Patents

Literature

287results about How to "Guaranteed Penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

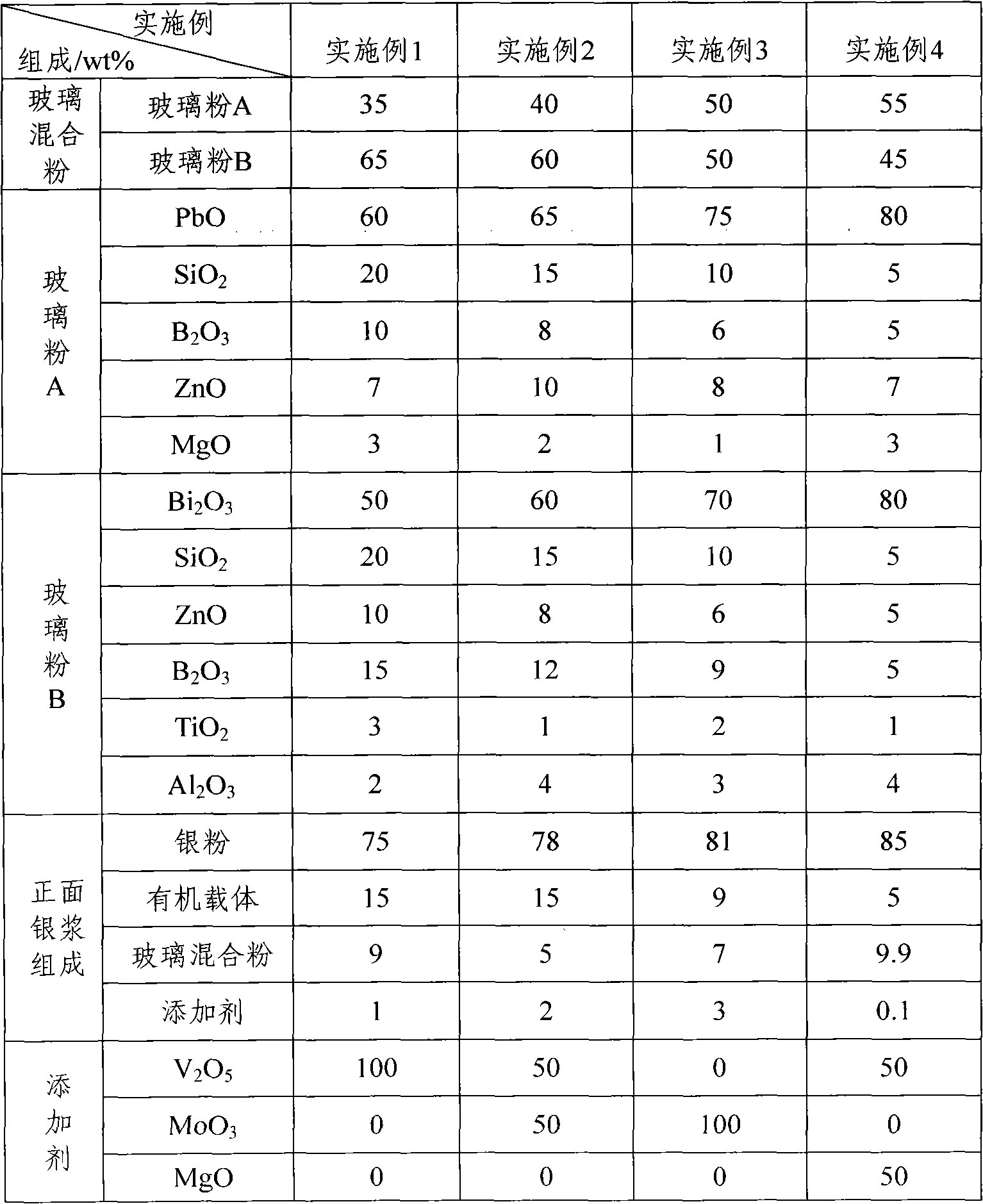

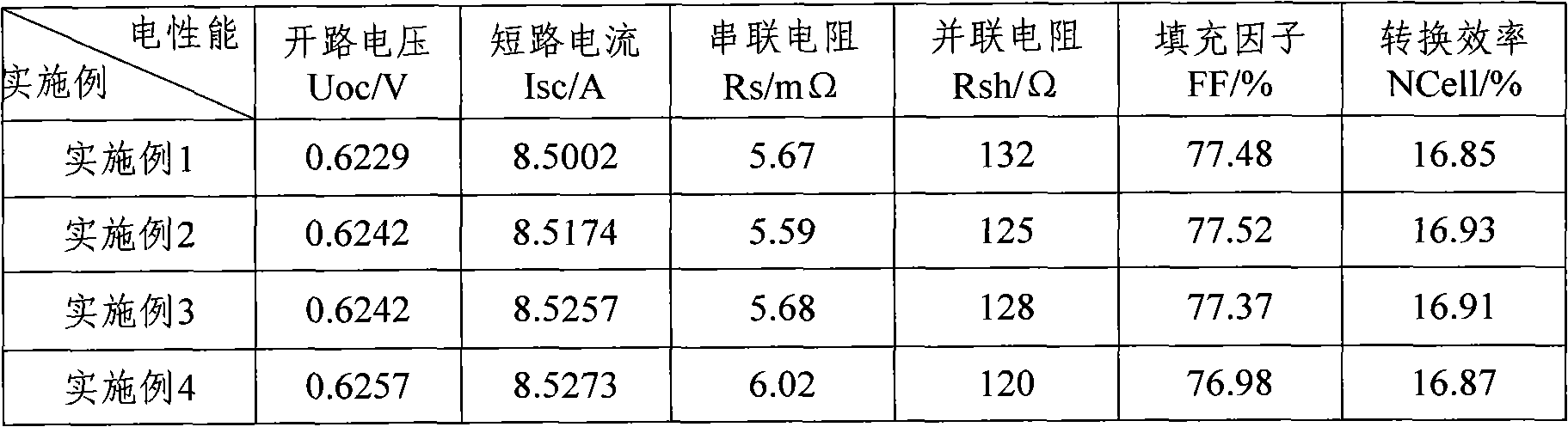

Glass mixing powder, preparation method thereof and conductive silver paste containing glass mixing powder

ActiveCN102603196AImprove photoelectric conversion efficiencyGuaranteed PenetrationNon-conductive material with dispersed conductive materialSilver particlesProcess window

The invention discloses glass mixing powder, a preparation method of the glass mixing powder as well as conductive silver paste containing the glass mixing powder. The glass mixing powder contains 35-55wt% of glass powder A and 45-65wt% of glass powder B, wherein the softening point of the glass powder A is lower than the softening point of the glass powder B. The preparation method of the glass mixing powder comprises two steps of formulating materials and mixing. The conductive silver paste containing the glass mixing powder comprises the following components by weight: 75-85 percent of silver powder, 5-15 percent of organic carrier and 1-10 percent of glass mixing powder. The two glass powder systems in different proportions are collocated to enable the conductive silver paste to have a wider sintering process window, ensure the glass powder to penetrate an antireflective film and the transportation of silver particles, excellent ohmic contact between an electrode and a battery silicon wafer can be facilitated, series resistance is reduced, and the photon-to-electron conversion efficiency of a battery piece and the peel strength of the electrode are improved.

Owner:JIANGSU RUIDE NEW ENERGY TECH

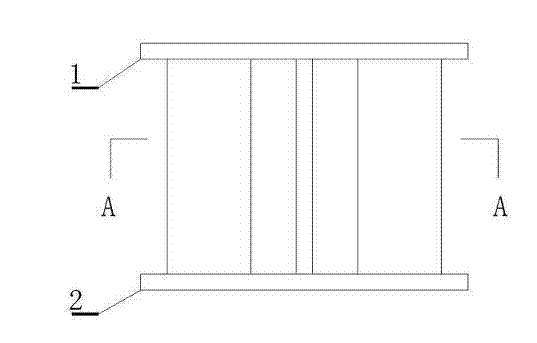

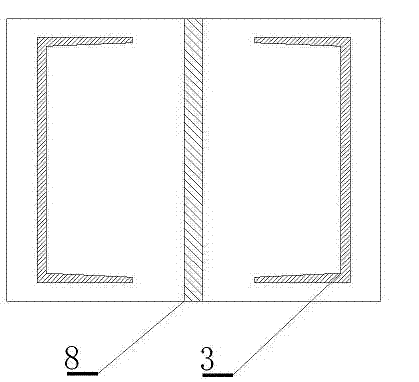

Method for welding thick aluminum alloy plate

ActiveCN102922098AReduce welding distortionEasy post-weld calibrationArc welding apparatusProduct gasWelding deformation

The invention discloses a method for welding a thick aluminum alloy plate. The method comprises a cleaning process, a preheating process and a welding process, wherein the cleaning process is carried out in a chemical cleaning way and comprises steps of: dipping a part to be welded in a 8-10% NaOH solution for more than 10 minutes, and then dipping in a 40-50% HNO3 solution for 30 seconds to 1 minute, wherein sensing heating equipment is adopted in the preheating process, and the preheating is carried out at 230 to 250 DEG C; joints in the welding process are in form of angle joint, and the non-melting electrode tungsten electrode gas shielded welding is carried out in the welding method, the welding parameter can be shown as that the current is 250 to 290A, the current polarity is performed by alternating current, Ar with purity not less than 99.99% is adopted as the protective gas, and the gas flow is at 7-13 liters per minute. Through the method, little welding deformation is generated, the correcting is easily carried out after welding, the product quality can be improved, the production efficiency can be increased, and the manufacturing cost can be greatly reduced.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

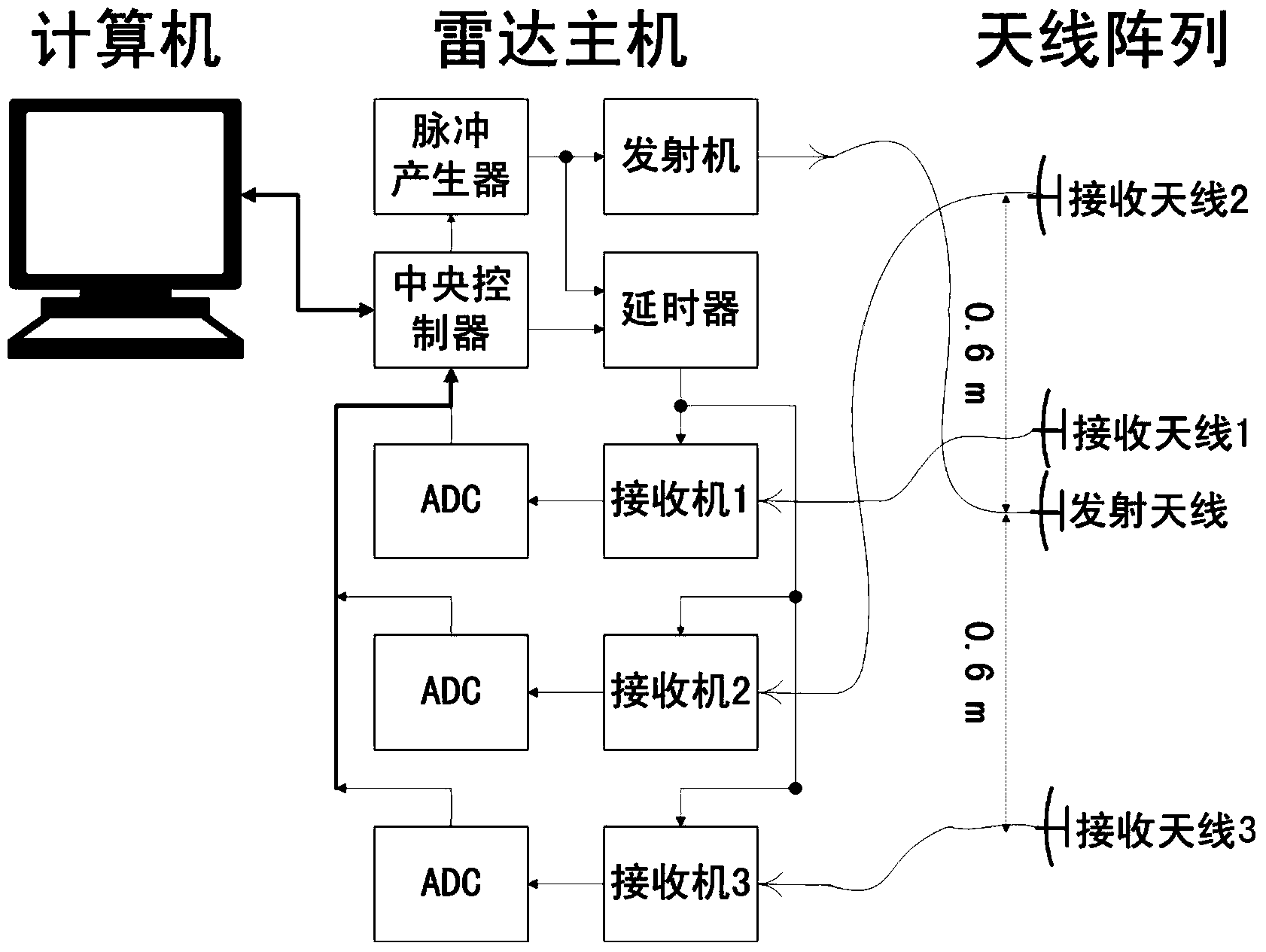

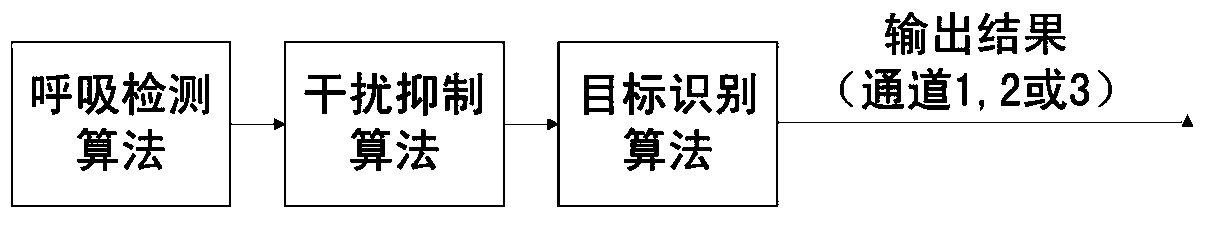

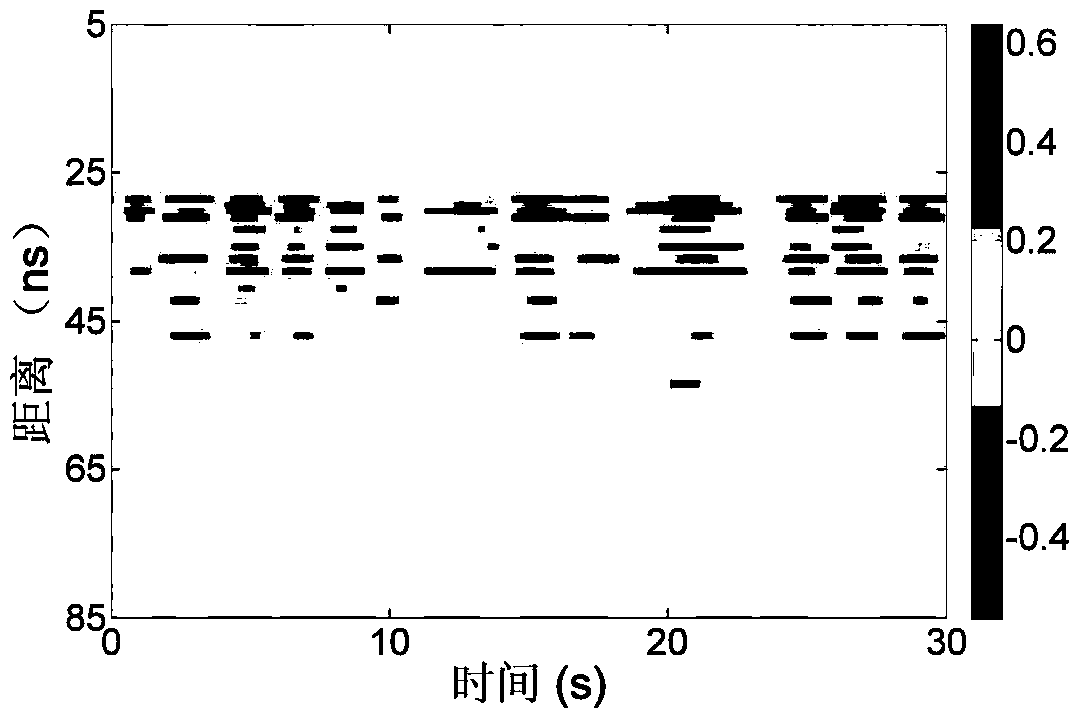

UWB bio-radar-based multiple-human body object estimation method and system

InactiveCN103616729AImprove the level ofImprove abilitiesDetection using electromagnetic wavesRadio wave reradiation/reflectionHuman bodyEstimation methods

The invention discloses a UWB bio-radar-based multiple-human body object estimation method and a UWB Bio-radar-based multiple-human body object estimation system, and belongs to the technical field of bio-radar biological life detection. According to the UWB bio-radar-based multiple-human body object estimation method of the invention, echo data obtained through collection are processed through the following manners that: a breath detection algorithm, an adaptive cancellation method and a target recognition algorithm are adopted to process the echo data in each channel; correlation processing is performed among each channel according to processing results; and finally, threshold values are set such that clutter left in the channels after processing can be removed, and at the same time, target classification and number estimation are realized. With the UWB bio-radar-based multiple-human body object estimation of the invention adopted, a technological base can be provided for further implementation of bio-radar detection and positioning of multiple human body objects, and the improvement of the level and ability of bio-radar technique to obtain information of human bodies can be facilitated.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

