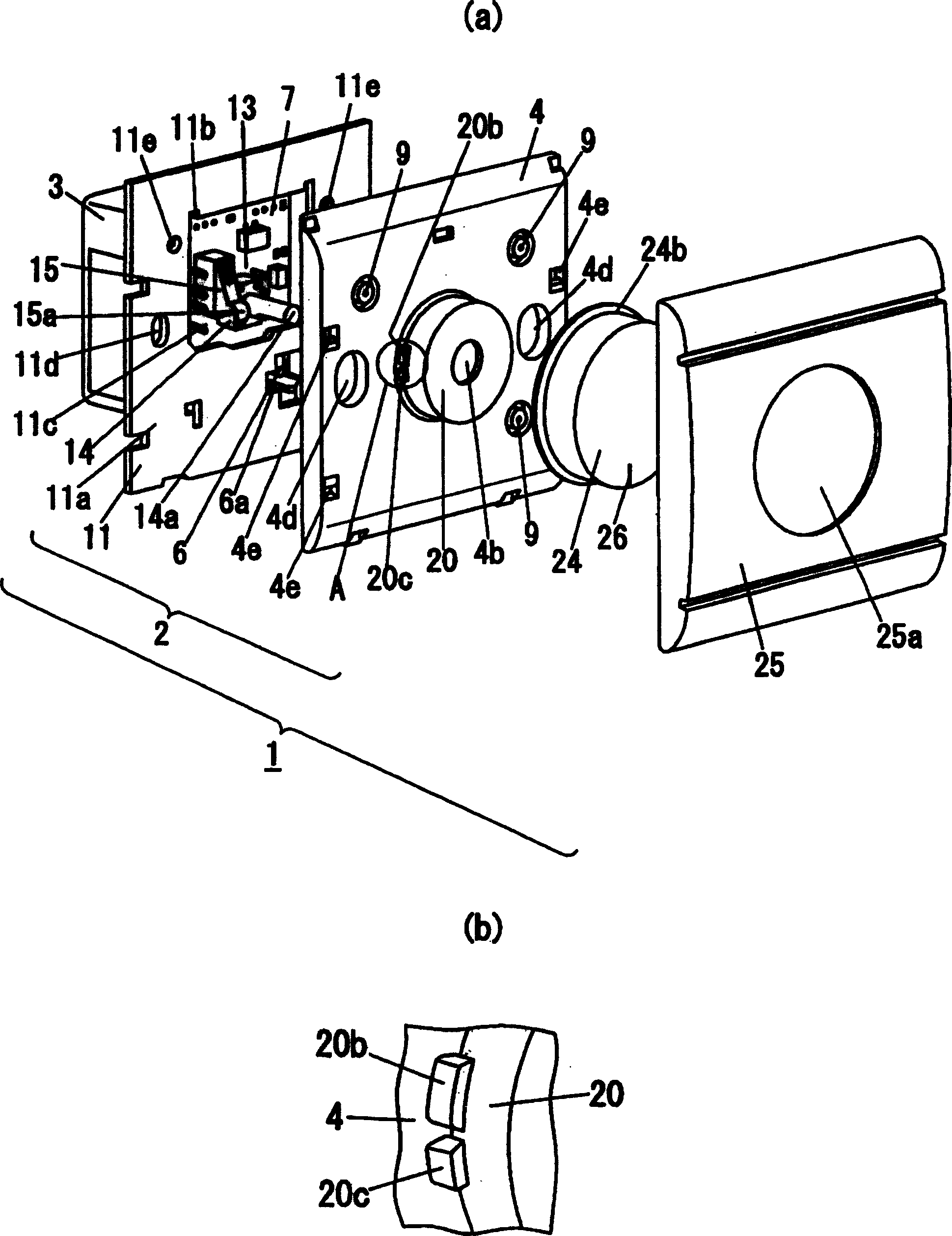

Light modulator

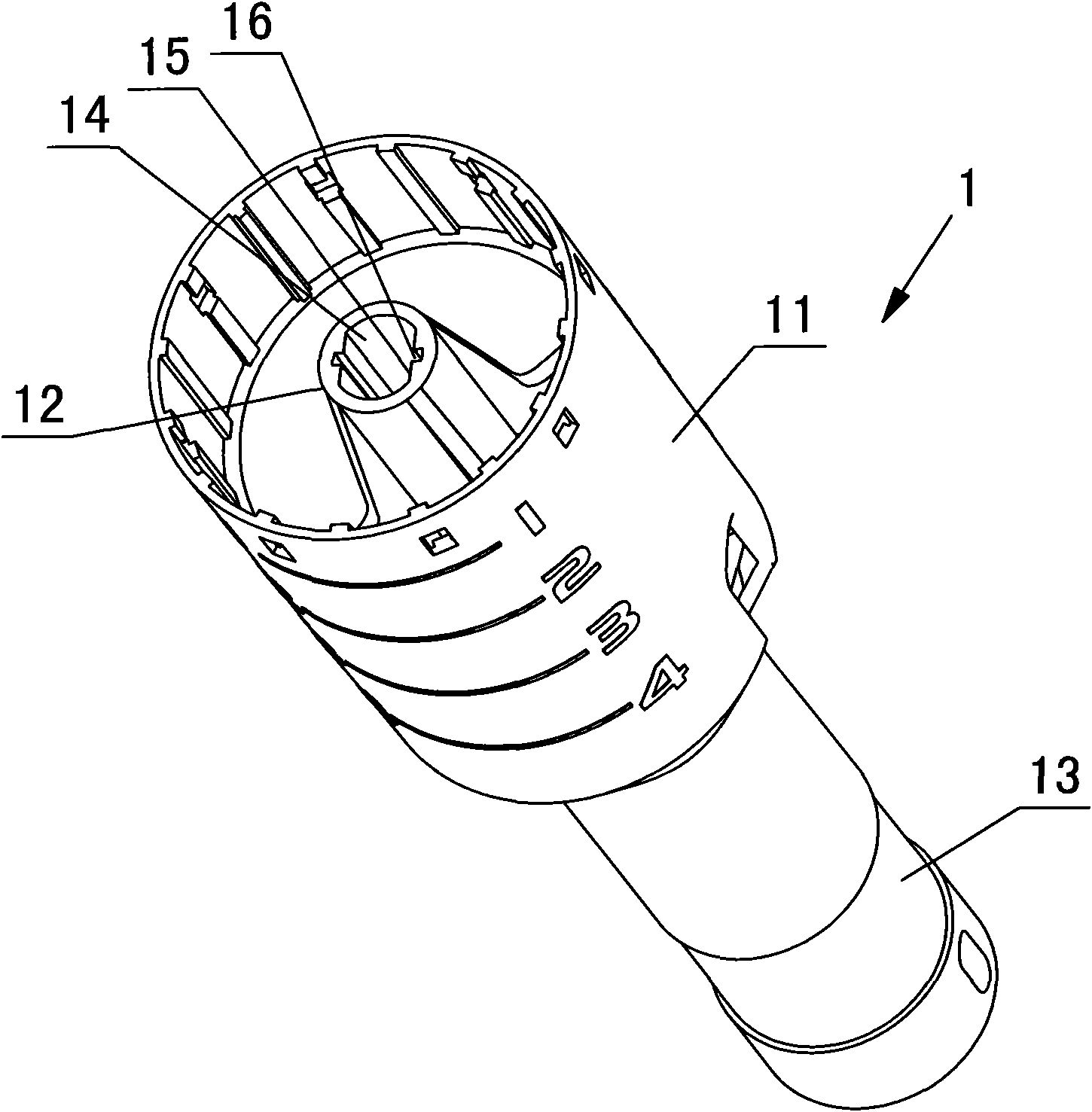

ActiveCN1713793AIncrease temperatureMake sure it fitsElectric light circuit arrangementEnergy efficient lightingFree rotationEngineering

