Battery cell group processing equipment and processing method thereof

A technology for processing equipment and cell groups, which is applied to cell group processing equipment and its processing field, can solve problems such as unfavorable welding processing, and achieve the effect of facilitating processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the terminology used and specific structural and functional details disclosed herein are merely representative for describing specific embodiments, but the invention may be embodied in many alternative forms and should not be construed as merely Be limited by the examples set forth herein.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and alternative embodiments.

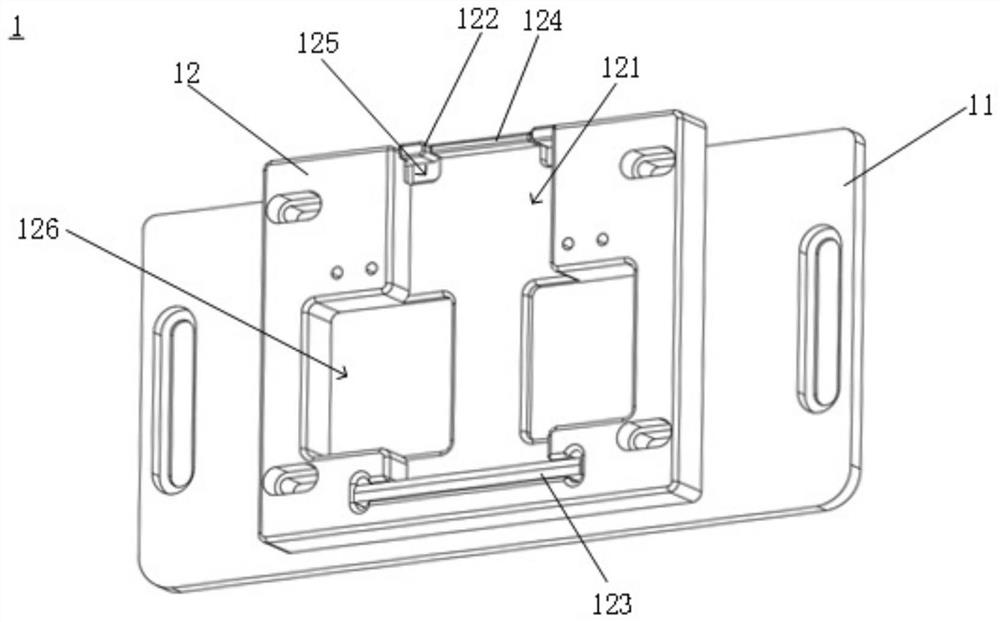

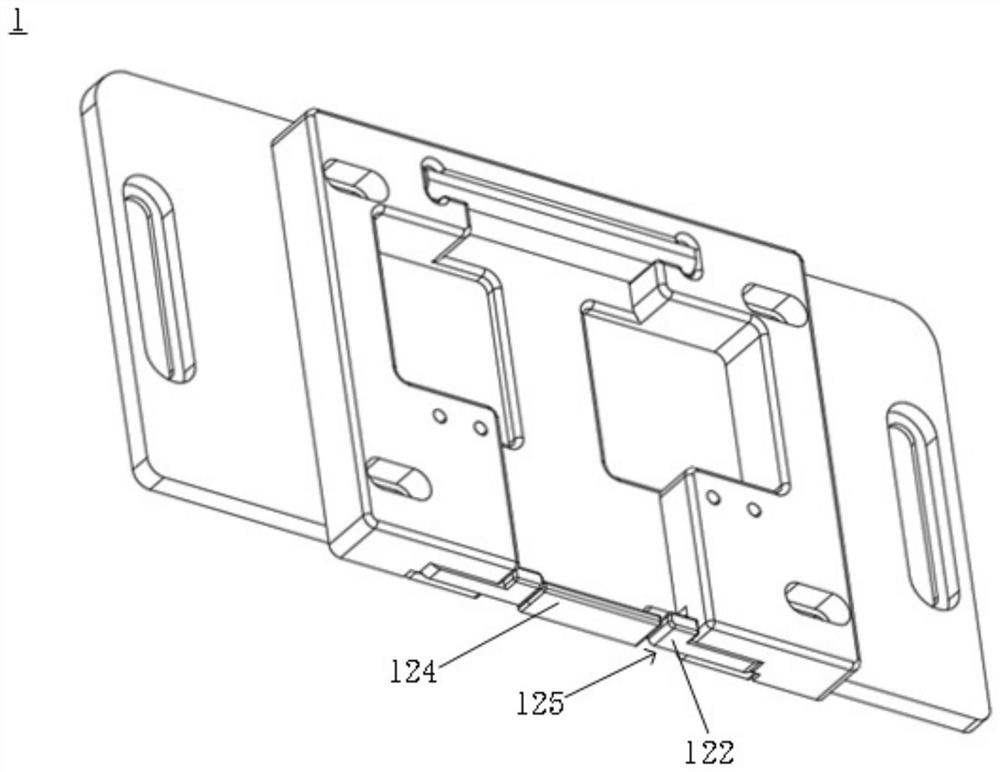

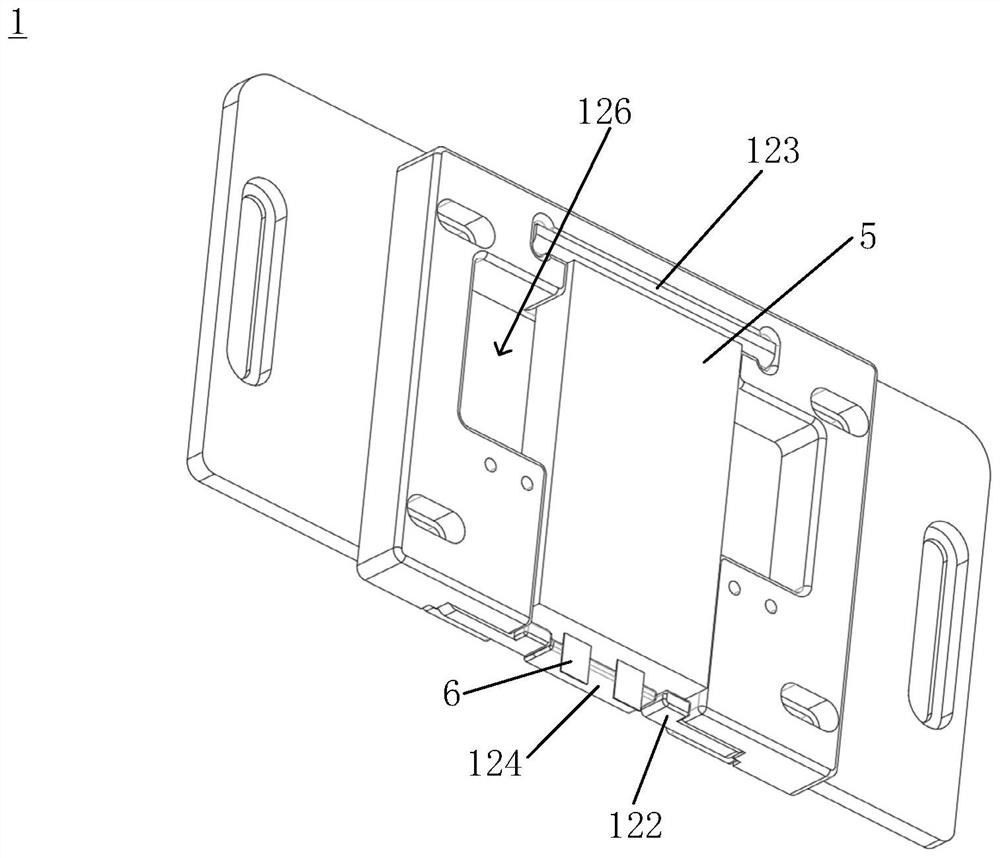

[0032] Such as Figure 1 to Figure 3 As shown, as an embodiment of the present invention, a cell pack processing equipment is disclosed, including a tab cutting and positioning mechanism 1; the tab cutting and positioning mechanism 1 includes a first bottom plate 11, and is installed on the first bottom plate 11. The positioning plate 12; the positioning plate 12 is formed with a positioning groove 121 for positioning the electric core 5; the positioning plate 12 is movably provided with an elastic positioning piece 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com