Patents

Literature

35 results about "Secondary mineral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries

ActiveCN104593606ANo secondary pollutionLow costWaste accumulators reclaimingProcess efficiency improvementElectrical batteryFiltration

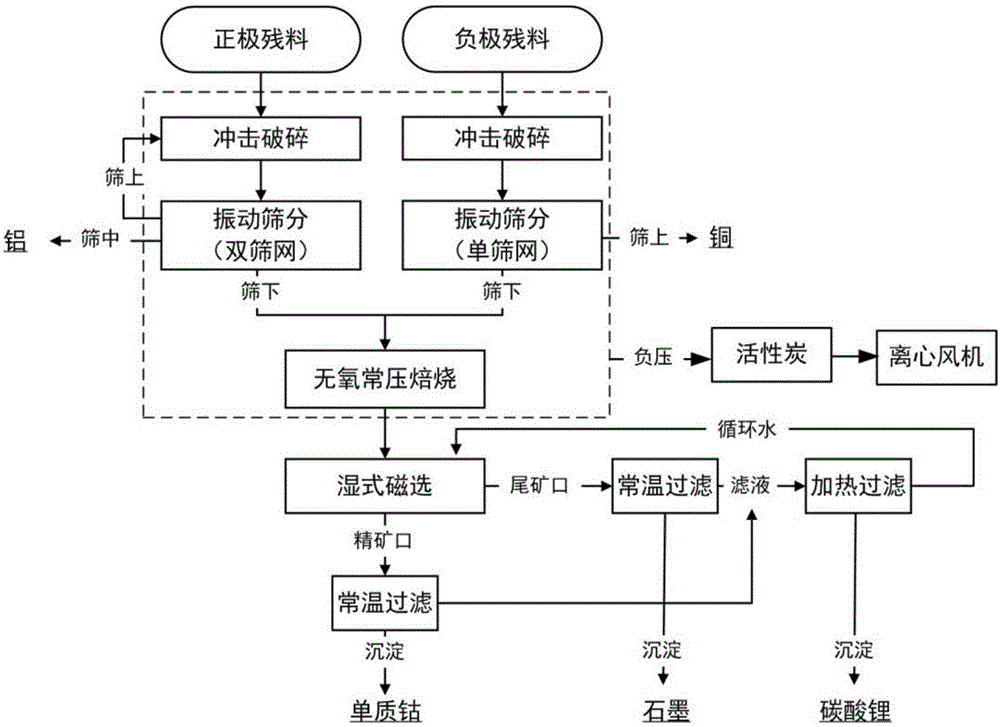

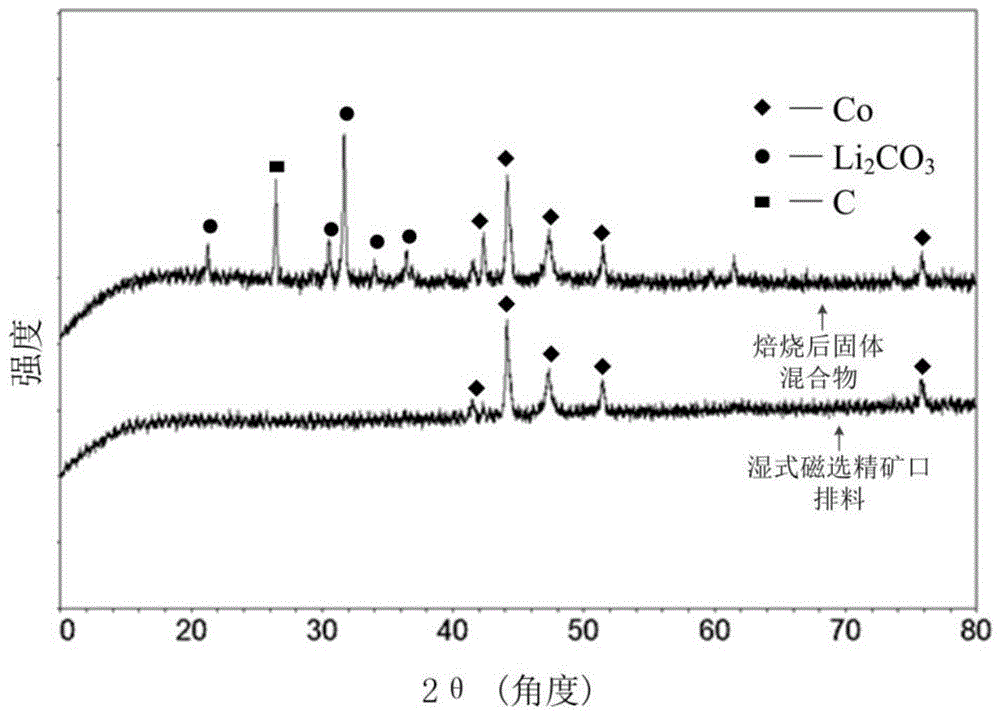

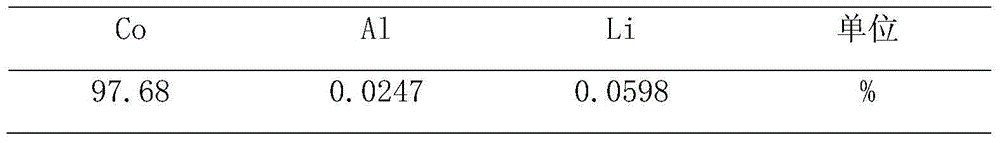

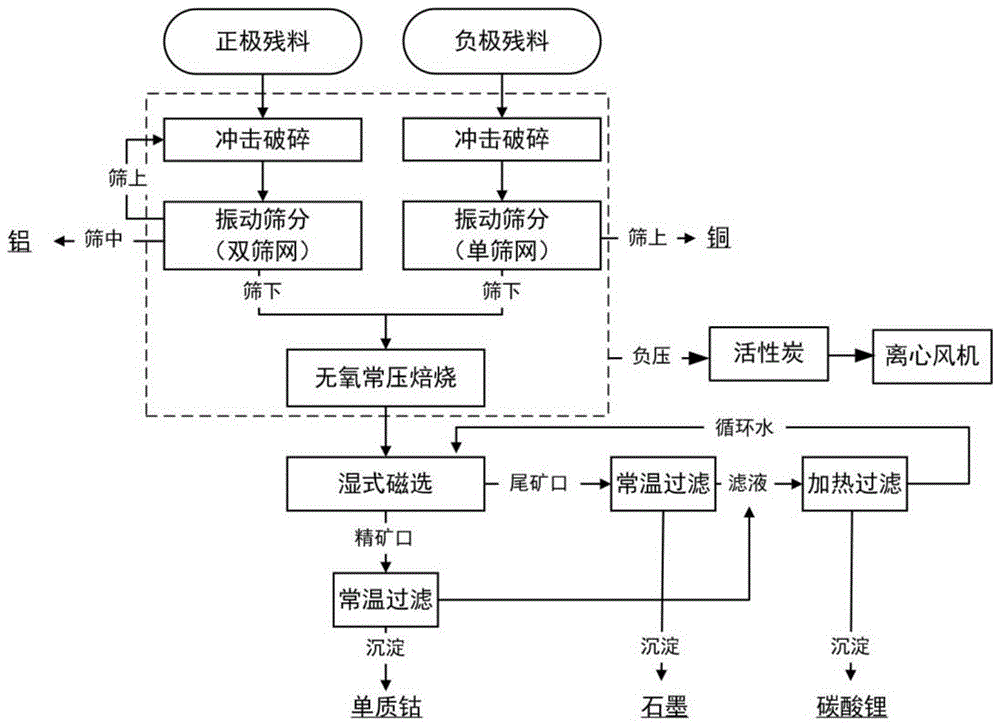

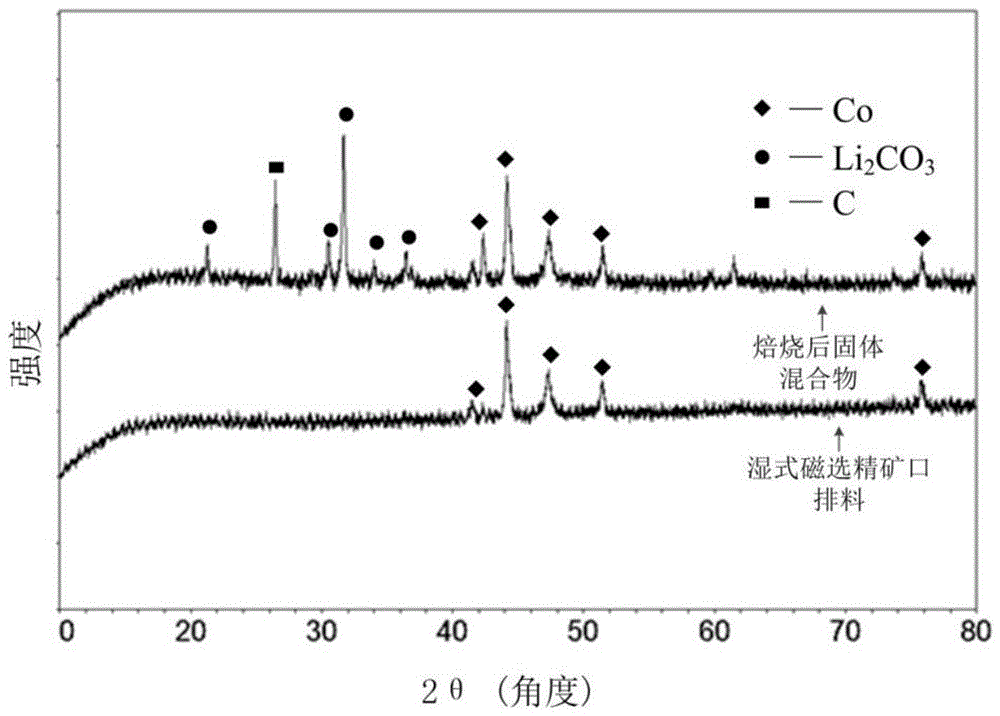

The invention discloses a method for recycling positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries. By combing technologies such as high-speed impact crushing, vibration screening, anaerobic atmospheric roasting, wet-type magnetic separation and temperature-variable filtration, products such as elemental cobalt, lithium carbonate and graphite powder are prepared from the positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries; the materials are separated and enriched in such manners as high-speed impact crushing, vibration screening and wet-type magnetic separation, the original physical properties of the materials are retained, the negative electrode graphite material is fully utilized, the in-situ preparation of resources is achieved and the cost is saved; the anaerobic atmospheric roasting is adopted, the reaction conditions are relatively loose, the graphite material loss is decreased, the flow is simplified, any chemical agent is not needed in the entire process, no secondary pollution is caused and the industrial application practice is facilitated. By the method, the problem of pollution-free treatment of leftover material generated in the manufacturing of the lithium-ion batteries for battery manufacturers is solved and meanwhile, a method for mining secondary mineral, namely, a cobalt resource is provided.