PROBLEM TO BE SOLVED: To provide a light control device which secures a click feeling without increasing the number of components and has an improved electrostatic resistance, and can prevent temperature rise of the operating knob. SOLUTION: The light control device 1 comprises a rotation type variable resistor 14 which has an operating shaft 14a and is used for control setting of the illumination; a device body 2, having a protruded part 20 through which, the operating shaft 14a is rotation freely inserted, making an insertion hole 4b having an inner peripheral face drawn near to the operating shaft 14a and the peripheral part of the insertion hole 4b protrude toward surface side, having a housing part 20a on its rear side, housing the variable resistor 14; the operating knob 24 mounted on the top end side of the operating shaft 14a, arranged in free rotation on the surface side of the device body 2 by housing the protruded part 20 at the recessed part 24a formed on the rear side; and a projection for click 24d having a projection protrusively arranged on the outer circumference of the protruded part 20, protrusively arranged at the inside face of the recessed part 24a of the operating knob 24 so as to be able to climb over the above projection. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:MATSUSHITA ELECTRIC WORKS LTD

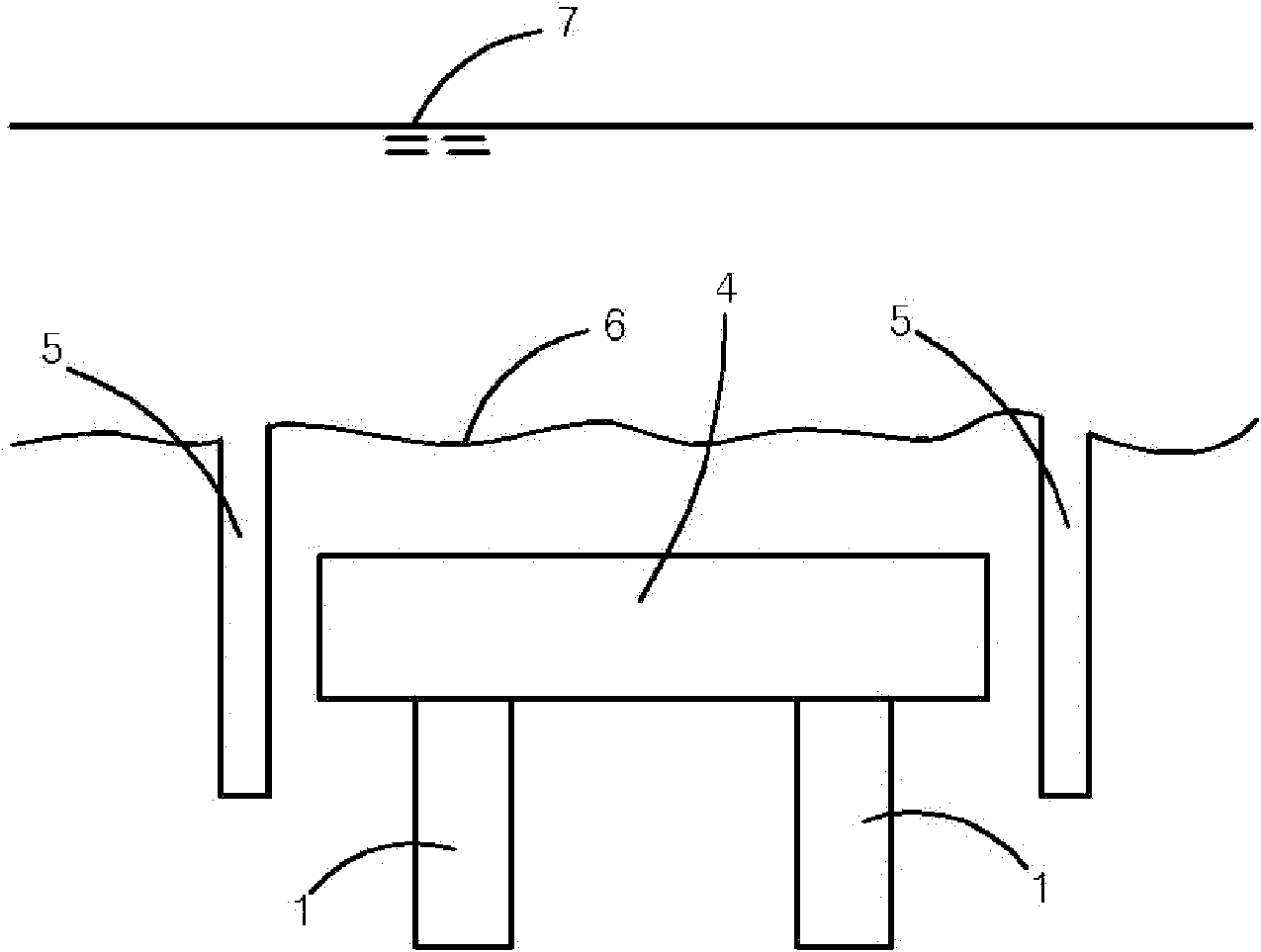

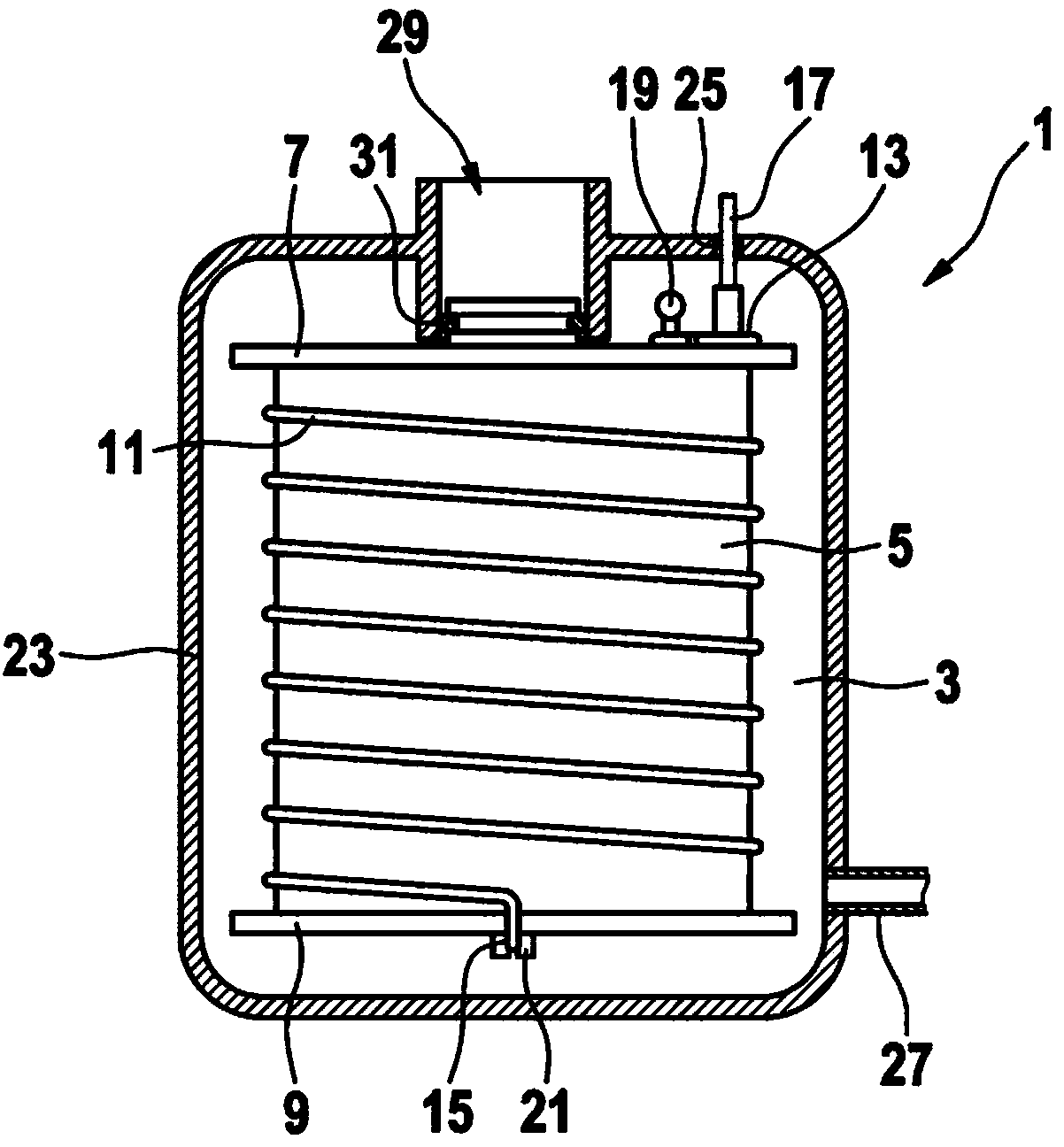

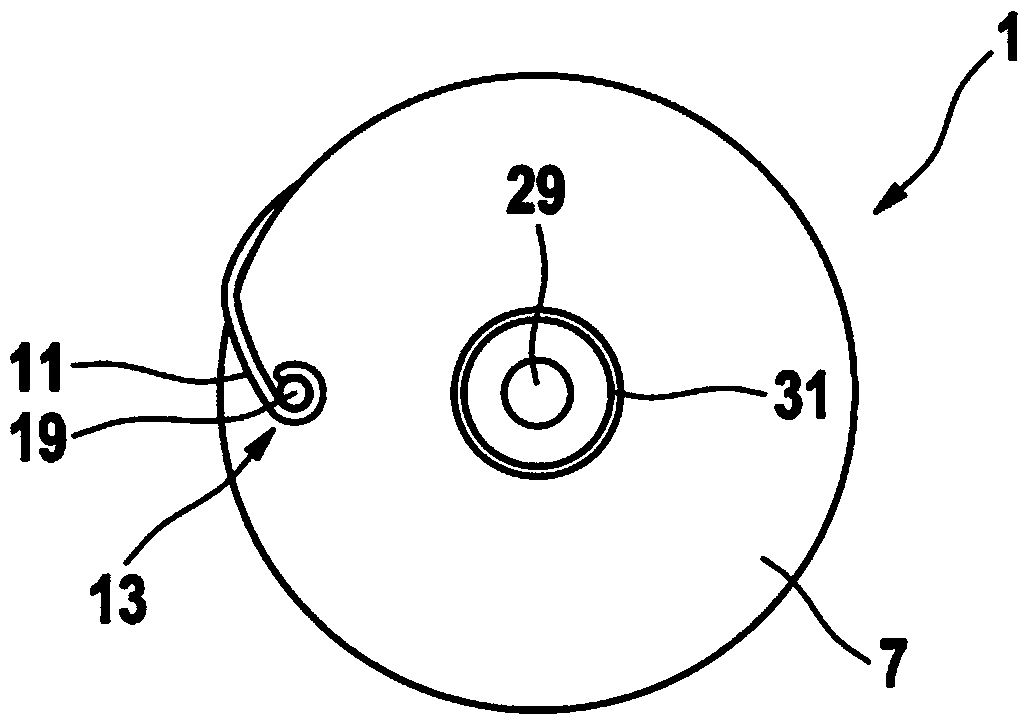

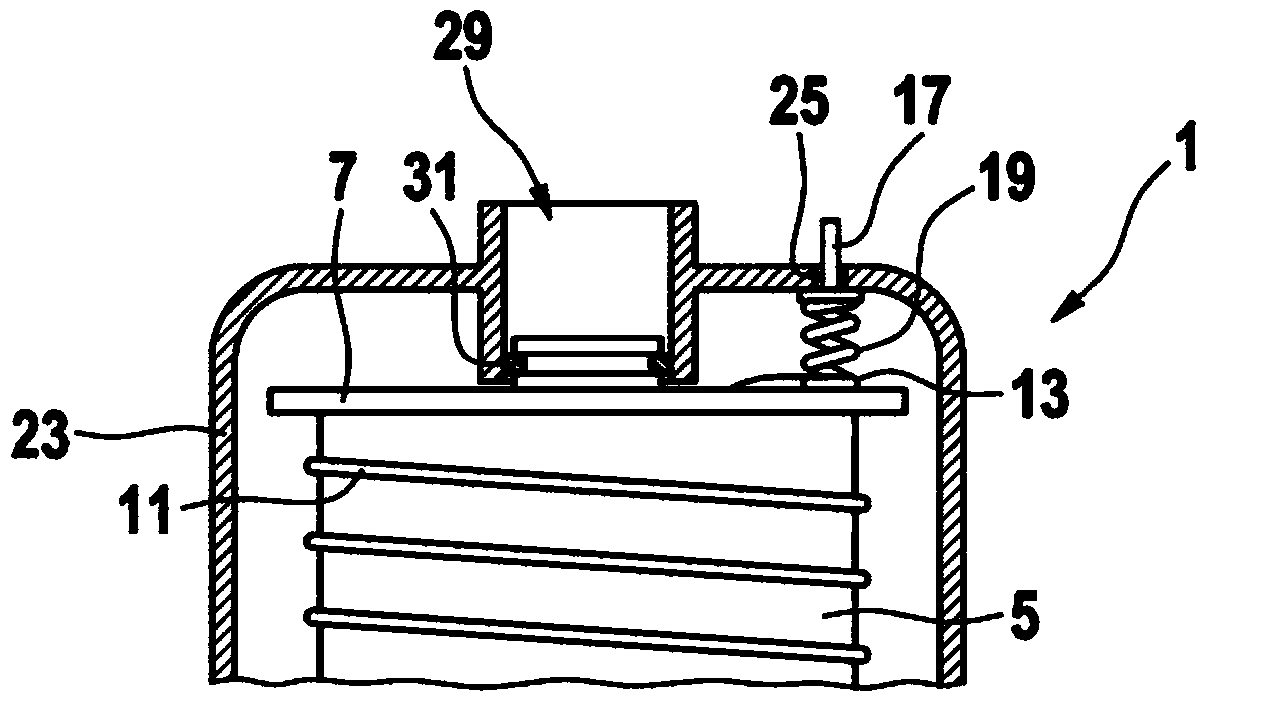

Grounding of a filter by means of an electrically conductive conductor trace on the filter element

InactiveCN103764248AStretch size smallNo electrostatic discharge occursMembrane filtersFiltration separationElectrical conductorEngineering

The invention relates to a filter (1) for filtering a liquid (3). The filter (1) comprises a filter element (5) that is designed to clean the liquid (3) of undesired particles. The filter element (5) is arranged between a first end cap (7) and a second end cap (9). The filter element (5), the first end cap (7) and the second end cap (9) are designed to be electrically nonconductive. An electrically conductive conductor trace (11) is arranged on the filter element (5) in order to dissipate electric charge.

