Patents

Literature

76results about How to "Flexible adjustment ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A preparation method of carbonized adsorption particles for water body purification

InactiveCN102266752ATo overcome the poor adsorption effectPromote decompositionOther chemical processesWater/sewage treatment by sorptionInorganic materialsSawdust

The invention relates to the technical field of water treatment, in particular to a method for preparing carbonizing absorption grains used for purifying water. The method comprises the following steps: preparing organic materials, such as peat, sawdust, straw, bamboo dregs, and the like, and inorganic materials, such as diatomite, vermiculite, perlite, cement, and the like, according to proportion; and then mixing the organic materials and the inorganic materials with diatomite, kaolin, cement, slaked lime and the like; and adopting a high-temperature carbonizing process for forming the grains which are porous, high in absorption property, and different in sizes and shapes. The prepared grains are used for purifying polluted water.

Owner:NORTHEAST NORMAL UNIVERSITY

Light diffusion agent mother material used for light diffusion film, preparation method and application thereof

ActiveCN101812220AHigh light transmittanceHigh hazeFlat articlesNon-linear opticsLiquid-crystal displayMicrosphere

The invention provides a light diffusion agent mother material used for a light diffusion film, a preparation method and application thereof. A light diffusion agent is compounded from organic polymer cross linking microspheres with different refractive indexes and grain diameters, the light diffusion agent mother material is prepared from 100 weight parts of polyester resin, 60 to 100 weight parts of compounded light diffusion agents and 1 to 7 weight parts of diffusion resin through high-speed diffusion and fused extrusion grain cutting by a double-screw extruding machine. The invention also provides a high-transparency heat-resistance light diffusion film prepared by using the light diffusion agent mother materials as additives. The light diffusion layer of the light diffusion film is formed by mixing the light diffusion agent mother materials and polyester slices according to the mixture ratio of 40 to 60 weight percent of polyester slices and 40 to 60 weight percent of the light diffusion agent mother materials. The light diffusion film prepared by the invention has high light transmission rate, high mist degree, excellent heat resistance performance and excellent dimension stability, and is particularly suitable for being used as the light diffusion film in a back light module of a large-dimension liquid crystal display.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

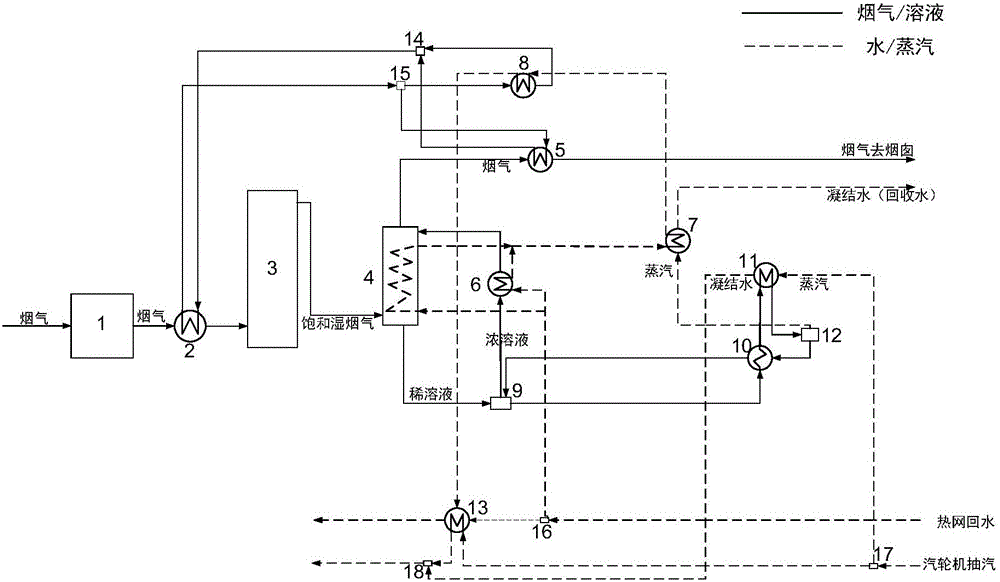

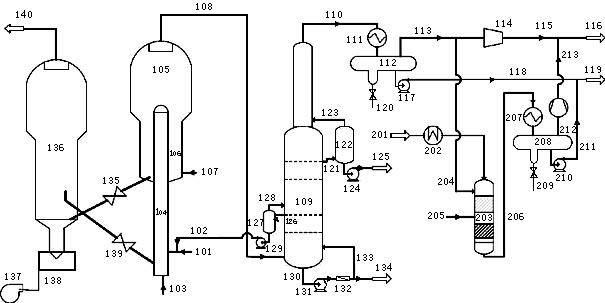

System and method for recycling flue gas waste heat and water while white fog of coal-fired power station chimney is eliminated

ActiveCN106500122AIncrease superheatReduce water vapor contentEnergy efficient heating/coolingClimate change adaptationFlue gasWater vapor

The invention provides a system and method for recycling flue gas waste heat and water while white fog of a coal-fired power station chimney is eliminated. The system comprises an absorber absorbing water vapor in flue gas through a salt solution, a solution reproducer, a corresponding heat recycling system and an integrated system for flue gas heat recycling before wet desulphurization. By means of the system and method, white fog of the wet desulphurization coal-fired power station chimney can be eliminated, especially, white fog in winter is eliminated, waste heat and water of flue gas can be recycled, the energy utilizing efficiency of a power station is improved, and consumed water of the power station is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

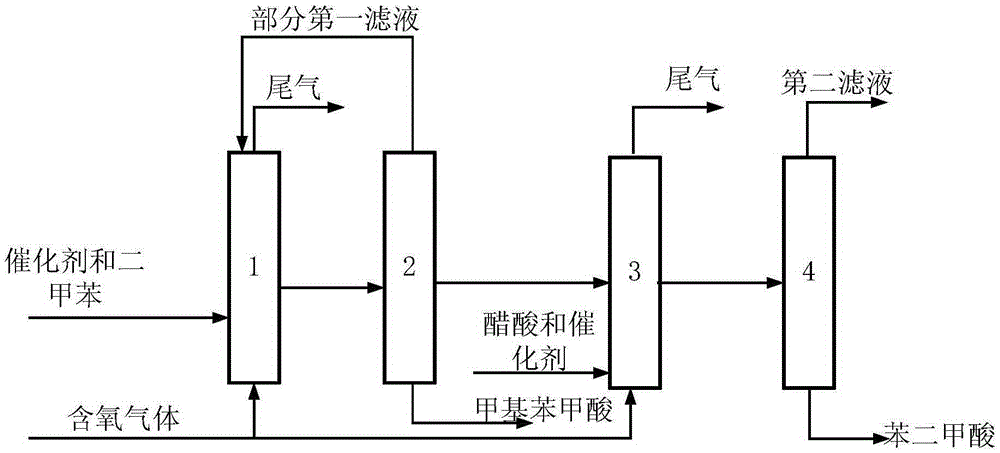

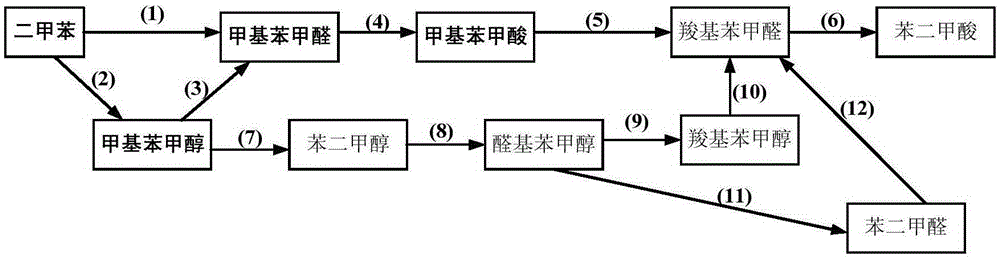

Co-production method for methyl benzoic acid and phthalic acid

ActiveCN105348067AHigh activityRealize online in-situ generationOrganic compound preparationCarboxylic compound preparationBenzoic acidAcetic acid

The invention discloses a co-production method for methyl benzoic acid and phthalic acid. The co-production method comprises the following steps: (1) continuously introducing fresh dimethylbenzene, a catalyst and oxygen-containing gas into a primary oxidation reactor for a reaction to obtain a primary oxidation reaction solution containing methyl benzoic acid and an eight-carbon oxygen-contained compound; (2) carrying out continuous cooling, crystallization and filtration on the primary oxidation reaction solution to obtain filter liquor and filter cake, circulating 1-98% of the filter liquor back the primary oxidation reactor continuously, and continuous rectifying the filter cake continuously, to obtain a low-boiling point front cut fraction, distillation raffinate and a methyl benzoic acid product separately; (3) adding the remaining filter liquor in the step (2) and the obtained front cut fraction and distillation raffinate in the step (2) into a secondary oxidation reactor continuously, and meanwhile continuously introducing a Co / Mn / Br catalyst, acetic acid and oxygen-containing gas into the secondary oxidation reactor for an oxidation reaction to obtain a secondary oxidation reaction mixture; and (4) continuously cooling, crystallizing and filtrating the secondary oxidation reaction mixture to obtain a filter liquor and a phthalic acid product. The co-production method has advantages of a simple process, a low cost, a high yield, good selectivity, good economic benefits, and environmental protection.

Owner:山东友道化学有限公司

Method for synchronously preparing hydrofluoroether and fluorine-containing olefine ether

InactiveCN105906489AShort processHigh yieldEther preparation by compound additionEther preparation by ester reactionsAlcoholDistillation

The invention discloses a method for synchronously preparing hydrofluoroether and fluorine-containing olefine ether. The method for synchronously preparing the hydrofluoroether and the fluorine-containing olefine ether comprises the following steps of making fluorine-containing olefine react with alcohol in a solvent in the presence of a catalyst, and controlling reaction pressure to be 0.2MPa to 1.5MPa through regulating the introduction amount of the fluorine-containing olefine in a reaction process, wherein the molar ratio of the alcohol to the solvent to the catalyst is 1: (0.5 to 3): (0.1 to 1.5), and a reaction temperature is 50 DEG C to 150 DEG C; when the molar ratio of the introduction amount of the fluorine-containing olefine to the alcohol is (1.0 to 1.2): 1, terminating a reaction, and carrying out distillation separation to obtain products of the hydrofluoroether and the fluorine-containing olefine ether respectively. The method for synchronously preparing the hydrofluoroether and the fluorine-containing olefine ether has the advantages of being simple in technique, high in operating flexibility, low in cost, green and environmentally-friendly.

