Substrate connection process and substrate assembly of LED automobile headlamp

A technology for substrates and headlights, applied in connection, motor vehicles, road vehicles, etc., can solve problems such as labor-intensive, time-consuming connection between substrates and substrates, low product consistency, etc., and achieve uniform specifications and high product consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

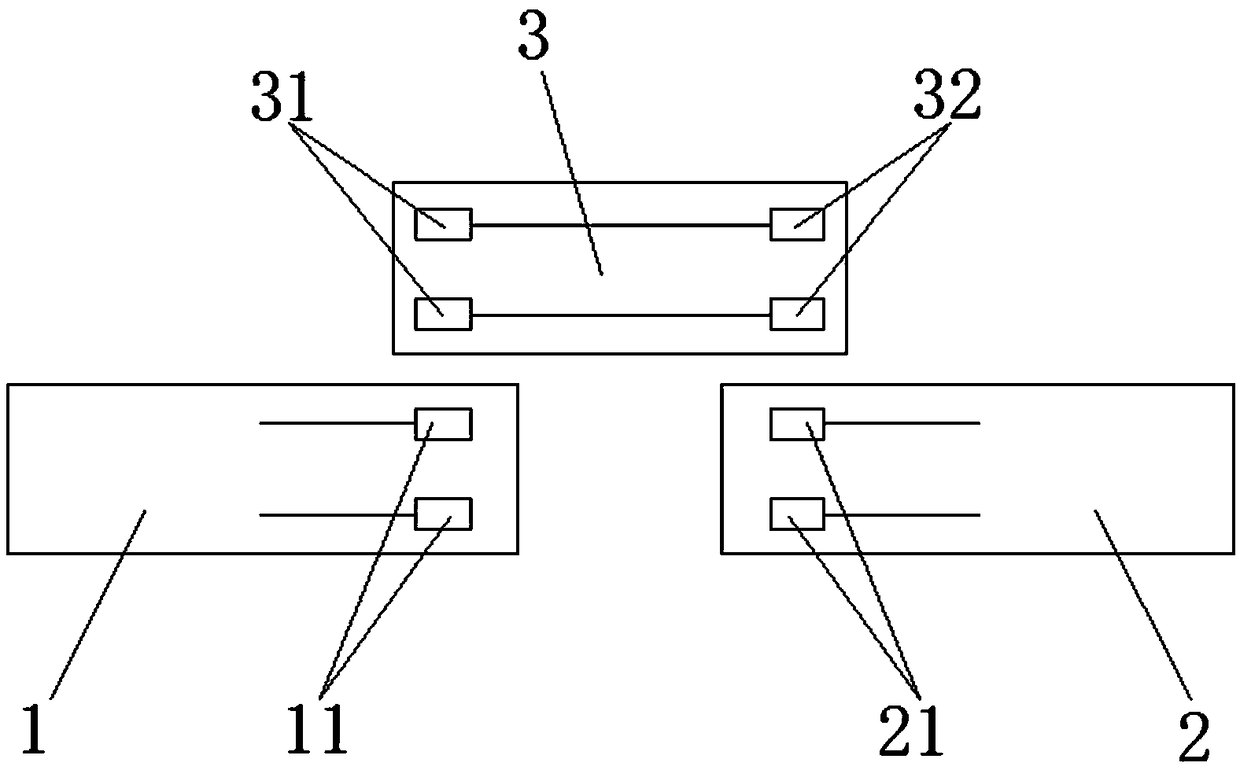

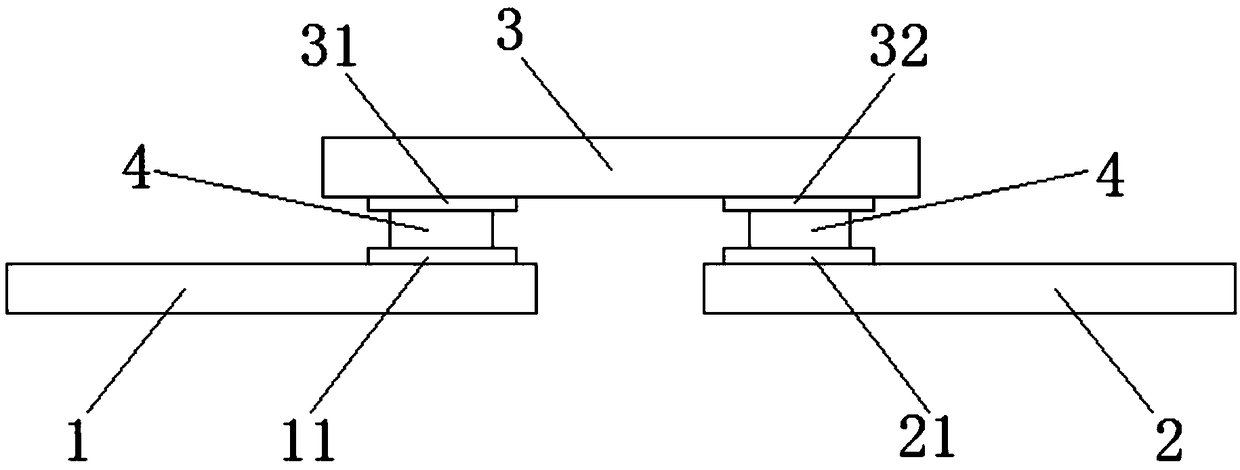

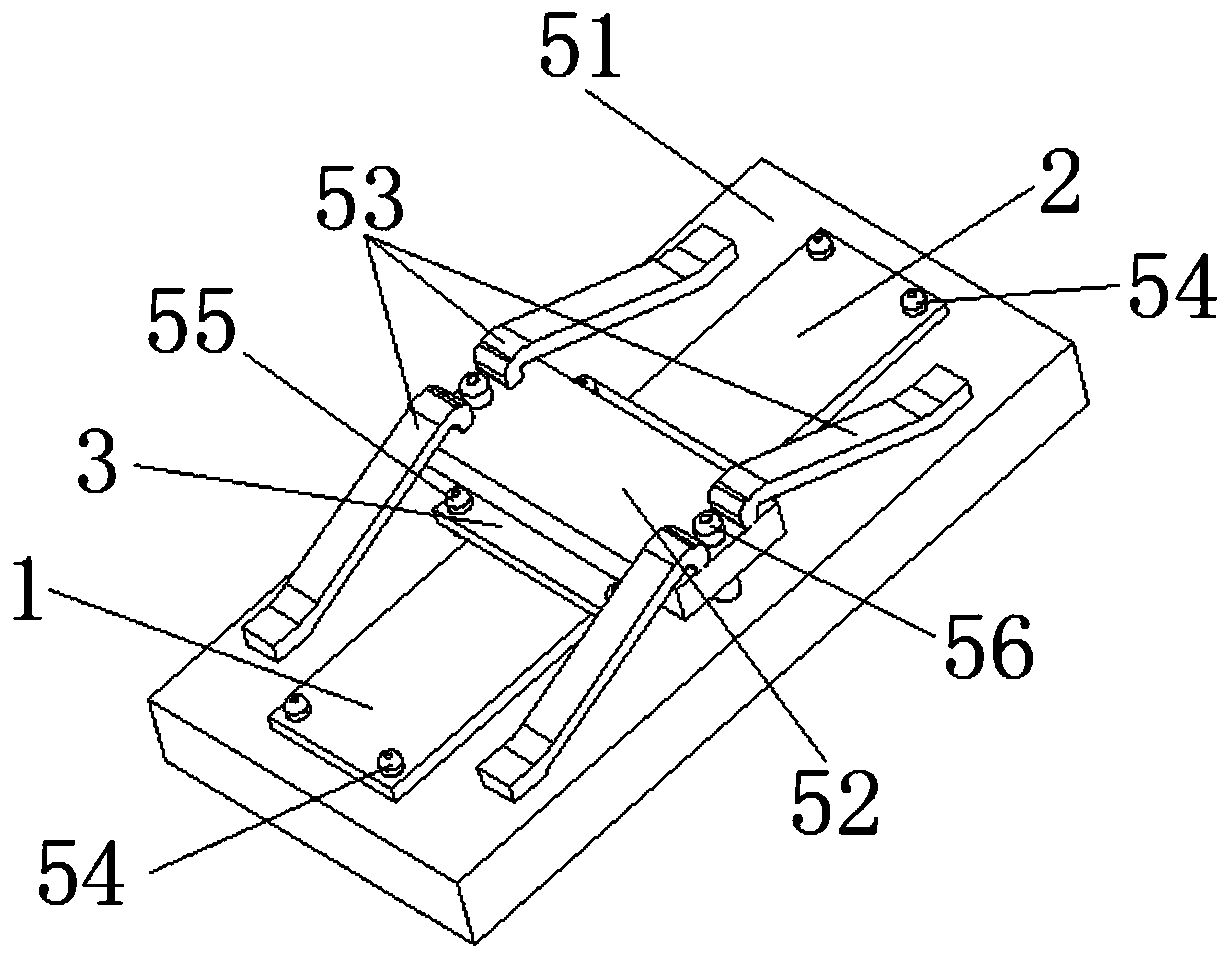

[0032] The invention provides a substrate connection process for LED automotive headlights, such as figure 1 and figure 2 As shown, it includes the following steps: A, setting the first substrate 1 and the second substrate 2 to be connected, the first substrate 1 includes the first pad 11, and the second substrate 2 includes the second pad 21; B, setting the flexible Substrate 3, flexible substrate 3 includes the third pad 31 and the fourth pad 32 electrically connected by means of substrate wiring; C, make the first pad 11 and the third pad 31 align and solder, the second pad 21 and the fourth pad 32 are aligned and soldered.

[0033] Preferably, before step C, solder paste is brushed on the first pad 11 and / or the third pad 31 , and solder paste is brushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com