Patents

Literature

67results about How to "Facilitate subsequent welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of super-thick alloy steel plate

ActiveCN103692166AShorten welding timeAvoid Crack SensitivityWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyWelding joint

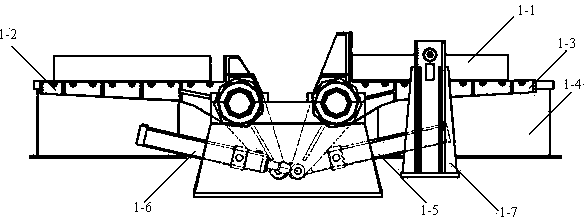

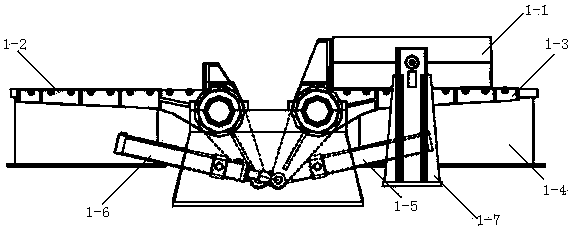

The invention belongs to the technical field of metallurgy and particularly relates to a preparation method of a super-thick alloy steel plate. The preparation method comprises steps that surface treatment is performed on two alloy steel continuous casting slabs matched in length and width dimension; the alloy steel continuous casting slabs are overlapped on a steel feeding swing arm of a tilting gear and align to each other; the alloy steel continuous casting slabs are fed into a vacuum chamber and welded through a structure with two electronic guns; when carbon equivalent of the continuous casting slabs to be compounded is smaller than 0.3%, a front electronic gun begins to perform welding from ends of the alloy steel continuous casting slabs, and a rear electronic gun begins to perform welding from middles of the alloy steel continuous casting slabs; when carbon equivalent of the continuous casting slabs to be compounded is higher than or equal to 0.3%, the distance between the two electronic guns is shortened, an electron beam of the front electronic gun is regulated into a defocusing mode, the front electronic gun preheats welding joints, and the rear electronic gun performs welding soon afterwards; heating rolling is performed on the welded slabs to obtain the super-thick alloy steel plate. By means of the technical scheme, compound interfaces between the continuous casting slabs to be compounded completely align, and yield of the super-thick alloy steel plate is increased.

Owner:沈阳科安捷材料技术有限公司

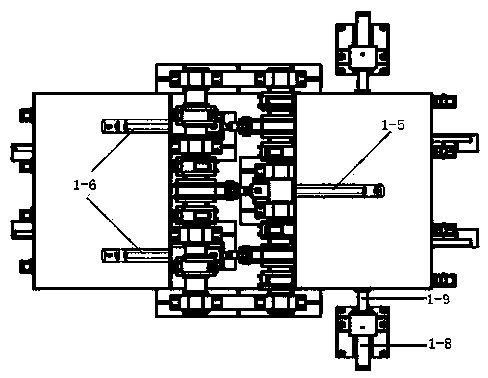

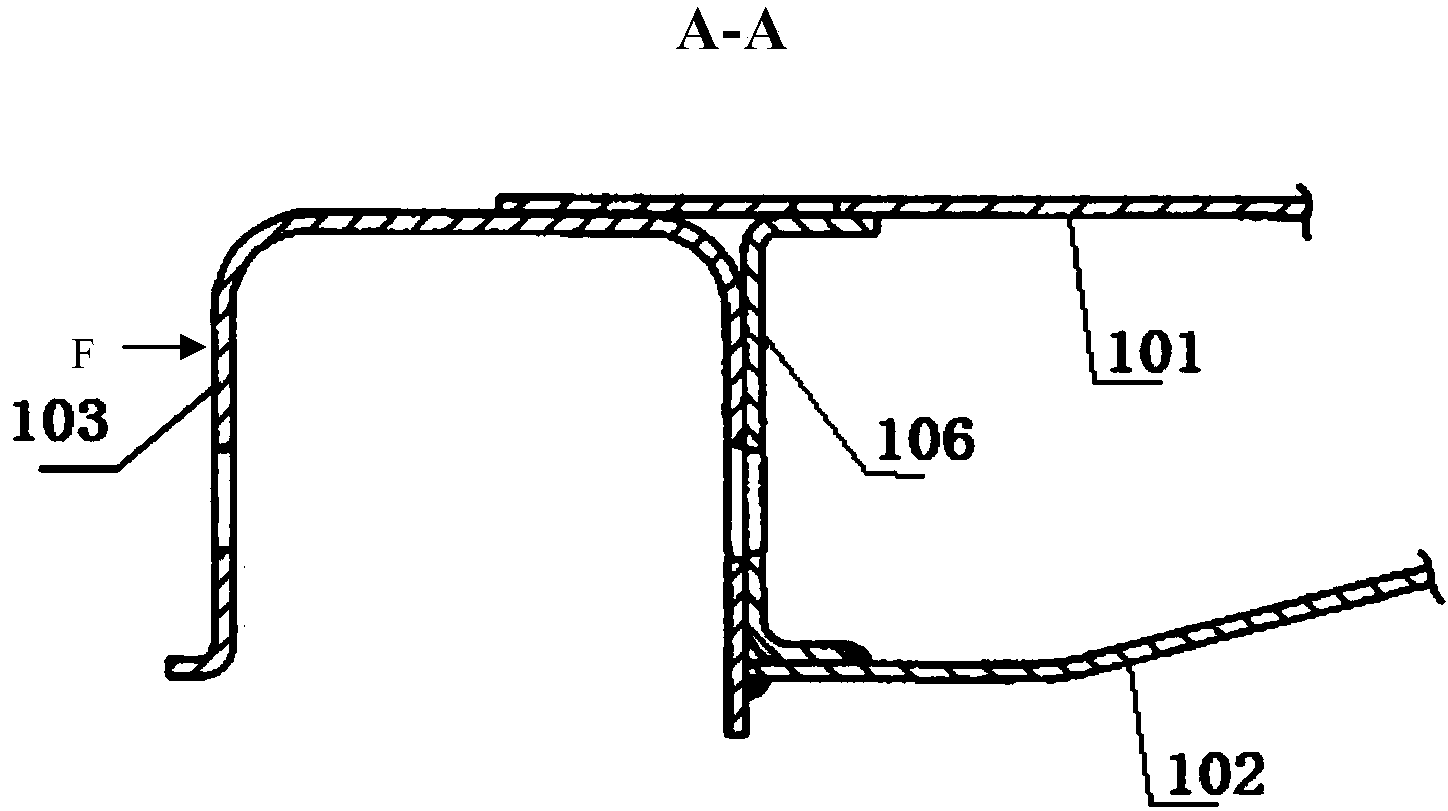

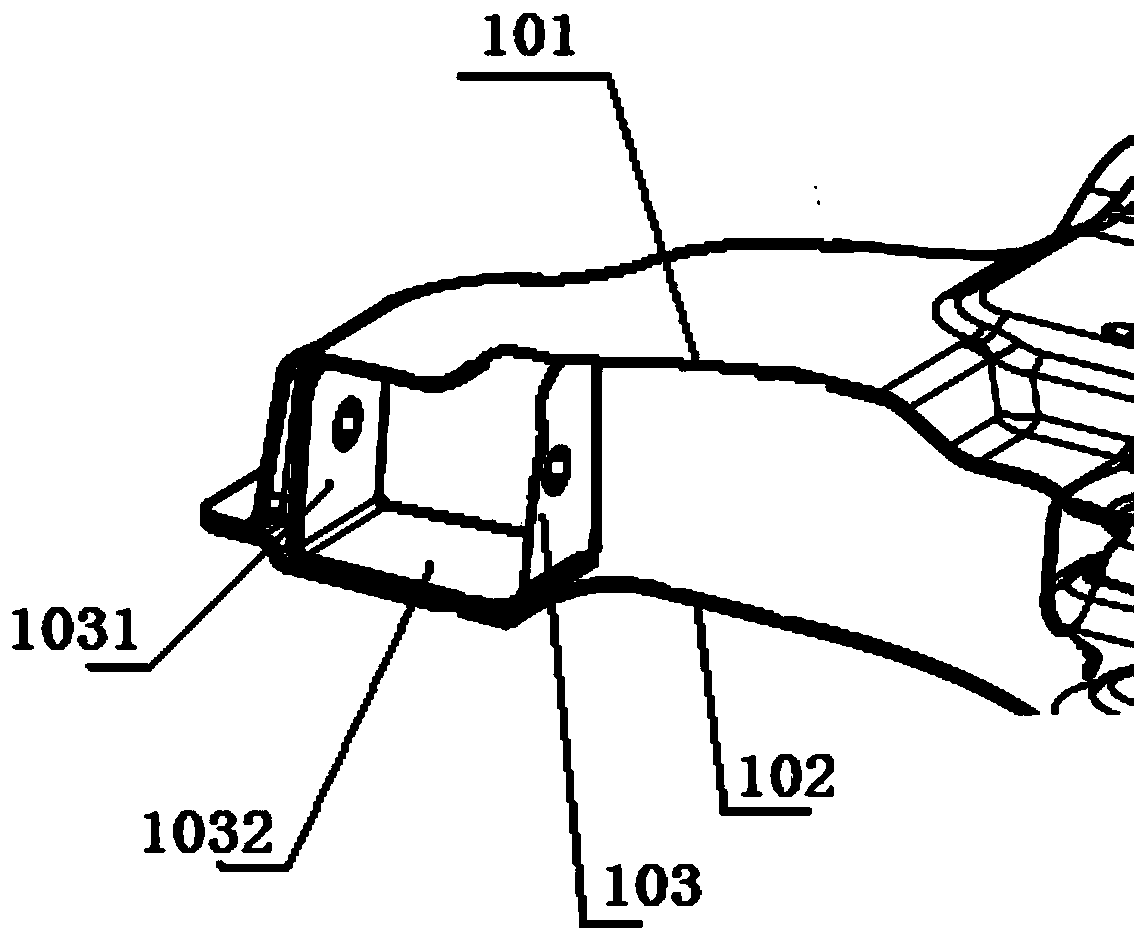

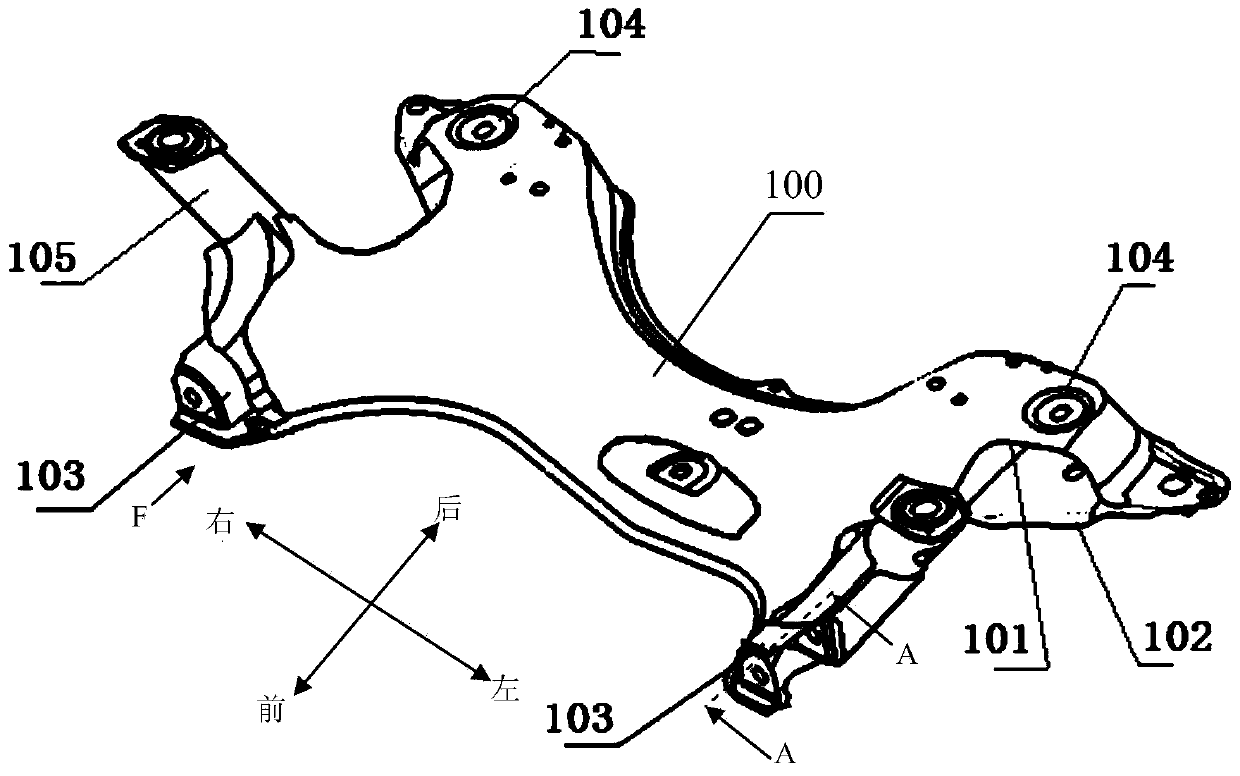

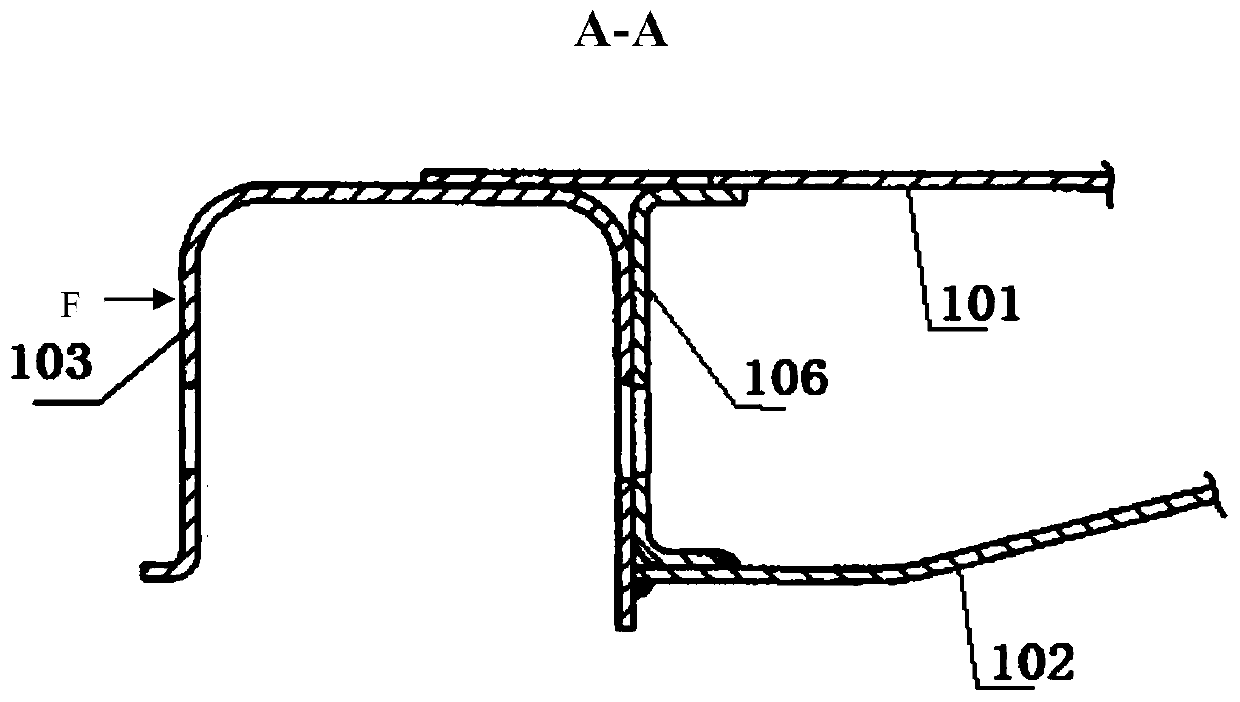

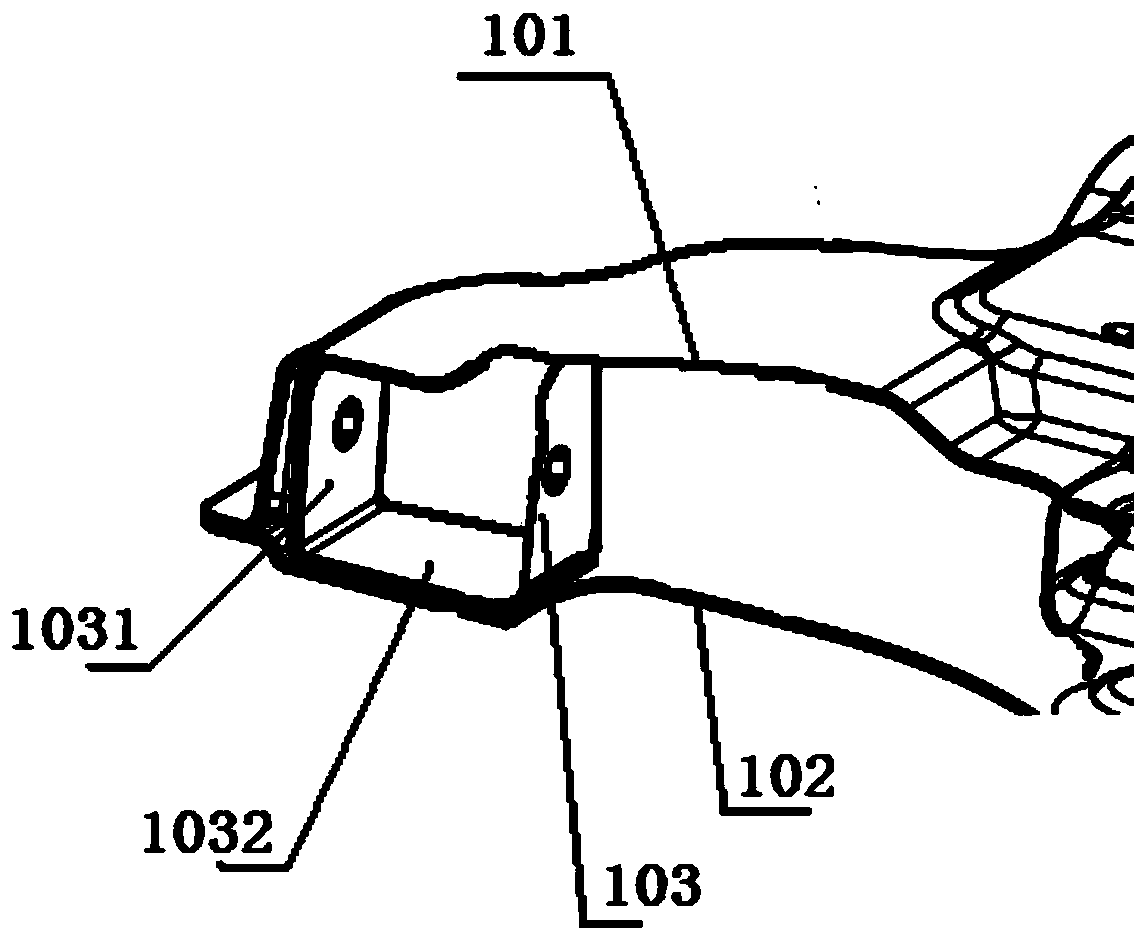

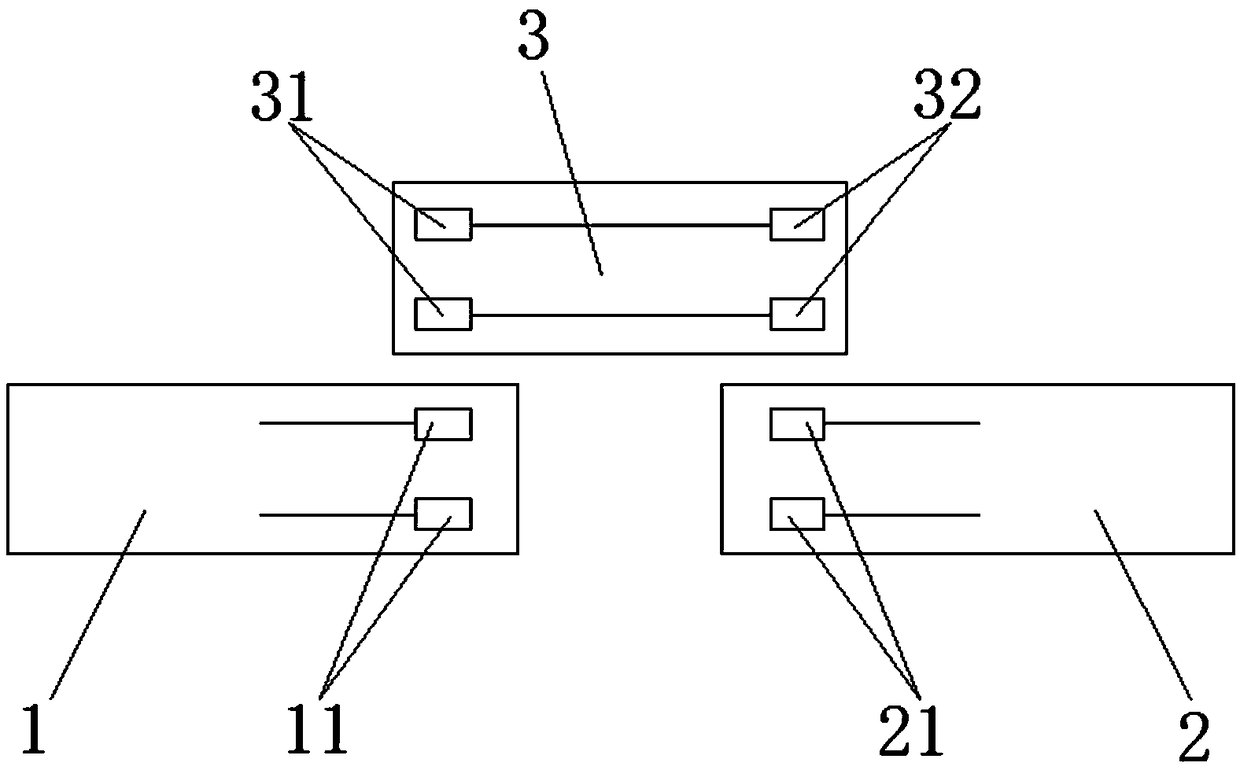

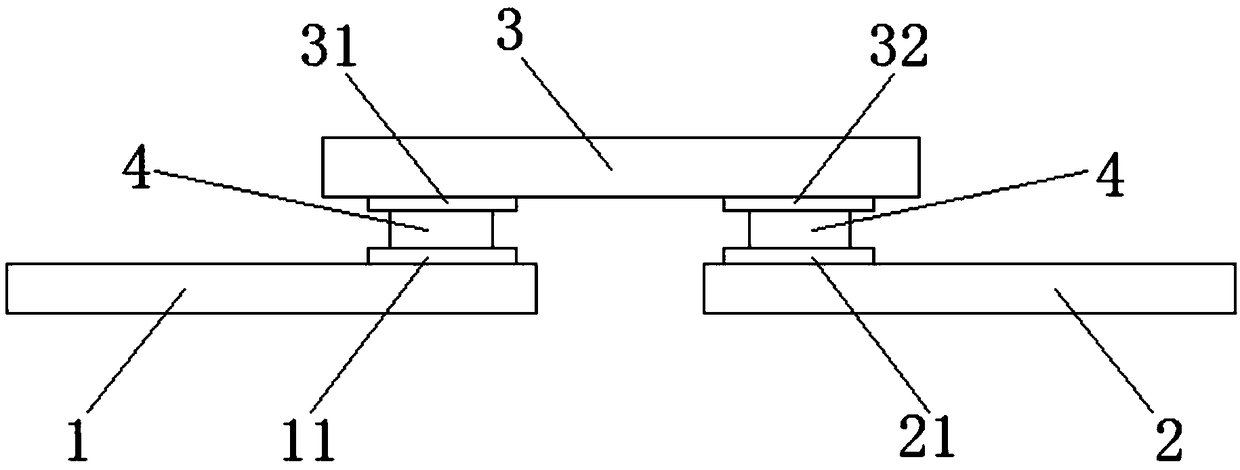

Front auxiliary frame

ActiveCN103832473ATroubleshoot Connection Strength IssuesImprove the strength of forceUnderstructuresPunchingVehicle frame

The invention provides a front auxiliary frame. The front auxiliary frame comprises a front auxiliary frame body and a front side component. The front auxiliary frame body comprises an upper plate and a lower plate, the upper plate and the lower plate are connected together, and a front mounting support of a lower suspension arm and a rear mounting portion of the lower suspension arm are arranged between the upper plate and the lower plate. The front side component is used for connecting the front auxiliary frame body onto a vehicular body. The front side component and the front mounting support are integrally formed by punching, and the front side wall of the front mounting support is connectedly welded to the upper plate or the lower plate while the bottom wall is connectedly welded to the lower plate to form a front-rear double-layer reinforcement structure and an upper-lower double-layer reinforcement structure. A cushion plate is welded between two side walls of the front side component, and the cushion plate and an upper end cover of the front side component jointly clamp a sleeve. The front auxiliary frame has the advantages of high strength, convenience in welding and high positioning precision.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

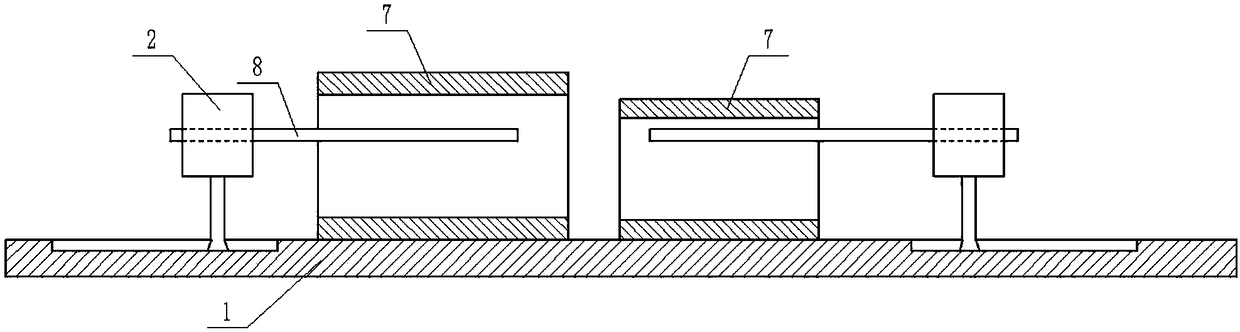

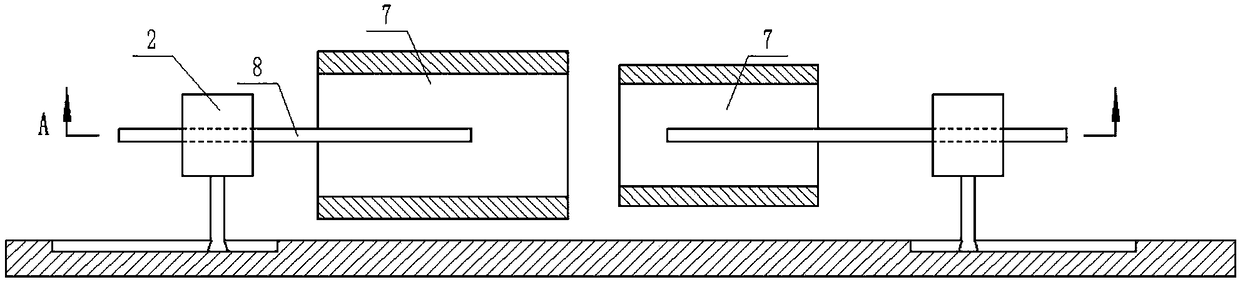

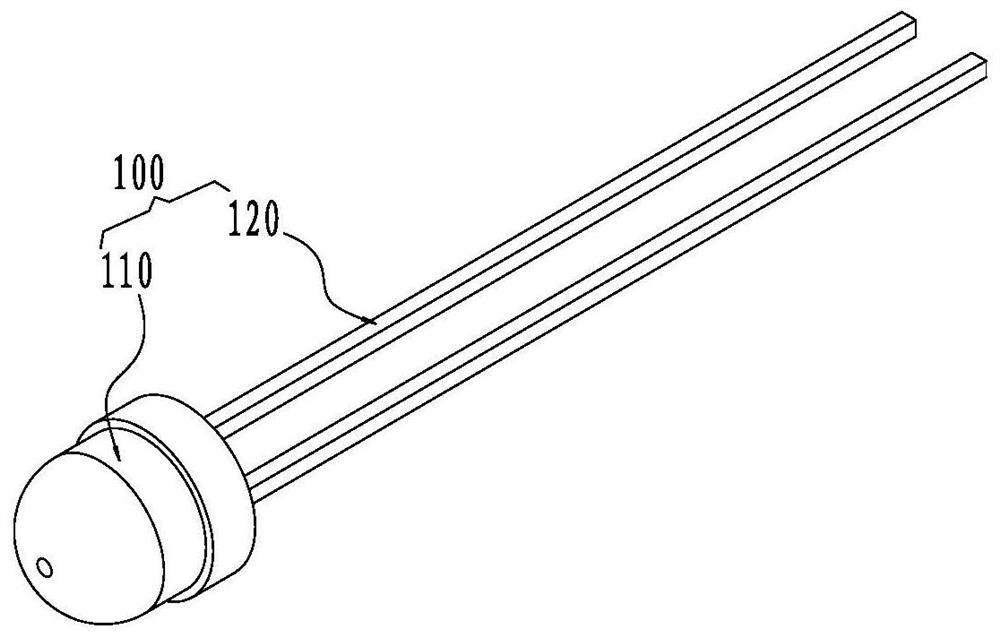

Welding fixing device for automobile pipe

InactiveCN108213828ASolve the problem of difficult alignmentEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to the technical field of welding, in particular to a welding fixing device for an automobile pipe. The welding fixing device for the automobile pipe comprises a machining table.Two box bodies are symmetrically arranged on two sides of the machining table separately and connected to the surface of the machining table in a sliding mode. Two parallel conveying belts are further arranged on the machining table and located between the two box bodies. The box bodies are provided with sliding holes. The sides, facing the conveying belts, of the box bodies are provided with fixing mechanisms. Each fixing mechanism comprises two positioning rods which are located at the same height and are parallel to each other, wherein the two positioning rods are the same in length, and one ends of the positioning rods are fixedly connected with the corresponding box body. The problem that alignment of pipes with different pipe diameters is difficult is solved.