Owner:JUHUA GROUP TECH CENT

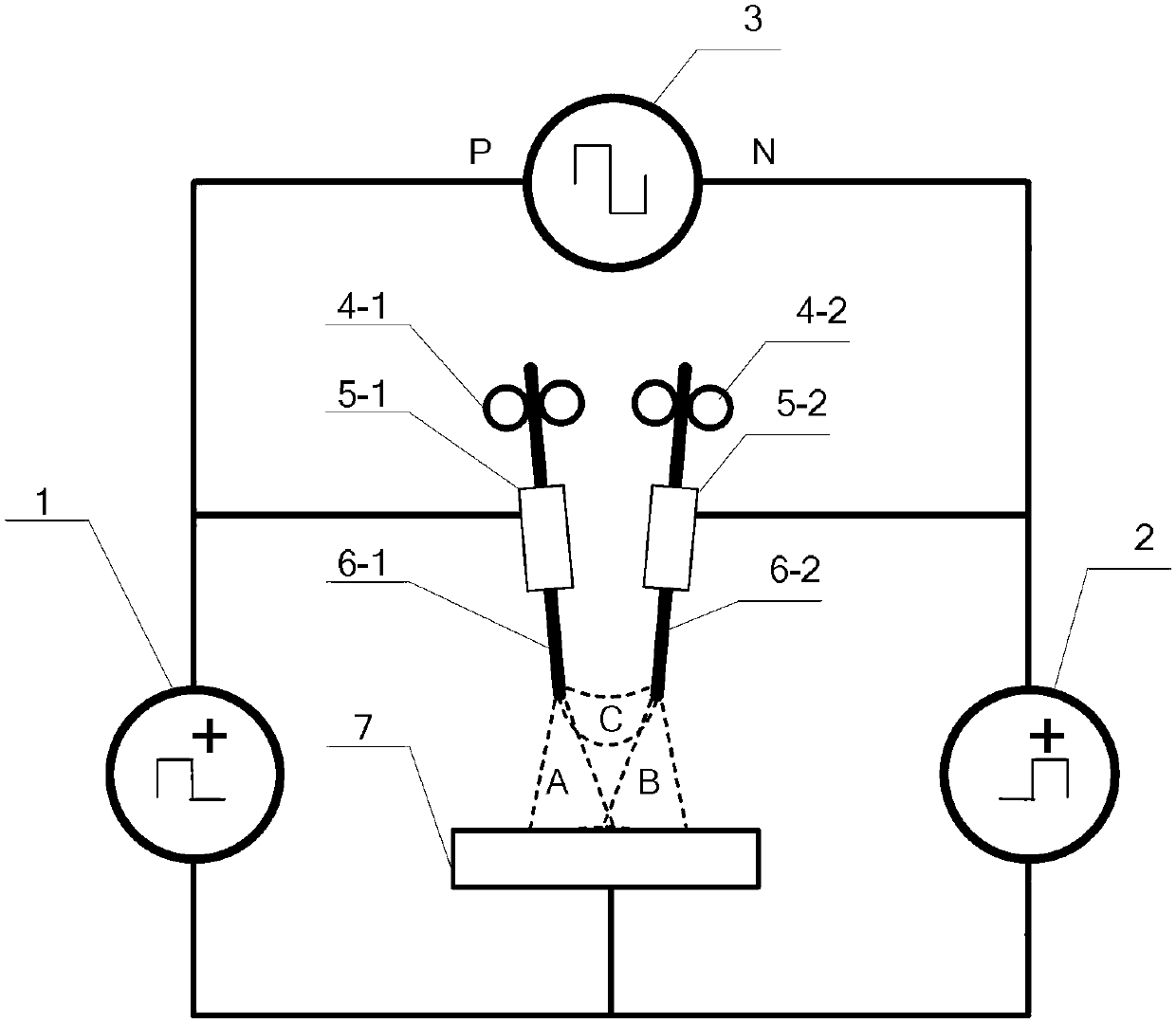

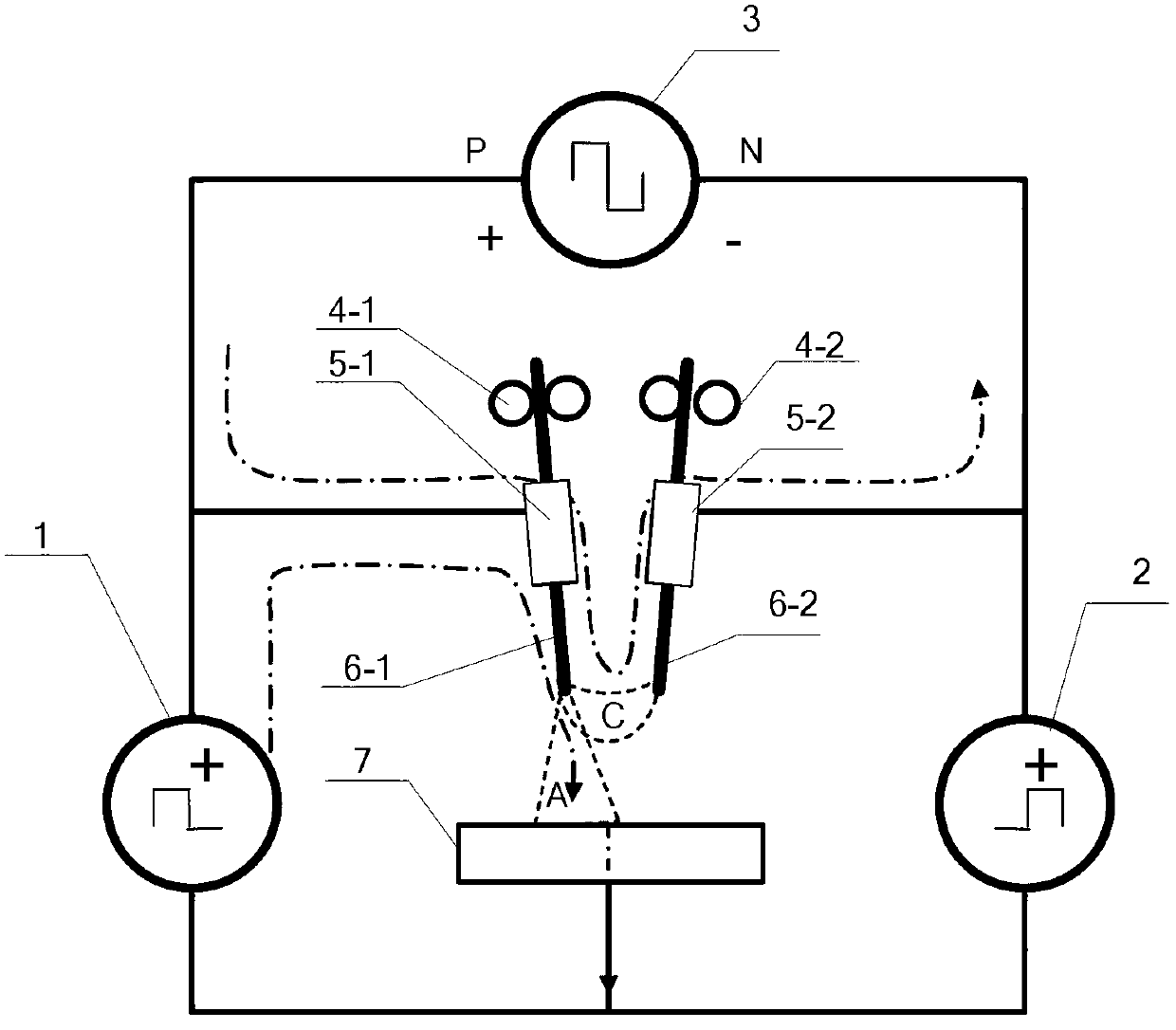

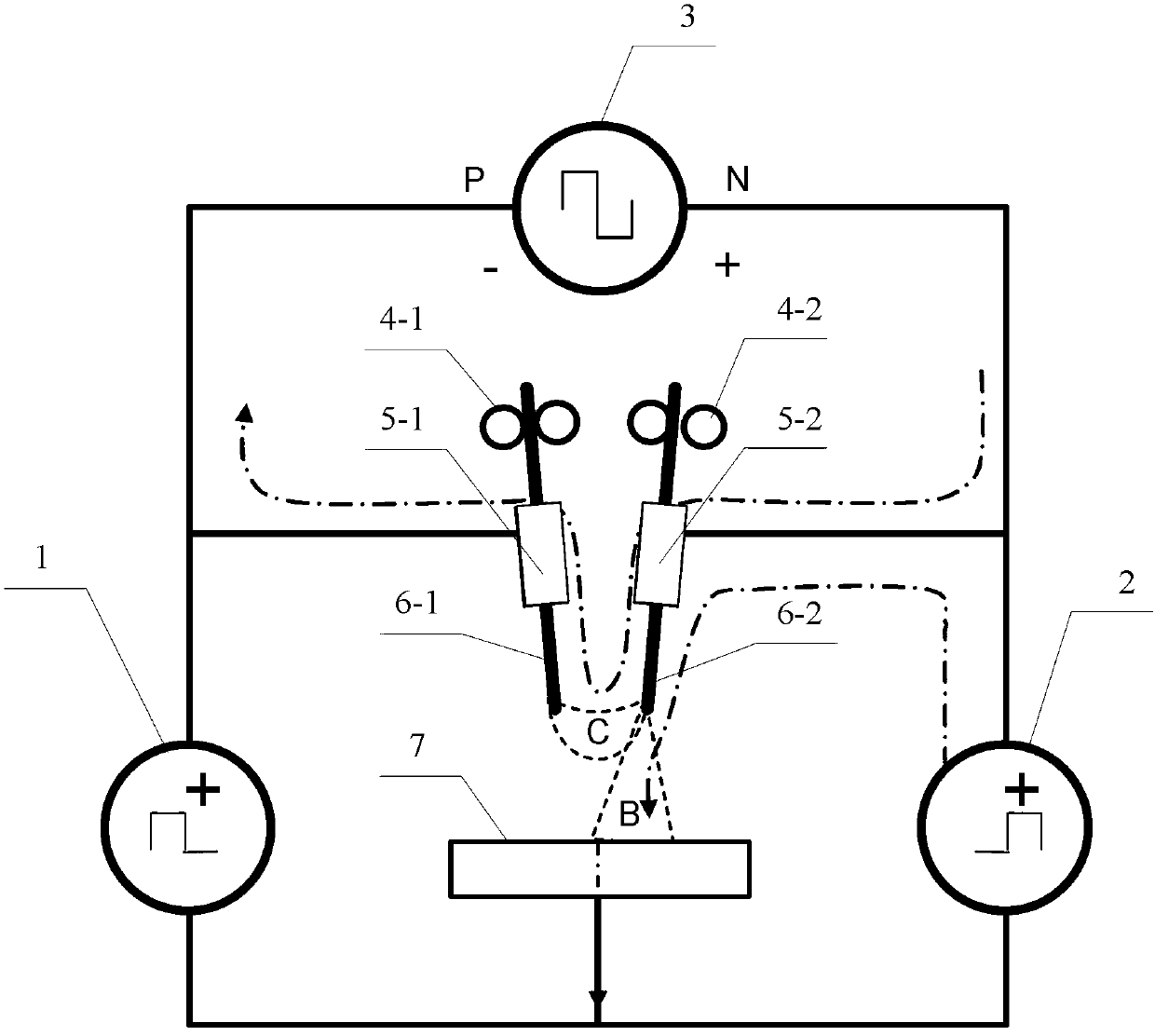

Multi-state double-wire electrical arc welding device and welding method

ActiveCN103341681AFlexible adjustment ratioGuaranteed PenetrationArc welding apparatusWelding power supplyPulse power supply

The invention provides a multi-state double-wire electrical arc welding device and welding method to solve the problem that in an existing electrical arc welding method, due to the fact that a fixed proportional relationship exists between the welding wire deposition rate and the weld heat input, contradictions exist between welding wire deposition rate increase and weld heat input reduction, and belongs to the technical field of consumable electrode electrical arc welding. The device comprises a first direct-current pulse power supply, a second direct-current pulse power supply, a welding power supply with the alterable polarity, a first wire sending mechanism, a second wire sending mechanism, a first contact tube, a second contact tube, a first welding wire and a second welding wire. In the welding process, the first direct-current pulse power supply, the first welding wire and a workpiece to be welded form a left electrical arc welding circuit, the second direct-current pulse power supply, the second welding wire and the workpiece to be welded form a right electrical arc welding circuit, and the welding power supply with the alterable polarity, the first welding wire and the second welding wire form a shunt circuit. The multi-state double-wire electrical arc welding device and welding method are used for electrical arc welding.

Owner:HARBIN INST OF TECH

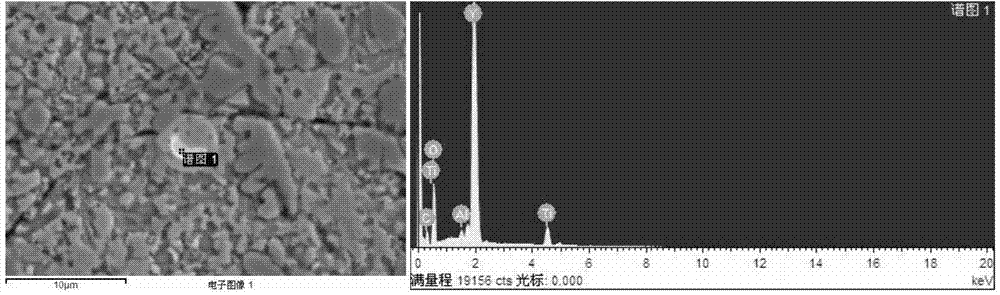

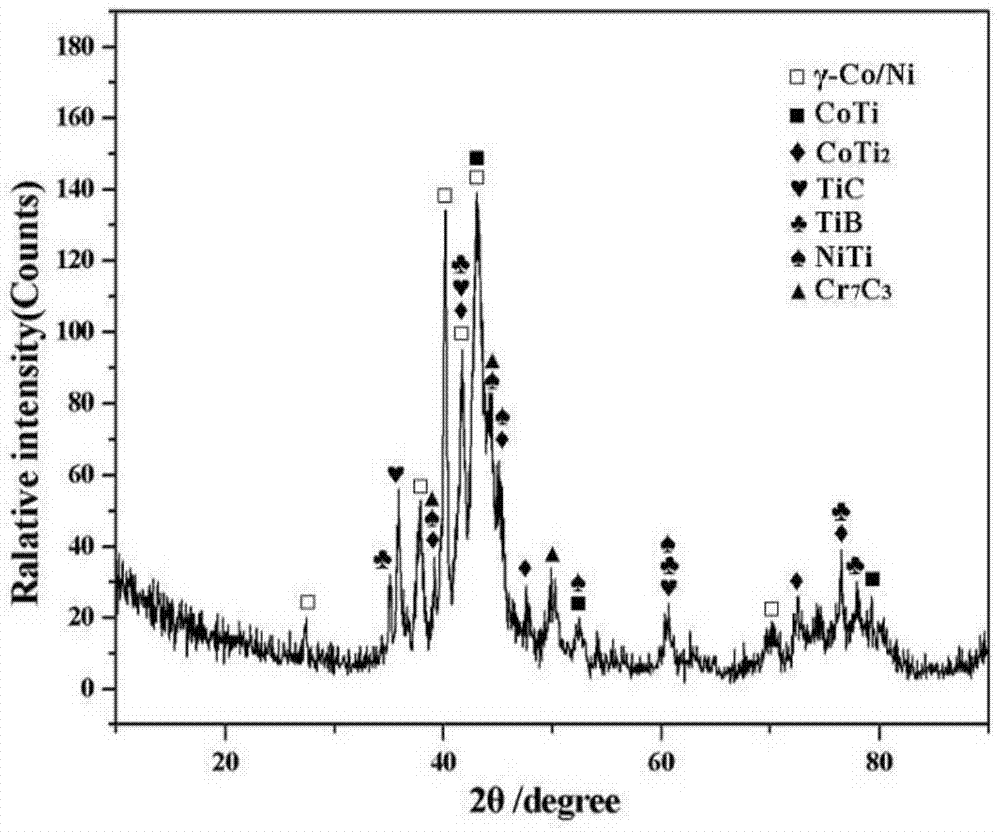

Titanium alloy laser cladding surface reinforcing method

ActiveCN103668186AImprove surface qualityImprove organizationMetallic material coating processesHardnessWear resistance

The invention relates to a titanium alloy laser cladding surface reinforcing method which comprises the following steps: mixing the following components by weight: 50-100% of Co42 cobalt-based self-fluxing alloy powder, 0-50% of B4C0, 0-50% of SiC, 0-39% of TiN, 0-1.5% of Y2O and 0-1.5% of CeO2, uniformly blending the mixture powder into paste by using a sodium silicate solution, uniformly coating the paste mixture powder on the surface of a titanium alloy, keeping the coating uniform in thickness, drying in air naturally, and performing laser cladding on the coating on the surface of the titanium alloy. By the adoption of the method provided by the invention, the microstructure of a cladding layer can be improved, and the hardness and the wear-resistance of the cladding layer can be further improved.

Owner:SHANDONG UNIV

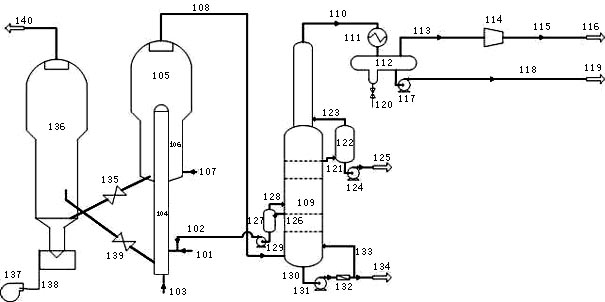

Method and system for producing gasoline and propylene by integrating heavy oil catalytic cracking with oxygen-containing compound conversion

InactiveCN101928598AQuality improvementFlexible adjustment ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystFixed bed

The invention discloses a method and a system for producing gasoline and propylene by integrating heavy oil catalytic cracking with oxygen-containing compound conversion. The oil-gas separation part of the conventional heavy oil catalytic cracking device is integrated with a fixed bed reactor group for oxygen-containing compound catalytic conversion. The propylene and the gasoline are prepared from part of rich gas components in an oil-gas separator on the top of a catalytic cracking fractionating tower in an oil refinery and dry gas, light olefin components and organic oxygen-containing compounds from other crude oil secondary processing devices serving as raw materials under the action of a special catalyst, so that raw materials for catalytic cracking processing are expanded, the propylene yield of a catalytic cracking process is improved and the yield and quality of the gasoline can be improved. The invention provides a method and a device for increasing the yield of catalytic cracking gasoline and the propylene. The yield of catalytic cracking light olefin and the ratio of olefin products can be flexibly adjusted by only integrating the heavy oil catalytic cracking device with an oxygen-containing compound device; and the method and the system have the advantages of simple process, mature technology, small investment and easy implementation.

