Patents

Literature

35results about How to "Solve the problem of poor welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

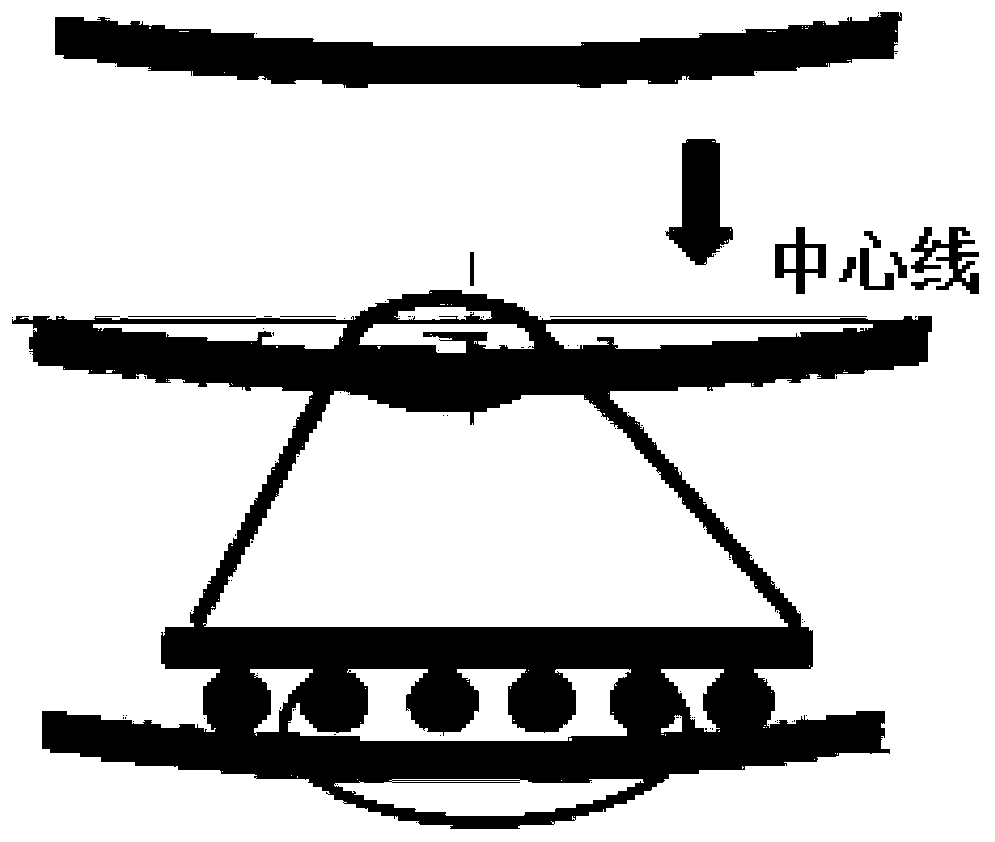

Spot welding method of galvanized steel sheets

InactiveCN105252130ASolve the problem of poor weldingMetal working apparatusResistance welding apparatusSheet steelPower flow

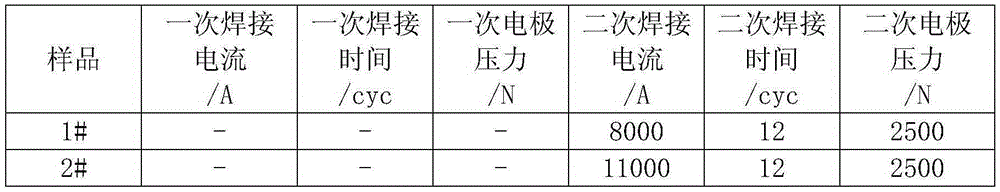

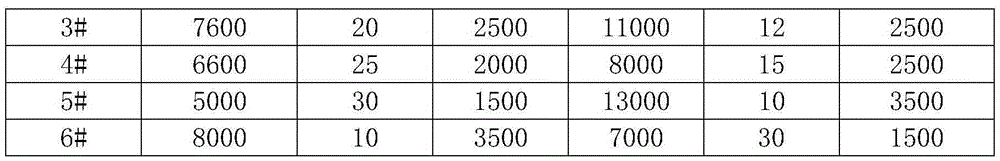

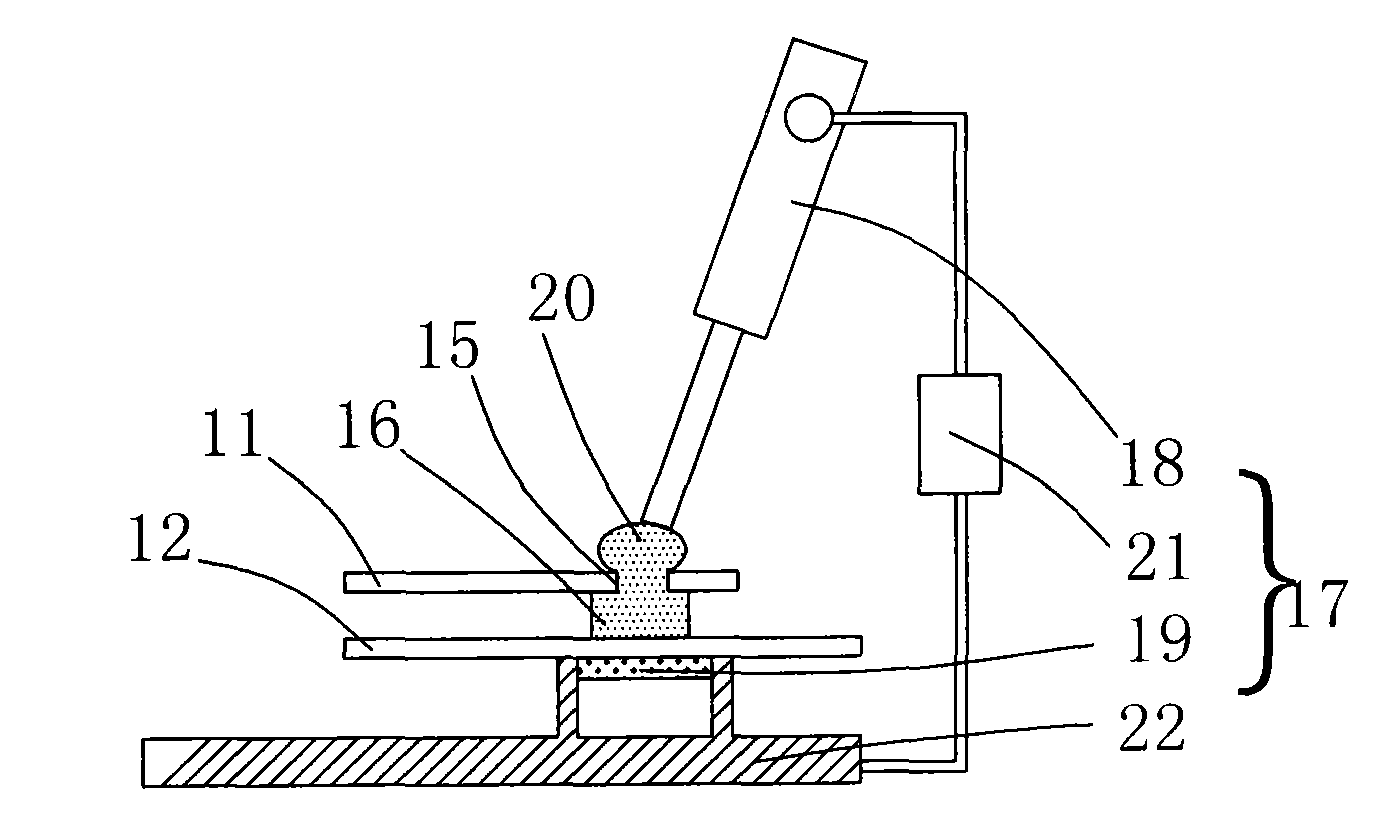

The invention relates to a spot welding method of galvanized steel sheets. The spot welding method comprises the following sequential steps: holding down two galvanized steel sheets needing to be welded by using two electrodes of a spot welding machine, respectively; carrying out first welding current outputting: setting a welding current to the range of 5000-8000A, a discharge duration to the range of 10-30 cycles and an electrode pressure value to the range of 1500-3500N; carrying out second welding current outputting: setting the welding current to the range of 7000-13000A, the discharge duration to the range of 10-30 cycles and the electrode pressure value to the range of 1500-3500N; and separating the two electrodes from the two galvanized steel sheets and finishing spot welding. By means of the spot welding method, after the two galvanized steel sheets are held down by the electrodes of the spot welding machine, the first welding current outputting is carried out to damage an original passivation film, and then the second welding current outputting so that the two steel sheets are fused and welded at a welding point; as a result, the problem of poor welding due to the passivation film is solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

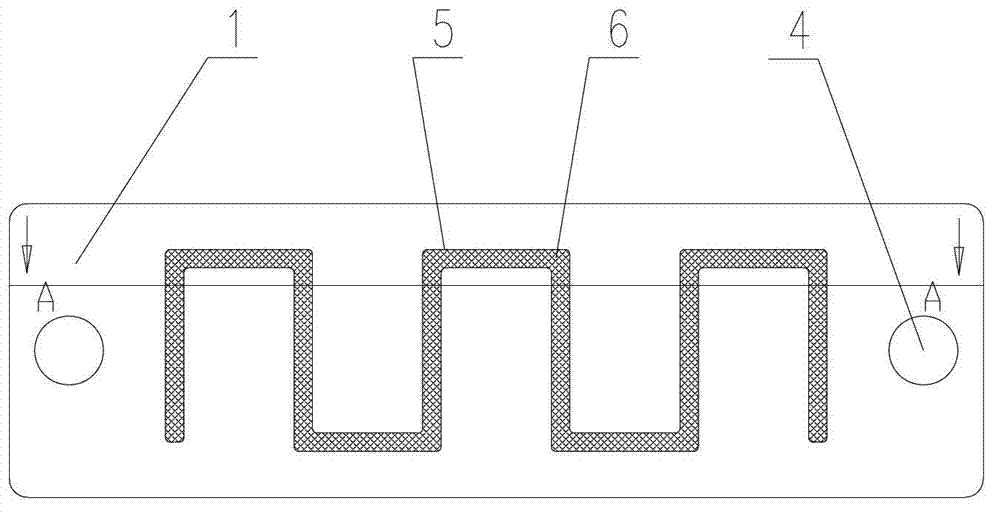

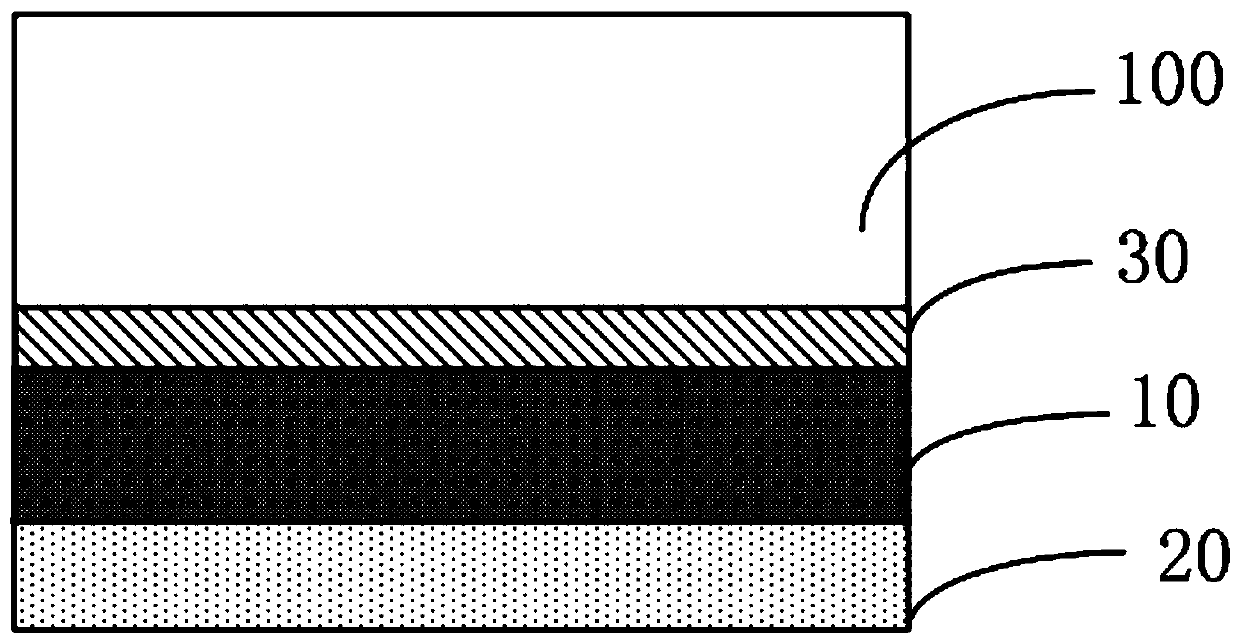

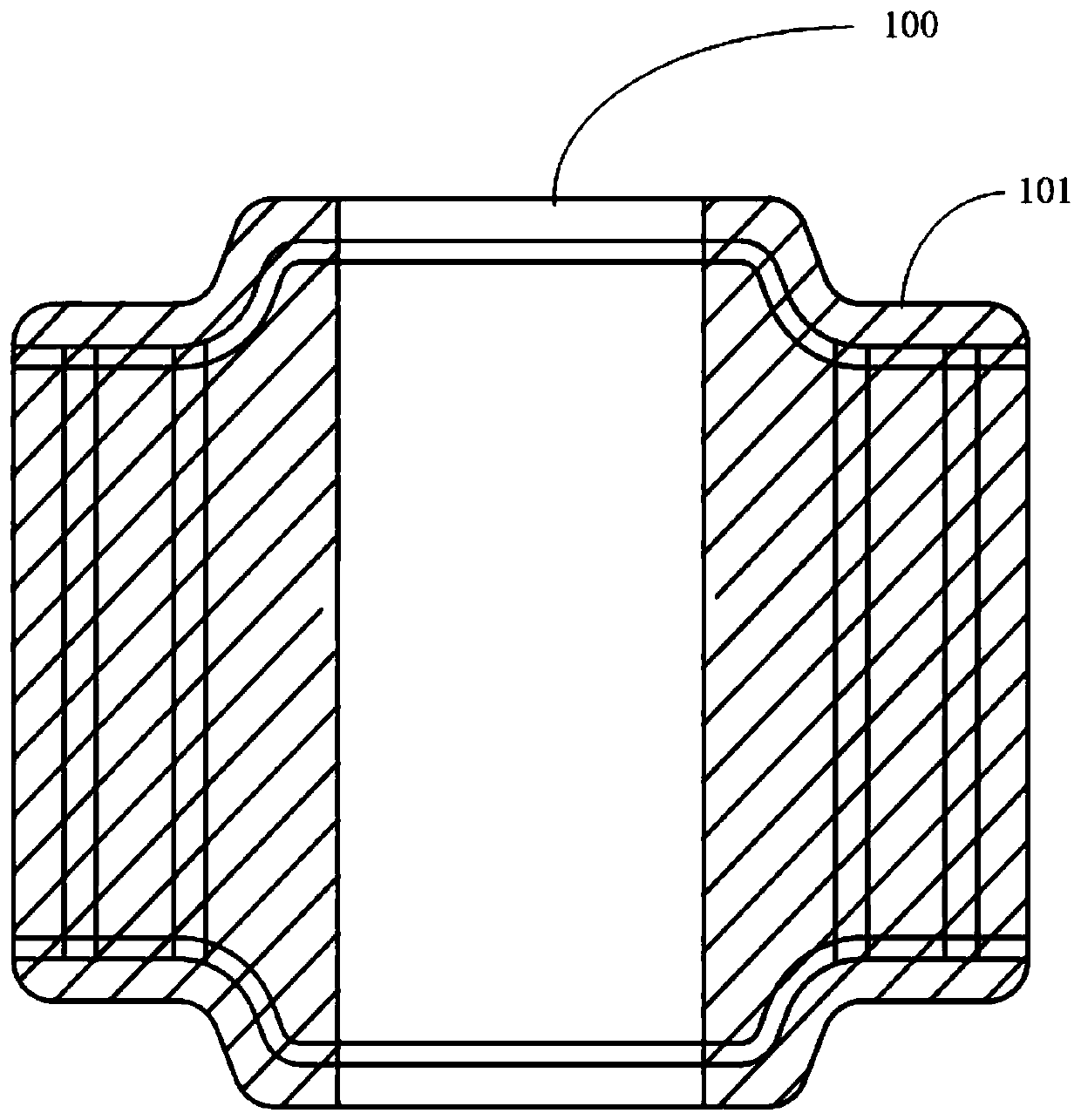

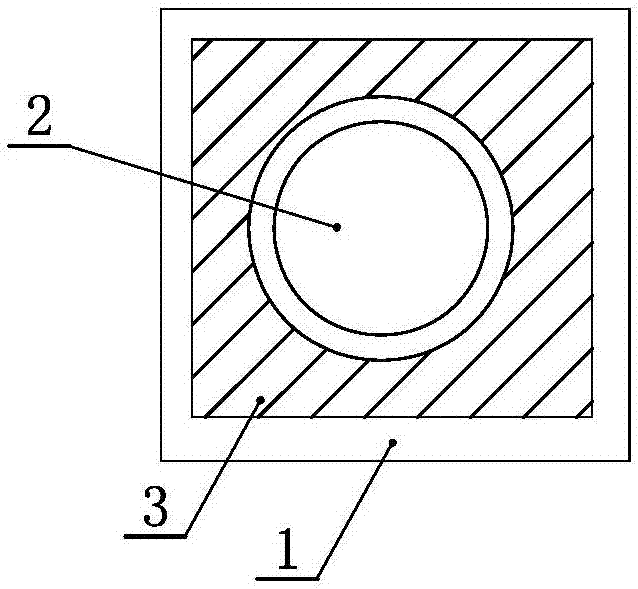

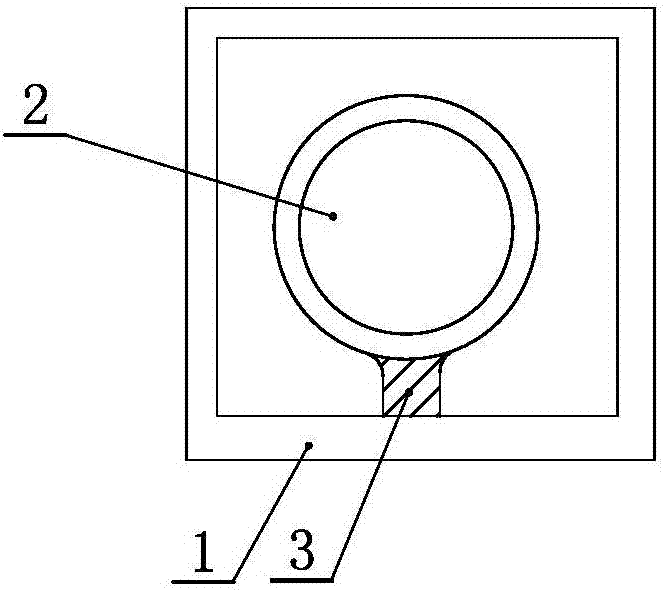

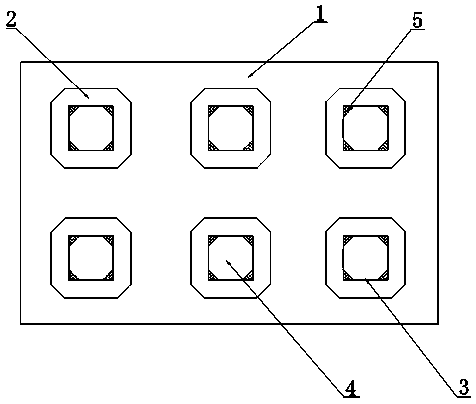

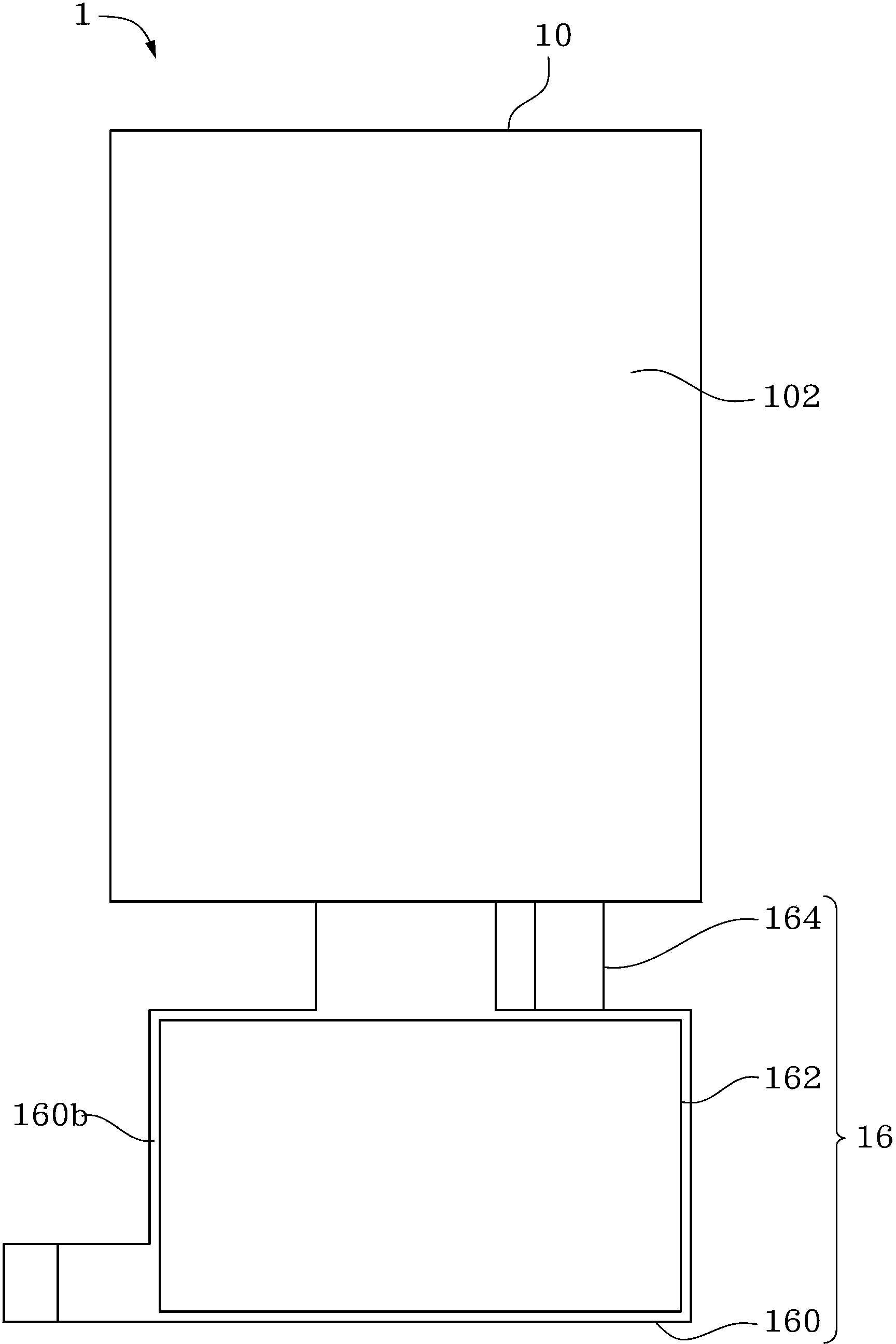

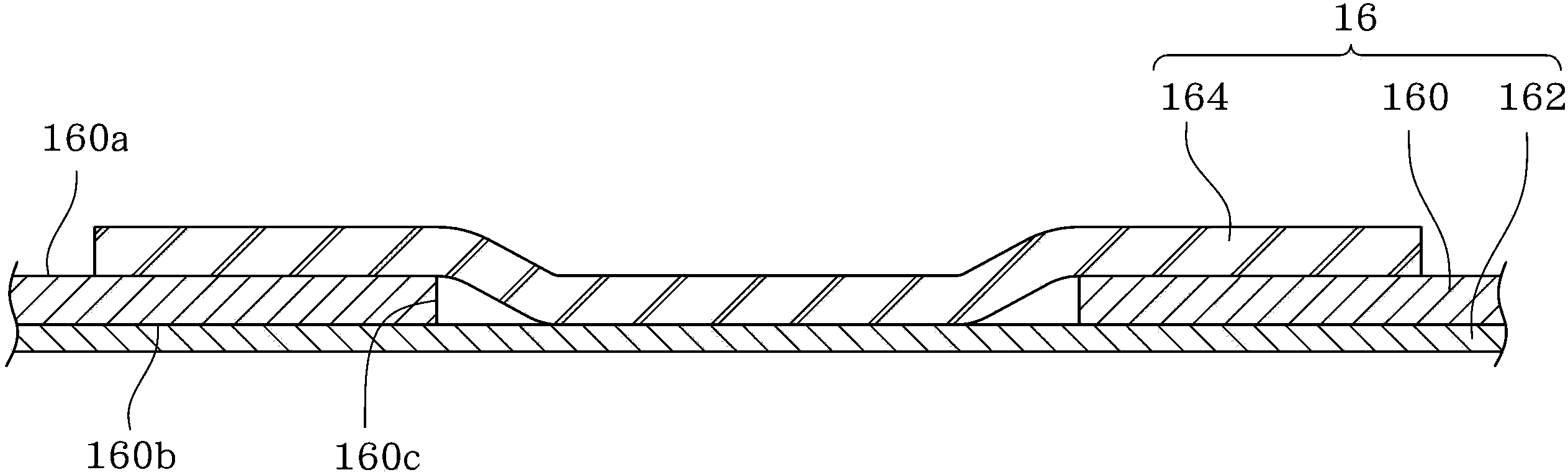

Metal base plate used for welding power module

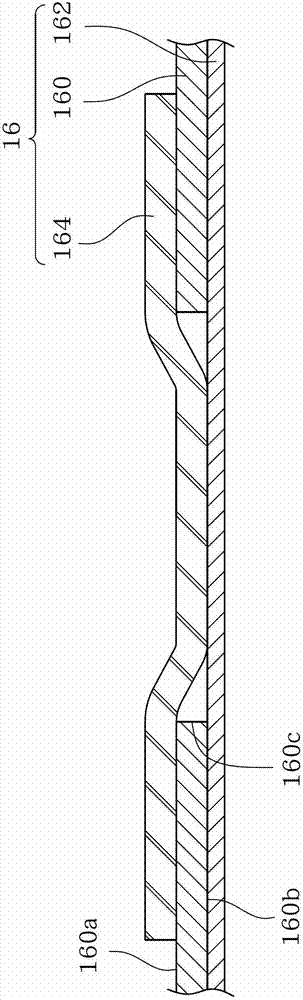

ActiveCN102832179AImprove temperature uniformityAvoid offsetSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention relates to a metal base plate used for welding a power module, which comprises a plate body, wherein more then four spacing protrusions for spacing the outer periphery of a welding flux layer are arranged on the front face of the plate body, a groove is arranged on the bottom of the plate body, and the groove is filled with a heat conducting silicon grease. In the invention, the metal base plate is improved, so that the metal base plate has reasonable structure, the welding flux layer can be conveniently positioned, the welding reliability is increased, so that the metal base plate has the characteristic of good heat conductivity and can maintain the consistent heat conductivity of the power module and prolong the service life of the power module.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

