Positioning device for phase shifter welding and method for positioning phase shifter by using positioning device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Phase shifters are the core components of base station antennas. When in use, the phase shifter and the power splitter board need to be soldered together by reflow soldering. Wherein, the side of the power splitter facing the phase shifter has a first pad, specifically, the bottom surface of the cavity wall of the phase shifter is welded and fixed to the first pad, that is, the phase shifter and the power splitter are welded vertically. Before welding, the phase shifter and power splitter need to be positioned, and then welded. If the positioning effect is poor, there will be a gap between the bottom surface of the cavity wall of the phase shifter and the first pad, resulting in weak solder joints and affecting the soldering quality.

[0057] Based on this, this embodiment provides a positioning device for phase shifter welding, which can ensure that the phase shifter sticks to the power sub-board and ensure the welding quality at the solder joints.

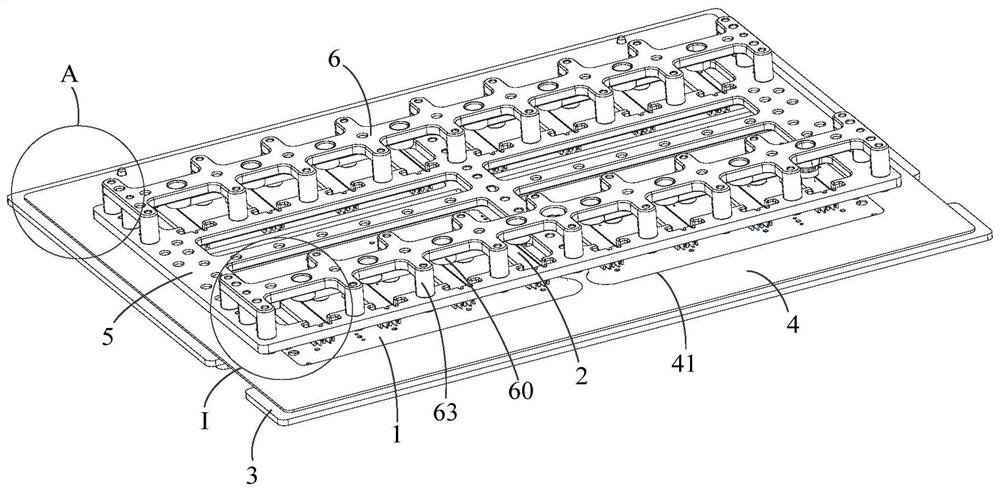