Owner:SHANGHAI INST OF TECH

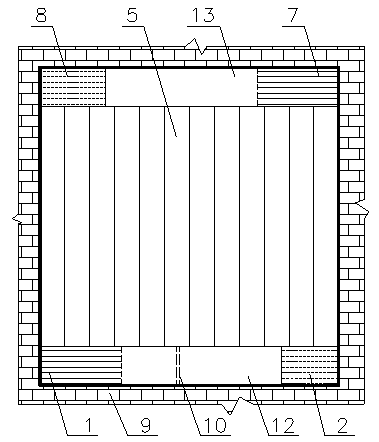

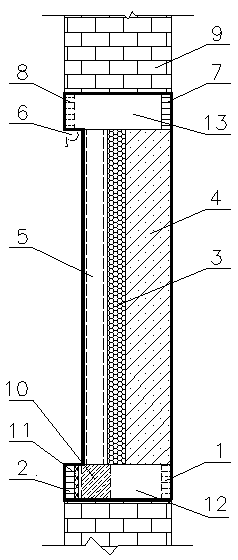

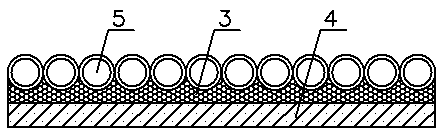

Solar vacuum tube heating and ventilation device integrated with buildings

ActiveCN103062827ARealize integrationIncrease flexibilityRoof covering using slabs/sheetsSolar heating energyBuilding integrationFresh air

The invention relates to a solar vacuum tube heating and ventilation device integrated with buildings. A plurality vacuum collector tubes are densely distributed without clearance and embedded into a building structural layer through a back heat preserving plate. Each vacuum collector tube is a trough type full glass vacuum solar collector tube, an inner cavity of the vacuum collector tube serves as an air heating passage, an air inlet passage is arranged below the inner cavity, one end of the air inlet passage is provided with a fresh air port which can be opened and closed and leads to the exterior, and the other end of the vacuum collector tube an air return port vacuum collector which can be opened and closed and leads to the interior. An air outlet passage is arranged above each vacuum collector tube, one end of the air outlet passage is provided with an air outlet which can be opened and closed and leads to the exterior, and the other end of the air outlet passage is provided with an air inlet which can be opened and closed and leads to the interior. The vacuum tube solar collecting device is integrated with buildings in appearance, the good heat preservation performance of vacuum tubes are used for heat preservation and heat insulation of buildings, and the solar vacuum tube heating and ventilation device has multiple functions of heating, ventilation, heating fresh air and the like.

Owner:京彩未来智能科技股份有限公司

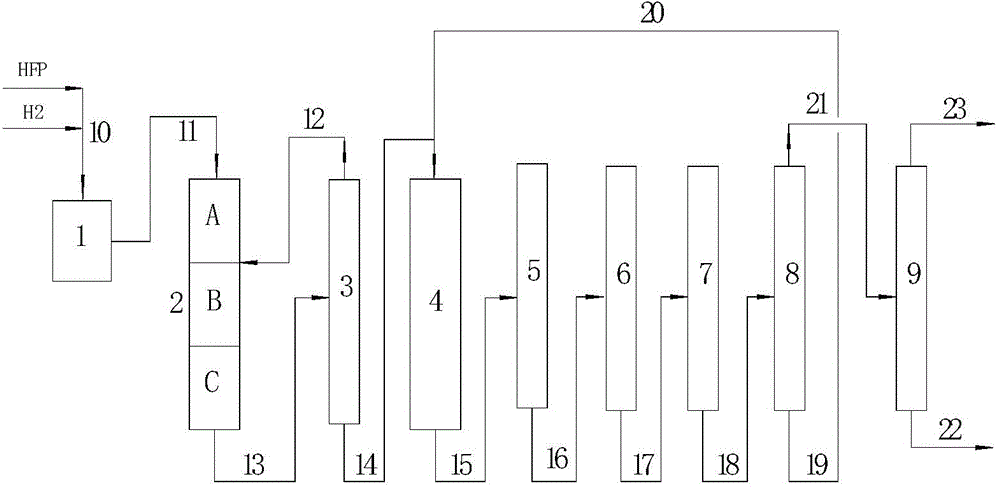

Method for co-production of 2,3,3,3-tetrafluoropropene and 1,3,3,3-tetrafluoropropene

ActiveCN104945221ASimple processImprove conversion ratePreparation by hydrogen halide split-offHalogenated hydrocarbon separation/purificationHydrogen fluorideHydrogen

The invention discloses a method for co-production of 2,3,3,3-tetrafluoropropene and 1,3,3,3-tetrafluoropropene. The method includes the following steps: the raw materials, namely hexafluoropropene and hydrogen, enter a first reactor after preheating, wherein the first reactor is divided into three sections A, B and C, and the three sections are filled with different catalysts; different reaction conditions are controlled for the reaction, so that a mixture of 1,1,1,2,3-pentafluoropropane, 1,1,1,2,3,3-hexafluoropropane and hydrogen fluoride is obtained; after separation, 1,1,1,2,3,3-hexafluoropropane returns to the lower part of the section A of the reactor, 1,1,1,2,3-pentafluoropropane and a small amount of hydrogen fluoride enter a second reactor and react under the action of a catalyst, so that a mixture of 2,3,3,3-tetrafluoropropene, 1,3,3,3-tetrafluoropropene, hydrogen fluoride and unreacted 1,1,1,2,3-pentafluoropropane is obtained; the products are washed with water and then with alkali, dried, and distilled to obtain 2,3,3,3-tetrafluoropropene and 1,3,3,3-tetrafluoropropene products. The method provided by the invention is simple in process, small in investment, low in energy consumption and high in conversion rate.

Owner:ZHEJIANG QUHUA FLUOR CHEM

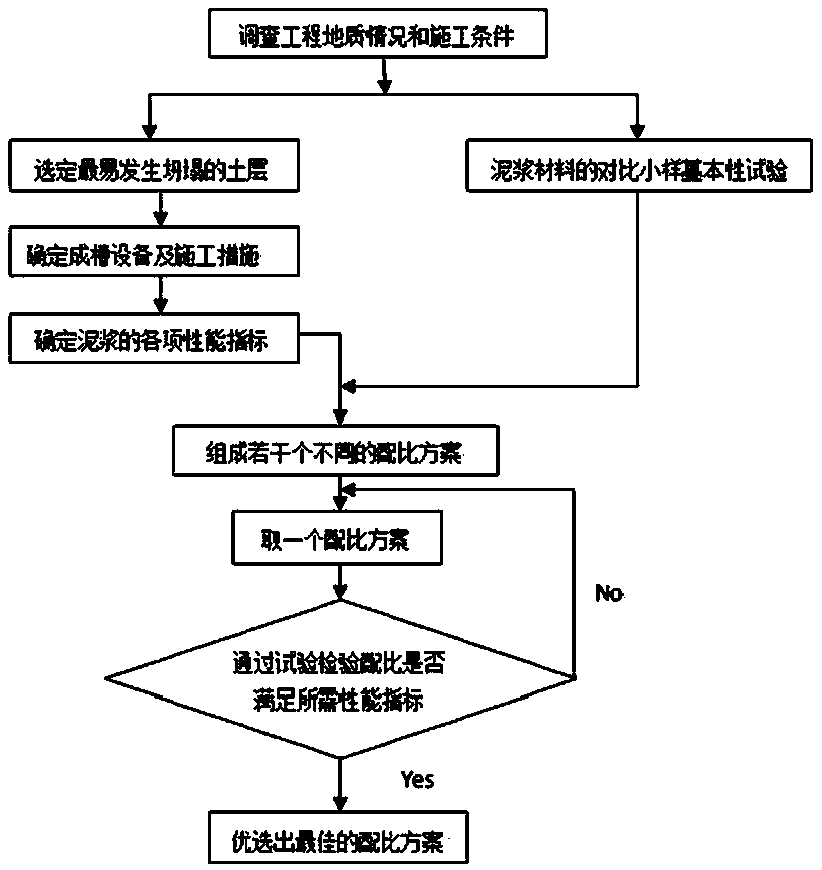

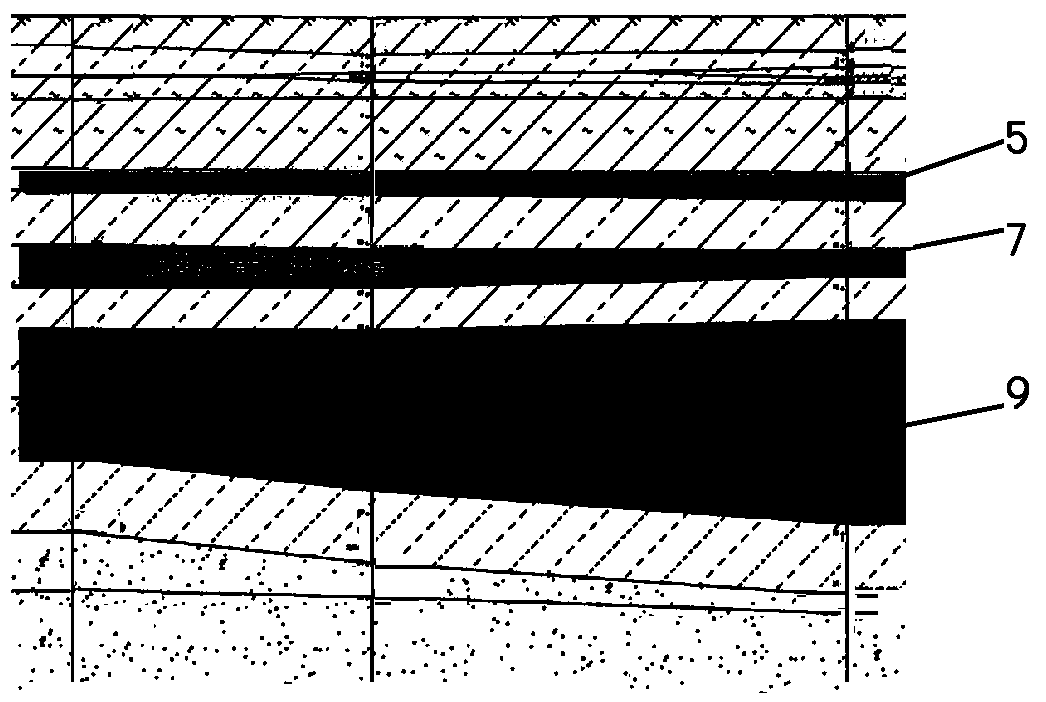

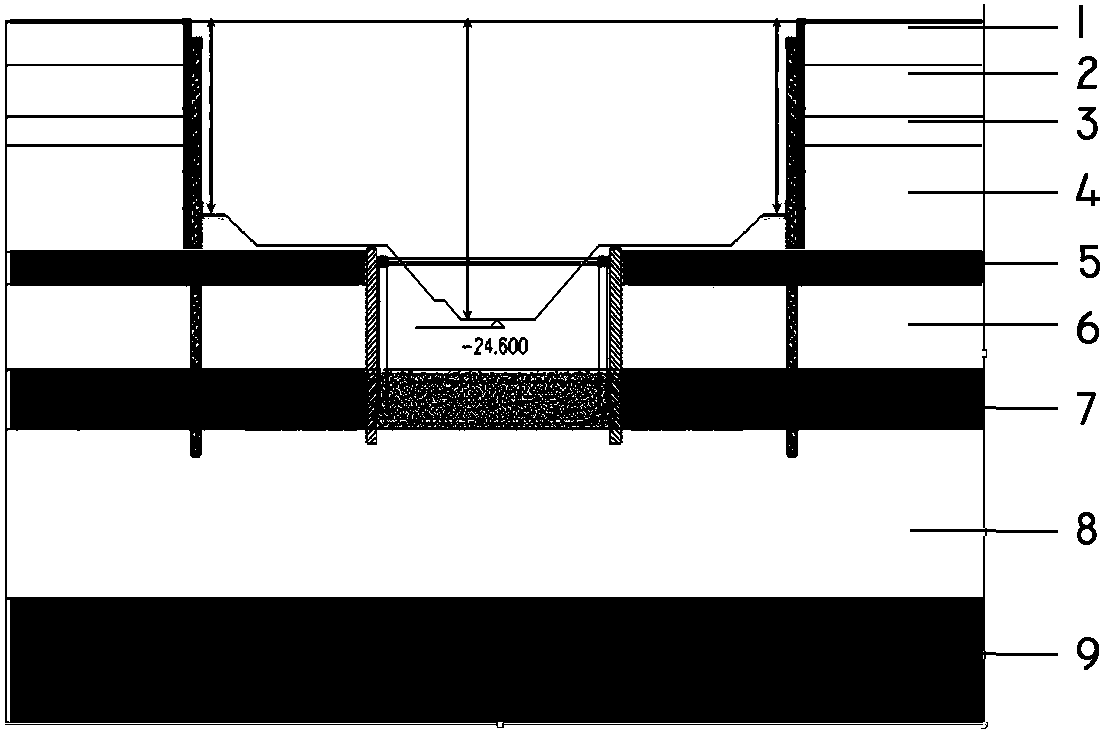

Soft-soil area underground diaphragm wall supporting slurry and method of determining slurry ratio thereof

InactiveCN109574620AGuaranteed stabilityImprove protectionExcavationsBulkheads/pilesRailway tunnelCellulose

The invention discloses a soft-soil area underground diaphragm wall supporting slurry and a method of determining slurry ratio thereof. The soft-soil area underground diaphragm wall supporting slurryis made by mixing bentonite, water and an admixture; per cubic meter, 110-120 kg of bentonite is added, 900-1000 kg of water is added, 4-5 kg of sodium carbonate is added, and 0.45-0.6 kg of sodium cellulose is added. The method herein is scientific and highly feasible. In practice, subsequent reinforcement cage tripping, concrete placing and other procedures can be finished quickly under high quality without affecting rail traffic operation; mainly, stability of an underground diaphragm wall is well guaranteed. Foundation pit deformation control and railway tunnel deformation control are bothwithin expectations. Safety can be ensured for a foundation pit and the ambient; the underground diaphragm wall can be stably and constantly in controllable and known state. The method herein help effectively solves problems of soft-soil area deep-large foundation pit engineering in construction layout, period control and protection; stability of the underground diaphragm wall is guaranteed.