Owner:SHANGHAI JIAO TONG UNIV

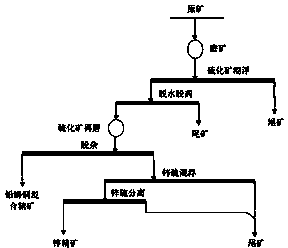

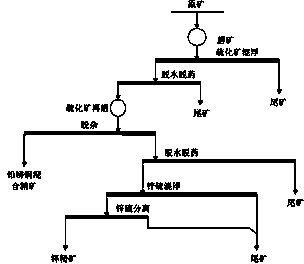

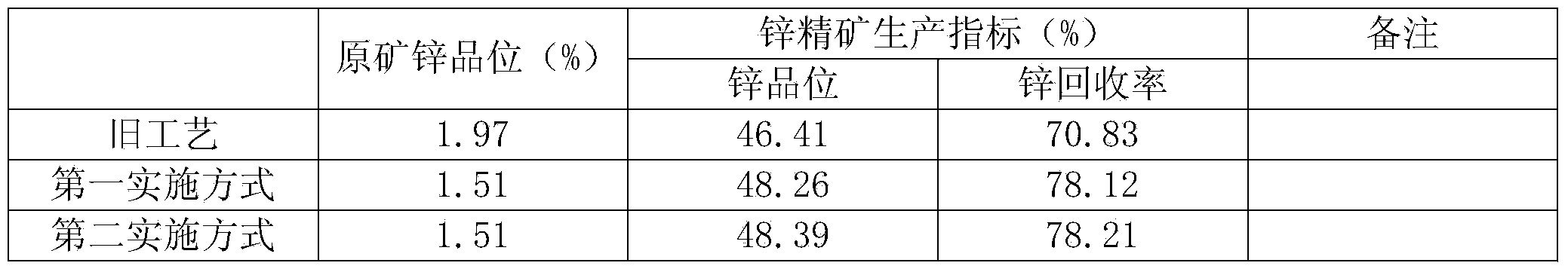

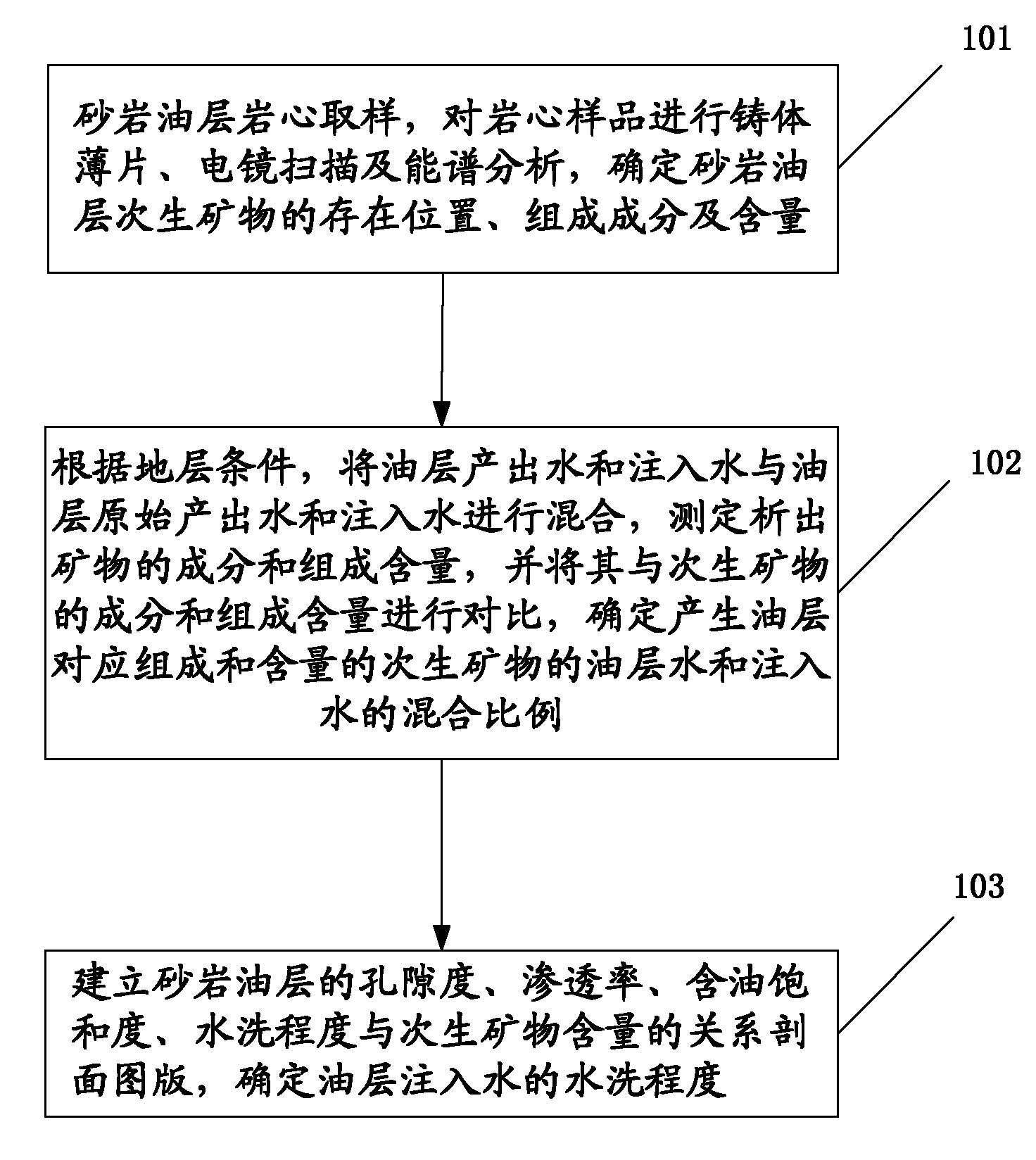

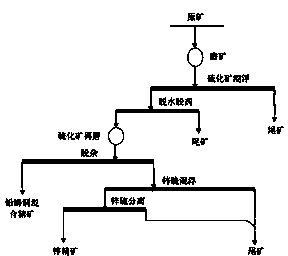

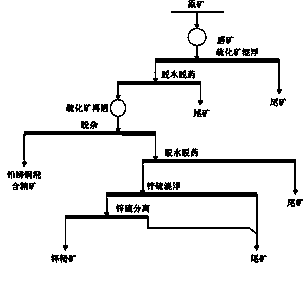

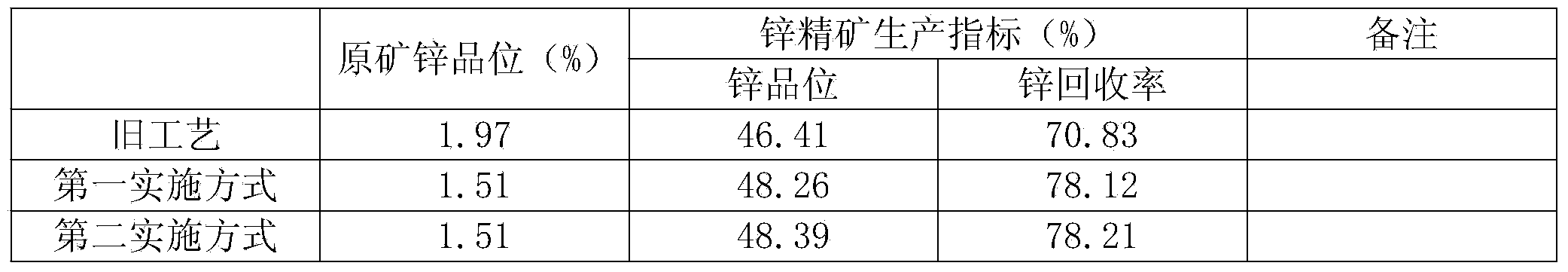

Polymetallic sulphide ore flotation process capable of increasing zinc index

ActiveCN103433149AReduce lossesImprove production indicatorsFlotationCleaning using liquidsSecondary mineralImpurity

The invention provides a polymetallic sulphide ore flotation process capable of increasing a zinc index, belonging to the technical field of ore dressing. Aiming at the disturbing influence of excess reagents and other minerals in a polymetallic sulphide ore flotation system on a zinc flotation index, the polymetallic sulphide ore flotation process adopts the process steps including sulphide ore mixed flotation, reagent removal and impurity removal, zinc-sulphur mixed flotation, zinc-sulphur separation and the like, other sulphide ores with good flotability relative to zinc are preferably floated, and then zinc flotation is carried out, so that the quality and recovery rate of zinc concentrate are significantly improved. Meanwhile, the comprehensive recovery of lead, antimony, sulphur, copper and other metals is realized, and the emission of heavy metals is reduced. The polymetallic sulphide ore flotation process also can be used for increasing the utilization rate of mineral resources, and has great significance for the exploitation and utilization of low-grade or secondary mineral resources.

