Chip packaging manufacturing equipment

A technology for manufacturing equipment and chip packaging, which is applied in semiconductor/solid-state device manufacturing, transportation and packaging, electrical components, etc. It can solve the problems of high labor cost, inability to realize automatic continuous production, and low production efficiency, so as to avoid follow-up testing, Improve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

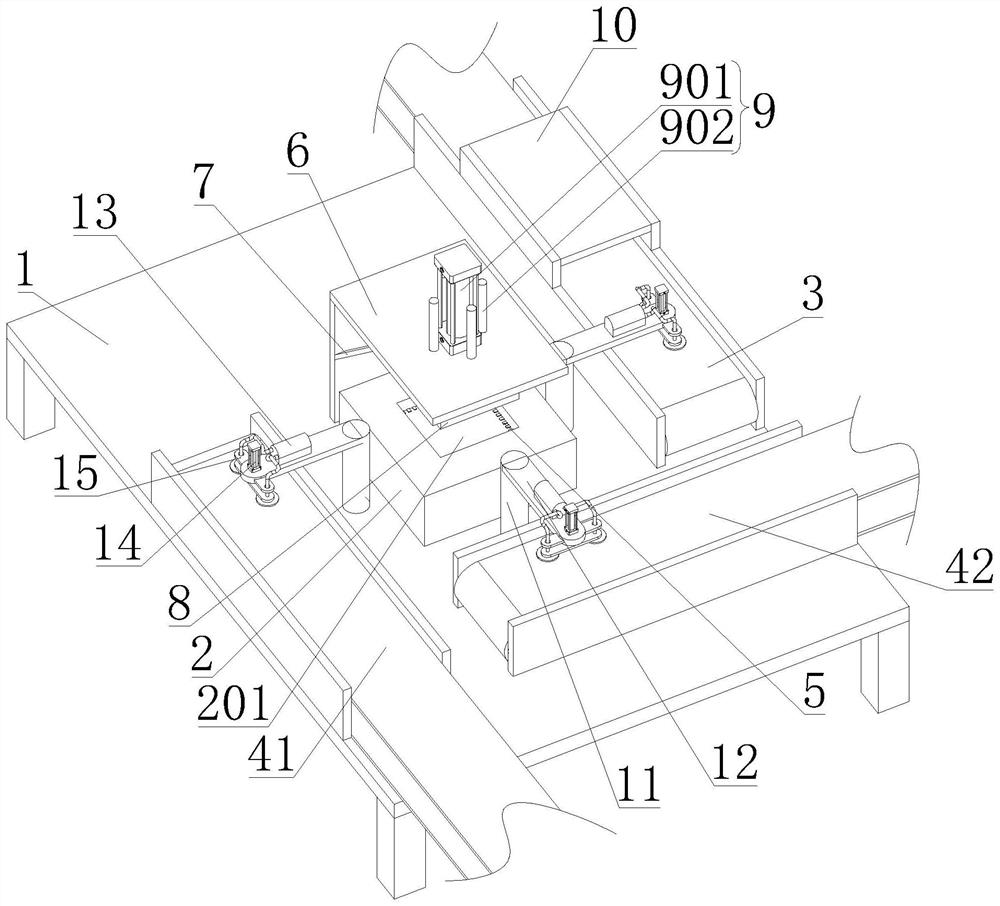

[0030] like Figure 1-3 As shown in the figure, a chip packaging manufacturing equipment proposed by the present invention includes a workbench 1, a packaging table 2, a feeding mechanism 3, a feeding mechanism 41, a feeding mechanism 42, a detection contact 5, a support frame 6, a welding Mechanism 8, rotating column 11, support arm 12 and adsorption mechanism 13;

[0031] The packaging table 2, the unloading mechanism 3, the a feeding mechanism 41, the b feeding mechanism 42 and the support frame 6 are all arranged on the work table 1; the packaging table 2 is provided with a positioning groove 201; the detection contact 5 is arranged in the positioning groove 201; the welding mechanism 8 is slidably arranged above the positioning groove 201; the supporting frame 6 is provided with a lifting mechanism 9 for driving the welding mechanism 8 to move; three rotating columns 11, support arms 12 and adsorption mechanisms 13 are provided; One end of 12 is arranged on the upper end...