Owner:BEIJING NO 3 CONSTR ENG

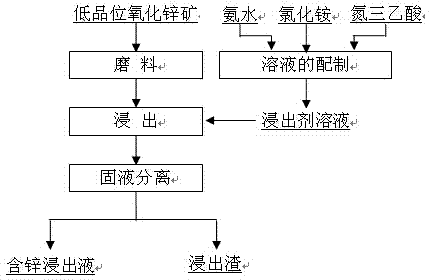

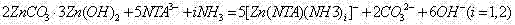

Method for leaching low-grade zinc oxide ore

InactiveCN104762473AImprove leaching effectFlexible adjustment ratioProcess efficiency improvementOxidation stateMaterials science

A method for leaching low-grade zinc oxide ore includes the steps of preparing a leaching agent solution, wherein the sum of ammonium chloride molar concentration and ammonia water molar concentration ranges from 1 mol / L to 10 mol / L, the nitrilo triacetic acid molar concentration ranges from 0.1 mol / L to 1 mol / L, and the ratio of the ammonium chloride molar concentration to the ammonia water molar concentration is between 1 to 1 and 5 to 1; secondly, conducting agitation leaching in the leaching agent solution after refining the low-grade zinc oxide ore to a screen with the 100% aperture of 50 micrometers to 100 micrometers, and conducting solid-liquid separation to obtain a zinc-contained leaching agent after the reaction is conducted for 4 hours under the ratio (mL / g), ranging from 5 to 20, of the liquid volume to the solid weight. The method has good leaching effects on various oxidation-state zinc species in the low-grade zinc oxide ore, the ratio of the total ammonia concentration to the nitrilo triacetic acid concentration can be flexibly regulated through a leaching system which is used, and the dosage of organic ligands can be reduced on the basis of ensuring high leaching rate.

Owner:CENT SOUTH UNIV

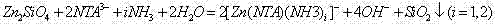

High-rigidity high-transparency polypropylene composite material

The invention discloses a high-rigidity high-transparency polypropylene composite material, and belongs to the technical field of high polymer alloy materials. The high-rigidity high-transparency polypropylene composite material is compounded by 2-4wt% of nanoscale barium sulfate master batch, 0.1-0.3wt% p-tertiary butyl hydroxyl aluminum benzoate and 0.1-0.3wt% sorbitol acetal as a nucleating agent of polypropylene. According to the high-rigidity high-transparency polypropylene composite material, the nanoscale barium sulfate master batch is added to achieve a certain compatible effect on two nucleating agents, so that the two nucleating agents are prevented from resisting against each other; and meanwhile, the effects of nucleating heterogeneously, promoting the polypropylene to quicken crystallization and refining spherocrystal effects are achieved, so that the rigidity and the transparency of a PP (polypropylene) product are further improved.

Owner:广东顺威赛特工程塑料开发有限公司

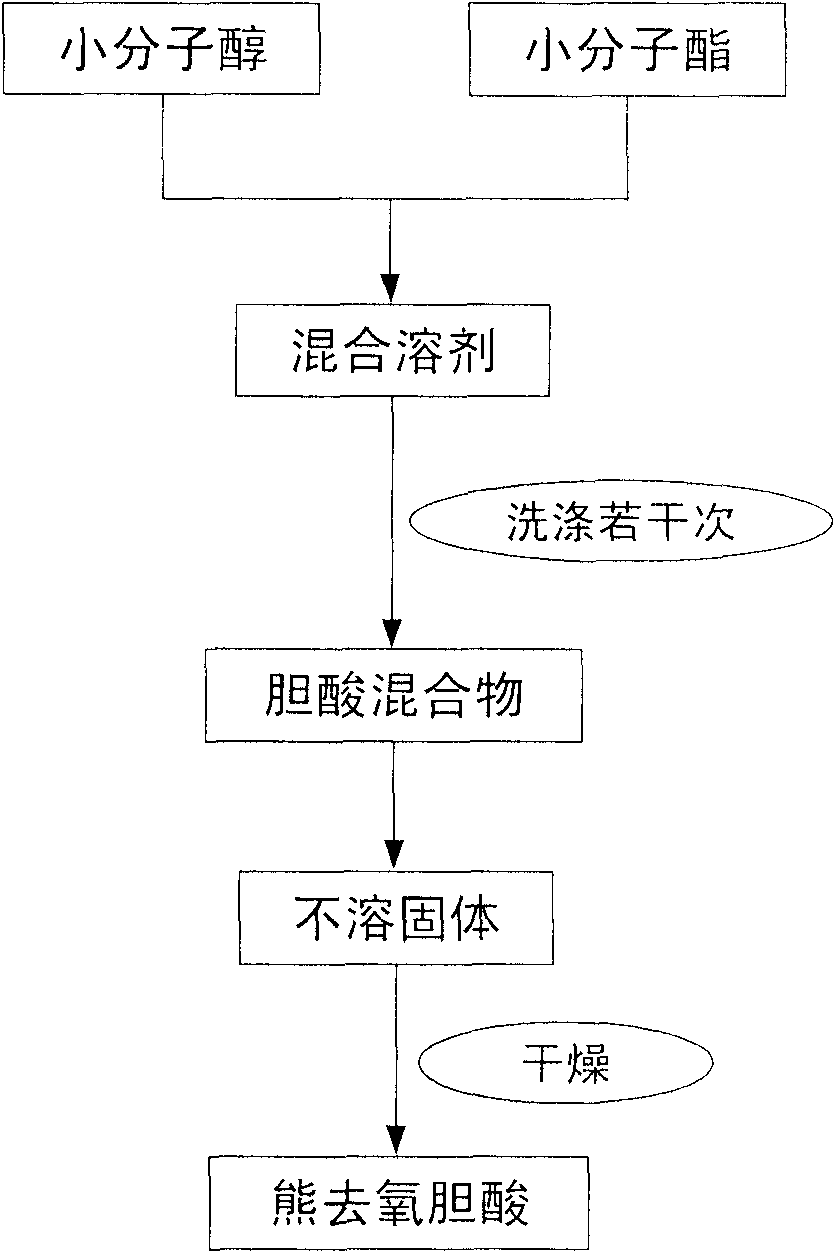

Method for purifying ursodeoxycholic acid by mixed solvent

The invention provides a method for purifying ursodeoxycholic acid by a mixed solvent, which comprises three steps of preparing the mixed solvent, washing a cholic acid mixture and drying to obtain the ursodeoxycholic acid. The method is characterized by using the mixed solvent prepared from 1-80 parts of small molecule alcohol and 99-20 parts of small molecule ester by weight. The mixed solvent can selectively dissolve impurities of chenodeoxycholic acid, and the like in the cholic acid mixture and reserve the ursodeoxycholic acid. The mixed solvent not only reserves strong dissolving capacity of alcohol on the chenodeoxycholic acid, but also reserves the characteristic of ester for selectively dissolving the chenodeoxycholic acid. Under the premise of the same production capacity, the method for purifying the ursodeoxycholic acid of the invention can obviously reduce the consumption of organic solvent, saves the energy consumption of solvent recovery, and is suitable for preparing high purity ursodeoxycholic acid.