Owner:广西华锡矿业有限公司铜坑矿业分公司 +1

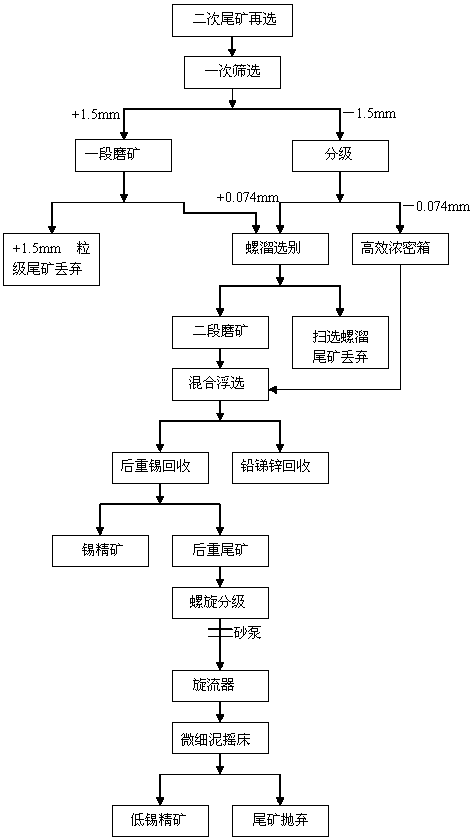

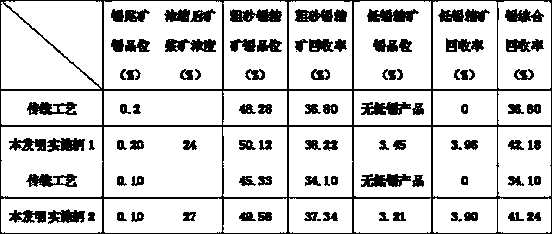

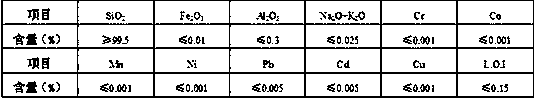

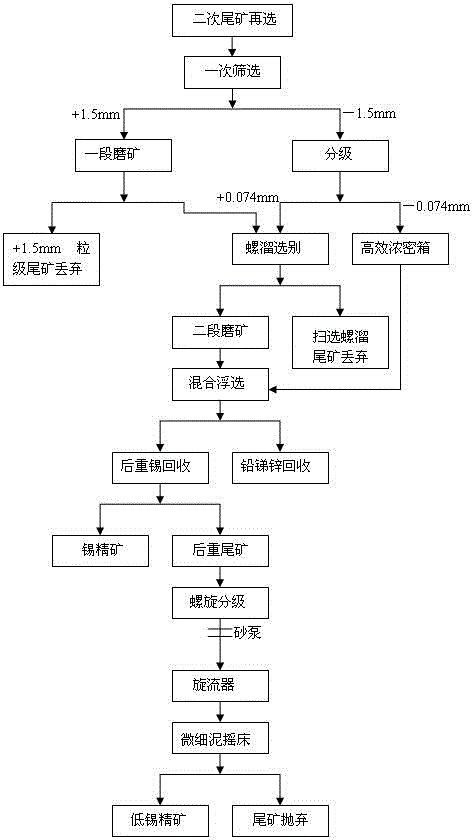

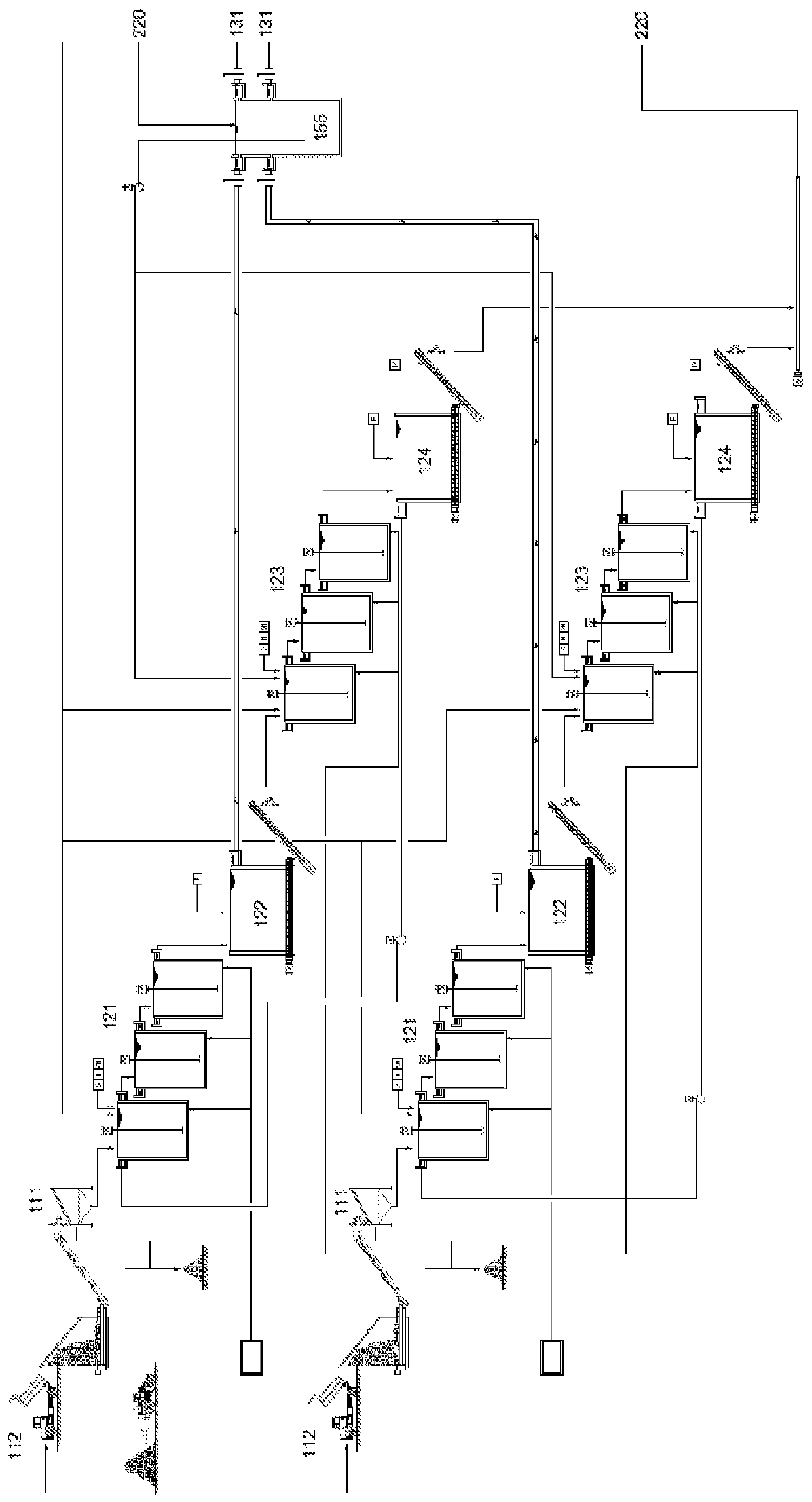

Tin reclaiming method for fine-grain and low-grade secondary mineral tailings

The invention discloses a tin reclaiming method for fine-grain and low-grade secondary mineral tailings. The tin reclaiming method comprises the procedures including front hoisting and tailings throwing, fine silt separating, and the like, wherein the procedure of front hoisting and tailings throwing of secondary mineral tailings comprises the steps of primary screening and classification, primary ore grinding and secondary screening and classification; the procedure of fine silt separating comprises the steps of classification and swirler treatment. According to the invention, separated mineral tailings are classified again, and a swirler is used for desliming, so that the equilibrium quantity and the concentration of ore slurry flowing into a fine silt yun tin shaking bed are ensured, separation of tin and silt slag is improved, the defect that in the traditional process, tin separation is complicated and difficult, the degree of dissociation of tin monomer is poor and the recovery rate is low due to low grade of mineral tailings can be overcome, the separating capability of tin separation is improved, the tin concentrate recovery rate of the shaking bed is improved, and reclaiming and cyclic utilization of waste material are realized.