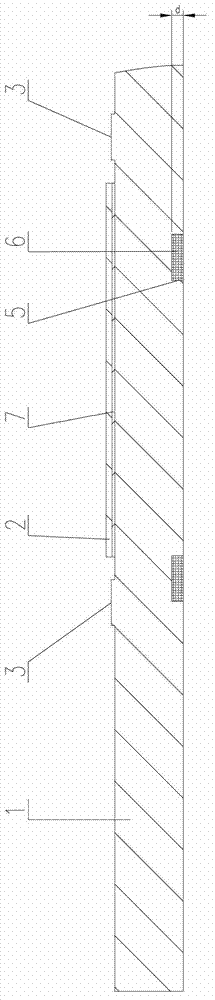

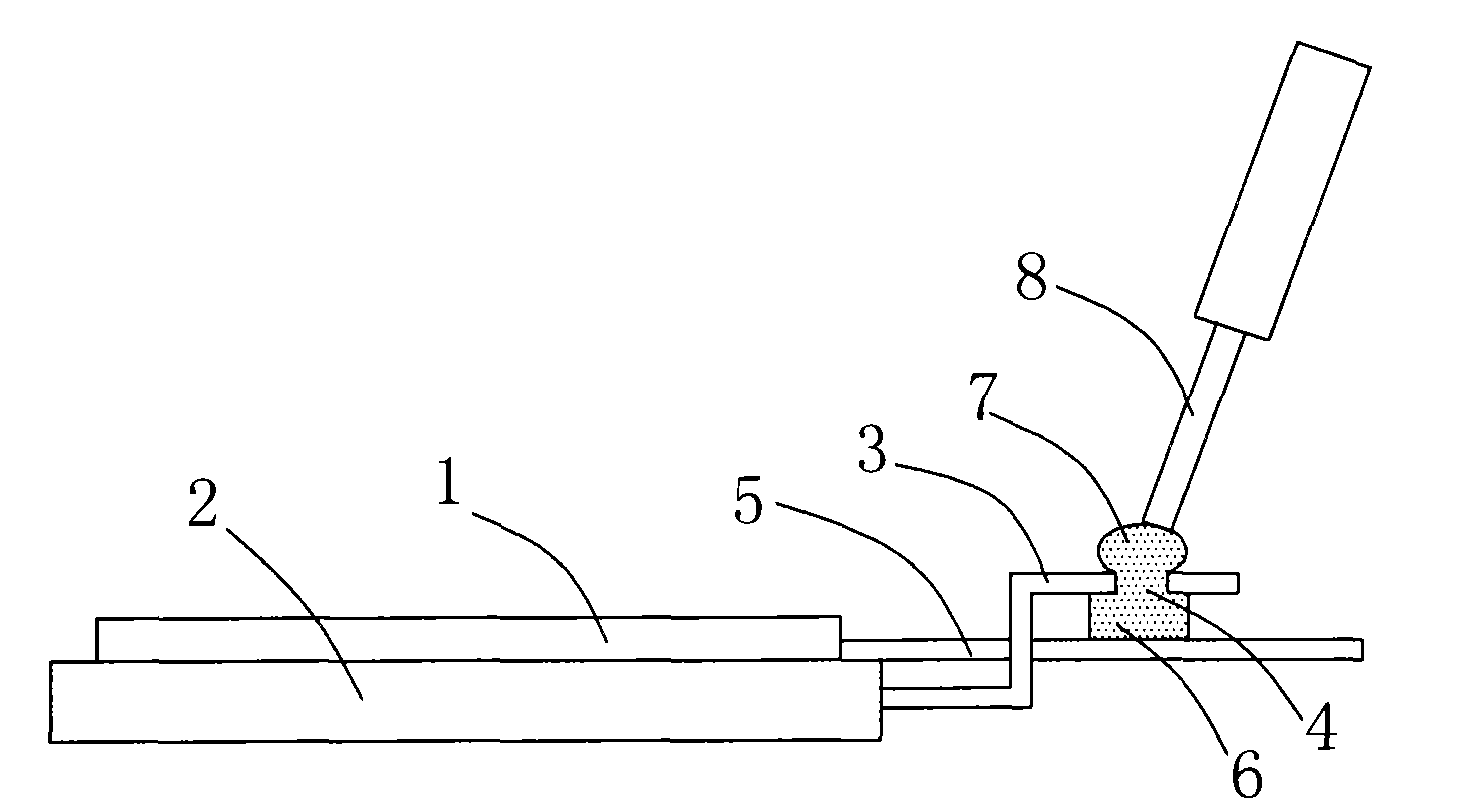

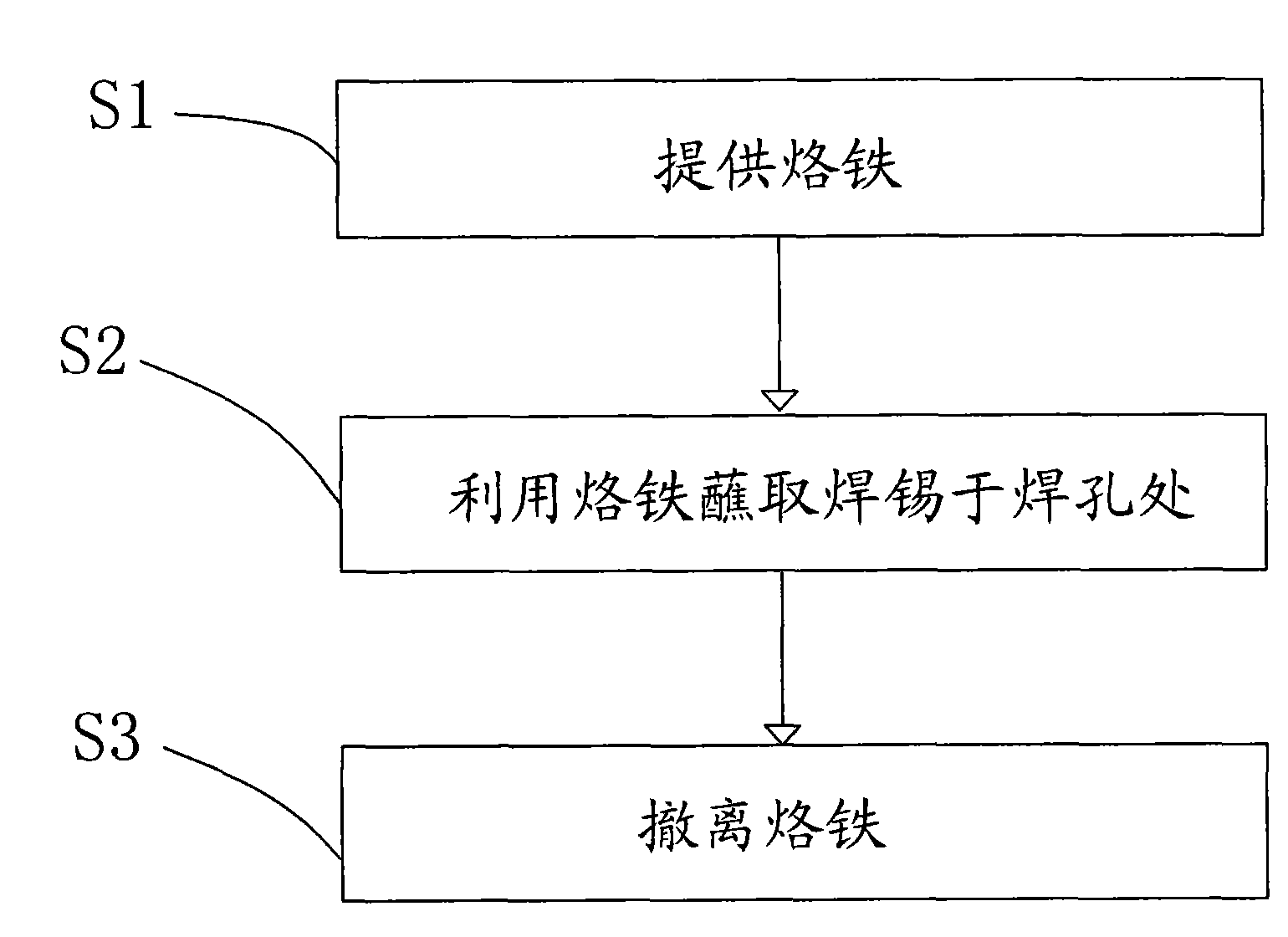

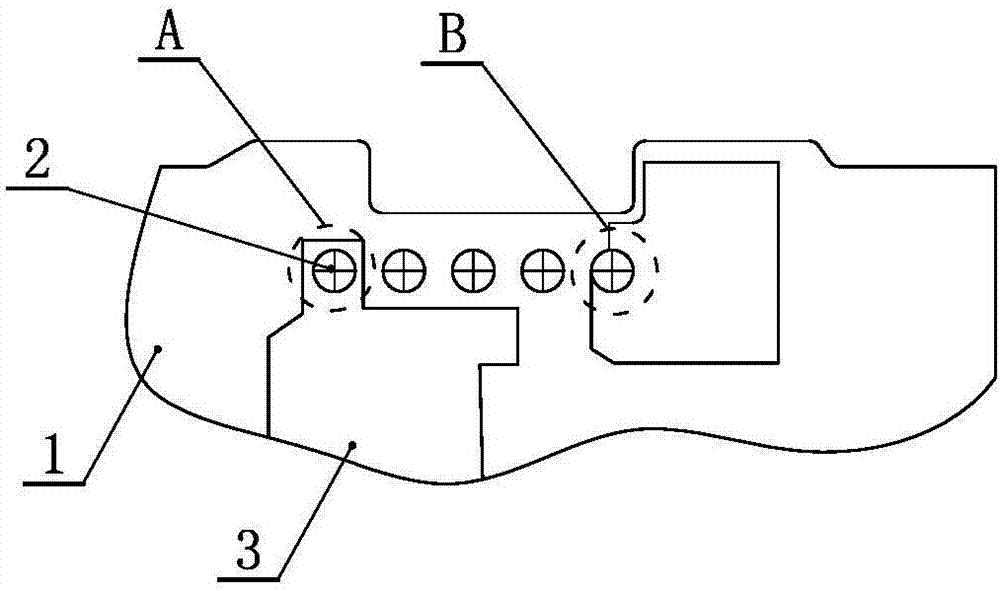

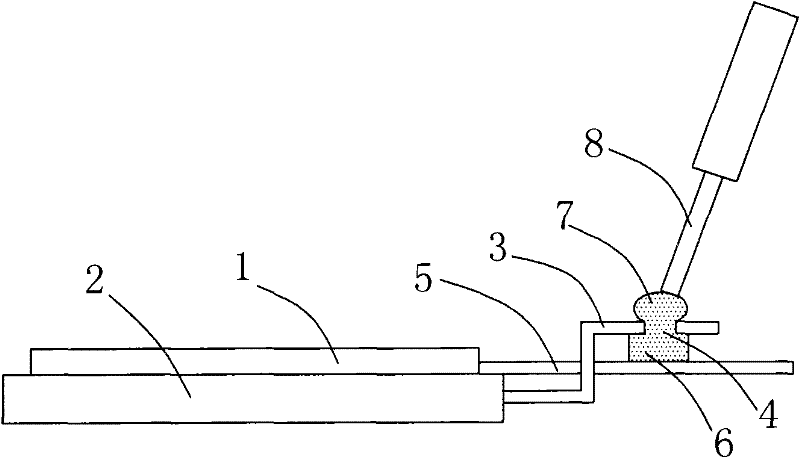

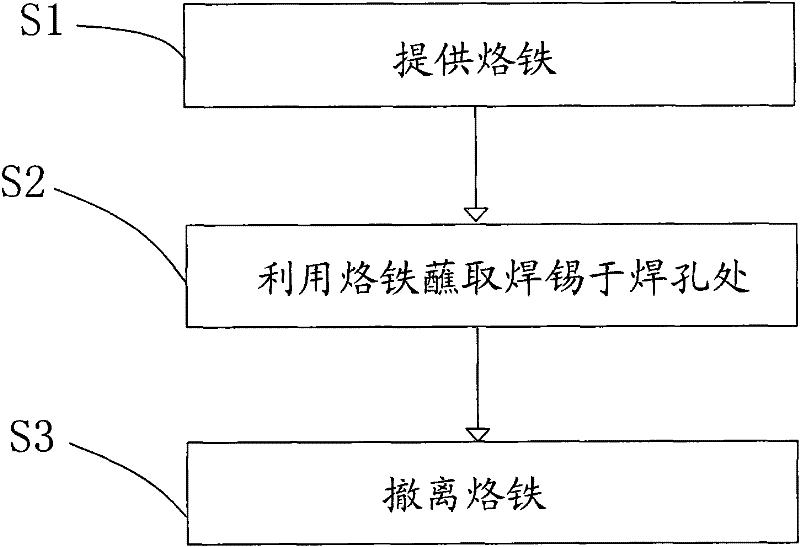

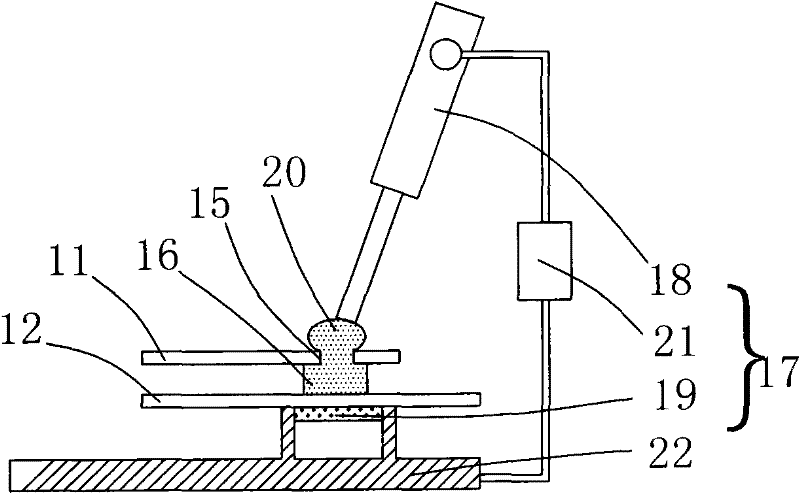

Welding fixture and welding method

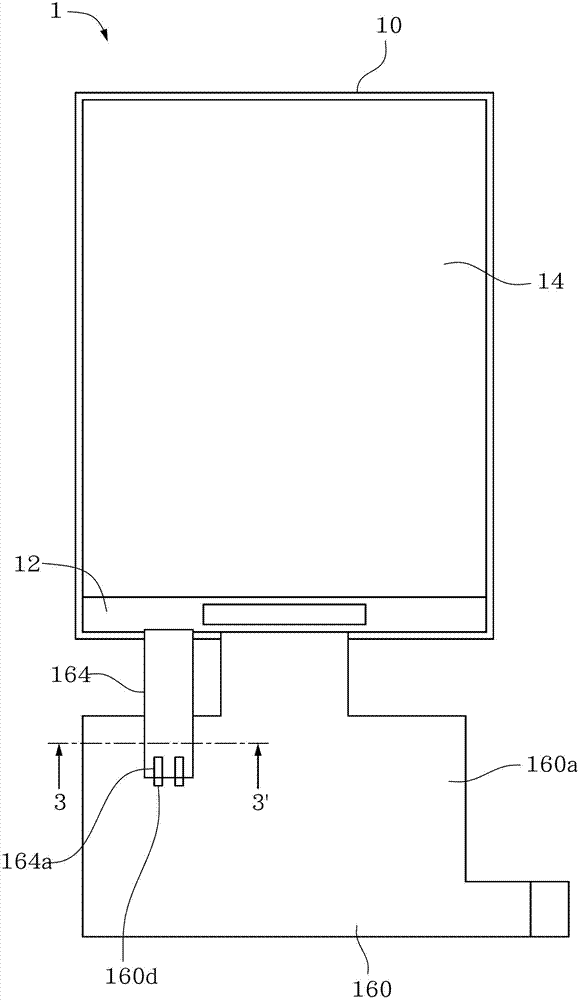

ActiveCN101585104ASolve the problem of poor weldingSoldering apparatusWelding/soldering/cutting articlesEngineeringTin

The invention provides a welding fixture and a welding method. The welding fixture is used for welding a first circuit board and a second circuit board which are oppositely mounted. The first circuit board is provided with welding holes; the second circuit board, near one side of the circuit board, is provide with welding points corresponding to the welding holes, and the welding points are provided with soldering tins; the welding fixture comprises an soldering iron and a heating device. The soldering iron is used for dipping the first soldering tin to the welding holes; the heating device is installed on one side of the first circuit board which is far from and corresponding to the second circuit board.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

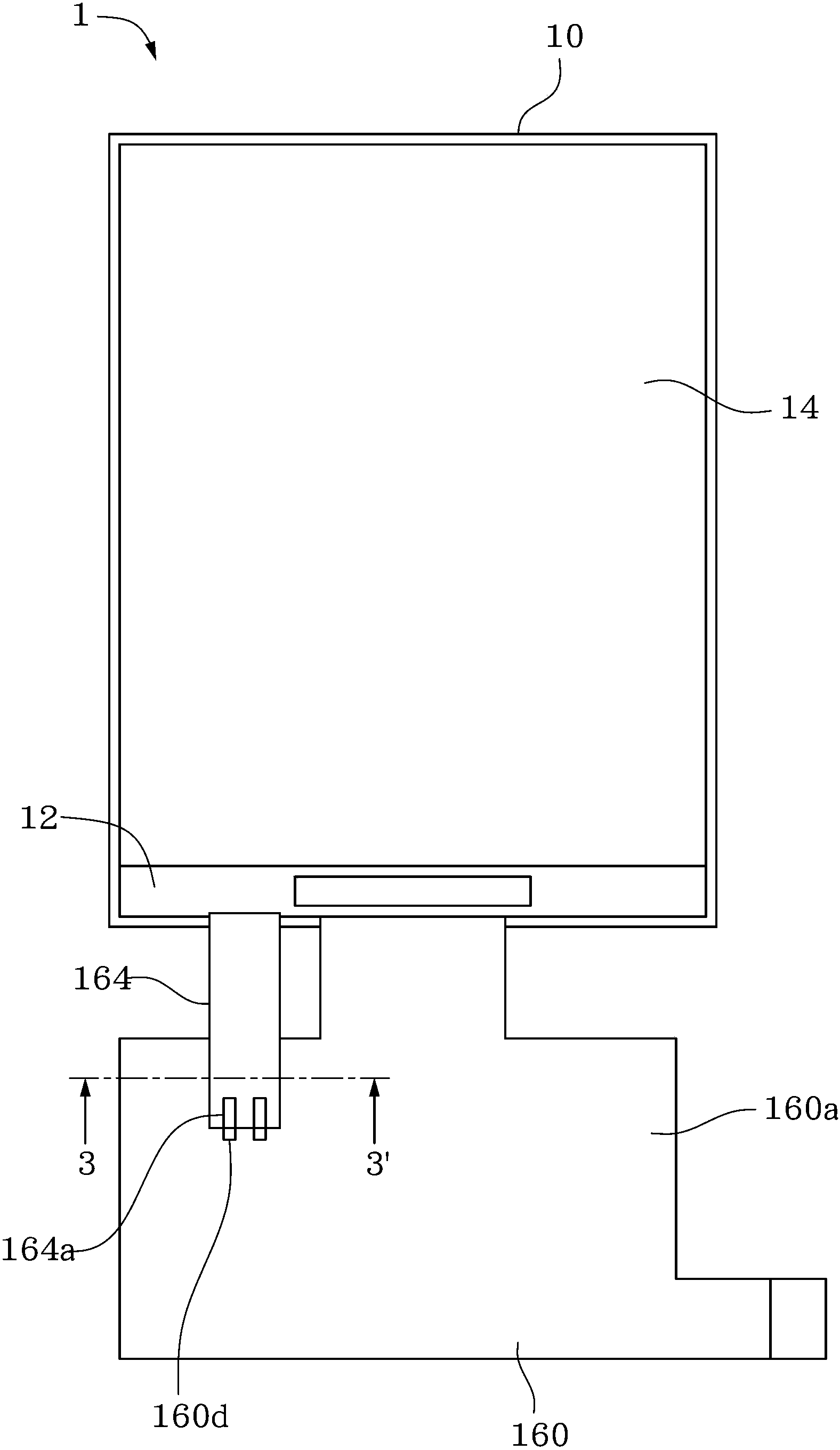

Flexible circuit board assembly and assembling method thereof

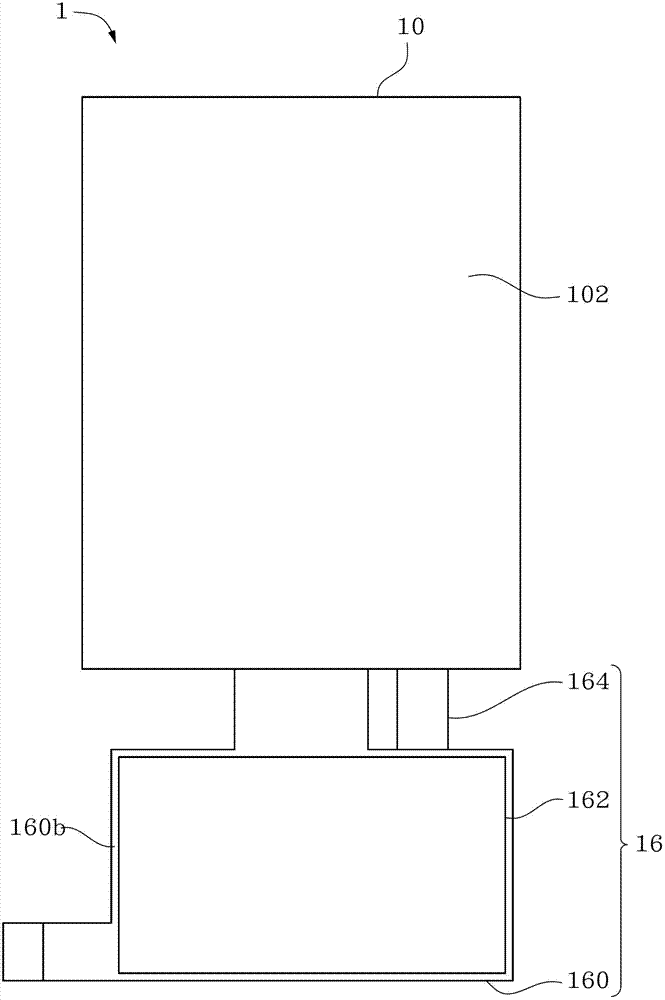

ActiveCN102769994AAchieve mutual positioningSolve the problem of poor weldingPrinted circuit assemblingPrinted circuits structural associationsFlexible circuitsEngineering

The invention provides a flexible circuit board assembly and an assembling method thereof. The flexible circuit board assembly comprises a first flexible circuit board, an adhesion piece and a second flexible circuit board. The first flexible circuit board is provided with a first surface, a second surface and a through hole for communicating the first surface with the second surface. The adhesion piece is arranged on the second surface and covers the through hole. The second flexible circuit board is arranged on the first surface. Part of the second flexible circuit board is glued with the adhesion piece through the through hole. Due to the adoption of the flexible circuit board assembly, the adhesion piece glued on the second surface of the first flexible circuit board is utilized to be simultaneously glued with the second flexible circuit board on the first surface of the first flexible circuit board. An area of the first flexible circuit board, which is overlapped relative to second flexible circuit board, is partially excavated to form the through hole, so that the second flexible circuit board on the first surface can be mutually glued with the adhesion piece on the second surface through the through hole. Therefore, the aim of mutual location of the first soft flexible circuit board and the second soft flexible circuit board is achieved.

