Method for leaching low-grade zinc oxide ore

A zinc oxide ore, low-grade technology, applied to the improvement of process efficiency, etc., can solve problems such as complex instability, limited solubility and coordination ability, unstable ammonium carbamate, etc., and achieve good leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

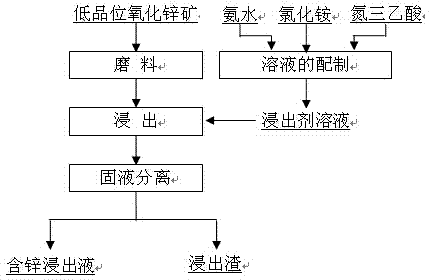

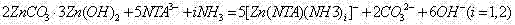

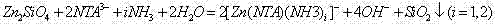

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Grind low-grade zinc oxide ore to a particle size of 100% and pass through a sieve with an aperture of 75 μm, and prepare NH with a concentration of ammonia water of 2 mol / L, an ammonium chloride concentration of 2 mol / L, and an NTA concentration of 0.2 mol / L 4 Cl-NH 3 -1000 mL of NTA solution was used as the leaching agent solution, and 100 g of the above-mentioned low-grade zinc oxide ore was placed in the prepared leaching agent solution for slurrying, and the temperature was 40 ° C and the stirring speed was 400 r / min. After reacting for 2 h After filtering, washing and drying, 72.9 g of leaching residue was obtained, in which the zinc content was 1.83%, and the zinc leaching rate was 79.91%.

Embodiment 2

[0031] Example 2: The low-grade zinc oxide ore is ground to a particle size of 100% and passed through a sieve with an aperture of 75 μm, and NH with an ammonia concentration of 2 mol / L, an ammonium chloride concentration of 4 mol / L, and an NTA concentration of 0.4 mol / L is prepared. 4 Cl-NH 3-1000 mL of NTA solution was used as the leaching agent solution, and 200 g of the above-mentioned low-grade zinc oxide ore was placed in the prepared leaching agent solution for slurrying, and reacted for 4 h at a temperature of 60 °C and a stirring speed of 200 r / min After filtration, washing and drying, 144.4 g of leaching residue was obtained, in which the zinc content was 1.37%. Zinc leaching rate was 85.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com