Owner:NINGBO HAIMAN AUTOMOTIVE TECH CO LTD

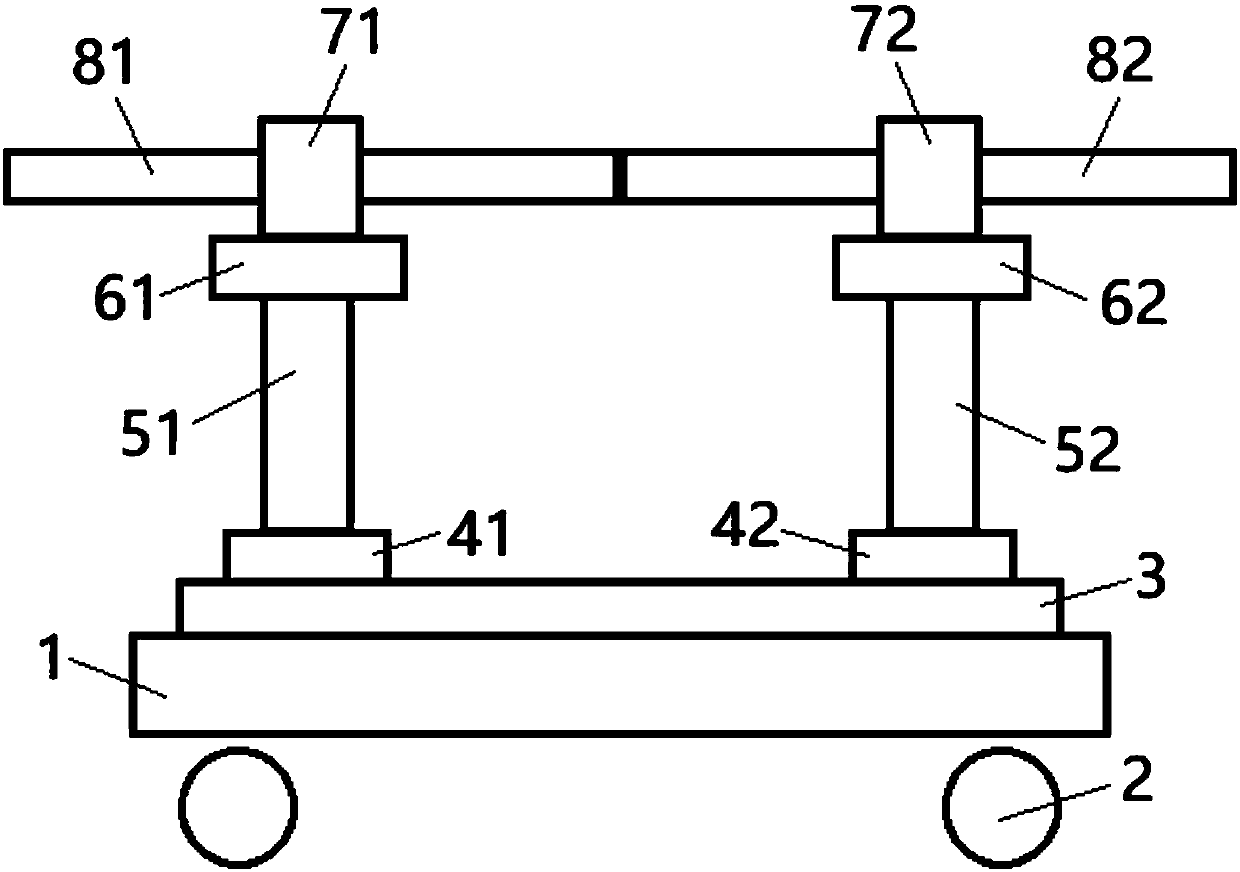

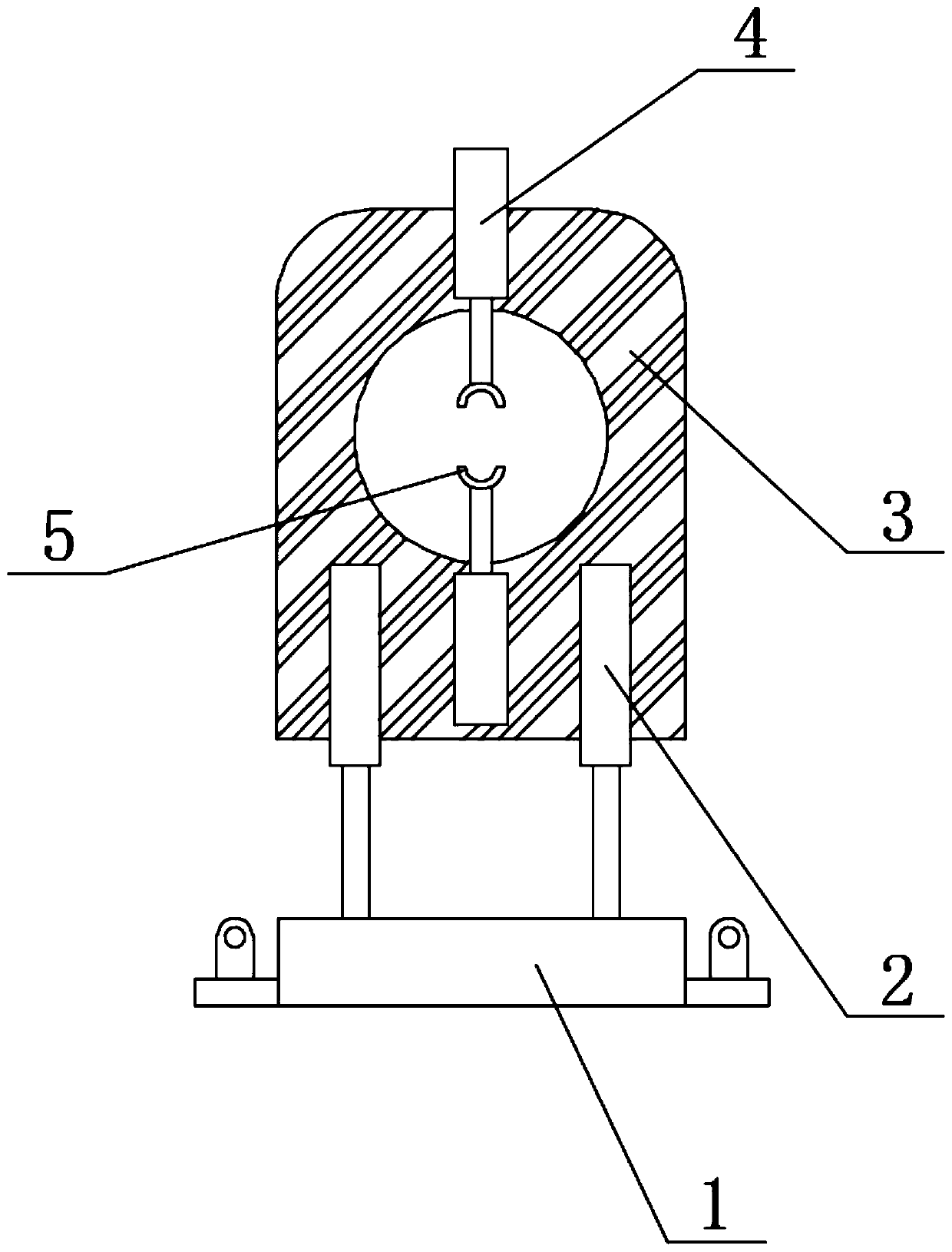

Titanium tube welding tool

PendingCN107695608AFacilitate subsequent weldingEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention discloses a titanium tube welding tool, which is used for welding a pair of titanium tubes. The pair of titanium tubes comprise a first titanium tube and a second titanium tube; the toolcomprises a frame, wherein universal wheels are arranged at four corners of the bottom surface of the frame, and each universal wheel is provided with a locking mechanism; a horizontal sliding rail is arranged on the top surface of the frame, and a first sliding seat and a second sliding seat are arranged on the sliding rail; a first vertical lifting support is arranged on the first sliding seat,and a second vertical lifting support is arranged on the second sliding seat; a first rotating table is arranged at the top end of the first lifting support, and a second rotating table is arranged at the top end of the second lifting support; and the first rotating table is provided with a first tube clamp used for fixing the first titanium tube, and the second rotating table is provided with asecond tube clamp used for fixing the second titanium tube. According to the titanium tube welding tool, the pair of titanium tubes can be welded conveniently.