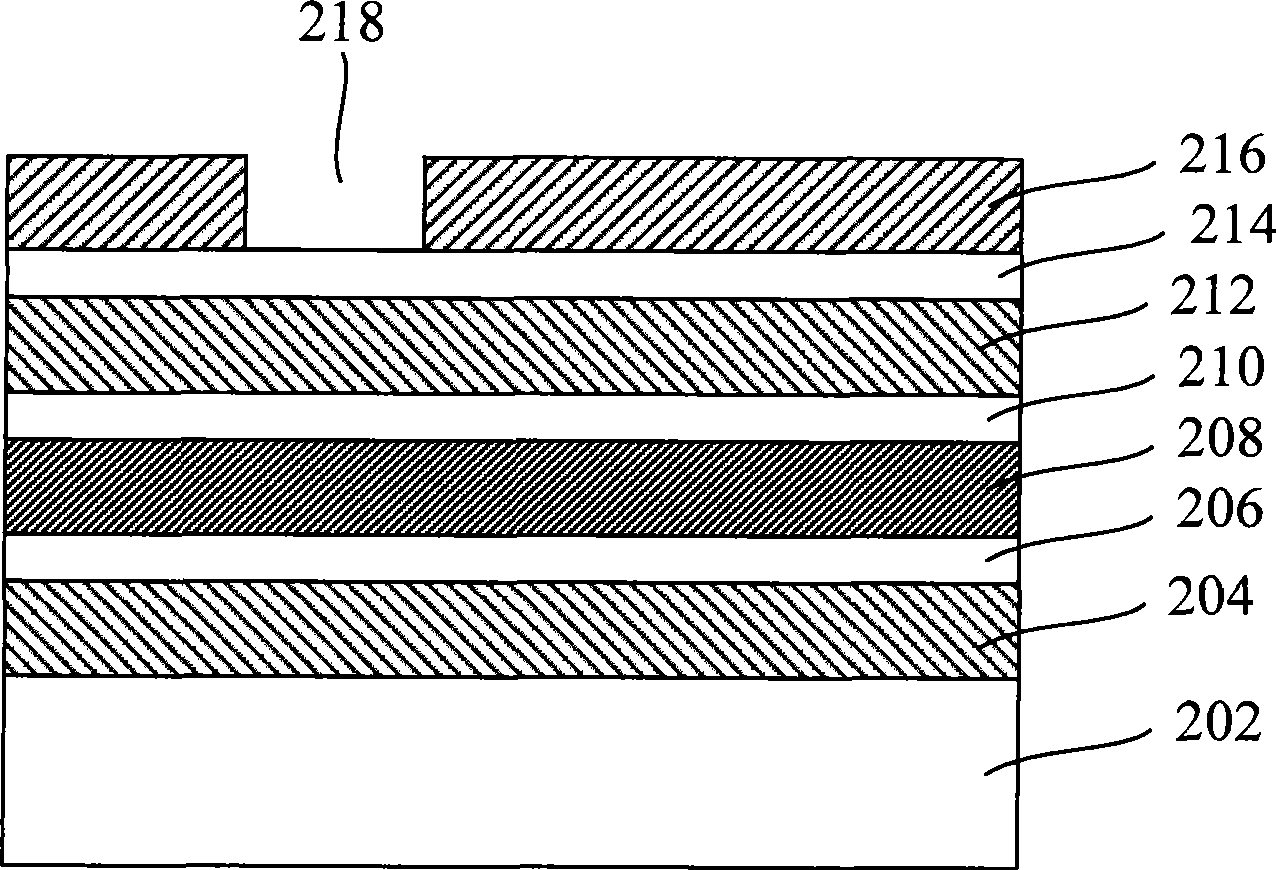

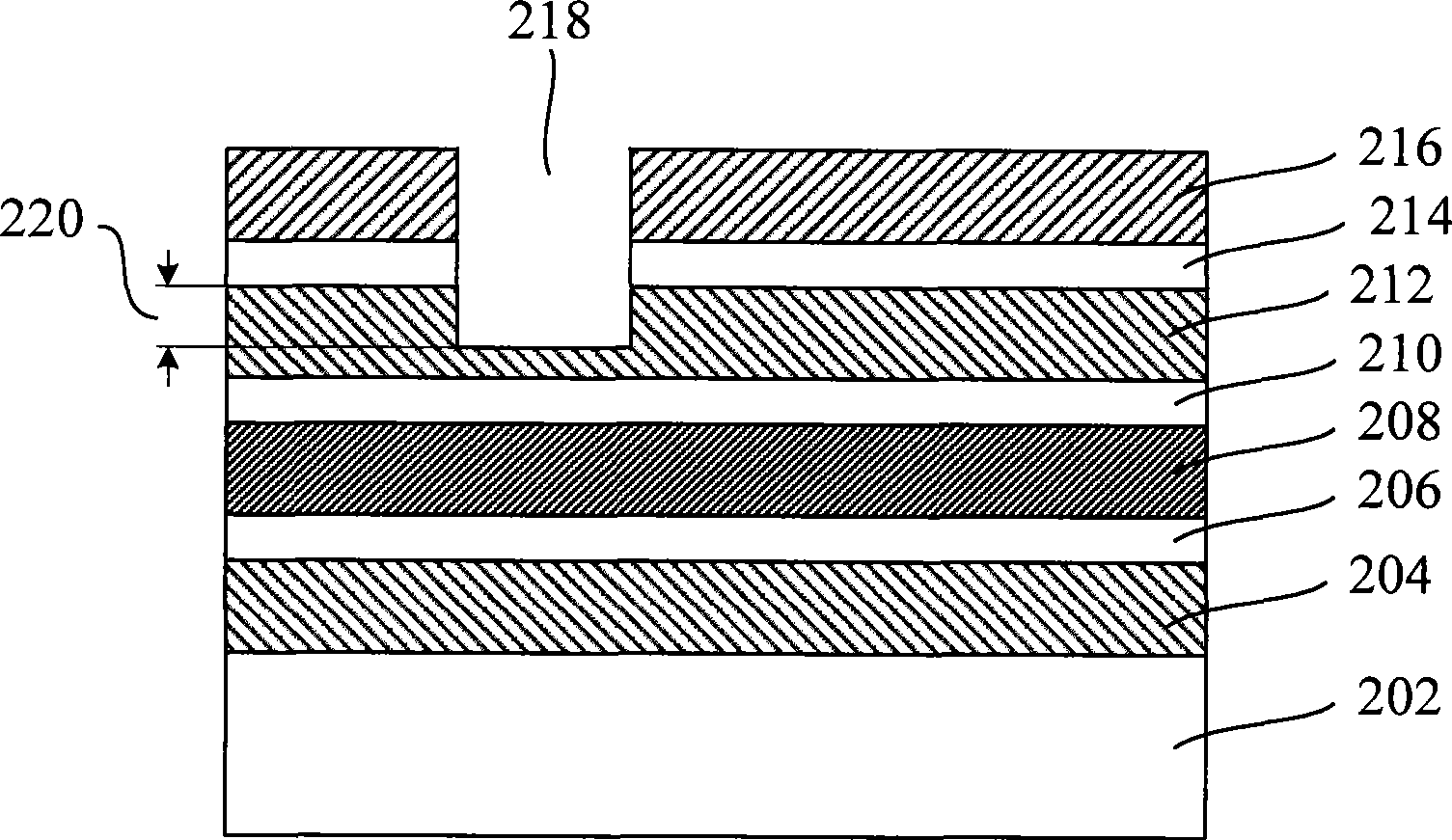

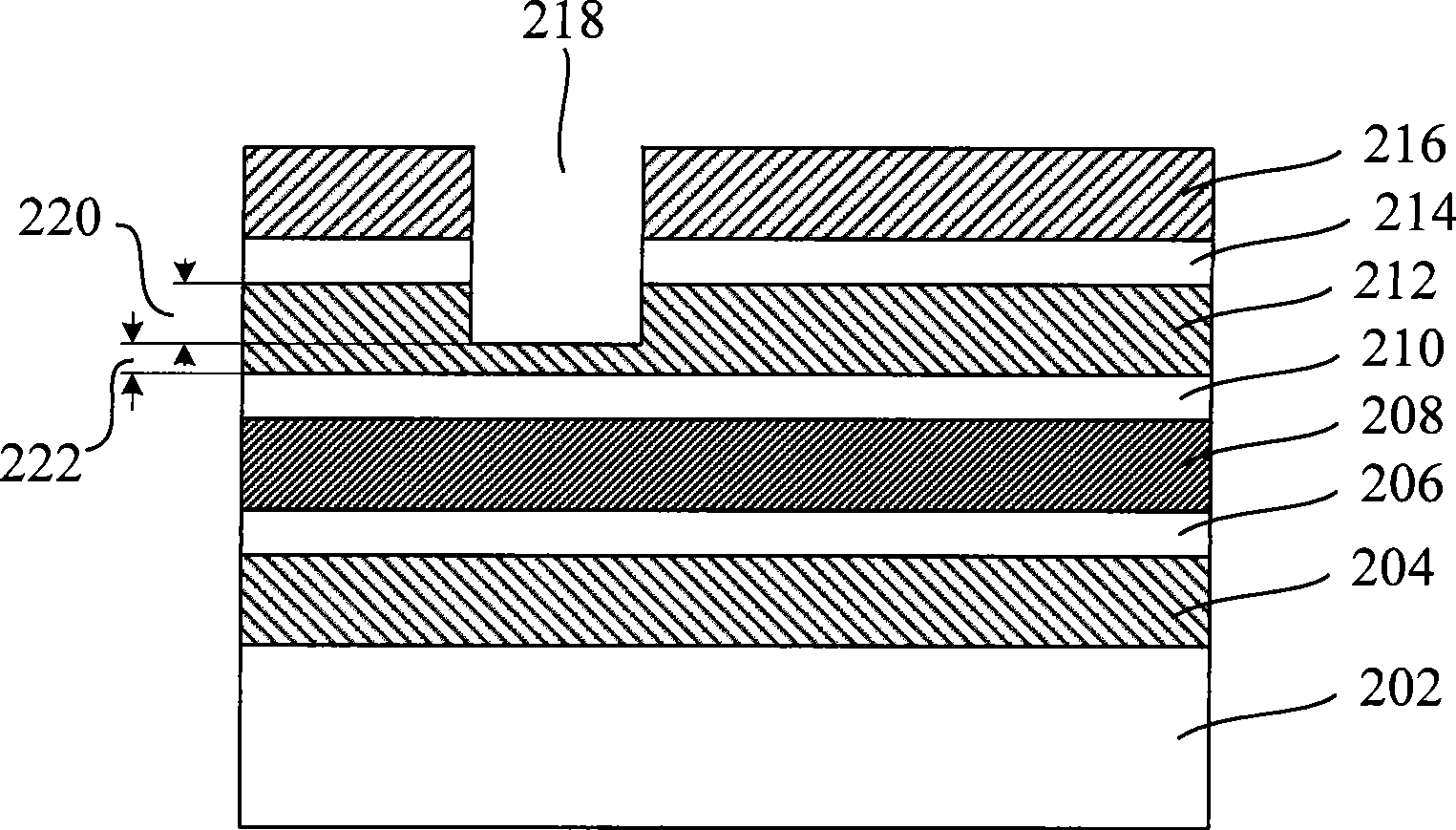

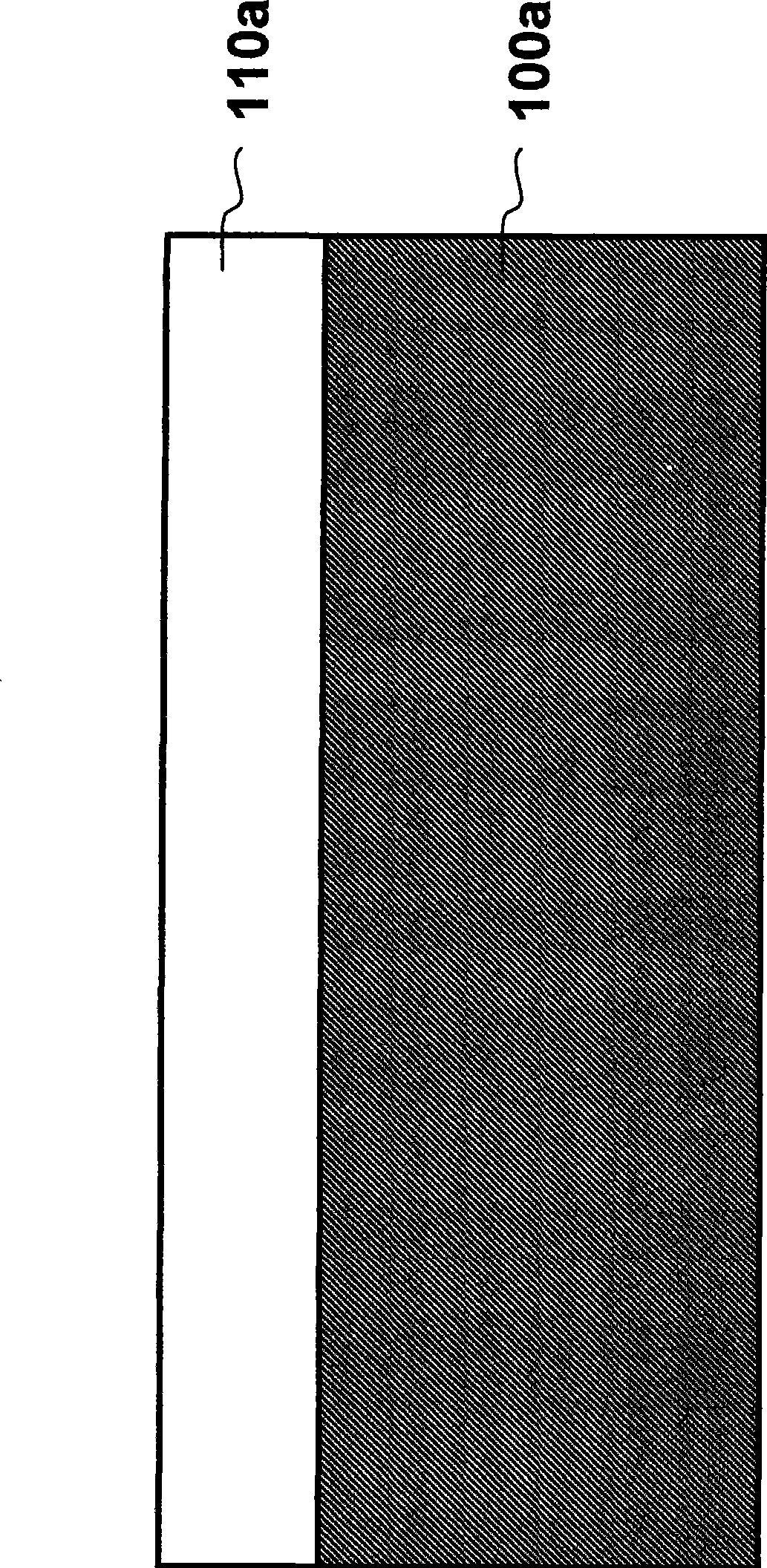

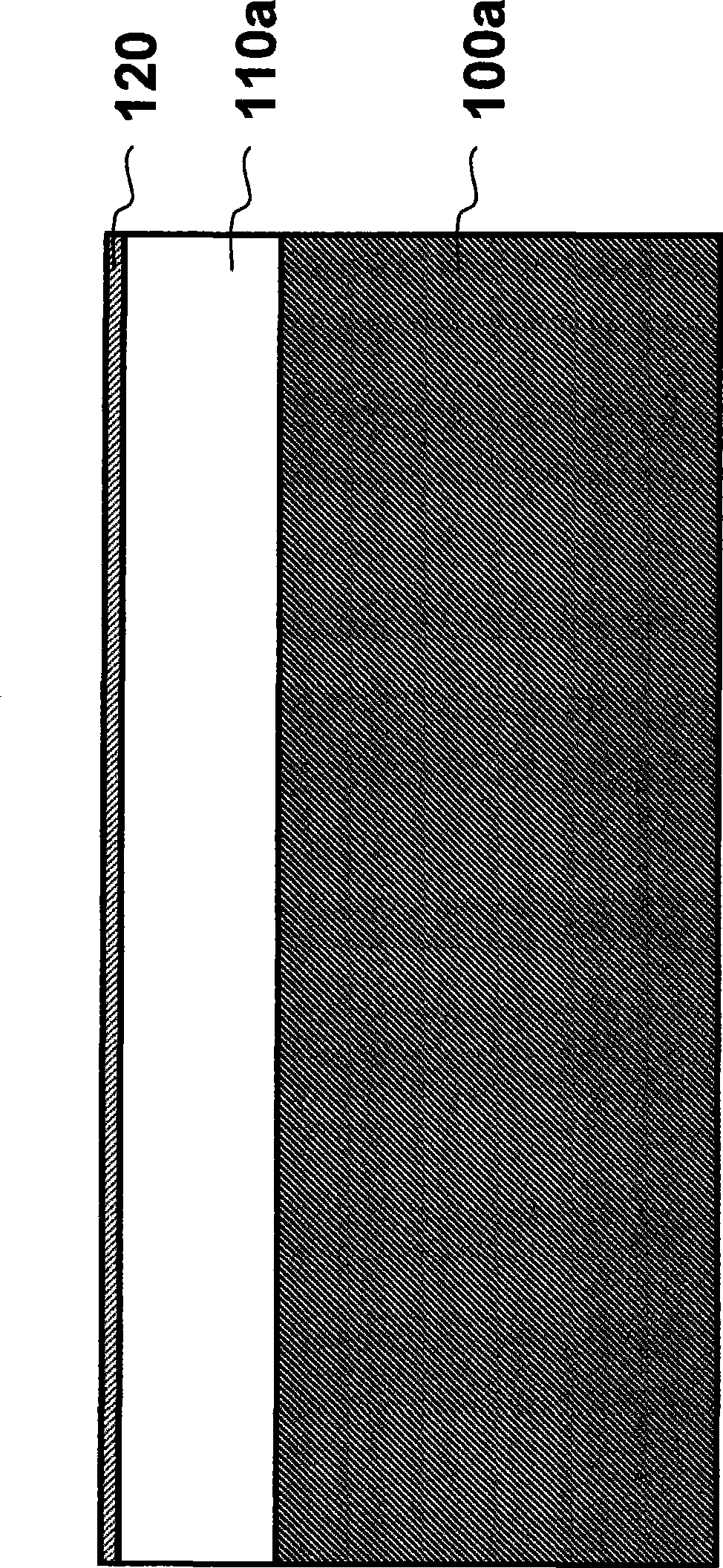

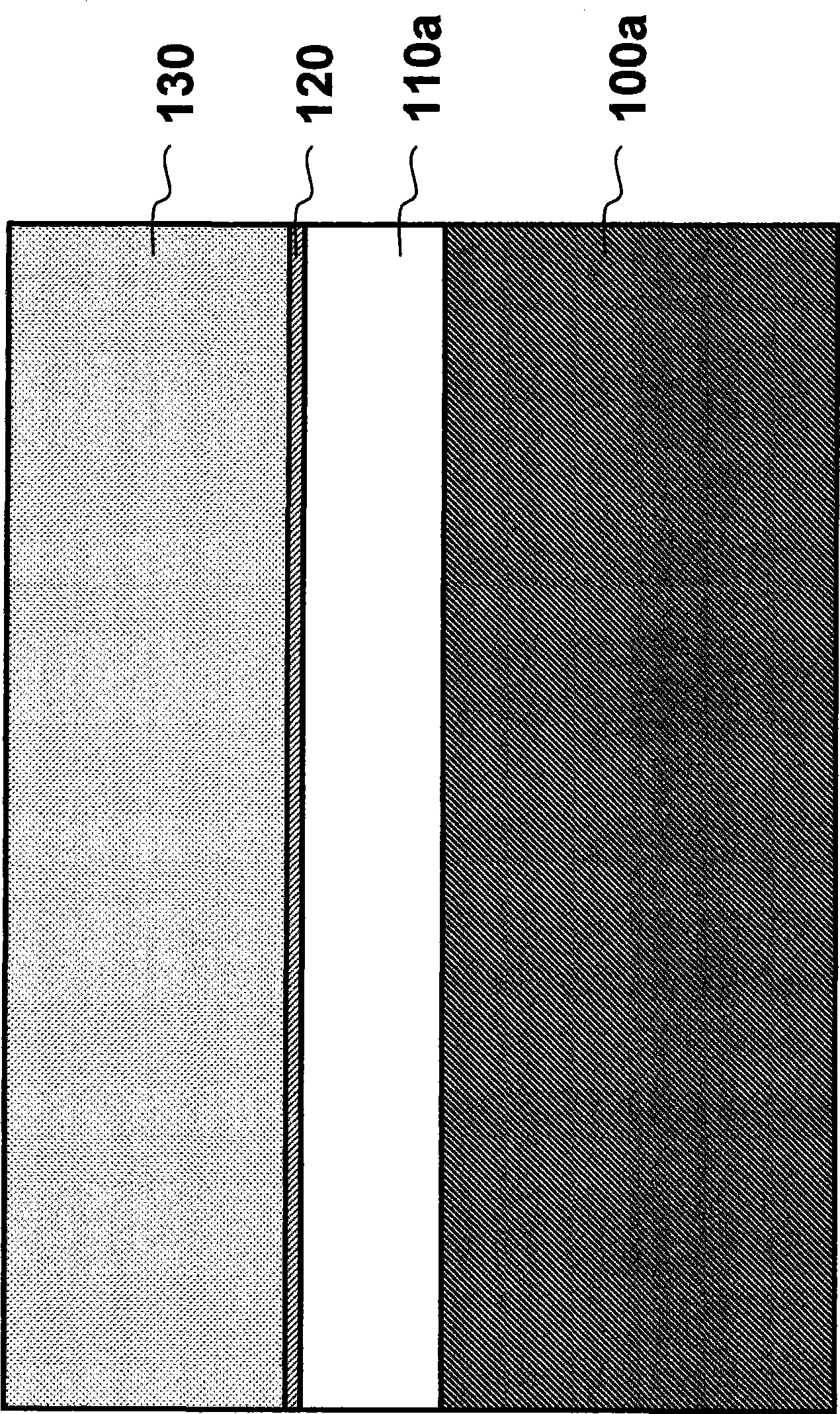

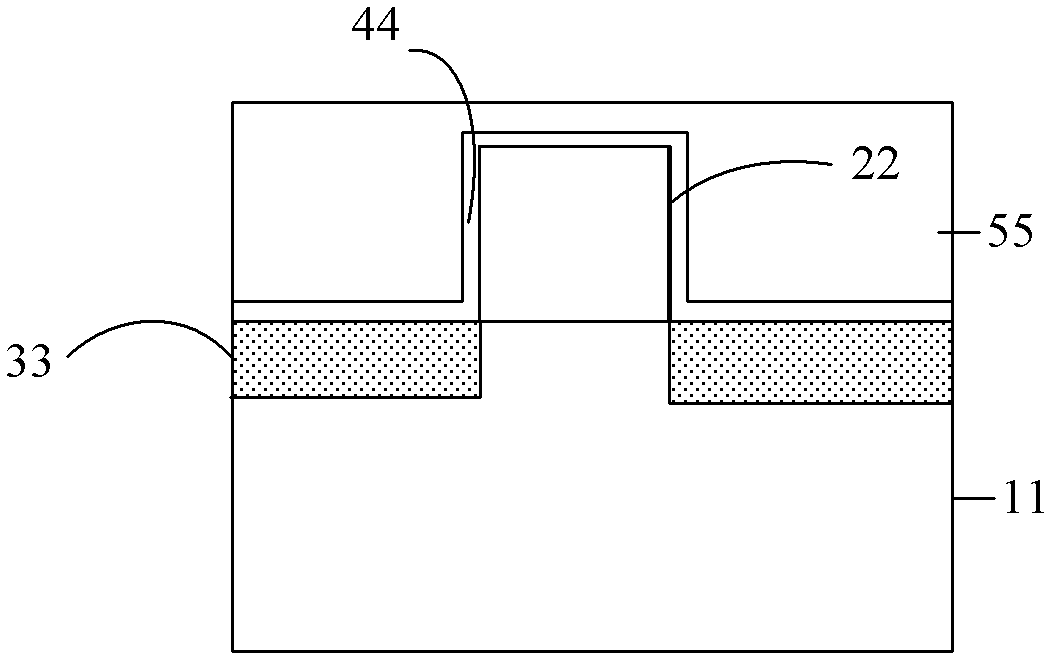

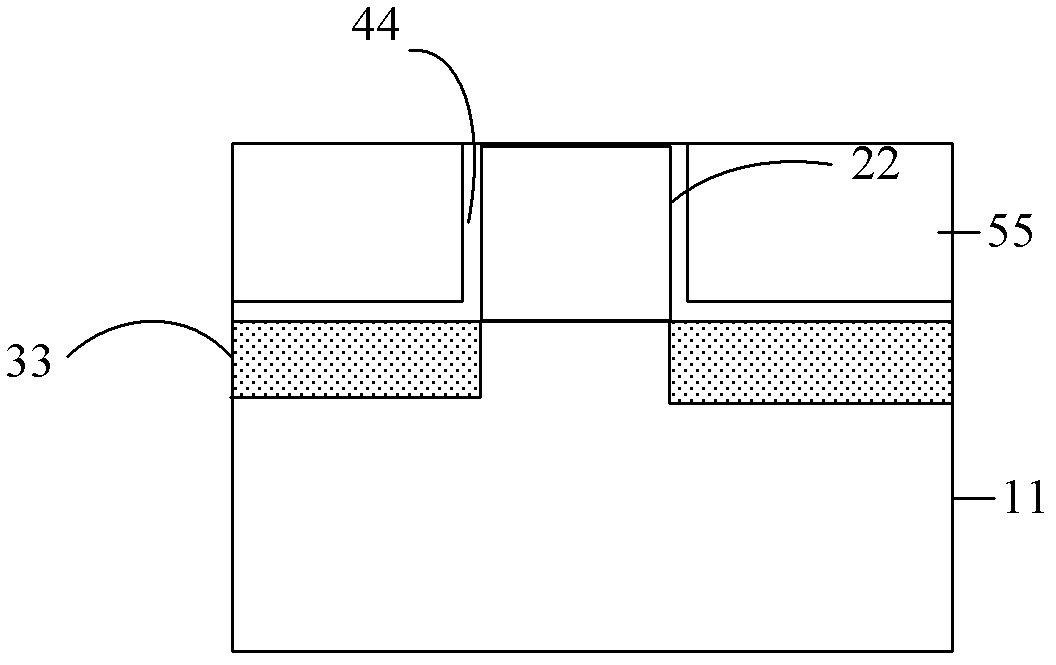

Connection pore forming method

ActiveCN101459125AGuaranteed PenetrationAvoid etch-throughSemiconductor/solid-state device manufacturingSemiconductor structureDielectric layer

A method of forming connecting holes comprises steps of providing a semiconductor structure with an etch stop layer, wherein the etch stop layer is equipped with an intermetallic dielectric layer, forming a photoresist layer on the intermetallic dielectric layer, patterning the photoresist layer to form a connecting hole pattern, executing the major etching process to etch part of thickness of the intermetallic dielectric layer at the bottom portion of the connecting hole pattern, after the major etching process is finished, executing the first step of the over-etching process to etch residual thickness of the intermetallic dielectric layer and form an opening in the intermetallic dielectric layer, wherein the bottom of the opening exposes out of the etch stop layer, then executing the second step of the over-etching process to etch the bottom of the opening, and finally removing the etch stop layer at the bottom of the opening. The invention can avoid the defect that the bottom of the connecting hole is not opened.

Owner:SEMICON MFG INT (SHANGHAI) CORP

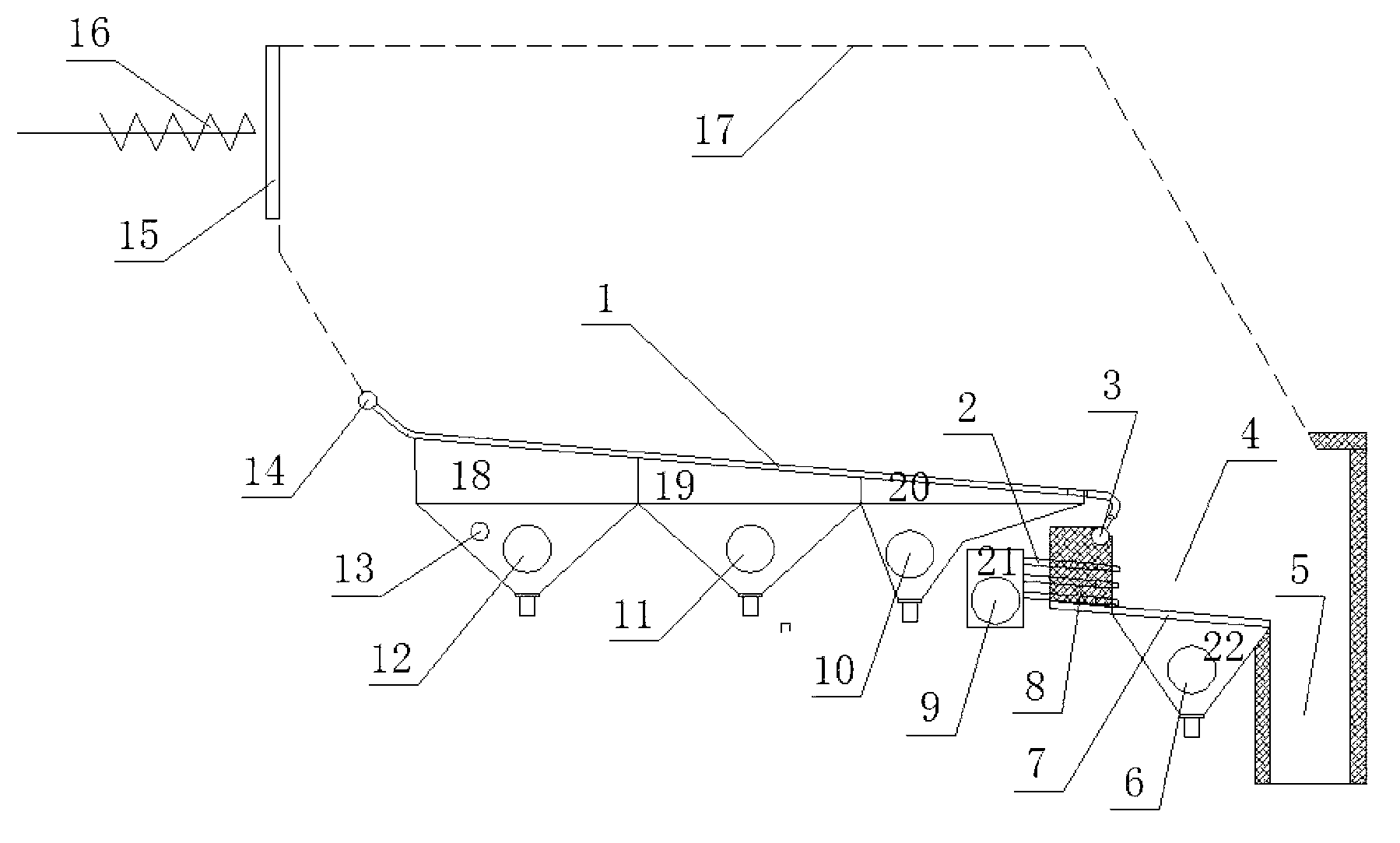

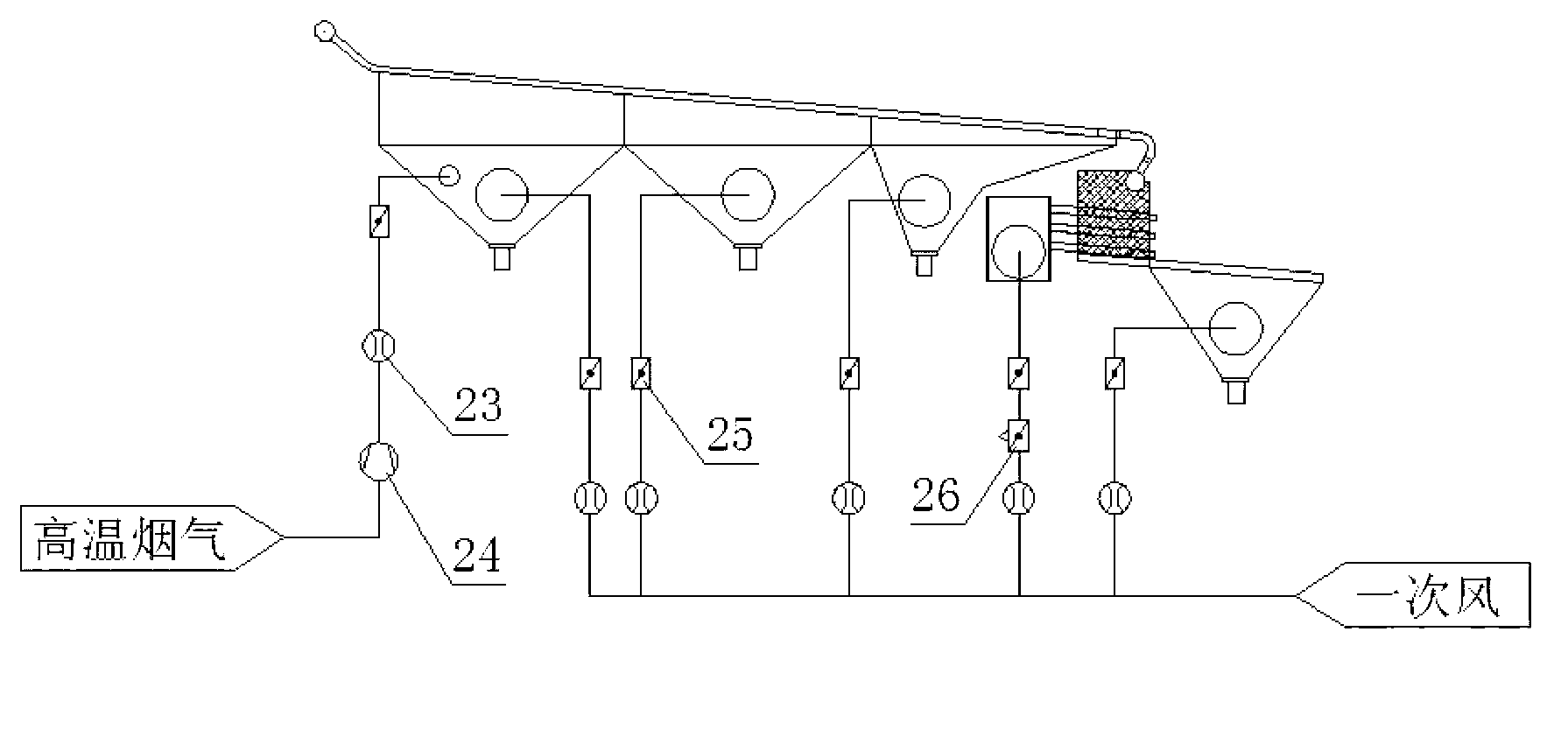

Efficient segmentation control combustion method and system for biomass boiler with charcoal combustion cell

InactiveCN103017145AEasy to removeIncrease the drying medium temperatureSolid fuel combustionCombustion apparatusSlagHearth

The invention discloses an efficient segmentation control combustion method and system for a biomass boiler with a charcoal combustion cell, and belongs to the technical field of the fire grate combustion of a biomass direct-combustion power generation boiler. A water cooling vibration fire grate is arranged on the bottom of a hearth; a smoke and air mixing box and a plurality of primary air bellows are arranged below the water cooling vibration fire grate; the charcoal combustion cell is arranged below the front end of the water cooling vibration fire grate; the bottom of the charcoal combustion cell is provided with a fixed fire grate; and the front end of the charcoal combustion cell is provided with a slag well. The external moisture of biomass fuel is removed in the drying area of the water cooling vibration fire grate; then, the biomass fuel is moved to the pyrolysis combustion area of the fire grate to generate a great quantity of volatile component to enter the hearth; when the volatile component of the biomass fuel is almost burnt, residual fixed carbon covered by ash is vibrated into the charcoal combustion cell; in the falling process, the residual fixed carbon covered by ash is overturned and collided to remove surface ash; oxygen is directly diffused to the surface of the charcoal to react with the charcoal; and the ash slag is blown into the slag well. According to the invention, the biomass fuels of different types and moistures can be subjected to efficient segmentation control combustion on the fire grate of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

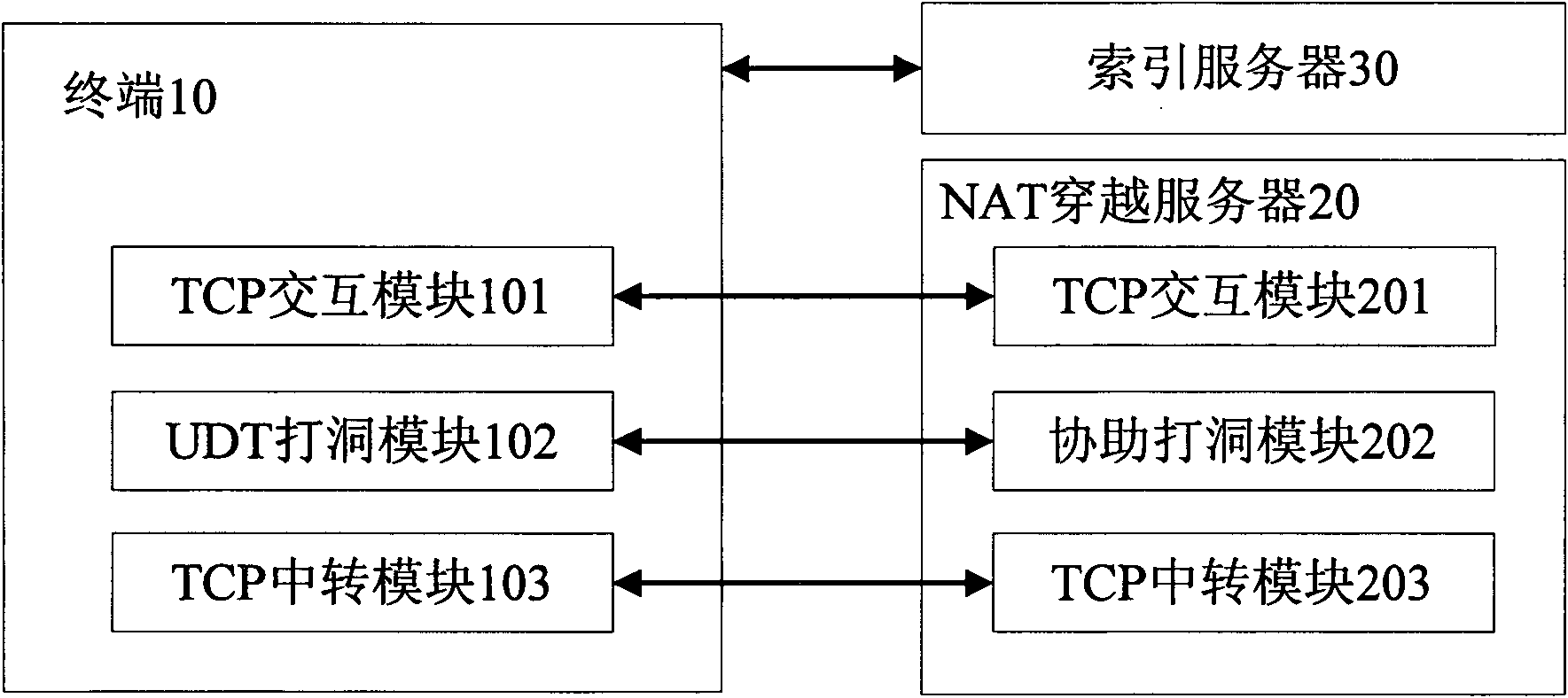

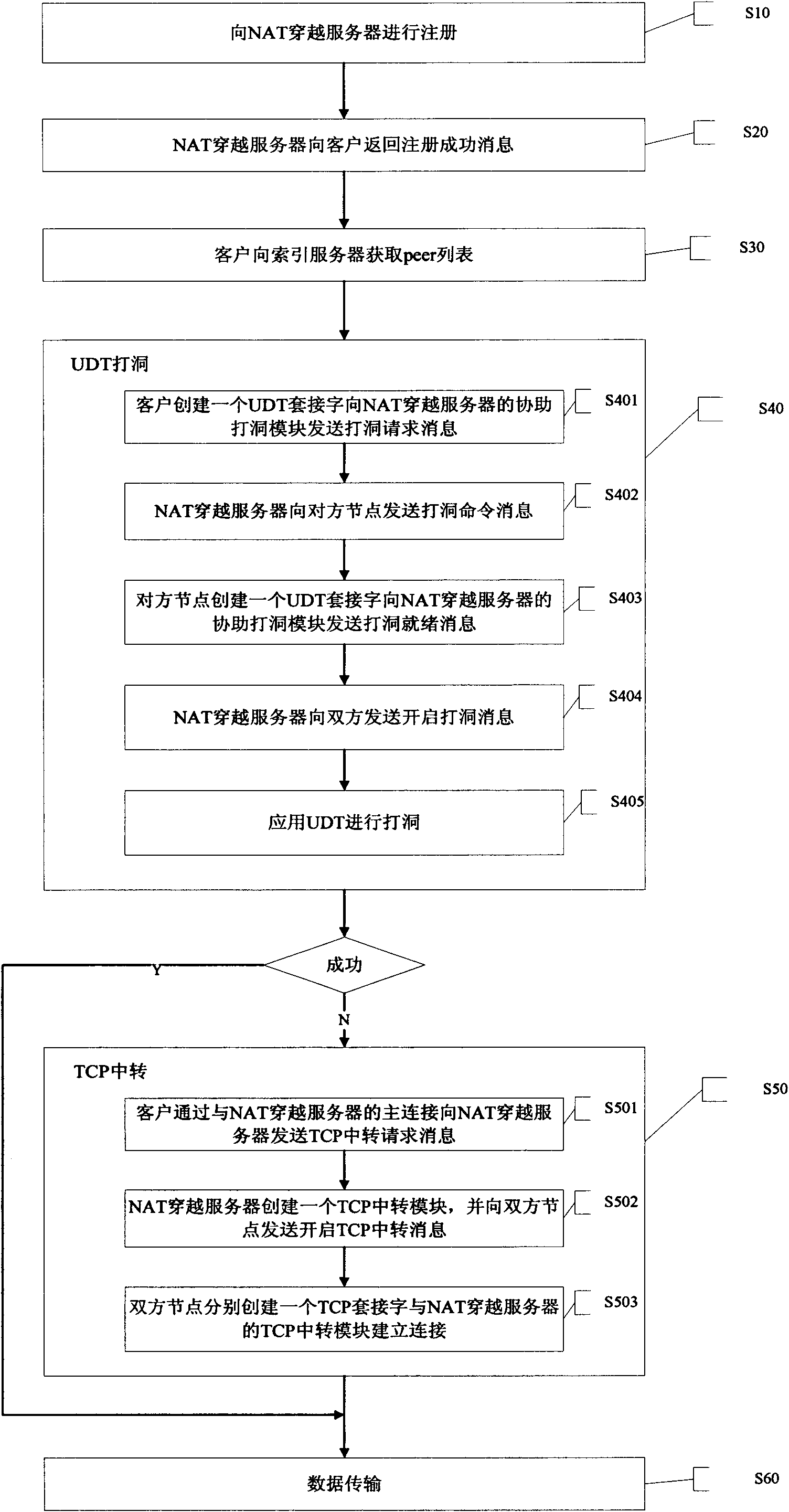

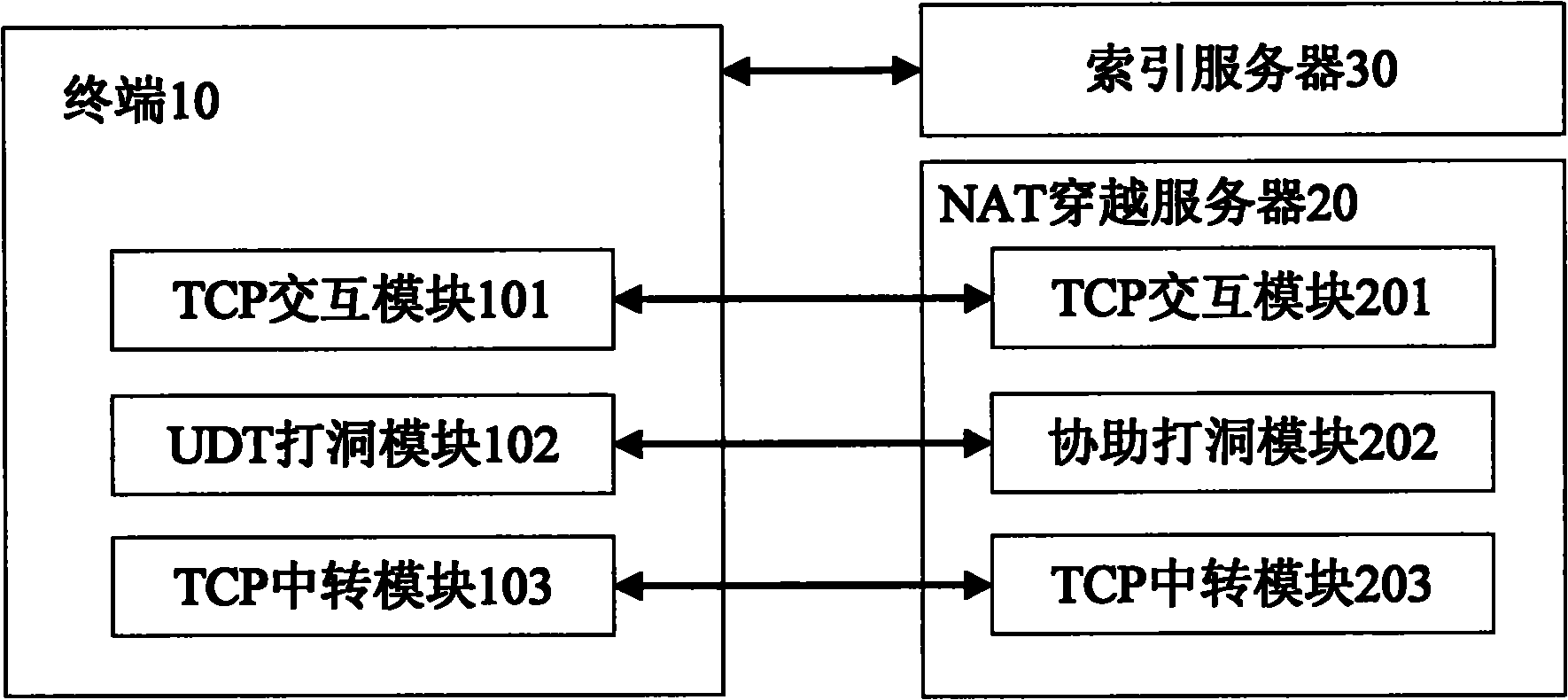

System and method for realizing NAT (Network Address Translation) traversal on basis of UDT (UDP (User Datagram Protocol)-based Data Transfer) and TCP (Transmission Control Protocol) transfer