Owner:AU OPTRONICS (XIAMEN) CORP +1

LED (Light Emitting Diode) lamp bulb light strip connecting portion structure and LED lamp bulb light strip and conducting wire connection method

InactiveCN104329640ASolve the problem of poor weldingGuaranteed fastnessPoint-like light sourceLight fasteningsEngineeringLED lamp

The invention relates to an LED (Light Emitting Diode) lamp bulb light strip connecting portion structure and an LED lamp bulb light strip and conducting wire connection method. A connecting portion is provided with an annular or semi-annular or fork-shaped bayonet which is used for clamping a conducting wire, and the bayonet is formed through dividing the connecting portion into three parts and molding the middle portion; during connection, the conducting wire is firstly snapped into the molded bayonet, namely being inserted into a ring or semi ring or being snapped into a fork, the bayonet is enabled to clamp the conducting wire, and then, welding is carried out. The LED lamp bulb light strip connecting portion structure and the LED lamp bulb light strip and conducting wire connection method have the advantages that the fastness of welding is ensured, the difficulty of welding is lowered, the problem of poor welding between the connecting portion and the conducting wire is solved, and the quality of a product is improved.

Owner:HAINING XIN GUANG YUAN LIGHTING TECH CO LTD

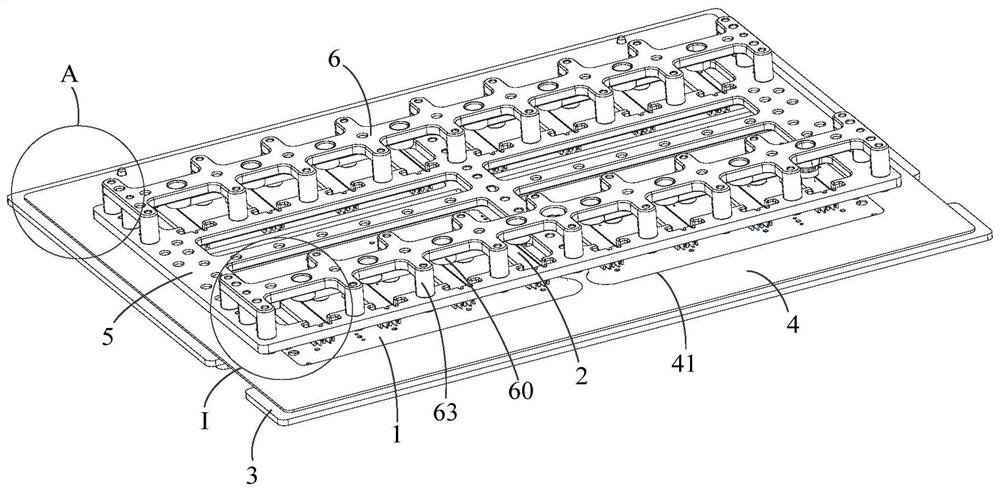

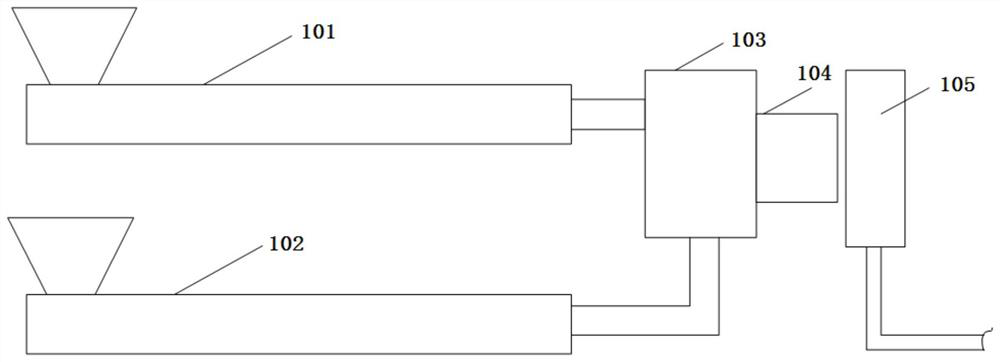

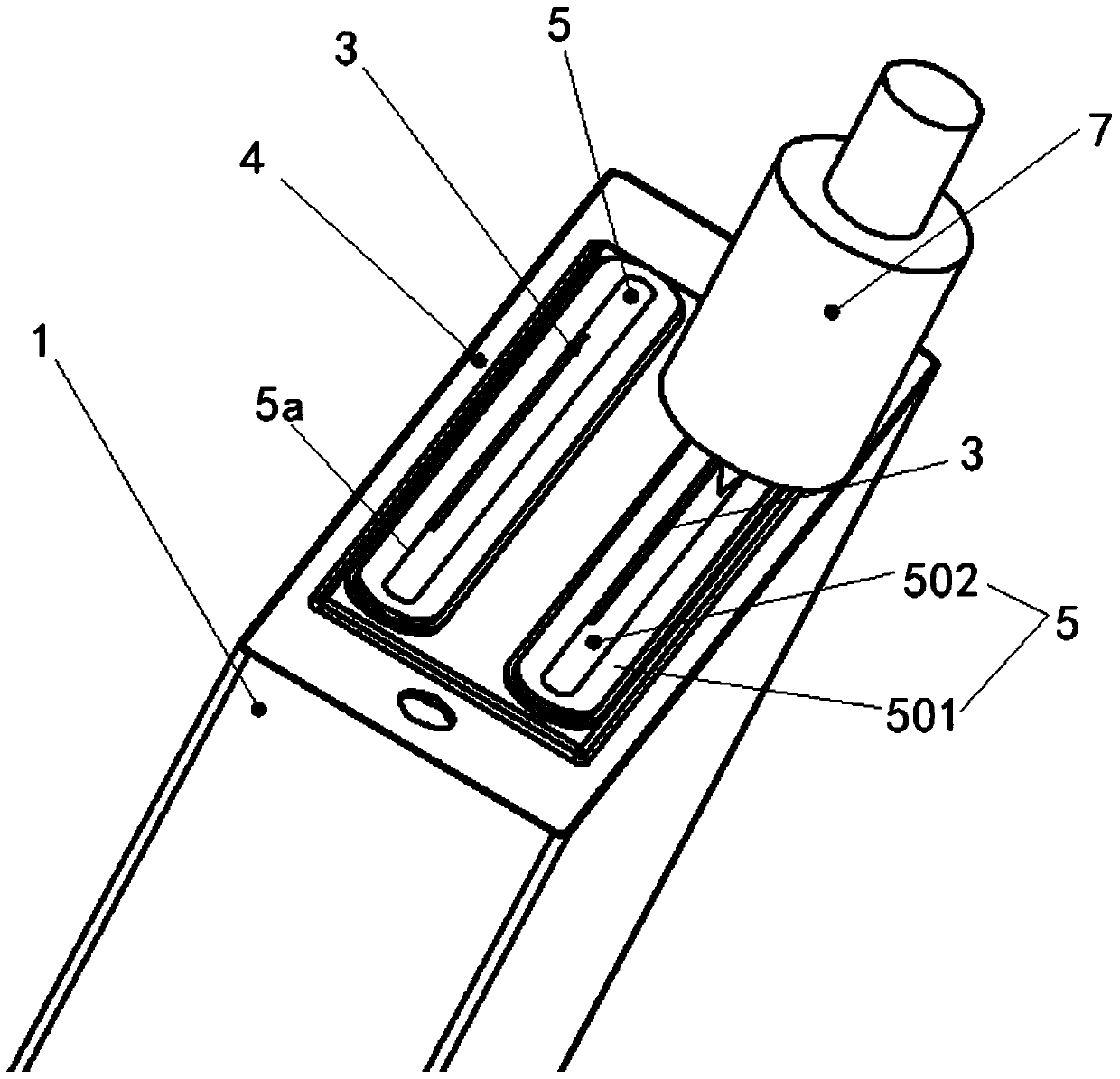

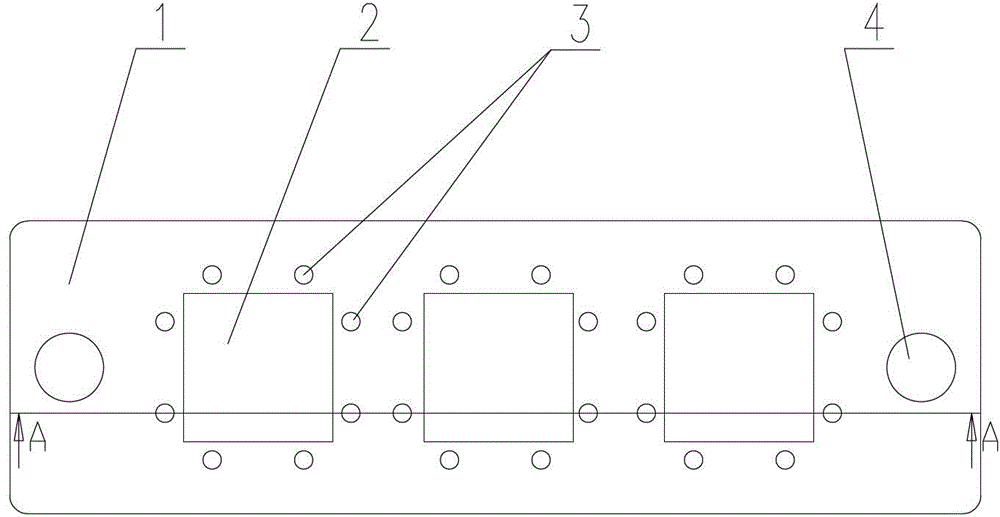

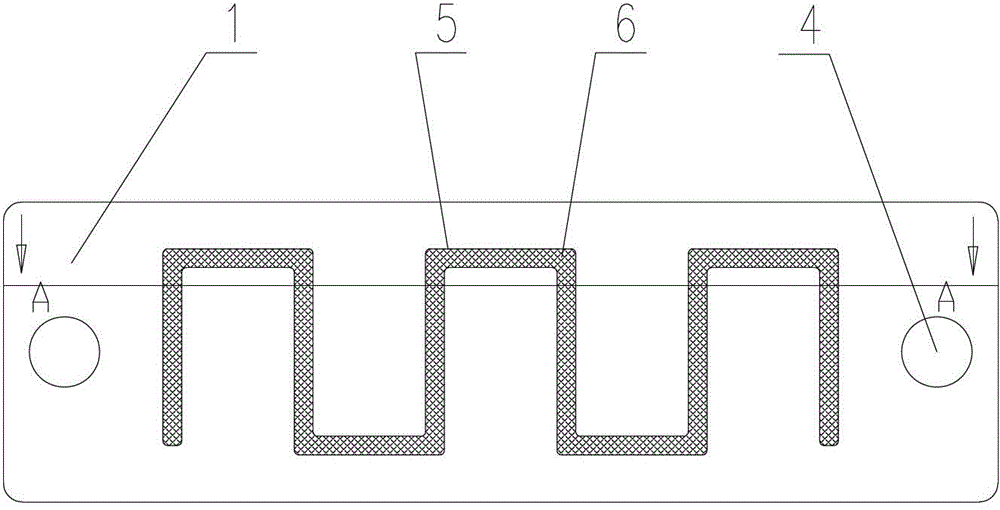

Positioning device for phase shifter welding and method for positioning phase shifter by using positioning device

PendingCN112157387ANo lateral offsetPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringControl theory

The invention relates to a positioning device for phase shifter welding and a method for positioning a phase shifter by using the positioning device. The positioning device comprises a power dividingplate positioning bottom plate and a phase shifter limiting plate which are oppositely arranged. A limiting hole used for limiting the phase shifter is formed in the phase shifter limiting plate; thephase shifter is located in the limiting hole; the surface, facing the phase shifter limiting plate, of the power dividing plate positioning bottom plate forms a bearing surface used for bearing a power dividing plate; and a first positioning column used for being connected with a first positioning hole in the power dividing plate in a matched mode is arranged on the power dividing plate positioning bottom plate. The positioning device for phase shifter welding further comprises a pressing structure arranged on the phase shifter limiting plate, wherein the pressing structure is used for pressing the phase shifter on the power dividing plate, so that the bottom face of the cavity wall of the phase shifter can be attached to a first bonding pad on the face, facing the phase shifter, of the power dividing plate, a positioning effect on the phase shifter is improved, and gaps generated by contact between the phase shifter and the power dividing plate can be effectively eliminated.