Owner:ROBERT BOSCH GMBH

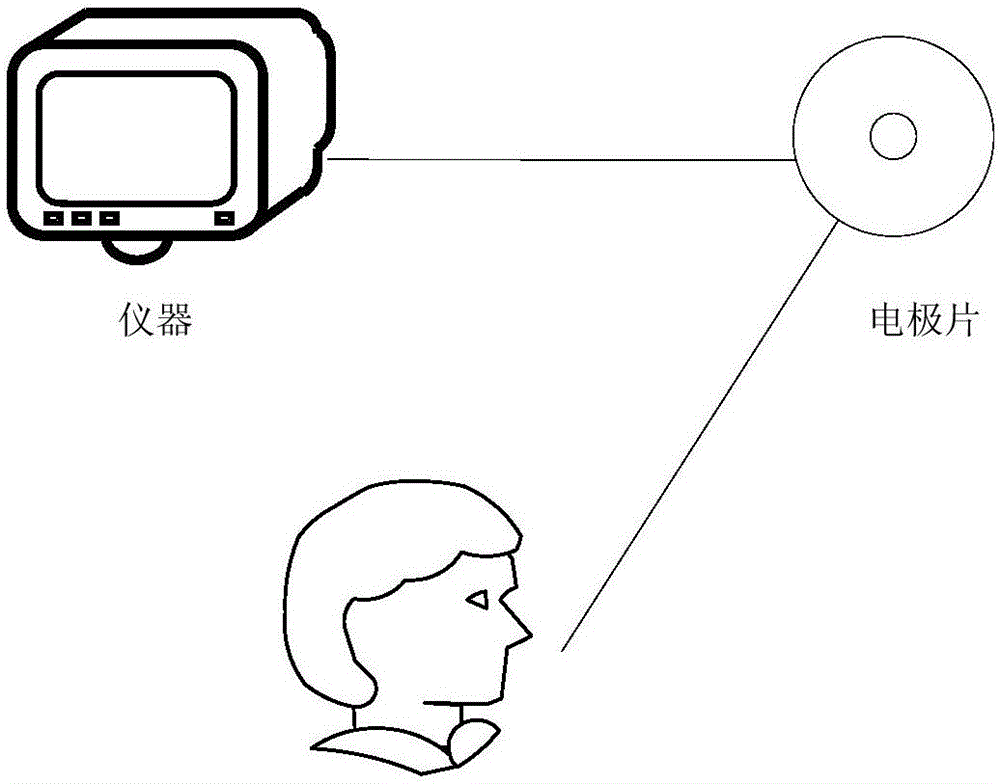

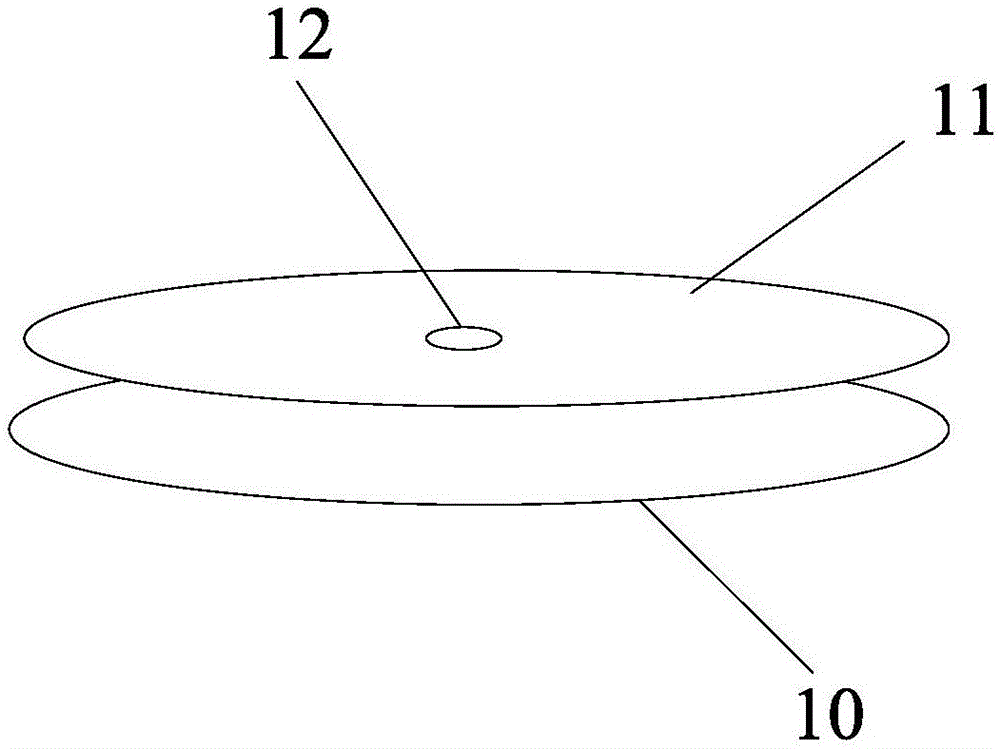

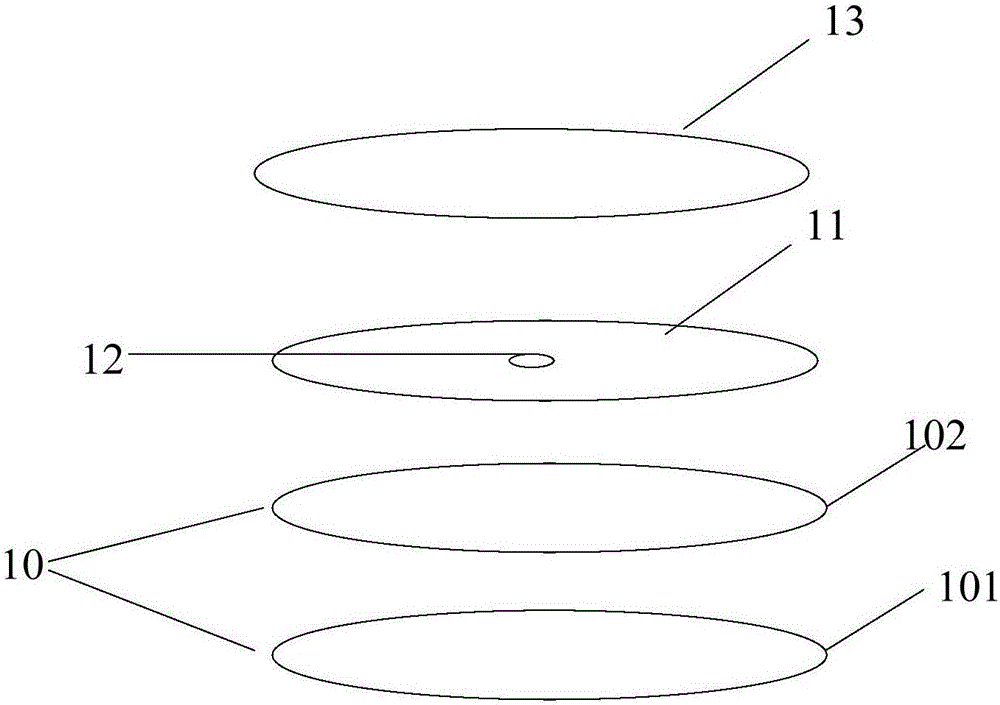

Electrode plate

ActiveCN106450863AImprove securityImprove effectivenessCoupling contact membersMedicine/surgery connectorsPower flowBiochemical engineering

The invention provides an electrode plate. The electrode plate comprises a flexible insulating layer and a conducting layer, wherein the conducting layer is a structural layer formed by paving fused metal on the upper surface of the flexible insulating layer; and an interface connected with an instrument is arranged on the conducting layer. The electrode plate can guarantee uniform paving of the conducting layer, and after current passes through the uniformly paved conducting layer, the current flowing to a human body is relatively uniform, so that the possibility that skin is burnt is reduced, and the safety and effectiveness of making a diagnosis and giving treatment by using the electrode plate are greatly improved; and moreover, through the design of the flexible insulating layer, the electrode plate is unlikely to fall off when the electrode plate is attached to a joint part, so that the electrode plate is tightly attached to human skin, and the reliability of the electrode plate is improved.

Owner:EASYMED INSTR CO LTD

Sliding vane type three-way electromagnetic valve

PendingCN109323012AReliable fluid sealMake sure it fitsOperating means/releasing devices for valvesMultiple way valvesEngineeringElectromagnetic valve

The invention discloses a sliding vane type three-way electromagnetic valve. The sliding vane type three-way electromagnetic valve comprises a valve body, a sealing base, a valve element assembly andan electromagnetic driving assembly, wherein the valve body is provided with a valve cavity, an inlet, a first outlet and a second outlet; the sealing base is provided with a first valve port communicating with the first outlet and a second valve port communicating with the second outlet, the valve element assembly comprises a valve element, the valve element comprises a first slide piece and an elastic sealing element, and the face, facing the first sliding piece, of the elastic sealing element is provided with a first protruding part and a second protruding part; the first sliding piece is provided with a first protruding part penetrating hole and a second protruding part penetrating hole, and each protruding part penetrates through the corresponding protruding part penetrating hole correspondingly, and abuts against the sealing base; when the valve element assembly is in a first position, the second protruding part is used for blocking a second valve port, and the inlet communicateswith the first outlet through the first valve port; when the valve element assembly is in a second position, the first protruding part is used for blocking the first valve port, the inlet communicates with the second outlet through the second valve port. According to the valve, the closed outlet can be ensured to obtain a reliable fluid seal.