InactiveCN101883056AGuaranteed PenetrationImprove reliabilityData switching networksNAT traversalData transmission

The invention relates to a system and a method for realizing NAT (Network Address Translation) traversal on the basis of UDT (UDP (User Datagram Protocol)-based Data Transfer) hole punching and TCP (Transmission Control Protocol) transfer. The system comprises a terminal, an NAT traversal server and an index server, wherein the terminal is used for carrying out registration on the NAT traversal server and realizing the NAT traversal by utilizing TDT hole punching or the TCP transfer; the NAT traversal server is interactive with the terminal and used for storing registration information of theterminal and assisting the terminal to carry out the UDT hole punching and the TCP transfer; and the index server is interactive with the terminal and used for providing peer list information containing an on-line terminal ID. The invention is simple and practicable and has high penetration success ratio and high data transmission reliability.

Owner:SOUTH CHINA UNIV OF TECH

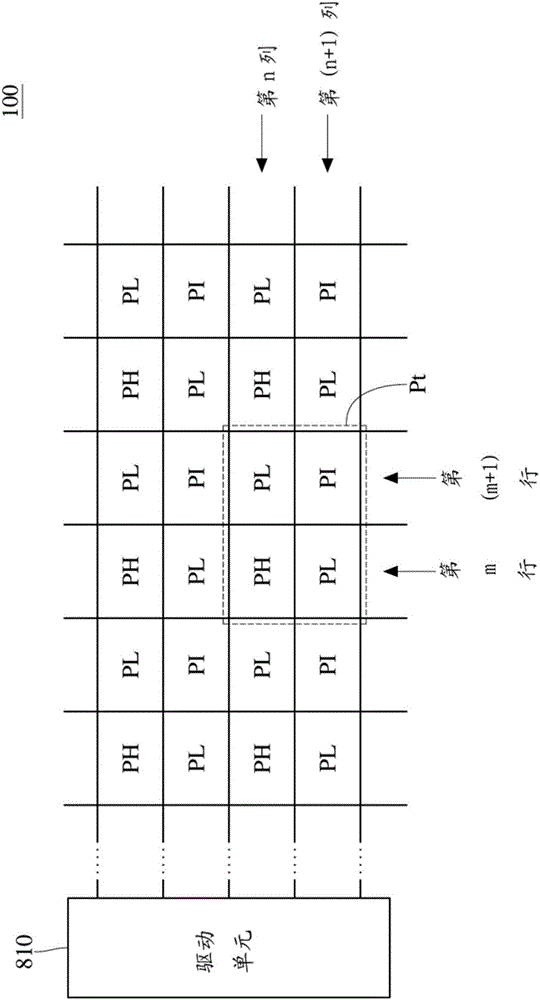

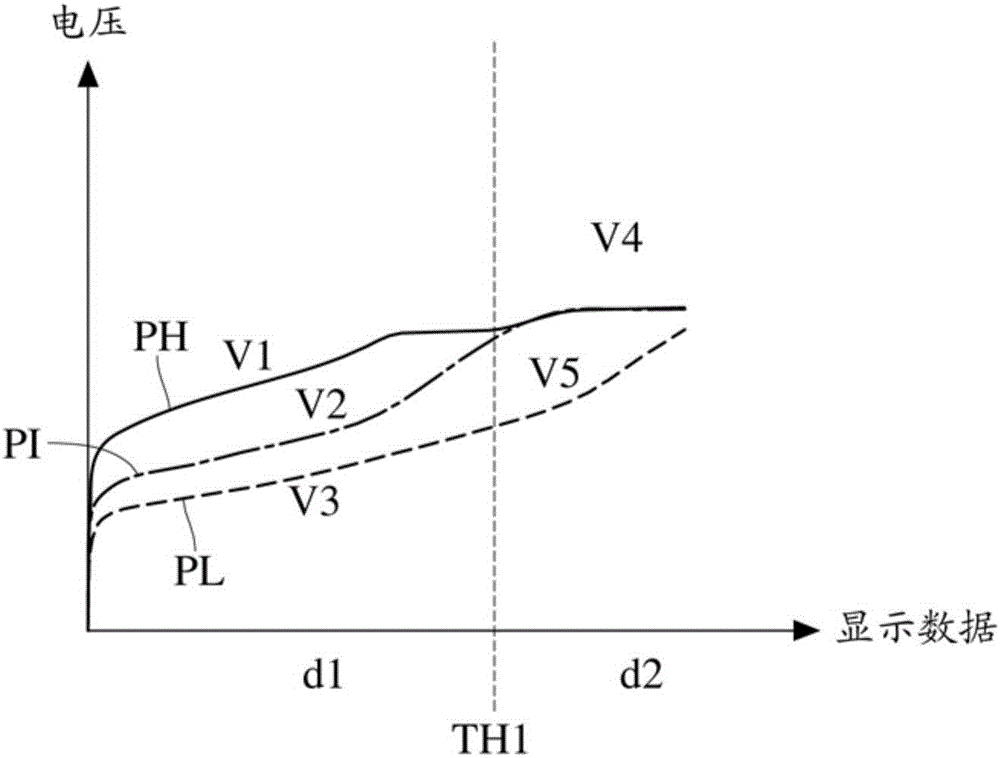

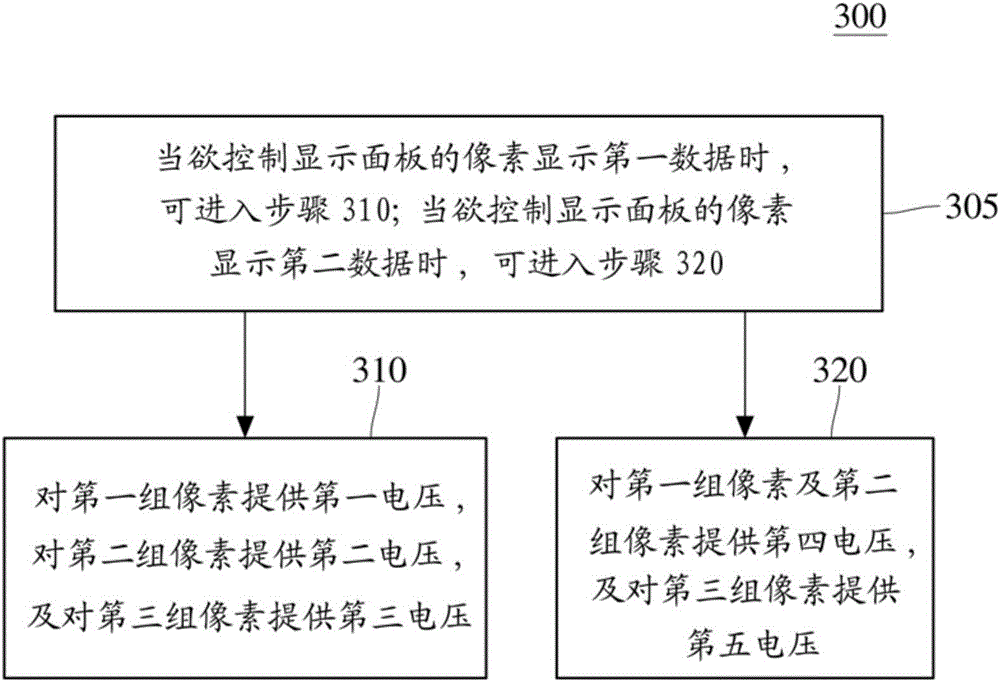

Display apparatus

ActiveCN107180606AInsufficient improvementImprove the whitening problem of side viewing angleCathode-ray tube indicatorsData signalElectrical polarity

Provided is a display apparatus including a plurality of gate lines for outputting corresponding scanning signals to corresponding pixels, a plurality of data lines including 12 continuous data lines from left to right and used for receiving display data and outputting corresponding pixel voltages to the corresponding pixels, a gate driver electrically coupled to the gate liens and used for driving the pixels, and a data driver electrically coupled to the data lines and sued for providing data signals for the pixels, the polarities of the data provided for the 12 data lines by the data driver are respectively positive, negative, positive, negative, positive, negative, negative, positive, negative, positive, negative, and positive, each row of pixels include two types of pixels, and when the display data is the same grayscale, the data driver respectively provides two different pixel voltages to the two types of pixels.

Owner:AU OPTRONICS CORP

Method for manufacturing film LED chip device based on gapless plane bonding

ActiveCN101465402AGuaranteed flatnessImprove flatnessSemiconductor devicesOptoelectronicsLaser beams

The invention discloses a preparation method of a film LED chip device based on the gapless plane bonding; the method makes use of the smooth surface of an epitaxial wafer without isolated processing to prepare a permanent or temporary substrate; then laser beams are used for unit isolated processing of devices at the interface position between the epitaxial layer and the substrate so as to ensure the combination yield rate of the substrate and the epitaxial layer, thereby ensuring the film-remaining yield rate of the epitaxial thin film layer after laser stripping and also simplifying the traditional production process.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

