Preparation method of box body of box-shaped structure

A box-shaped structure and box body technology, which is applied in welding equipment, manufacturing tools, laser welding equipment, etc., can solve problems such as product scrapping, damage to laser lenses, and box body failure to achieve full coverage of internal fillet welds. Strength, meet the assembly position requirements, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

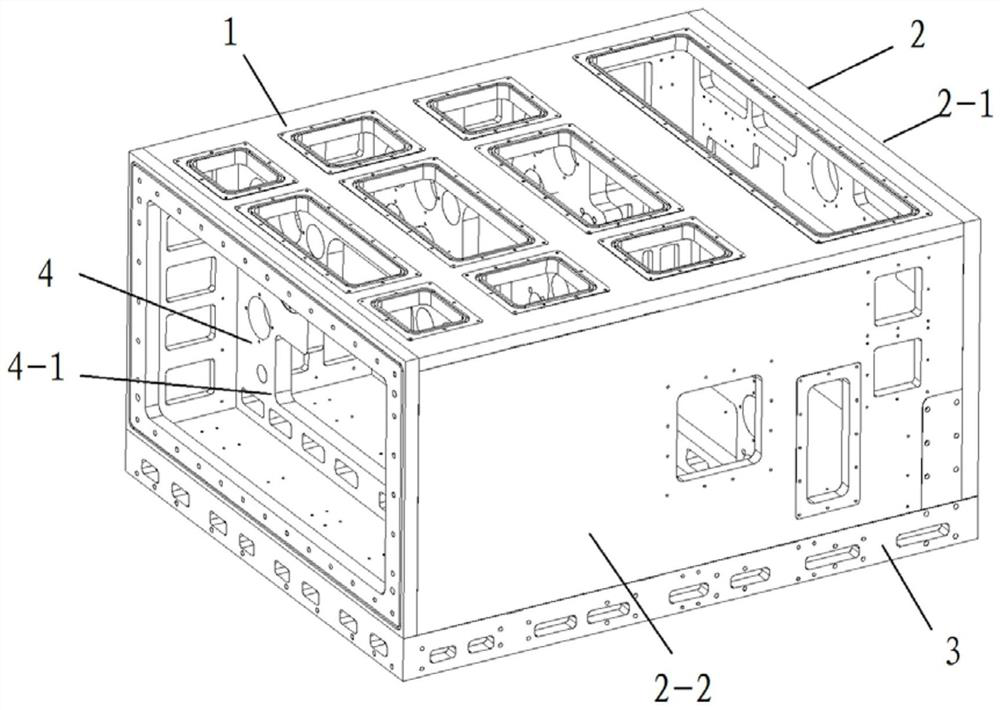

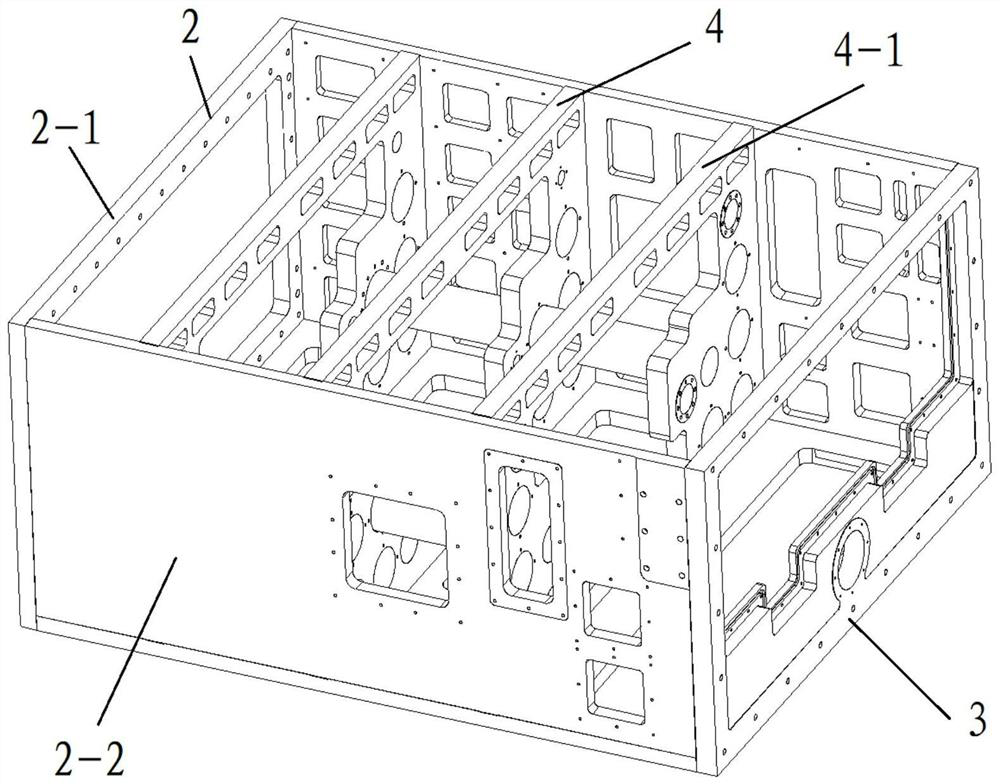

[0023] see Figure 1-3 , a method for preparing a box-shaped structure box provided by an embodiment of the present invention includes:

[0024] Prepare the top plate 1 , the hoarding plate component 2 , the bottom plate component 3 and the vertical plate component 4 .