Owner:嘉兴科奥电磁技术有限公司

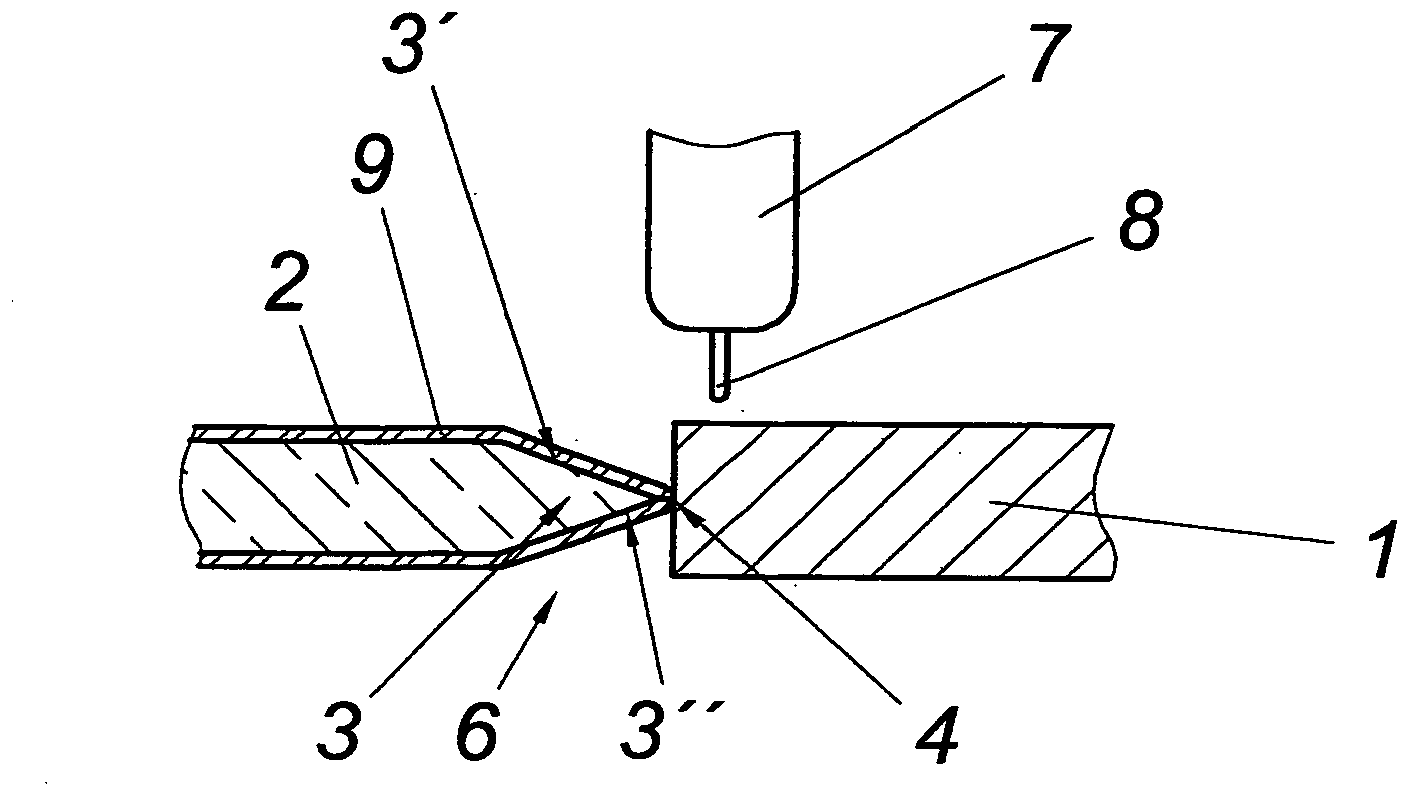

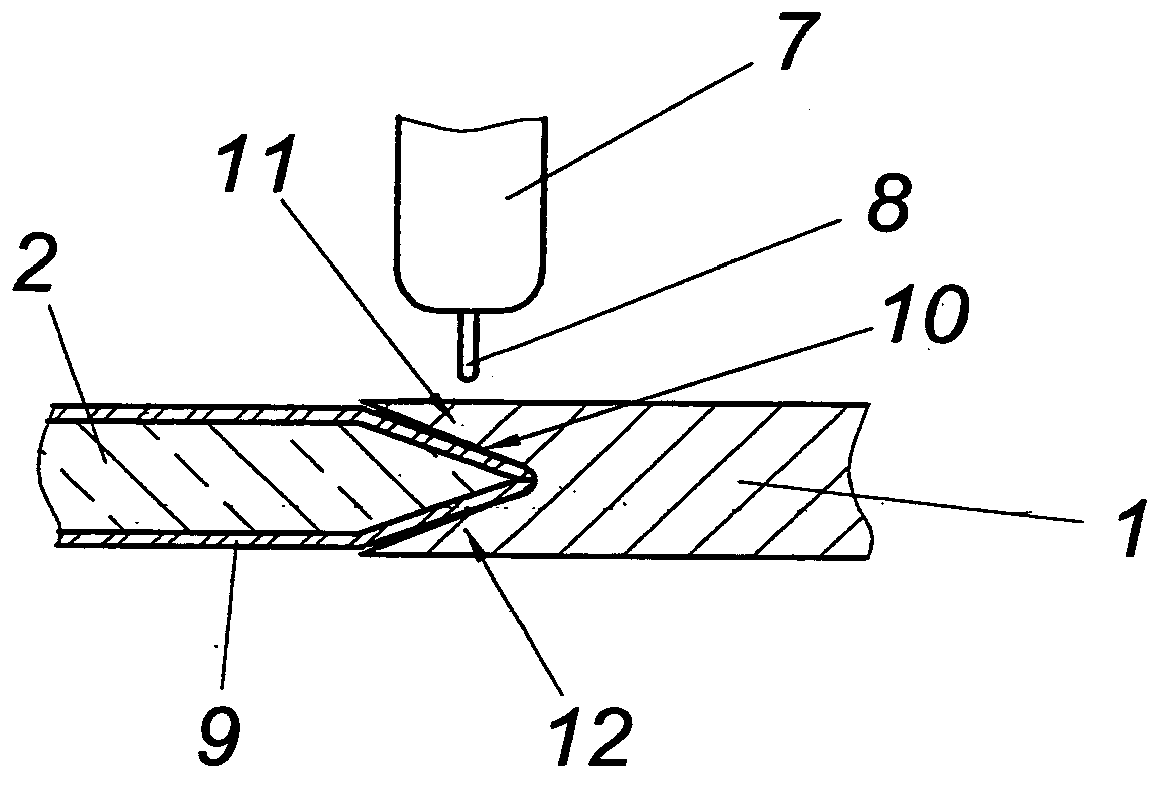

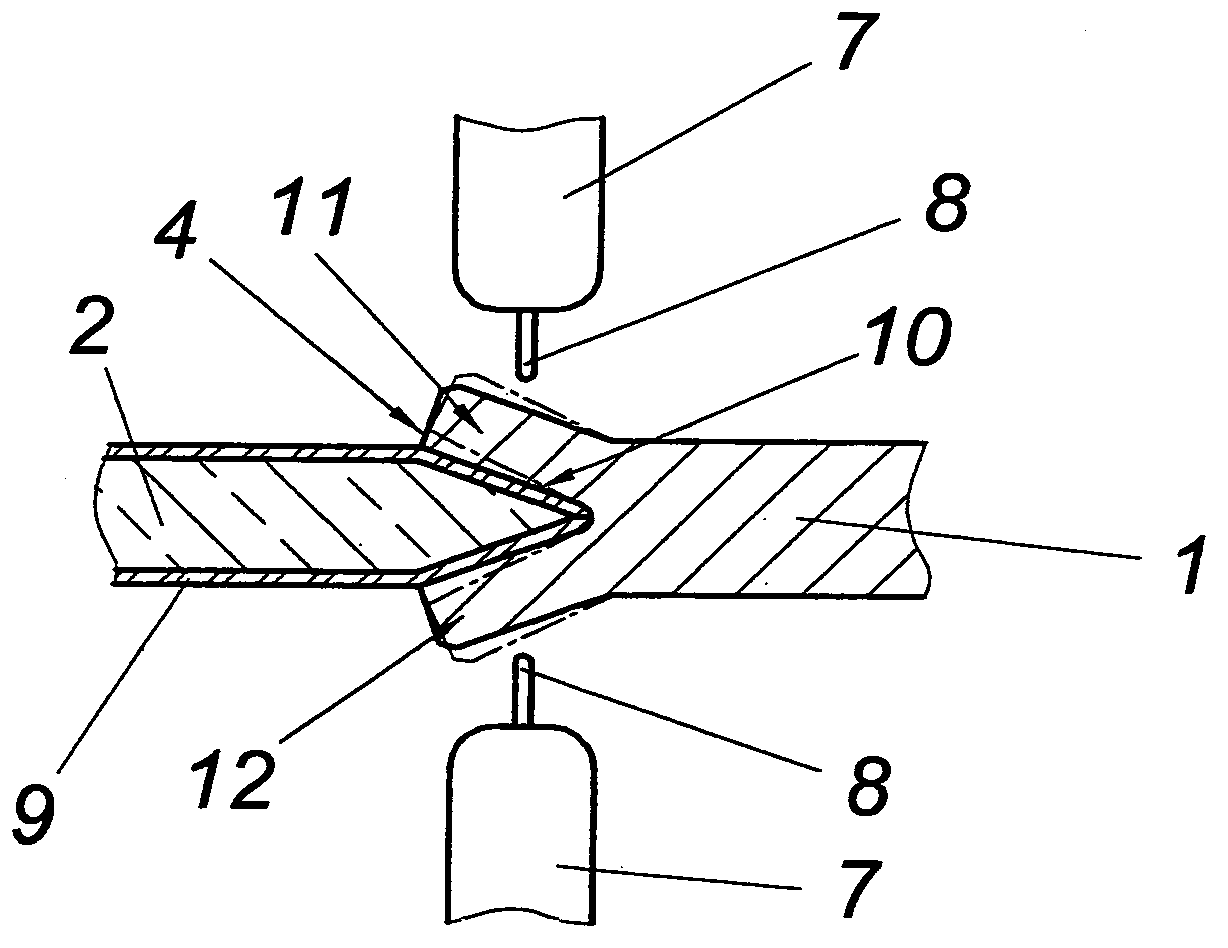

Apparatus and process for cohesive joining

InactiveCN102844140APrecise positioningImproves the strength of brazed connectionsSoldering apparatusArc welding apparatusTitaniumProcess conditions

The invention relates to an apparatus and to a process for cohesively joining two plates (1 and 2) having differing melting points, one of which plates, the end plate (1), comprises a light metal material, in particular aluminium material, and the other of which plates, the connecting plate (2), comprises an iron and / or titanium material, wherein a coating (9) preferably on the basis of zinc or aluminium is provided at least partially on at least one of the abutting faces (3', 3'') of the abutting edge (3) of the connecting plate (2) which extend inclined with respect to one another, in which process both plates (1 and 2) are joined together by braze welding so as to abut against one another along their common joint using an additional material (5) on the basis of light metal, in particular on the basis of aluminium. In order to provide advantageous process conditions, the invention proposes that a recess (10) be made, before joining, in the abutting edge (4) of the end plate (1) for receiving at least part of the coated abutting edge (3) of the connecting plate (2), wherein, during joining, braze welding is carried out at least partially over a flank (11 or 12) of the recess (10) overlapping the coating (9) of the connecting plate part.