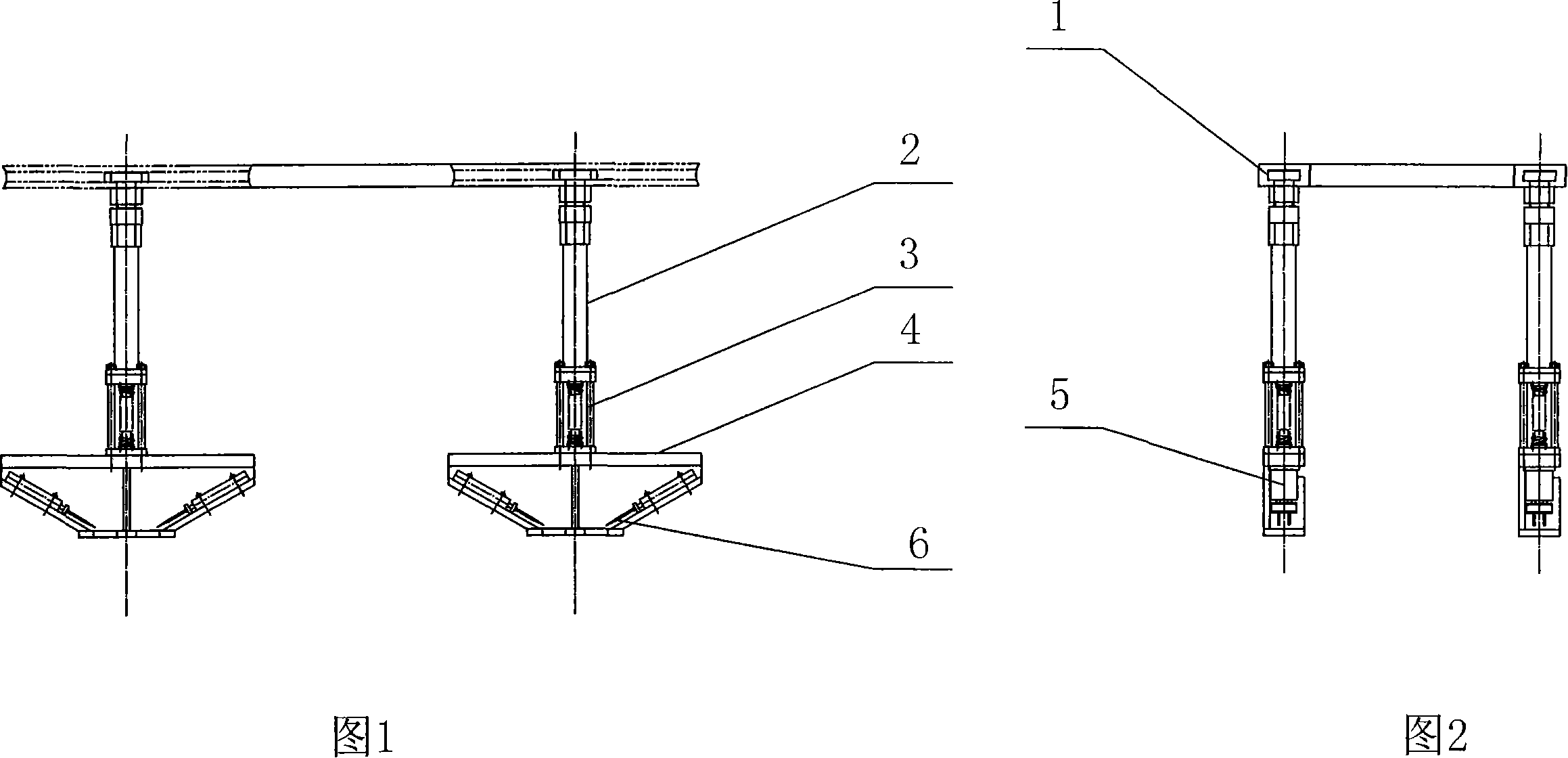

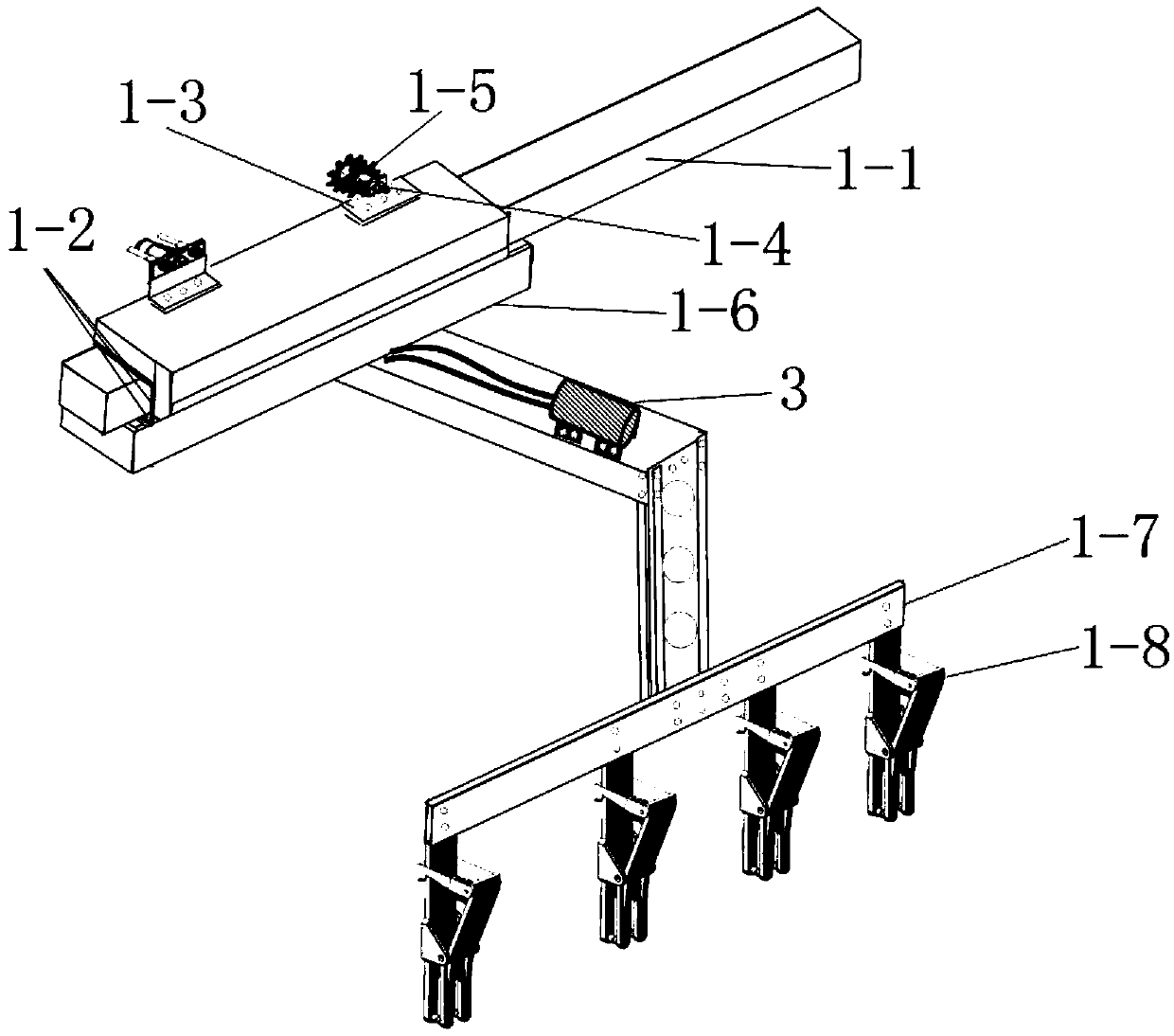

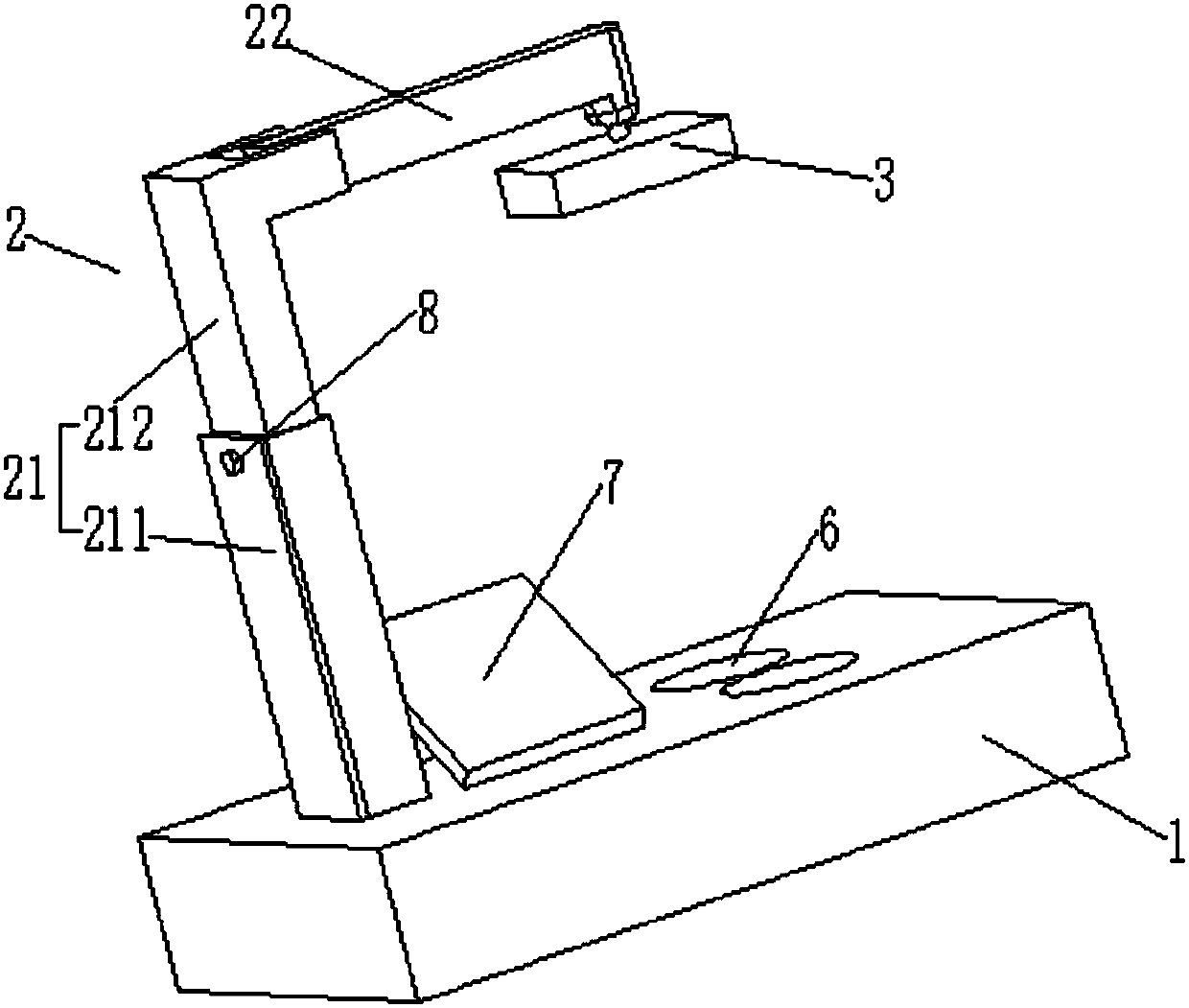

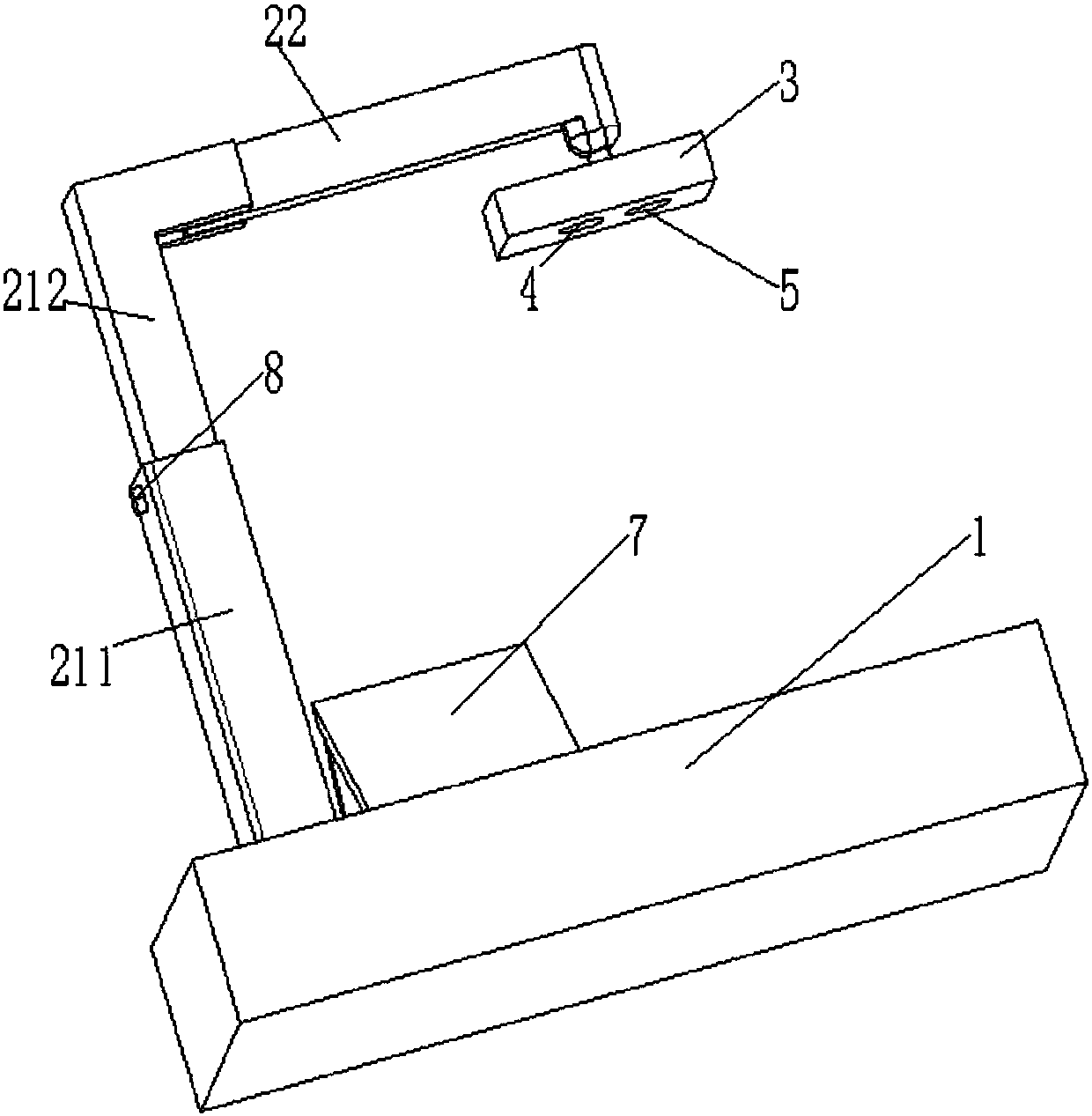

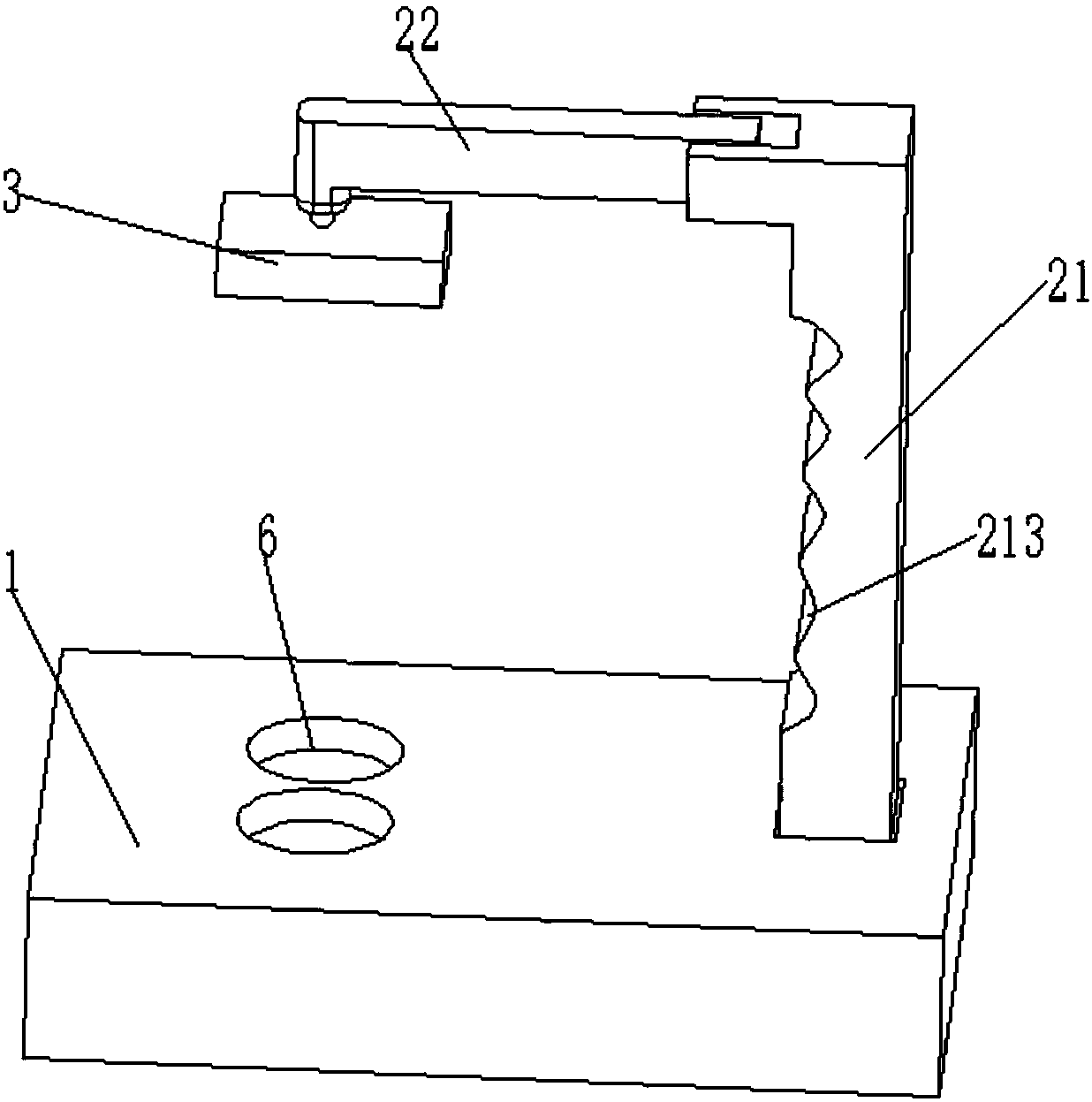

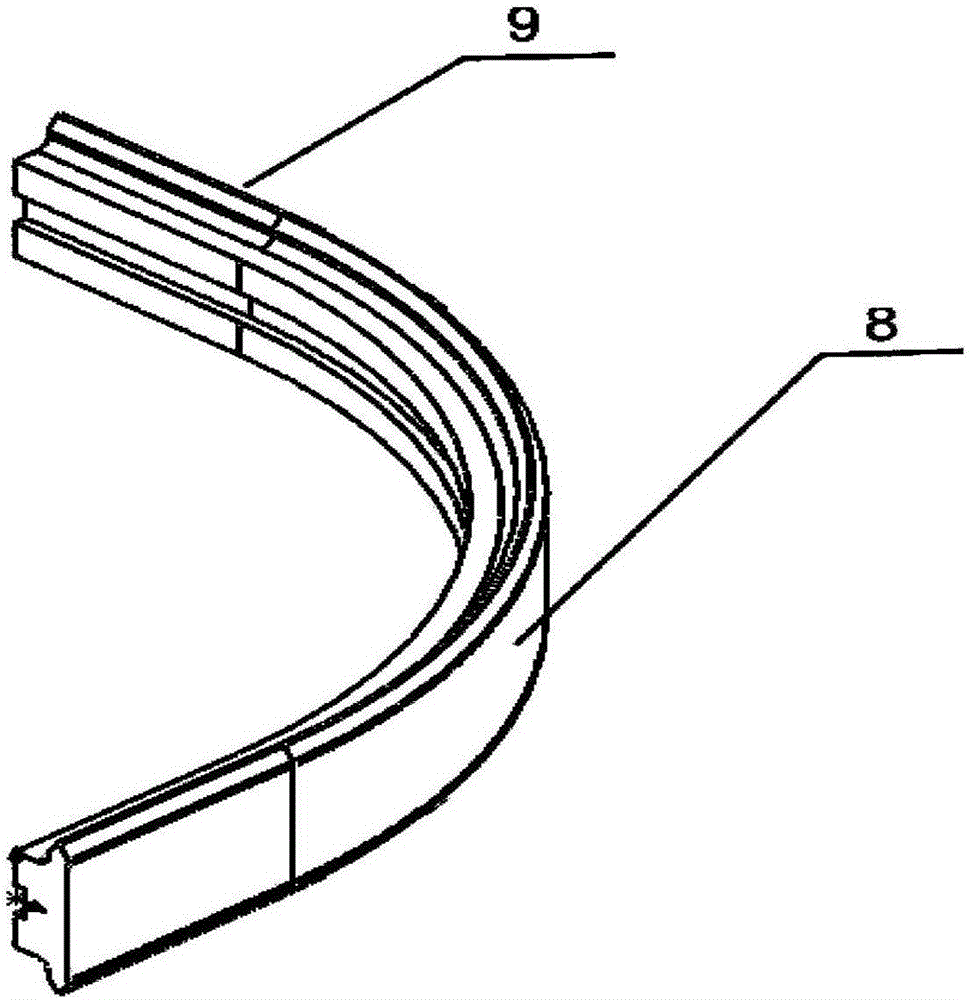

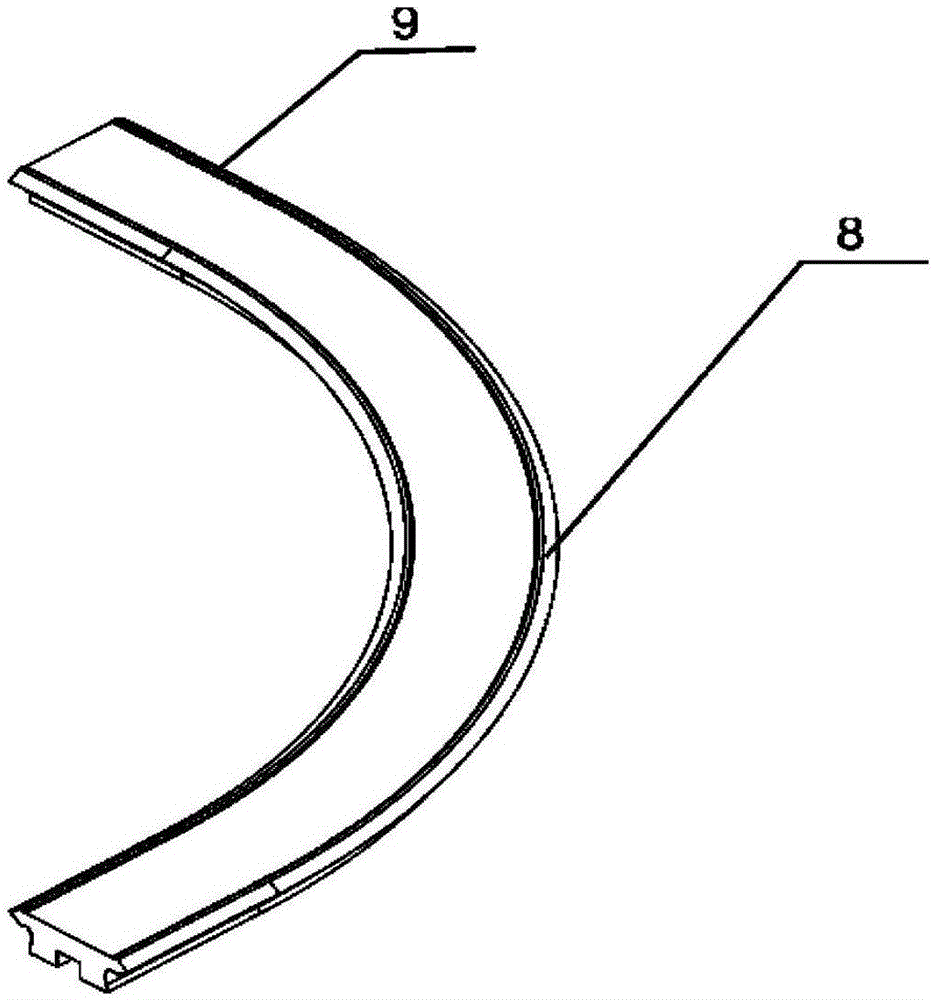

General automatic feeding pinprick mechanism for vehicle decoration product line

InactiveCN101108702AGuaranteed penetrationGuaranteed stabilityGripping headsArticle separationProduction lineBiochemical engineering

The utility model relates to an equipment on the car production line, in particular to a car carpet production line universal type automatic loading acupuncture mechanism. According to the technical proposal provided by the invention, a support pillar is provided below a bracket. The invention is characterized in that: an oblique insertion cylinder block is arranged on the lower end of the support pillar and two slider cylinders are symmetrically mounted below the oblique insertion cylinder block; the lower end of each slider cylinder inclines inward and a pricker is arranged on a piston rod of each slider cylinder. The invention can improve the degree of the automation, the stability and the production efficiency of loading and product quality and reduce the labor intensity of workers.

Owner:刘明春

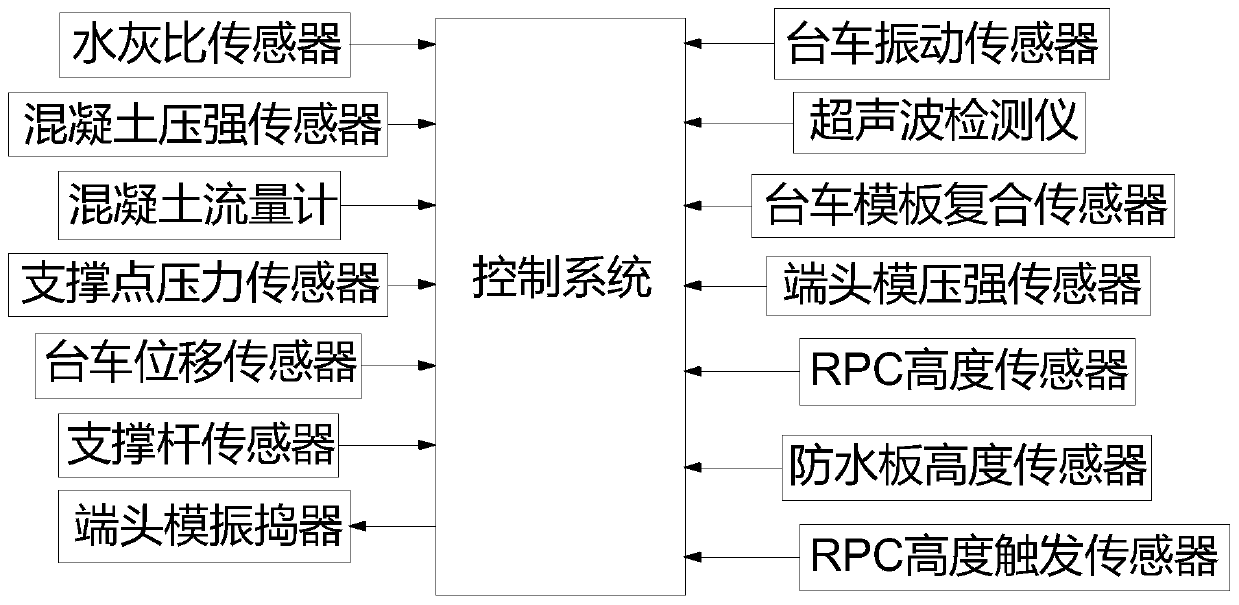

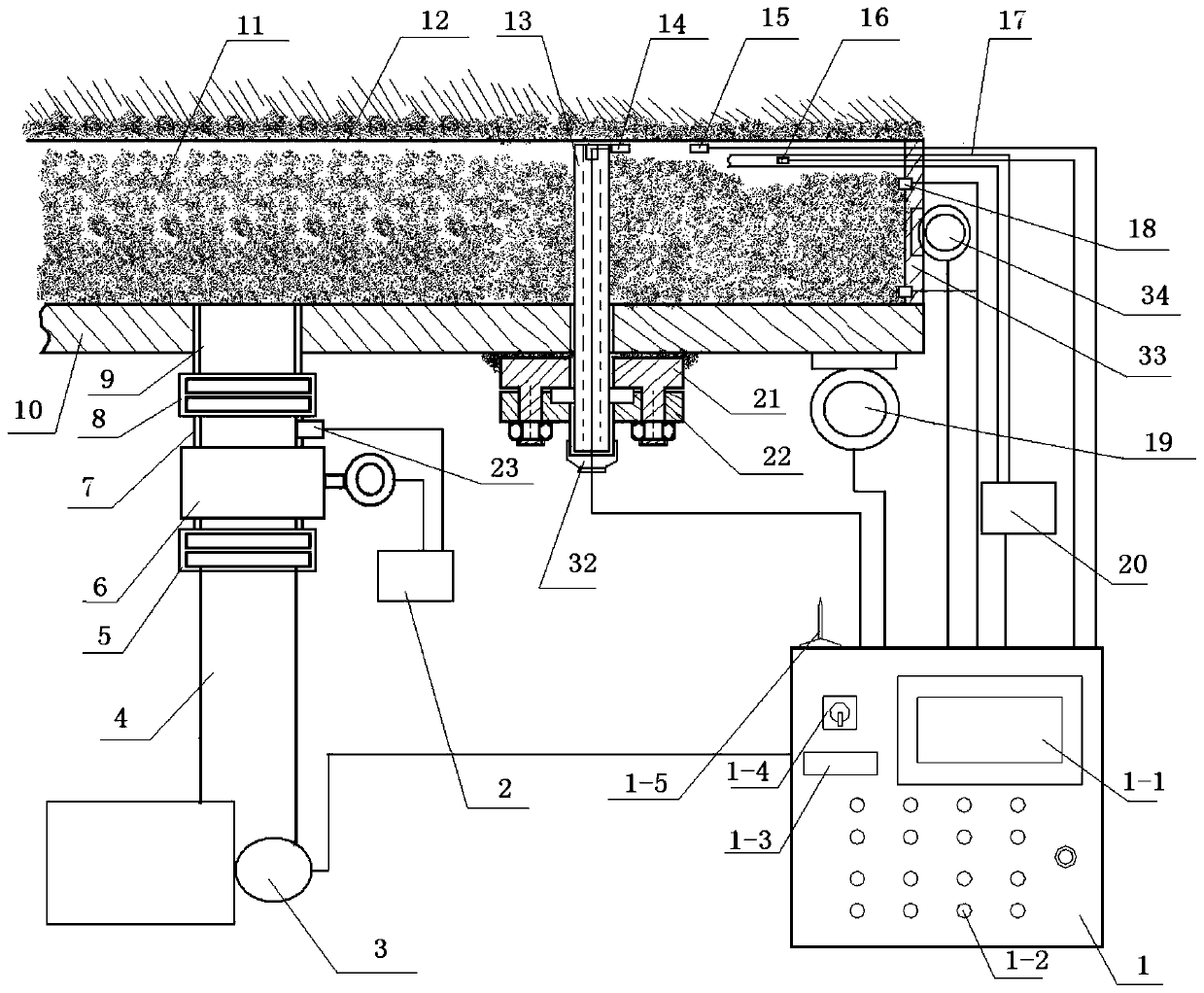

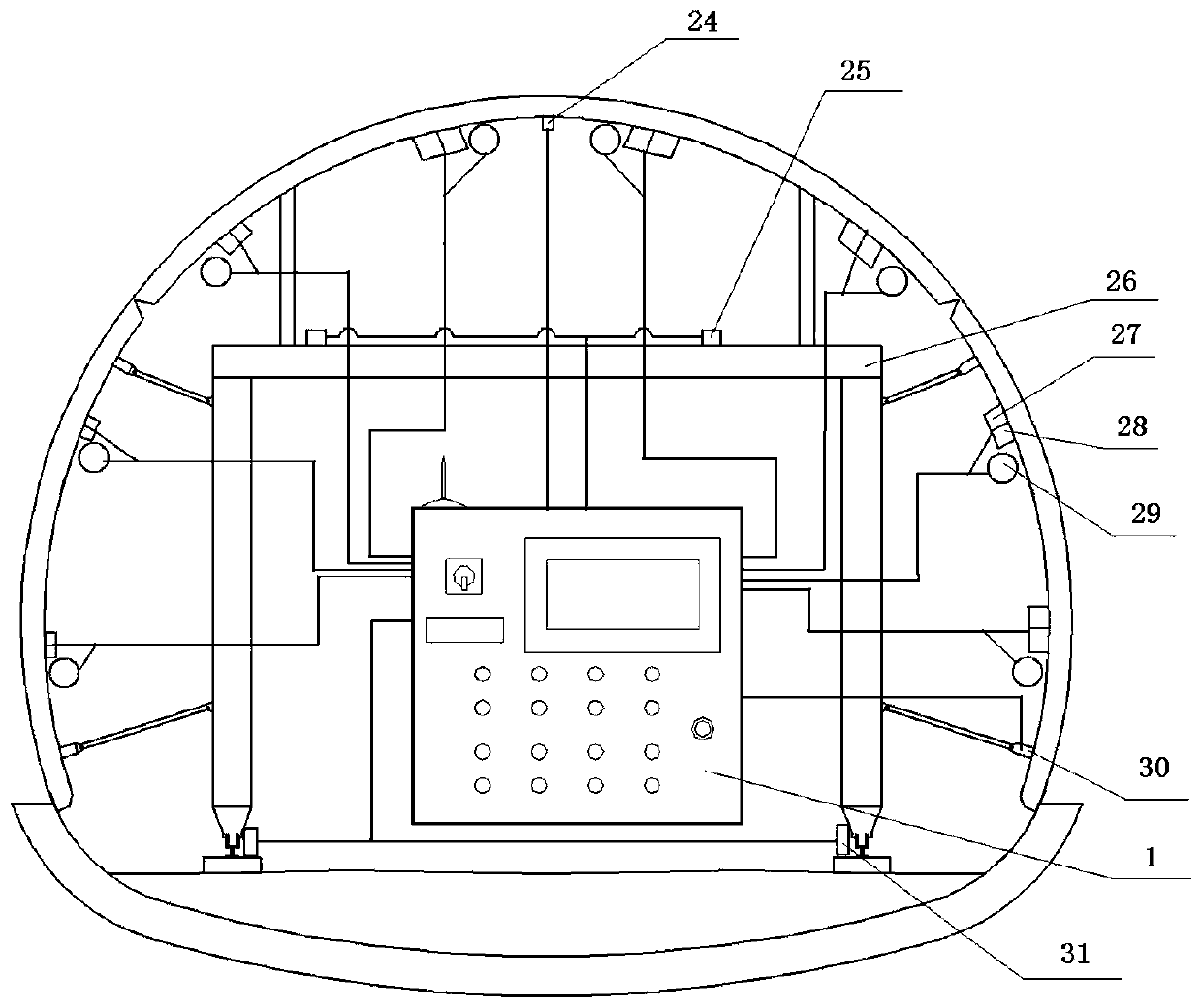

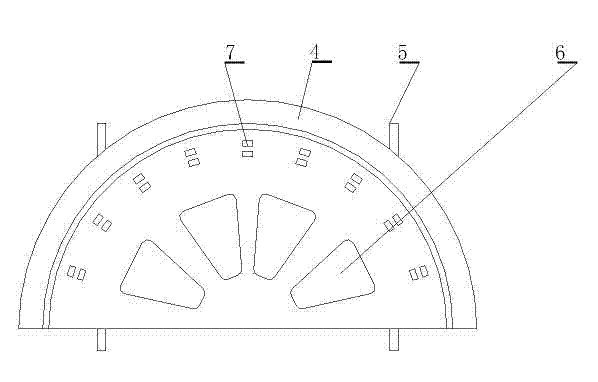

Tunnel lining concrete pouring quality control method and device

ActiveCN109707405AAvoid intensityInhibition of segregationMining devicesUnderground chambersCavitationQuality control

The invention discloses a tunnel lining concrete pouring quality control method and device. The tunnel lining concrete pouring quality control method comprises the steps that concrete pouring of sidewalls is carried out, and a concrete defect preventing method and a trolley excessive-vibration moving preventing method are triggered; and vault concrete is poured, a concrete vault cavitation preventing method and a trolley overloading preventing protection method are triggered, and an end formwork protection method is triggered when concrete reaches the position of an end formwork and extrudesan end formwork pressure intensity sensor during vault concrete pouring. According to the tunnel lining concrete pouring quality control method, through the concrete defect preventing method, the concrete vault cavitation preventing method, the end formwork protection method, the trolley excessive-vibration moving preventing method and the trolley overloading preventing protection method, the lining concrete pouring process can be strictly controlled in the construction process, and quality problems of concrete strength insufficiency, separation, aggregate stacking, lining thickness insufficiency, cavitation, cracking and the like are effectively avoided.

Owner:北京鸿锐嘉科技发展有限公司

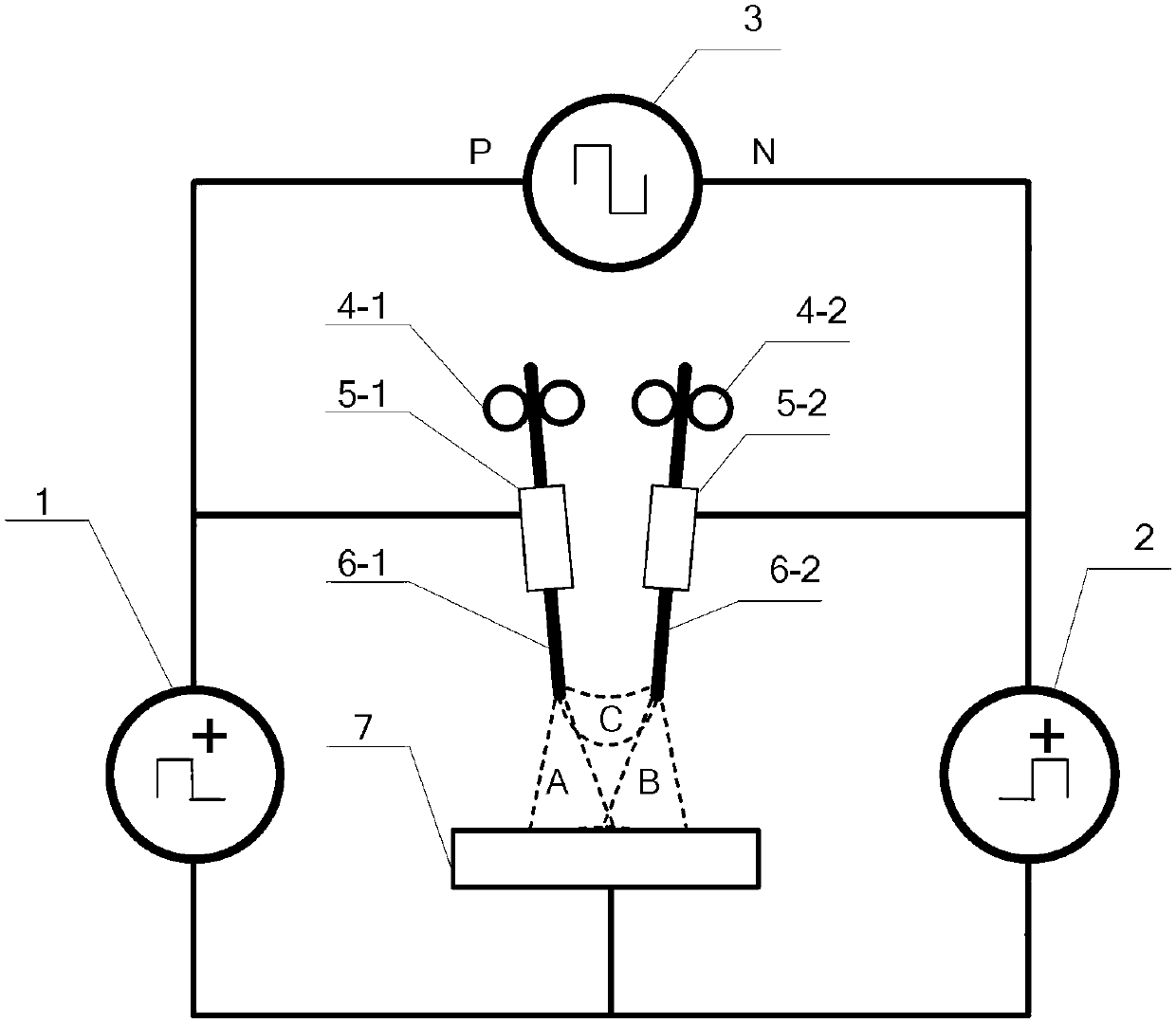

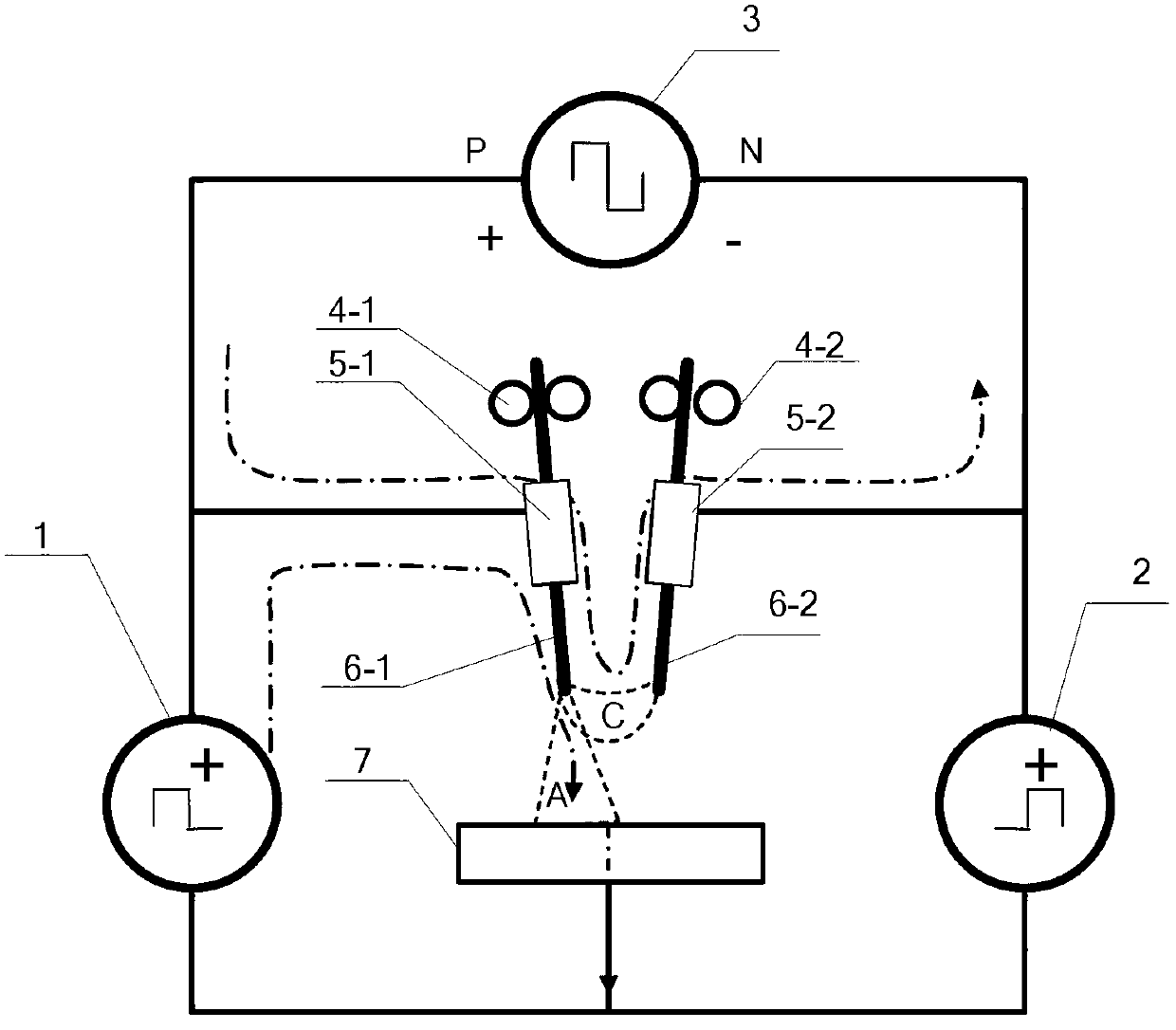

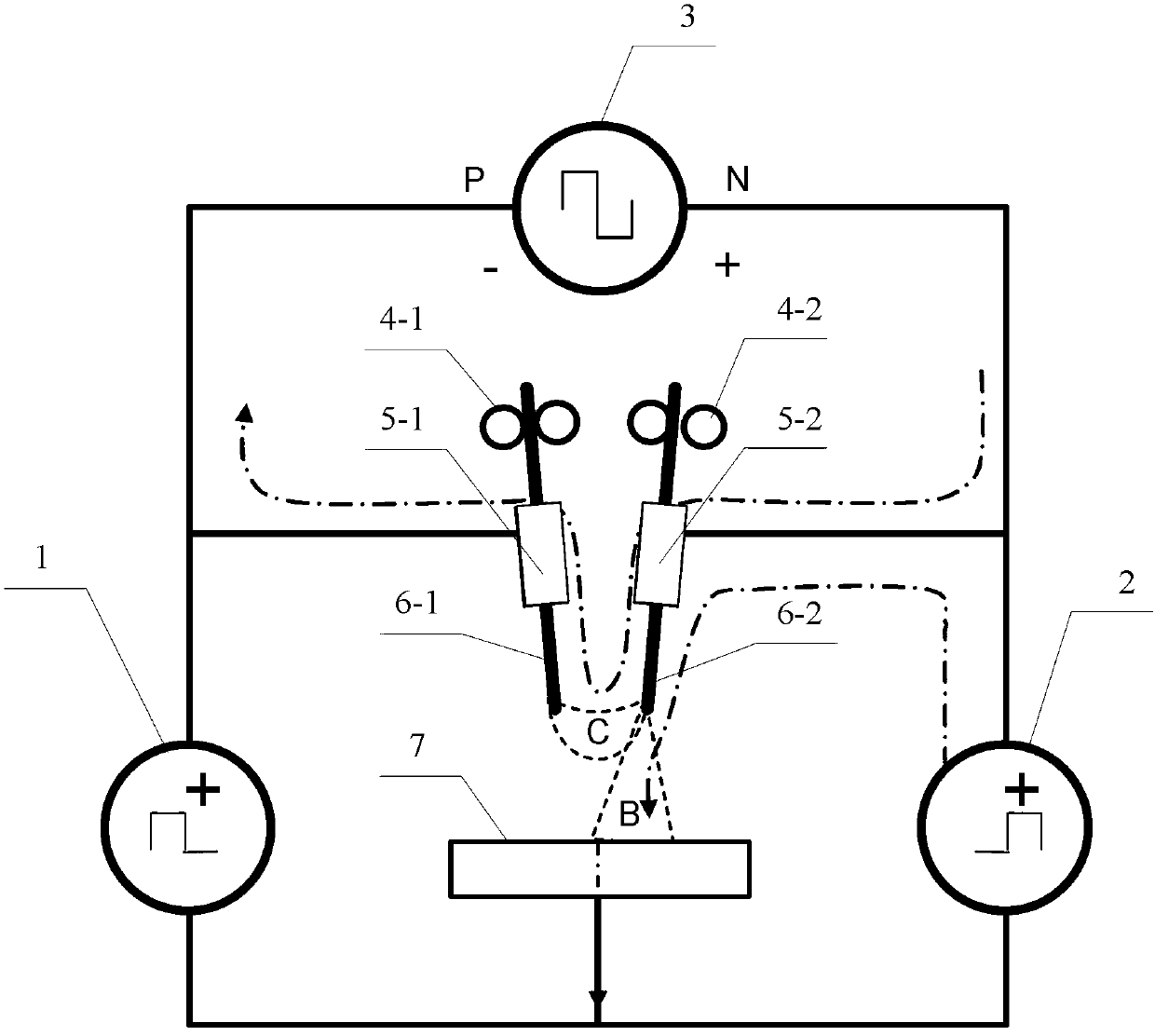

Multi-state double-wire electrical arc welding device and welding method

ActiveCN103341681AFlexible adjustment ratioGuaranteed PenetrationArc welding apparatusWelding power supplyPulse power supply

The invention provides a multi-state double-wire electrical arc welding device and welding method to solve the problem that in an existing electrical arc welding method, due to the fact that a fixed proportional relationship exists between the welding wire deposition rate and the weld heat input, contradictions exist between welding wire deposition rate increase and weld heat input reduction, and belongs to the technical field of consumable electrode electrical arc welding. The device comprises a first direct-current pulse power supply, a second direct-current pulse power supply, a welding power supply with the alterable polarity, a first wire sending mechanism, a second wire sending mechanism, a first contact tube, a second contact tube, a first welding wire and a second welding wire. In the welding process, the first direct-current pulse power supply, the first welding wire and a workpiece to be welded form a left electrical arc welding circuit, the second direct-current pulse power supply, the second welding wire and the workpiece to be welded form a right electrical arc welding circuit, and the welding power supply with the alterable polarity, the first welding wire and the second welding wire form a shunt circuit. The multi-state double-wire electrical arc welding device and welding method are used for electrical arc welding.