Owner:CHANGSHU OUDI PIPE IND CO LTD

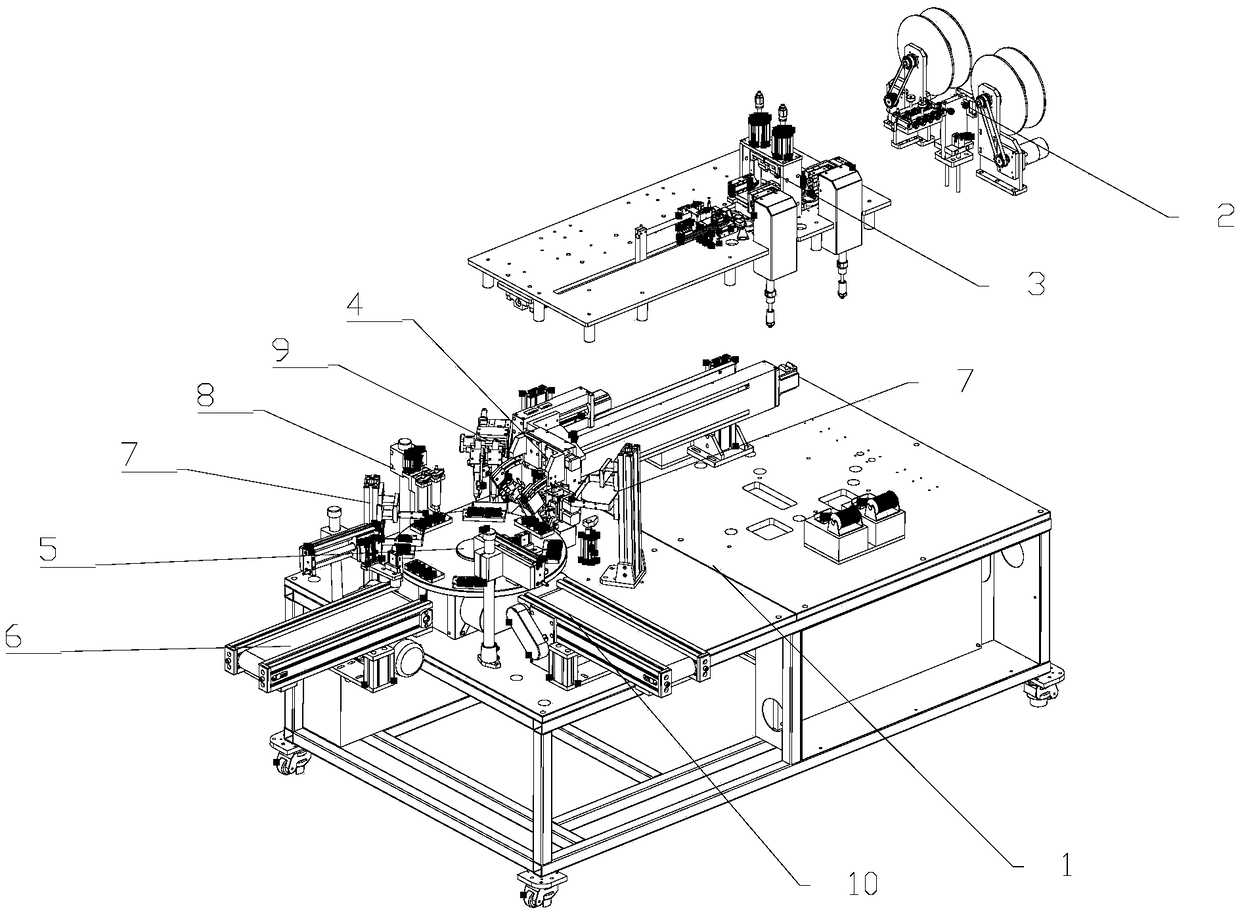

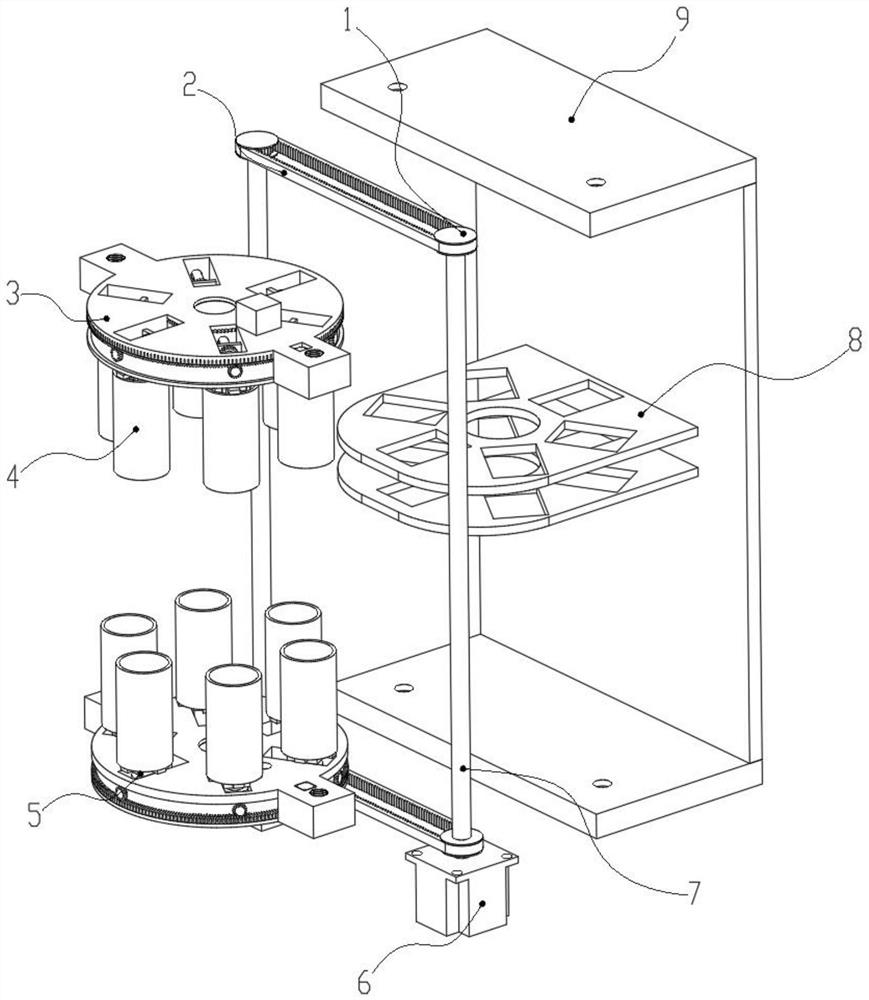

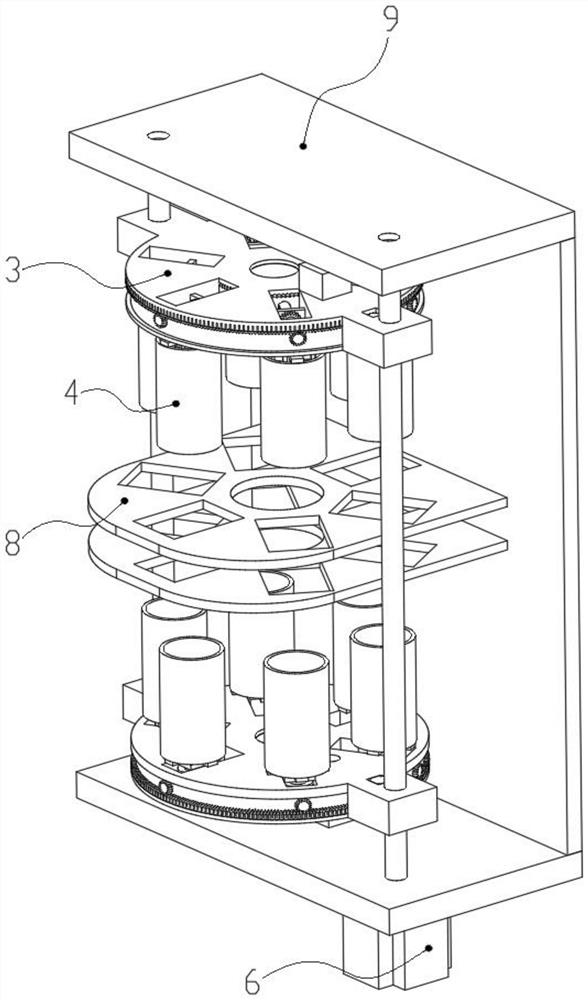

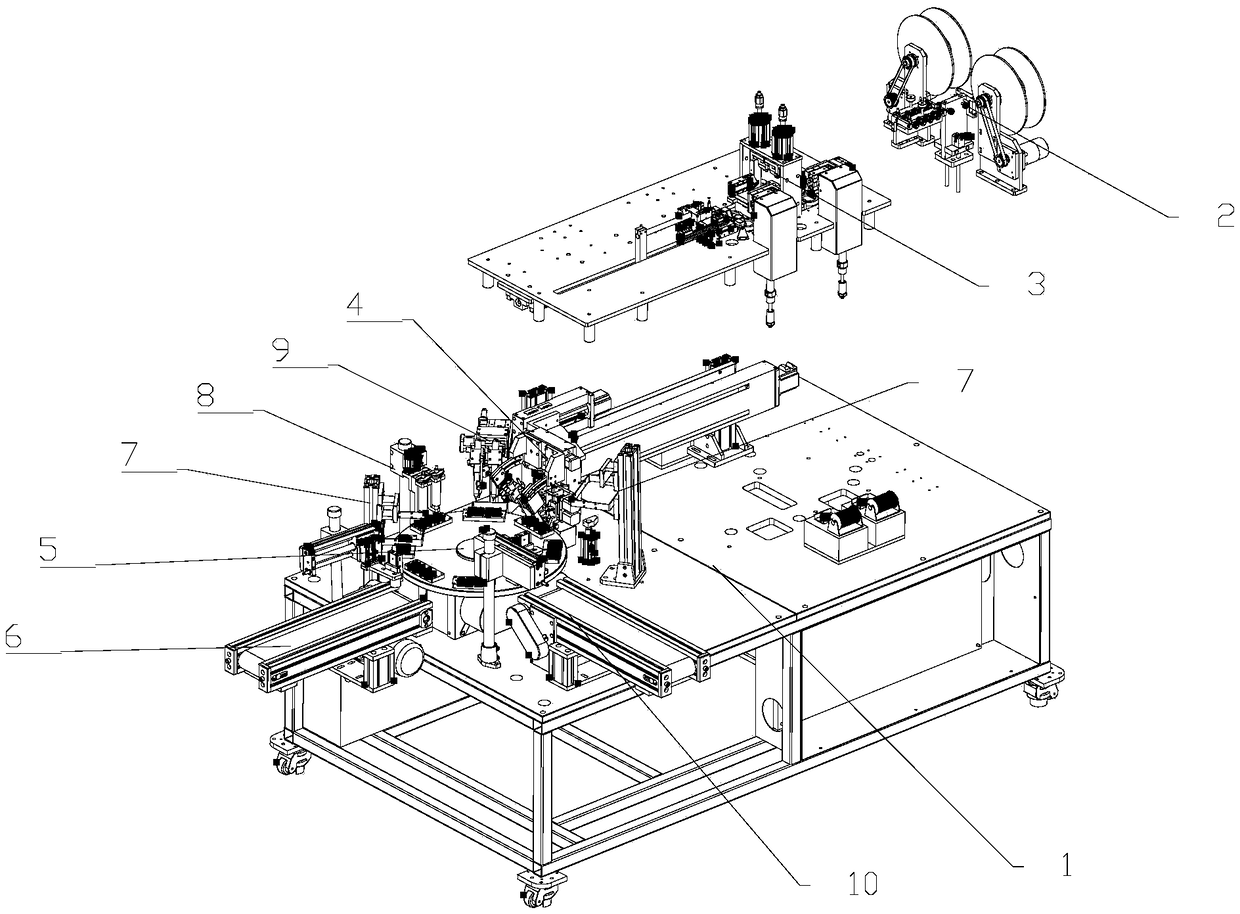

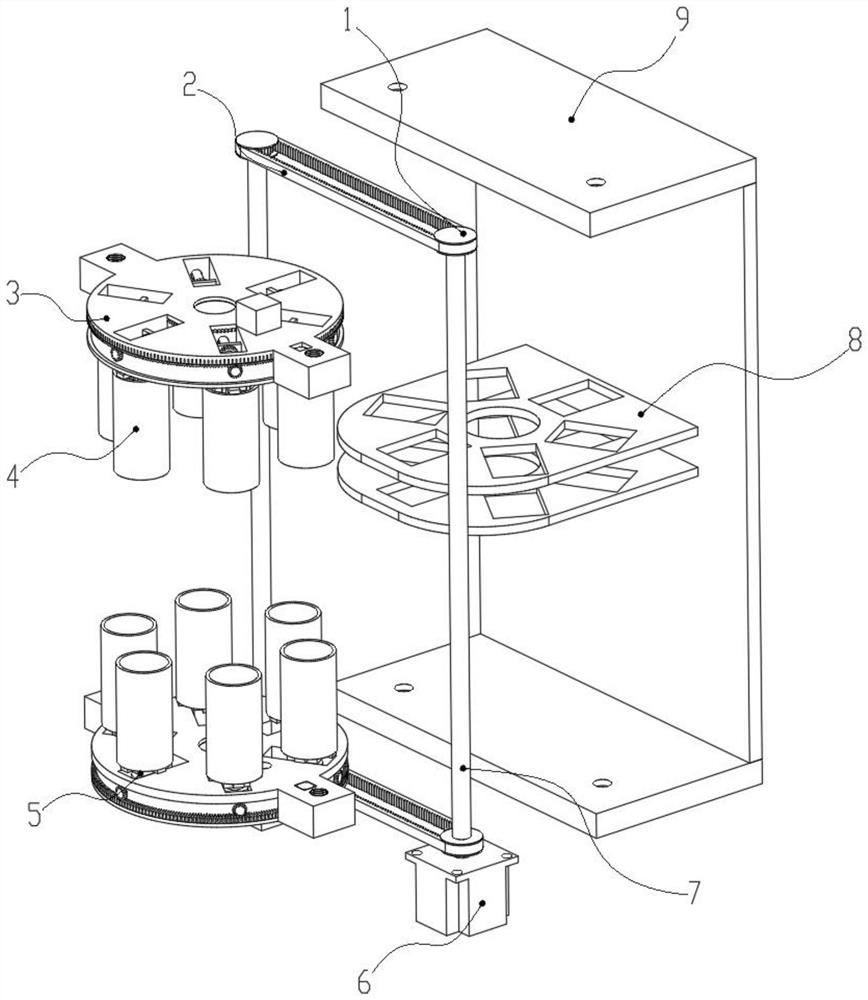

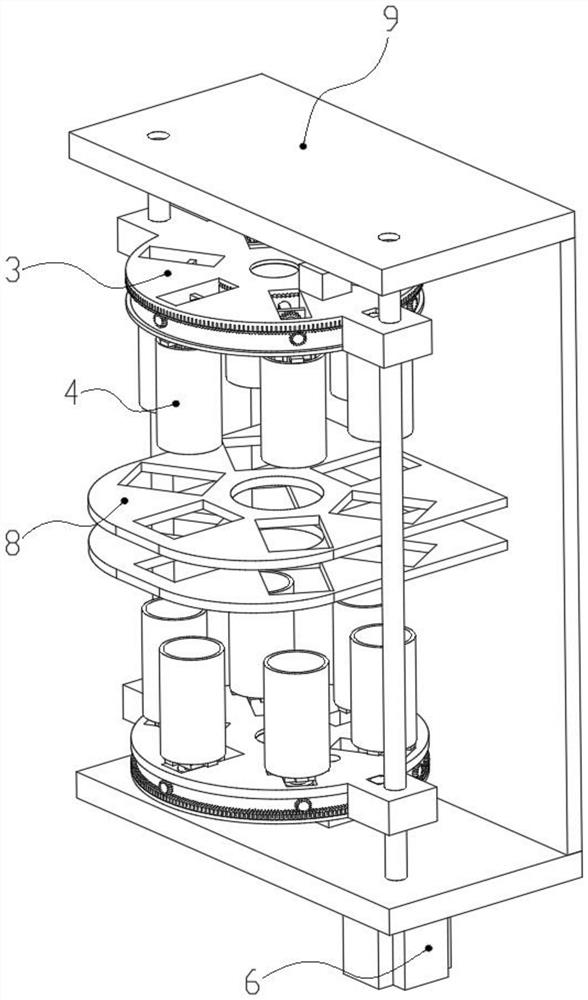

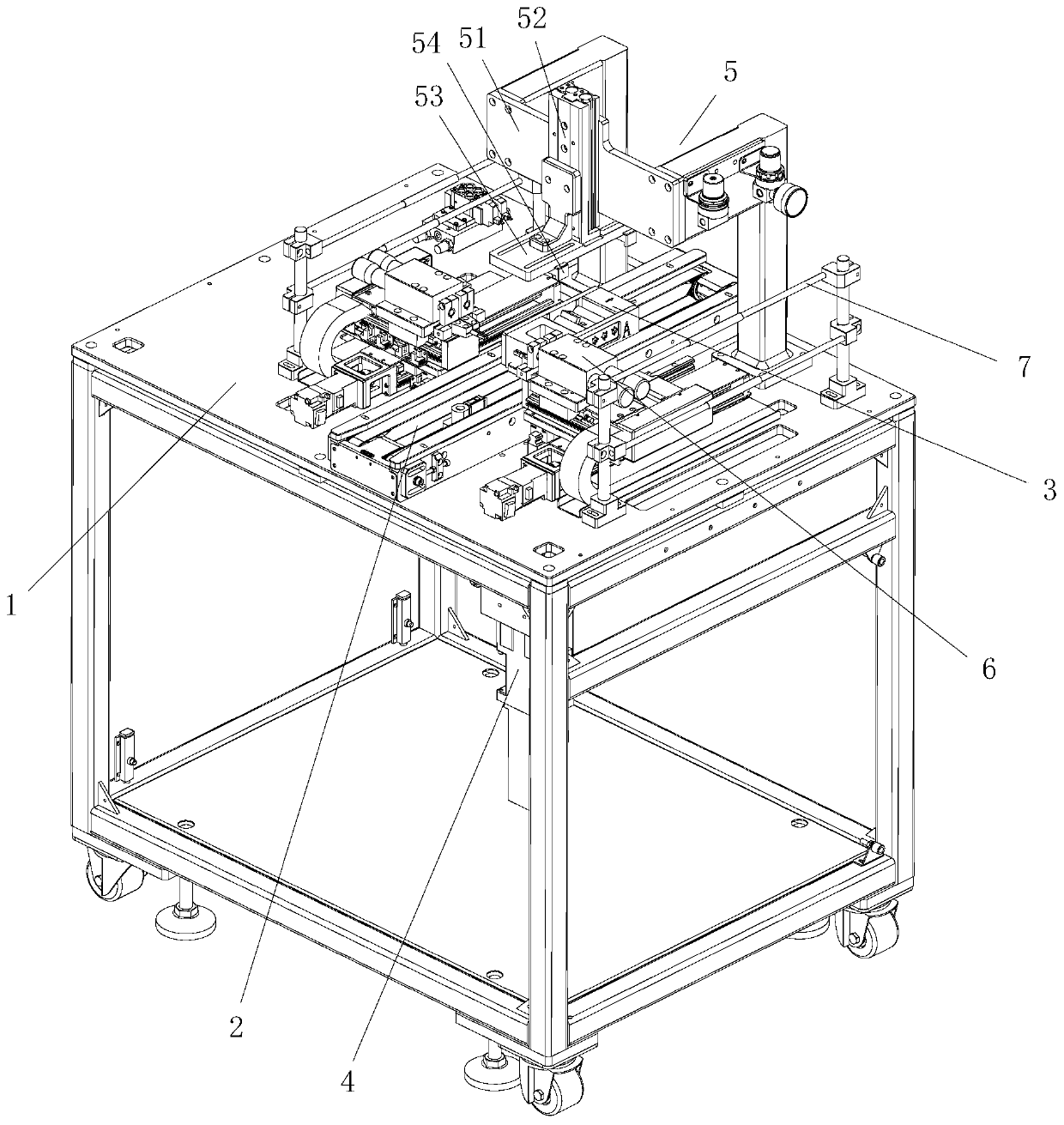

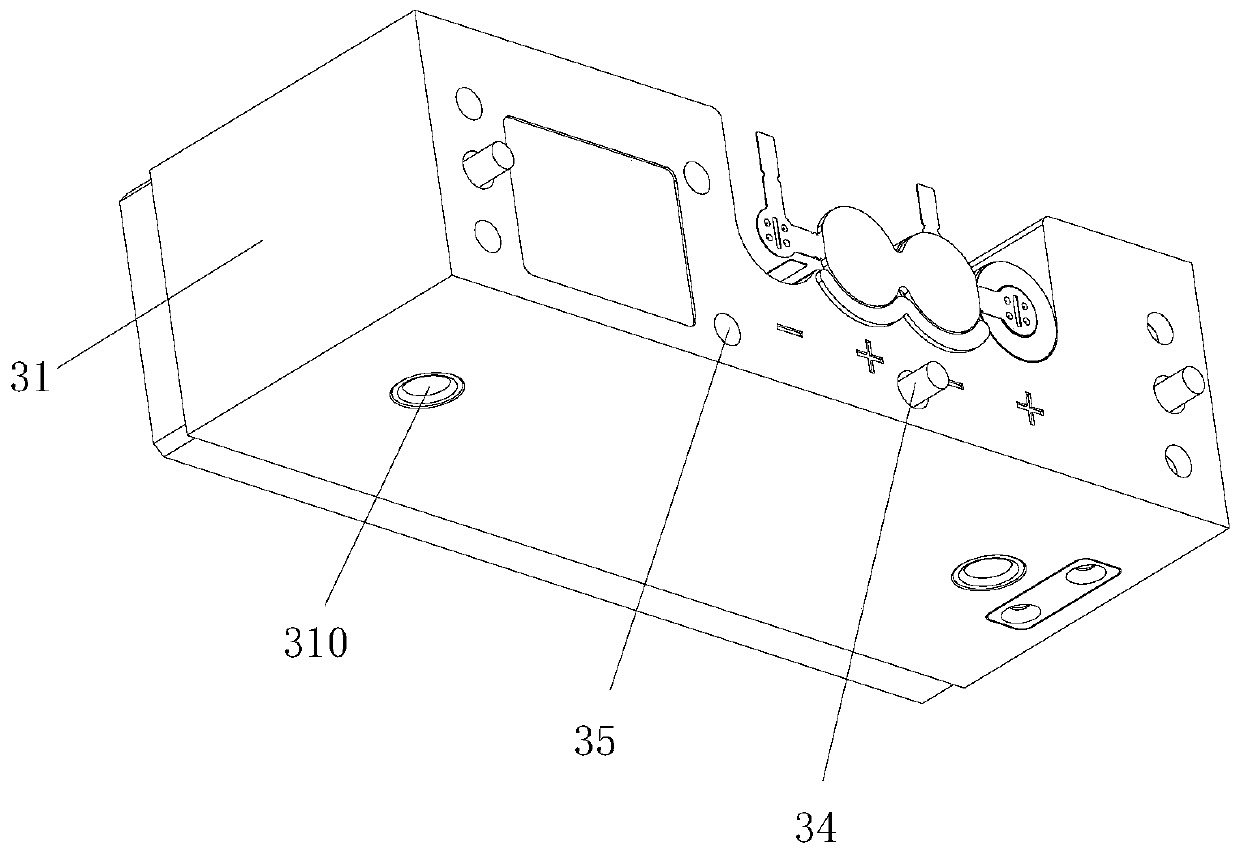

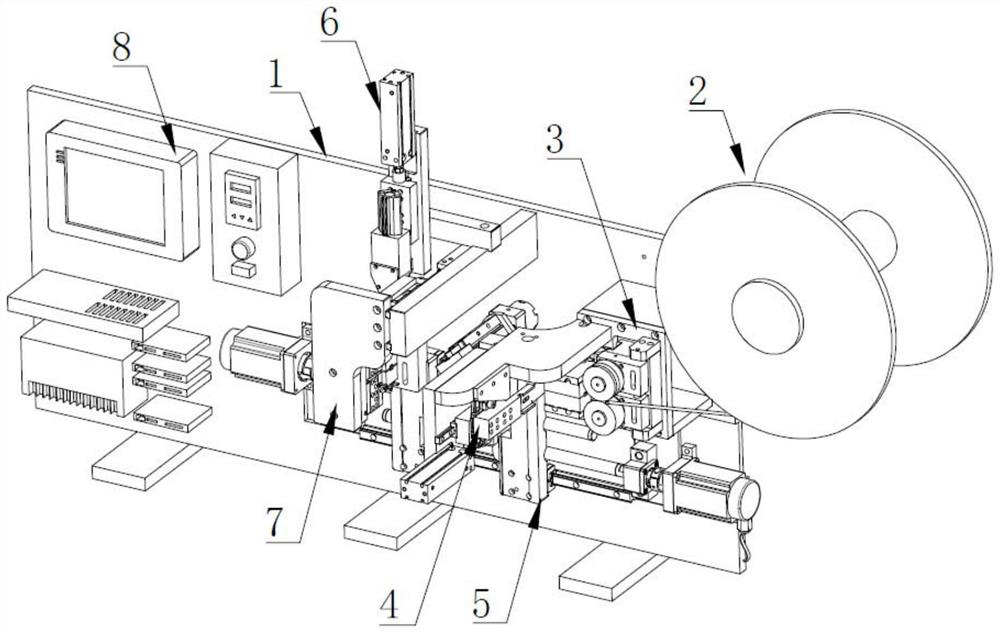

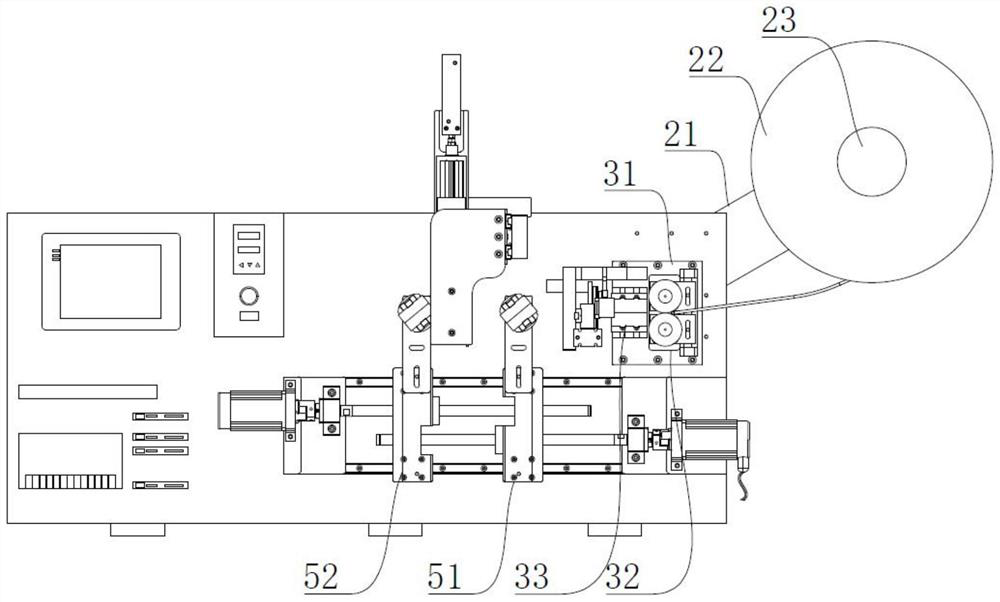

Pressure sensor full-automatic production equipment

ActiveCN109462114AHigh degree of automationImprove work efficiencyLine/current collector detailsVision inspectionEngineering

The invention relates to the field of sensor production. Pressure sensor full-automatic production equipment comprises a rack and a rubber-covered wire feeding device, a wire stripping and cutting device, a soldering device, a rotary table device, a sensor feeding device, CCD vision inspection devices, a flux coating device, a soldering assisting device and a blanking device which are mounted on the rack; and the CCD vision inspection devices are divided into a first CCD vision inspection device and a second CCD vision inspection device. The pressure sensor full-automatic production equipmenthas the advantages of high automation degree, high working efficiency and high qualified rate of finished products.

Owner:海底鹰深海科技股份有限公司

Front subframe and producing method thereof

ActiveCN103738399APrecise positioningFacilitate subsequent weldingUnderstructuresVehicle frameEngineering

The invention provides a front subframe comprising an upper plate and a lower plate which are connected to form a front subframe body, and a front component used for connecting the front subframe body to a vehicle. A lower swing arm front mounting support and a lower swing arm rear mounting portion are arranged between the upper plate and the lower plate on the left and right sides of the front subframe body. The front component and a front mounting support are punched and formed integrally. The front wall of the front mounting support is welded to the upper plate or the lower plate, and the bottom wall is connected to the lower plate in welded manner so that a front-rear double-layered reinforcing structure and an upper-lower double-layered reinforcing structure are formed. The invention further provides a method for producing the front subframe. The front subframe has the advantages of high strength, convenience of welding and high positioning accuracy.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

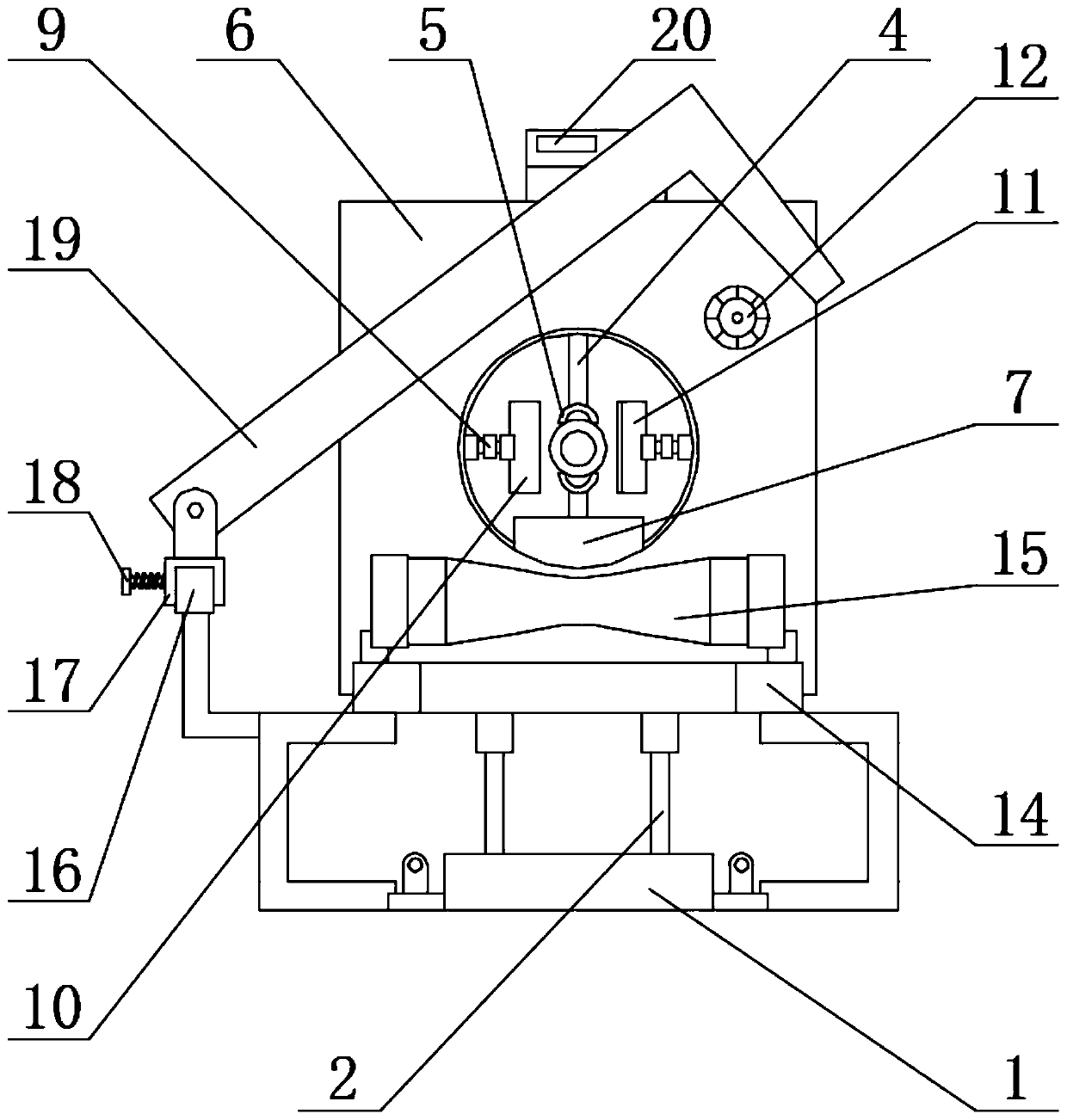

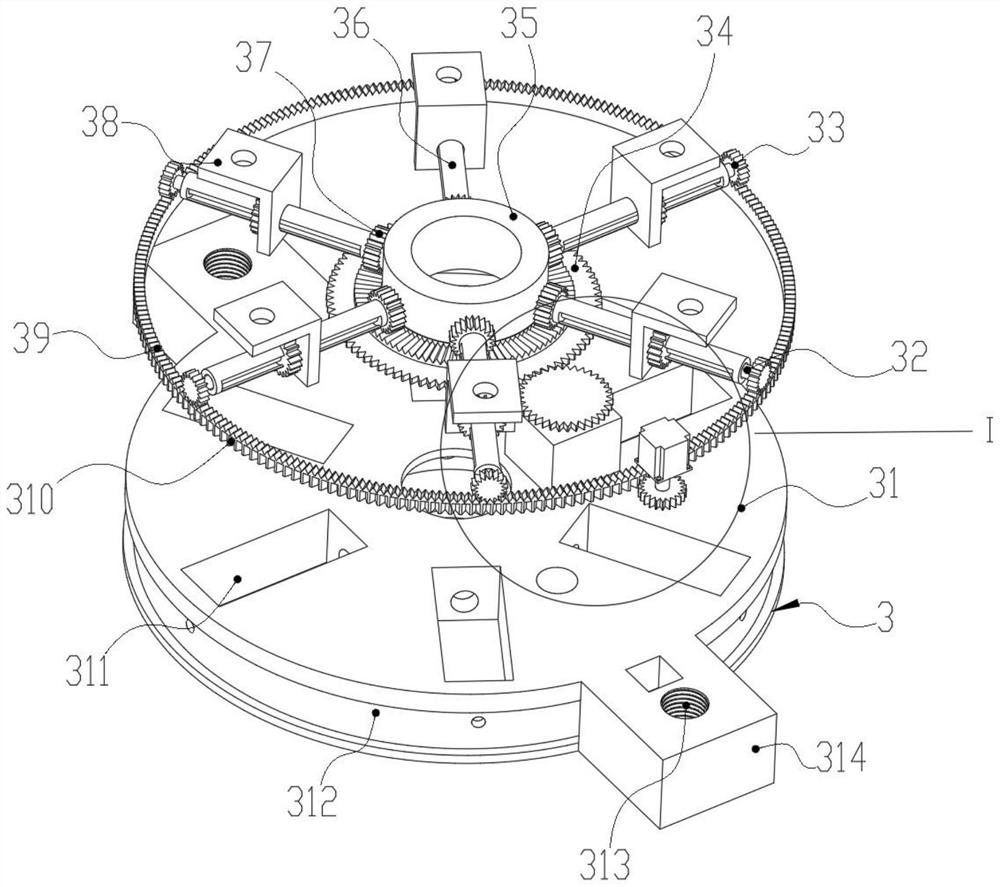

Welding device for industrial pipeline machining

InactiveCN114227128AStable and precise welding operationImprove adaptabilityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryProcess engineering

The invention discloses a welding device for industrial pipeline machining, which comprises a connecting belt pulley, a tooth-shaped belt, a limiting mechanism, an industrial pipeline, a supporting mechanism, a connecting motor, two-way screw rods, a welding mounting frame and a supporting bottom plate, and connecting belt wheels are symmetrically and fixedly connected to the outer end faces of the two sets of bidirectional lead screws, the two sets of connecting belt wheels are rotationally connected in a meshed mode through a tooth-shaped belt, and connecting motors are fixedly installed at the positions, right opposite to the connecting belt wheels, of the outer end face of the supporting bottom plate. According to the industrial pipeline welding device, industrial pipelines with different radiuses can be rapidly and stably limited, so that subsequent stable and accurate welding operation on the industrial pipelines is facilitated, meanwhile, the distance between the multiple sets of industrial pipelines can be automatically adjusted according to requirements, the adaptability of machining of the industrial pipelines is improved to the maximum extent, and then the machining efficiency is improved.

Owner:吴文瑛

Welding method of composite copper bar conducting layer, and composite copper bar

ActiveCN104319010AReduce hardnessReduce intensitySingle bars/rods/wires/strips conductorsSoldering apparatusBar productHardness

The invention relates to a welding method of a composite copper bar conducting layer. A welding part of a lead workpiece is positioned on a mounting part of a copper bar substrate by a positioning structure, so that next welding is facilitated. After positioning, a resistance soldering technology instead of chamfering is adopted, so that the mounting part can be arranged in any position of the copper bar substrate, the lead workpiece can be welded on the mounting part, a complicated composite copper bar product comprising a small forming part structure is obtained, and the welding strength and the connection reliability are improved. A non-welding part of the lead workpiece is placed in a heat-dissipation mold, so that heat of the non-welding part of the lead workpiece conducted by welding can be dissipated by the heat-dissipation mold, the non-welding part of the lead workpiece can avoid softening deformation and hardness and strength reduction due to overheating, the hardness and the strength of the non-welding part are ensured, and torsion resistance of riveting a nut in a non-welding area is ensured. In addition, the invention further relates to a composite copper bar.

Owner:浙江冠华电气有限公司

Piece type radiator welding method and tool

PendingCN111230284ANot easy to shakeFast weldingNon-electric welding apparatusFriction weldingElectric machinery

The invention relates to the technical field of radiators, and discloses a piece type radiator welding method and tool. The tool comprises a bottom plate, wherein the top of the base is fixedly connected to two motor boxes; the inner sides of the motor boxes are fixedly connected to drive motors; the output shafts of the drive motors are fixedly connected to threaded rods; the outer sides of the threaded rods are in threaded connection to slide bases; the tops of the slide bases are fixedly connected to clamping bases; and spring cavities are arranged inside the clamping bases. The piece typeradiator welding method and tool can accelerate cooling at a welding position, increases cooling speed, and improves processing efficiency; the welding tool is reasonable and reliable in design, and does not make a radiator obviously deform; a friction welding head is used for friction welding, and other materials are not added to guarantee uniform radiation of the radiator, so that the problems such as processing difficulty, easy cracking and the like are solved; the processed surface is attractive and does not generate chromatic aberration, and the tool has universality for the piece type radiator, so that the tool can be used for welding most of piece type radiators.

Owner:镇江市东亚电子散热器有限公司

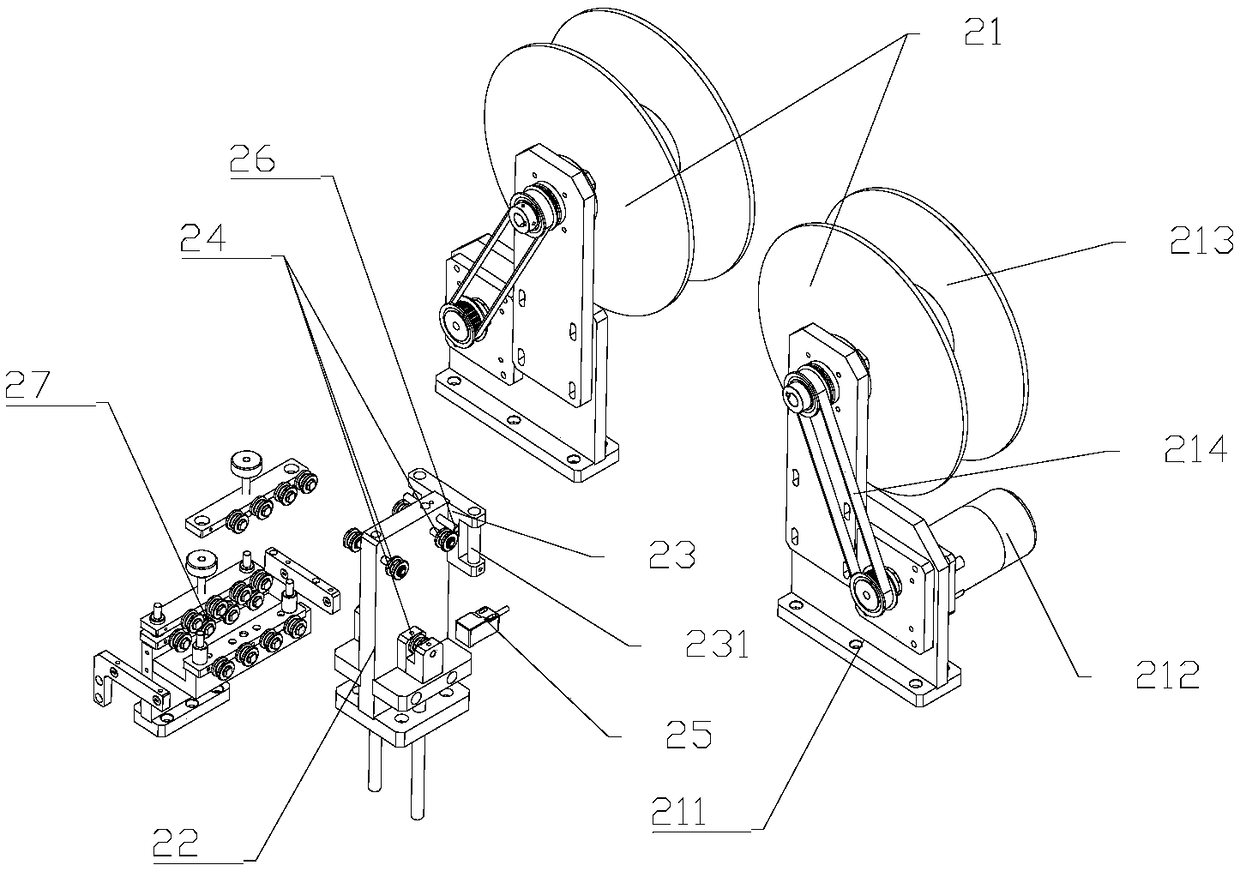

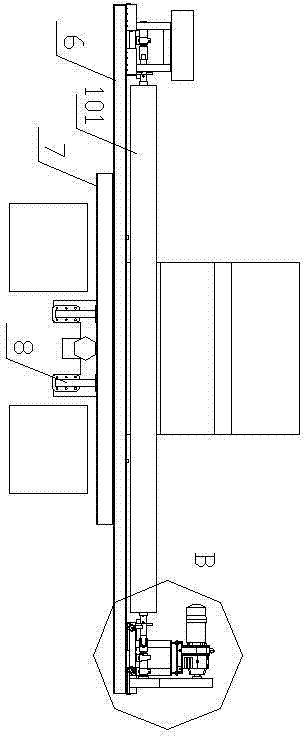

Refuse landfill film laying machine

ActiveCN107253639AEasy to place and weldEffective coverageLandfill technologiesUnfolding thin materialsElectric machineryRoll film

The invention relates a refuse landfill film laying machine. The refuse landfill laying machine comprises a base vertical supporting piece fixed to a bulldozer, the base vertical supporting piece is fixedly provided with a base transverse supporting piece, a fixed support is fixedly arranged at the upper portion of the base transverse supporting piece, and a first main shaft supporting frame and a second main shaft supporting frame are fixedly arranged at the two sides of the upper portion of the fixed support; main shafts are supported on the first main shaft supporting frame and the second main shaft supporting frame, the two ends of each main shaft are supported on each of the first main shaft supporting frame and the second main shaft supporting frame, thin film is twined on the main shafts, and the main shafts can rotate on the first main shaft supporting frame and the second main shaft supporting frame. The refuse landfill film laying machine is reasonable in structure, convenient to use and advanced and scientific in method, through the refuse landfill film laying machine, manual film laying is replaced, by making a motor control the speed through variable frequencies, making a left probe and a right probe conduct control and making a left slide rail and a right slide rail manually pushed to place the rolled film, film rolling equipment is attached to an on-site bulldozer, and garbage is effectively covered with the rolled film.