Owner:COMBA RF TECH GUANGZHOU LTD +1

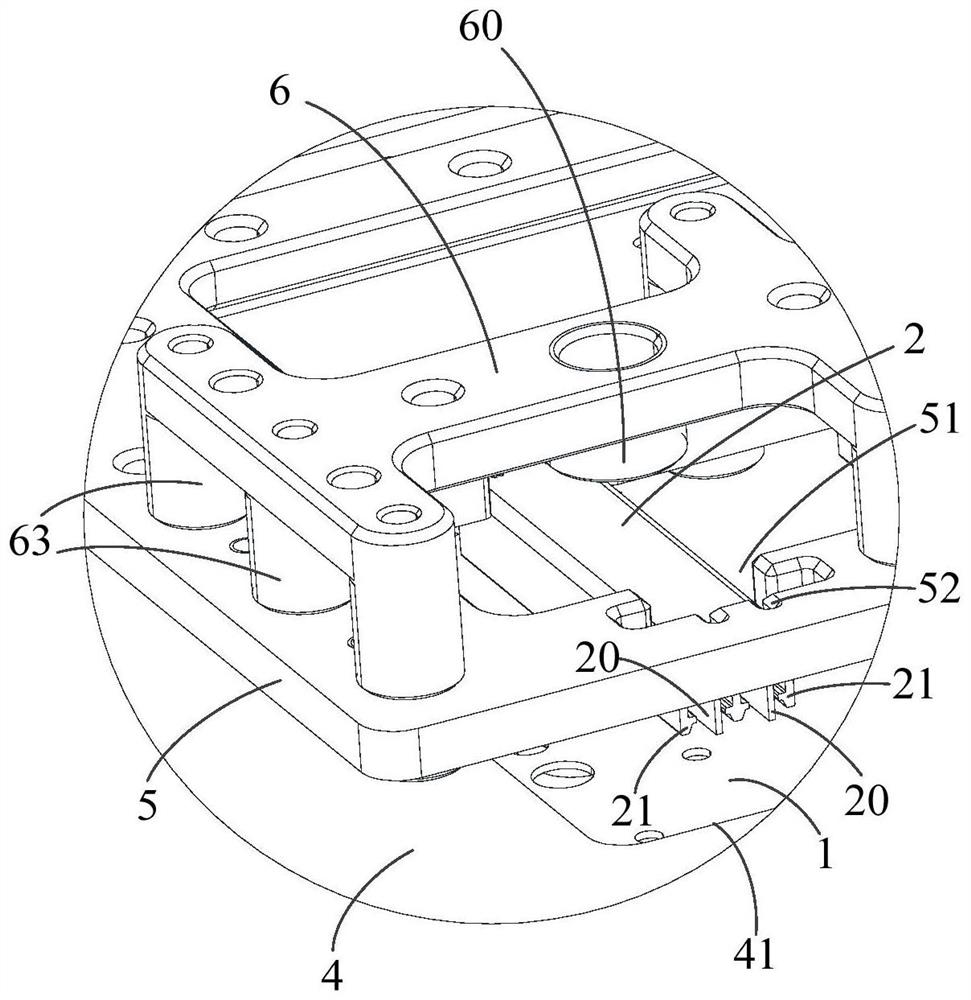

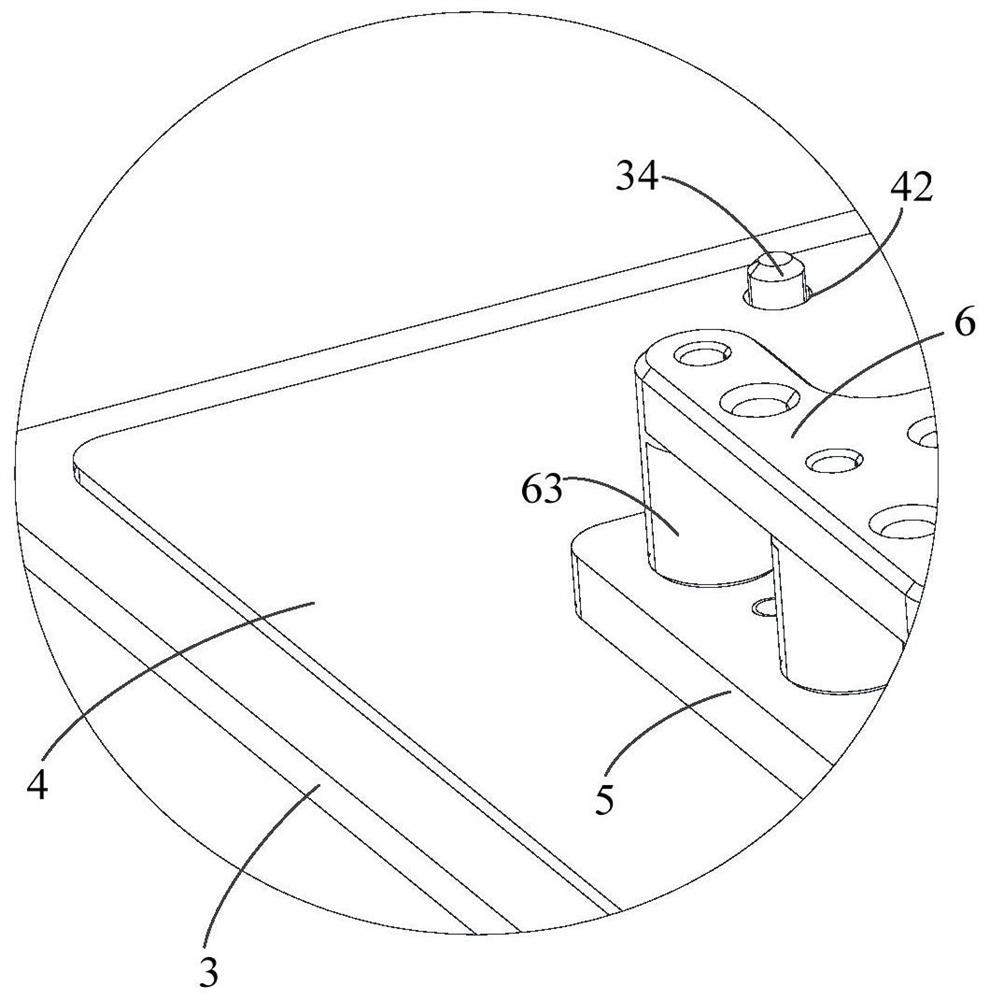

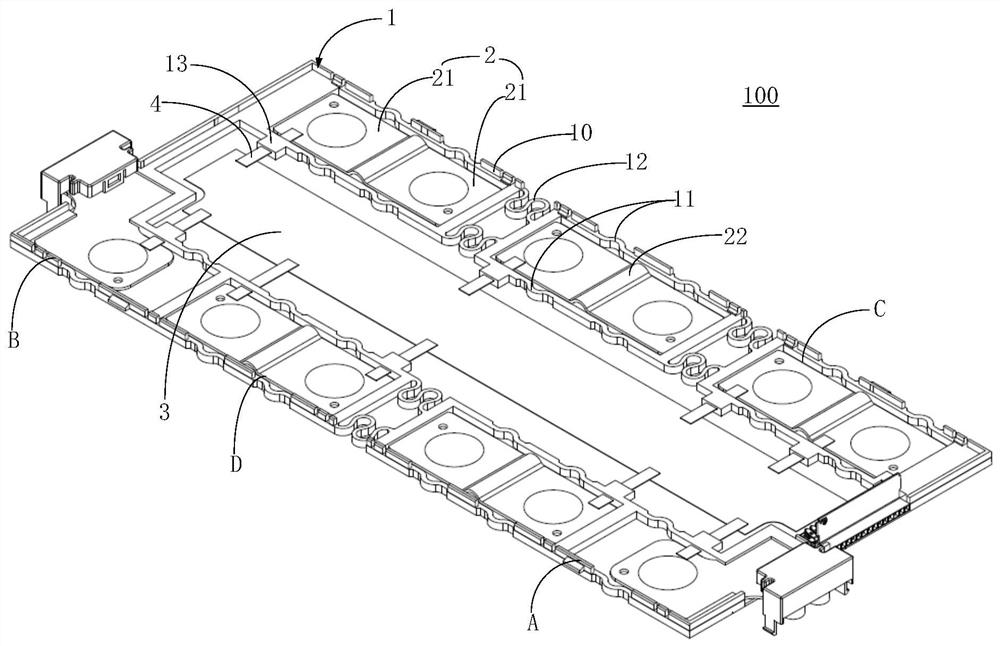

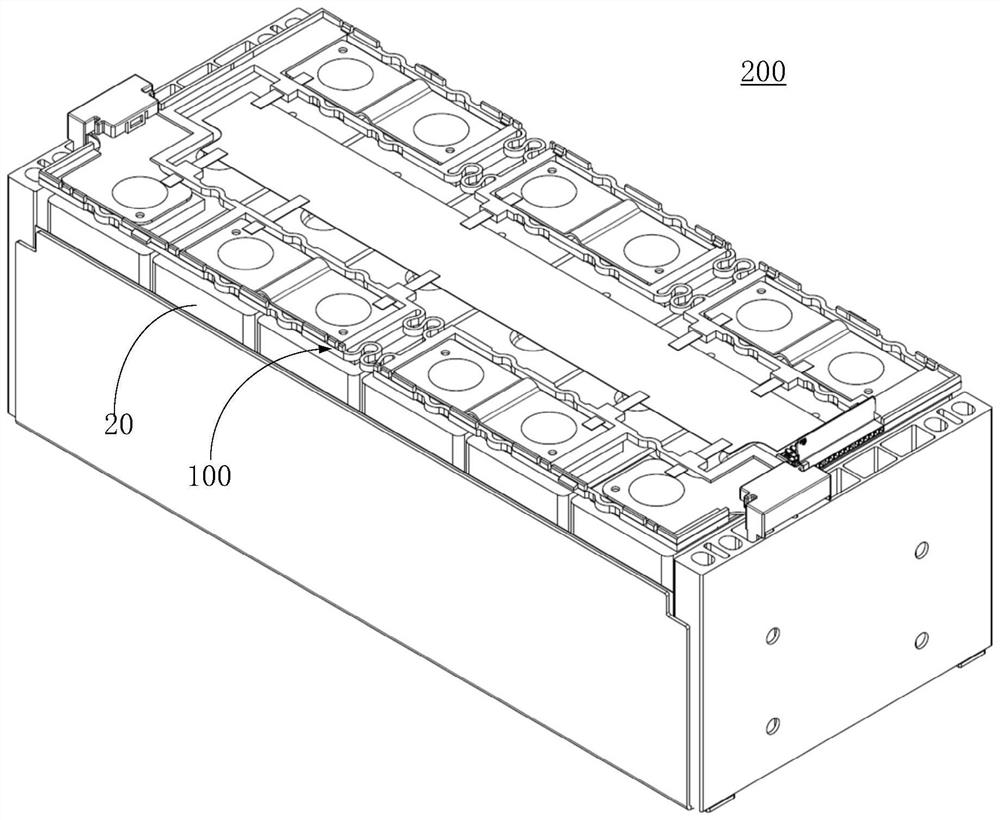

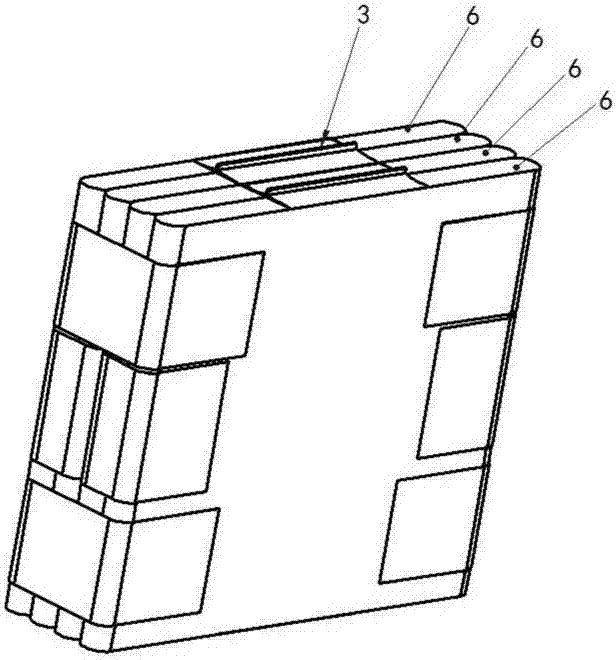

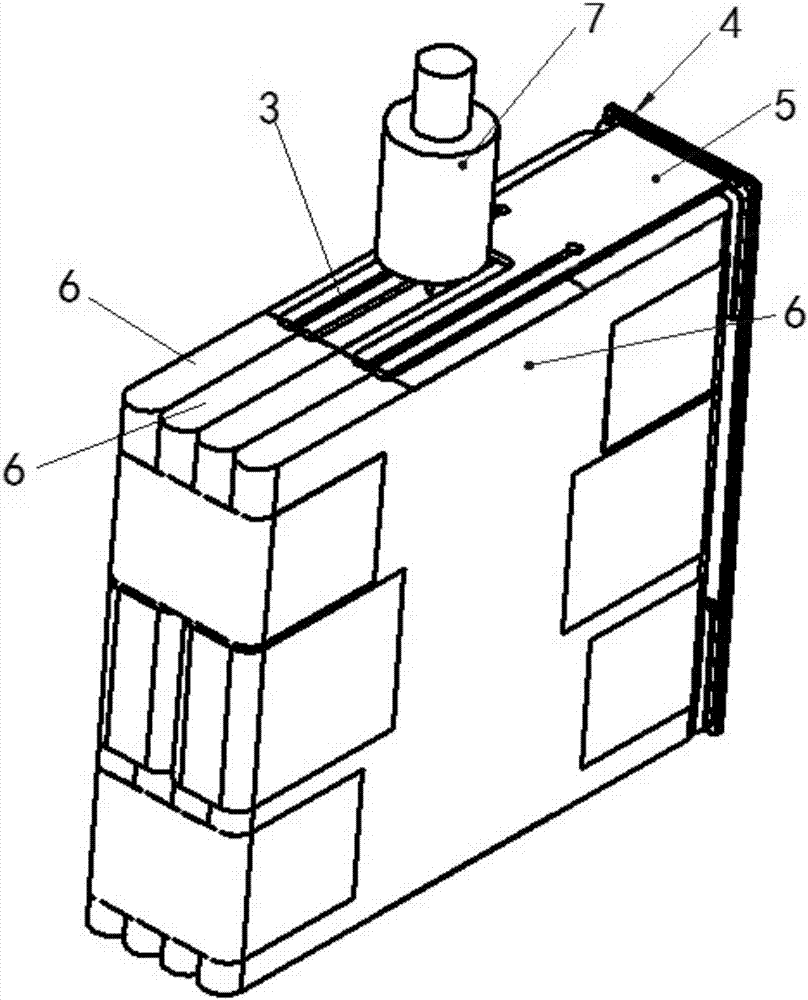

Integrated battery module

PendingCN113871786AAvoid breakingSolve the problem of poor weldingCell component detailsEngineeringStructural engineering

The invention provides a battery module. The battery module comprises a wire harness isolation plate integration module which is integrally and horizontally arranged above a plurality of battery cells of the battery module. According to the wire harness isolation plate integration module, the conducting strip group and the isolation plate are integrated into an integral structure, and the two side edge parts of each isolation unit are respectively provided with at least one elastic part, so that in specific application practice, if a battery cell expands, the elastic parts of the two side edge parts of the isolation unit generate elastic deformation, therefore, the pulling force generated by the expansion of the battery cell is absorbed, and the separation plate is prevented from being broken; in addition, the problem of poor welding between the low-height battery cell pole and the conducting strip caused by inconsistent heights of the battery cells can be well solved.