Owner:HARBIN INST OF TECH

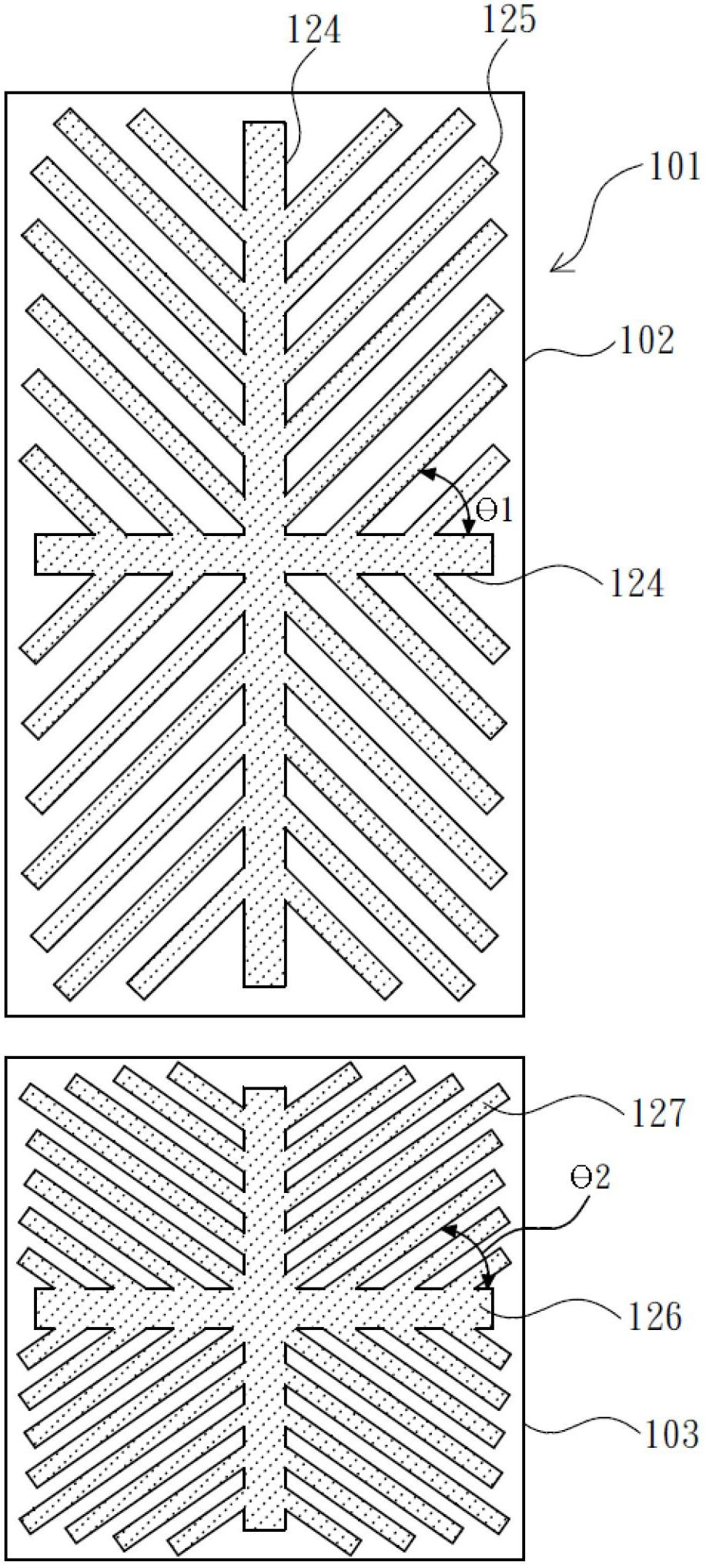

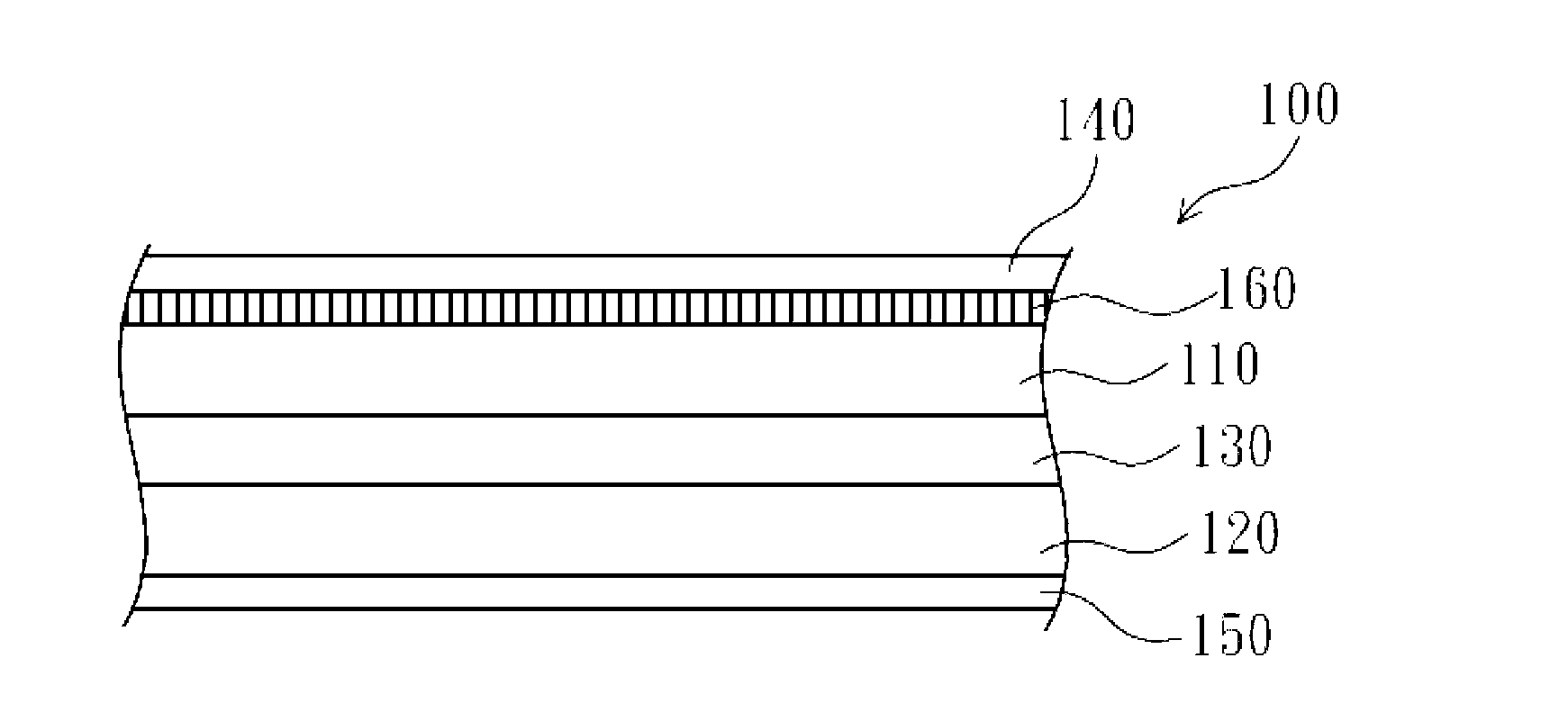

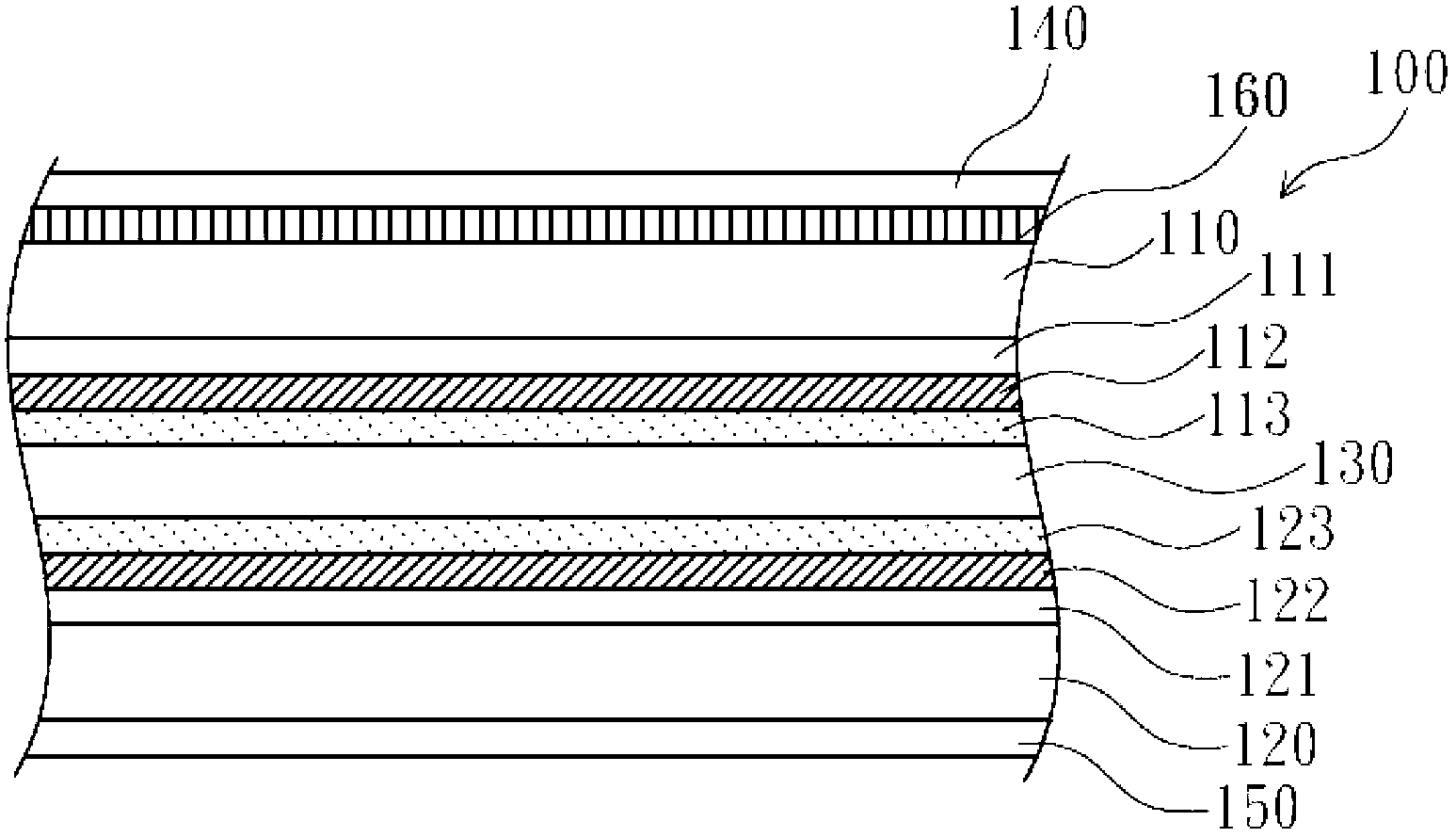

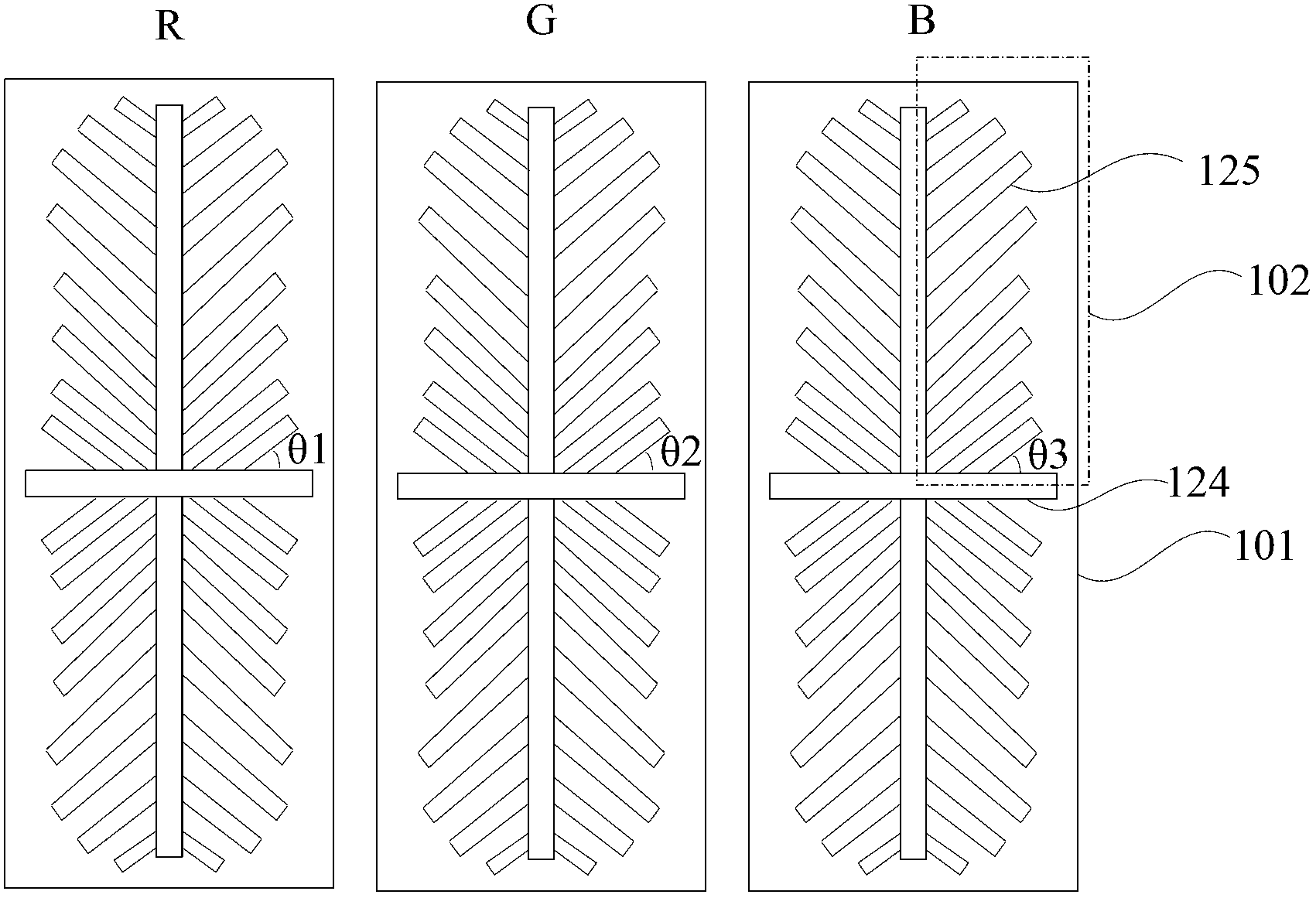

Liquid crystal display panel and display device utilizing same

InactiveCN102681270AGuaranteed PenetrationImprove color castNon-linear opticsLiquid-crystal displayColor shift

The invention provides a liquid crystal display panel and a display device utilizing the same. The liquid crystal display panel comprises a first substrate, a second substrate, a liquid crystal layer and a half-wavelength-pattern phase difference film. The second substrate comprises a second electrode and a plurality of pixel areas, the second electrode includes a main part and a branch part, each pixel area includes a main pixel area and a sub pixel area, an included angle formed between a branch portion and main portion in the main pixel area is 45 degrees, and a pre-set angle between a branch portion and a main portion in the sub pixel area is not equal to 45 degrees. The half-wavelength-pattern phase difference film is glued on an outer lateral surface of the first substrate or the second substrate and comprises a zero-wavelength phase difference array and a half-wavelength phase difference array. By the aid of the above structure, the problems of color shift and penetration rate decrease of an existing liquid crystal display panel can be alleviated.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