Embodiment 2

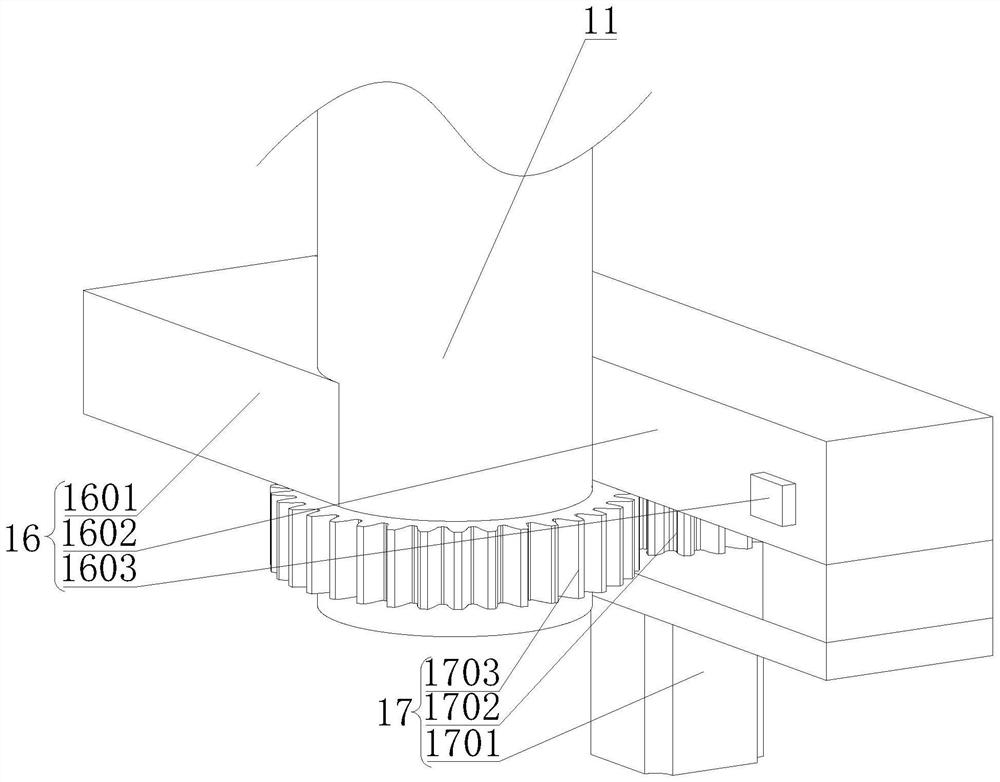

[0045] like Figure 1-3 As shown in the figure, a chip packaging manufacturing equipment proposed by the present invention, compared with the first embodiment, the lifting mechanism 9 in this embodiment includes a telescopic cylinder 901 and a guide rail 902; a telescopic cylinder 901 is arranged on the support frame 6, a telescopic The output end of the cylinder 901 is connected with the upper end of the welding mechanism 8 .

[0046] In this embodiment, after the casing and the chip body are placed in the positioning groove 201, a telescopic cylinder 901 drives the welding mechanism 8 to move downward, and the guide rail 902 guides and supports the welding mechanism 8, so that the welding mechanism 8 moves more easily Stable, the welding mechanism 8 is in contact with the chip body, so that the chip body and the pins can be welded together, and packaging can be performed.

Embodiment 3

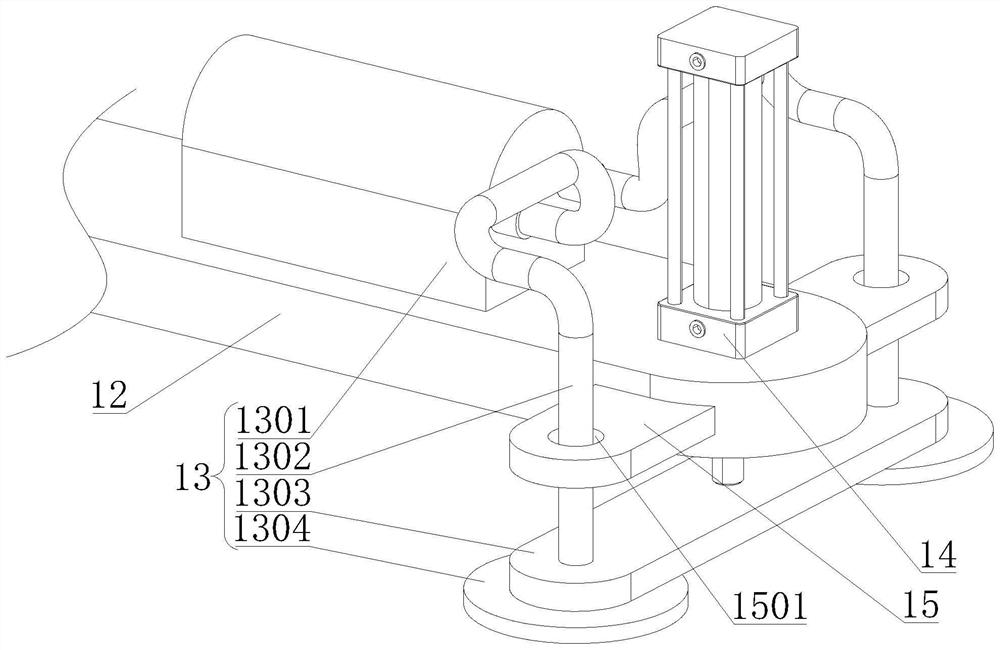

[0048] like Figure 1-3 As shown, in a chip packaging manufacturing apparatus proposed by the present invention, compared with Embodiment 1 or Embodiment 2, the adsorption mechanism 13 in this embodiment includes an air pump 1301, a communication pipe 1302, a lifting plate 1303 and a suction cup 1304; the air pump 1301 is provided with On the support arm 12; a plurality of communicating pipes 1302 and suction cups 1304 are provided; a plurality of suction cups 1304 are arranged on the lower end of the lift plate 1303; the lift plate 1303 is slidably arranged on the lower end of the support arm 12; The lift plate 1303 is driven to move the telescopic cylinder 14; the two ends of the communication pipe 1302 are respectively connected with the air pump 1301 and the suction cup 1304. The support arm 12 is provided with a support plate 15 , and the support plate 15 is provided with a guide groove 1501 ;

[0049] In this embodiment, taking the casing on the feeding mechanism 41 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com