Owner:扬州铭德环境科技有限公司

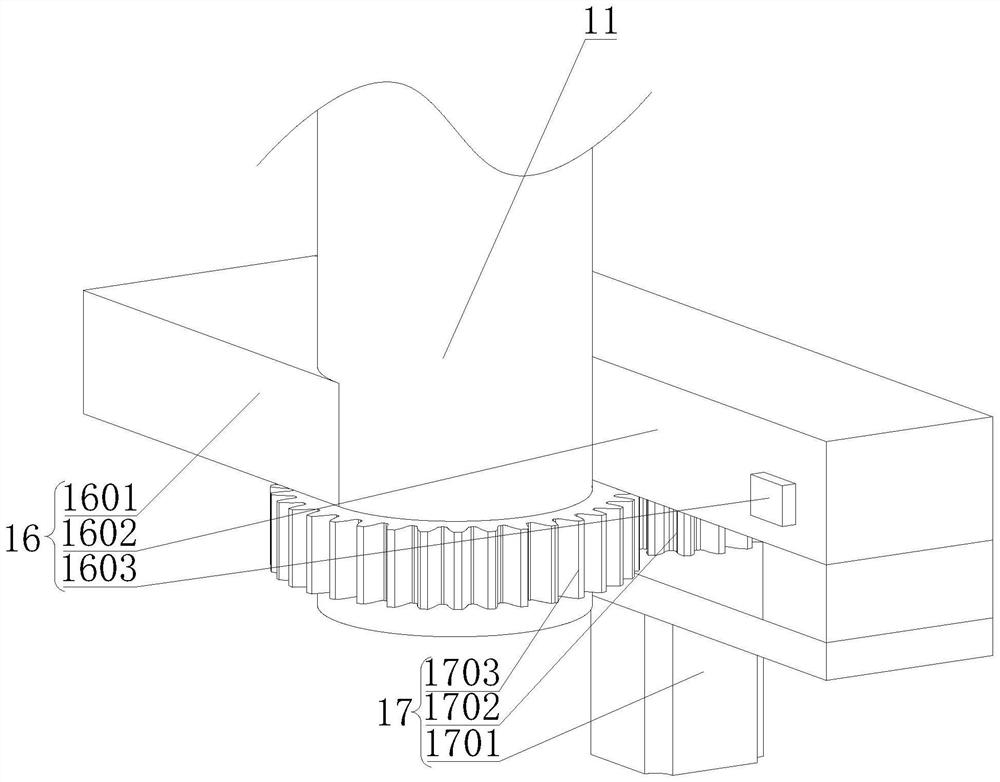

Numerical control high-speed groove cutting integrated machine and operation method thereof

ActiveCN109807640AFacilitate subsequent weldingShorten the timeOther manufacturing equipments/toolsNumerical controlGear wheel

The invention relates to a numerical control high-speed groove cutting integrated machine and an operation method thereof. A base and first electric telescopic rods are included. The rear side of thetop end of the base is fixedly connected with the lower ends of the first electric telescopic rods. A limiting plate is fixedly connected to the top ends of the outer sides of the first electric telescopic rods. The inner side of the limiting plate is fixedly connected with a second electric telescopic rod. A clamping claw is fixedly connected to one end of the second electric telescopic rod. A protection cover is fixedly connected to the front end of the outer side of the limiting plate. The top end of the outer side of the protection cover is fixedly connected with a controller. A waste boxis detachably connected to the inner side of the protection cover, and the inner side of the protection cover is rotationally connected with a gear ring. In the numerical control high-speed groove cutting integrated machine and the operation method thereof, through the arrangement of the gear ring, an air cylinder and a gear, a groove is ground at the cutting fracture surface position during piperotary cutting, so that subsequent pipe welding is convenient, the time consumed for machining is shortened, and the machining efficiency can be better improved.