Owner:MECAPLAST CAR COMPONENTS SHANGHAI

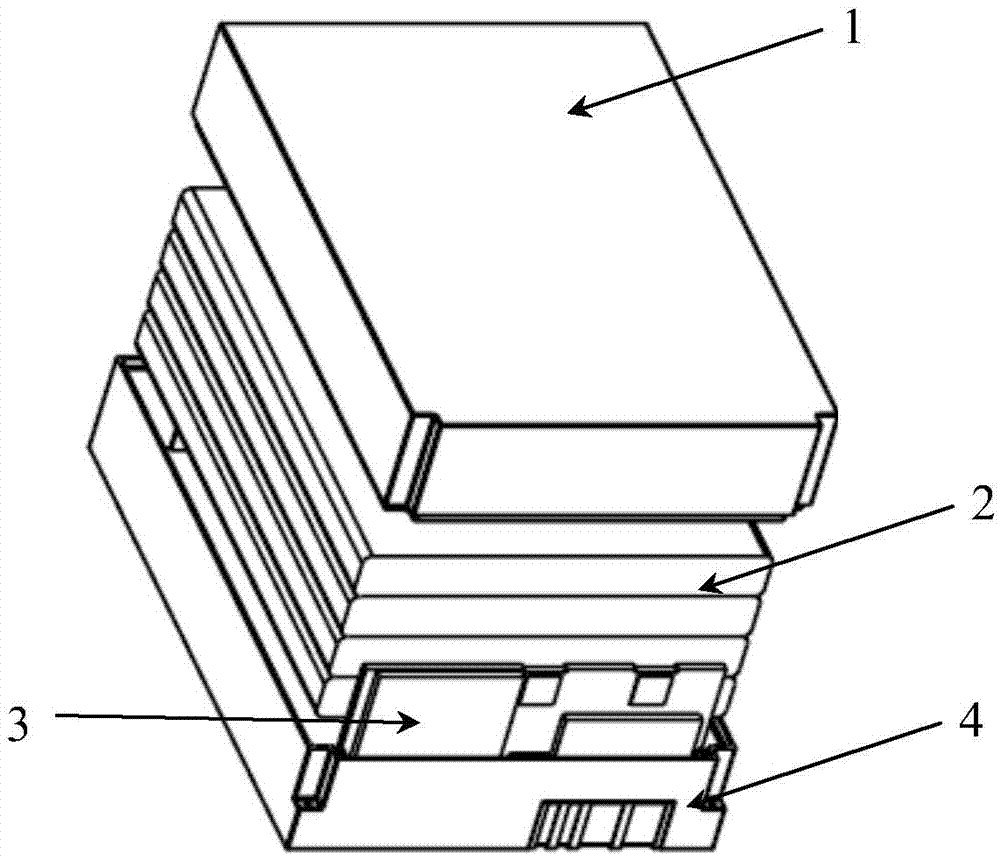

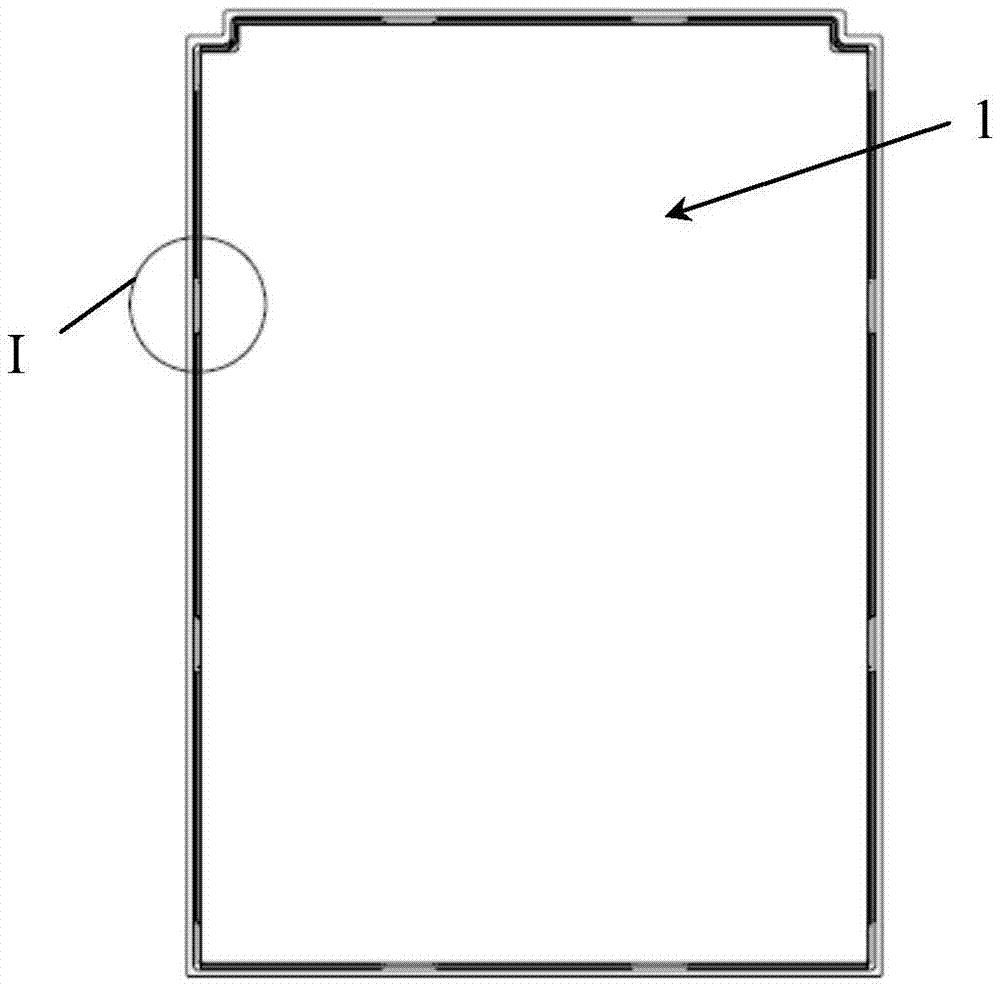

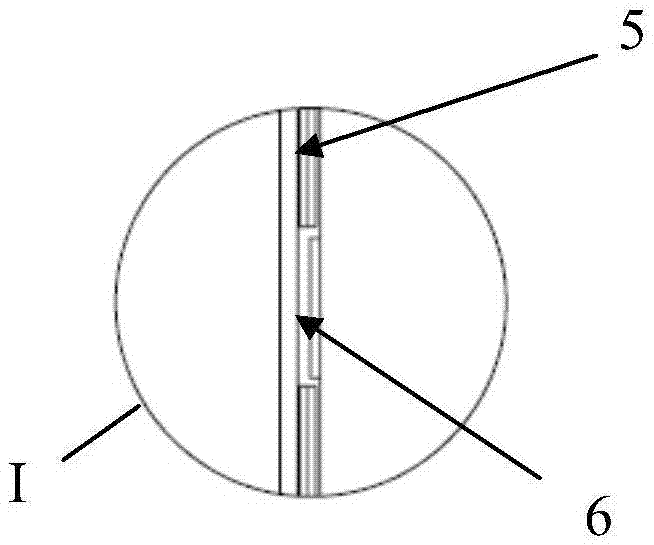

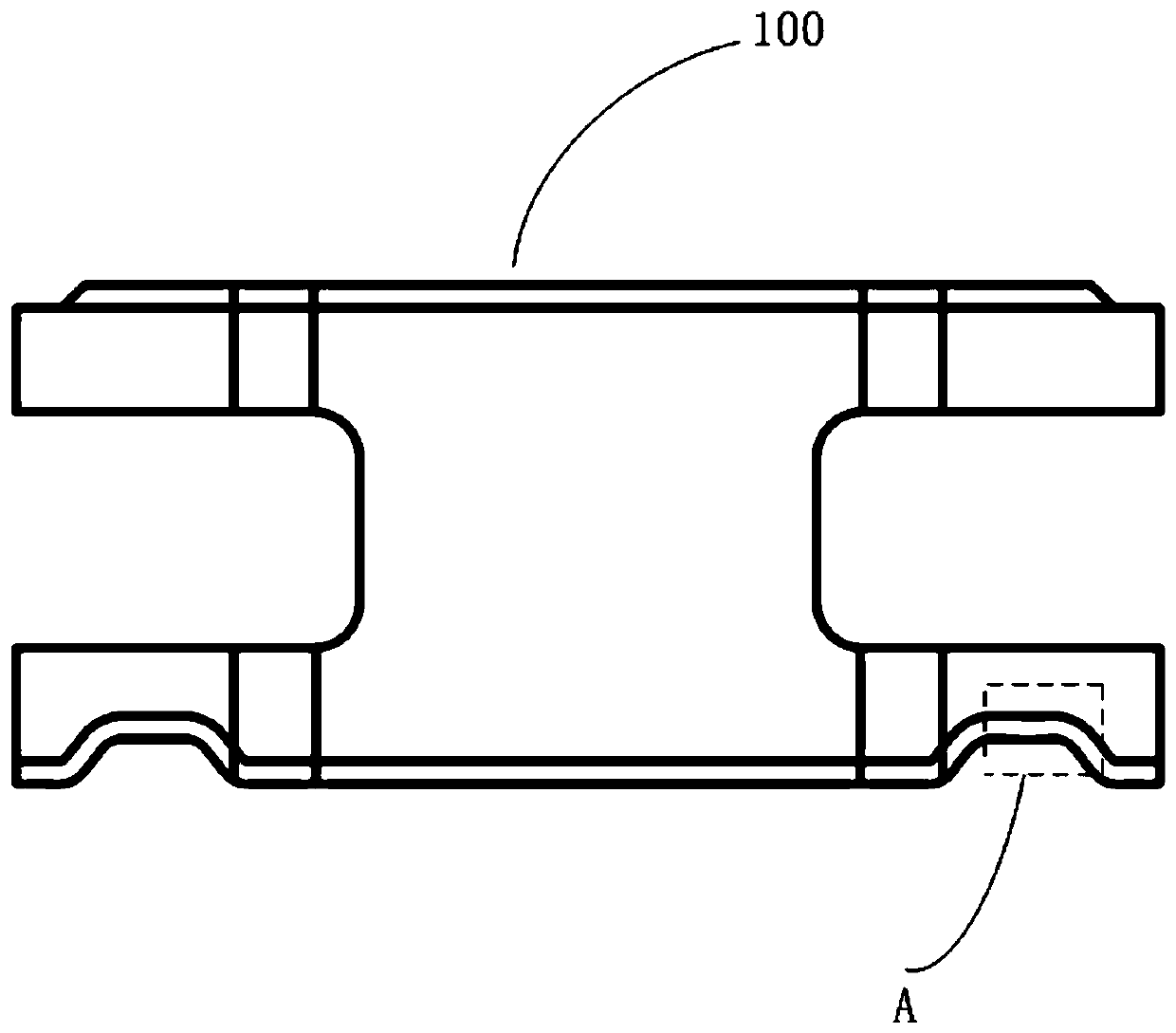

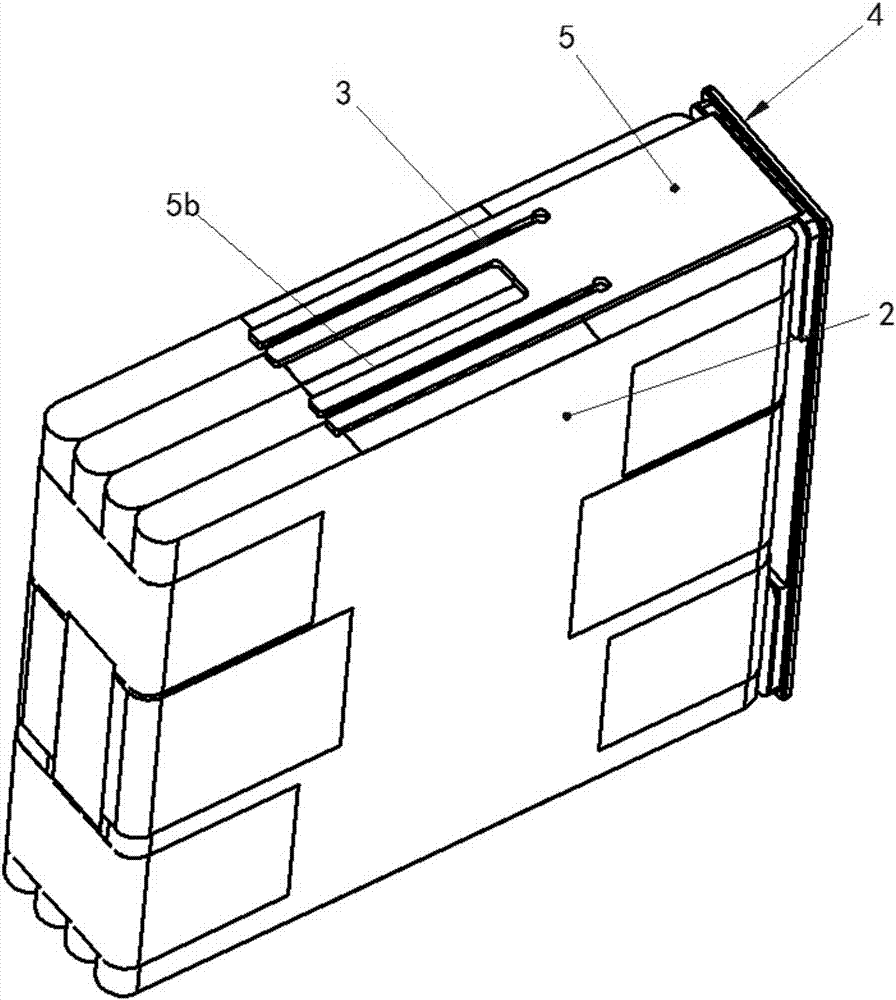

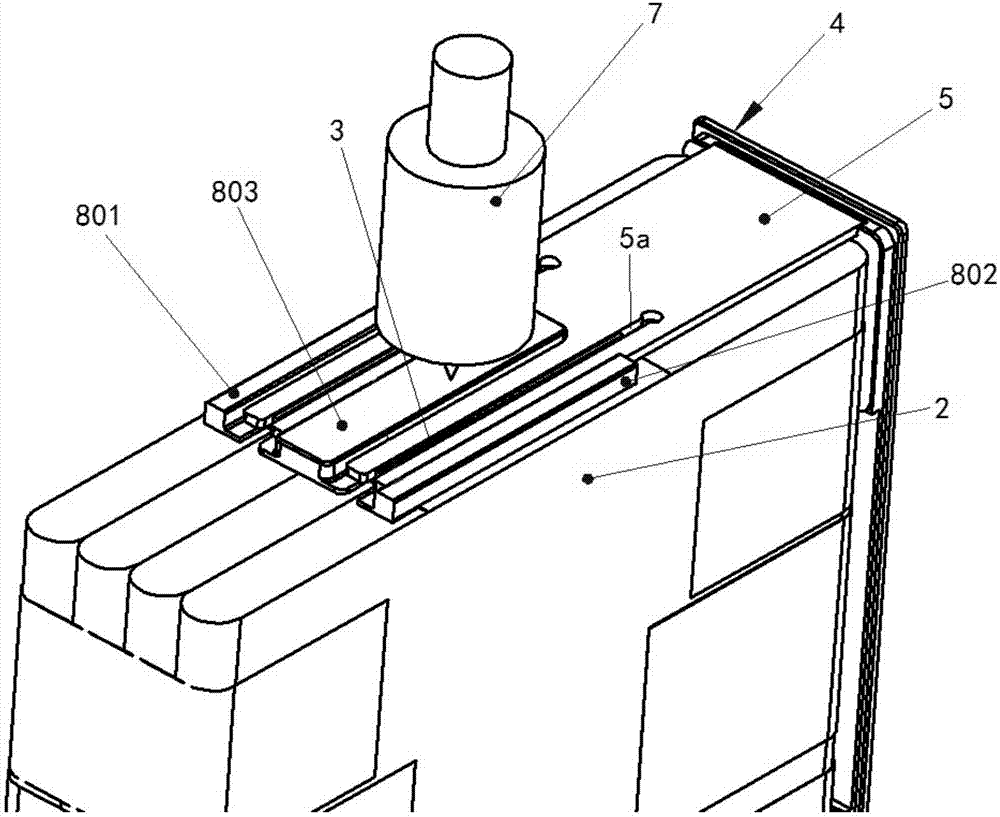

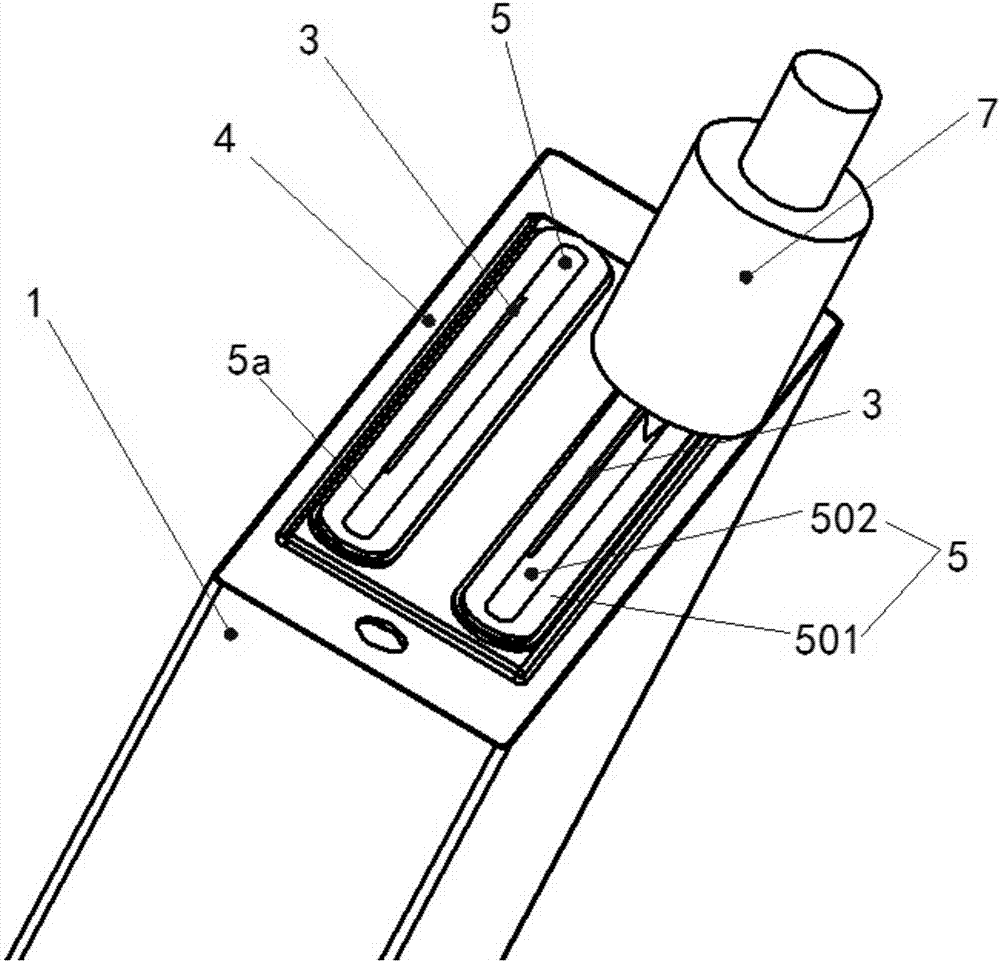

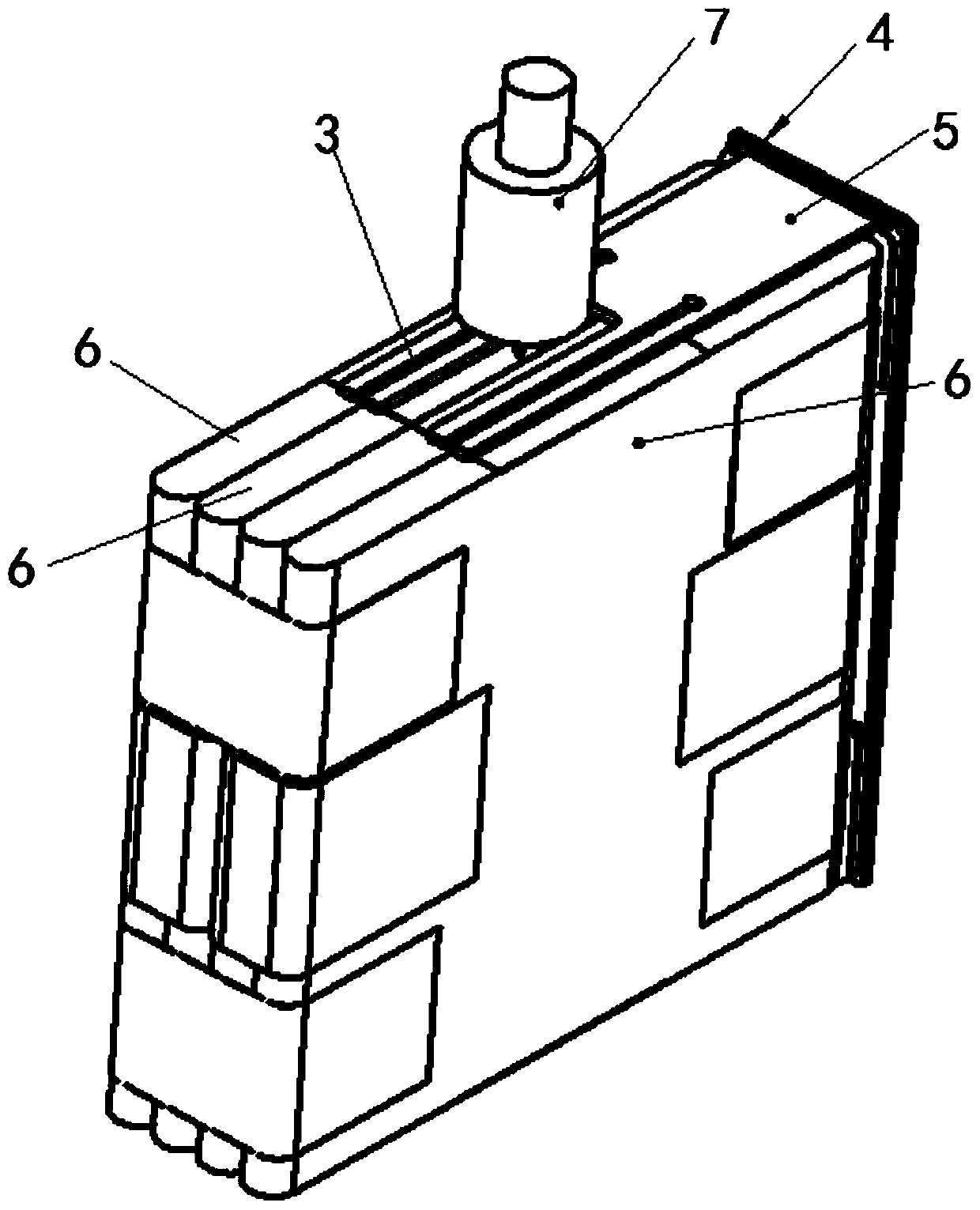

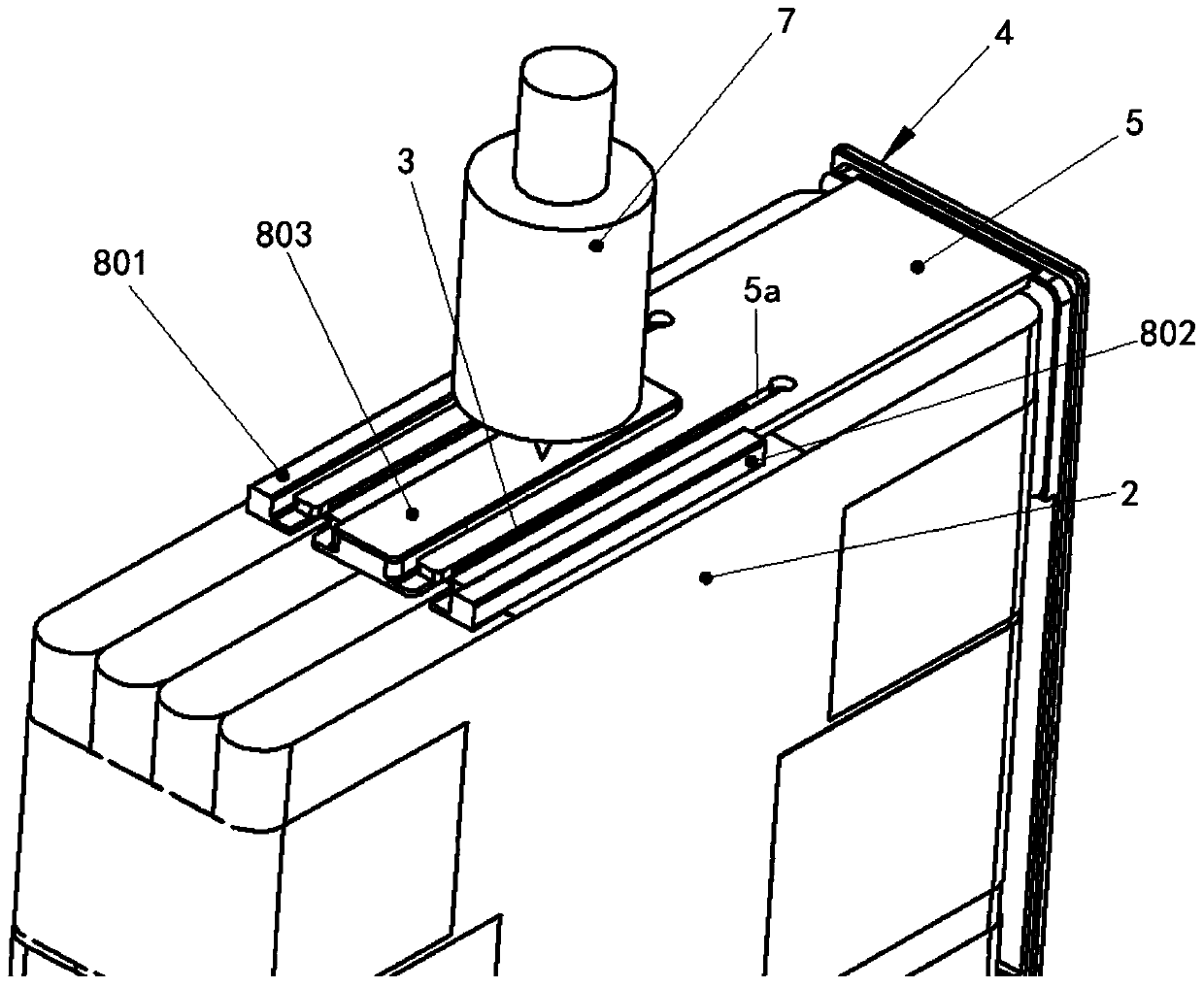

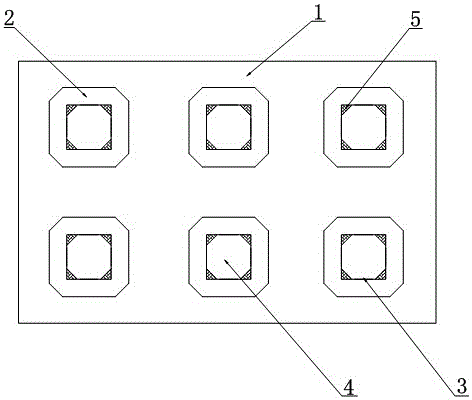

Thin-wall plastic ultrasonic welded and encapsulated lithium-ion battery pack

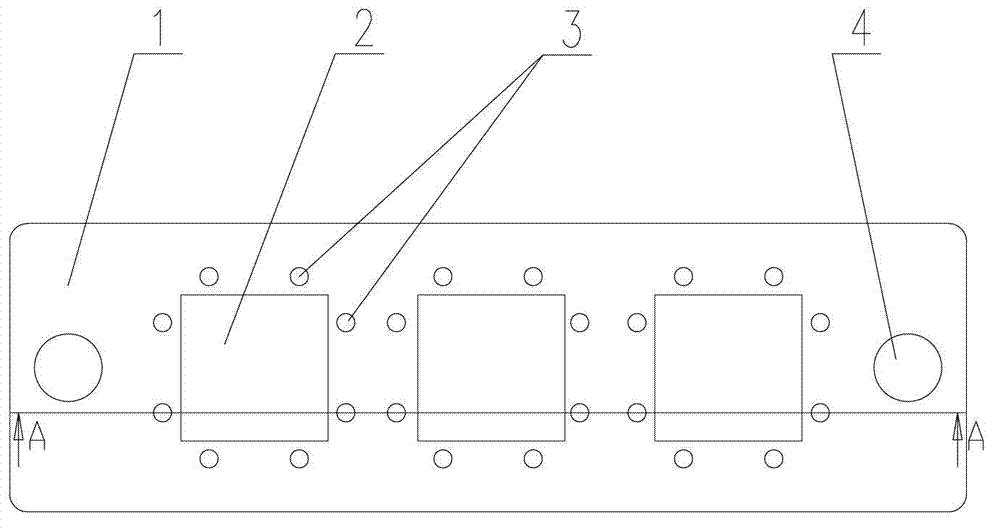

InactiveCN105449267ACompact structureConvenient thin-wall plastic ultrasonic welding packageSecondary cellsCell component detailsL-shellThin walled

The invention discloses a thin-wall plastic ultrasonic welded and encapsulated lithium-ion battery pack, which comprises a hollow upper shell (1) and a hollow lower shell (4), wherein the upper shell (1) is located at the top part of the lower shell (4); the upper shell (1) is fastened to the lower shell (4); and a plurality of square single batteries (2) are placed on the lower shell (4) and are connected with a protection circuit board (3). The thin-wall plastic ultrasonic welded and encapsulated lithium-ion battery pack disclosed by the invention is compact in structure and good in encapsulation effect; thin-wall plastic ultrasonic welding and encapsulating are facilitated; the problem of poor part welding due to the fact that a weld line deviates from a weld surface can be solved; a large scale of industry can be formed; wide application is facilitated; and the thin-wall plastic ultrasonic welded and encapsulated lithium-ion battery pack has great production practice significance.

Owner:天津力神特种电源科技股份公司

Multi-arc bottomed metalized magnetic core and preparation method thereof, and chip inductor

PendingCN109741914AQuality improvementImprove welding qualityTransformers/inductances coils/windings/connectionsVacuum evaporation coatingMagnetic coreNickel Chromium Alloys

The invention provides a multi-arc bottomed metalized magnetic core. The multi-arc bottomed metalized magnetic core comprises a magnetic core, a metal film is formed on an electrode region of the magnetic core, the metal film comprises a multi-arc bottoming layer, a first plating layer and a second plating layer; the multi-arc bottoming layer is a titanium layer, a chromium layer, an aluminum layer or a nickel-chromium alloy layer; the first plating layer comprises n layers of first metal layers and n-1 layers of second metal layers in alternate arrangement; the material of each of the first metal layer and the second metal layer is independently selected from one or multiple of nickel-copper alloy, the nickel-vanadium alloy, silver, copper, ferric-nickel-copper alloy, and the first metallayer and the second metal layer are made of different materials, n is the integer from 2-8, and the second plating layer is a silver layer and a tin layer. The multi-arc bottomed metalized magnetic core is prepared from multi-arc bottoming and magnetron sputtering; the film is high in density, good in strength and soldering resistance, and good in adhesive strength; the multilayer structure design can reduce the film layer stress and improve the bonding force strength, and the preparation process is green, environment-friendly and pollution-free. The invention further provides a preparation method of the multi-arc bottomed metalized magnetic core and a chip inductor.

Owner:SHENZHEN KANGCI ELECTRONICS CO LTD

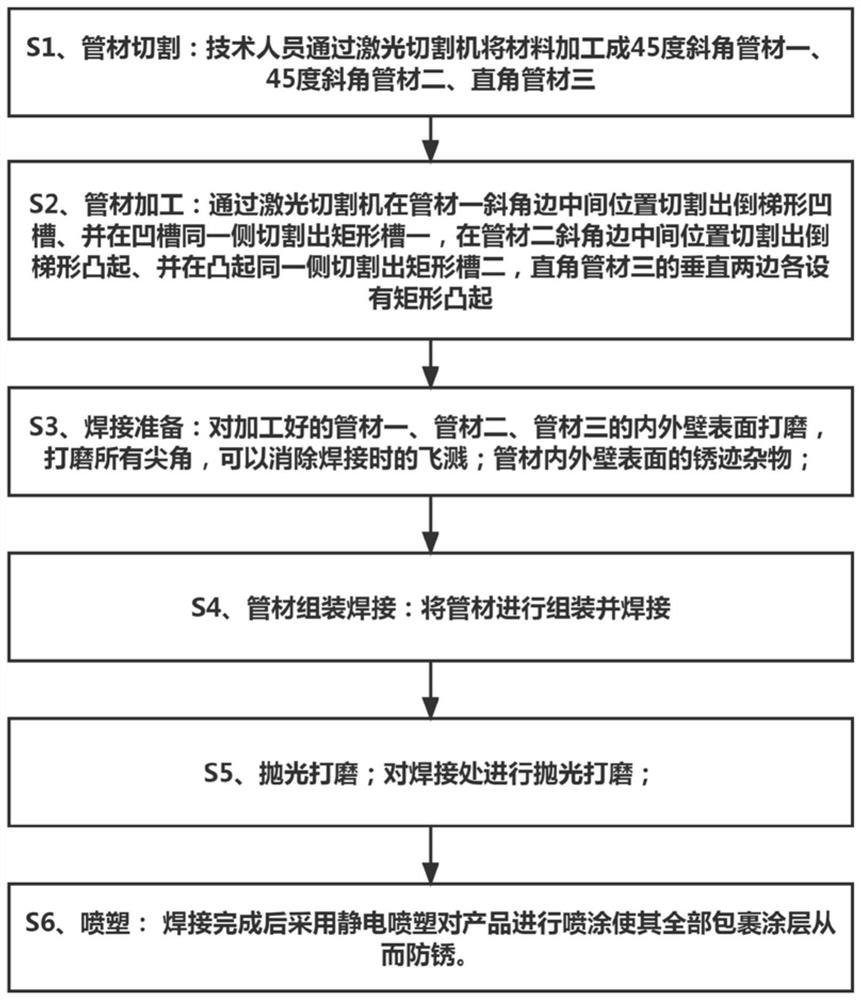

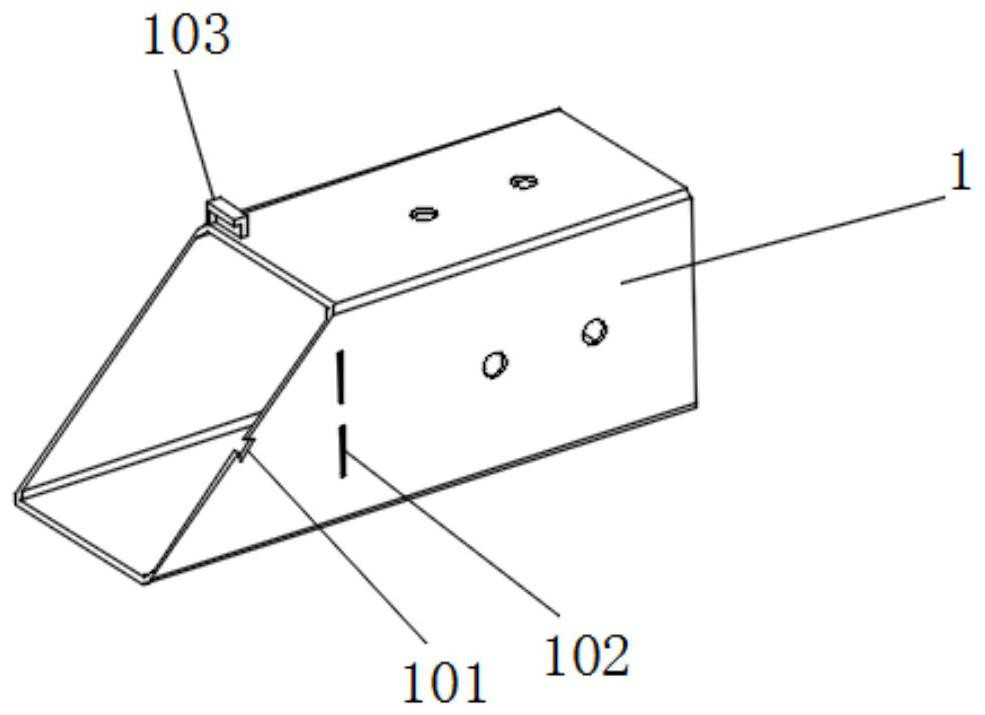

Assembled welding part and machining method thereof

PendingCN114850798AGuaranteed dimensional accuracyFacilitate subsequent weldingWorkpiece edge portionsEngineeringLaser cutting

The invention discloses a machining method of an assembled welding part. The machining method is characterized by specifically comprising the following steps that S1, pipe cutting is conducted, specifically, a technician machines materials into a first 45-degree oblique angle pipe, a second 45-degree oblique angle pipe and a third right-angle pipe through a laser cutting machine; s2, pipe machining is conducted, specifically, an inverted trapezoidal groove is cut in the middle of the bevel edge of the first pipe through a laser cutting machine, a first rectangular groove is cut in the same side of the groove, an inverted trapezoidal protrusion is cut in the middle of the bevel edge of the second pipe, a second rectangular groove is cut in the same side of the protrusion, and rectangular protrusions are arranged on the two perpendicular sides of a third right-angle pipe correspondingly; the inverted trapezoidal groove and the inverted trapezoidal protrusion can be embedded, the first rectangular groove and the second rectangular groove can be embedded with the rectangular protrusion respectively, and the problems of poor welding and unattractive welding are solved through assembling, welding and the like.