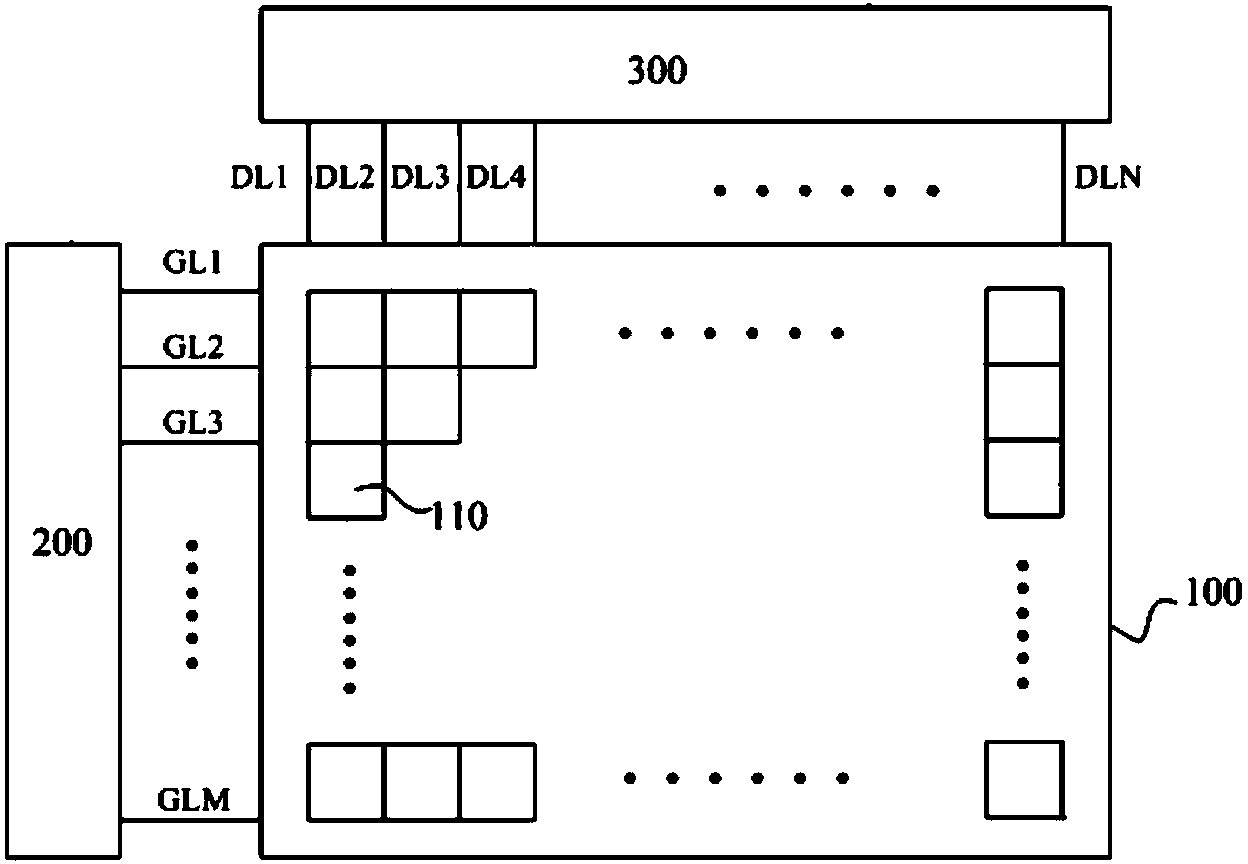

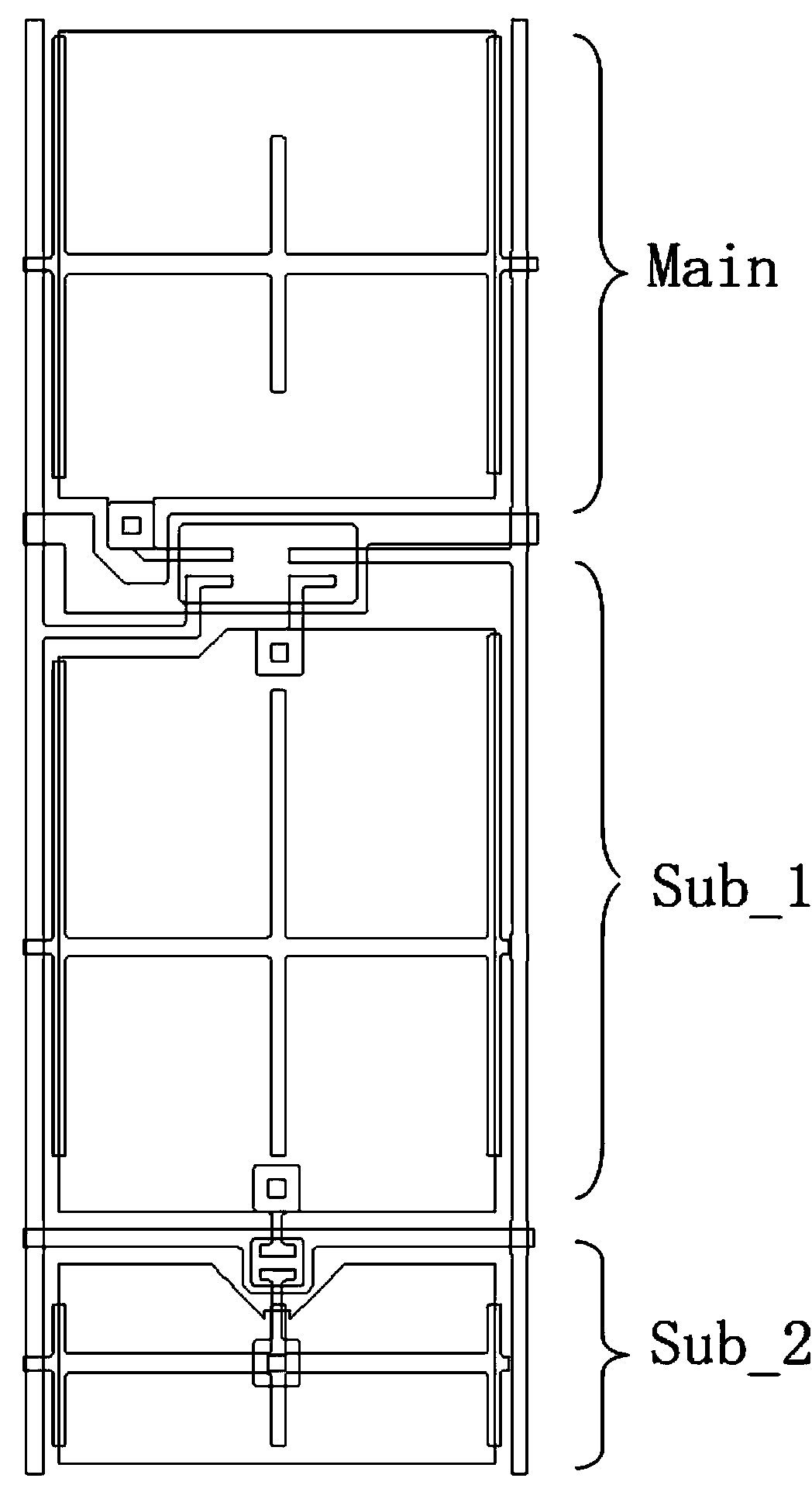

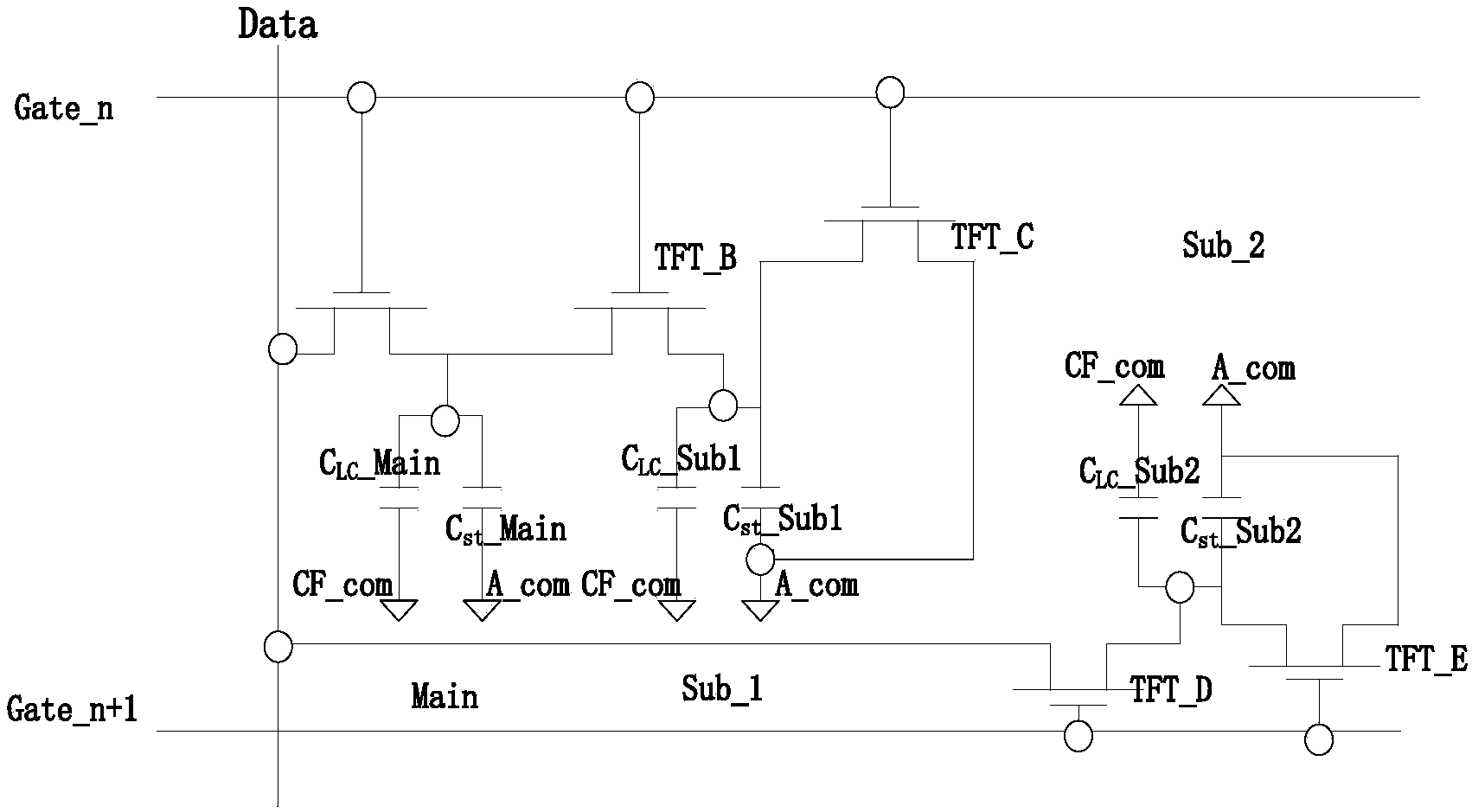

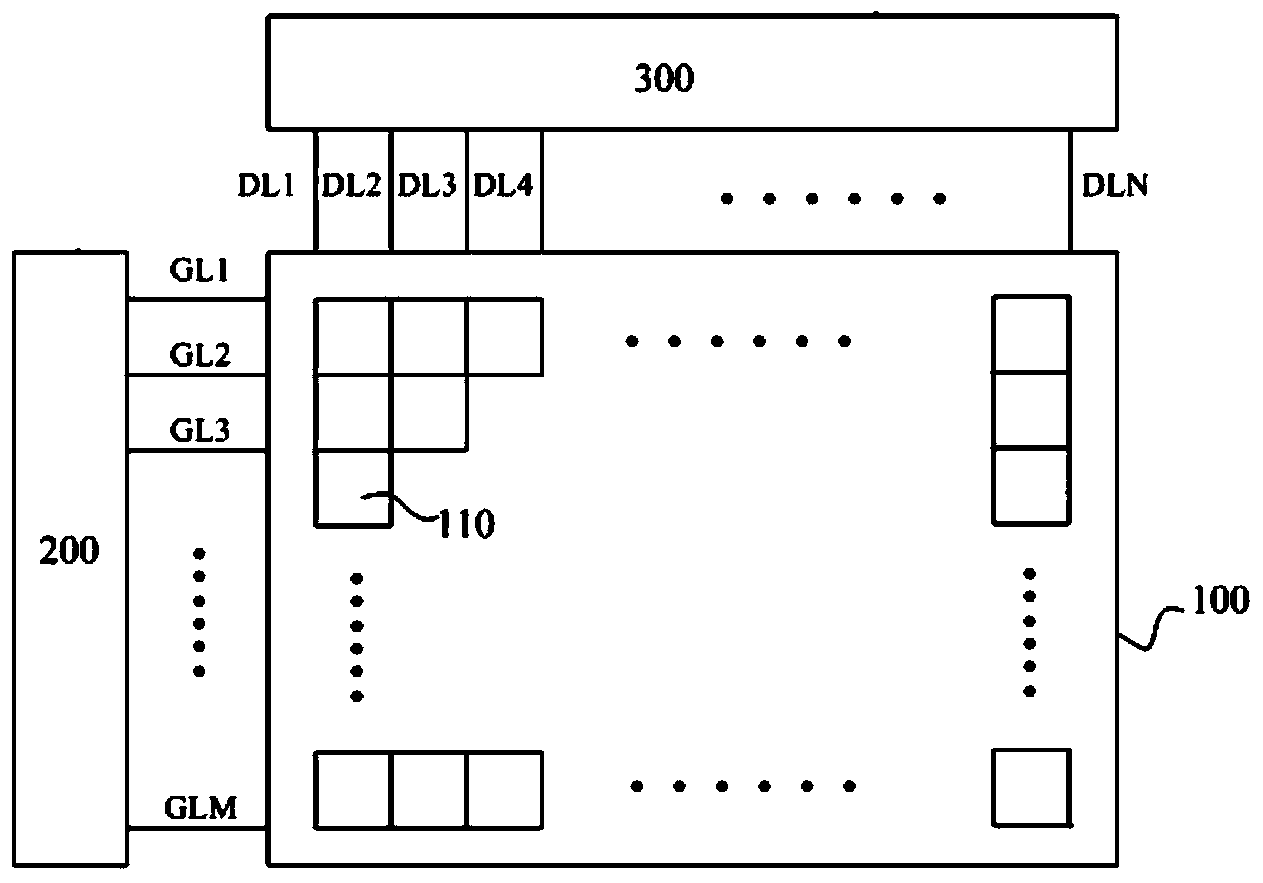

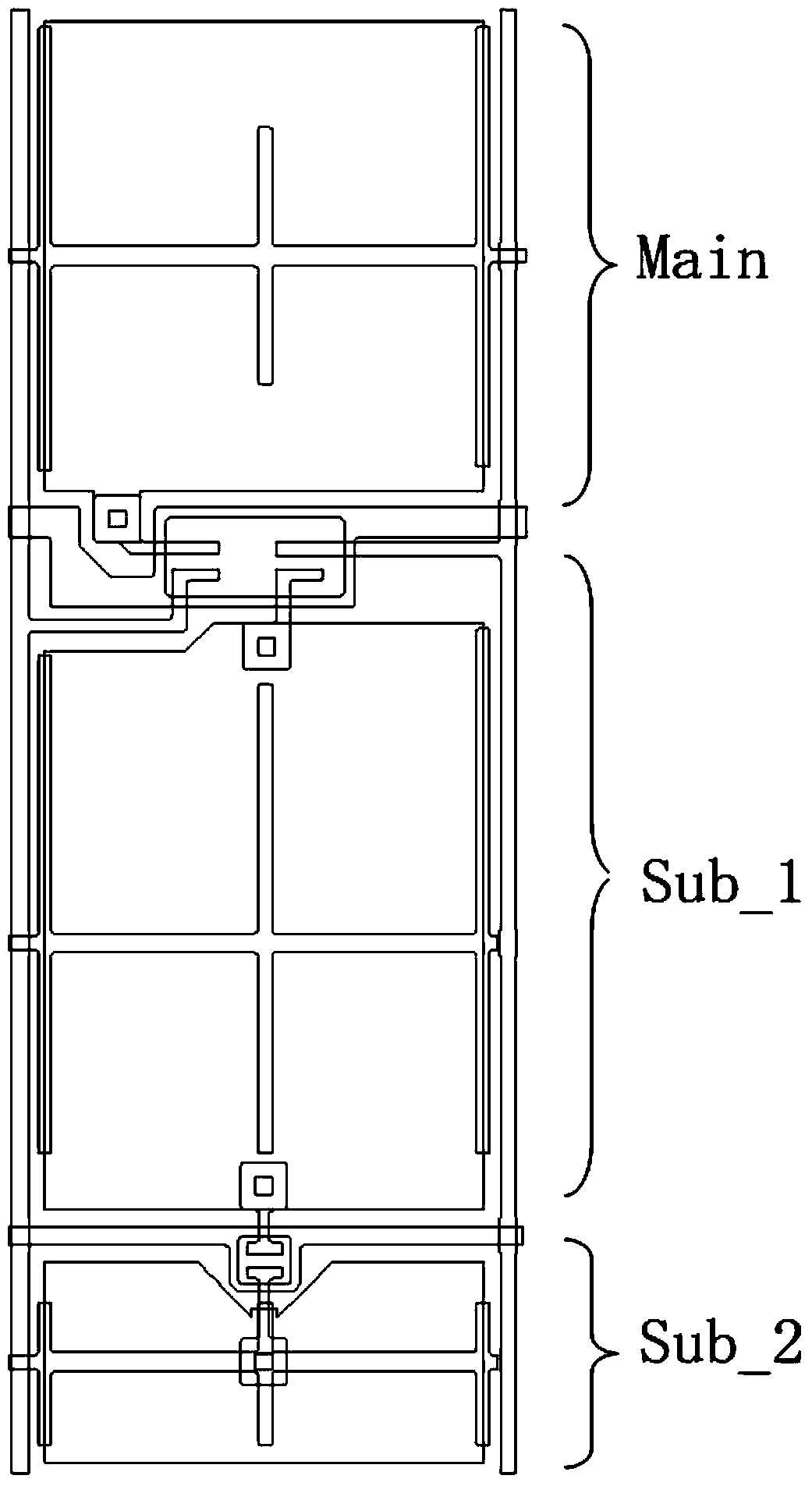

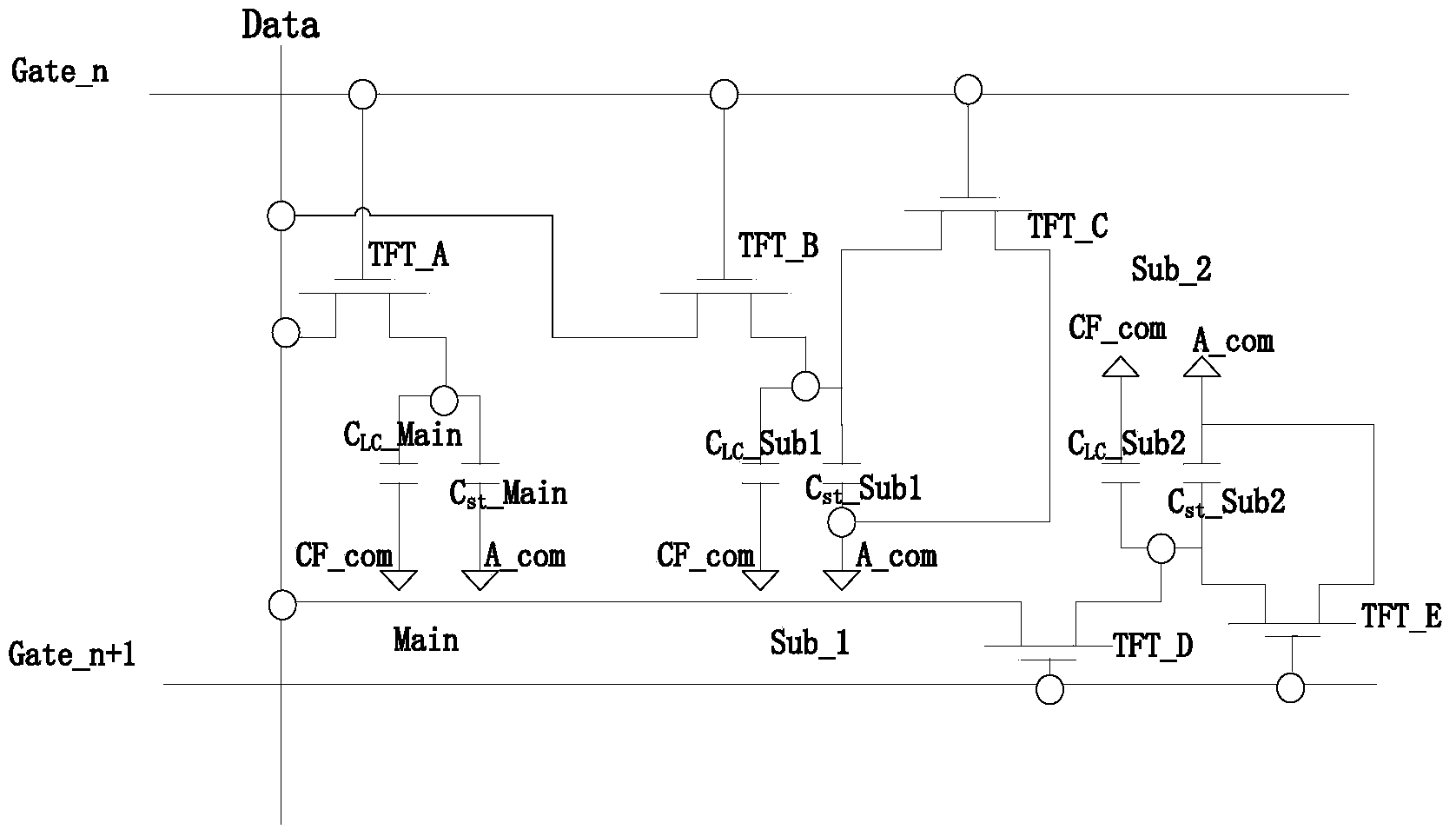

Display panel, and pixel structure and driving method thereof

InactiveCN104238209AGuaranteed PenetrationAchieve low color cast effectStatic indicating devicesNon-linear opticsColor shiftData signal

The invention discloses a display panel, and a pixel structure and a driving method thereof. The pixel structure comprises a plurality of sub-pixels; each sub-pixel comprises a main area, a first sub-area and a second sub-area; the main area is configured to receive a scanning signal of a first scanning line to further receive a data signal on a data line to have main area voltage; the first sub-area is electrically connected with the main area, and is configured to receive the scanning signal of the first scanning line to further receive the main area voltage to have first sub-area voltage; the second sub-area is configured to receive a scanning signal of a second scanning line to further receive the data signal on the data line to have second sub-area voltage; the main area voltage, the first sub-area voltage and the second sub-area voltage are different from one another. The display panel can realizes 2D low color-shift display, and can also realize 3D low color-shift display through voltage difference between the main area and the first sub-area after the second sub-area forms a shading area.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Stainless steel A-TIG welding active agent and welding method

InactiveCN108247236AImprove securityAvoid harmArc welding apparatusWelding/cutting media/materialsActive agentStainless steel welding

The invention belongs to the technical field of stainless steel welding, and particularly relates to a stainless steel A-TIG welding active agent and a welding method. To solve the problem that an existing stainless steel A-TIG welding active agent contains halide, influences are caused to the human body health, the stainless steel A-TIG welding active agent is disclosed. The stainless steel A-TIGwelding active agent comprises active agent powder. The active agent powder comprises, by mass percent, 10%-30% of SiO2 powder, 5%-20% of Cr2O3 powder, 15%-50% of Al2O3 powder, 10%-20% of TiO2 powder, 5%-20% of MnO2 powder, 5%-20% of Fe2O3 powder, 5%-30% of B2O3 powder and 3%-8% of La2O3 powder. The active agent is adopted for conducting stainless steel A-TIG welding, influences of the halide onthe operator health can be avoided, and the welding efficiency can be improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

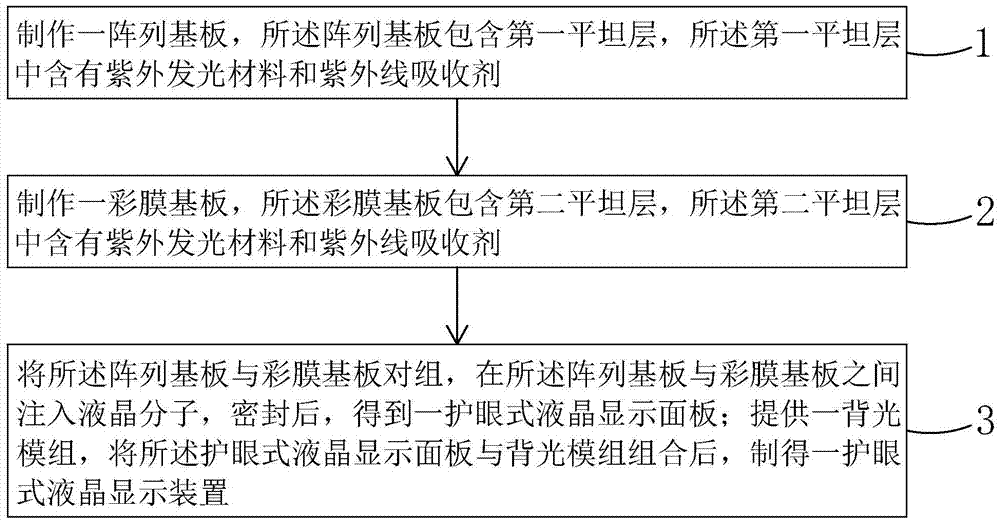

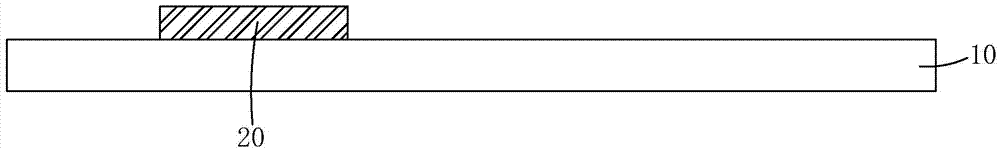

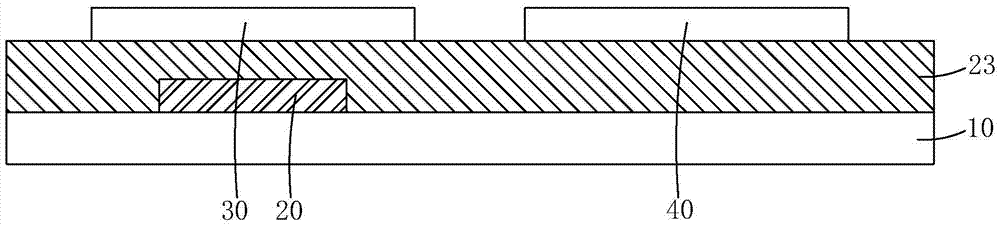

Making method of eye protection type liquid crystal display device

ActiveCN105446000AGuaranteed PenetrationDoes not reduce display brightnessSolid-state devicesNon-linear opticsUltraviolet lightsLightness

The invention provides a making method of an eye protection type liquid crystal display device. According to the making method, an ultraviolet luminescence material and ultraviolet light absorber are added to a first flat layer (70) of an array substrate (100) and a second flat layer (240) of a color film substrate (200), the ultraviolet light absorber is made to absorb shortwave blue light and ultrasonic light which are emitted out by a backlight module and with wavelength below 400 nm, and meanwhile the absorbed shortwave blue light and ultrasonic light stimulate the ultraviolet luminescence material to emit out long-wave blue visible light which is over 400 nm in wavelength, in another word, the first flat layer (70) and the second flat layer (240) are utilized to convert the ultraviolet light which harms the human eyes and the shortwave blue light with the wavelength below 400 nm into the long-wave blue visible light not harmful to the human eyes and with the wavelength over 400 nm. By means of the making method, the human eyes are protected, the display brightness of a liquid crystal display panel is not lowered, and the backlight rate and the penetration rate of the liquid crystal display device are guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

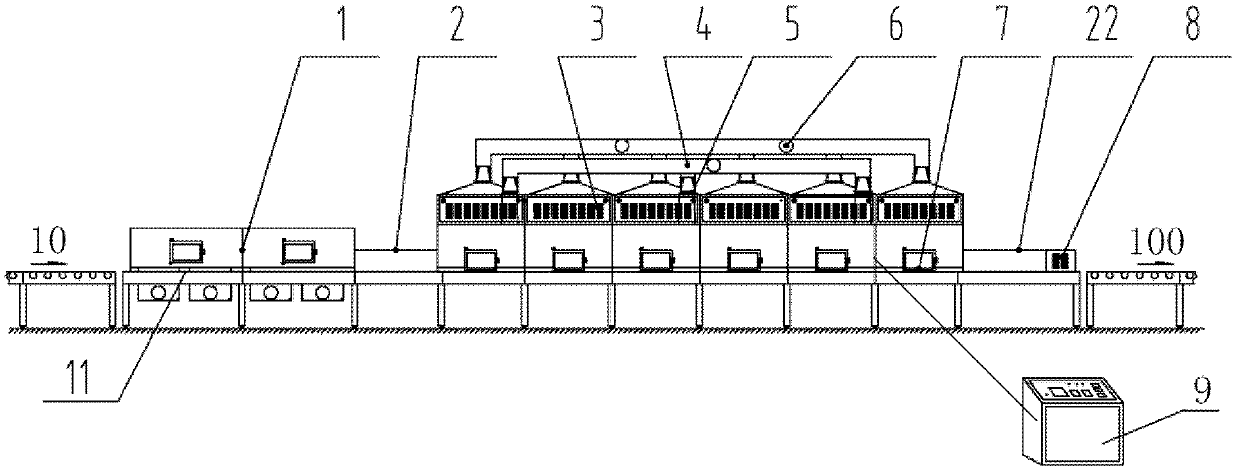

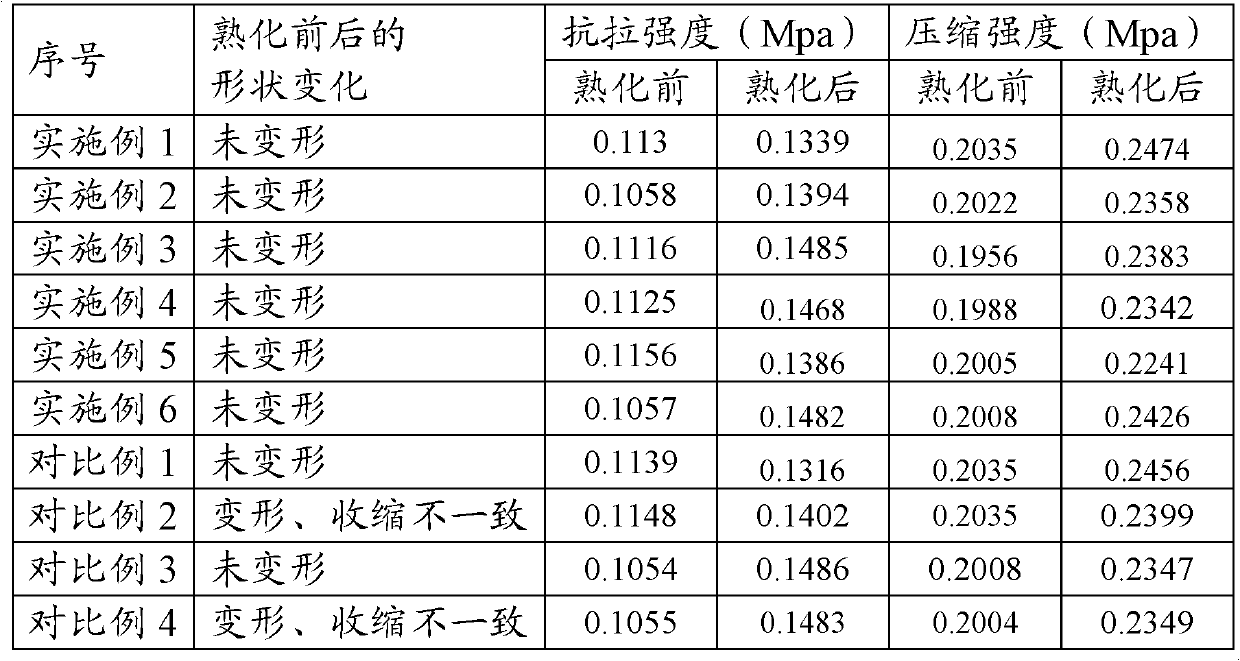

Method and equipment for curing phenolic aldehyde foam material

The invention discloses a method and equipment for curing a phenolic aldehyde foam material. The method for curing the phenolic aldehyde foam material comprises the steps of radiating the phenolic aldehyde foam material to be cured by using microwaves and cooling the phenolic aldehyde foam material. The equipment for curing the phenolic aldehyde foam material has the advantages that moisture, residual foaming agents and formaldehyde inside the phenolic aldehyde foam material are evaporated rapidly, and a chemical reaction inside the phenolic aldehyde foam material is greatly accelerated, so that the curing time is shortened. The microwaves are penetrable, so that the surface and inside of the phenolic aldehyde foam material are subjected to microwave radiation at the same time; and polar molecules absorb the energy of electromagnetic waves and generate uniform heat, so that the product quality is guaranteed, and the phenomenon that the phenolic aldehyde foam material shrinks discordantly, cracks or deforms is avoided.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

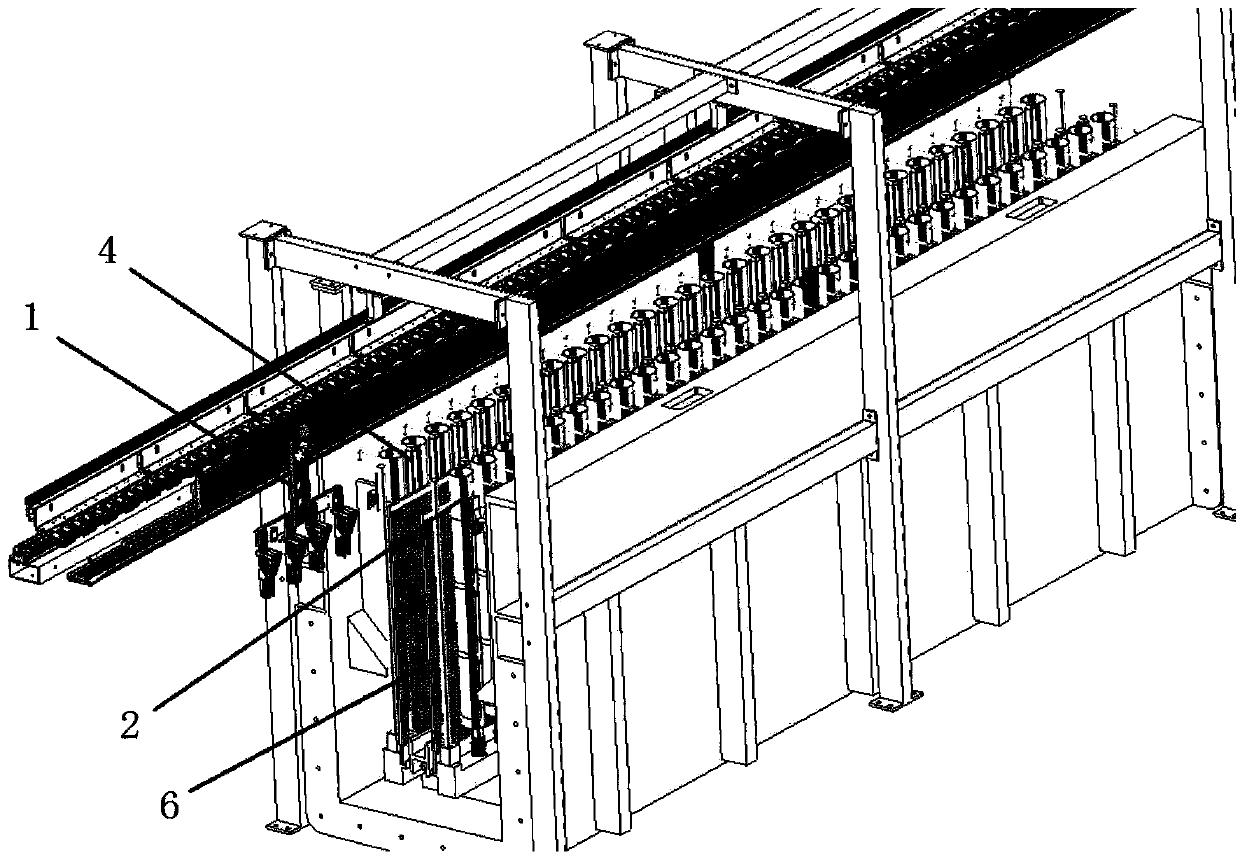

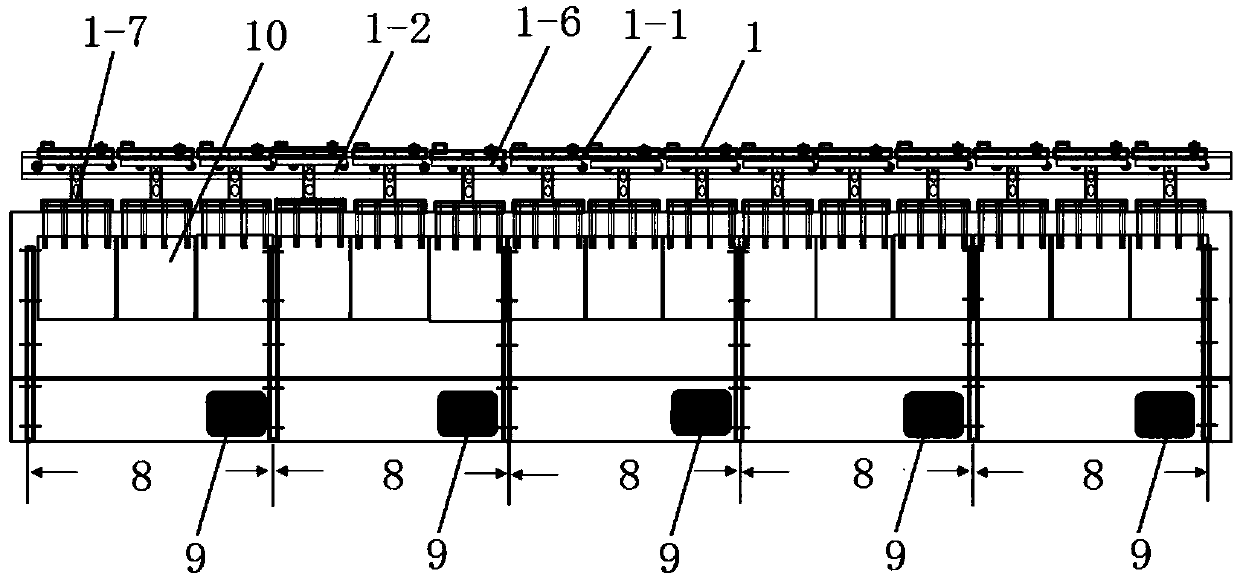

Electroplating equipment for improving PCB high-aspect-ratio hole-filling capacity and copper plating uniformity

ActiveCN109576768AHigh vibration frequencyImprove uniformityElectrolysis componentsCopper platingSpray nozzle

The invention discloses electroplating equipment for improving the PCB high-aspect-ratio hole-filling capacity and copper plating uniformity so as to improve the hole-filling capacity during high-aspect-ratio PCB electroplating. The equipment comprises an electroplating bath, a transmission feiba part which is disposed over the electroplating bath, electroplating titanium baskets, spaying pipes and processing solution tank bases, wherein the electroplating titanium baskets, the spaying pipes and the processing solution tank bases are arranged in the electroplating bath; spray nozzles are disposed on the spraying pipes; the electroplating titanium baskets and the spraying pipes are divided into two groups and are arranged in the electroplating bath; the processing solution tank bases are arranged corresponding to the two groups of electroplating titanium baskets and spraying pipes; anode baffles are disposed on the opposite sides of the two groups of spraying pipes correspondingly; andthe spray nozzles are located in leakage holes formed in the anode baffles. During electroplating, a to-be-electroplated PCB is located between the anode baffles, and then the spray nozzles face the to-be-electroplated PCB.