Owner:上海工业锅炉(无锡)有限公司

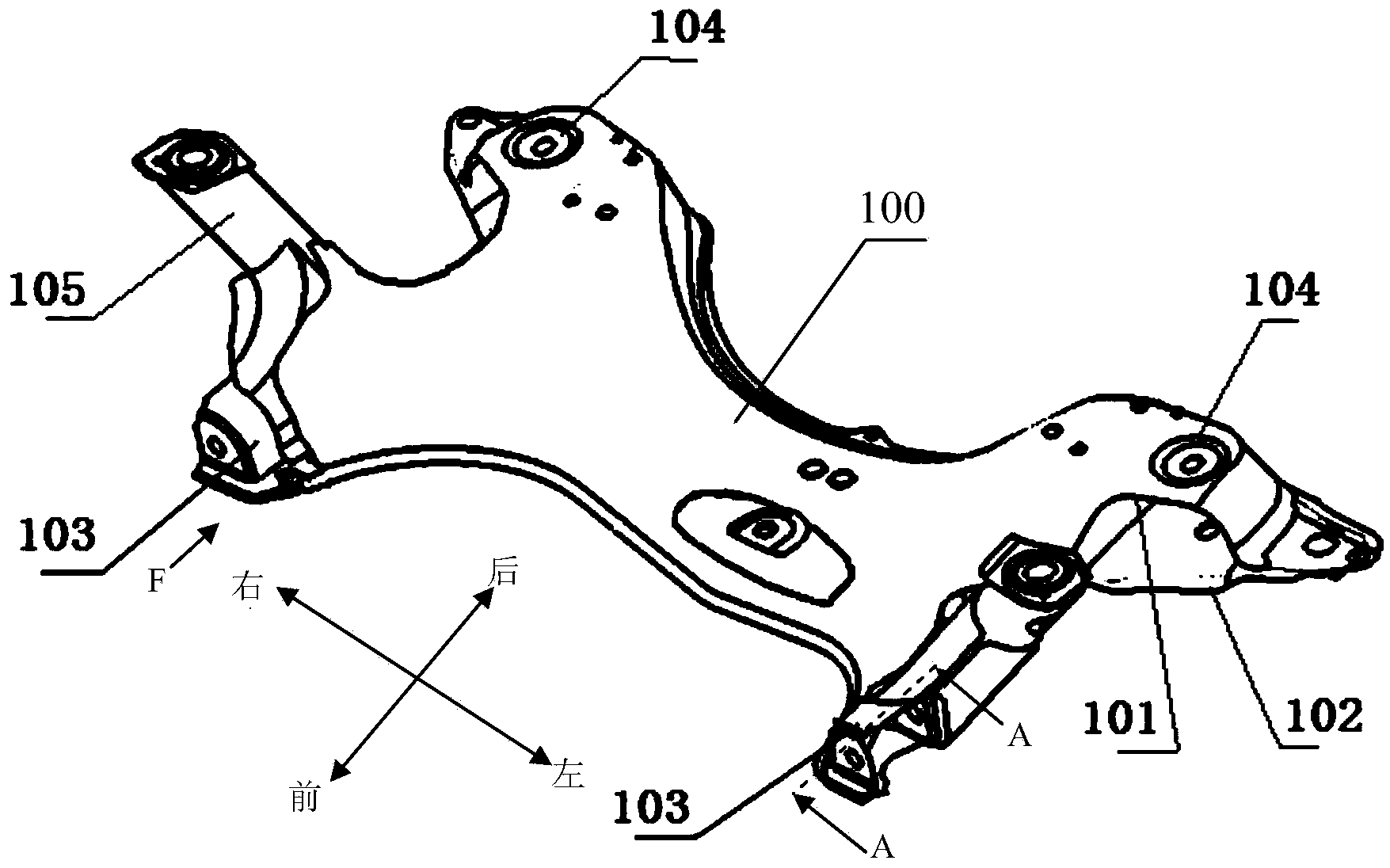

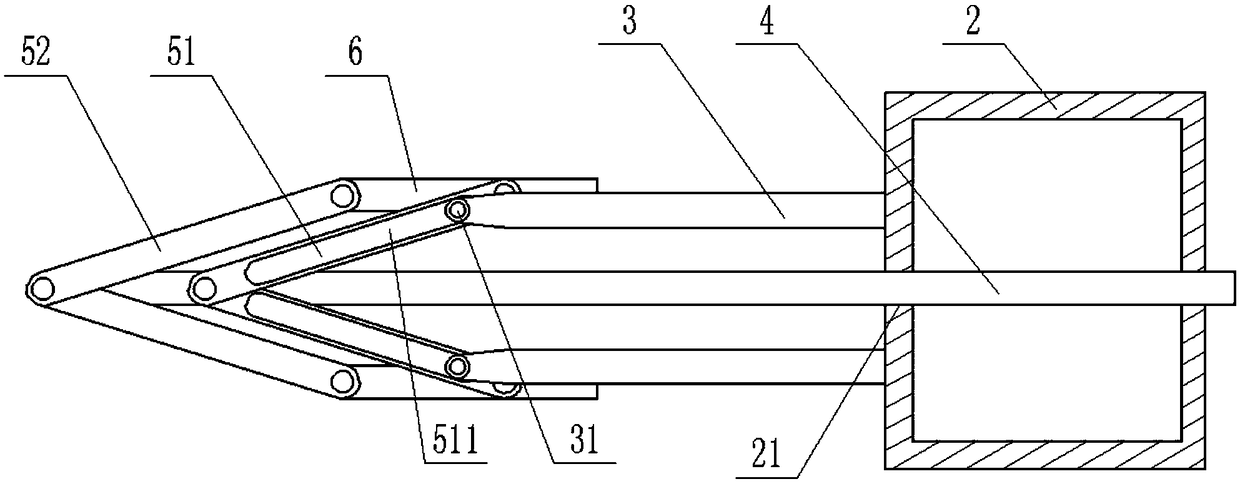

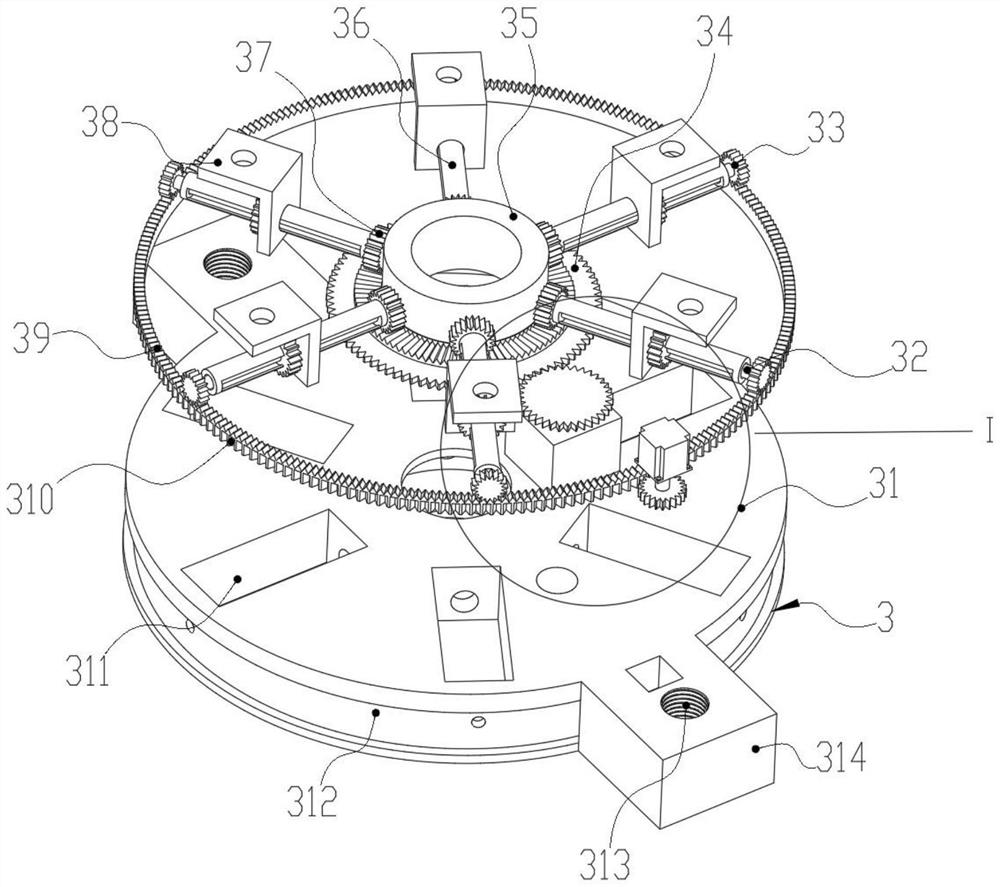

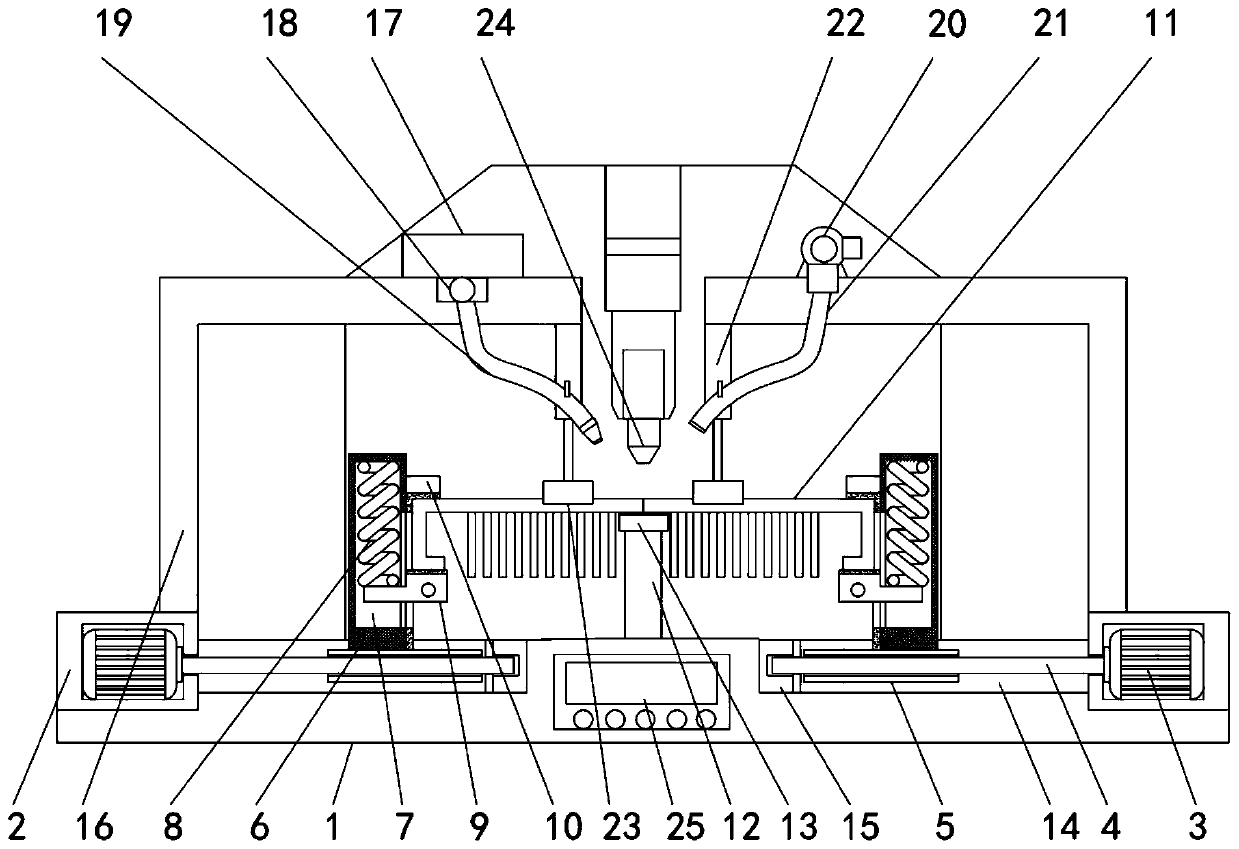

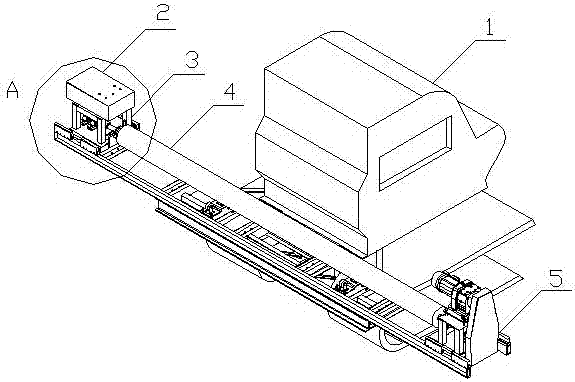

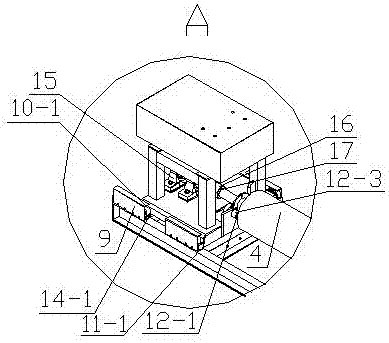

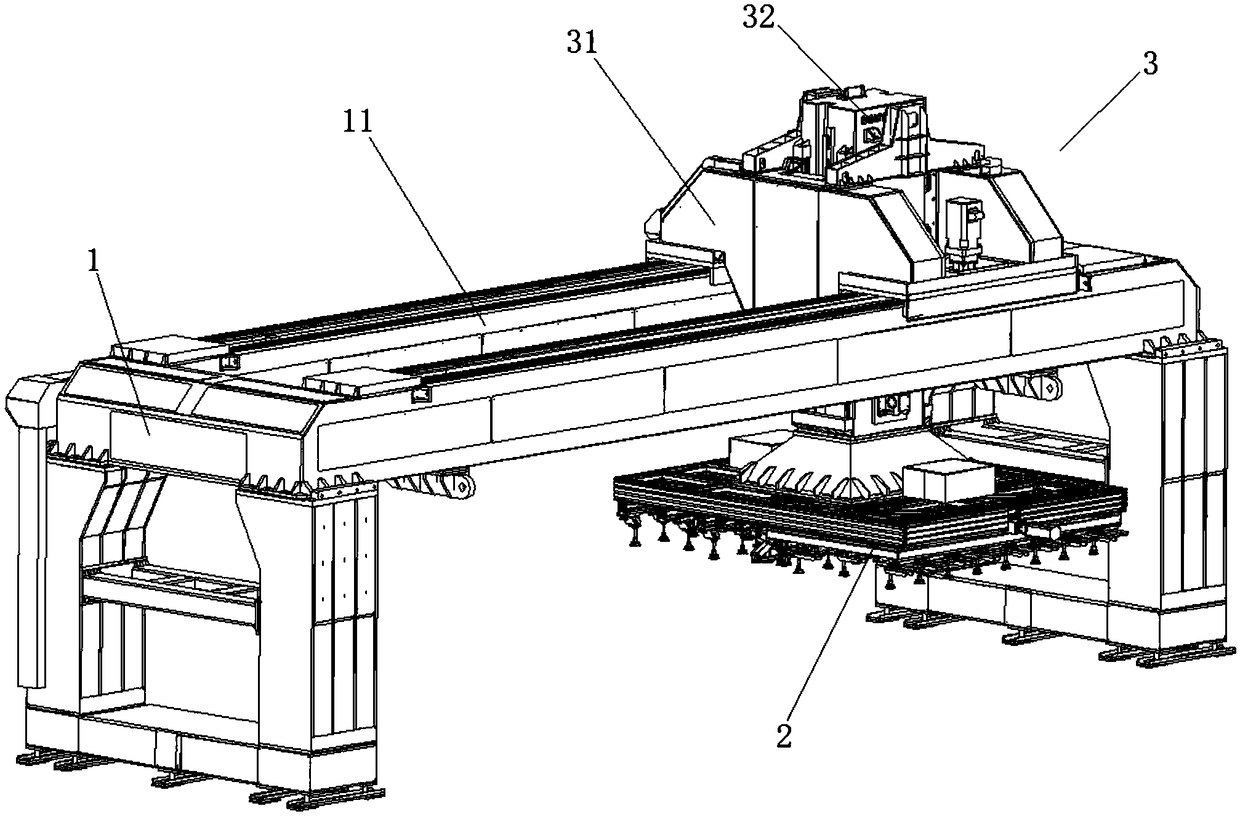

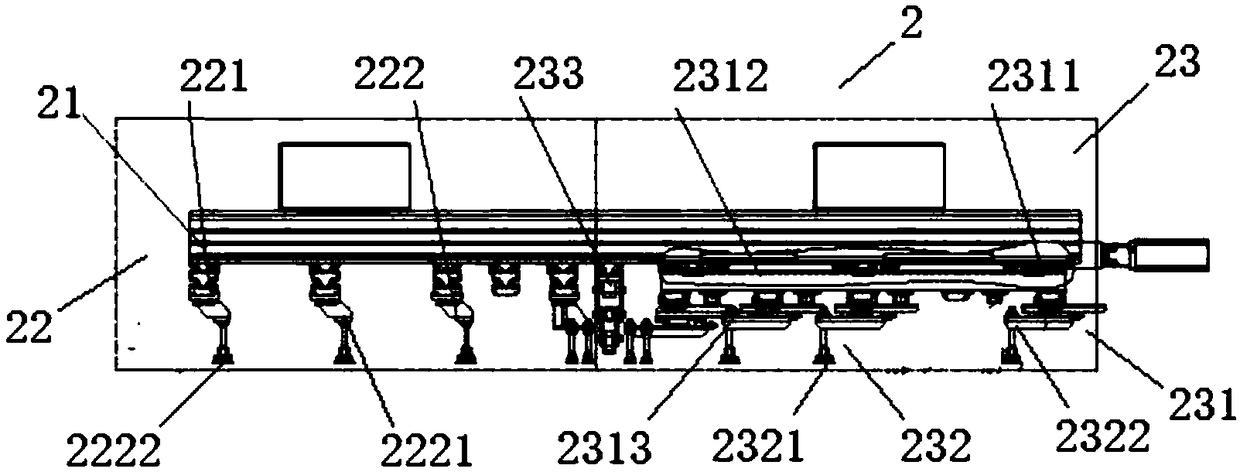

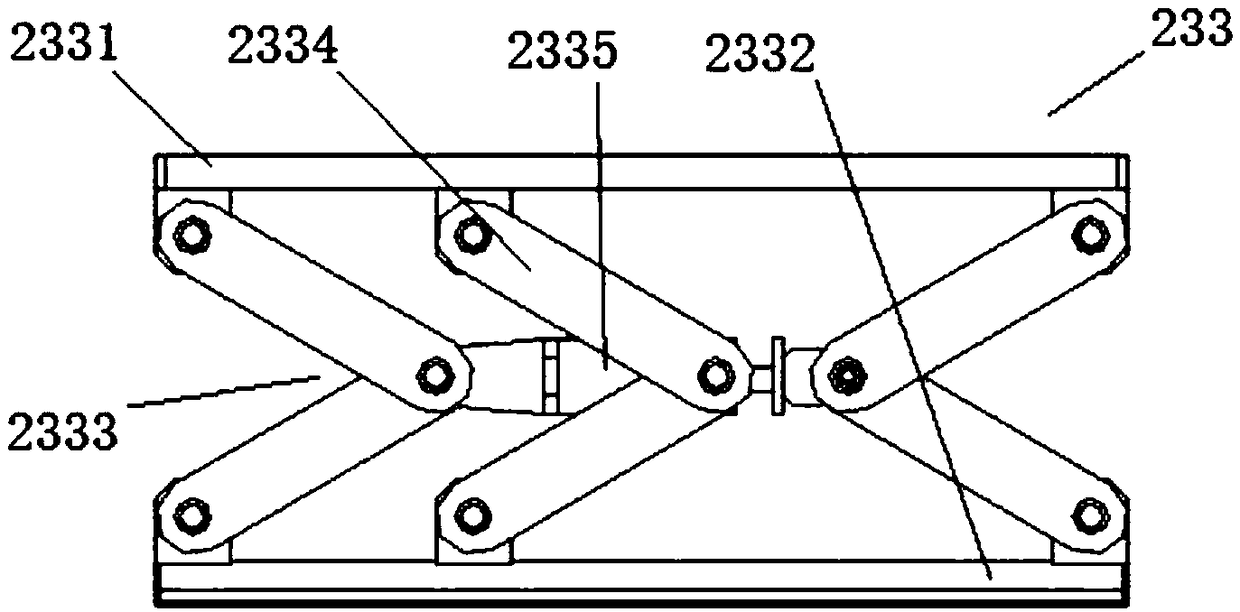

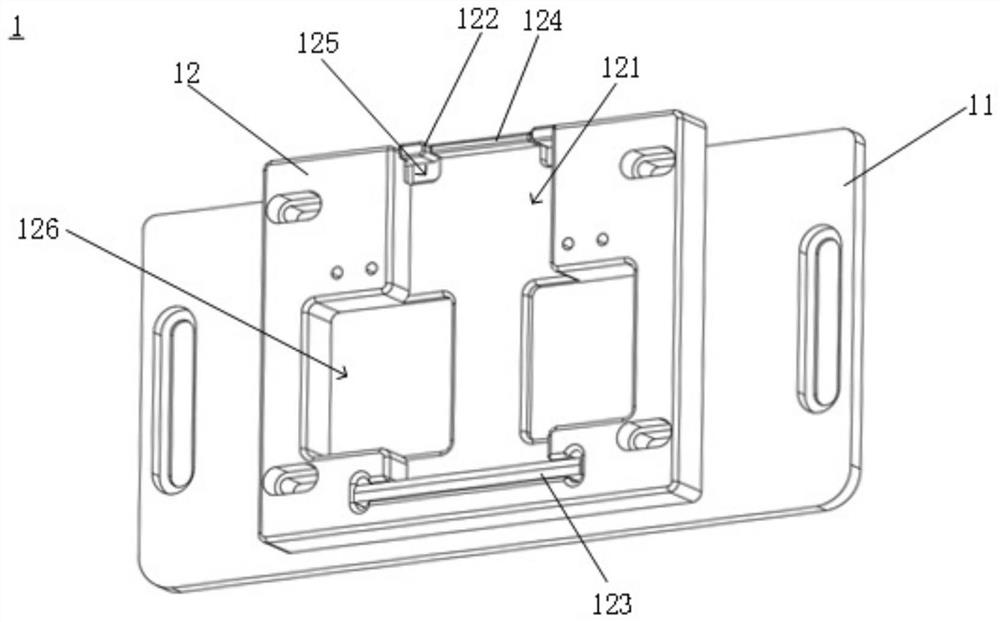

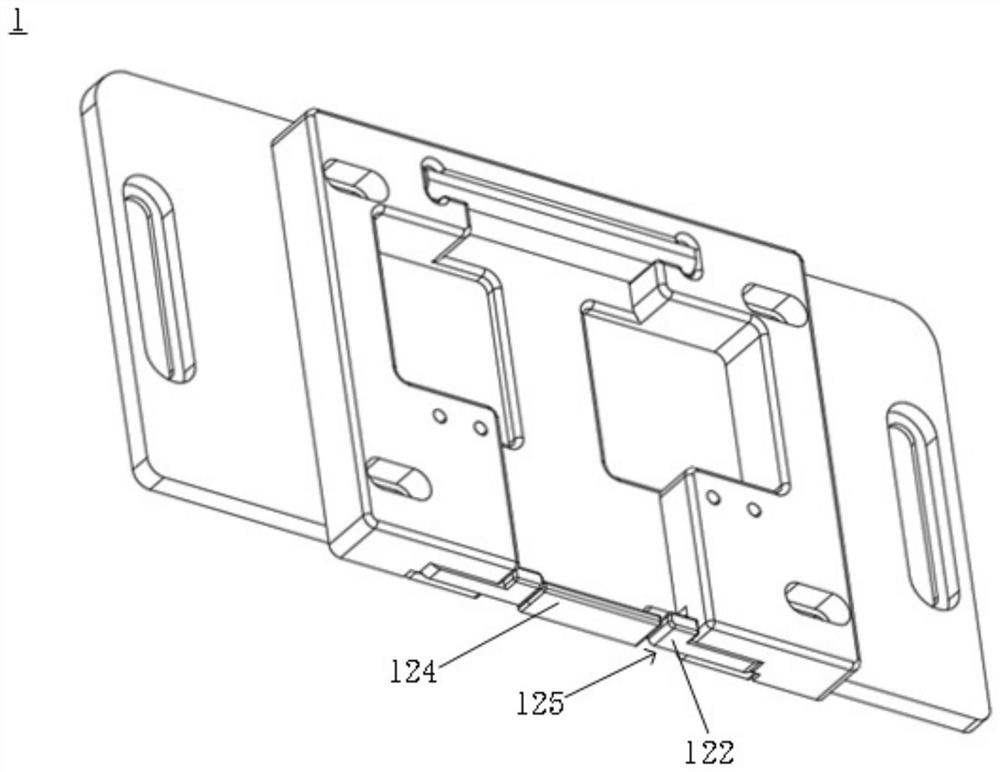

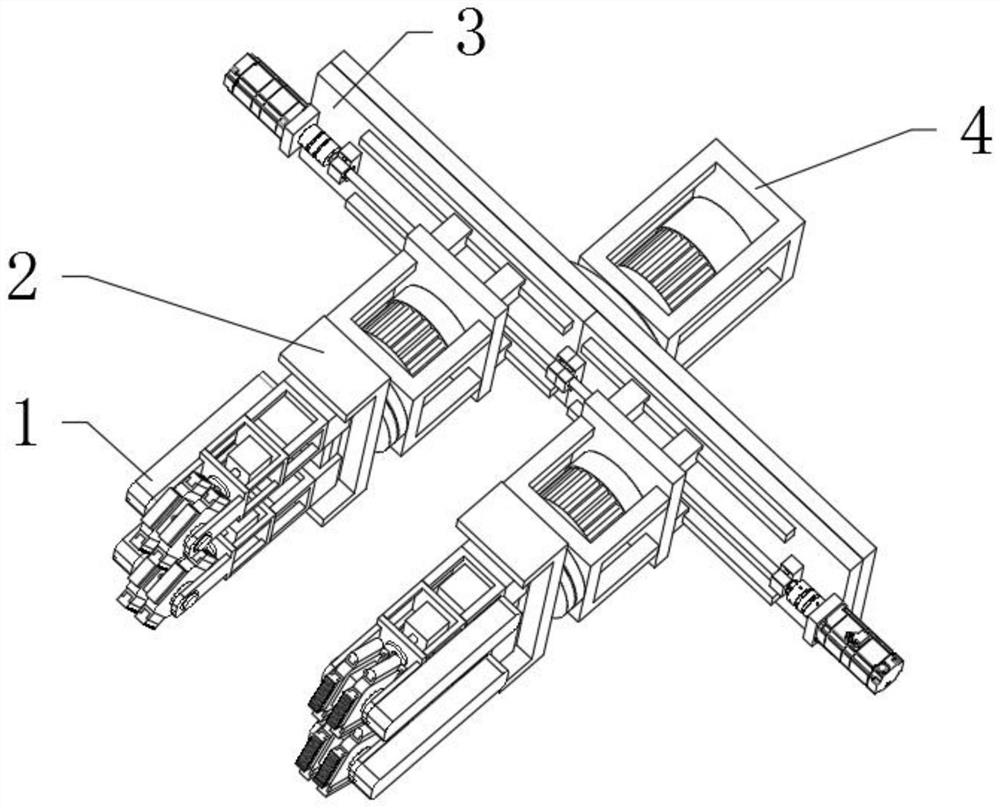

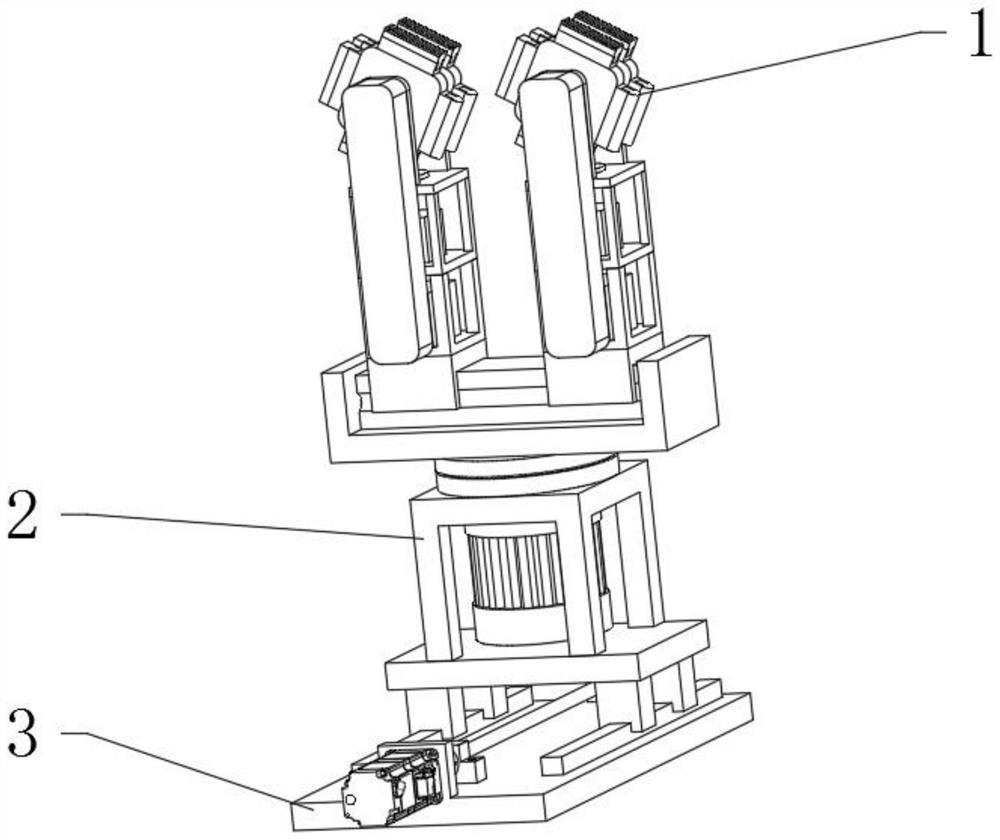

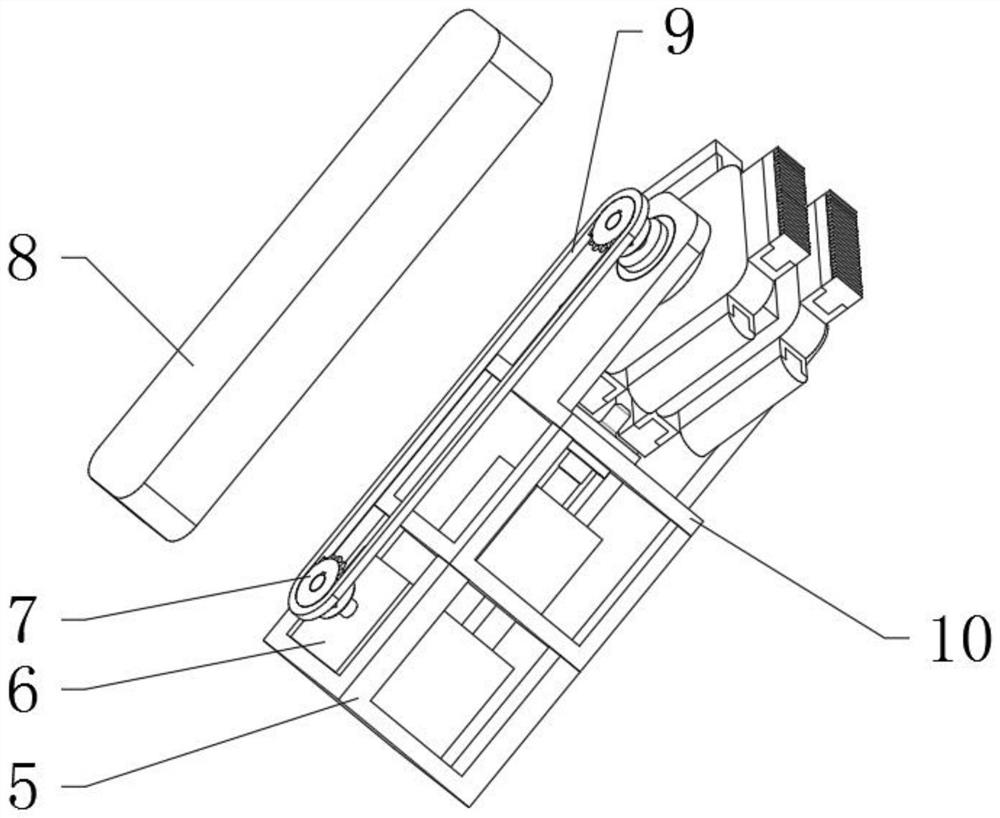

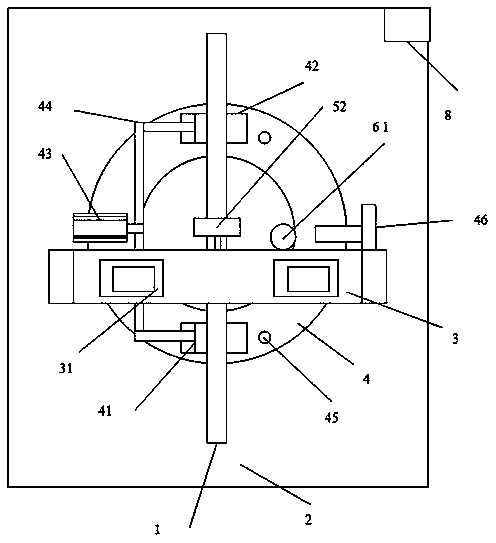

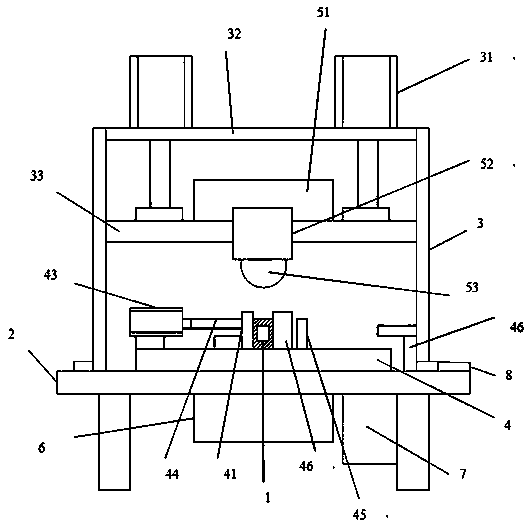

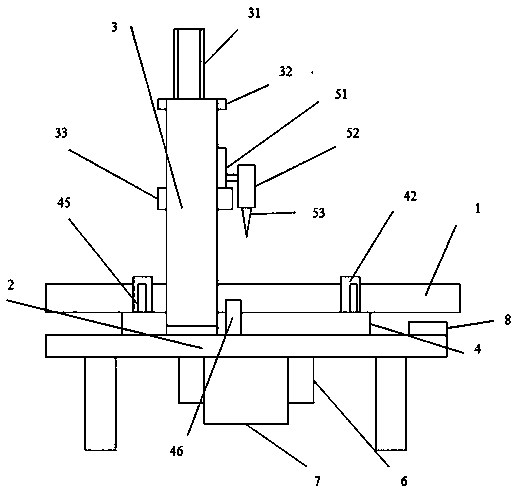

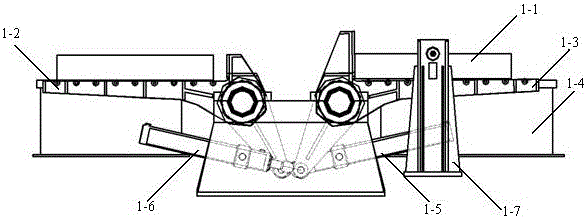

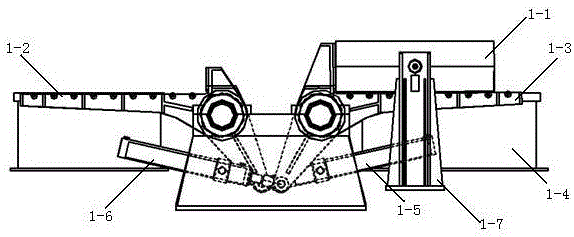

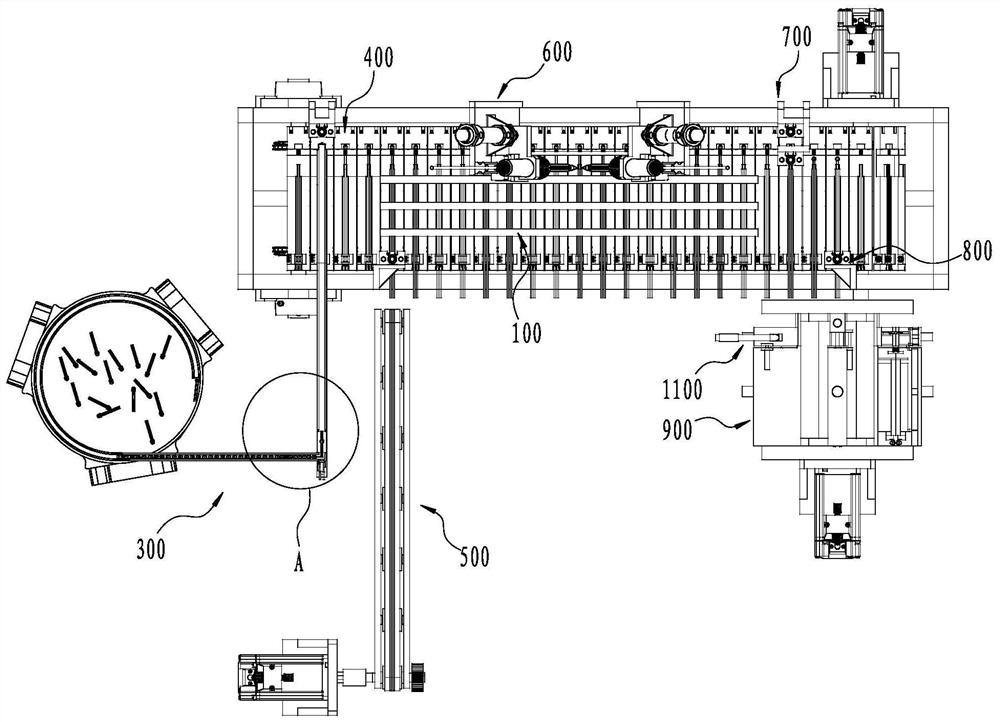

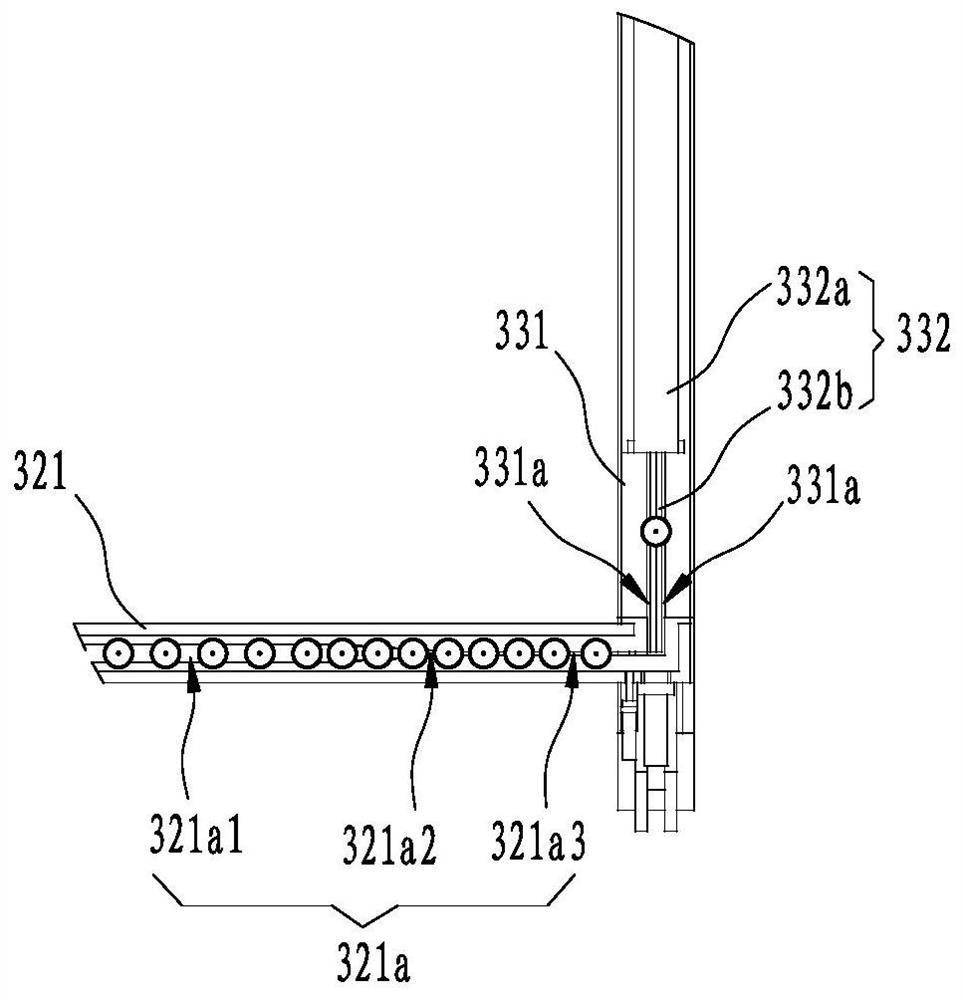

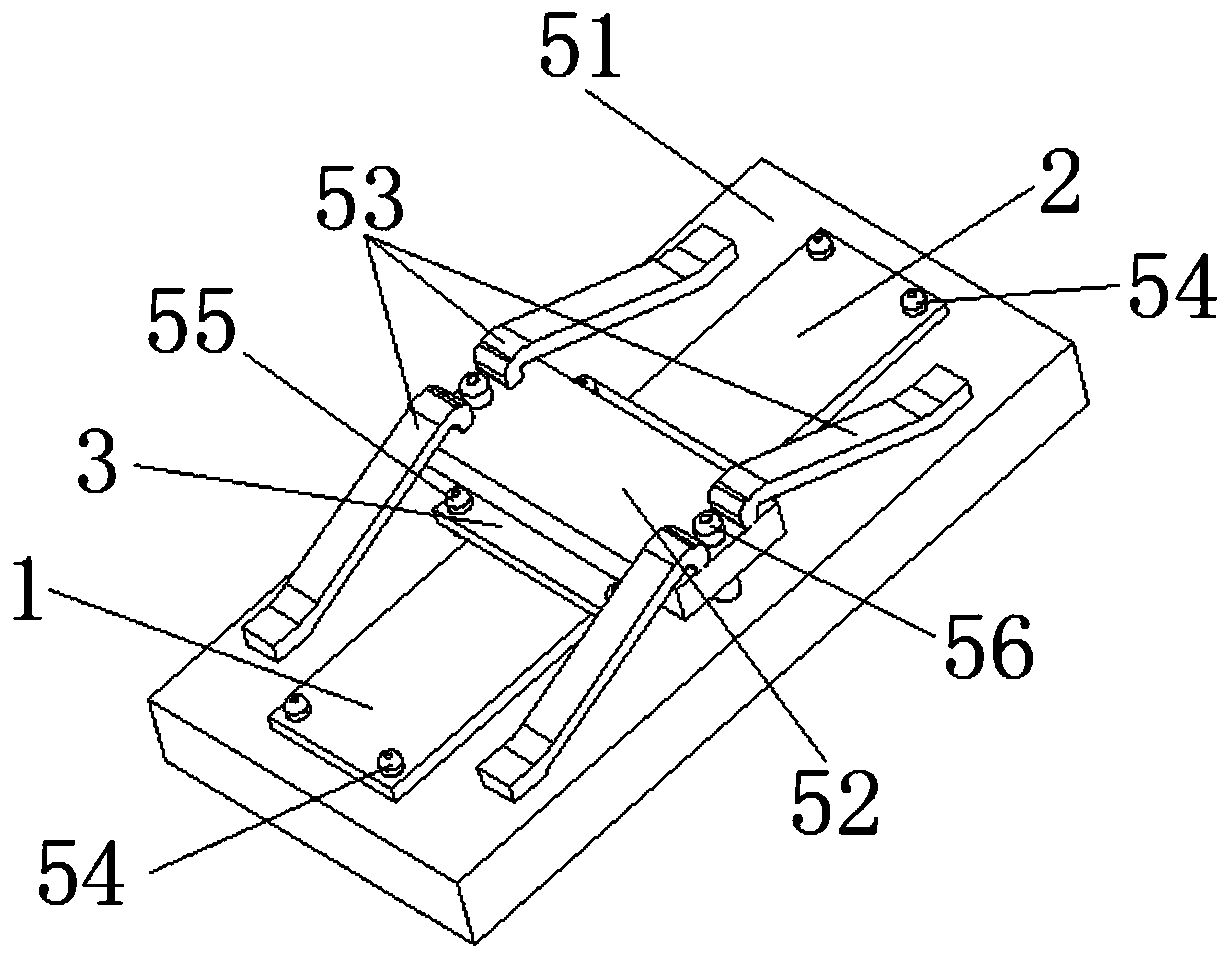

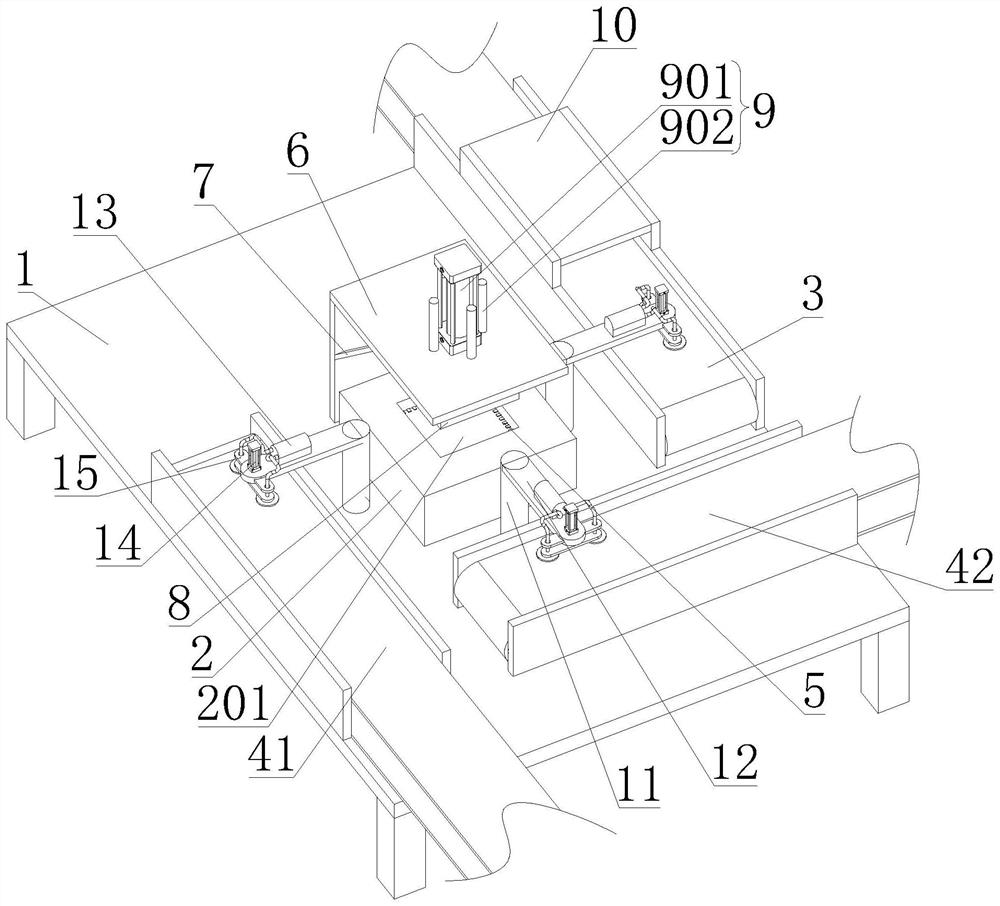

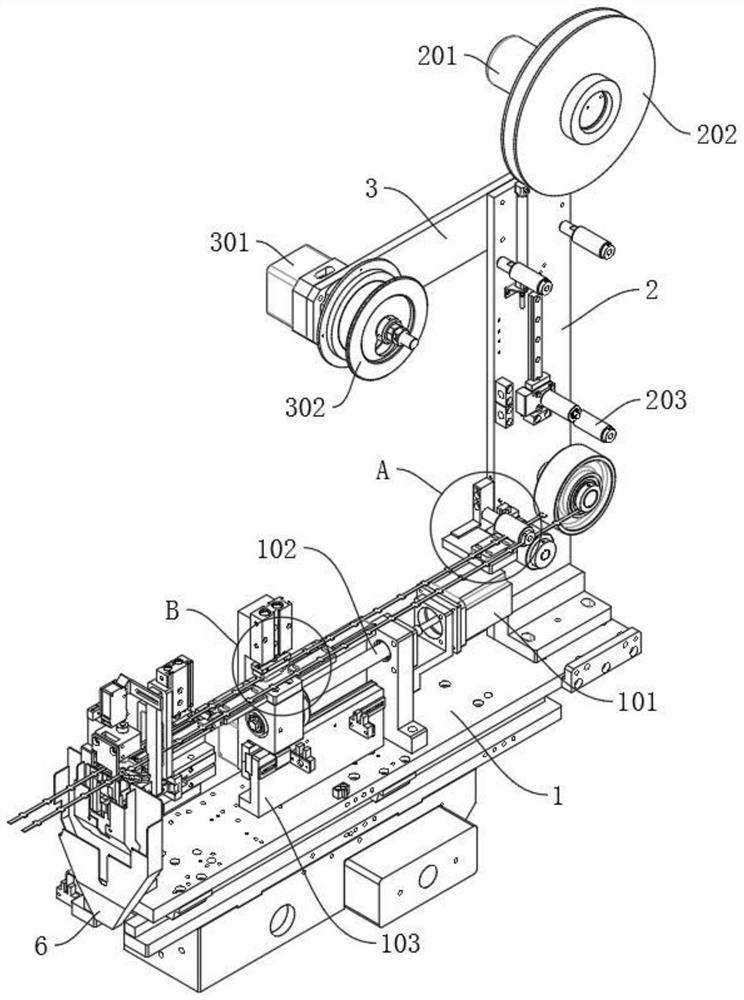

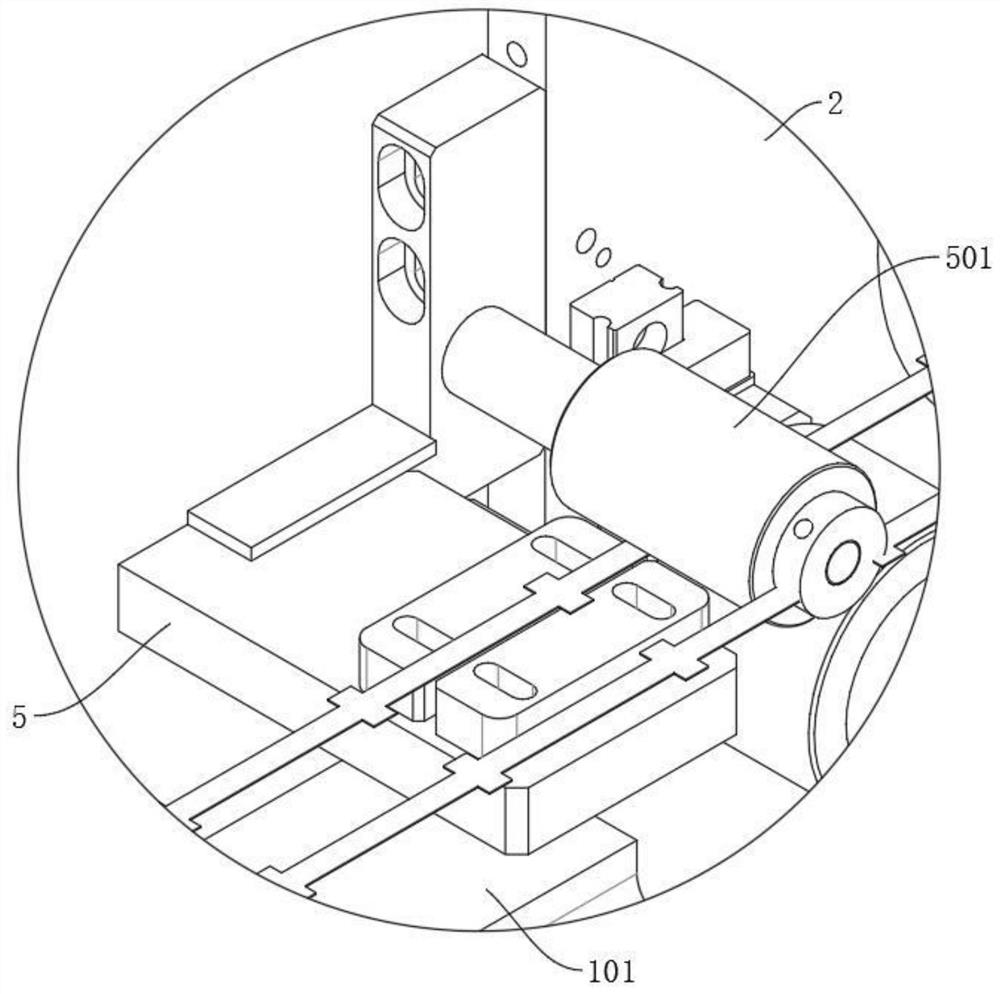

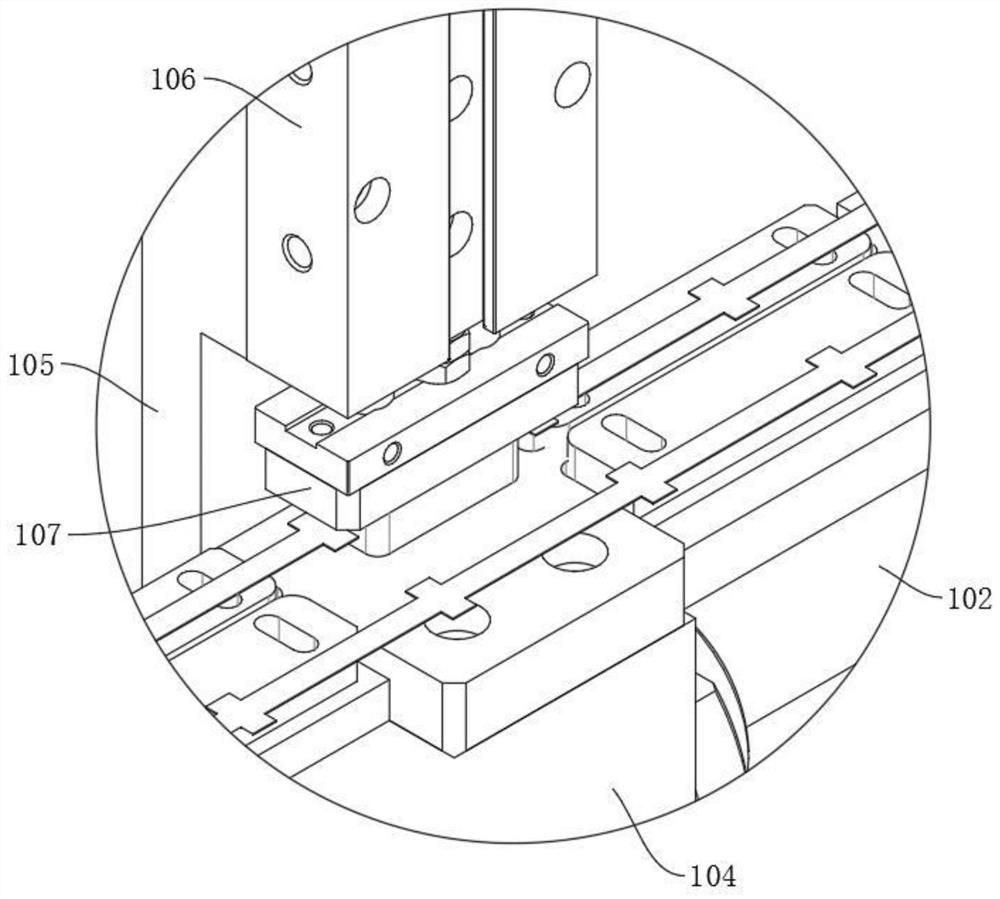

Tailor welding manipulator and laser tailor welding system

ActiveCN106271075BImprove splicing efficiencyImprove stitching accuracyWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

The invention relates to laser tailor welding, and provides a tailor welding and splicing manipulator, which includes a base and a splicing positioning device. The splicing and positioning device includes an integral frame, and a first splicing positioning area and a second splicing positioning area are arranged side by side in the integral frame. At least one set of first Y-direction slide rails is arranged in the first jigsaw positioning area, and each first Y-direction slide rail is sequentially distributed along the X direction, and each first Y-direction slide rail is sequentially provided with several The first suction cup gripper is provided with a plurality of second suction cup grippers and an XY slide table capable of driving each second suction cup gripper to move in the X direction and in the Y direction in the second jigsaw positioning area. In the present invention, by adjusting the XY slide table and the first Y-direction slide rail, the two opposite surfaces of the two panels grasped by each second suction cup gripper and each first suction cup gripper are close to or attached to each other, which not only improves the splicing efficiency High, and the splicing accuracy is relatively high, and when it cooperates with the laser, it can realize laser welding between the panels, which can effectively ensure the welding quality.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

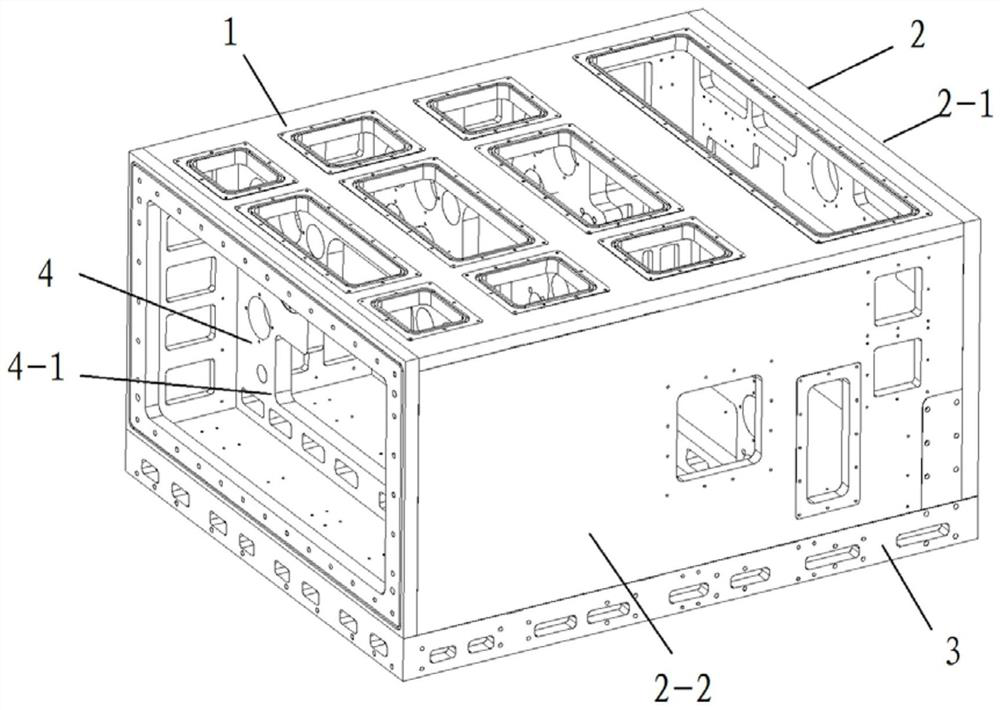

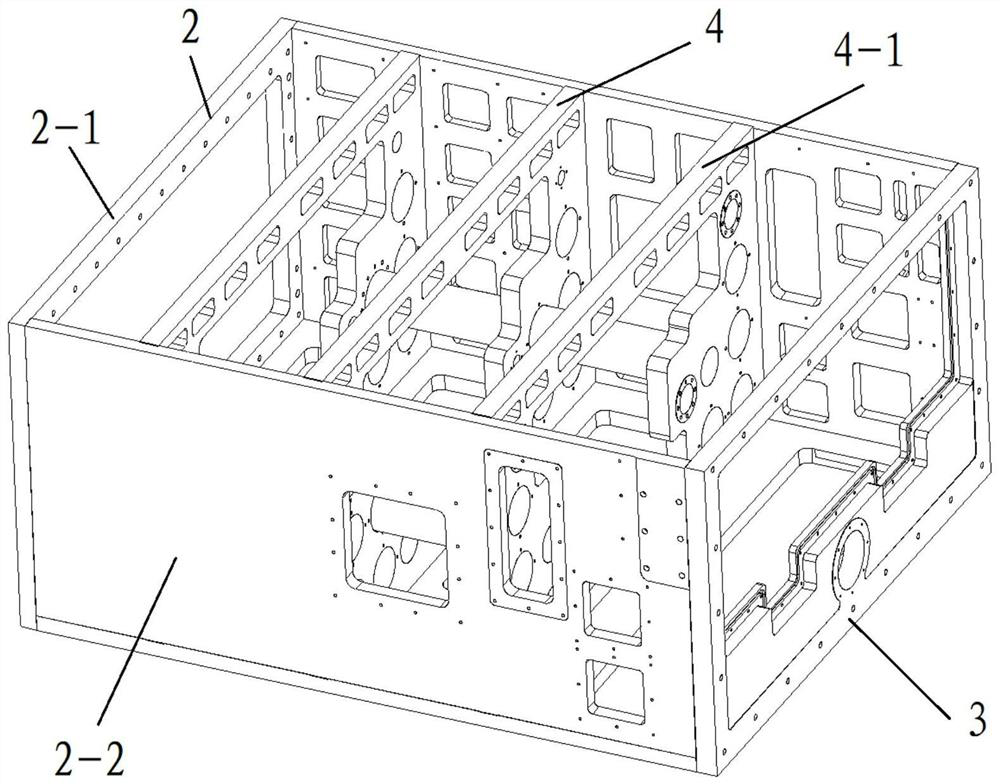

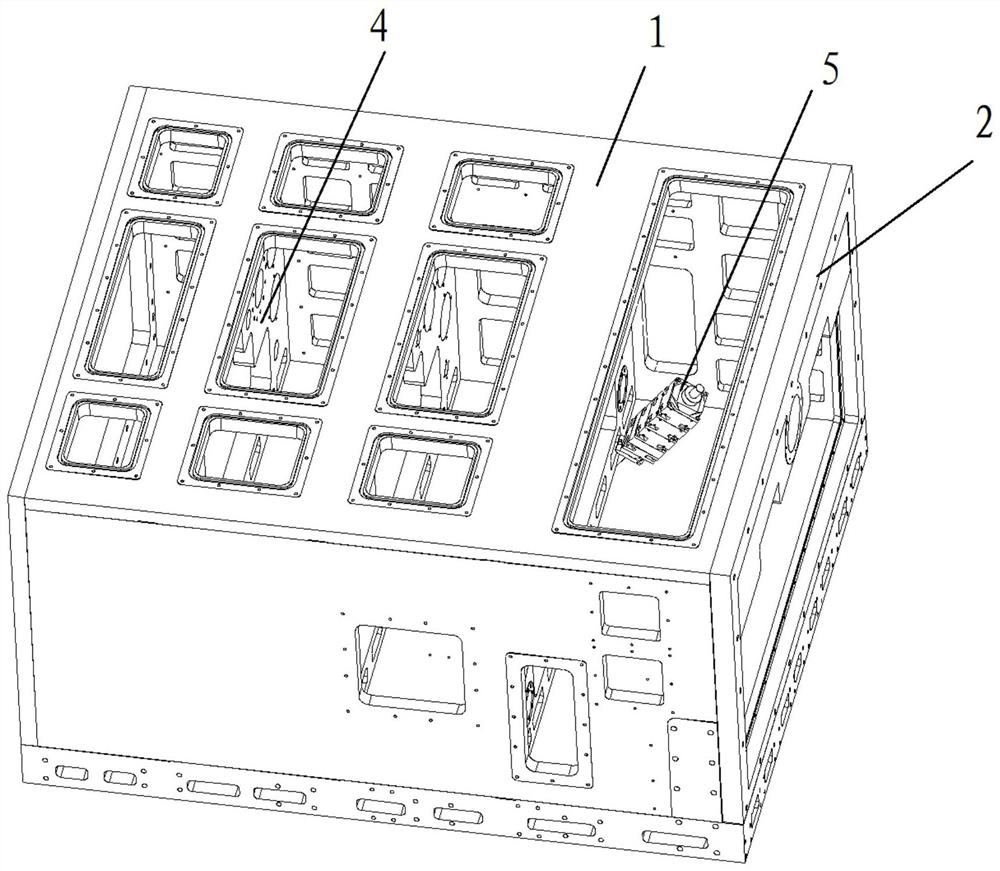

Preparation method of box body of box-shaped structure

ActiveCN112846502AGuaranteed StrengthImprove cleanlinessLaser beam welding apparatusFillet weldEngineering

The invention discloses a preparation method of a box body of a box-shaped structure, and belongs to the technical field of laser welding. The preparation method of the box body of the box-shaped structure comprises the steps that a top plate and the outer surface of a surrounding plate assembly are positioned and welded; a bottom plate assembly is disassembled, a welding gun enters from the bottom of the box body, inner side fillet welds of the top plate, the surrounding plate assembly and a vertical plate assembly are all welded, and it is guaranteed that the fusion depth is larger than or equal to 2.5 mm; the bottom plate assembly is installed, the welding gun enters the box body from a window in the top plate and the surrounding plate assembly, all inner side fillet welds of the bottom plate assembly, the surrounding plate assembly and the vertical plate assembly are welded, and it is guaranteed that the fusion depth is larger than or equal to 2.5 mm; and the outer surfaces of the top plate assembly, the surrounding plate assembly and the bottom plate assembly are subjected to laser large-fusion-depth back sealing weld and laser wire filling cosmetic welding, and it is guaranteed that the fusion depth is larger than or equal to 6 mm. According to the preparation method of the box body of the box-shaped structure, full coverage of internal welding seams is achieved, the phenomenon that redundant objects fall off from fillet welding seams to damage laser lenses is avoided, and the cleanliness is guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