Owner:SUZHOU DIHANG DEFENSE FACILITIES CO LTD

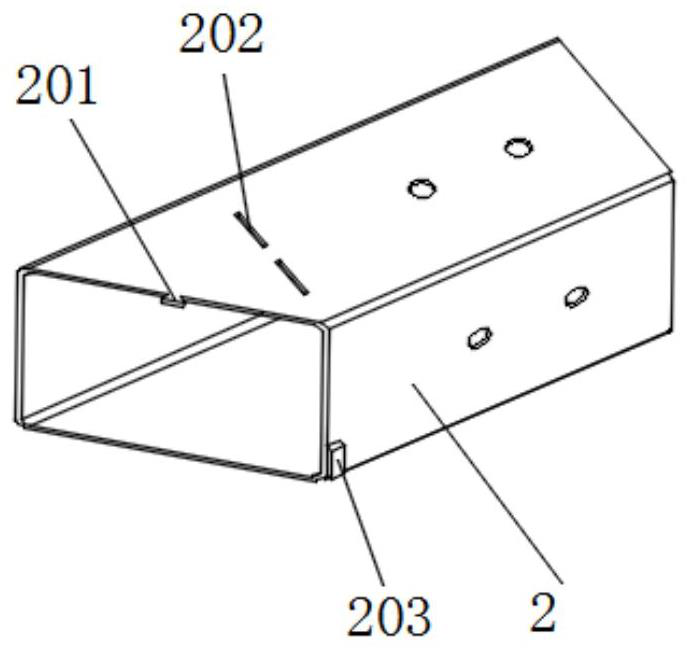

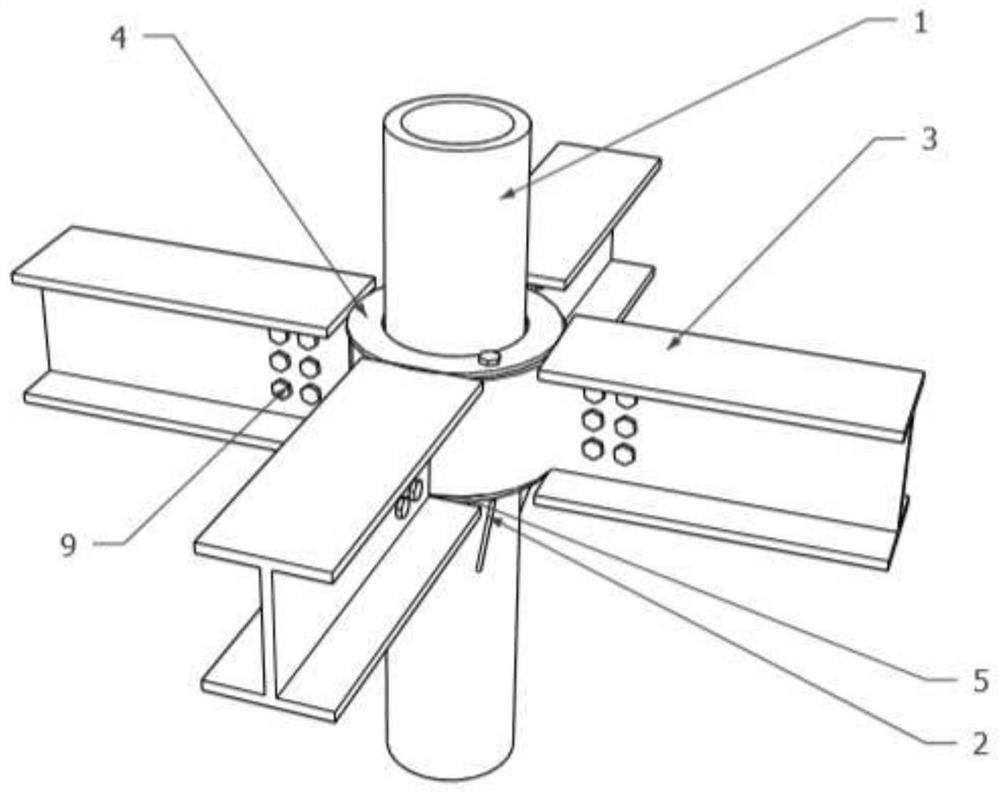

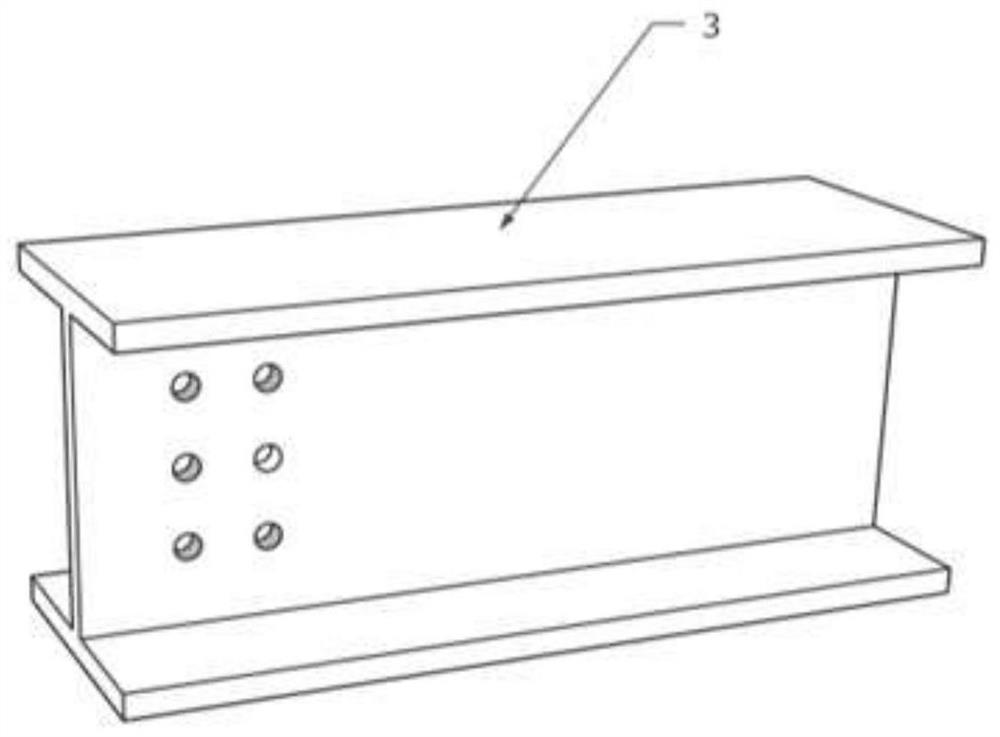

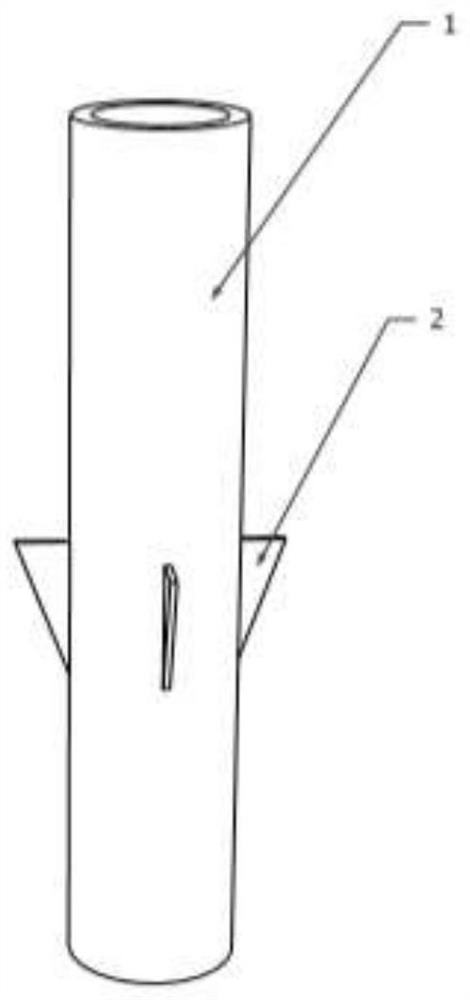

Assembly type circular steel pipe column joint connecting device and assembly method

PendingCN113668701ASolve the problem of poor weldingIncrease stiffnessBuilding constructionsSheet steelPipe

The invention discloses an assembly type circular steel pipe column joint connecting device and an assembly method. The assembly type circular steel pipe column joint connecting device comprises a steel pipe column, connecting pieces and steel beams, a plurality of steel beams are arranged on the outer side of the steel pipe column in an annular array mode, the steel beams and the steel pipe column are connected through the connecting pieces, and a plurality of outer ribs are arranged on the lower portion of the steel pipe column in the annular array mode; the connecting pieces are correspondingly installed at the tops of the outer ribs, each connecting piece comprises a steel body, a plurality of clamping grooves are formed in each steel body in the annular array mode, and steel plates are connected into the clamping grooves and connected with the steel beams. According to the assembly type circular steel pipe column joint connecting device and the assembly method, the problem that welding between an existing circular steel pipe column and a profile steel beam is poor can be solved, and the space occupancy rate is small; the rigidity and the bearing capacity of a joint are improved to a great extent by overlapping and sleeving the connecting pieces such as annular thin steel plates, and meanwhile, the joint also has better integrity and stability; the assembly type circular steel pipe column joint connecting device has more mobility in a bolt penetrating hole fixing mode, connection between materials is reinforced, and the assembly type circular steel pipe column joint connecting device further has the advantages of being convenient to mount and dismount, large in application range and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Lithium ion battery with positive electrode and negative electrode in same-side arrangement and manufacturing method thereof

PendingCN107195957ASolve Welding ProblemsHigh capacity densityFinal product manufactureElectrolyte accumulators manufactureEngineeringLithium-ion battery

The application discloses a lithium ion battery with a positive electrode and a negative electrode arranged at the same side and a manufacturing method thereof. The lithium ion battery comprises a shell with an opening structure at an upper end, a naked cell held in the shell and provided with lugs at the left side and the right side, and a shell cover arranged at the upper opening of the shell and provided with poles at the left side and the right side; one end of the pole extends into the shell, and a lug connecting seam corresponding to the lug is formed on the pole extending into the shell; the lug extends into the lug connecting seam on the pole, and the lug is connected with the pole through the friction-stir welding process; the shell cover and the shell are connected together through the friction-stir welding process. By using the lithium ion battery disclosed by the application, the battery production efficiency and yield are improved, the battery capacity and the energy density are improved, the welding quality and the battery rate discharge performance are promoted, and the equipment input cost in the battery production process is lowered.

Owner:GEESUN AUTOMATION TECH

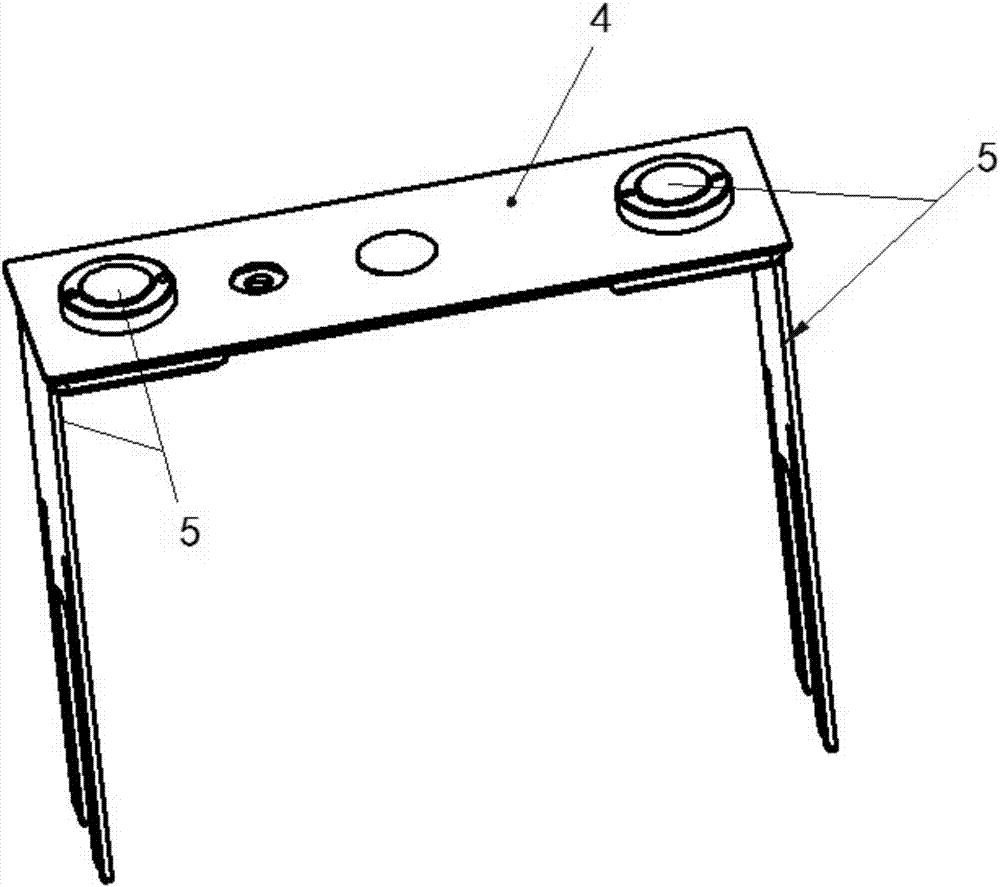

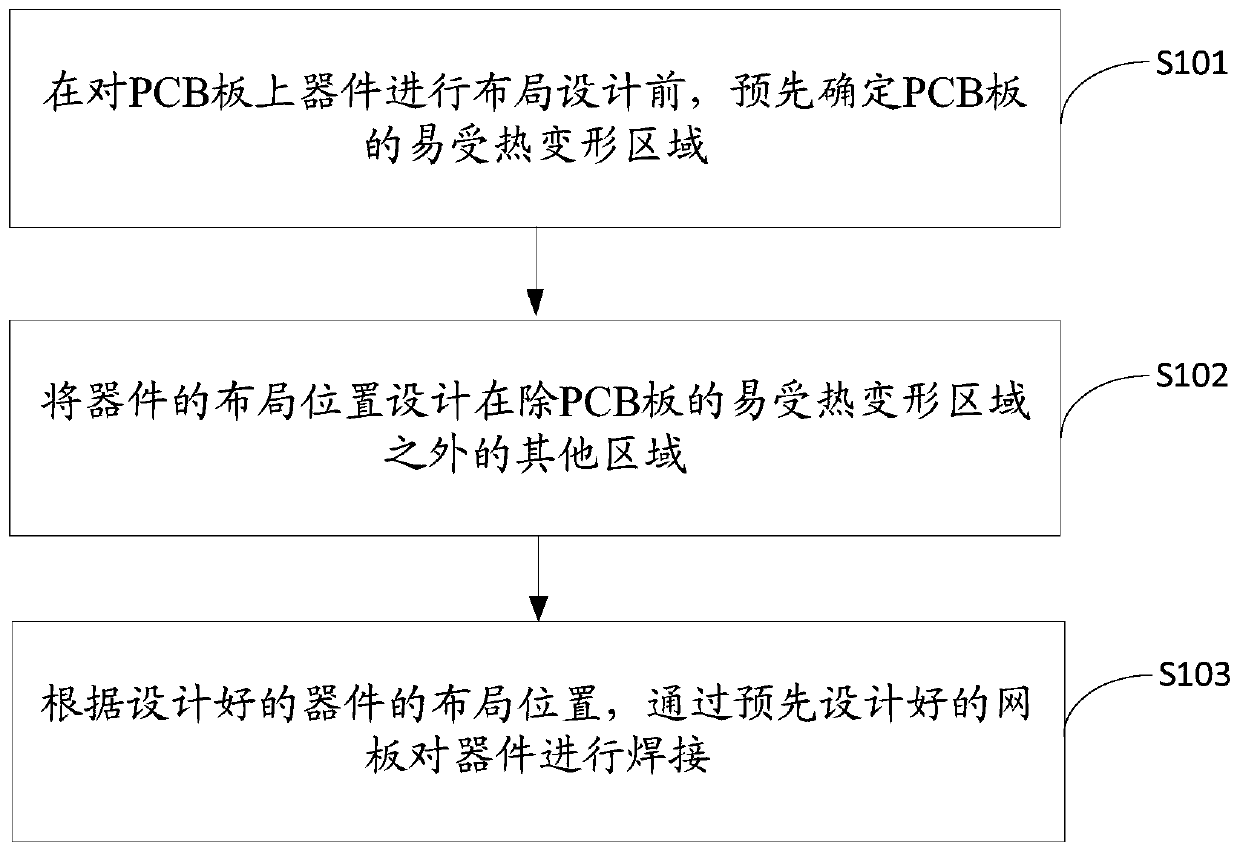

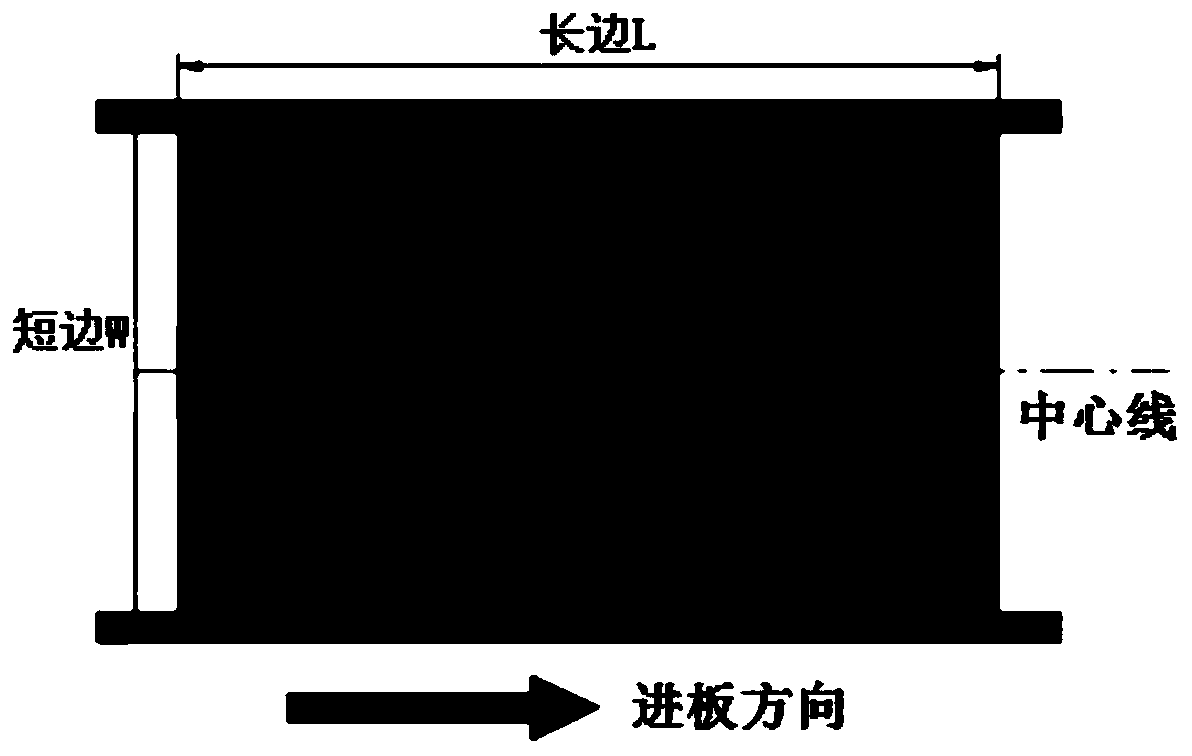

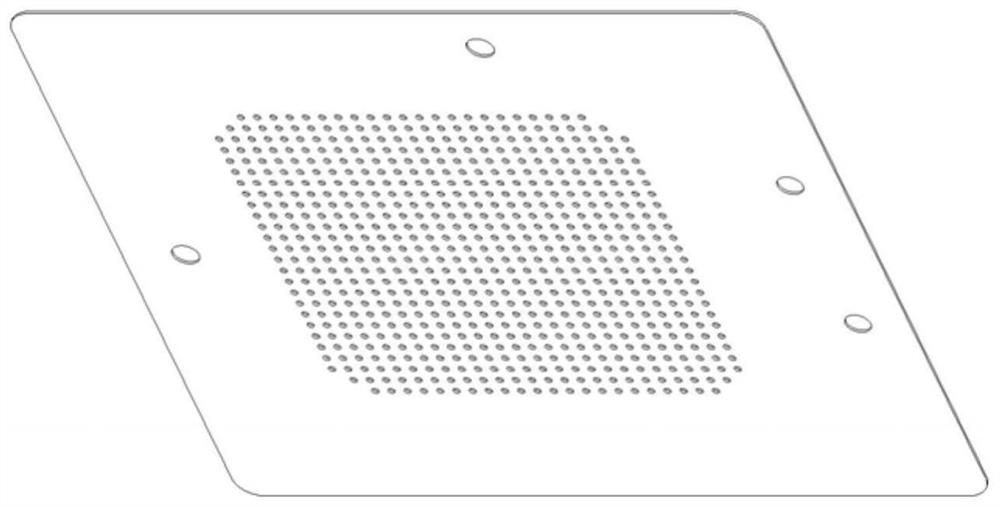

PCB device welding method and device

InactiveCN110933866ASolve the problem of poor weldingHigh outputPrinted circuit assemblingEconomic benefitsThermal deformation

The invention discloses a PCB device welding method and device, and the method comprises the steps of pre-determining an area easy to be heated and deformed, of a PCB before the layout design of the devices on the PCB; designing the layout positions of the devices in other areas except the area easy to be heated and deformed, of the PCB; and welding the devices through a pre-designed screen plateaccording to the designed layout positions of the devices. According to the present invention, firstly, by determining the area easy to be heated and deformed of the PCB before layout, keeping away the layout position of the devices from the area with the maximum deformation, and then welding after the reasonable layout is completed, so that the problem of poor device welding is effectively solved, and the maintenance cost, manpower cost and the like caused by the poor welding are effectively saved. the PCBA device welding method and device is suitable for all PCBA board cards with large device chips, a large number of cost resources can be saved, the yield of the good products is effectively enhanced, and therefore the productivity benefits and economic benefits are increased.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Battery connector for solving poor welding, and manufacturing method thereof

InactiveCN107172811AReduce heat gainGood tinning effectPrinted circuit assemblingLine/current collector detailsCopper platingEngineering

The invention discloses a battery connector for solving poor welding, and a manufacturing method thereof. The battery connector comprises a PCB, wherein copper foil is arranged between Pins and the PCB, the copper foil outside Pin jacks is line-shaped, one end of the line-shaped copper foil is in contact with each Pin, and the rest part of the copper foil is attached to and fixed on the PCB. The manufacturing method comprises the steps of: S1, drilling through holes / blind holes in the PCB, wherein part of the through holes serve as the Pin jacks; S2, plating copper to form in-hole copper foil; S3, plating copper to form outer-hole copper foil; S4, and inserting the Pins into the Pin jacks subjected to copper plating. According to the battery connector and the manufacturing method thereof, the area of the copper foil is reduced while other parts remain unchanged, and the original surface-type copper foil is changed into the line-shaped copper foil, thus the reduction of heat absorbed by the cooper foil in a welding region is realized, the tin soldering effect is improved, and the welding quality is ensured. That is, the large copper foil area in the welding region is reduced to decrease the heat absorbed by the cooper foil, the absorption ability of the copper foil is decreased when the area of the copper foil is reduced, and the heat dissipation of the Pins welded on the connector is slowed down, thereby achieving the effect of satisfying the tin soldering requirement.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

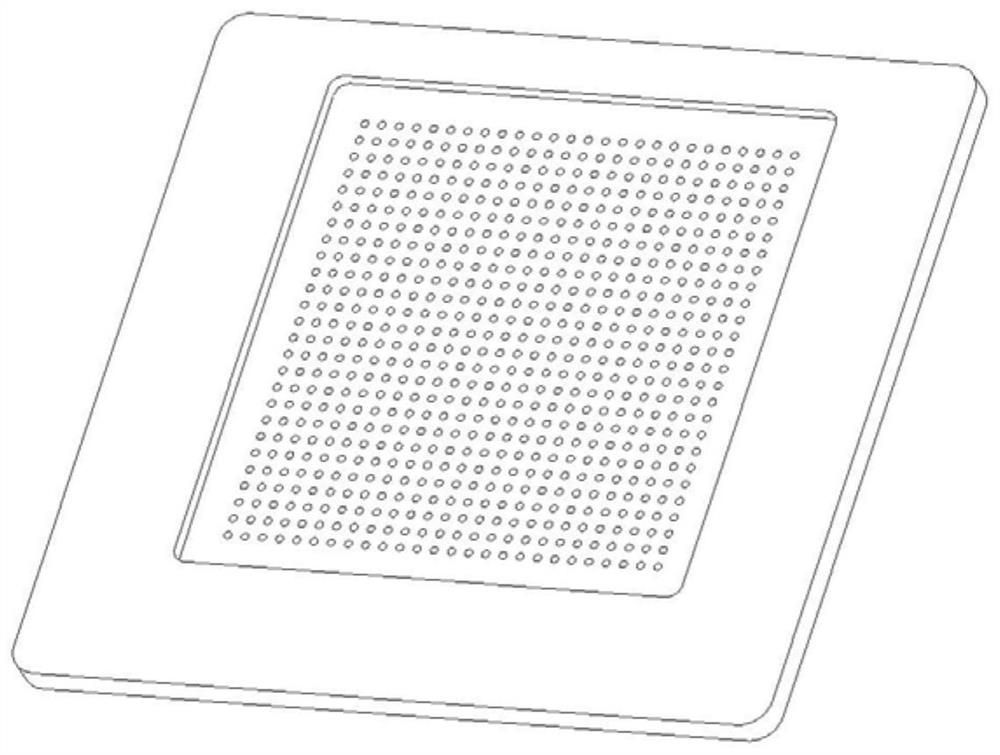

A kind of grid array device flatness detection tool and detection method

ActiveCN110940260BSolve the problem of poor weldingEasy to operateMechanical roughness/irregularity measurementsEngineeringSoldering

The invention relates to a grid array device flatness detection tool and a detection method, and belongs to the technical field of grid array device flatness detection. The method of the present invention determines the reference measurement size by sorting out the height of the welding terminal of the device, determines the measurement size according to the measurement requirements for flatness, and uses the superposition method to measure through the tooling. The measurement method is simple and easy to operate and effective in measurement In place, it can avoid damage to the lead legs of the device, and solve the problem of poor soldering caused by poor flatness of the soldered terminals of the device.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

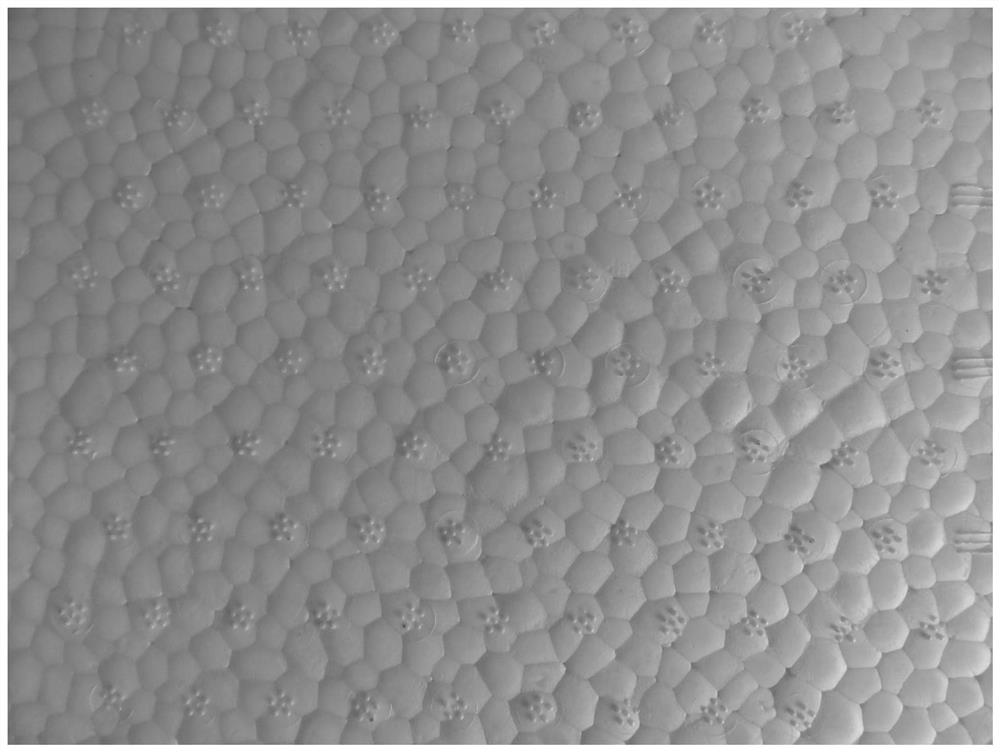

A polymer particle integrated foam molding process

The invention discloses an integrated foam molding process of polymer particles, which comprises the following steps: 1) preparing polymer particles coated with high melting point polymer resin by low melting point polymer resin; 2) foaming the polymer particles in one step Foam molding to obtain foamed products. The present invention prepares polymer particles with a core-shell structure coated with a low-melting-point high-molecular resin. During the foaming process, the foaming temperature is below the melting point of the core resin, so that the particle core can form foaming. Beads, and the foaming temperature is higher than the melting point of the shell resin, the surface is in a molten state, when the particles expand and squeeze each other, the shell resin in the molten state makes the particles weld together; at the same time, the particles are in the foaming process. In the fluidized state, all the particles have the same temperature to ensure that the particles will not be bonded in advance, and the internal welding is uniform when expansion occurs, so as to avoid filling defects.