Owner:黄湘琪

Display panel, and pixel structure and driving method for display panel

InactiveCN104238219AGuaranteed PenetrationAchieve low color cast effectStatic indicating devicesNon-linear opticsColor shiftData signal

The invention discloses a display panel, and a pixel structure and a driving method for the display panel. The pixel structure comprises a plurality of sub-pixels; each sub-pixel comprises a main area, a first sub-area and a second sub-area, wherein the main area configure to receive a scanning signal of a first scanning line to further receive a data signal on a data line to have main area voltage; the first sub-area configure to receive the scanning signal of the scanning line to further receive the data signal on the data line to have first sub-area voltage; the second sub-area configured to receive a scanning signal of a second scanning line to further receive the data signal on the data line to have second sub-area voltage; the main area voltage, the first sub-area voltage and the second sub-area voltage are different from one another. The display panel can realize 2D low-color-shift display, and also can realize 3D low-color-shift display through voltage difference between the main area and the first sub-area after the second sub-area forms a shading area.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

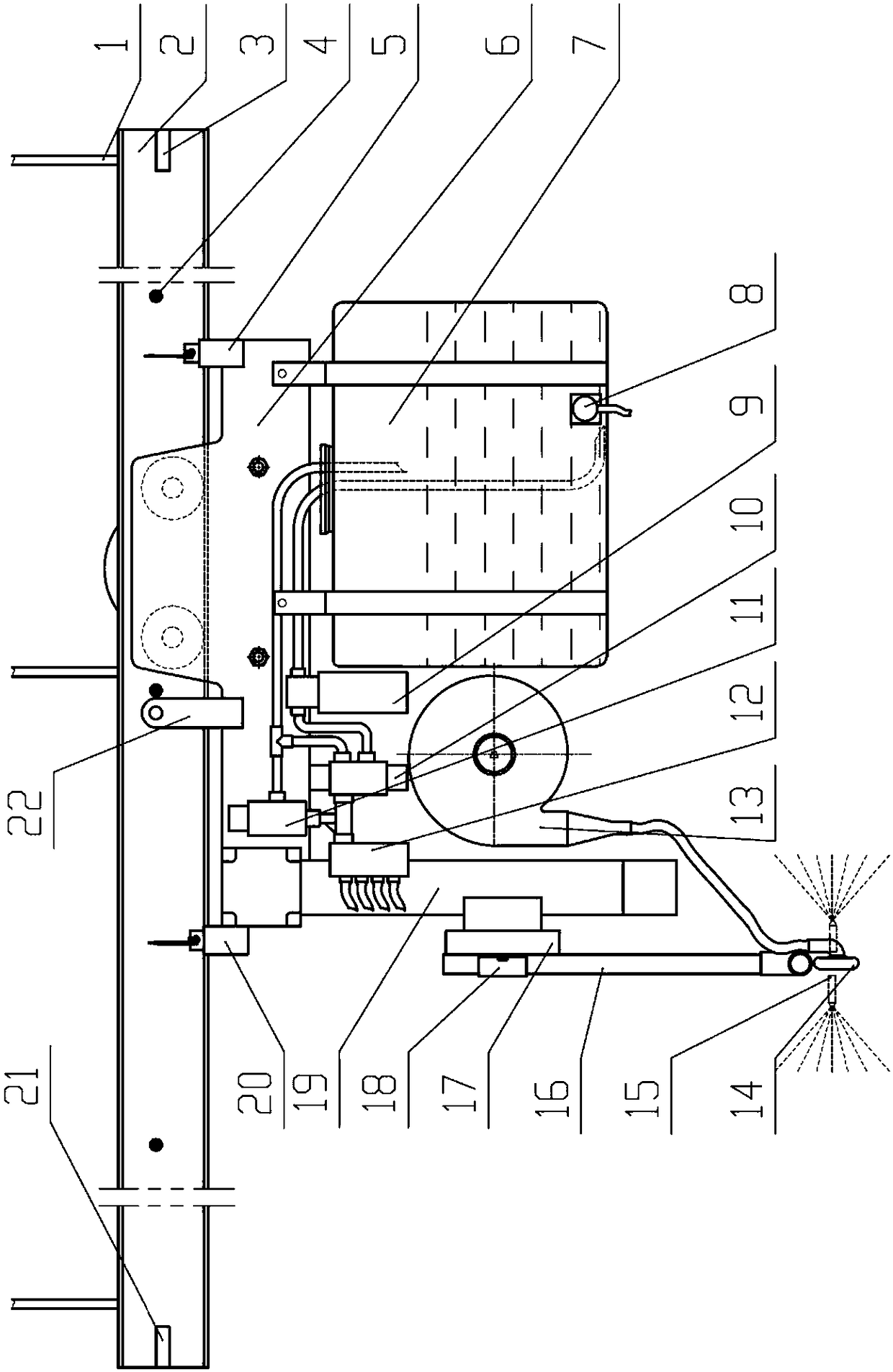

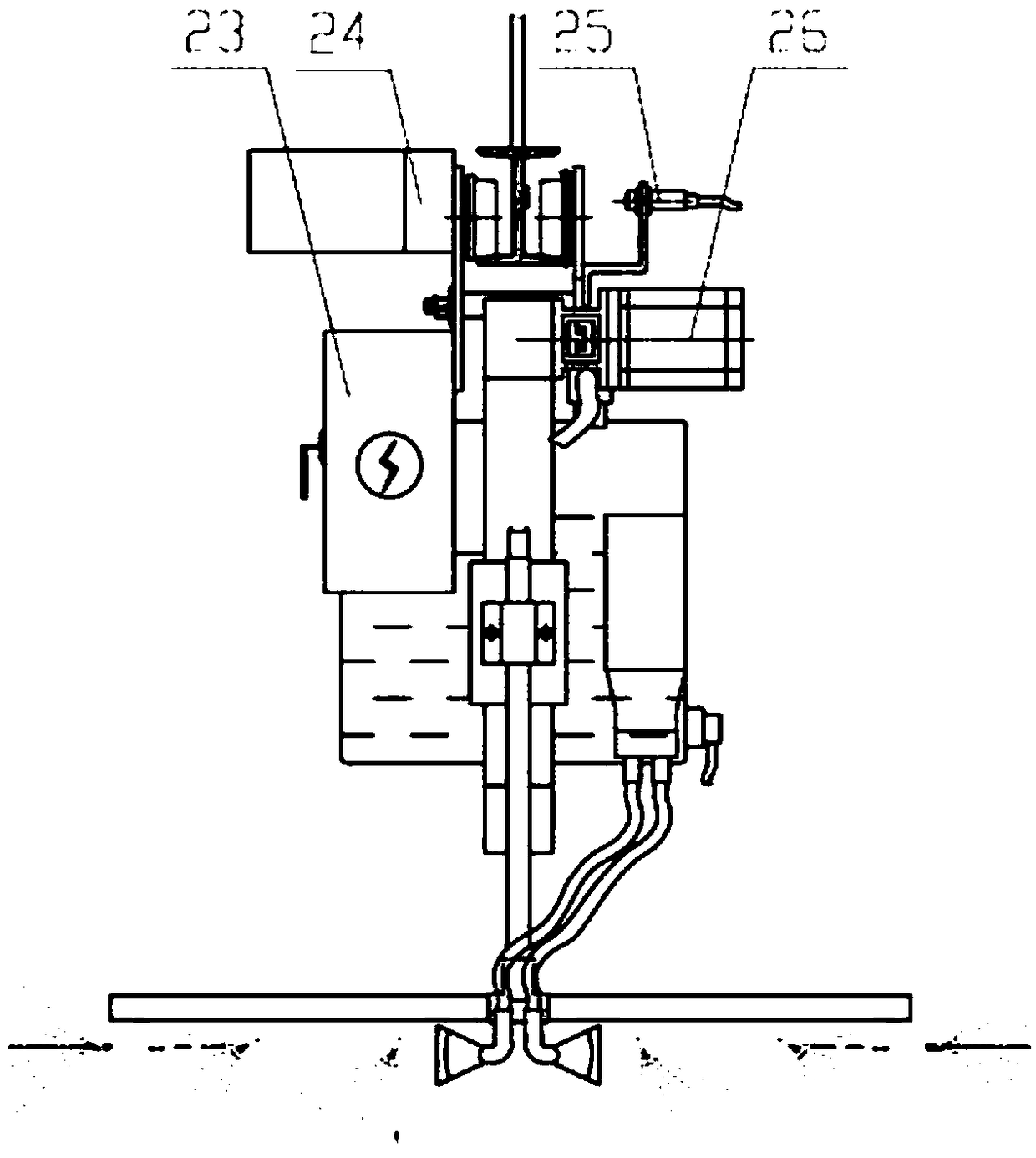

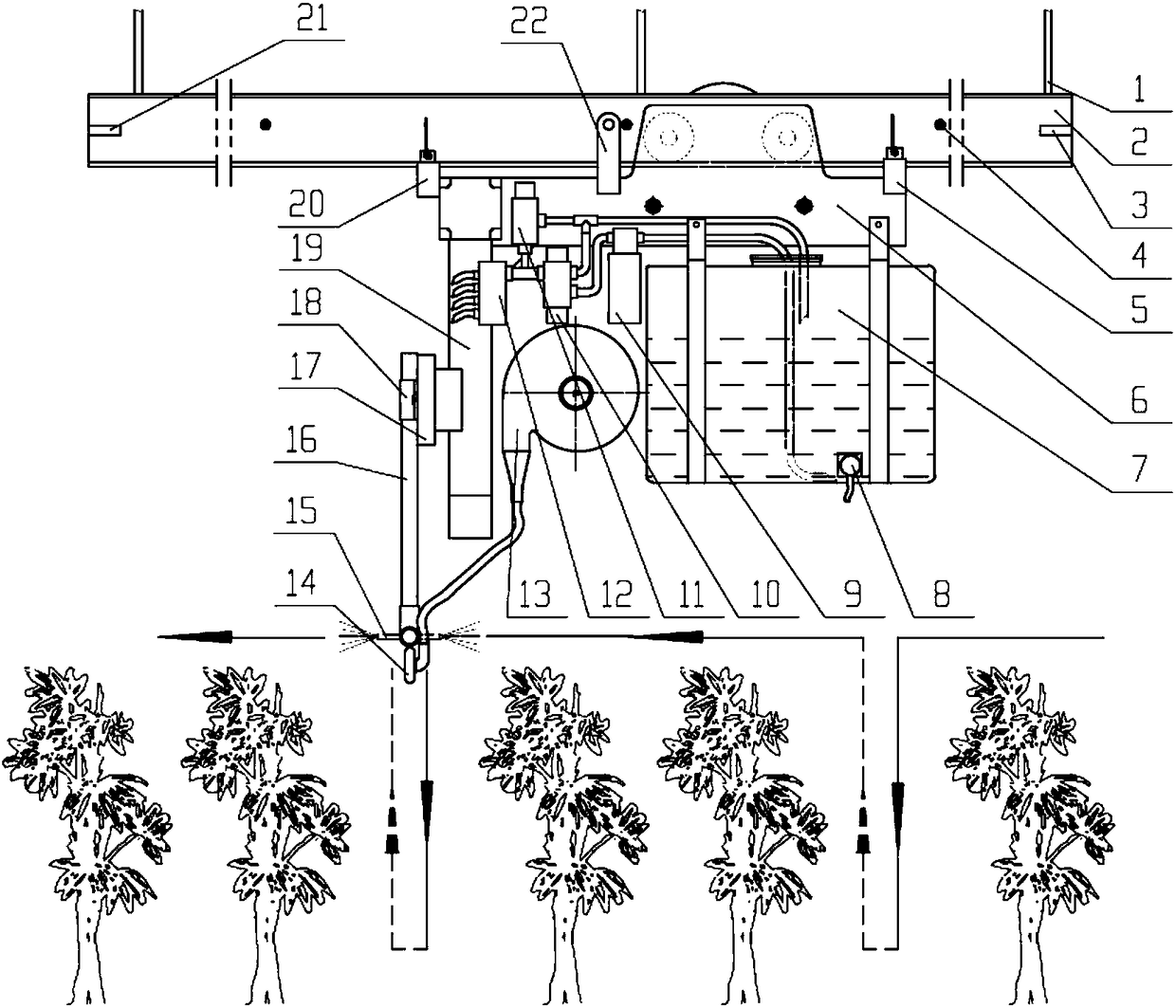

Railed self-propelled multimode automatic atomizing machine for greenhouses

ActiveCN108371168AImprove job qualityStrong penetrating powerInsect catchers and killersStart stopControl system

The invention relates to a railed self-propelled multimode automatic atomizing machine for a greenhouse. A rail is erected below a ceiling arch pipe of the greenhouse through hanging rods along the length direction of the greenhouse, and a self-propelled platform is mounted on the rail to move along the rail. A lifting module, an atomizing module, an air supply module, a control system and the like are mounted on a frame of the self-propelled platform to move on the rail along with the self-propelled platform. Nozzles and an air supply spray pipe are mounted on a T-shaped supporting frame which is fixed to a slider of the lifting module, and immersing into a tall crop canopy to implement atomization is realized. A remote control module, a position sensor and a stroke sensor are mounted onthe self-propelled platform, corresponding triggers are mounted on the rail, and a liquid level sensor is mounted on a pesticide tank. Sensor signals are all transmitted to a PLC controller, and the controller outputs control instructions to drive module executing terminals. The atomizing machine executes start-stop motion of the self-propelled platform according to a selected operating mode, enables on and off of the atomizing module, the air supply module and the lifting module and executes operation action to cooperatively complete atomization.

Owner:JIANGSU UNIV

Method for producing metal plug for metal gate

ActiveCN102983097AGuaranteed connectivityGuaranteed not to penetrateSemiconductor/solid-state device manufacturingSputteringHydrogen

The present invention discloses a method for producing a metal plug for a metal gate. When a metal gate oxide layer in the metal plug through hole of the metal gate is removed by using a dry method, small sputtering dose argon molecule sputtering and hydrogen reduction are combined to perform the remove. The small dose ensures that a barrier layer is not penetrated during the etching of the barrier layer on an active region; so, on the one hand, the barrier layer on an active region is not etched to get penetrated by using a small sputtering dose argon molecules for sputtering; on the other hand, the portion of the metal gate oxide layer in the metal plug through hole of the metal gate which cannot be completely removed, is reduced by using hydrogen reduction; thereby enabling the metal plug though hole of the metal gate to communicate with the metal gate, finally the metal plug filled in the metal plug hole of the metal gate can also be connected to the metal gate. Accordingly, by using the method of the present invention, it is ensured that the produced metal plug of the metal gate is enabled to connect with the metal gate on the basis of not damaging the active region of a semiconductor.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for preventing deformation of large-size thin-wall annular casting during welding process

ActiveCN102528218ANo mouth opening/neck deformationNo distortionWelding accessoriesLarge sizeMaterials science

The invention relates to a method for preventing deformation during a welding process, in particular to a method for preventing the deformation of a large-size thin-wall annular casting during the welding process. The method is characterized in that the method comprises the following steps of: preparation before welding: preparing a shim plate used for supporting at least five points of the casting so as to ensure that the casting is padded flatly and cannot be deformed by external forces during the welding, and an anti-deformation welding tooling, and then fixing the casting on the tooling; pre-heating before welding; selection of parameters of the welding process; and control of the welding process. The method provided by the invention is unique; the quality of the casting can be ensured; the production cycle can be shortened; the working efficiency can be improved; and the production cost can be saved.

Owner:KOCEL STEEL

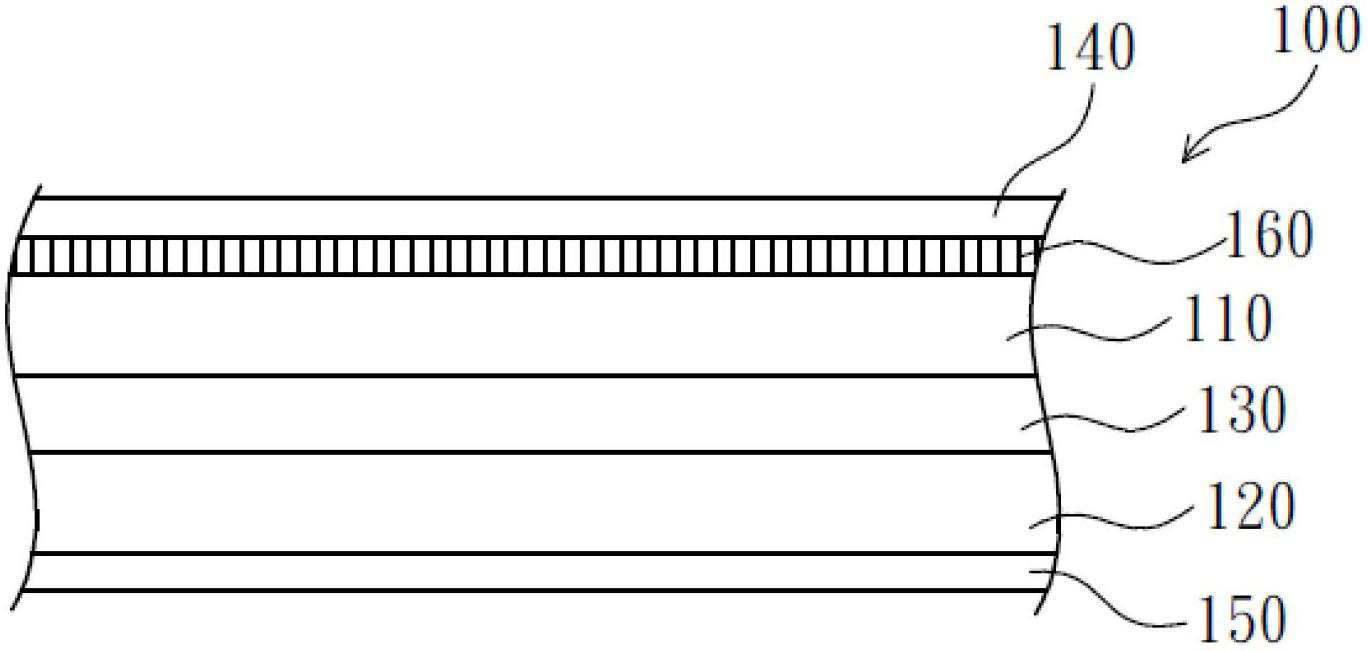

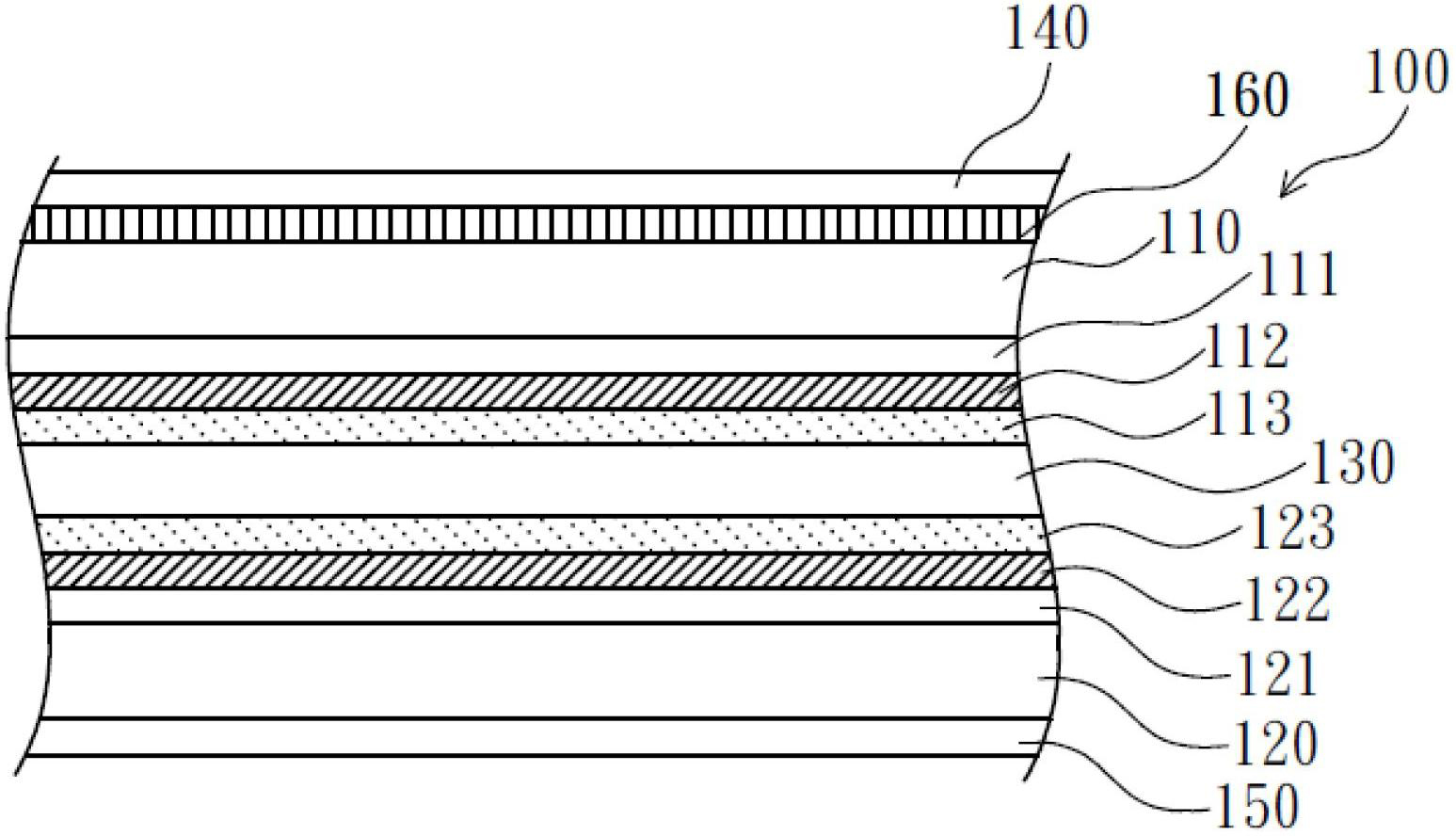

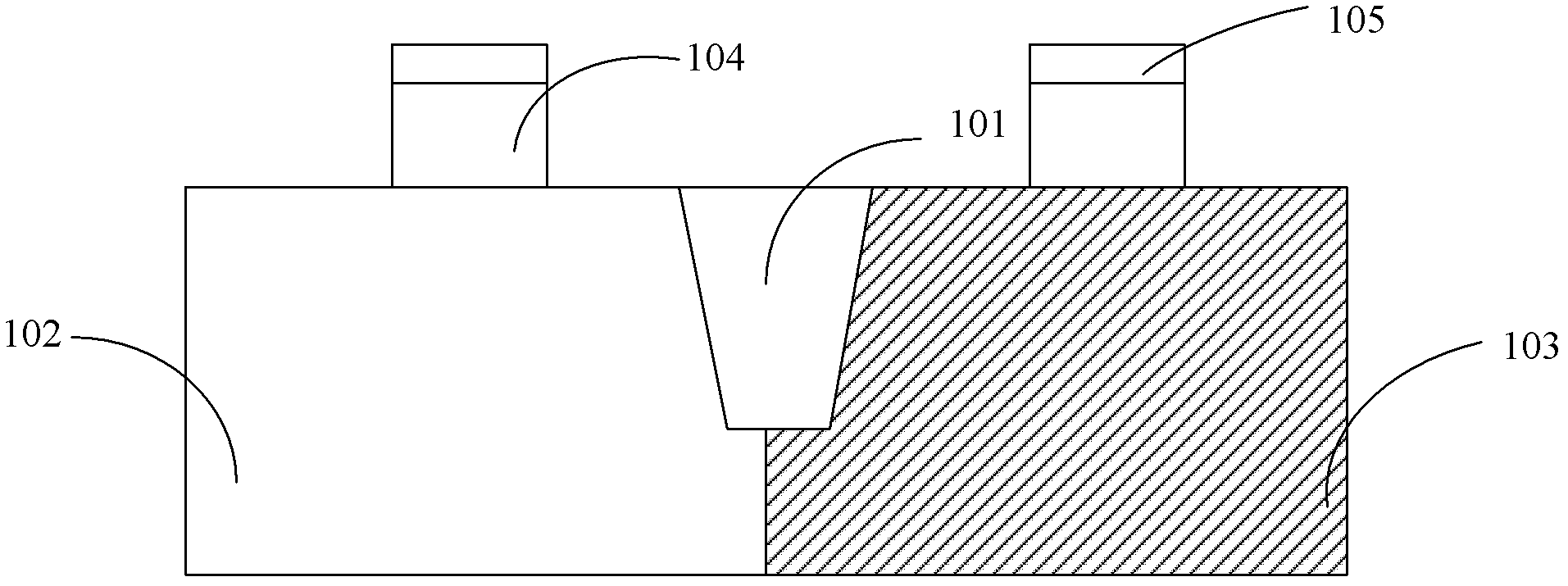

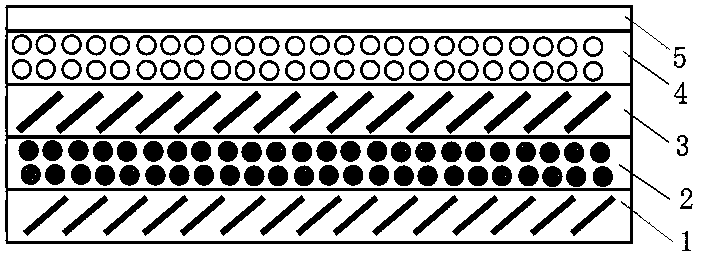

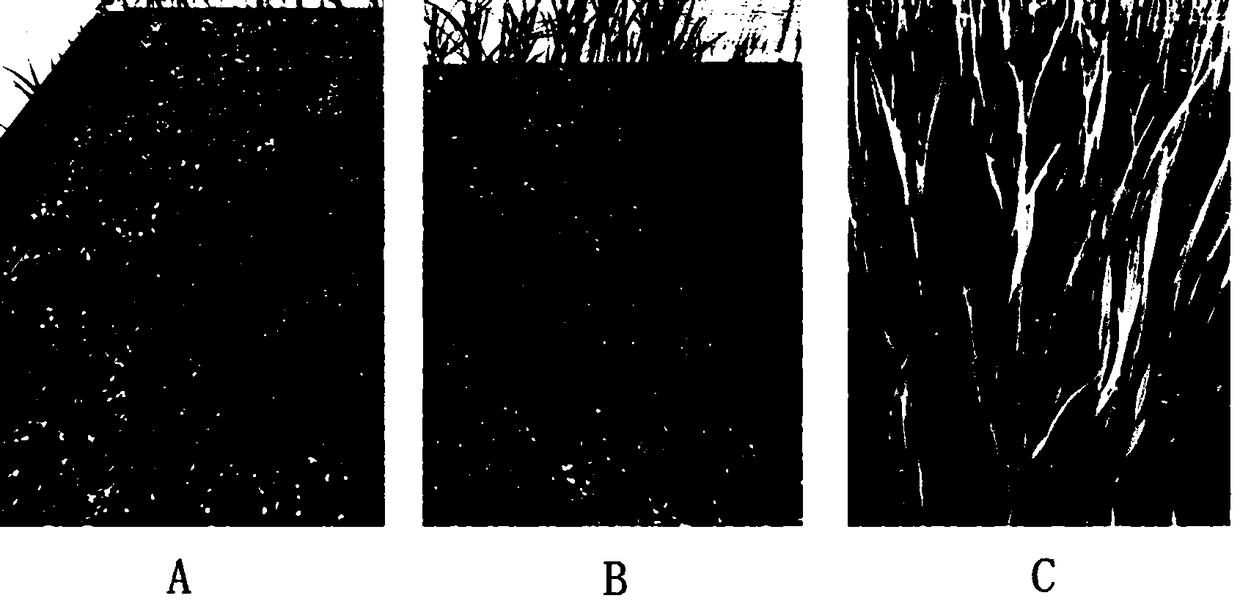

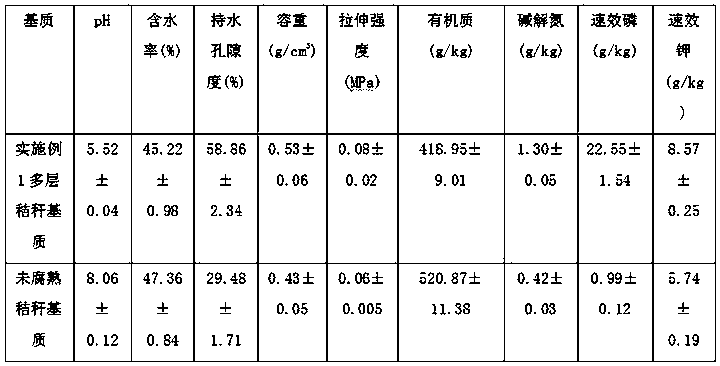

Multilayer straw substrate for rice hole tray dry nursery seedling and preparation method and application thereof

ActiveCN109362533AReduce crosslinkingGuaranteed PenetrationGrowth substratesCulture mediaFertilizerNutrient

The invention discloses a multilayer straw substrate for rice hole tray dry nursery seedling. The multilayer straw substrate comprises an expanded long stalk fiber layer, an expanded short stalk fiberlayer, a decomposed long stalk fiber layer, a decomposed short stalk fiber layer and a substrate layer; for the multilayer straw substrate, crop straw fiber obtained after rubbing and crushing are conducted is mixed with dung water for fermentation, decomposed straw fiber is obtained, by means of the extrusion expansion process, cellulose in long fiber straw is relieved, the cross-linking property between fiber and fiber is weakened, it is guaranteed that nutrient elements are reserved to the maximum extent and fully absorbed by rice seedlings, it is also guaranteed that the rice seedling rate is high, and additional fertilizer is not needed in the seedling raising stage; the root vigor is high, seedling emergence is neat, the cost is low, the dosage of the expensive substrate such as grass carbon is greatly reduced, the straw is recycled, and the phenomenon that due to misuse, the environment is affected is avoided.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

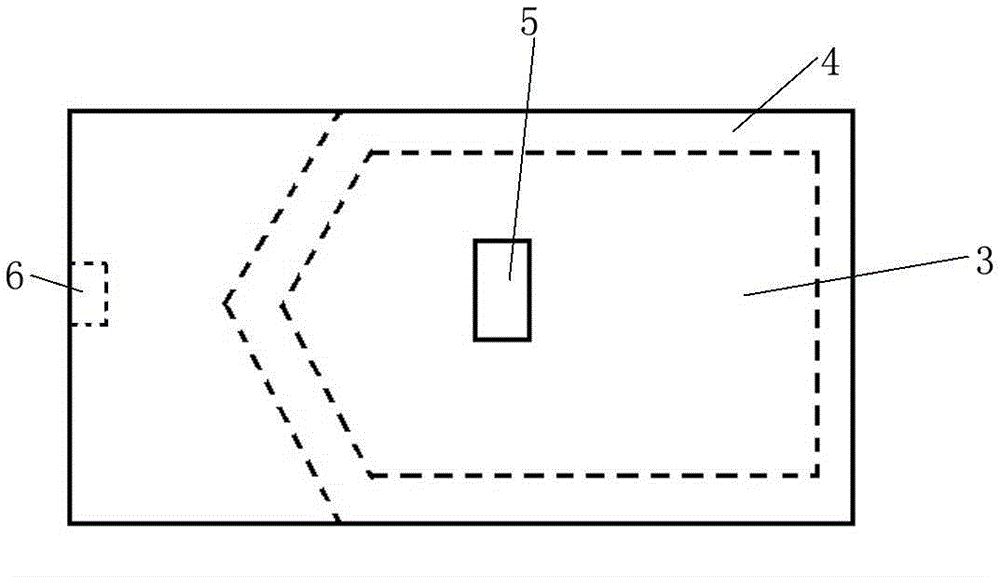

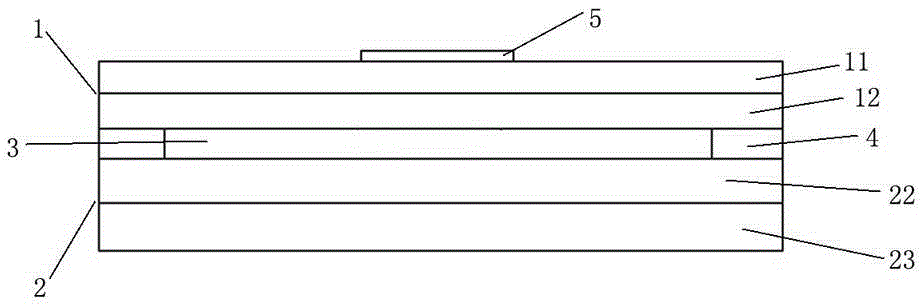

Artery blood vessel imaging device and blood vessel imaging instrument

PendingCN107788949AAccurate resolution of thicknessStrong absorption capacityDiagnostics using lightSensorsMedical equipmentBlood vessel spasm

The invention provides an artery blood vessel imaging device and a blood vessel imaging instrument, relating to the technical field of medical equipment. The artery blood vessel imaging device comprises a base, a support, a machine head and a display device used for imaging. One end of the support is fixedly connected with the base and the other end of the support is fixedly connected with the machine head. The machine head is equipped with a camera and a main light source. An auxiliary light source and an observation area are arranged on the base. The observation area is located above the auxiliary light source. The main light source and the auxiliary light source are infrared LED lamps with wavelengths being 850 nm. The camera and the main light source face directly the observation area.When a to-be-observed part of a patient is disposed in the observation area, the display device can display distribution positions of artery blood vessels of the to-be-observed part. Technical problems in the prior art are resolved so that the blood vessel imaging device can display thicknesses, shapes and layouts of artery blood vessels in deep layers.