[0025] Assemble the top plate 1, the coaming plate assembly 2, the bottom plate assembly 3 and the vertical plate assembly 4 to form a box body, and clamp them.

[0026] Fixing welding is performed on the outer surfaces of the top plate 1 and the enclosure assembly 2 .

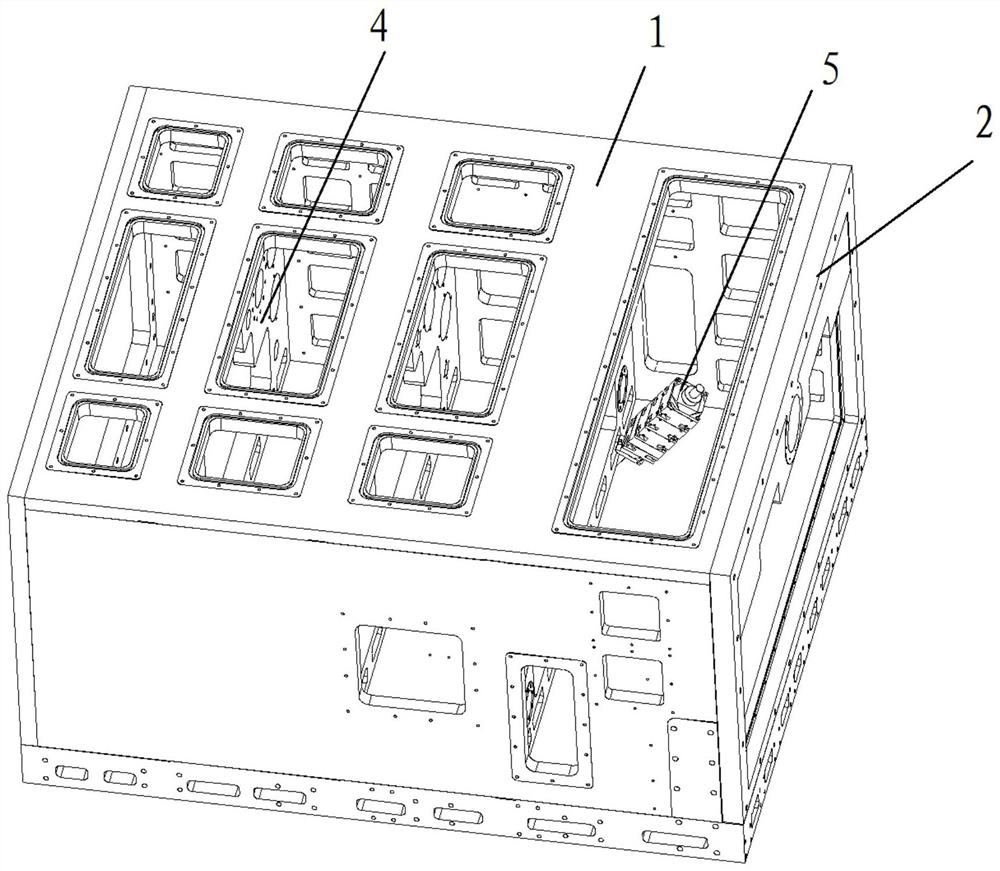

[0027] Disassemble the bottom plate assembly 3, enter the welding torch 5 from the bottom of the box, and weld all the inner fillet welds of the top plate 1, the hoarding plate assembly 2 and the vertical plate assembly 3 to ensure that the penetration depth is ≥ 2.5mm.

[0028] Install the bottom plate assembly 3, the welding gun 5 enters the box from the window on the top plate 1 and the enclosure assembly 2, and welds all the inner fillet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com