Owner:SHINCELL NEW MATERIAL CO LTD

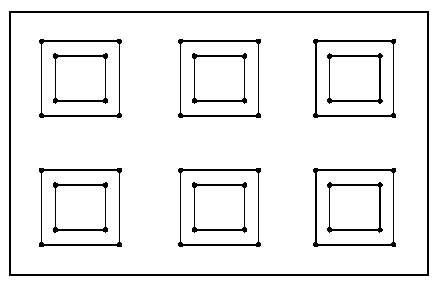

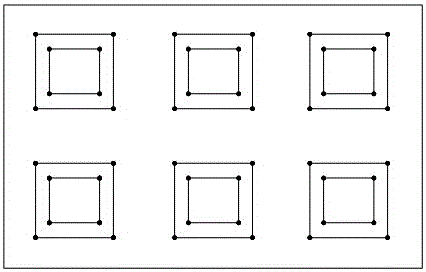

PCB packaging structure based on light-quality SMT component

ActiveCN104093267AReduce volumeReduce areaElectrical connection printed elementsPrinted circuit non-printed electric components associationSolder maskWindow opening

The invention discloses a PCB packaging structure based on a light-quality SMT component. The PCB packaging structure comprises a PCB substrate, at least two SMT solder mask layer windows which are straightened to be uniformly distributed on the PCB substrate and are provided with square pad windows, and an SMT pad which is arranged in the square pad window. The SMT pad is of a symmetrical octagon structure formed by connecting four equal long edges with four equal inclined edges in an end-to-end manner. The four long edges of the SMT pad are closely attached to the four edges of the square pad windows in one-to-one correspondence, the four inclined edges of the SMT pad are in one-to-one-correspondence with the four corners of the square pad window, the included angles between the inclined edges of the SMT pad and the long edges of the SMT pad are greater than 90 degrees, and the outer edges of the SMT solder mask layer windows have the same shape and arrangement modes as the SMT pad. The advantages are as follows: the structural design is reasonable, an electromagnetic radiation source can be effectively prevented from generating, and the problems of tin connection short circuits and insufficient welding or false welding are well solved.

Owner:深圳市磊科实业有限公司

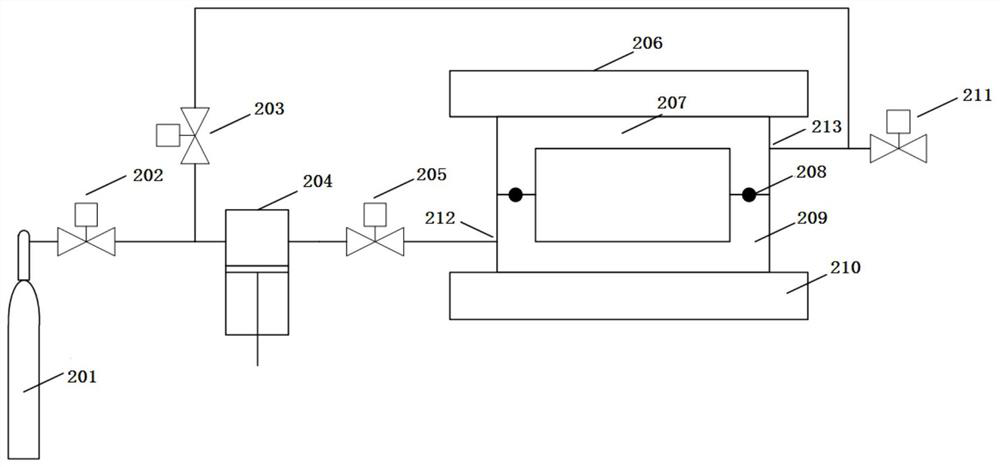

Diffusion welding method for molybdenum target material and back plate

PendingCN113275731AImprove solder joint rateSolve the problem of poor weldingNon-electric welding apparatusHot isostatic pressingAluminium alloy

The invention provides a diffusion welding method for a molybdenum target material and a back plate. The welding method comprises the following steps that turning end surface thread and step end surface thread treatment is performed on a welding surface of the molybdenum target material; step concave groove machining treatment is carried out on the back plate; ultrasonic cleaning and drying treatment is performed on the welding surface of the molybdenum target material; and the molybdenum target material and the back plate are assembled, and sheath welding, degassing and hot isostatic pressing welding are sequentially carried out. According to the method, the problem of poor welding of the molybdenum target material with the copper alloy back plate and the aluminum alloy back plate is solved, and the welding binding rate of the molybdenum target, the copper alloy back plate and the aluminum alloy back plate is increased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Connecting structure of lug and pole and connecting method

ActiveCN107195841ASolve Welding ProblemsIncrease productivityLine/current collector detailsCell component detailsEngineeringFriction stir welding

The application discloses a connecting structure of a lug and a pole, and a connecting method. The connecting structure comprises the lug and the pole, a lug connecting hole corresponding to the lug is formed on the pole; the lug extends into the pole connecting hole in the pole, and the lug is connected with the pole through a friction-stirring welding process. The connecting structure disclosed by the application improves the connecting quality and efficiency of the lug and the pole.

Owner:GEESUN AUTOMATION TECH

The connection structure and connection method of tabs and poles

ActiveCN107195841BSolve Welding ProblemsIncrease productivityLine/current collector detailsCell component detailsMechanical engineeringFriction stir welding

The application discloses a connecting structure of a lug and a pole, and a connecting method. The connecting structure comprises the lug and the pole, a lug connecting hole corresponding to the lug is formed on the pole; the lug extends into the pole connecting hole in the pole, and the lug is connected with the pole through a friction-stirring welding process. The connecting structure disclosed by the application improves the connecting quality and efficiency of the lug and the pole.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

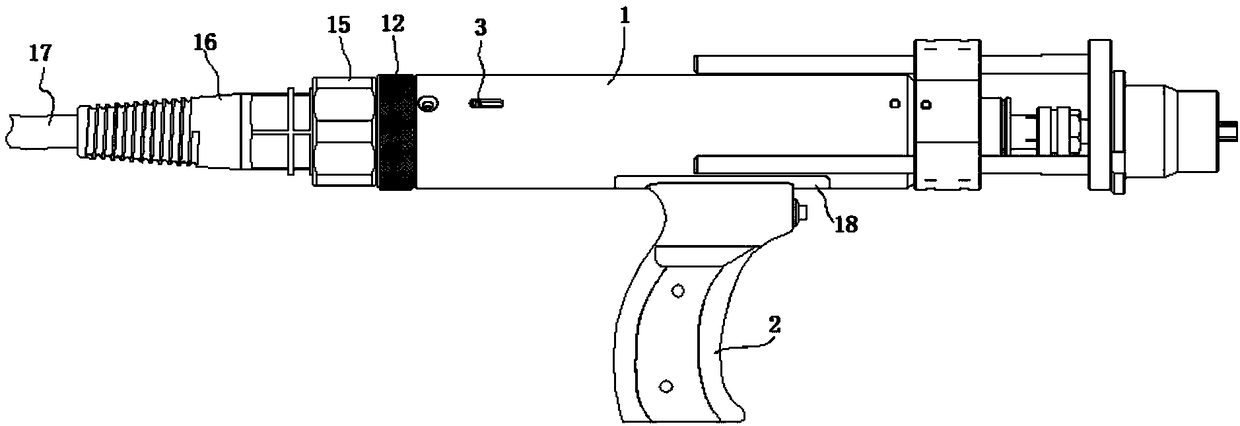

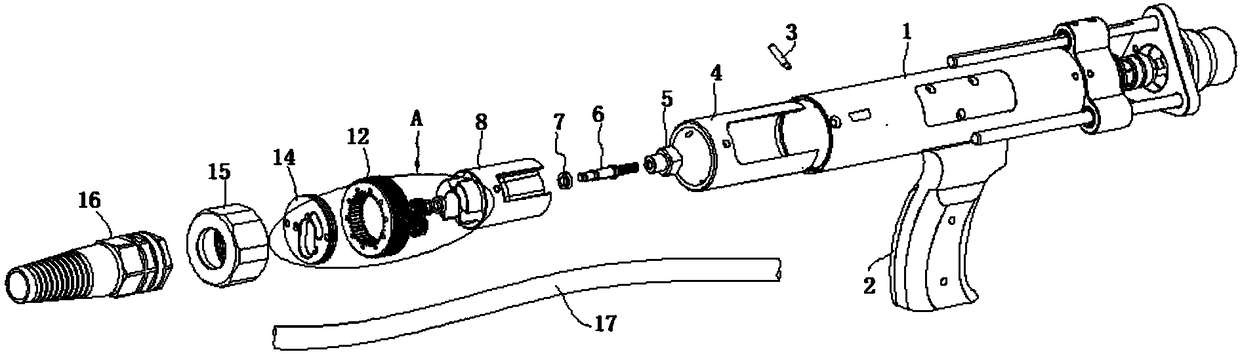

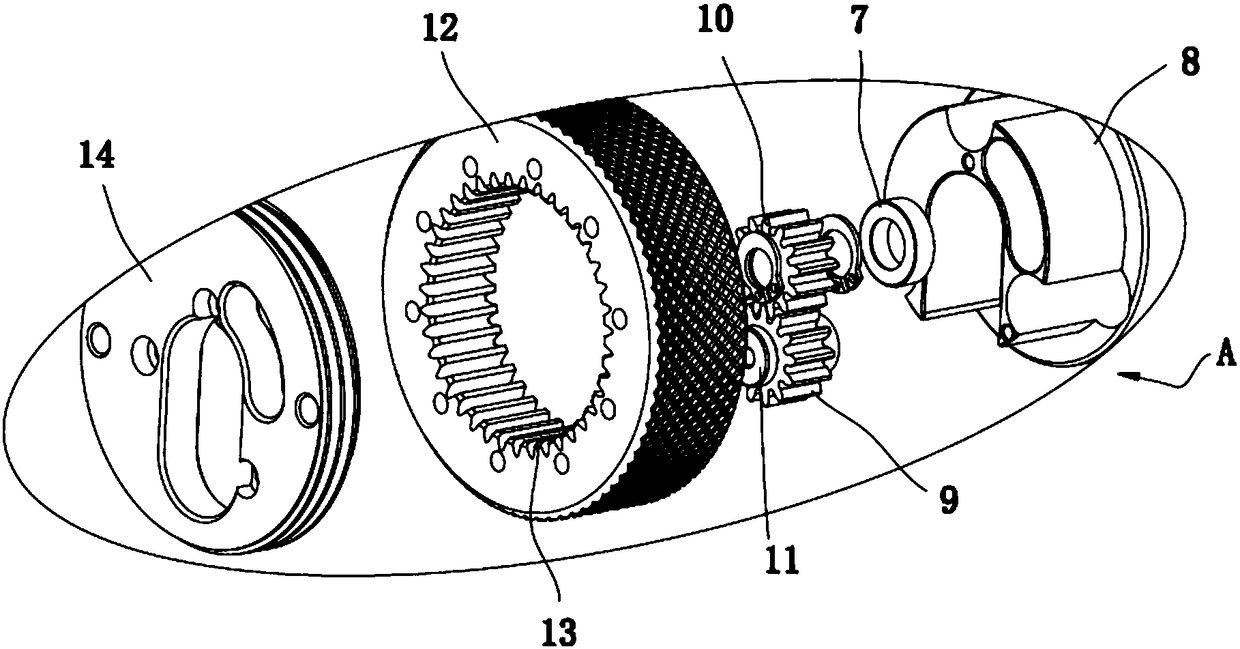

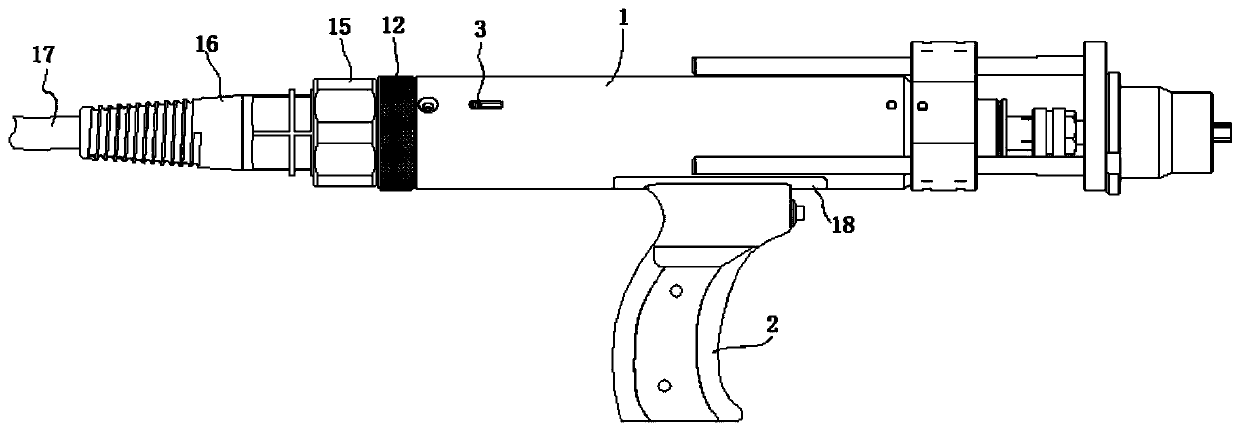

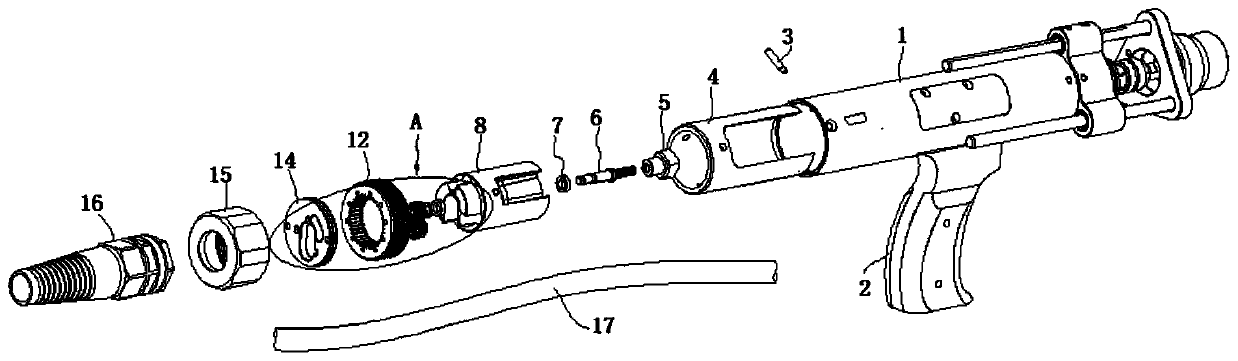

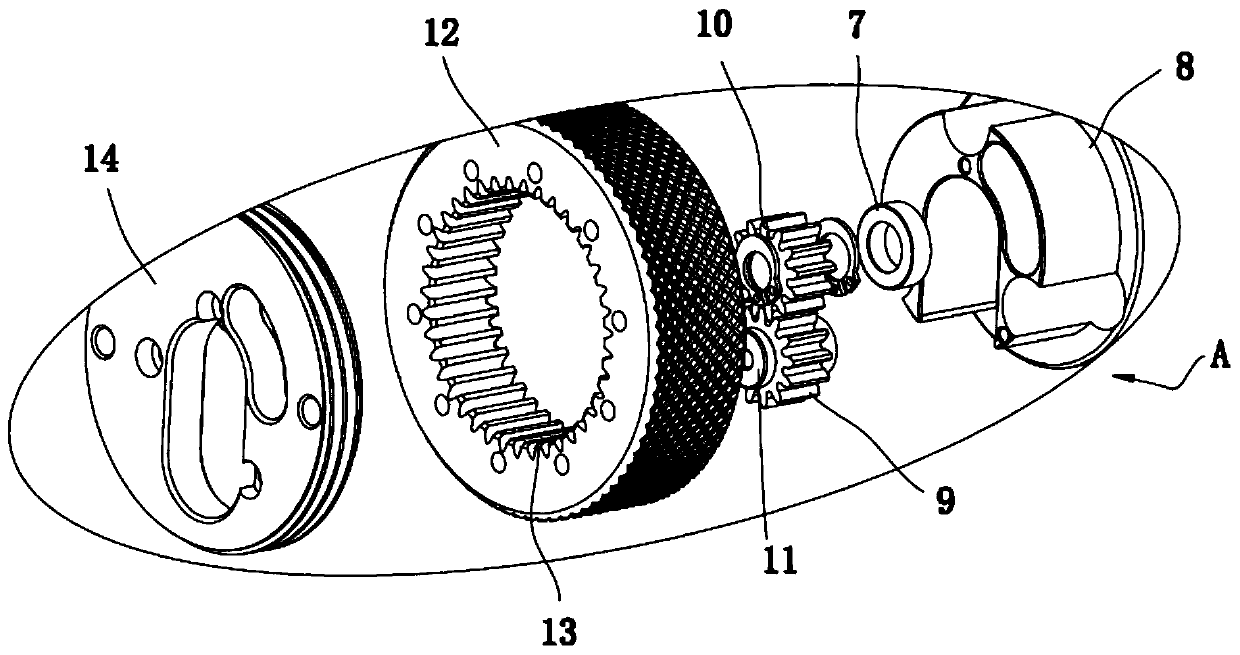

Tail line-out knob adjusting structure of draw-arc-type stud welding gun

ActiveCN108356398AEasy to adjustSmooth transmissionElectrode supporting devicesGear transmissionComing out

The invention discloses a tail line-out knob adjusting structure of a draw-arc-type stud welding gun. The tail line-out knob adjusting structure is arranged at the tail part of a welding gun main body. A power line is arranged at the tail part of the welding gun main body through the tail line-out knob adjusting structure. An inner gear is arranged in a knob. A transmission gear assembly meshes with the inner gear and a driven gear simultaneously. The driven gear is fixed to an adjusting screw rod. One end of the adjusting screw rod is movably mounted in an adjusting seat through two first bearings. The other end of the adjusting screw rod is mounted in a limiting seat through threads. According to the tail line-out knob adjusting structure, transmission is conducted by adopting the innergear, the transmission gear assembly and the driven gear, so that the adjusting screw rod is driven to rotate, the limiting seat is driven to move back and forth in the axial direction of the adjusting screw rod, and the function of adjusting the draw-arc distance is achieved; and because the tail line-out knob adjusting structure is a gear transmission system, the interior of the welding gun mainbody can have a large space for storing the power line, and the mode that the line only can come out from the bottom of a handle in the prior art is eliminated.