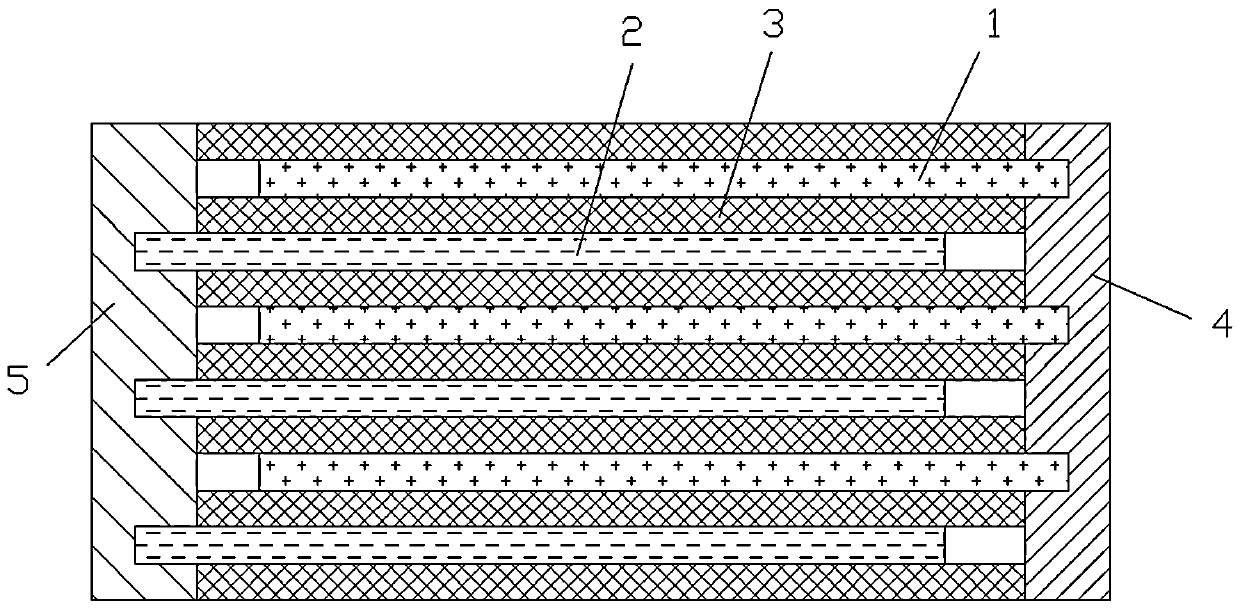

Lithium battery leading-out electrode with high charge-discharge rate

InactiveCN107946534AIncrease connection areaLower internal resistanceSmall-sized cells cases/jacketsPrimary cell electrodesElectricityInternal resistance

The invention discloses a lithium battery leading-out electrode with high charge-discharge rate. A positive current collector and a negative current collector are arranged in a staggered way, a protruding end of the positive current collector is arranged at one side of a lithium battery, a protruding end of the negative current collector is arranged at the other side of the lithium battery, the lithium battery leading-out electrode is characterized in that a positive gold spraying layer is deposited at the protruding end of the positive current collector and is electrically connected with thepositive current collector, and a negative gold spraying layer is deposited at the protruding end of the negative current collector and is electrically connected with the negative current collector. The gold spraying layers have certain thicknesses, subsequent welding is facilitated, the problem that a thin film current collector electrode is difficult to lead out is solved, current loading can beimproved, the internal resistance is reduced, and the charge-discharge rate is improved; and the positive gold spraying layer and the negative gold spraying layer are respectively arranged at different sides of the lithium battery, so that electrodes are lead out from different sides of the lithium battery, the problem that a positive electrode and a negative electrode are connected to cause short circuit due to a traditional mode that a tab is lead out from a signal side is prevented, no insulation cap is also needed to be additionally arranged, and the structure and the process are simplified.

Owner:ANHUI TATFOOK OPTOELECTRONICS TECH

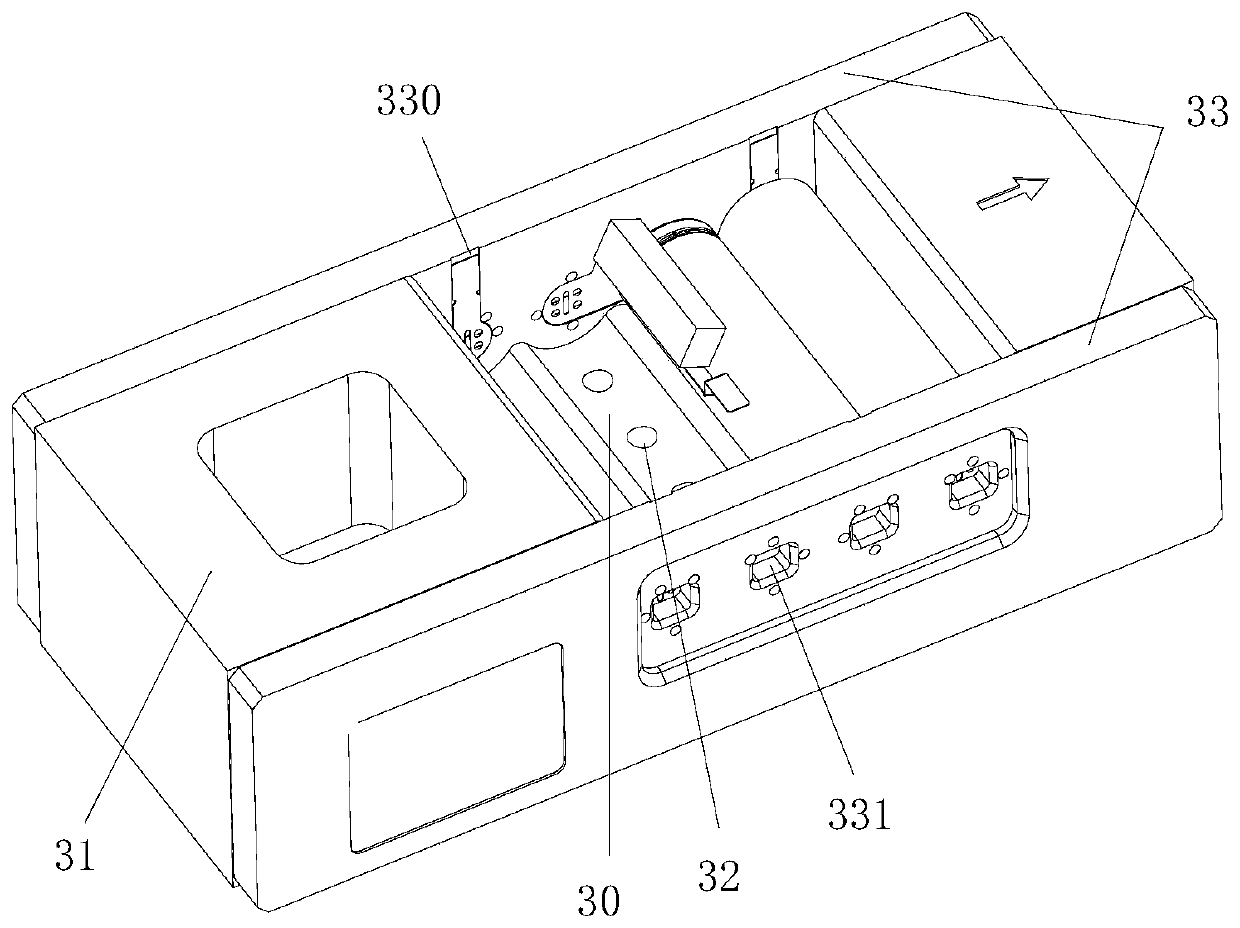

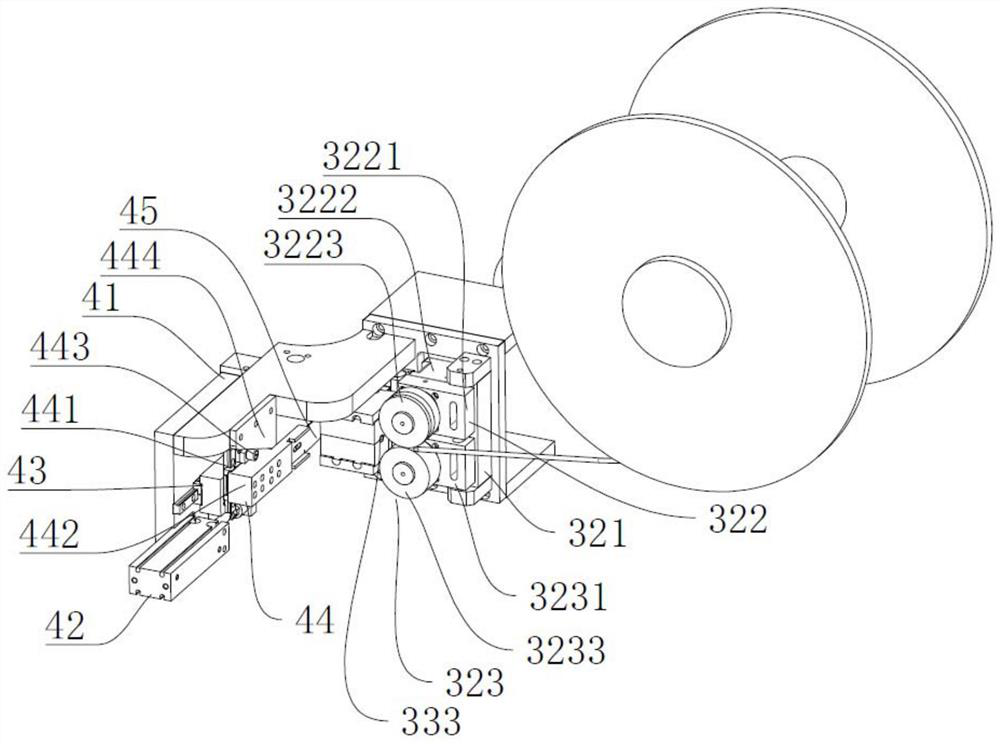

Pressure sensor production equipment and soldering tin assembly

InactiveCN109482999AImprove pass rateImprove welding precisionMetal working apparatusSoldering auxillary devicesSolderingMaterials science

The invention relates to the field of sensor production. A soldering tin assembly comprises a machine frame, a soldering flux coated device, a welding-aid device and a soldering tin device, wherein the soldering flux coated device, the welding-aid device and the soldering tin device are sequentially installed on the machine frame. The soldering tin assembly has the advantages that the welding precision, welding qualification rate and the welding quality of a sensor main body and covered wires are high.

Owner:庄再聪

Battery cell group processing equipment and processing method thereof

PendingCN114512705AFacilitate subsequent weldingFinal product manufactureLi-accumulatorsMechanical engineeringBattery cell

The invention discloses battery cell group processing equipment and a processing method thereof.The battery cell group processing equipment comprises a battery cell group tab shaping mechanism, the battery cell group tab shaping mechanism comprises a third bottom plate and a positioning assembly, and the positioning assembly is installed on the third bottom plate; the positioning assembly is used for fixing a battery cell group; the positioning assembly comprises an automatic comb-shaped shaping piece, a plurality of comb teeth are arranged on the automatic comb-shaped shaping piece, and the comb teeth are arranged at intervals so as to form gaps for battery cell group tabs to penetrate through. The battery cell group processing equipment comprises the battery cell group tab shaping mechanism, and after the tabs are inserted into the gaps among the comb teeth of the automatic comb-shaped shaping piece, the comb teeth of the automatic comb-shaped shaping piece can straighten the bent tabs, so that the subsequent processing procedures such as welding are facilitated.