Owner:青岛浦利医疗技术有限公司

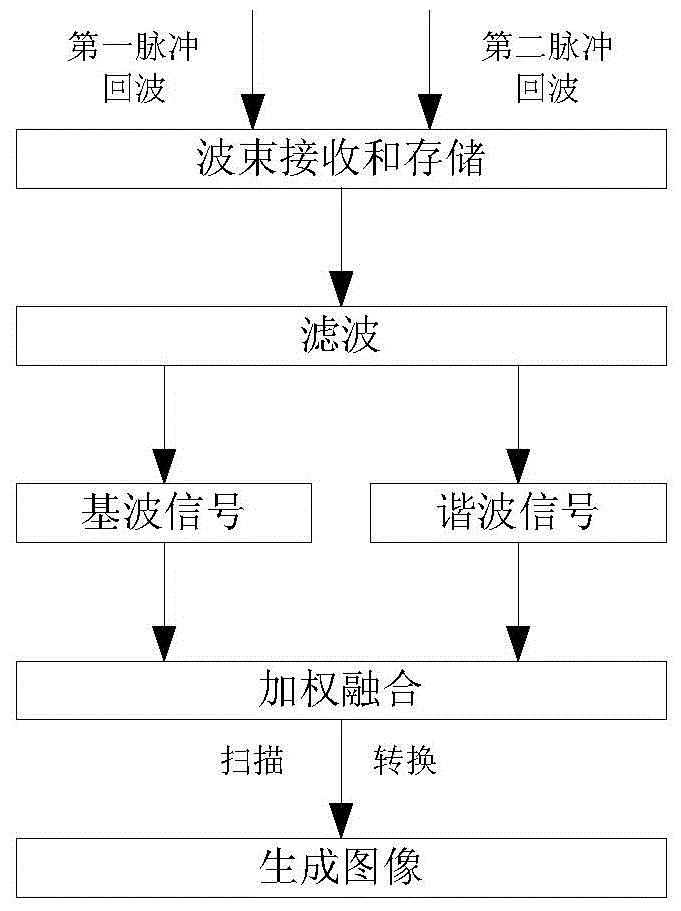

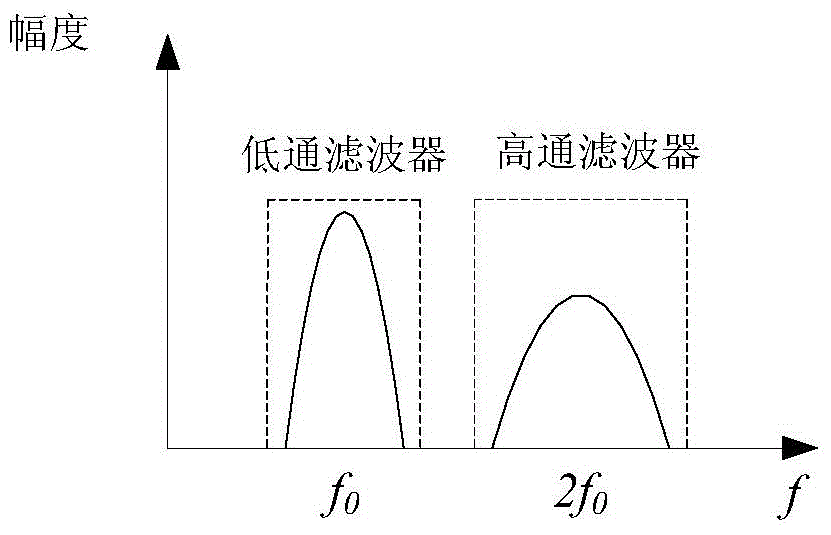

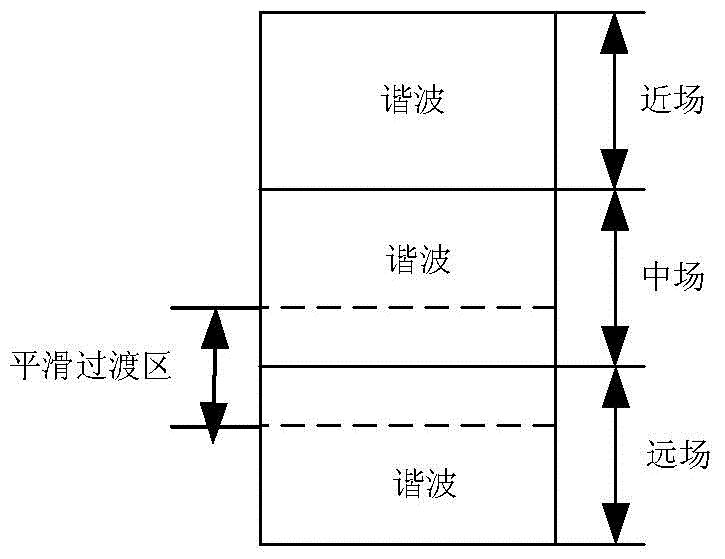

Ultrasonic imaging system and ultrasonic imaging method

InactiveCN105982695AGuaranteed PenetrationHigh resolutionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationImage resolution

The present invention provides an ultrasonic imaging system and method based on fundamental wave fusion harmonic imaging. After receiving and storing beams and matching filtering, extracting envelope signals from fundamental wave signals and harmonic signals and then weighting fusion. To make up for the weak far-field penetration of harmonics, combined with the advantages of good resolution of harmonic signals and strong penetration of fundamental signals, the far-field fundamental signal is fused with near-field and mid-field harmonic signals, thereby improving Image Quality. At the same time, in the process of signal fusion, in order to prevent the boundaries between the mid-field and far-field images to be clear, a smooth transition between the harmonic signal and the fundamental wave signal is used. While improving the resolution of the near field, it can ensure the penetration of the far field.

Owner:CHISON MEDICAL TECH CO LTD

Paper-plastic packing bag for medical sterilization

InactiveCN105346820AGuaranteed PenetrationGuarantee analysisSynthetic resin layered productsBagsWater basedAir knife

The invention discloses a paper-plastic packing bag for medical sterilization. The paper-plastic packing bag for medical sterilization is characterized by comprising a surface layer (1) and a base layer (2), wherein the surface layer (1) is connected with the base layer (2) to form a closed cavity (3) for placing contents; the surface layer is formed by coating water-based EVA dispersion emulsion on a piece of dialyzing paper by using an air knife; the base layer is made from a polyethylene and polyester composite film. The paper-plastic packing bag for medical sterilization, disclosed by the invention, can be used for guaranteeing penetration of sterilization factors during sterilization and disintegration of the sterilization factors after the sterilization is ended and is also used for guaranteeing the heat sealing strength; enough heat sealing strength can guarantee no bag explosion during sterilization, satisfy the bacteria resistance of instruments during storage within the guarantee period and further guarantee cleanness and no dust when the pack of an instrument in a medical environment is opened; therefore the requirement of clean removal can be satisfied, medical instrument products are prevented from secondary pollution, and safety is guaranteed.

Owner:江门市新时代外用制剂有限公司

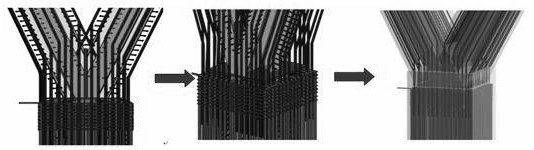

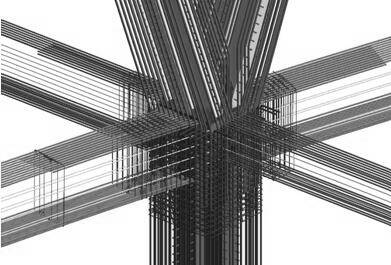

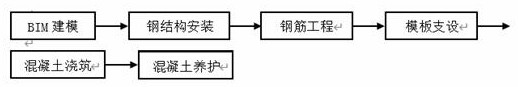

Cross construction method for complex V-shaped stiff columns and irregular ring beams of large stadium

ActiveCN112627434AImprove ultimate tensile strengthHydration goes wellStrutsGirdersArchitectural engineeringRebar

The invention relates to the field of construction of large public stadiums, and particularly relates to a cross construction method for complex V-shaped stiff columns and irregular ring beams of a large stadium. The method comprises the steps of 1, BIM modeling; 2, steel structure hoisting; 3, steel bar binding engineering; 4, formwork erecting; 5, concrete pouring; and 6, concrete curing. According to the principle of the construction method, due to the fact that adjacent V-shaped columns have a corner of a certain angle, bottom projections of the V-shaped columns are staggered and overlapped. According to the method, coordinate points are extracted through the BIM technology, on-site corner point positioning is conducted through a total station, and then V-shaped column bottom edge lines are popped up according to positioning points for construction. The construction method for complex cross of the V-shaped super-complex stiff columns and the irregular ring beams of the stadium is achieved in a focused mode, flexibility is achieved, and the concept of sustainable development is met.

Owner:SHANGHAI BAOYE GRP CORP

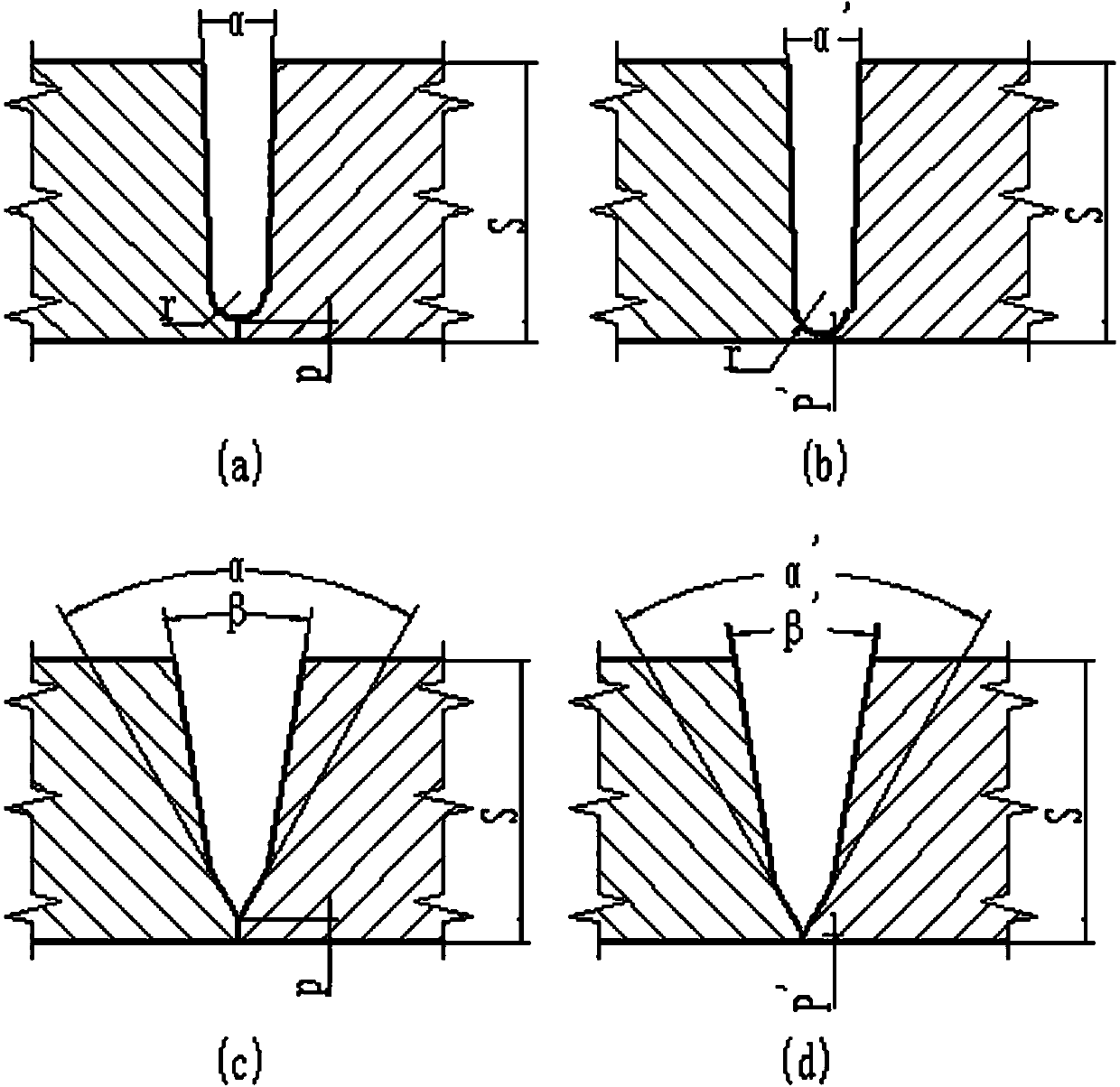

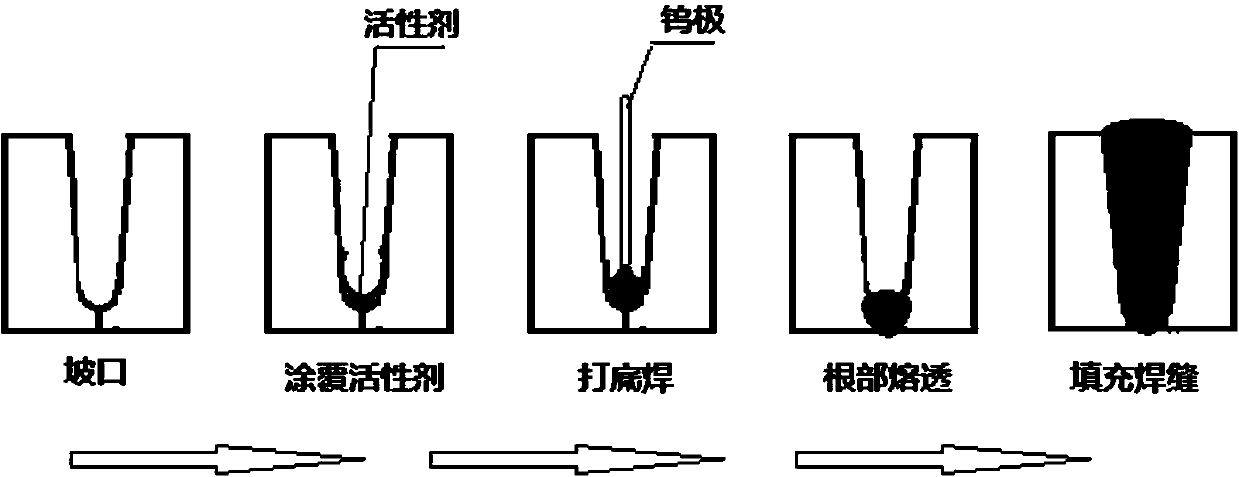

Method for improving welding efficiency of narrow-gap argon tungsten-arc welding

InactiveCN104043894AReduced processing performanceReduce residual materialArc welding apparatusWorkpiece edge portionsWeld seamMelt depth

The invention discloses a method for improving the welding efficiency of narrow-gap argon tungsten-arc welding. The method includes the steps of (1) machining a narrow-gap notch with a truncated edge 6 mm to 12 mm in thickness on base metal, (2) coating the root of the notch with active welding flux, (3) carrying out notch root welding with the A-TIG welding technology, and (4) filling the narrow-gap notch, and completing narrow-gap welding. By means of the method, due to the adoption of the design of the narrow-gap notch with the truncated edge 6 mm to 12 mm in thickness, the processing amount and waste materials of the notch are reduced, the base metal is saved, the filling amount of welded joint metal is reduced, and a welding wire is saved; first welding on the root is carried out through the high fusion depth of the A-TIG technology, it is guaranteed that the root and the two sides of the notch are completely melted, and therefore the welding efficiency and the welding quality are effectively improved; notch filling and notch surface covering are carried out with the welding technology, such as the MIG / MAG, with the high efficiency and the slightly-poor quality, narrow-gap combination welding is achieved, and the method can be applied to the condition with the high requirement for the welding efficiency.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Liquid crystal display panel and display device applied by liquid crystal display panel

InactiveCN102707519AGuaranteed PenetrationImprove color castNon-linear opticsLiquid-crystal displayPhase difference

The invention provides a liquid crystal display panel and a display device applied by the liquid crystal display panel. The liquid crystal display panel comprises a first substrate, a second substrate, a liquid crystal layer and a 1 / 2 wavelength pattern phase difference slice, wherein the second substrate comprises a second electrode, a first pixel region and a second pixel region; in the first pixel region, a trunk part and branch parts of the second electrode are provided with first preset angles, in the second pixel region, the trunk part and the branch parts of the second electrode are provided with second preset angles, and the first preset angles and the second preset angles are different; and the 1 / 2 wavelength pattern phase difference slice is bonded on the outer surface of the first substrate or the second substrate. The problems of color offset and penetration rate reduction are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

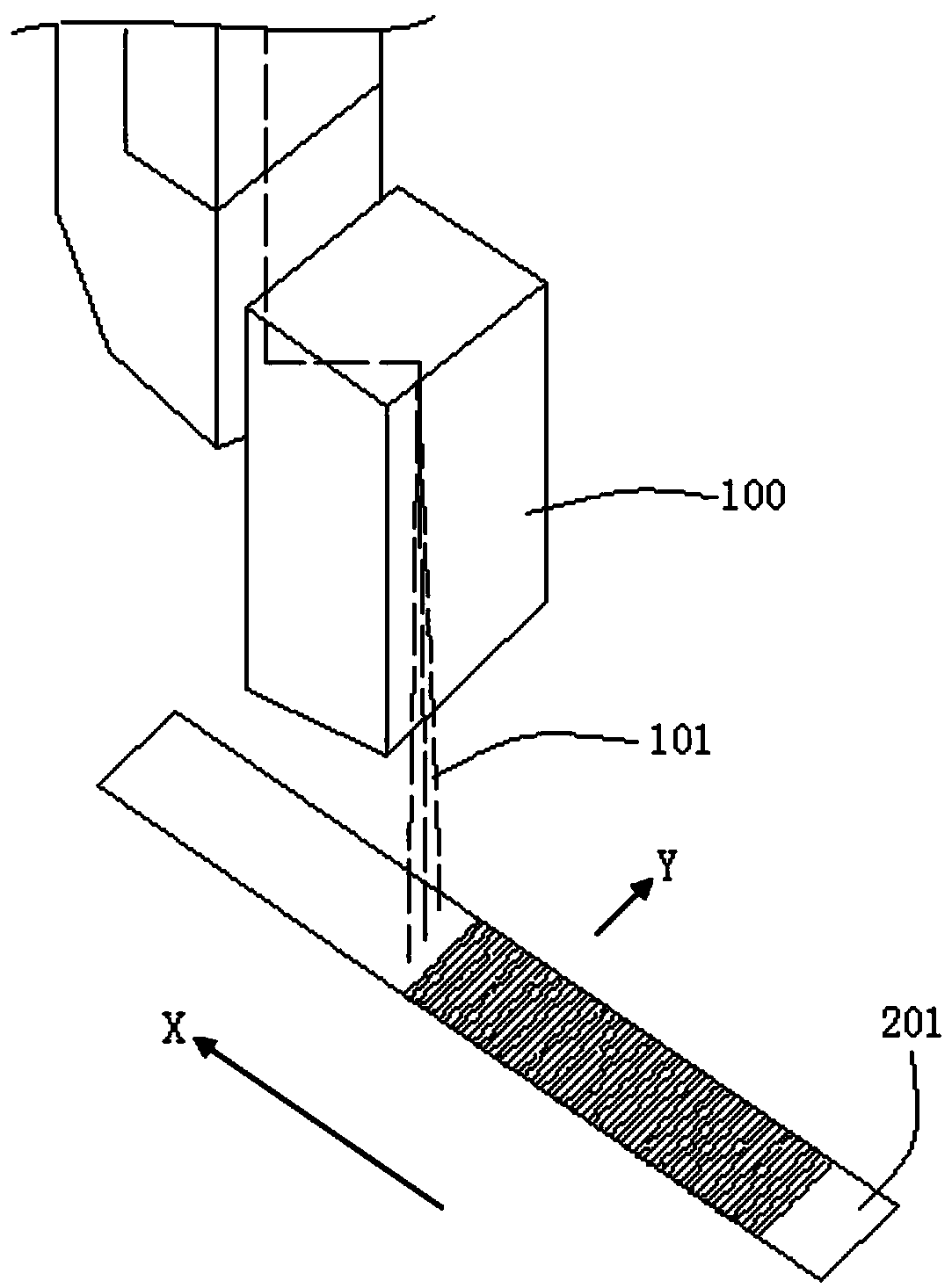

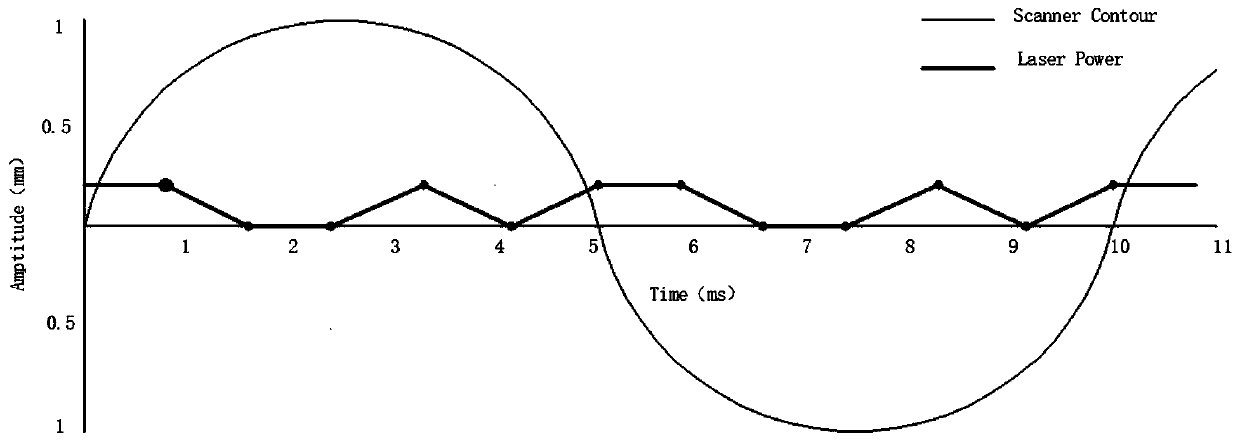

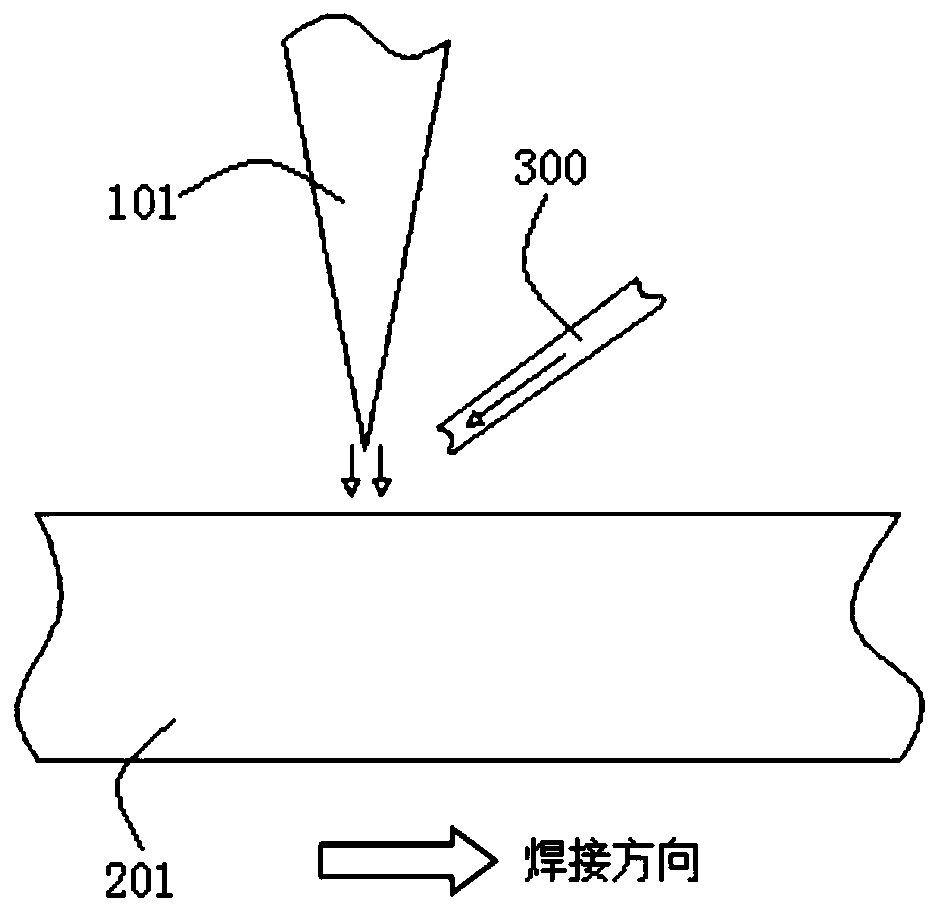

Aluminum alloy laser welding method

PendingCN109702342AFast welding speedSolve problemsWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingUltimate tensile strength

The invention relates to an aluminum alloy laser welding method. A laser spot performs swing movement in a welding seam width direction at a set frequency while a laser welding head runs in a length direction of a welding seam, and laser deep penetration welding is performed on an aluminum alloy base material, wherein a laser processing power at the middle position of the welding seam is larger than a laser processing power at the edge position of the welding seam. The aluminum alloy laser welding method adopts a laser deep penetration welding technology, has the advantages of large energy density, small welding heat input, high welding speed and the like and can well solve the problems and the defects existing in the aluminum alloy welding process in the prior art. For the aluminum alloylaser welding method, by being combined with the deflection movement of a laser beam, adopting different laser processing powers in a width direction of the welding seam and adopting a relatively large power at the middle position of the welding seam for processing, the energy is concentrated so as to ensure the weld penetration depth and the strength of the welding seam; and by adopting a relatively small power at the edge position of the welding seam for processing, obvious edge biting and ablation marks can be ensured not to occur on the edge of the welding seam, and good welding seam effect is achieved.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

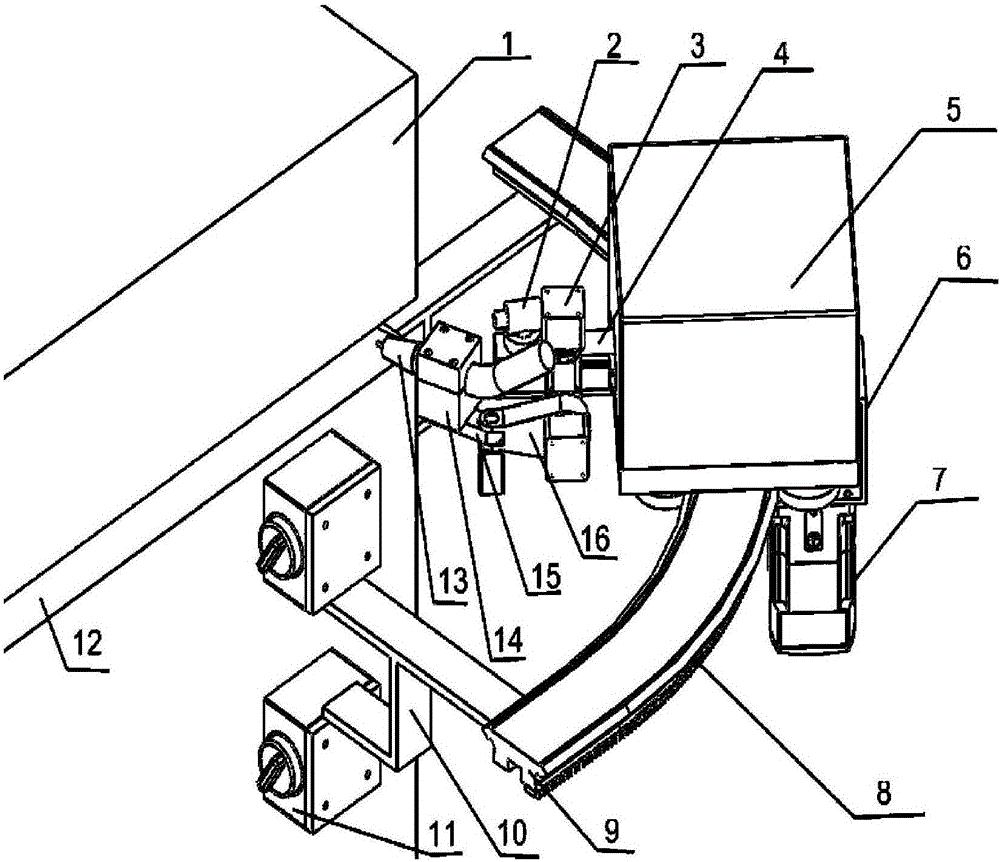

Full-automatic welding robot

InactiveCN106271287AGuaranteed PenetrationGuaranteed forming qualityWelding/cutting auxillary devicesAuxillary welding devicesDegrees of freedomDigital control

The invention belongs to the technical field of robots and provides a full-automatic welding robot. The full-automatic welding robot comprises a track, and a mounting mechanism is arranged on the left side of the track. A sliding block is sliably connected to the track. A servo motor is arranged on the lower portion of the sliding block. A control box is arranged on the upper portion of the sliding block. A digital control system is arranged in the control box. An executing mechanism is arranged on the left side of the control box and provided with a charge coupled device (CCD). A welding gun clamp is arranged at the left end of the executing mechanism. According to the full-automatic welding robot, two sets of welding robot moving mechanisms carry out welding at the opposite positions of the box-type steel structure section in the same rotation direction, symmetry welding is achieved, and welding stress is reduced. The technical requirements for welding of different positions in a V-shaped groove and a Y-shaped groove are met through four-degree-of-freedom movement of the executing mechanism, so that the penetration and molding quality are ensured, the full-automatic welding robot also adapts to the influence of the angle of a welding gun on stability of the welding process during welding in different positions, and the weld penetration and molding quality are ensured.

Owner:谢克庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com