Owner:安徽华生机电集团有限公司

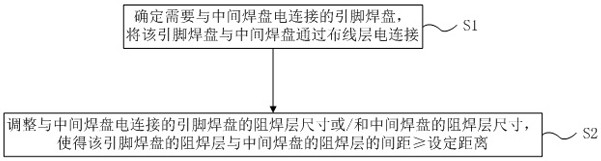

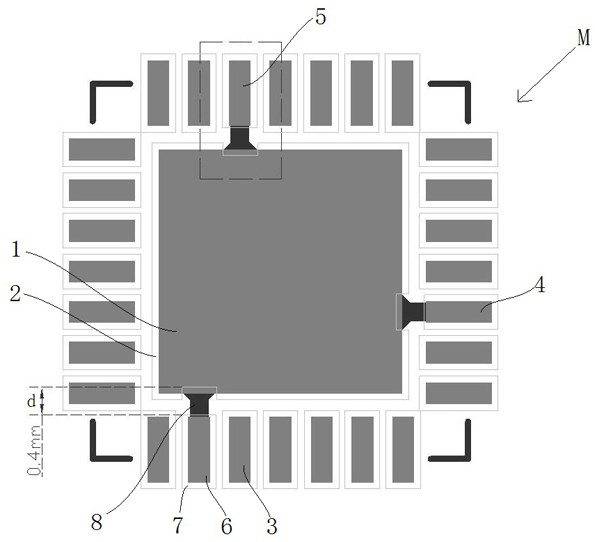

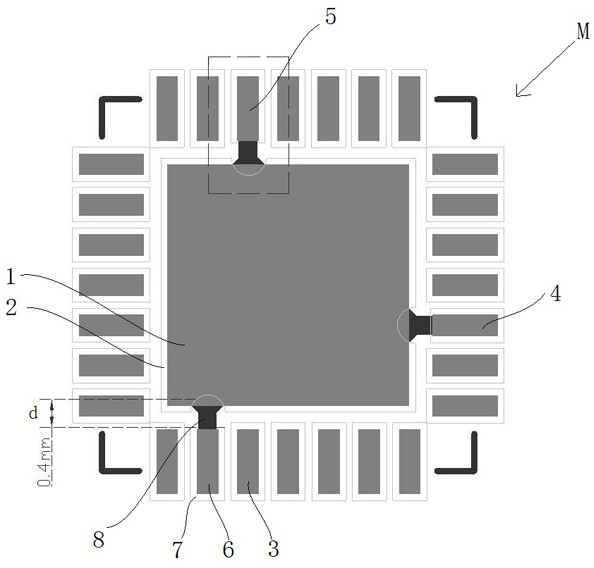

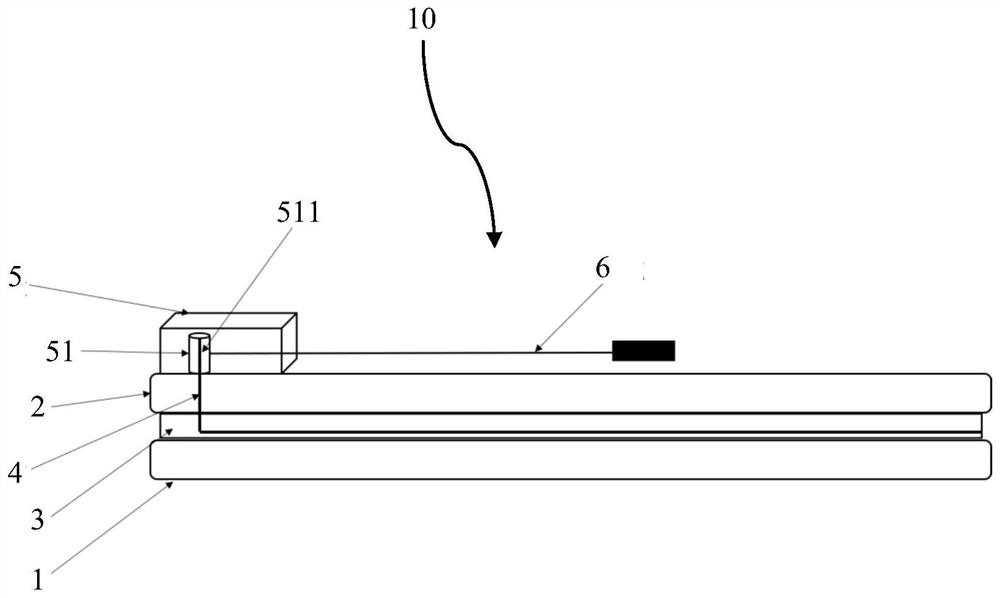

A kind of qfn chip pcb packaging method and pcb board

ActiveCN107613666BSolve the problem of poor weldingGuaranteed stabilityPrinted circuit assemblingSemiconductor/solid-state device detailsSolder maskMechanical engineering

The invention discloses a QFN chip PCB packaging method and a PCB board. The method includes: determining a pin pad that needs to be electrically connected to an intermediate pad, and electrically connecting the pin pad and the intermediate pad through a wiring layer; Adjust the size of the solder mask of the pin pad electrically connected to the middle pad or / and the size of the solder mask of the middle pad so that the distance between the solder mask of the pin pad and the solder mask of the middle pad ≥ Set the distance. The QFN chip PCB packaging method and the PCB board of the present invention solve the problem of poor soldering of the QFN chip in the reflow soldering process, ensure that the performance of the chip itself is not affected, ensure the stability of the chip work and the heat dissipation effect, and improve product reliability. Reduce the defective rate in the market; and the method is simple, easy to realize, without adding additional material costs, and low in cost.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

Solar cell double-glass assembly and assembling method thereof

ActiveCN112003563AAvoid efficiency lossAvoid lifePhotovoltaicsPhotovoltaic energy generationEngineeringBattery cell

The invention provides a solar cell double-glass assembly and an assembling method thereof. The solar cell double-glass assembly comprises front plate glass and back plate glass. A solar cell is packaged between the front plate glass and the back plate glass, and the solar cell is located on the back plate glass. The back plate glass is provided with a conductive bus bar connected with the solar cell, and the conductive bus bar passes through the back plate glass and is connected with a junction box. A wiring terminal connected with the conductive bus bar is arranged in the junction box, and the wiring terminal and the conductive bus bar are connected in a curable conductive fluid filling mode. According to the solar cell double-glass assembly and the assembling method thereof, the problems that the service life of the solar cell double-glass assembly is shortened even a fire disaster is caused and the efficiency of the solar cell is reduced due to overlarge series resistance in an existing bus bar connecting mode can be solved.

Owner:重庆神华薄膜太阳能科技有限公司

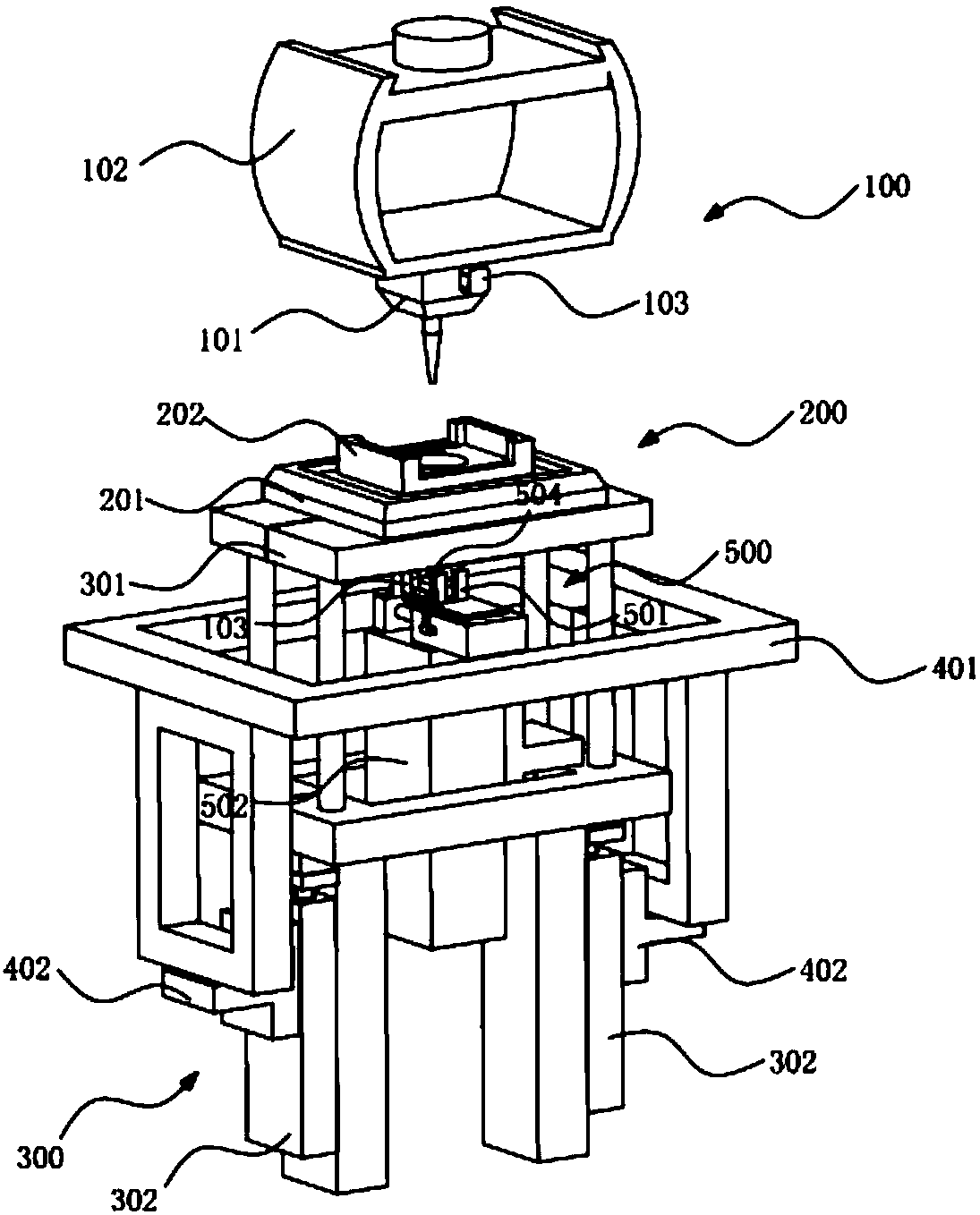

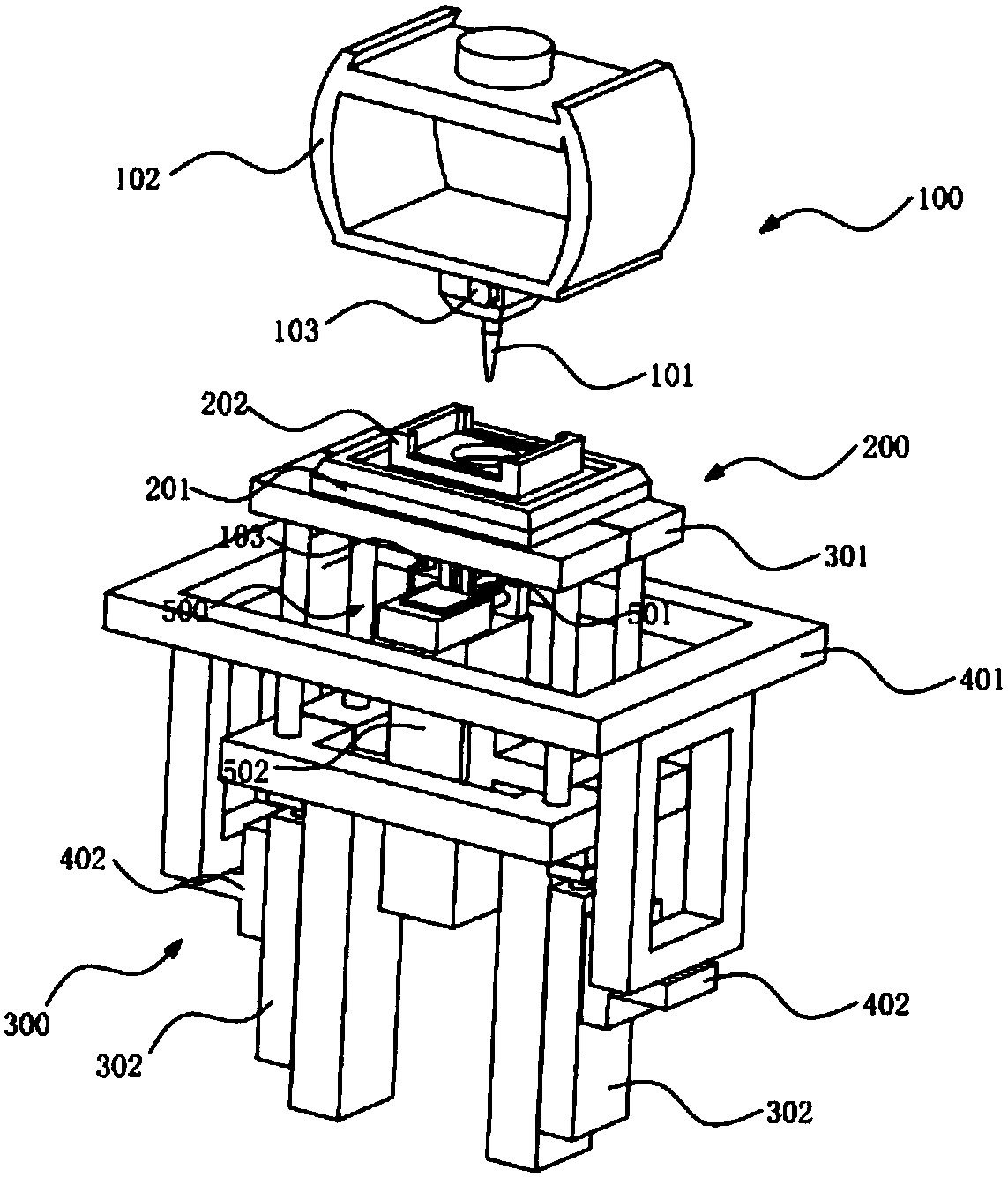

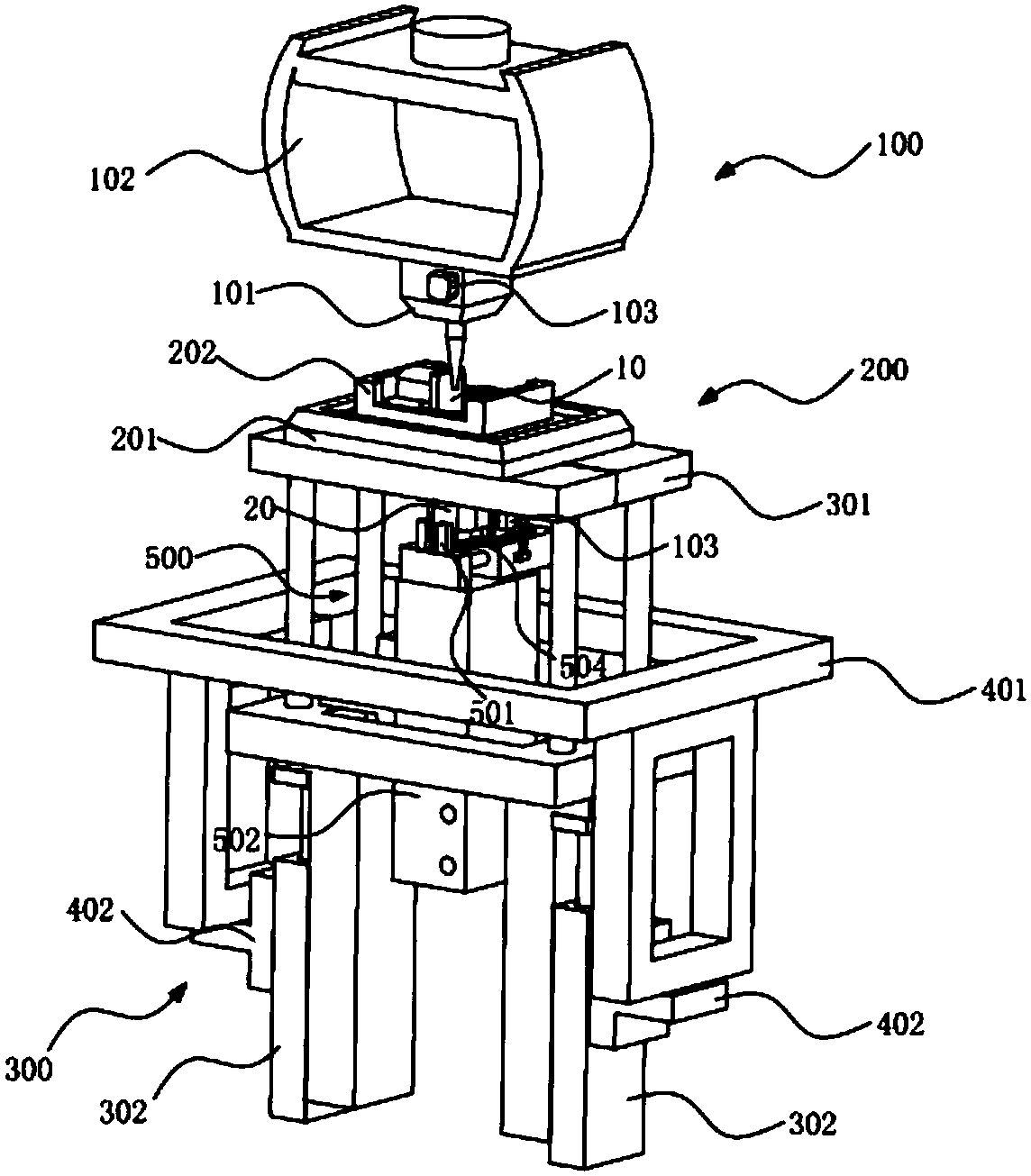

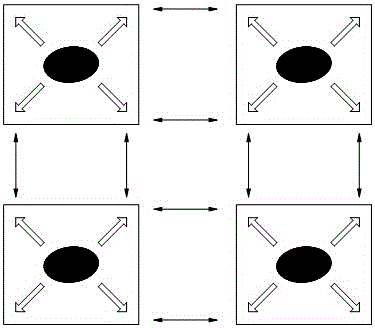

Device and method for detecting welding of automobile accessories

PendingCN108326485ASolve the problem of poor weldingResolve locationWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention discloses a device and a method for detecting welding of automobile accessories. The device comprises a welding structure, a jig structure, a jacking structure, a fixing frame, fixing blocks and a cooling structure; the jig structure is arranged at the lower end position of the welding structure; the jacking structure is arranged at the lower end position of the jig structure; the fixing frame is arranged on the outer side position of the jacking structure; the fixing blocks are arranged on the inner side position of the fixing frame, one ends of the fixing blocks are fixed to the fixing frame, and the other ends of the fixing blocks are fixed to the jacking structure; and the cooling structure is arranged at the lower end of the jig structure and the inner position of the jacking structure. According to the device and the method, a temperature sensor is arranged between the welding structure and the jig structure, a pressure sensor and the temperature sensor are arrangedon cooling tongs, so that the situation that product welding is poor or the welding position is shifted due to the fact that the welding temperature is too high and the pressure of the cooling tongsis too large in the welding combination technology process is effectively avoided.

Owner:斯沃博达汽车电子(昆山)有限公司

Welding fixture and welding method

ActiveCN101585104BSolve the problem of poor weldingSoldering apparatusWelding/soldering/cutting articlesEngineeringTin

The invention provides a welding device and a welding method. The welding device is used for welding a first circuit board and a second circuit board which are oppositely mounted. The first circuit board is provided with welding holes; the second circuit board, near one side of the circuit board, is provide with welding points corresponding to the welding holes, and the welding points are provided with soldering tins; the welding device comprises an soldering iron and a heating device. The soldering iron is used for dipping the first soldering tin to the welding holes; the heating device isinstalled on one side of the first circuit board which is far from and corresponding to the second circuit board.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

A Knob Adjustment Structure for Outlet Wires at the Tail of a Drawn-Arc Stud Welding Torch

ActiveCN108356398BIdeal adjustment limit actionEasy to adjustElectrode supporting devicesGear driveGear wheel

Owner:安徽华生机电集团有限公司

PCB packaging structure based on light-weight miniature smt components

ActiveCN104093267BReduce volumeReduce areaElectrical connection printed elementsPrinted circuit non-printed electric components associationSolder maskEngineering

The invention discloses a PCB packaging structure based on a light-quality SMT component. The PCB packaging structure comprises a PCB substrate, at least two SMT solder mask layer windows which are straightened to be uniformly distributed on the PCB substrate and are provided with square pad windows, and an SMT pad which is arranged in the square pad window. The SMT pad is of a symmetrical octagon structure formed by connecting four equal long edges with four equal inclined edges in an end-to-end manner. The four long edges of the SMT pad are closely attached to the four edges of the square pad windows in one-to-one correspondence, the four inclined edges of the SMT pad are in one-to-one-correspondence with the four corners of the square pad window, the included angles between the inclined edges of the SMT pad and the long edges of the SMT pad are greater than 90 degrees, and the outer edges of the SMT solder mask layer windows have the same shape and arrangement modes as the SMT pad. The advantages are as follows: the structural design is reasonable, an electromagnetic radiation source can be effectively prevented from generating, and the problems of tin connection short circuits and insufficient welding or false welding are well solved.

Owner:深圳市磊科实业有限公司

Flexible circuit board assembly and assembling method thereof

ActiveCN102769994BAchieve mutual positioningSolve the problem of poor weldingPrinted circuit assemblingPrinted circuits structural associationsFlexible circuitsEngineering

Owner:AU OPTRONICS (XIAMEN) CORP +1

Metal base plate used for welding power module

ActiveCN102832179BImprove temperature uniformityAvoid offsetSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention relates to a metal base plate used for welding a power module, which comprises a plate body, wherein more then four spacing protrusions for spacing the outer periphery of a welding flux layer are arranged on the front face of the plate body, a groove is arranged on the bottom of the plate body, and the groove is filled with a heat conducting silicon grease. In the invention, the metal base plate is improved, so that the metal base plate has reasonable structure, the welding flux layer can be conveniently positioned, the welding reliability is increased, so that the metal base plate has the characteristic of good heat conductivity and can maintain the consistent heat conductivity of the power module and prolong the service life of the power module.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

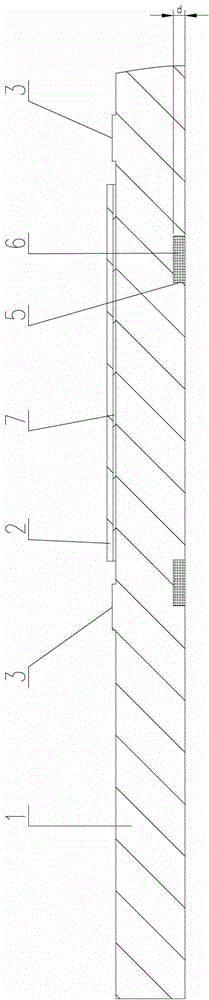

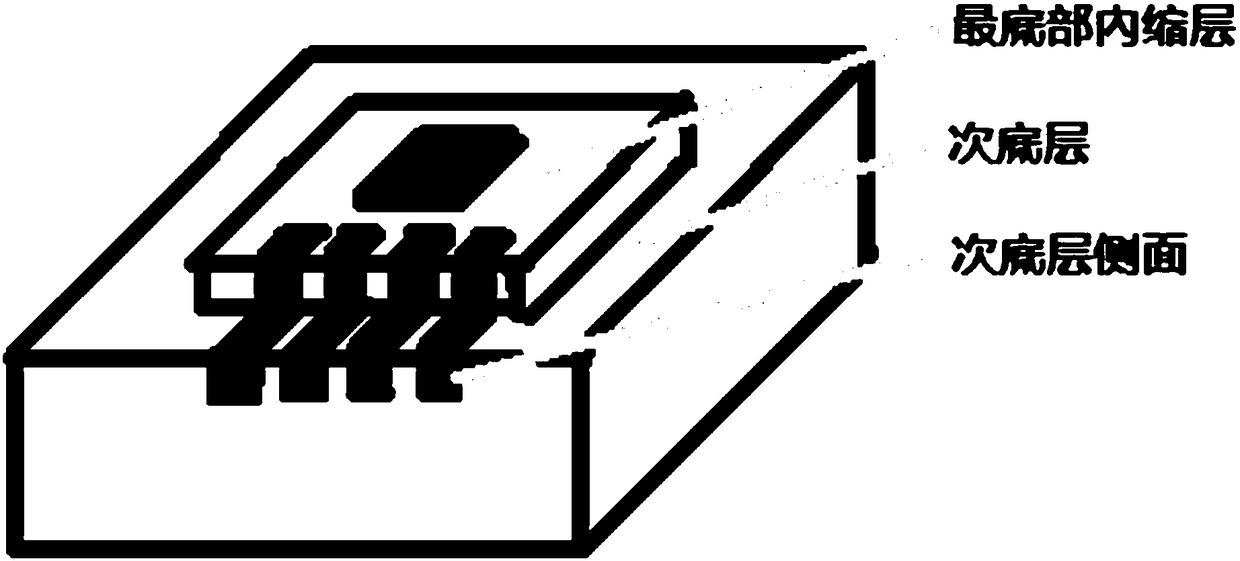

Method for enhancing welding effect of QFN package and QFN package

InactiveCN108257878AIncrease contentQuality improvementSemiconductor/solid-state device detailsSolid-state devicesHeight differenceTin

The invention provides a method for enhancing the welding effect of a QFN (Quad Flat No-lead) package and a QFN package. An inward structure layer is formed at the bottom of the QFN package, and the very bottom is slightly smaller than the normal package size. A height difference is formed between the bottom structure layer and the sub-bottom layer in order to form a tin climbing channel. During welding, the bottom structure layer is welded with tin, and tin can climb to the sub-bottom and the side of the sub-bottom in order to increase the welding area and tin content and enhance the qualityof parts welding of the QFN package. The problem of poor welding due to the fact that the pins of QFN package parts are all at the bottom is solved. The welding quality and reliability of QFN packageparts are ensured. Therefore, the stability and safety of products are ensured.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com