Owner:博科能源系统(深圳)有限公司

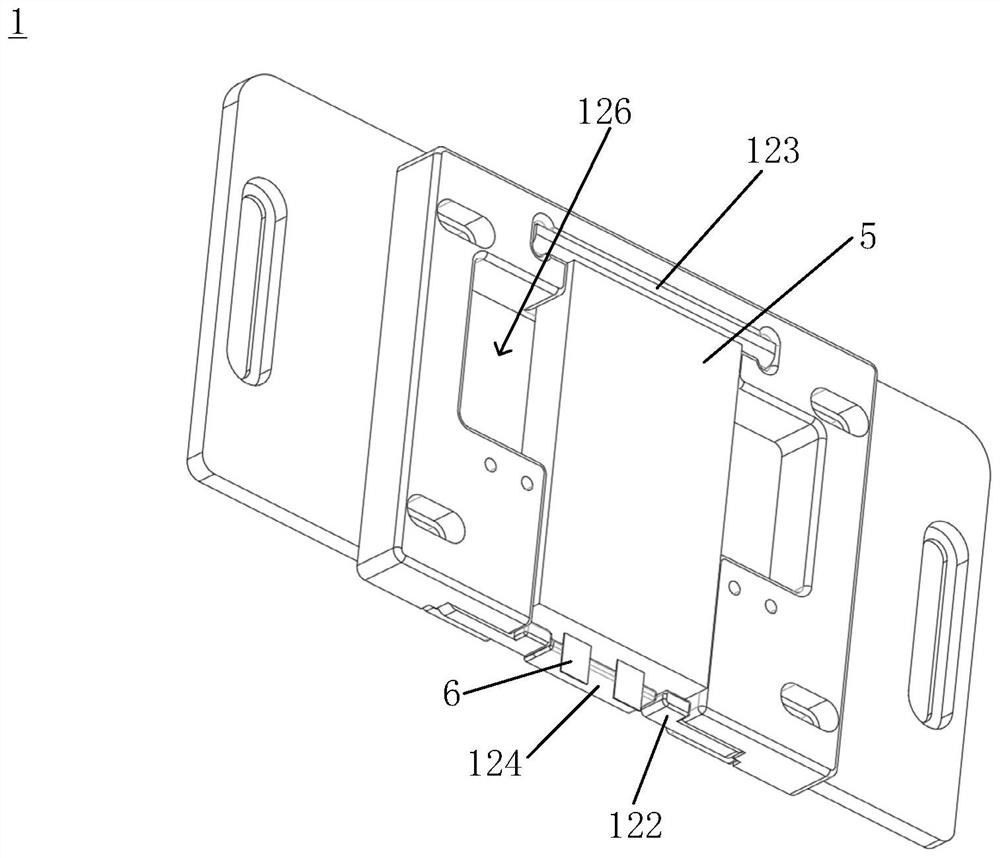

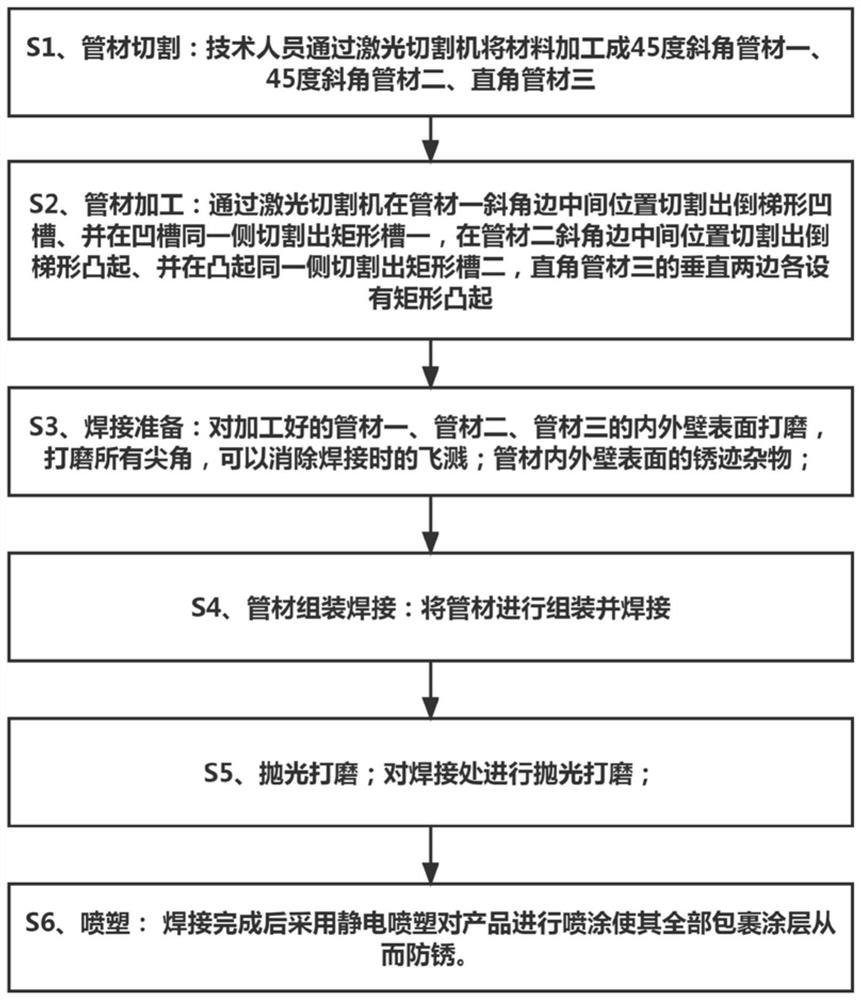

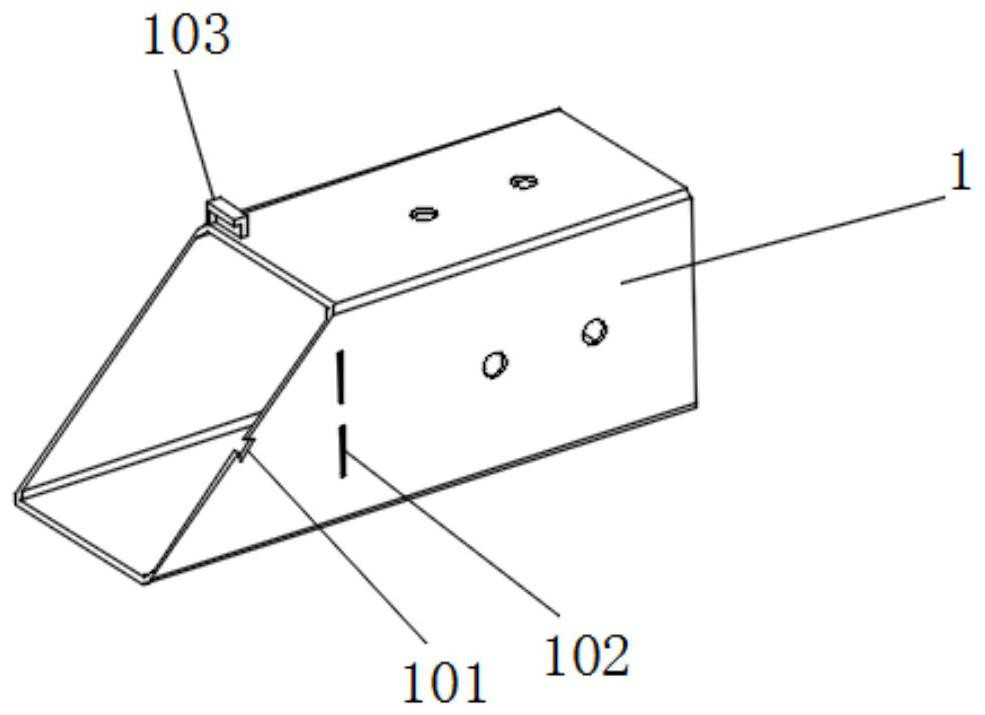

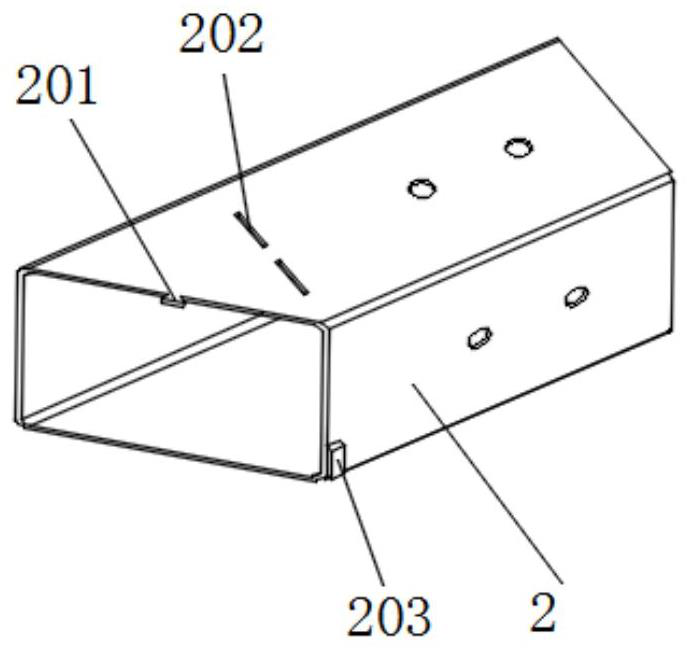

Assembled welding part and machining method thereof

PendingCN114850798AGuaranteed dimensional accuracyFacilitate subsequent weldingWorkpiece edge portionsEngineeringLaser cutting

The invention discloses a machining method of an assembled welding part. The machining method is characterized by specifically comprising the following steps that S1, pipe cutting is conducted, specifically, a technician machines materials into a first 45-degree oblique angle pipe, a second 45-degree oblique angle pipe and a third right-angle pipe through a laser cutting machine; s2, pipe machining is conducted, specifically, an inverted trapezoidal groove is cut in the middle of the bevel edge of the first pipe through a laser cutting machine, a first rectangular groove is cut in the same side of the groove, an inverted trapezoidal protrusion is cut in the middle of the bevel edge of the second pipe, a second rectangular groove is cut in the same side of the protrusion, and rectangular protrusions are arranged on the two perpendicular sides of a third right-angle pipe correspondingly; the inverted trapezoidal groove and the inverted trapezoidal protrusion can be embedded, the first rectangular groove and the second rectangular groove can be embedded with the rectangular protrusion respectively, and the problems of poor welding and unattractive welding are solved through assembling, welding and the like.

Owner:SUZHOU DIHANG DEFENSE FACILITIES CO LTD

Welding device for industrial pipeline machining

PendingCN114535876AStable and precise welding operationImprove adaptabilityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryProcess engineering

The invention discloses a welding device for industrial pipeline machining, which comprises a connecting belt pulley, a tooth-shaped belt, a limiting mechanism, an industrial pipeline, a supporting mechanism, a connecting motor, two-way screw rods, a welding mounting frame and a supporting bottom plate, and connecting belt wheels are symmetrically and fixedly connected to the outer end faces of the two sets of bidirectional lead screws, the two sets of connecting belt wheels are rotationally connected in a meshed mode through a tooth-shaped belt, and connecting motors are fixedly installed at the positions, right opposite to the connecting belt wheels, of the outer end face of the supporting bottom plate. According to the industrial pipeline welding device, industrial pipelines with different radiuses can be rapidly and stably limited, so that subsequent stable and accurate welding operation on the industrial pipelines is facilitated, meanwhile, the distance between the multiple sets of industrial pipelines can be automatically adjusted according to requirements, the adaptability of machining of the industrial pipelines is improved to the maximum extent, and then the machining efficiency is improved.

Owner:徐俊傅

Clamping mechanical claw for automobile glass welding

InactiveCN112265011AAvoid scratchesImprove gripGripping headsGlass reforming apparatusPhysicsWelding

The invention discloses a clamping mechanical claw for automobile glass welding, and relates to the technical field of mechanical claws. The grabbing problem of a multi-action part is solved. The clamping mechanical claw specifically comprises a connecting frame, wherein the outer wall of one side of the connecting frame is fixedly connected to the outer wall of clamping equipment; a second fixeddisc is fixedly connected to the outer wall of one side of the connecting frame; a second rotary disc is slidably connected to the outer wall of one side of the second fixed disc; a supporting plate is fixedly connected to the outer wall of one side of the second rotary disc; folding assemblies are fixedly connected to the outer wall of one side of the supporting plate; an adjusting assembly is fixedly connected to the outer wall of one side of a folding assembly; clamping arm assemblies are fixedly connected to the outer wall of one side of the adjusting assembly; the number of the folding assembly and the number of the adjusting assembly are both two; and the number of the clamping arm assemblies is four. By arranging the clamping arm assemblies, firstly, the mechanical claw can grab different parts correspondingly, secondly, contact blocks on the outer walls of inserting strips can be replaced, subsequent grabbing is optimized, and thirdly, ejector rods go deep into positioning holes to clamp placement blocks, and the grabbing effect is enhanced.

Owner:刘少波

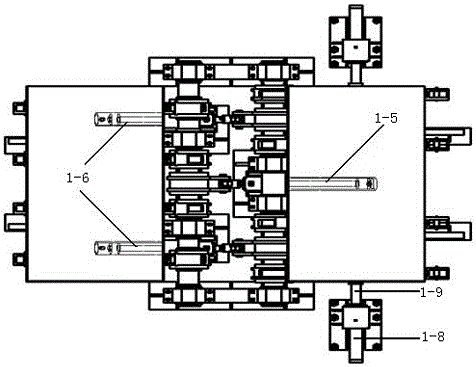

Variable-angle square tube automatic cutting machine

InactiveCN109454289ARapid positioningSolve the problem of inaccurate angle positioningTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a variable-angle square tube automatic cutting machine. The variable-angle square tube automatic cutting machine comprises a workbench, a cutting device, a square tube clampingdevice and a PLC, wherein the cutting device and the square tube clamping device are arranged on the workbench; the square tube clamping device can rotate, the cutting angle of the cutting head of the cutting device is not changed, the square tube clamping device comprises a clamp and a clamp seat, the clamp seat is of an annular rotatable structure, and the clamp seat can drive the square tube to rotate to change the cutting angle. By means of the mode, the square tube in the clamp can be driven to change the angle through rotation of the clamp seat, so that the cutting device can be conveniently fed at an accurate angle, the machining efficiency of the square tube is improved, follow-up welding and other procedures are facilitated, and further machining is facilitated.

Owner:风范绿色建筑(常熟)有限公司

A kind of preparation method of extra-thick alloy steel plate

ActiveCN103692166BAvoid pollutionAvoid affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelVacuum chamber

Owner:沈阳科安捷材料技术有限公司

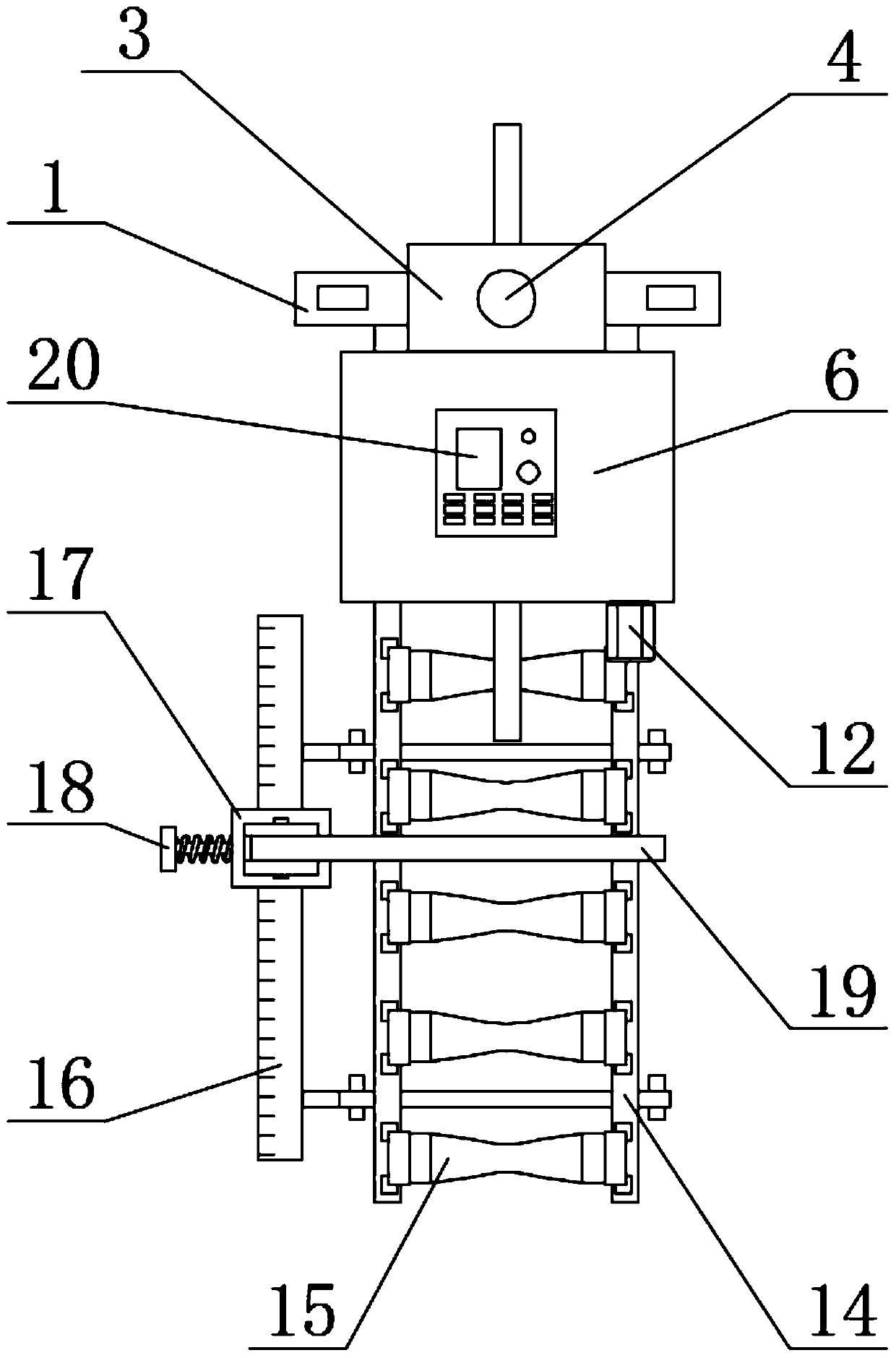

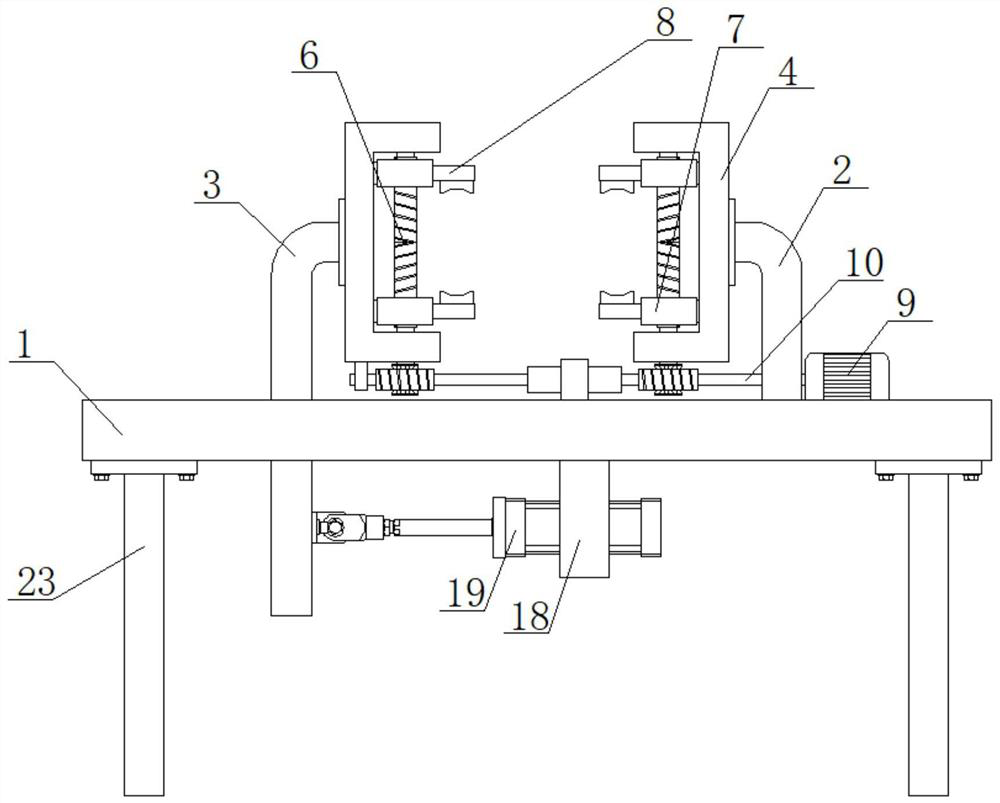

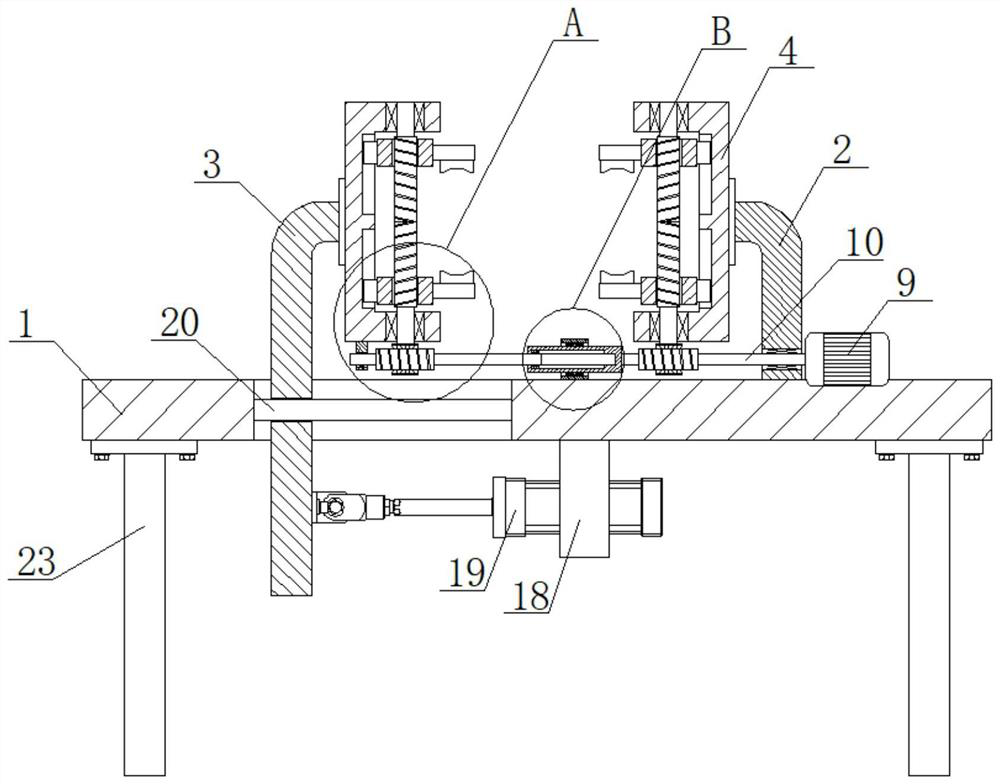

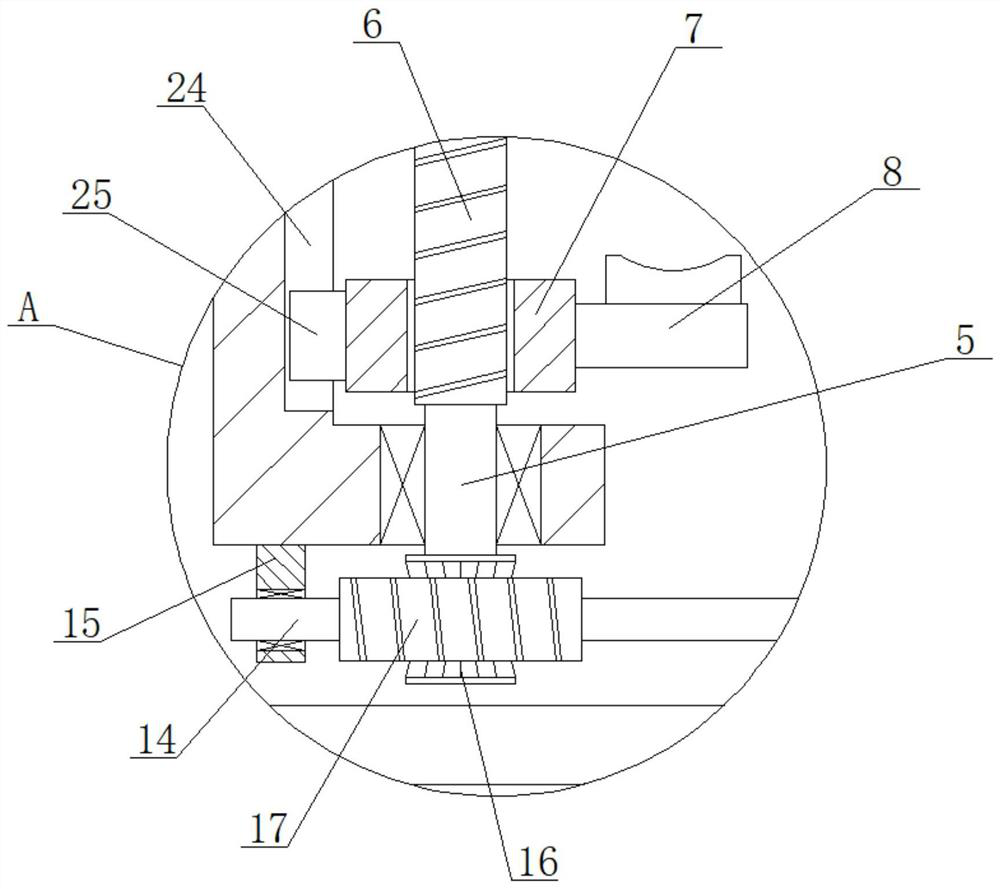

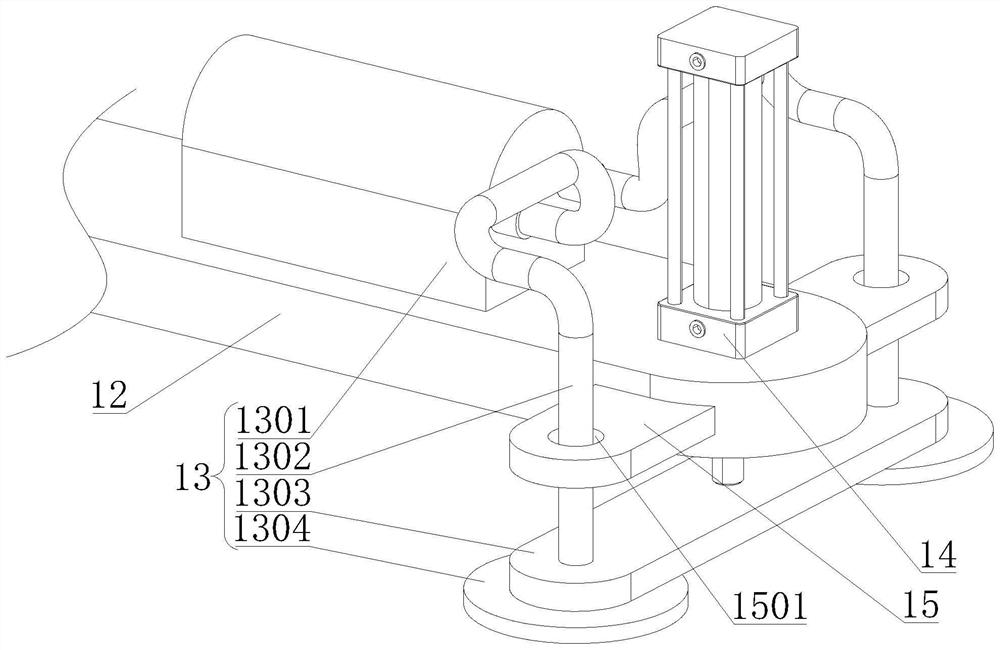

Alignment device for net rack rod part welding equipment

InactiveCN113084430AFacilitate subsequent weldingEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryManufacturing engineering

The invention relates to the technical field of welding equipment, and discloses an alignment device for net rack rod part welding equipment. The device comprises a base; the upper end of the base is fixedly connected with a fixed plate; the base is connected with a moving plate through a moving mechanism; the upper end of the moving plate and the upper end of the fixed plate are oppositely bent and are fixedly connected with mounting frames; rotating rods are jointly and rotationally connected with the interiors of the mounting frames through two first bearings; the rotating rods are fixedly sleeved with threaded rods; each threaded rod is provided with symmetrical threads in opposite directions; the threaded rods are in threaded connection with two threaded sleeves; the two threaded sleeves are symmetrically arranged; one side of each threaded sleeve is fixedly connected with a positioning clamp; the lower ends of the two rotating rods are jointly provided with a synchronous driving mechanism; and a driving motor is a servo motor. The alignment device for the net rack rod part welding equipment has the advantages that net rack rod parts can be positioned and fixed, and spot welding machining can be accurately conducted on the net rack rod parts.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