Owner:ZHEJIANG UNIV

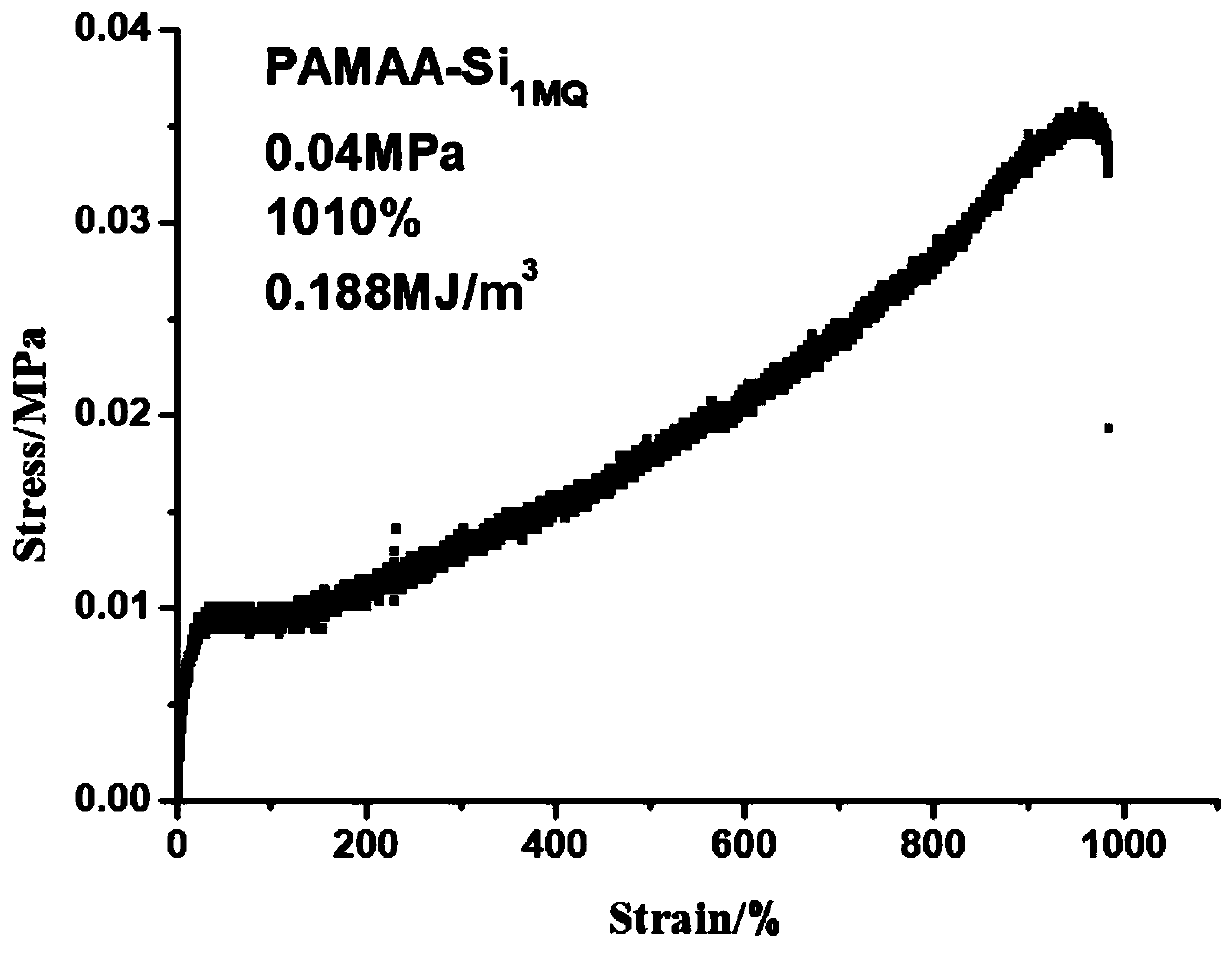

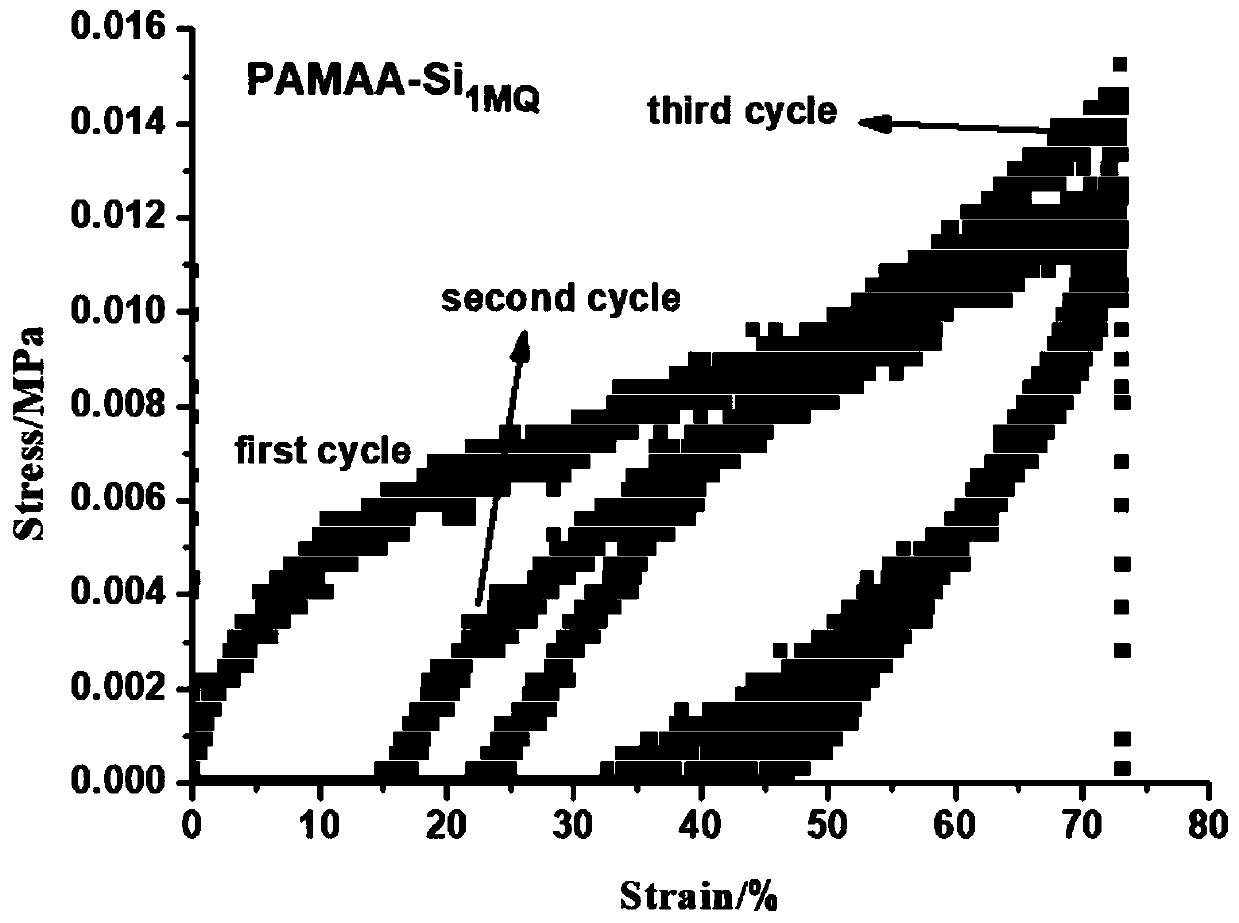

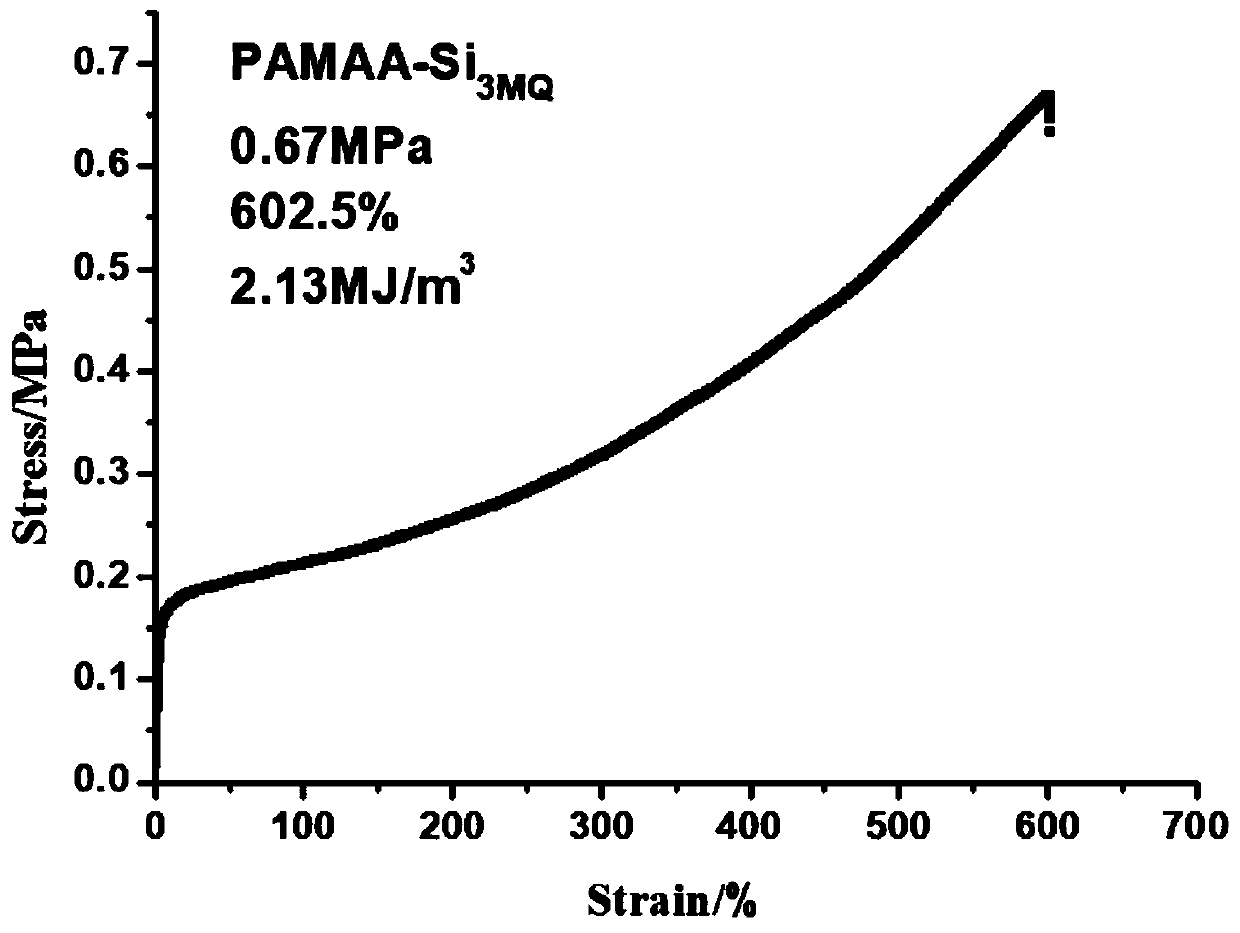

Tough anti-electrostatic double-network silicone hydrogel and preparation method thereof

ActiveCN110452395AImprove comprehensive mechanical and mechanical propertiesEasy to prepareSilicone hydrogelFree-radical addition

The invention discloses a tough anti-electrostatic double-network silicone hydrogel and a preparation method thereof. The double-network structure consists of a first macromolecule network and a second macromolecule network in mutual intersection, wherein the first macromolecule network is a cross-linking network which is formed by forming a carbon chain polymer prepared by free radicals through addition polymerization and by implementing chemical cross-linking or a hydrophobic association function; and the second macromolecule network is a cross-linking network which is formed by forming a silicon-containing polymer by a silicon-containing monomer through condensation polymerization and by implementing a hydrogen bond function. As an alkene monomer and a silicon monomer are dissolved intoa same system, one-step molding can be achieved through different polymerization mechanisms, processes such as first network drying and secondary swelling can be avoided, the preparation method is simple, the time is short, the production efficiency is high, the cost is low, the obtained double-network silicone hydrogel has excellent toughness, anti-fatigue performance, self recovery and anti-electrostatic properties and is beneficial to industrialization, and the application range of the hydrogel can be widened.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for feeding pulverized coal in power station pulverized-coal fired boiler

InactiveCN101886815AEmission reductionImprove utilization efficiencyLump/pulverulent fuel feeder/distributionThermal energyWater vapor

The invention relates to a method for feeding pulverized coal in a power station pulverized-coal fired boiler. The conventional method for feeding the pulverized coal has various drawbacks. The method comprises the following steps of: extracting 5 to 15 percent of the total smoke gas in a flue between a low temperature superheater and a coal economizer of a power station pulverized-coal fired boiler system, and taking the smoke gas as the smoke gas for feeding the pulverized coal; mixing 5 to 20 percent of water vapor with the smoke gas for feeding the pulverized coal to form mixed gas for feeding the pulverized coal; heating the mixed gas for feeding the pulverized coal to the temperature of between 800 and 1000 DEG C; feeding the pulverized coal with the density of 0.8 to 2kg / kg into a burner of the power station pulverized-coal fired boiler by using the heated mixed gas for feeding the pulverized coal; and keeping the airflow temperature of the mixed gas for feeding the pulverized coal between 800 and 1000 DEG C in the process of feeding the pulverized coal. The method has high primary air pulverized coal airflow density, can effectively reduce ignition heat of the pulverized coal airflow, saves energy by using partial waste heat of the smoke gas at the tail of a boiler, and improves thermal energy utilization efficiency.

Owner:HANGZHOU DIANZI UNIV

Clean recycling technology of air purification carbon material

InactiveCN108176415AEfficient processingReduce energy consumptionOther chemical processesCatalyst regeneration/reactivationCircular economyActivated carbon

The invention discloses a clean recycling technology of an air purification carbon material. According to the technology, as for filtered air purification activated carbon, the composition of a catalyst on the activated carbon is analyzed, an activated carbon recycling material formed by acid and a strong oxidant is adjusted according to ingredients, and normal-temperature and efficient recyclingof the activated carbon is realized in an impregnation, drying and reactivating manner. By means of the technology, regeneration of industrial and civil activated carbon can be realized, the use costis reduced, the development of circular economy is realized, environmental protection is realized and discharging is reduced.

Owner:江苏瑞丰科技实业有限公司

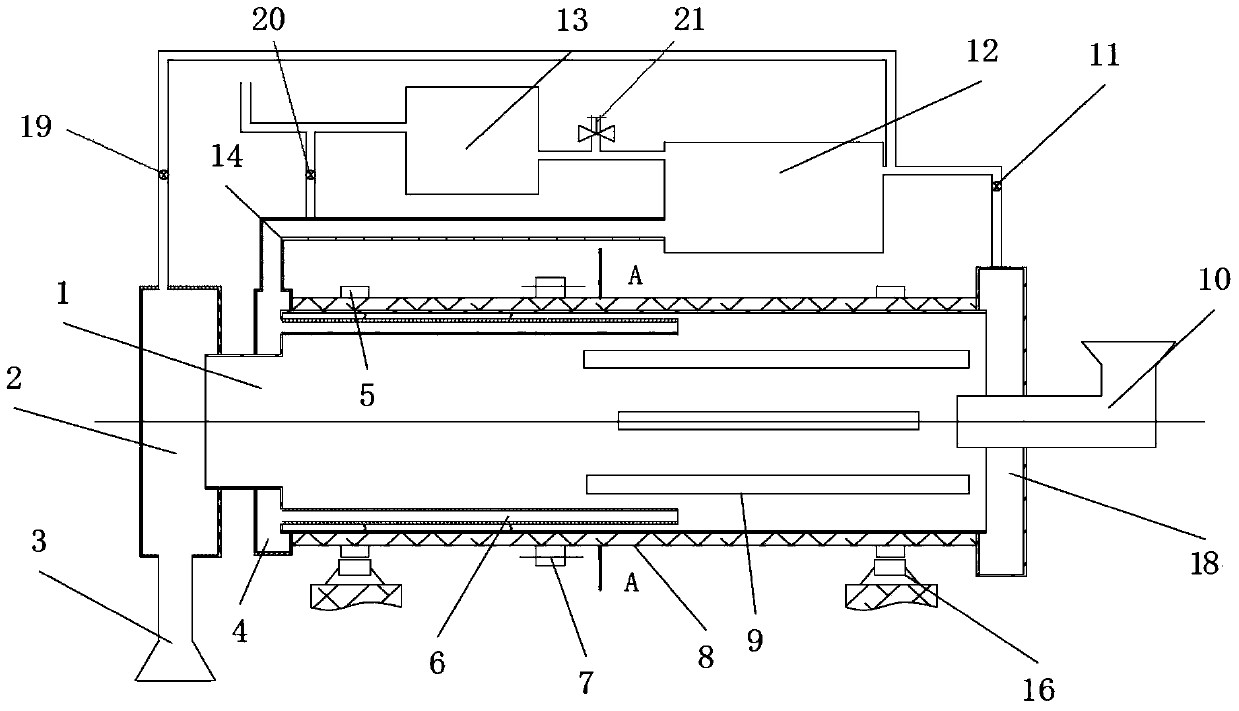

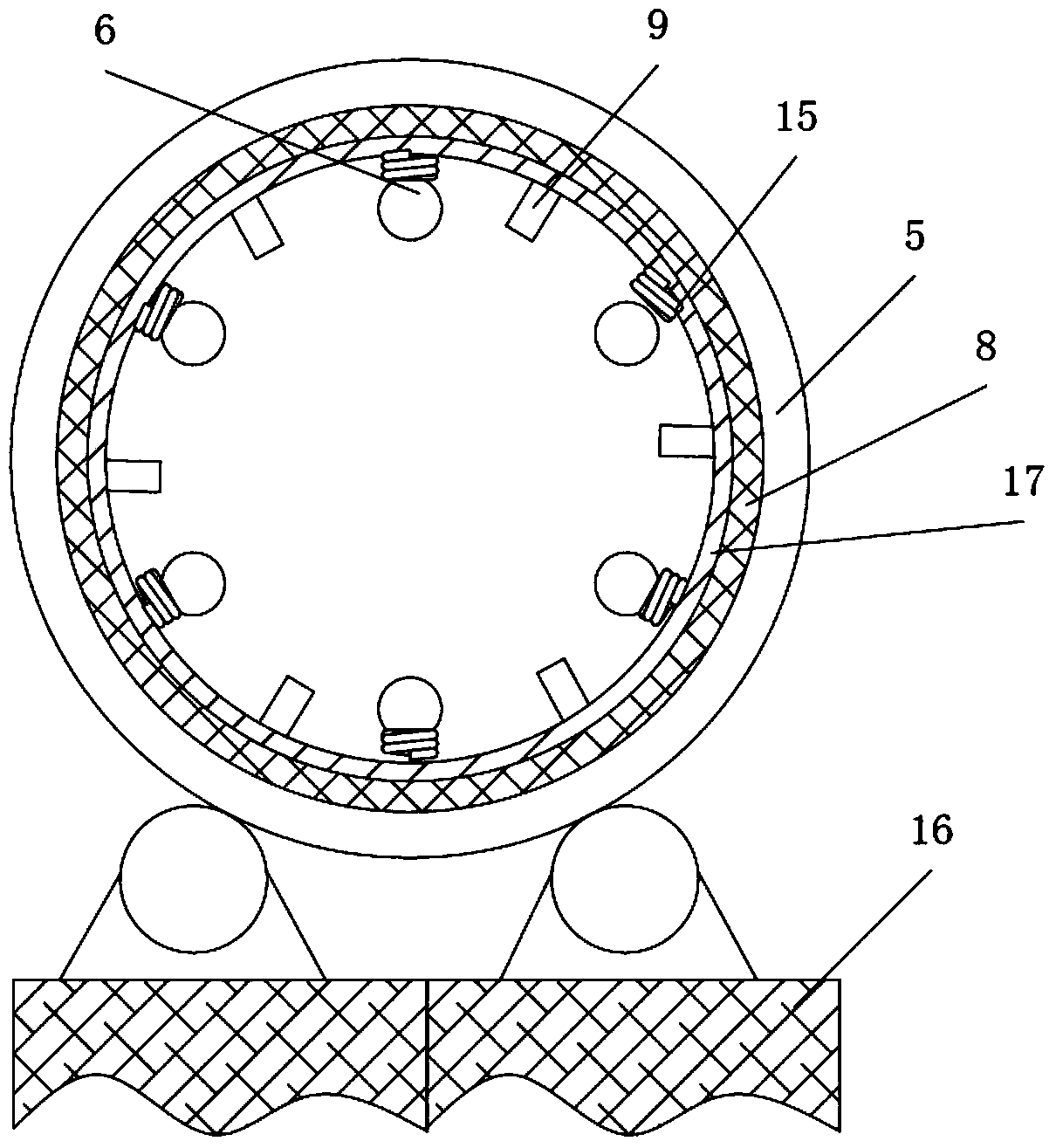

Continuous carbonization furnace

The invention provides a continuous carbonization furnace which comprises a rotary furnace, a feeding device and a blanking device, wherein the feeding device and the blanking devices are respectively connected to the two ends of the rotary furnace; the carbonization furnace also comprises a combustion chamber, a flame path and a flue gas channel; an inner cavity of the rotary furnace is provided with a flue gas heat exchange channel, the channel wall of the flue gas heat exchange channel is a heat-conducting wall, the flue gas heat exchange channel is provided with a flue gas inlet and a flue gas outlet, the flue gas inlet of the flue gas heat exchange channel is communicated with the combustion chamber through the flame path, and the flue gas heat exchange channel extends from the flue gas inlet to the flue gas outlet along a direction from a blanking port to a feed inlet; the flue gas channel is communicated with the combustion chamber and the inner cavity of the rotary furnace; the inner cavity of the rotary furnace comprises an outer hot area and an inner hot area, the area on one side of the inner cavity of the rotary furnace and provided with the flue gas heat exchange channel is the outer hot area, and the area on the other side is the inner hot area. The continuous carbonization furnace disclosed by the invention is small in occupied land and low in cost, solves a problem that pipelines are easily blocked, and improves the utilization rate of energy, and also can flexibly adjust the proportion of pyrolysis products, therefore, the continuous carbonization furnace has strong adaptability to production requirements.