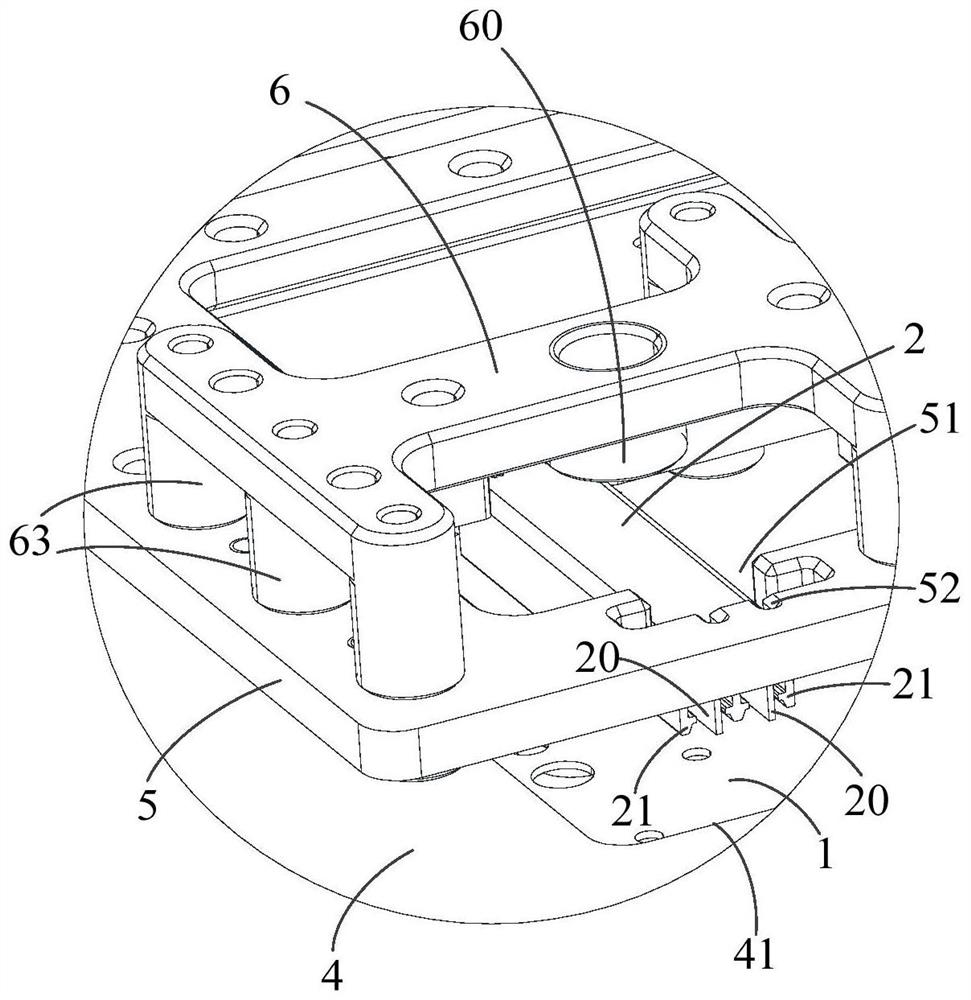

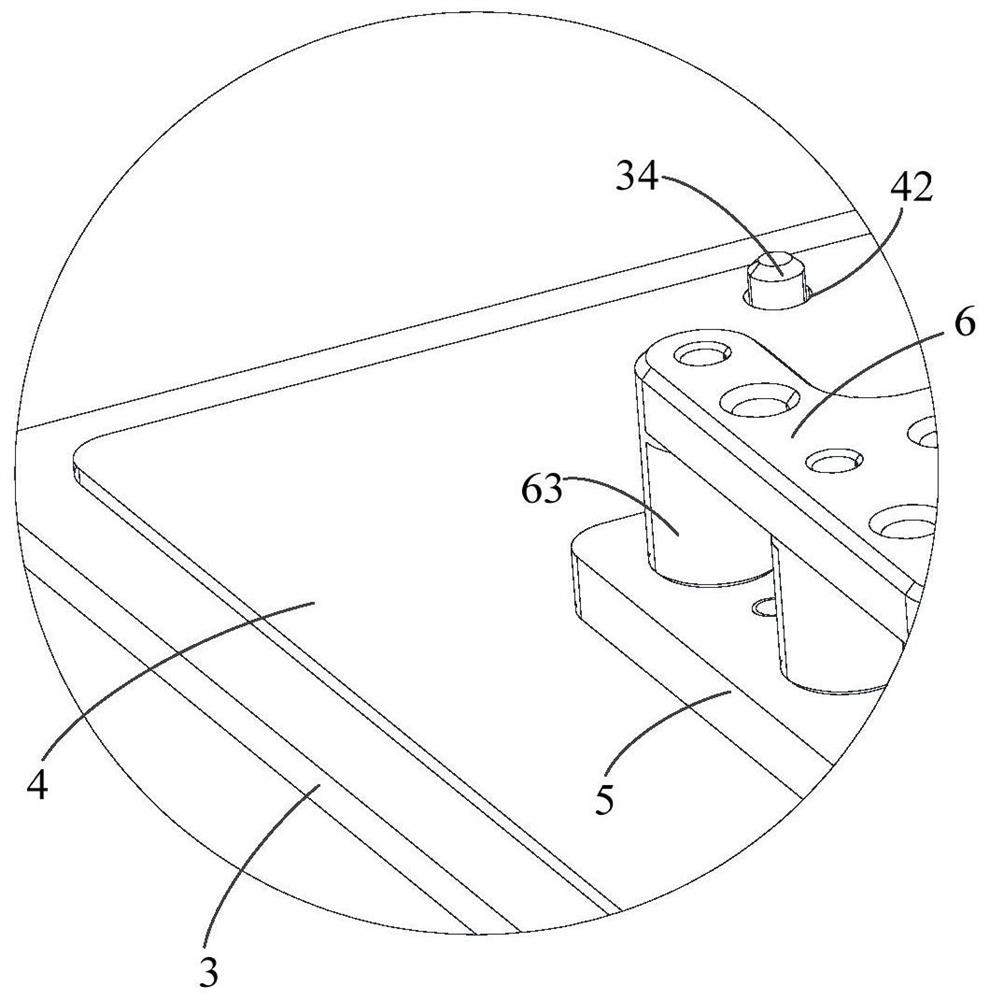

[0058] refer to ...

Embodiment 2

[0099] refer to Figure 16 As shown, the embodiment of the present disclosure also provides a method for positioning the phase shifter by using the positioning device for phase shifter welding, and the method can be executed by part or all of the positioning device for phase shifter welding in the above-mentioned embodiments.

[0100]combine Figure 1 to Figure 16 As shown, the positioning method is described below through specific embodiments, and the method specifically includes:

[0101] S101 , place the power distribution board 1 on the power distribution board positioning base 3 , and make the first positioning column 31 on the power distribution board positioning base 3 penetrate into the first positioning hole 12 of the power distribution board 1 .

[0102] S102 , installing the phase shifter limiting plate 5 on the positioning bottom plate 3 of the power dividing plate.

[0103] Specifically, the second positioning column 53 can be set on the phase shifter limiting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com