Owner:VOESTALPINE STAHL GMBH

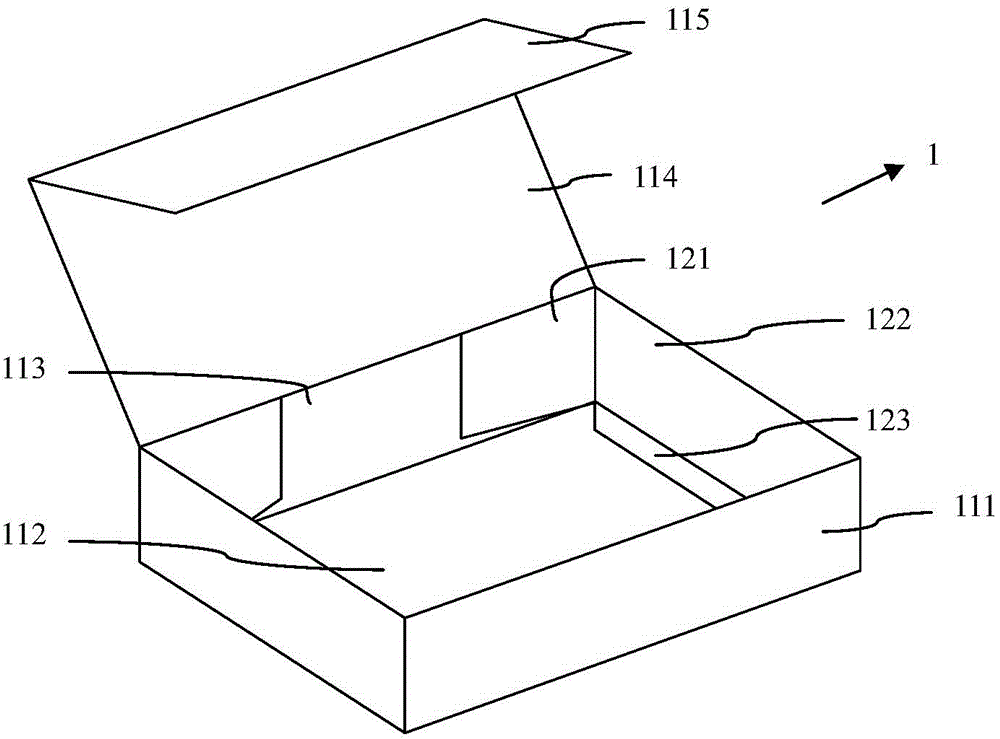

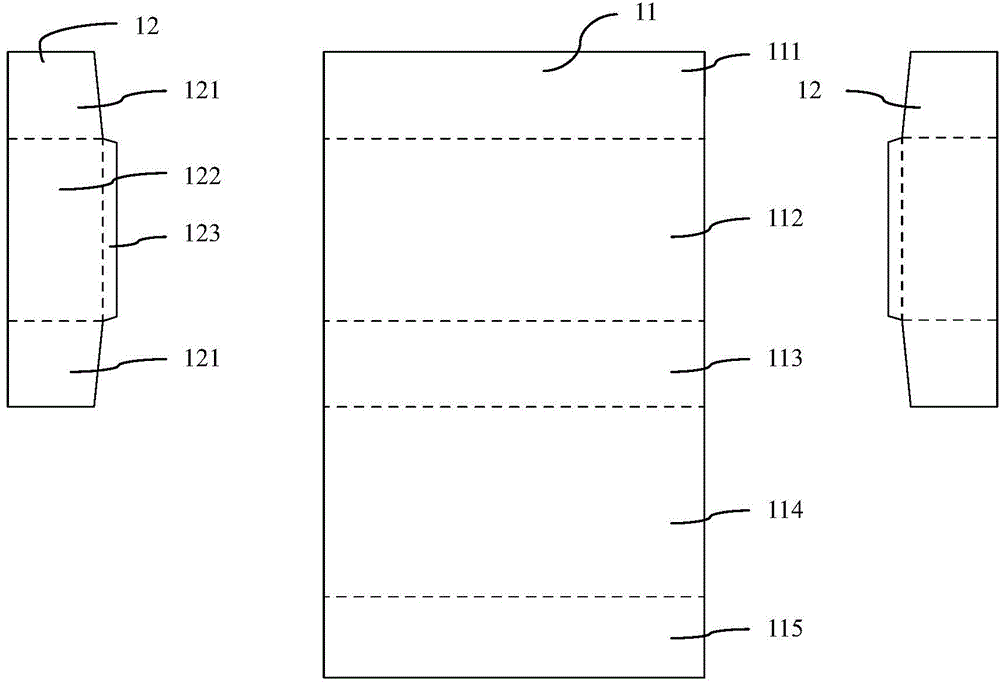

Automatic packing box forming machine and forming method thereof

ActiveCN104385681AMake sure it fitsHigh degree of automationBoxes/cartons making machineryAutomationPackaging Case

The invention relates to an automatic packing box forming machine and a forming method of the automatic packing box forming machine. The automatic packing box forming machine comprises a die assembly, a die lifting device and a die turning device. The die assemble comprises a movable die, a fixed die and auxiliary turning dies, wherein the movable die is arranged on the die lifting platform, the fixed die and the movable die are oppositely arranged, the auxiliary turning dies are arranged on the two sides of the fixed die respectively, and the auxiliary turning dies are connected with the die turning device. The die lifting device drives the movable die to press the end face, opposite to the movable die, of the fixed die. The die turning device makes the lateral sides, adjacent and parallel to the fixed die, of the auxiliary turning dies turn to press the side face of the movable die. The automatic packing box forming machine and the forming method can be used for manufacturing square packing boxes of different shapes and sizes, the automation degree of the production process can be improved, the production efficiency and the finished product rate can be increased, and the production cost can be reduced.