Owner:NANJING DEMIN NEW ENERGY TECH

Method for shortening oxidoreduction time of crude copper in anode furnace

Provided is a method for shortening the oxidoreduction time of crude copper in an anode furnace. At present, pyro-refining is carried out on crude copper, it is commonly required that oxidation finishing temperature at least reaches 1,150 DEG C in operation in most enterprises in the industry to prevent reduction finishing temperature from being too low, it is required that the oxidation finishing temperature reaches 1,200 DEG C in part of copper smelting enterprises, and oxidation is finished at this moment. The crude copper has reduction conditions. By means of the method, the oxidoreduction time of the crude copper in the anode furnace is shortened, cost is saved, and efficiency is improved.

Owner:YUNNAN TIN

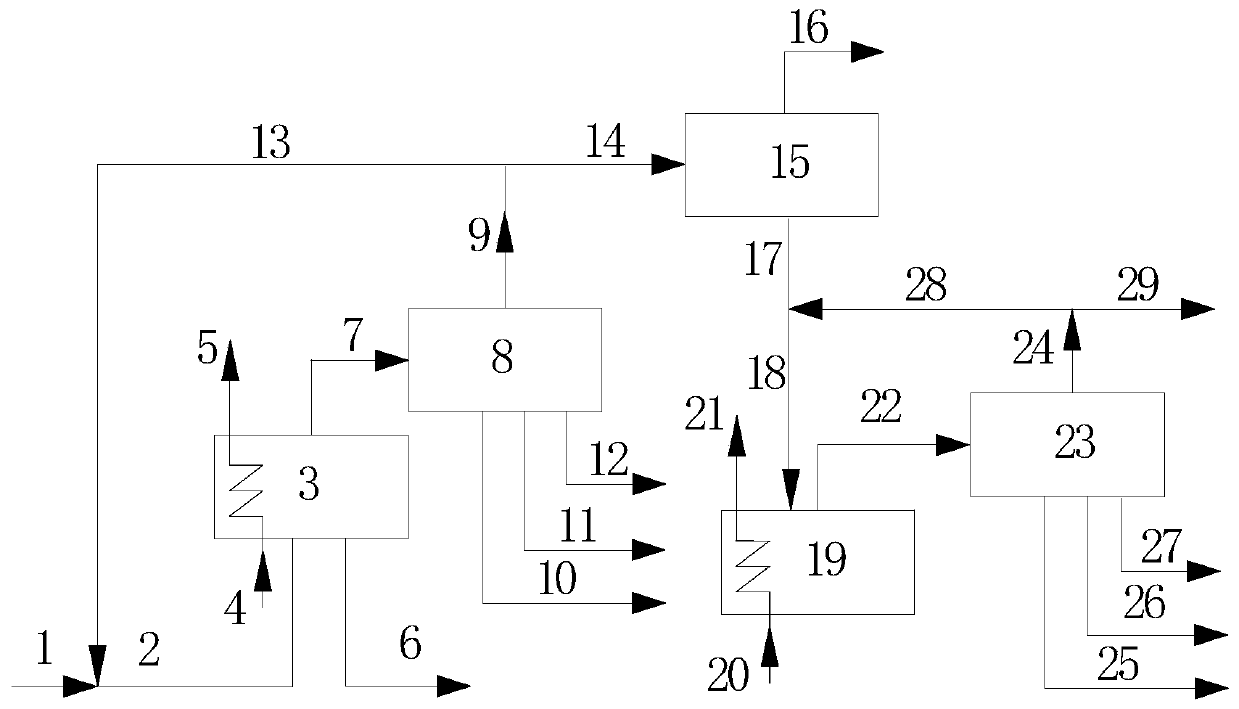

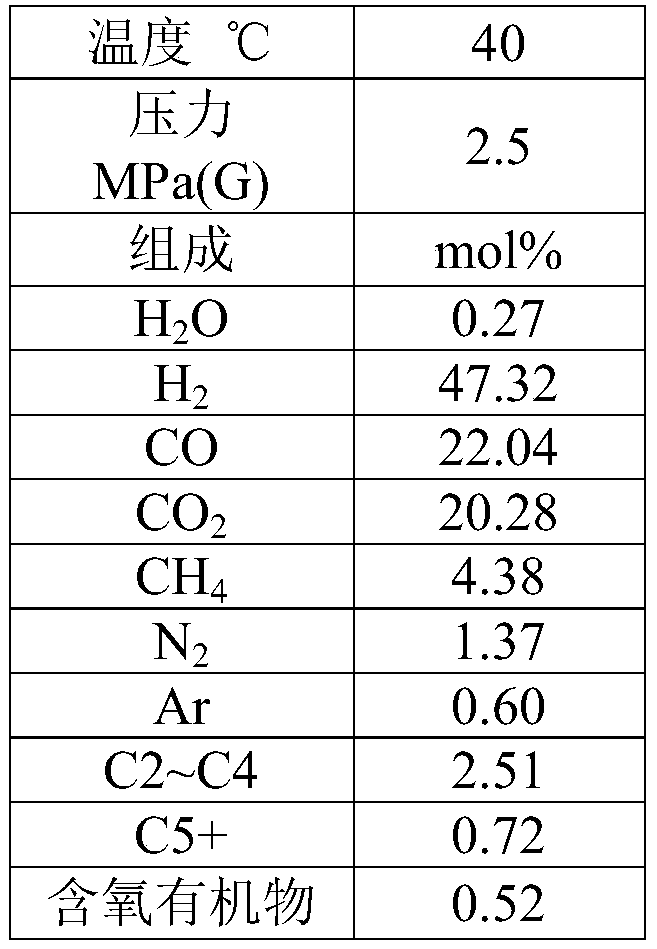

Method and device for producing hydrocarbons by connecting low-temperature Fischer-Tropsch section and high-temperature Fischer-Tropsch section in series

InactiveCN111286354ALow phase yieldHigh phase yieldLiquid hydrocarbon mixture productionPhysical chemistryLiquid hydrocarbons

The invention relates to a method for producing hydrocarbons by connecting a low-temperature Fischer-Tropsch section and a high-temperature Fischer-Tropsch section in series, wherein the method comprises the following steps: (1) introducing synthesis gas into a low-temperature Fischer-Tropsch synthesis reactor, carrying out a reaction, and separating reaction products to obtain high-carbon-numberhard paraffin, a low-temperature liquid hydrocarbon product, low-temperature reaction water and low-temperature Fischer-Tropsch tail gas; (2) feeding the low-temperature Fischer-Tropsch tail gas intoa decarburization device to completely or partially remove CO2, feeding the CO2-removed gas as a high-temperature Fischer-Tropsch raw material gas into a high-temperature Fischer-Tropsch synthesis reaction for reaction, and separating reaction products to obtain a high-temperature liquid hydrocarbon product, high-temperature reaction water and high-temperature Fischer-Tropsch tail gas; and (3) carrying out separation treatment on the low-temperature liquid hydrocarbon product and the high-temperature liquid hydrocarbon product to obtain the product. Compared with the prior art, efficient conversion of raw material gas and gradient utilization of energy are realized, the utilization efficiency of carbon is improved, the diversity of coal chemical products is realized, and the risk resistance of the Fischer-Tropsch synthesis device is improved.

Owner:YANKUANG ENERGY R&D CO LTD

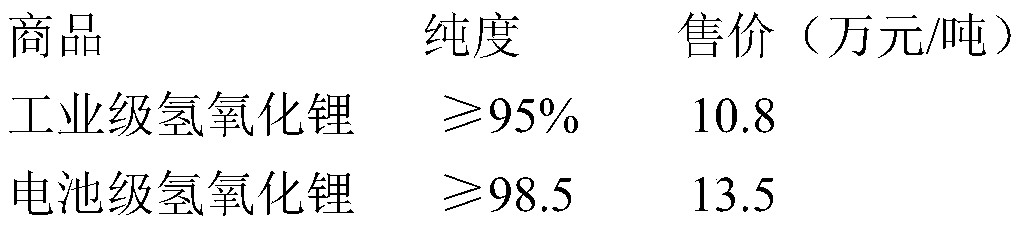

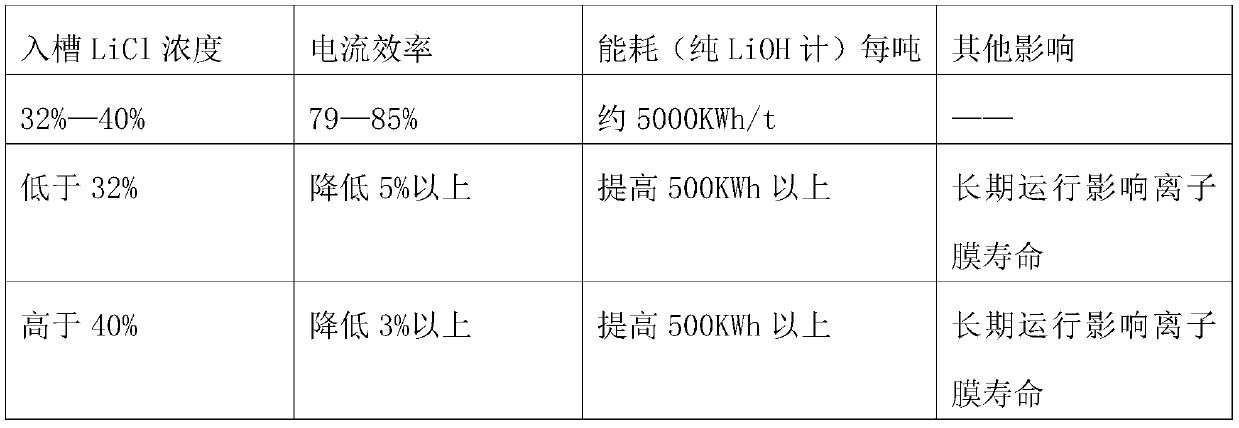

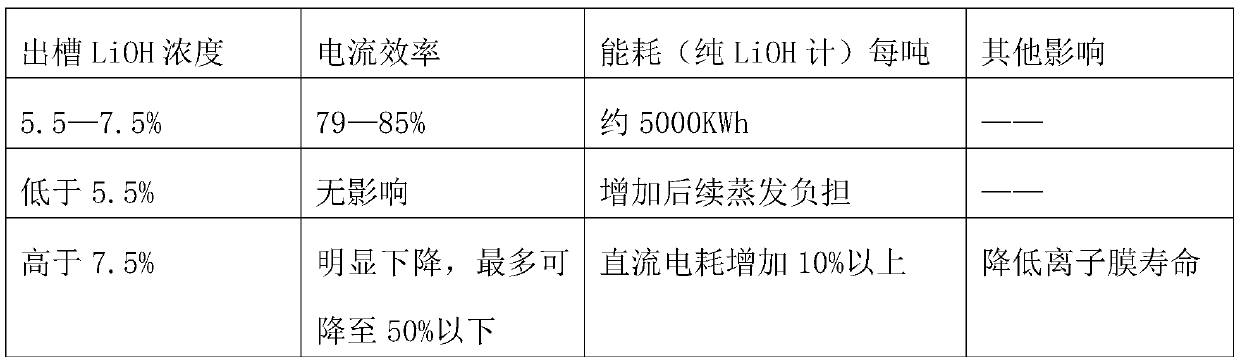

Method of preparing battery grade lithium hydroxide by directly electrolyzing lithium chloride

ActiveCN110029354AReduce manufacturing costHigh purityElectrolysis componentsLithium chlorideLithium hydroxide

The invention relates to a method of preparing battery grade lithium hydroxide by directly electrolyzing lithium chloride. The method comprises the steps of refining a lithium chloride solution, adding the refined lithium chloride solution into an anode chamber of a bipolar natural circulation ion-exchange membrane electrolyzer, adding a lithium hydroxide solution with a mass percent concentrationof 5.5-7.5% into a cathode chamber of the bipolar natural circulation ion-exchange membrane electrolyzer, adding pure water into the cathode chamber, and preparing the mass percent concentration of the lithium hydroxide solution to be 4.9-6.5%, wherein an ion exchange membrane of the bipolar natural circulation ion-exchange membrane electrolyzer is a cation exchange membrane. The invention aims at providing the method of preparing battery grade lithium hydroxide by directly electrolyzing lithium chloride; produced battery grade lithium hydroxide is high in purity and few in impurity; a utilization ratio of a lithium element resource is high; the waste of the lithium element resource is low; circular economic utilization of all raw materials and products in a whole lithium hydroxide preparation process is achieved; the method is environment-friendly and efficient; and almost no pollutant is discharged.