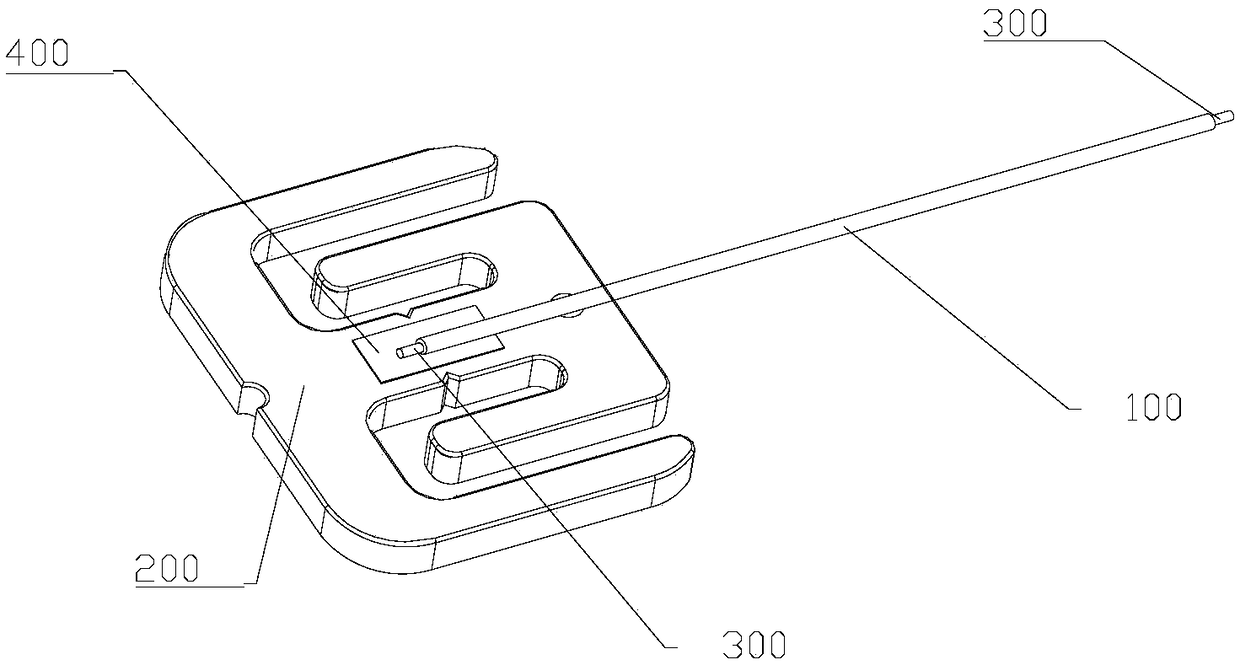

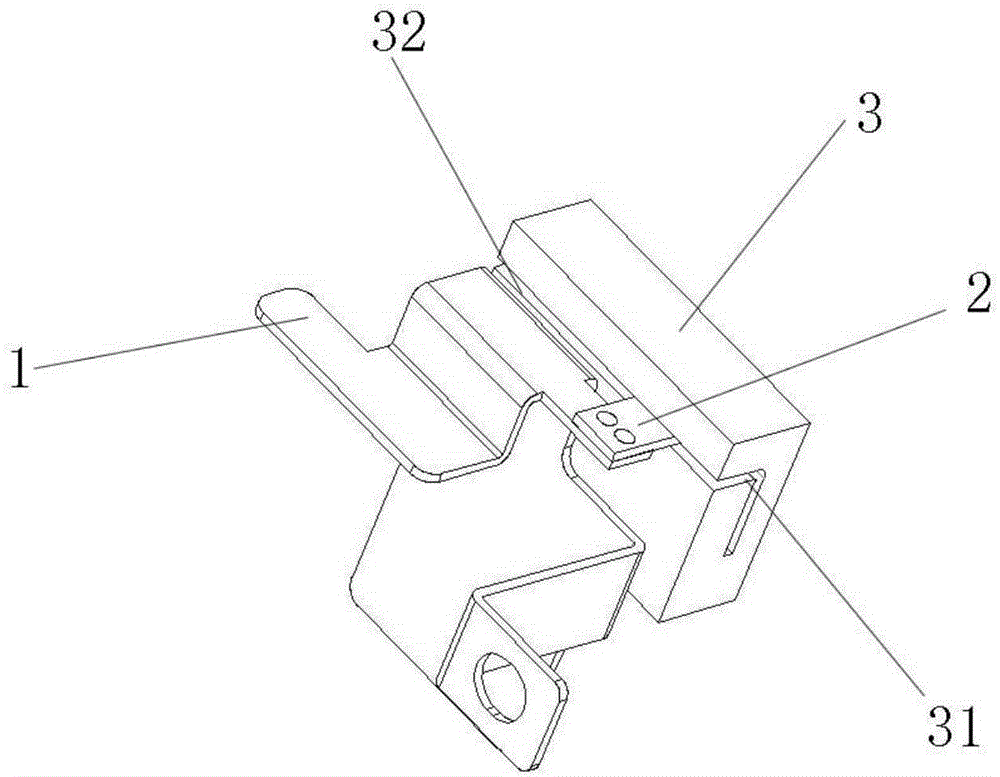

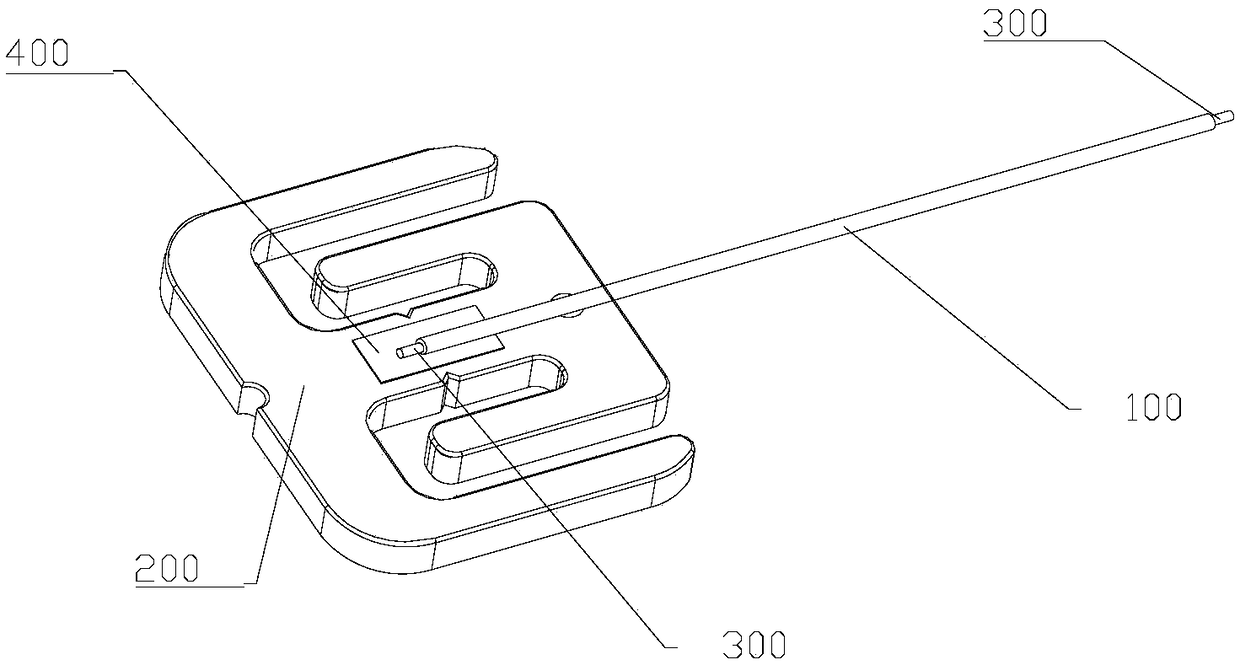

Positioning welding base of electronic component

InactiveCN112372204AImprove positioning efficiencyFacilitate subsequent weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCable harness

The invention relates to a positioning welding base of an electronic component, which comprises a welding base body, a C positioning part and a D positioning part, wherein the C positioning part and the D positioning part are arranged on the upper surface of the welding base body and are used for respectively positioning the component and a wire harness; and the positioning part C and the positioning part D are oppositely arranged on the welding base, so that two pins of the component and wire cores at the end parts of a wire A and a wire B forming the wire harness are arranged in a lap jointmanner. By adopting the positioning welding base provided by the invention, the positioning efficiency can be effectively improved, and subsequent welding is facilitated; and the labor intensity can be reduced, and the labor workload is reduced.

Owner:程艳云

Resistance welding mechanism for floor mopping robot battery

PendingCN111014918AWide applicabilityAvoid wire frayingResistance electrode holdersEngineeringBattery cell

The invention discloses a resistance welding mechanism for a floor mopping robot battery. The resistance welding mechanism comprises a machine frame, a conveyor, a resistance welding jig, a jacking assembly, a pressing-down assembly, a welding assembly and a wire follow-up assembly. The conveyor is arranged on the machine frame and conveys the resistance welding jig. The bottom of the machine frame is provided with the jacking assembly matched with the resistance welding jig. The pressing-down assembly is arranged on the upper side of the resistance welding jig. The welding assembly and the wire follow-up assembly are arranged at the positions, on the front side and the rear side of the resistance welding jig, of the machine frame. In this way, the resistance welding mechanism is compact in structure and stable in operation, can rapidly position and install the battery and a connector and weld the battery and the connector together, and is high in work efficiency.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

Substrate connection process and substrate assembly of LED automobile headlamp

ActiveCN108649409AImprove consistencyUnified specificationsLine/current collector detailsSignalling/lighting devicesManufacturing technologyEngineering

The invention relates to the technical field of LED automobile headlamp manufacturing, in particular to a substrate connection process of an LED automobile headlamp. The substrate connection process comprises the following steps of A, arranging a first substrate to be connected and a second substrate to be connected, wherein the first substrate comprises a first bonding pad, and the second substrate comprises a second bonding pad; B, arranging a flexible substrate, wherein the flexible substrate comprises a third bonding pad and a fourth bonding pad, and the third bonding pad and the fourth bonding pad are electrically connected by a substrate wire; and C, allowing the first bonding pad and the second bonding pad to be aligned and welded, and allowing the second bonding pad and the fourthbonding pad to be aligned and welded. By the process, the problems of time and labor consumption of connection between the substrates in the prior art and low product consistency can be solved, and production is facilitated. The invention also provides a substrate assembly of the LED automobile headlamp.

Owner:SHENZHEN YIKE PHOTOELECTRIC TECH

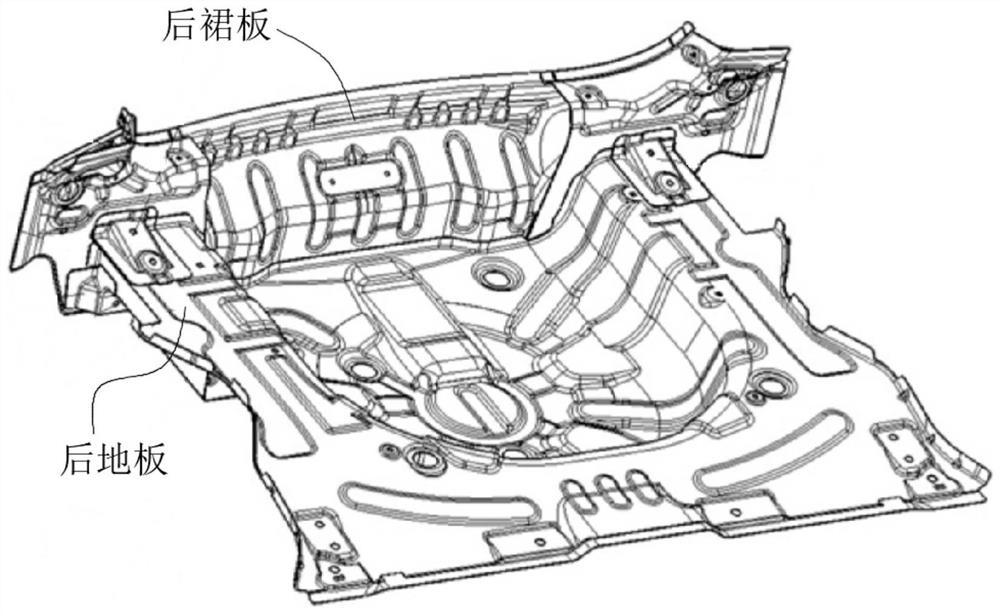

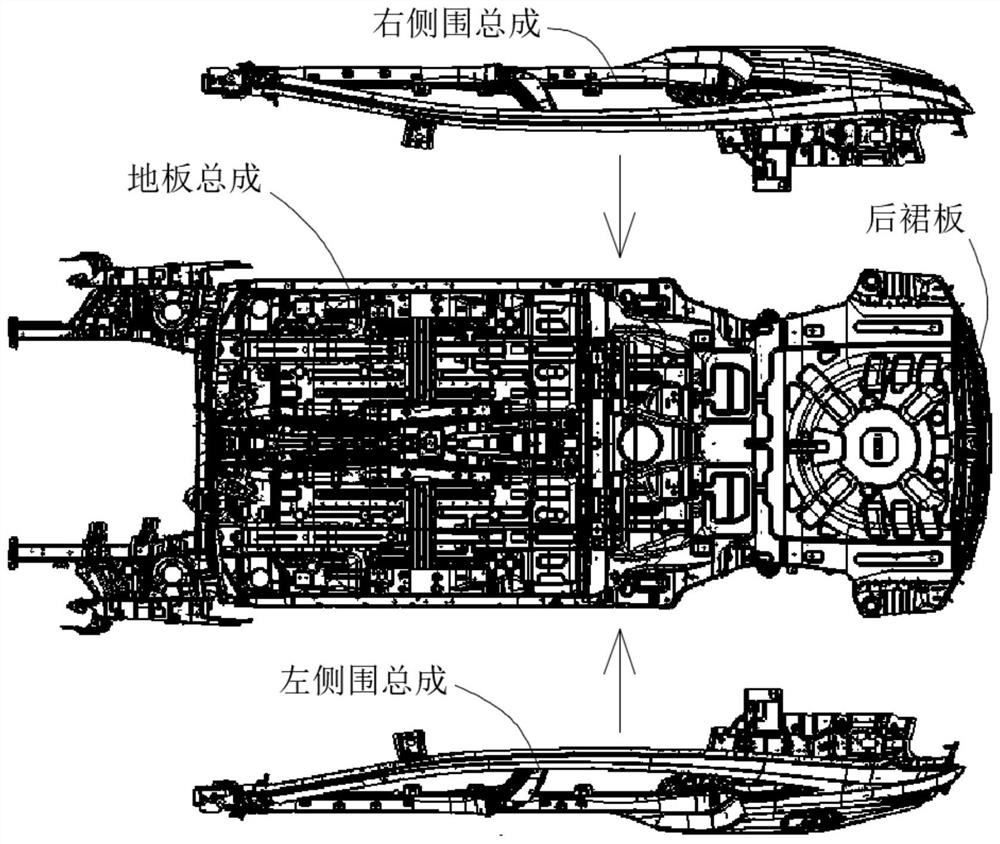

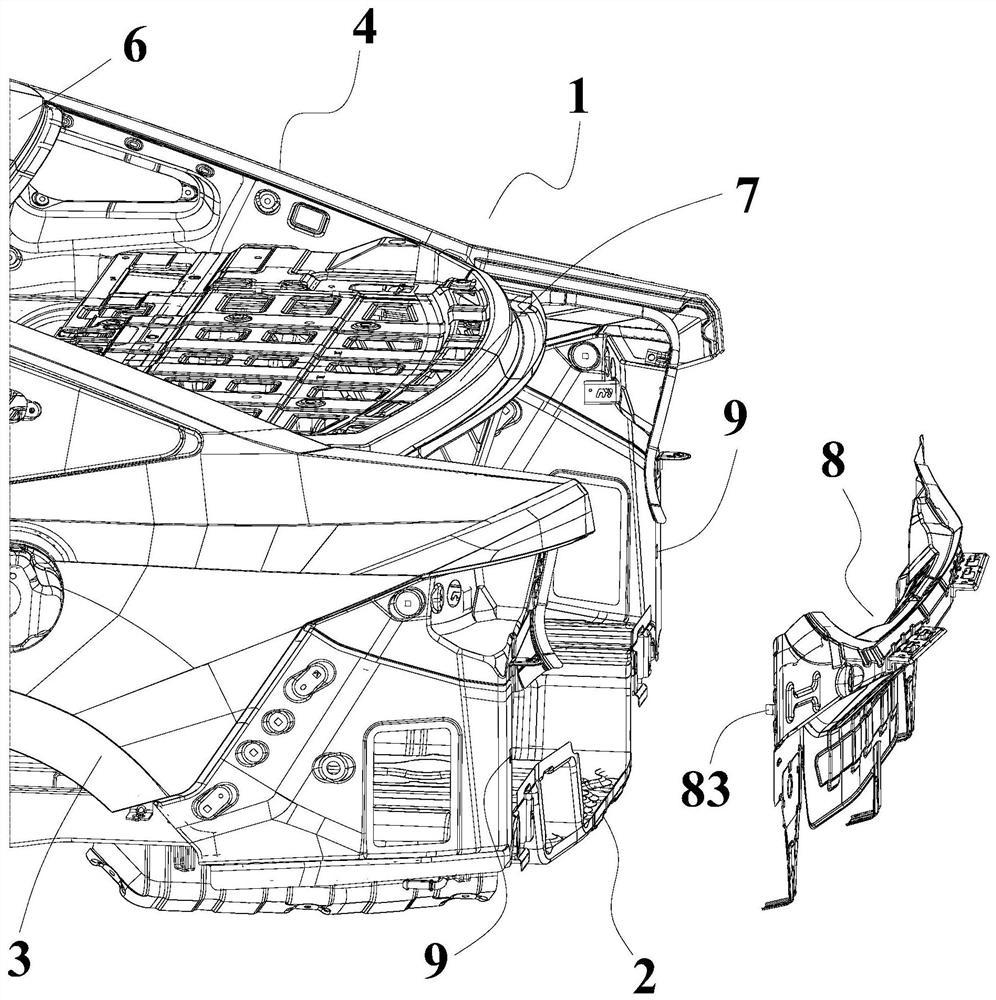

Automobile body rear end welding process

ActiveCN113601048AShorten production timeTechnical Issues Affecting AccuracyWelding/cutting auxillary devicesAuxillary welding devicesWelding processAutomotive engineering

The invention relates to the field of automobile production, in particular to an automobile body rear end welding process. The process comprises the following steps: welding an automobile body assembly: welding a lower automobile body assembly with a left side wall assembly and a right side wall assembly to form the automobile body assembly; performing pre-tightening: pre-tightening a top cover front cross beam, a top cover rear cross beam, a storage plate assembly, a rear apron board assembly and the automobile body assembly; and performing welding: welding the rear apron board assembly with the automobile body assembly. The process has the advantages that a welding tooling for the rear apron board assembly and a floor assembly in the prior art is omitted, additional clamping toolings are not needed, one welding procedure is omitted, the automobile body production time is shortened, the cost of the clamping toolings is reduced, and the problems that in the prior art, the left side wall assembly, the right side wall assembly and the rear apron board are not in place and the precision of the automobile body is influenced, are solved.

Owner:HEFEI CHANGAN AUTOMOBILE

Silica gel welding equipment

PendingCN113334785ASolve the problems of high welding difficulty and low welding efficiencyHigh degree of automationEngineeringMachine

The invention relates to the technical field of silica gel welding, in particular to silica gel welding equipment. The equipment comprises a machine frame, a discharging mechanism arranged at one side of the machine frame, a material guiding mechanism arranged on the machine frame, a material cutting mechanism arranged on the material guiding mechanism, a material clamping and pulling mechanism arranged on the machine frame, a gluing mechanism arranged on the machine frame and located above the material clamping and pulling mechanism, a welding mechanism arranged on the machine frame and located at one side of the material clamping and pulling mechanism, and a controller installed on the machine frame. Full-automatic feeding is adopted, clamping and pulling are matched with rotation after feeding, the head end and the tail end of a cut-off silica gel strip are clamped through a first clamping device and a second clamping device, the silica gel strip is rotated after being clamped, the two ends corresponding to the head end and the tail end are glued through the gluing mechanism, and a silica gel ring is formed through welding of the welding mechanism after gluing is completed. The overall automation degree is high.

Owner:DONGGUAN POLYTECHNIC

A method for splicing optical fibers

ActiveCN111352188BThere will be no excessive meltingExcessive melting will not occurCoupling light guidesFiberEngineering

The invention provides an optical fiber fusion splicing method, which is used for ultra-fine optical fiber fusion splicing, comprising: (1) removing the coating layer of the optical fiber by 30-40mm, and wiping it clean with anhydrous ethanol; (2) clamping the optical fiber with a clamp, and making the The coated optical fiber protrudes from the jig by 1-2mm; (3) Use a cutting machine to cut the optical fiber, and the cutting angle is ≤1°; (4) Place the cut optical fiber in the fusion splicer for fusion splicing, and wrap the optical fiber Input the layer diameter into the fusion splicer, set the cleaning discharge power as special 100bit to special 200bit, the cleaning discharge time as 60 to 100ms, the distance between fiber end faces 10 to 15μm, the fiber premelting power as special 60bit to special 120bit, and the fiber premelting time as 10~50ms, the main discharge power is special 30bit~special 100bit, the main discharge time is 1500~2000ms, the redischarge power is special 200bit~special 300bit, the redischarge time is 600~800ms, and the fiber alignment method is set to off ; (5) Coating the fusion-spliced optical fiber splicing points by using a coating machine. The optical fiber fusion splicing method provided by the invention is suitable for superfine optical fiber fusion splicing, has good fusion splicing effect, and has practical value in optical fiber technology.

Owner:AVIC SHAANXI HUAYAN AERO INSTR

Chip packaging manufacturing equipment

PendingCN114678302AImprove consistent productionFacilitate subsequent weldingSemiconductor/solid-state device manufacturingConveyor partsEngineeringWorkbench

The invention relates to chip packaging manufacturing equipment, which belongs to the technical field of chip packaging and comprises a workbench, a packaging table, a discharging mechanism, a feeding mechanism a, a feeding mechanism b, a detection contact, a supporting frame, a welding mechanism, a rotating column, a supporting arm and an adsorption mechanism. A positioning groove is formed in the packaging table; the detection contact is arranged in the positioning groove; the welding mechanism is arranged above the positioning groove in a sliding manner; a lifting mechanism used for driving the welding mechanism to move is arranged on the supporting frame. The rotating column is rotationally arranged on the workbench; a driving mechanism for driving the rotating column to rotate is arranged on the workbench; limiting mechanisms are arranged at the lower ends of the rotating columns; the discharging mechanism, the feeding mechanism a, the feeding mechanism b, the welding mechanism, the lifting mechanism, the adsorption mechanisms, the limiting mechanism and the driving mechanism are all in communication connection, and the three adsorption mechanisms are located above the discharging mechanism, the feeding mechanism a and the feeding mechanism b correspondingly. According to the invention, the chip can be automatically loaded and packaged, and the packaged chip can be taken down.

Owner:深圳市星芯科技有限公司

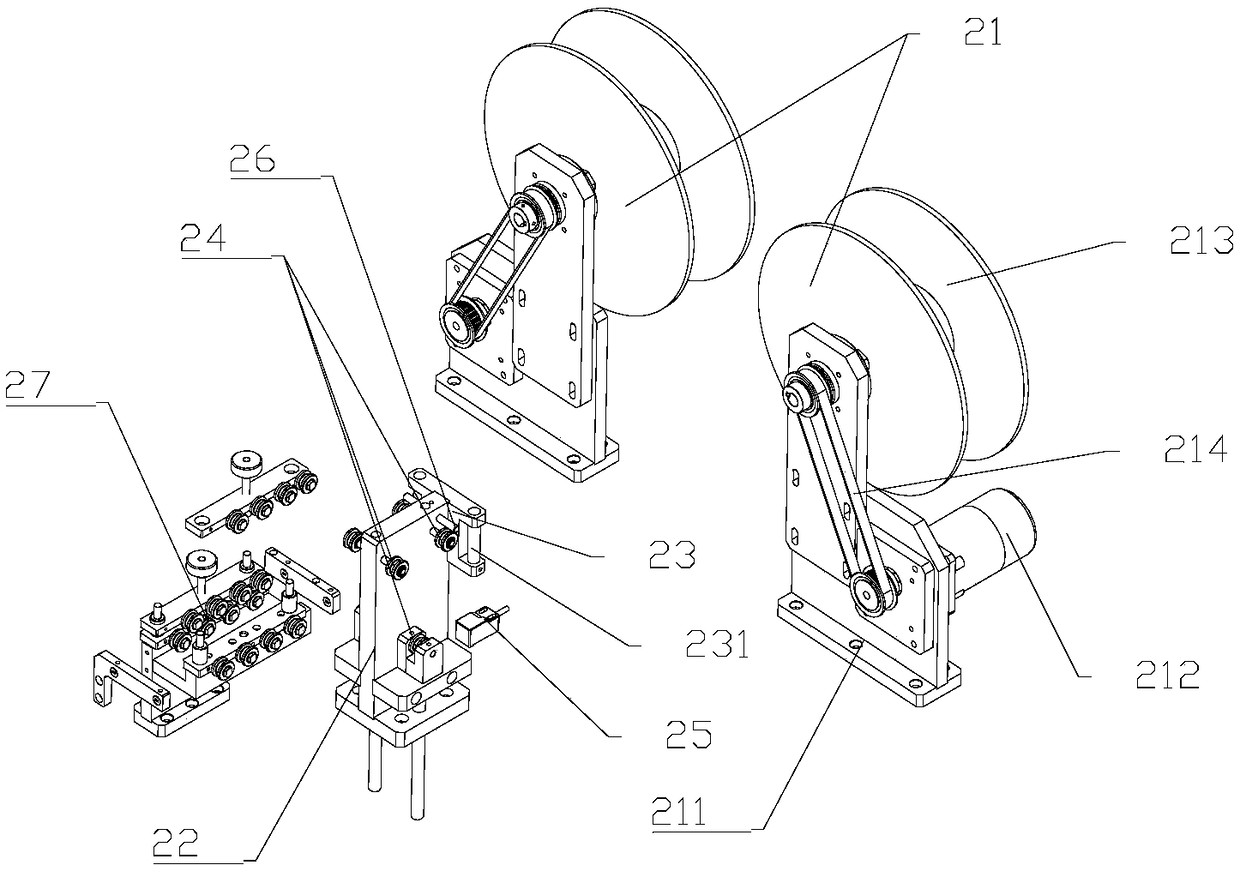

Tab supply device

PendingCN112787045ASame lengthAvoid damageAssembling battery machinesFinal product manufactureElectrical batteryStructural engineering

The invention discloses a tab supply device, and belongs to the technical field of battery assembly equipment. The tab supply device comprises a base, a first mounting plate and a second mounting plate, an unwinding assembly is arranged on the second mounting plate, a collecting assembly and a shaping assembly are arranged on the first mounting plate, a cutting assembly, a shaping assembly and a feeding assembly are arranged on the base, the cutting assembly comprises a first air cylinder and a cutter, and the first air cylinder is fixedly connected to the base. The output end of the first air cylinder is fixedly connected with a driving block, the base is fixedly connected with a positioning block, the cutter is connected to the positioning block in a sliding mode, the cutter is fixedly connected with a positioning column, a guide groove is formed in the driving block, the positioning column is connected into the guide groove in a sliding mode, and the driving block is fixedly connected with a blocking piece used for aligning tabs. According to the invention, the two sets of cutters cut off and separate the tab strips, and in the cutting process, the lengths of cut tabs can be ensured to be consistent by matching with the feeding assembly baffle, so that the positive tabs are regulated, the welding precision is ensured, and the damage to the tabs is reduced.

Owner:深圳市宏锦智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com