Owner:蚌埠诗天新型包装有限公司

Two-time cutting process for front piece of western-style clothes

InactiveCN108323850AEasy to shrinkAvoid attenuationClothes making applicancesEngineeringMechanical engineering

The invention relates to the technical field of western-style clothes making, and in particular to a two-time cutting process for a front piece of western-style clothes. The process comprises the following steps: (1) making a front piece fabric rough cutting sample; (2) making a lining rough cutting sample; (3) making a front piece fabric rough cutting sheet; (4) making a lining rough cutting sheet; (5) with the back side of the front piece fabric cutting sheet facing upwards and the side that an adhesive side is lined facing downwards, emptying empty lining of a front fly, a lapel, shoulder seams, muffs, side seams, a hem and a first dart in accordance with preset empty lining cutting openings and fish dart point eyes; (6) implementing natural flattening, and conducting binding via a binding machine; (7) after implementing binding, implementing natural flattening and promoting rebound; and (8) conducting secondary fine cutting via a fine cutting sample, so that a net front piece fabric sheet and a net lining sheet are obtained. With the application of the two-time cutting process provided by the invention, phenomenons that original cutting sheets can become shorter and become smaller easily, fish dart deformation can be caused, clothing sheets are not bilaterally symmetrical and the cutting sheets are not completely united with samples can be solved; the cutting sheets are united with the samples, so that the size of finished clothes can be guaranteed; and meanwhile, problems of the finished clothes that pockets are not flat and are not bilaterally symmetrical can be alsosolved; and uniform size can be guaranteed in various batches of the finished clothes.