Owner:BLUESTAR BEIJING CHEM MACHINERY

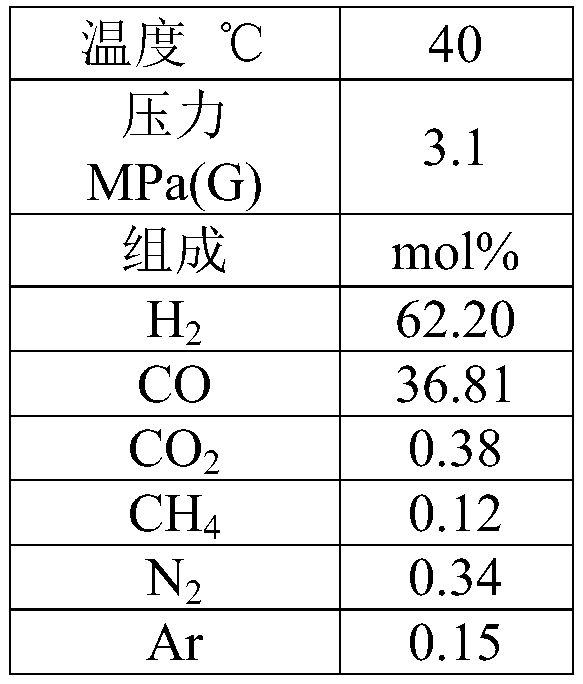

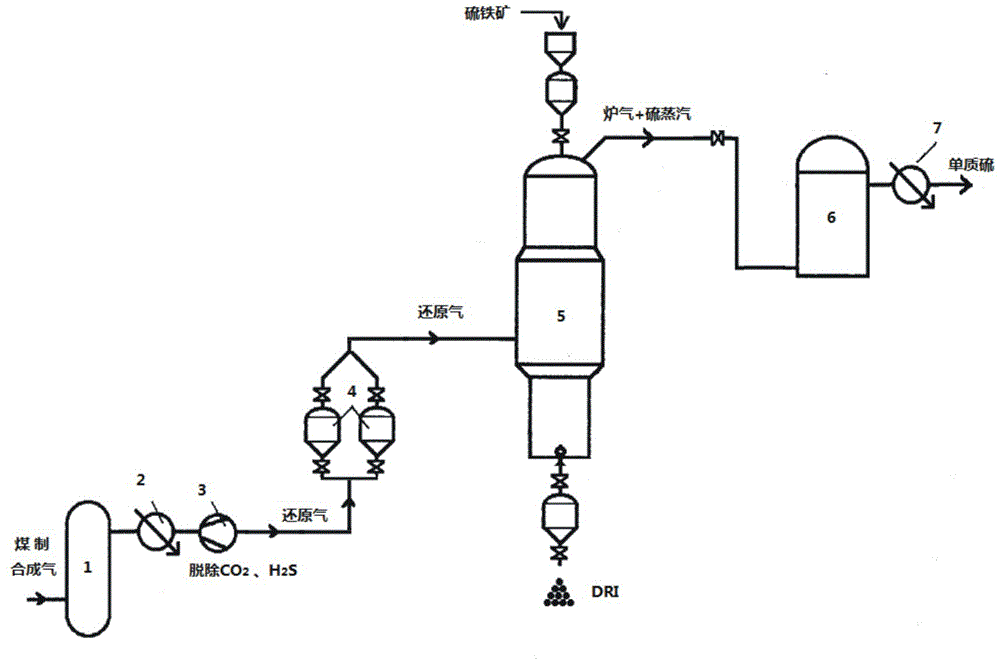

Method for producing sponge iron by reducing pyrites through coal synthesis gas in shaft furnace

InactiveCN106755690AIncrease contentFlexible adjustment ratioShaft furnaceShaft furnaceMaterials science

The invention discloses a method for producing sponge iron by reducing pyrites through coal synthesis gas in a shaft furnace. Hydrogen sulfide and carbon dioxide in the coal synthesis gas are removed through a gas purification process, reducing gas with carbonic oxide and hydrogen as main compositions is obtained, then heated to a preset temperature and introduced into the shaft furnace, the pyrites are reduced into the sponge iron through the reducing gas in the shaft furnace, and obtained sulfur vapor is recovered after being dedusted and condensed. According to the process, the heat furnace is adopted for directly heating the reducing gas, the influence of carbonic oxide carbon precipitation is avoided, the temperature of the reducing gas can be increased to 850-1000 DEG C, briquettes comprising the pyrites are used as raw materials of the shaft furnace, and the cost of the raw materials is lowered.

Owner:LUTIAN CHEM CORP

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475BFlexible adjustment ratioHomogeneous coprecipitationCell electrodesAir atmosphereOXALIC ACID DIHYDRATE

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Golf tee and preparation method thereof

The invention belongs to the technical field of sports equipment, and particularly relates to a golf tee and a preparation method thereof. The golf tee is mainly prepared from gum-containing pine barks, elm barks and / or banyan barks and cassava, and extra binders are omitted. The preparation method includes the steps: firstly, collecting and crushing various raw materials; secondly, performing high-temperature treatment and extrusion to form the golf tee. The method is simple in preparation process and convenient in operation. The golf tee turns into soil particles within 2 minutes when touching water, the golf tee can be effectively combined with soil and can be absorbed by a lawn after degradation to generate fertilizers, the problems of foot and tire stabbing properties and difficulty in recovery of other tees are solved, a large number of manpower and material resources are saved, and environments are protected. Besides, the transverse pressure resistance of the golf tee is 3-5 kilograms, the vertical pressure resistance of the golf tee is 15-20 kilograms, the golf tee is broken once being hit, a golf club cannot be blocked, and technical indexes of the golf tee are variously demonstrated at home and abroad to prove that the golf club cannot be damaged, and accuracy is improved.

Owner:朱君

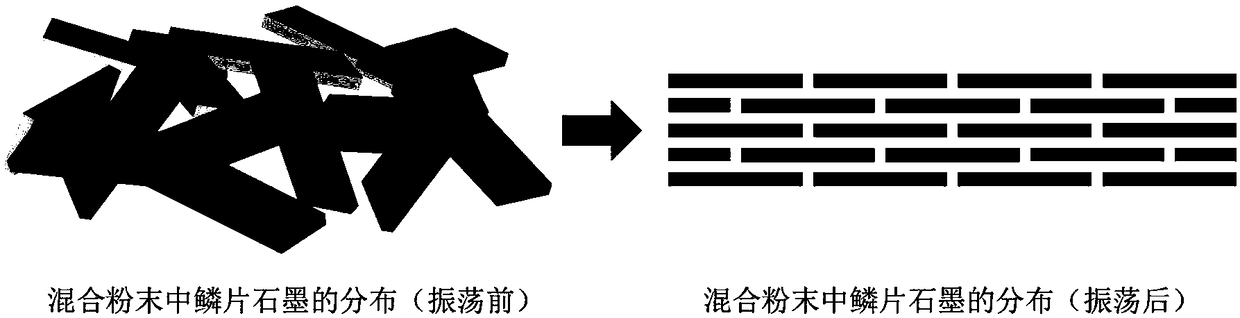

Directional high thermal conductivity uranium dioxide pellet and preparation method thereof

ActiveCN109243625AImprove radial thermal conductivityImprove securityNuclear energy generationReactors manufactureUranium dioxideMaterials science

The invention discloses a directional high thermal conductivity uranium dioxide pellet and a preparation method thereof, and solves the problem of low thermal conductivity of uranium dioxide in the prior art, especially low radial thermal conductivity which easily leads to safety accidents. The directional high thermal conductivity uranium dioxide pellet disclosed by the invention is prepared fromuranium dioxide powder and flake graphite which serve as raw materials, and the flake graphite is aligned in a horizontal direction in a uranium dioxide pellet. The preparation method disclosed by the invention comprises the following steps: uniformly mixing the uranium dioxide powder with the flake graphite serving as the raw materials, oscillating the mixed powder to enable the flake graphite to be aligned in the horizontal direction in the mixed powder, and then performing high temperature sintering to obtain the directional high thermal conductivity uranium dioxide pellet. The directionalhigh thermal conductivity uranium dioxide pellet is scientific in design, and the method is simple; the radial thermal conductivity of the uranium dioxide pellet can be obviously improved, and the safety of a fuel assembly is improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

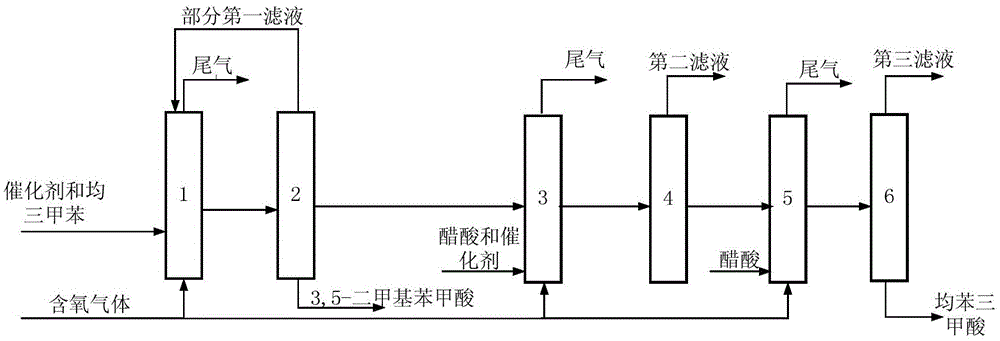

Method for co-producing 3,5-dimethylbenzoic acid and trimesic acid

ActiveCN105152906AMild reaction conditionsImprove conversion rateOrganic compound preparationCarboxylic compound separation/purificationMesityleneMedicinal chemistry

The invention discloses a method for co-producing 3,5-dimethylbenzoic acid and trimesic acid. The method comprises the steps that mesitylene is taken as raw materials and processed through first-time oxidizing, first-time separating, secondary oxidizing, secondary separating, curing and third-time separating, and then the 3,5-dimethylbenzoic acid and the trimesic acid are obtained. The method has the advantages of being simple in technology, low in cost, high in yield, good in selectivity, green and environmentally friendly.