Owner:LAMPO

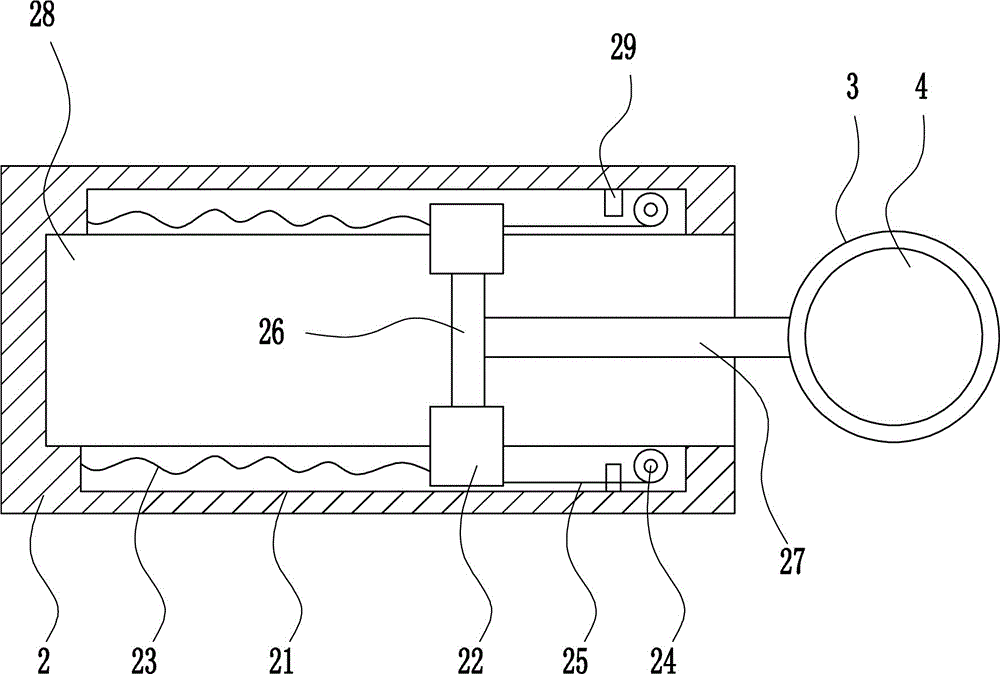

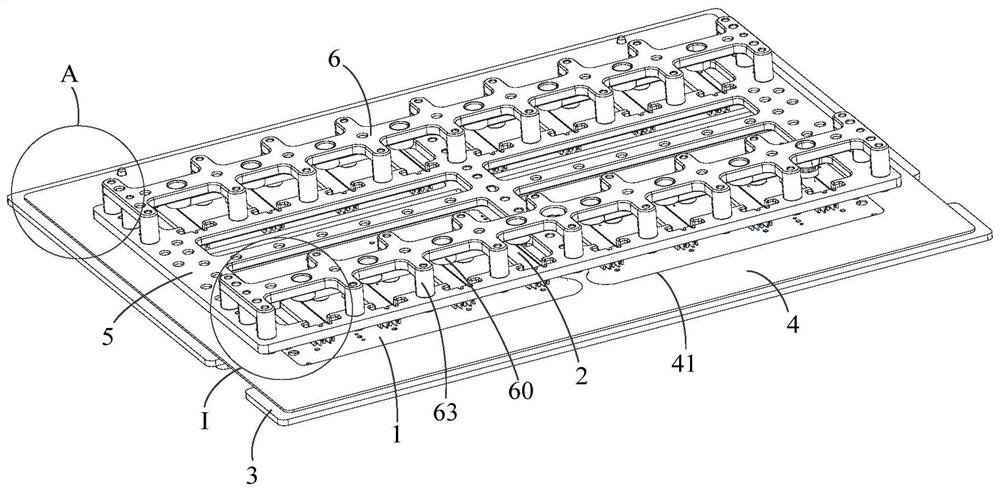

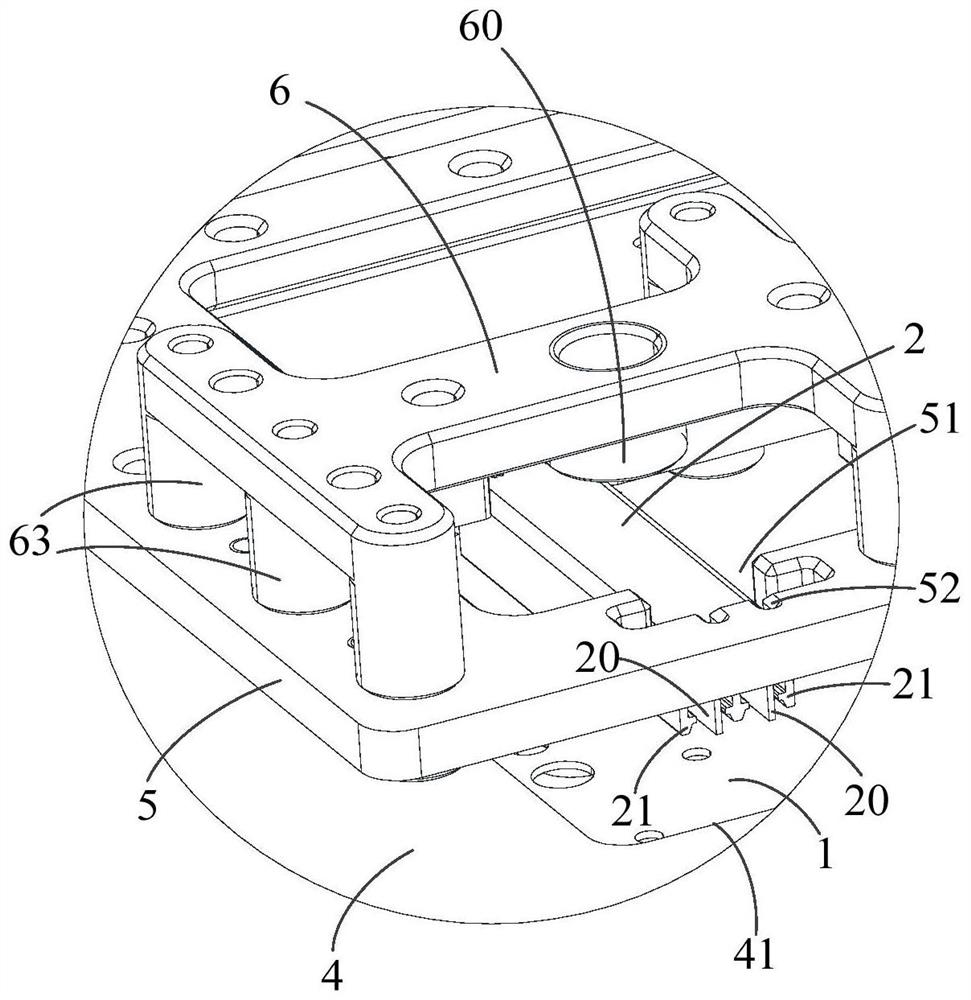

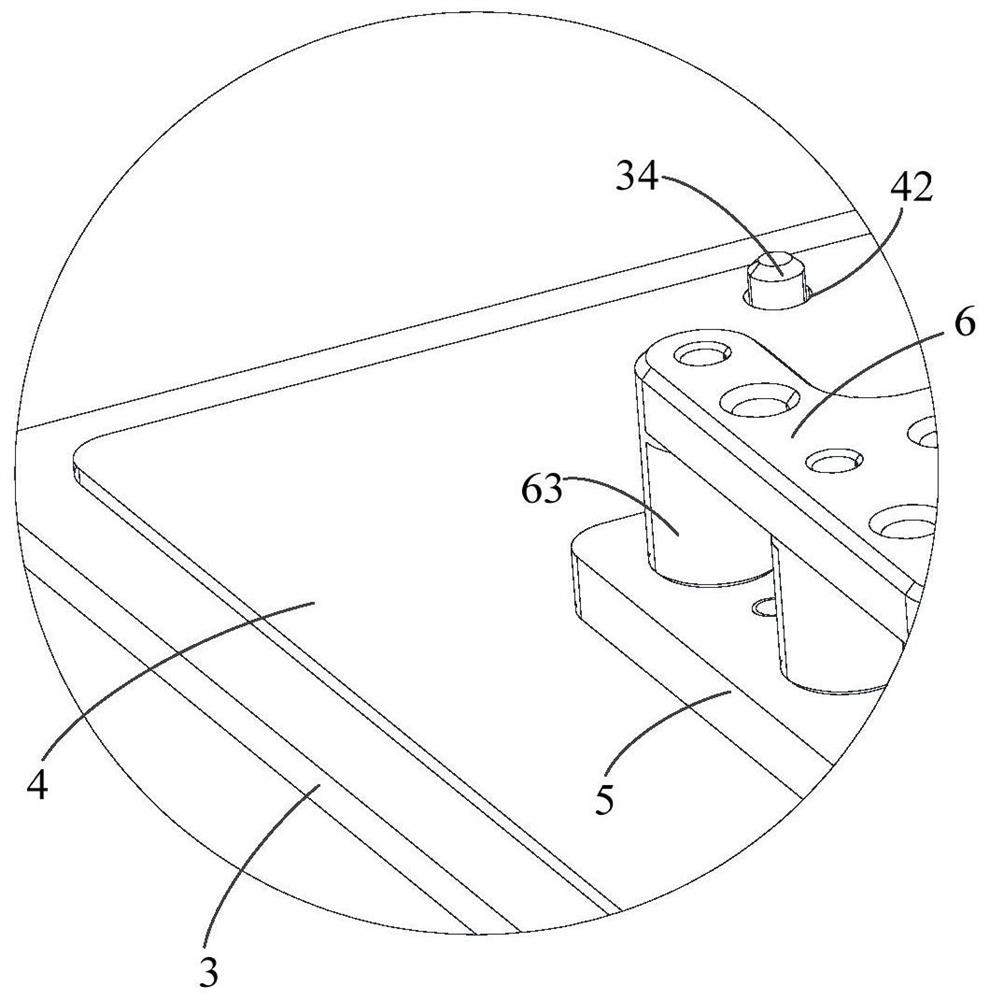

Positioning device for phase shifter welding and method for positioning phase shifter by using positioning device

PendingCN112157387ANo lateral offsetPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringControl theory

The invention relates to a positioning device for phase shifter welding and a method for positioning a phase shifter by using the positioning device. The positioning device comprises a power dividingplate positioning bottom plate and a phase shifter limiting plate which are oppositely arranged. A limiting hole used for limiting the phase shifter is formed in the phase shifter limiting plate; thephase shifter is located in the limiting hole; the surface, facing the phase shifter limiting plate, of the power dividing plate positioning bottom plate forms a bearing surface used for bearing a power dividing plate; and a first positioning column used for being connected with a first positioning hole in the power dividing plate in a matched mode is arranged on the power dividing plate positioning bottom plate. The positioning device for phase shifter welding further comprises a pressing structure arranged on the phase shifter limiting plate, wherein the pressing structure is used for pressing the phase shifter on the power dividing plate, so that the bottom face of the cavity wall of the phase shifter can be attached to a first bonding pad on the face, facing the phase shifter, of the power dividing plate, a positioning effect on the phase shifter is improved, and gaps generated by contact between the phase shifter and the power dividing plate can be effectively eliminated.

Owner:COMBA RF TECH GUANGZHOU LTD +1

Method and apparatus for producing baked goods

The invention relates to a method and to an apparatus for producing baked goods in a predefined form, wherein a piece of dough is baked in a closed molding chamber (5) in immediate succession after cooking while heat is supplied, wherein the piece of dough fills the mold chamber (5) completely while displacing gas. According to the invention, in order to ensure advantageous baking results, the piece of dough bears against the gastight molding wall delimiting the molding chamber (5), forming a finely structured crust, and the gas from the mold chamber (5) is discharged in the region of depressions (8) which are provided in the molding wall (7), which determine elevations of the baked goods projecting above a surface region, and into which the gas is displaced by the oven rising of the piece of dough.

Owner:迈克尔.霍贝尔 +2

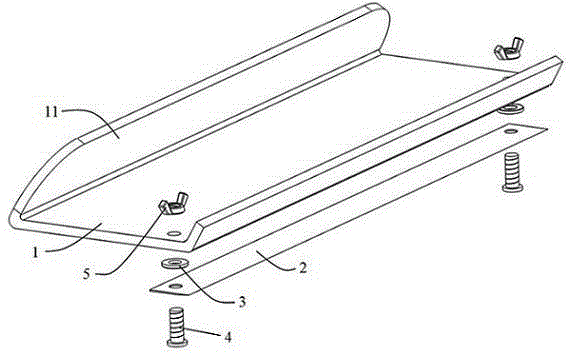

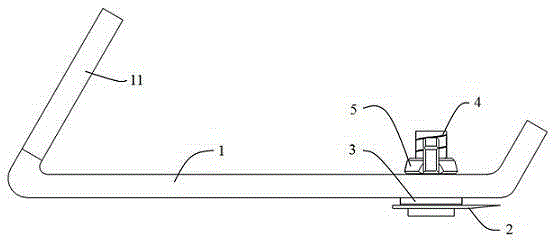

Household raw fish slice cutter

The invention discloses a household raw fish slice cutter and belongs to the field of kitchen serviceable tools. The household raw fish slice cutter comprises a transparent cutter body, a blade, a gasket and a fixing device, wherein one end of the cutter body is bent upwards to form a curved surface; and the gasket is arranged between the cutter body and the blade. The curved surface of the cutter body is tightly close to fish so that a cutting edge can be in sufficient contact with the fish in a cutting process; the state of the fish is observed through the transparent cutter body; and finally, fish slices are cut according to the thickness of the gasket. The household raw fish slice cutter provided by the invention has a simple structure and low cost and is convenient and easy to use; and the large and complete fish slices with the thickness of about 1mm can be sliced, so that the household raw fish slice cutter is very suitable for household application.

Owner:王井舟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com