Owner:山东友道化学有限公司

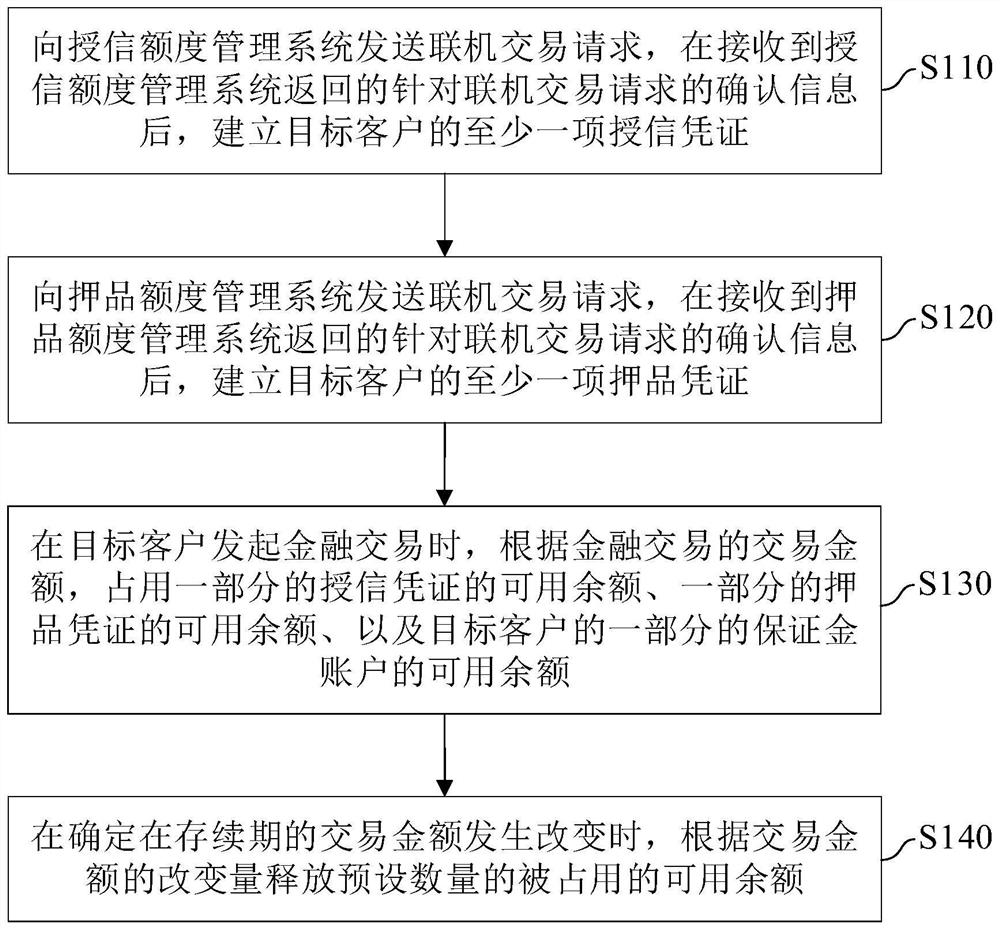

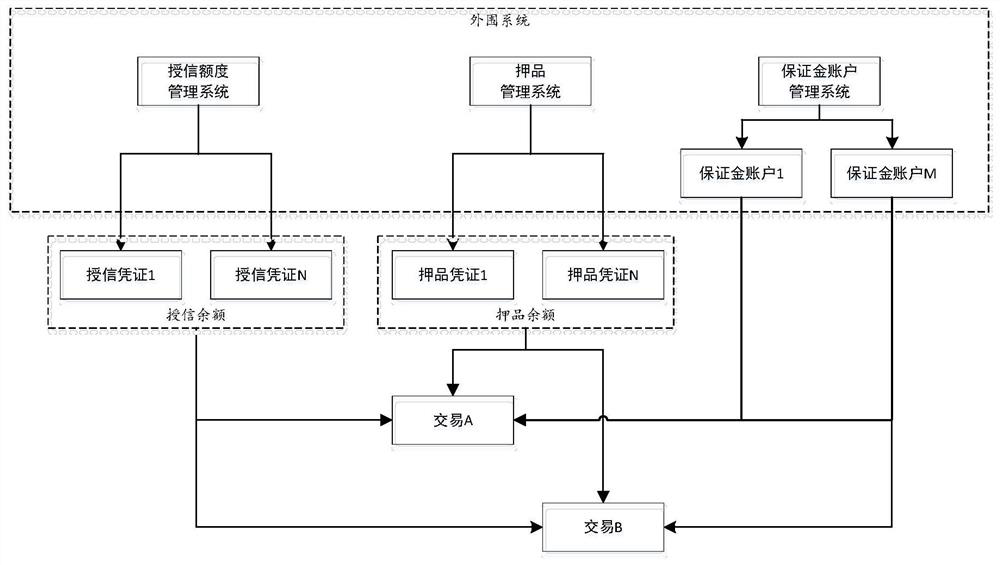

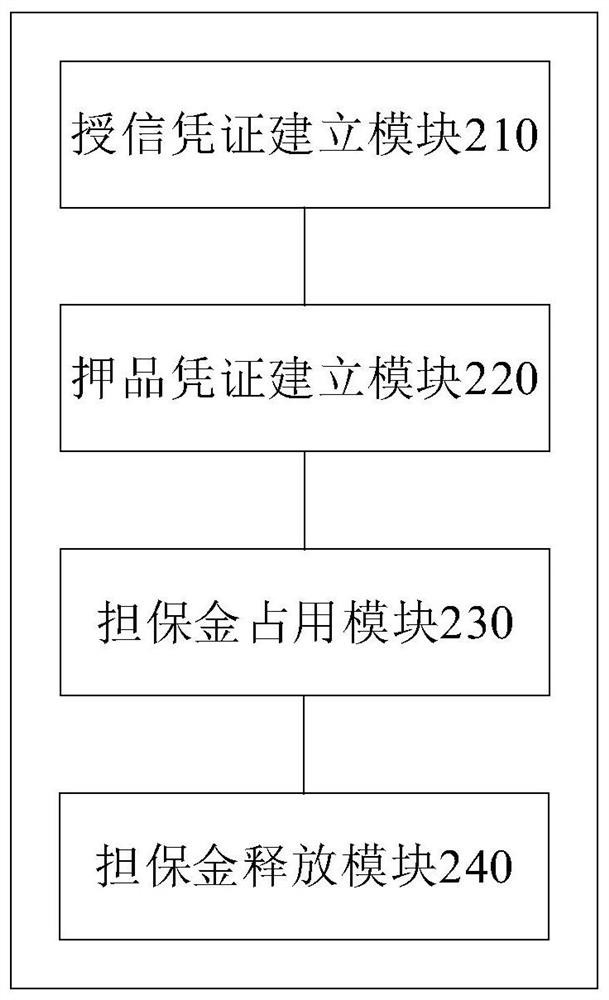

Traceable financial market transaction guarantee management method and device, equipment and medium

The invention provides a traceable financial market transaction guarantee management method and device, equipment and a medium. The method comprises the following steps: establishing at least one credit voucher of a target customer, and establishing at least one pledge voucher of the target customer; when the target customer initiates a financial transaction, according to the transaction amount of the financial transaction, occupying the available balance of a part of the credit voucher, the available balance of a part of the pledge voucher and the available balance of a part of the deposit account of the target customer; and when it is determined that the transaction amount in the duration is changed, releasing a preset amount of occupied available balance according to the change amount of the transaction amount. According to the method, the proportion of different types of guarantee occupied by each transaction can be flexibly adjusted, real-time release of the guarantee after each transaction is finished is supported, bank risks can be reduced, flexible occupation and release of customer funds are realized, and customer marketing by branch banks is facilitated.

Owner:CHINA CITIC BANK

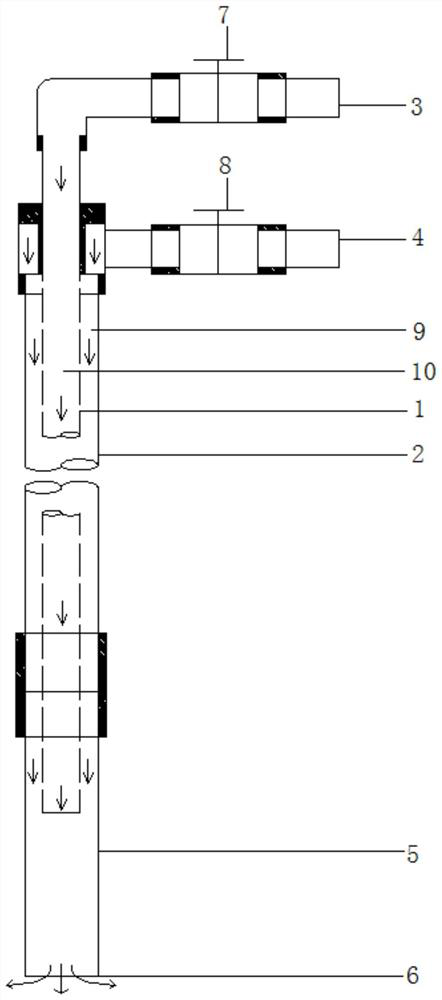

Double-liquid grouting device for leaking stoppage and emergency rescue of foundation pit engineering and construction method

PendingCN113832976AFlexible adjustment ratioWell mixedFoundation engineeringWater leakageEmergency rescue

The invention discloses a double-liquid grouting device for leaking stoppage and emergency rescue of foundation pit engineering and a construction method. The double-liquid grouting device comprises an inner pipe, an outer pipe, a first slurry pump and a second slurry pump, wherein the outer pipe is sleeved with the inner pipe, the inner pipe is connected with the first slurry pump, the outer pipe is connected with the second slurry pump, the inner pipe and the outer pipe are both in an L shape, a first pouring opening is formed in the upper end of the inner pipe, the upper end of the outer pipe is provided with a second pouring opening, the lower end of the inner pipe is provided with a mixing section, the mixing section is located in the outer pipe, the inner pipe and the outer pipe are connected in a sleeved mode, the field operation space can be saved, the mixing section is arranged at the lower end of the inner pipe, the proportion of cement paste and water glass can be flexibly adjusted, therefore, the cement paste and the water glass are fully mixed to achieve the purpose of blocking water leakage.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

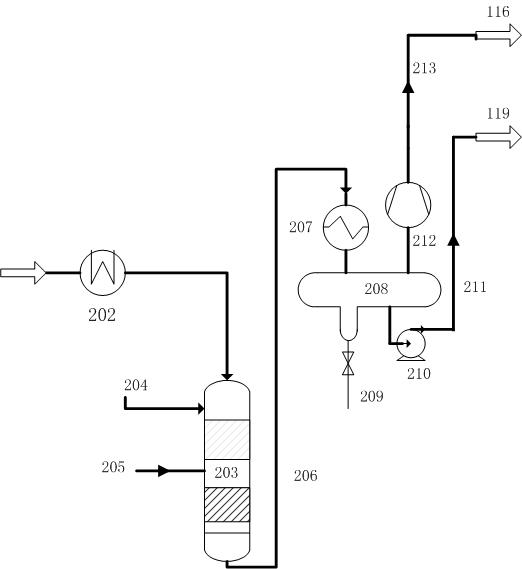

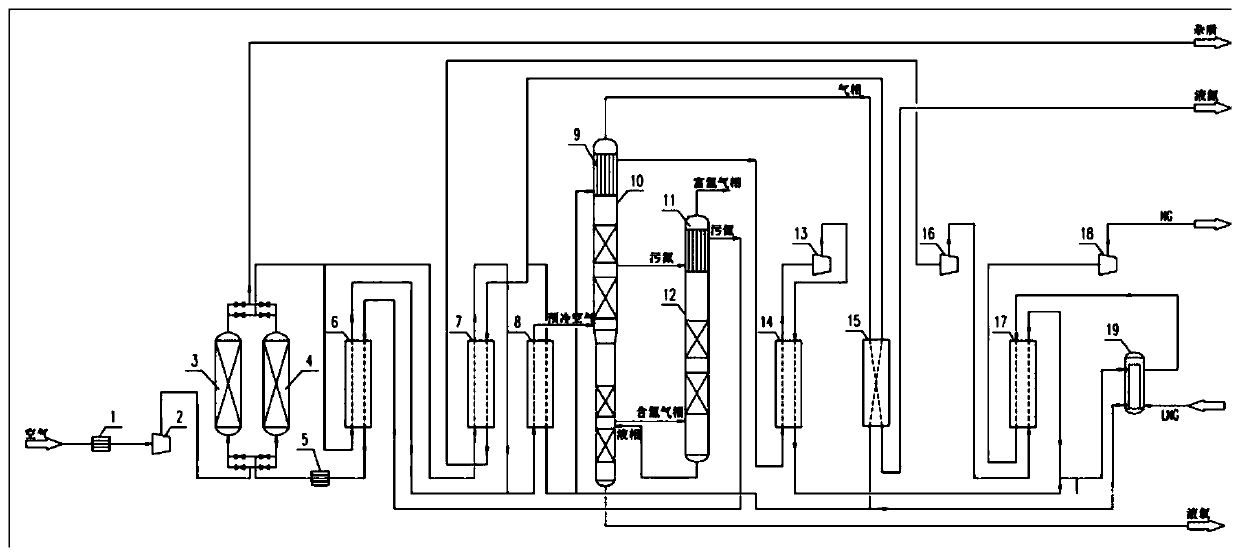

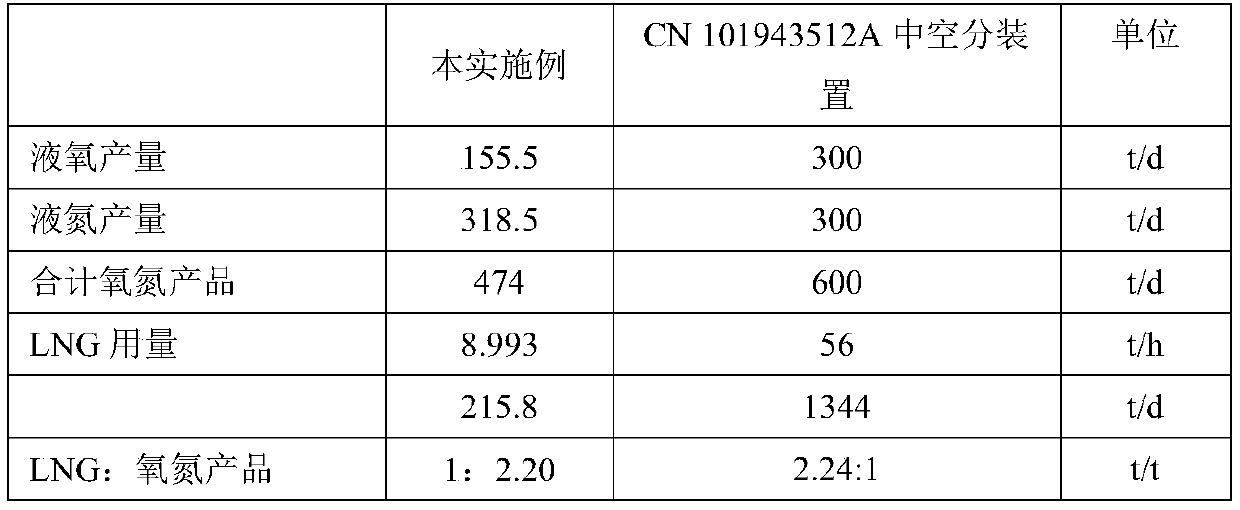

Method for producing liquid oxygen and liquid nitrogen through LNG cold energy and single-tower rectification technology

ActiveCN109855389APromote circulationReduce power consumptionSolidificationLiquefactionCyclic processCondensation process

The invention relates to a method for producing liquid oxygen and liquid nitrogen through LNG cold energy and a single-tower rectification technology, and belongs to the field of air separation-LNG utilization. The method comprises the steps of purifying, cooling, rectifying, and LNG cold energy conversion. According to the method, the liquid oxygen, the liquid nitrogen or gaseous nitrogen is generated through the single-tower rectification technology of a main rectification tower and an argon tower, cold energy for main rectification tower top condensation, gaseous nitrogen condensation and air pre-condensation comes from the processes of evaporating, heat exchange, compression, heat exchange and condensation of a refrigerant, and low-temperature whole process cold energy released duringLNG normal pressure gasification is sufficiently recycled by the refrigerant to serve as cold energy required in the air separation process. The circulation process of the refrigerant is simple and convenient, and the refrigerant can recycle 90% or above of the cold energy released during LNG gasification; the gaseous nitrogen of which the purity is higher than 99.99% and the pressure is higher than 0.5MPa, the liquid nitrogen of which the purity is higher than 99.99% and the pressure is higher than 0.5MPa, and the liquid oxygen of which the purity is higher than 99.6% and the pressure is higher than 0.5MPa are obtained, and the power consumption of the liquid oxygen and nitrogen is smaller than 300KW / t; and it can be achieved that production of conventional air separation gas products ofthe same scale is completed through small-size equipment.

Owner:中科慧智(北京)科技有限公司

Light diffusion agent mother material used for light diffusion film, preparation method and application thereof

ActiveCN101812220BHigh light transmittanceHigh hazeFlat articlesNon-linear opticsPolymer scienceMicrosphere

The invention provides a light diffusion agent mother material used for a light diffusion film, a preparation method and application thereof. A light diffusion agent is compounded from organic polymer cross linking microspheres with different refractive indexes and grain diameters, the light diffusion agent mother material is prepared from 100 weight parts of polyester resin, 60 to 100 weight parts of compounded light diffusion agents and 1 to 7 weight parts of diffusion resin through high-speed diffusion and fused extrusion grain cutting by a double-screw extruding machine. The invention also provides a high-transparency heat-resistance light diffusion film prepared by using the light diffusion agent mother materials as additives. The light diffusion layer of the light diffusion film is formed by mixing the light diffusion agent mother materials and polyester slices according to the mixture ratio of 40 to 60 weight percent of polyester slices and 40 to 60 weight percent of the light diffusion agent mother materials. The light diffusion film prepared by the invention has high light transmission rate, high mist degree, excellent heat resistance performance and excellent dimension stability, and is particularly suitable for being used as the light diffusion film in a back light module of a large-dimension liquid crystal display.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com