Owner:广西华锡矿业有限公司再生资源分公司

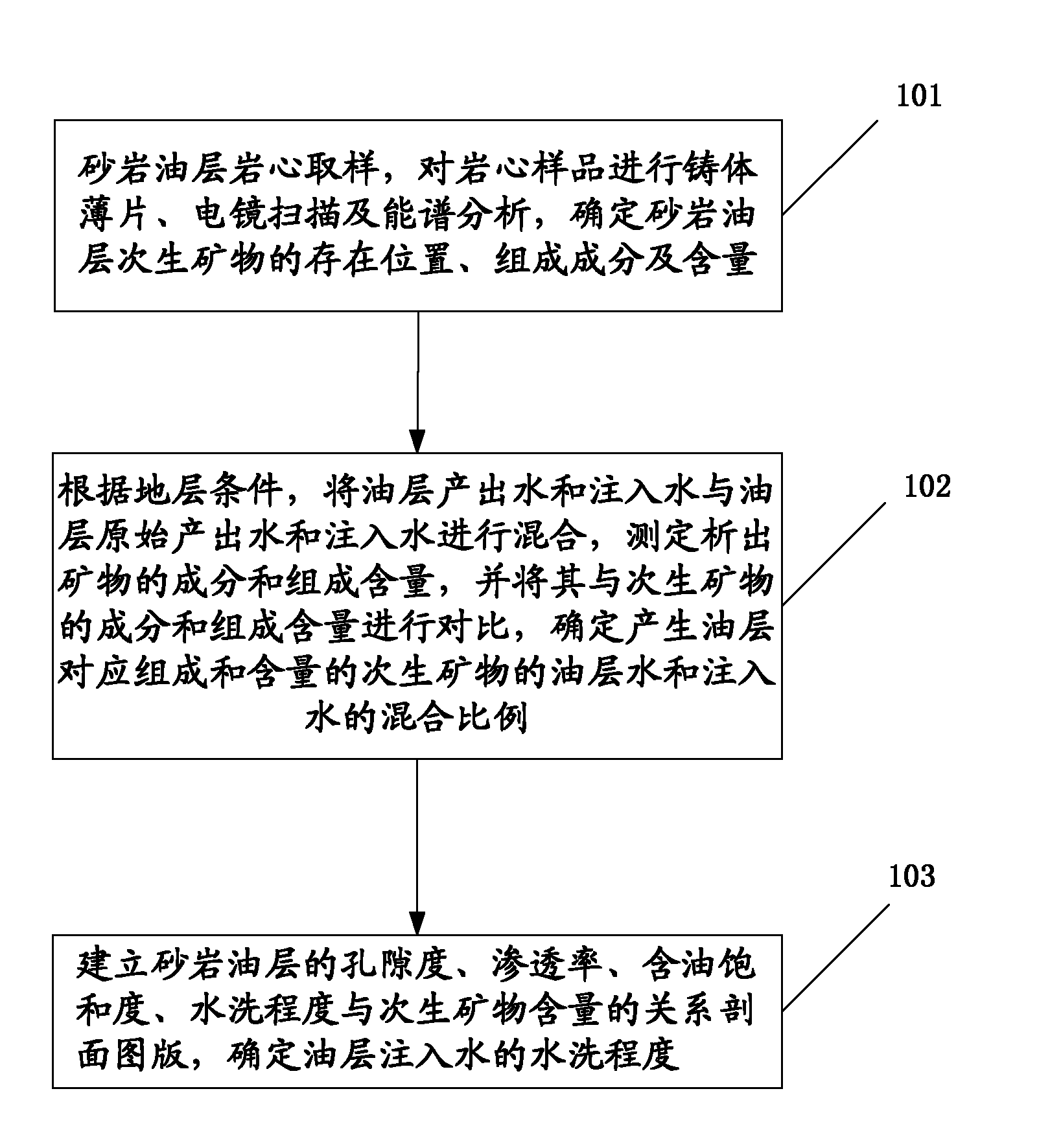

Method for evaluating watered-out degree of ultralow-permeability water-drive reservoir sandstone oil layer

ActiveCN101942995AReflect the actual degree of washingAvoid the phenomenon of multiple washing degreesFluid removalPorosityTerra firma

The invention discloses a method for evaluating the watered-out degree of an ultralow-permeability water-drive reservoir sandstone oil layer, which belongs to the technical field of oil-field development. The method comprises the following steps: analyzing the core sample of the sandstone oil layer, and determining the position, composition and content of secondary minerals in the sandstone oil layer; according to the conditions of the stratum, mixing the output water and injected water in the oil layer with the original output water and injected water of the oil layer, and determining the mixing ratio of oil layer water, which produces secondary minerals with oil layer composition and content, to injected water; and establishing a relation sectional drawing among porosity, permeability, oil saturation, watered-out degree and secondary mineral content of the sandstone oil layer, and determining the watered-out degree of the oil layer injected water. The evaluation analysis result provided by the invention can reflect the actual watered-out degree of the analyzed oil layer, prevents one oil layer from producing multiple watered-out degrees, and lays a firm foundation for determining the principal digging direction and technique for oil-field development adjustment.

Owner:PETROCHINA CO LTD

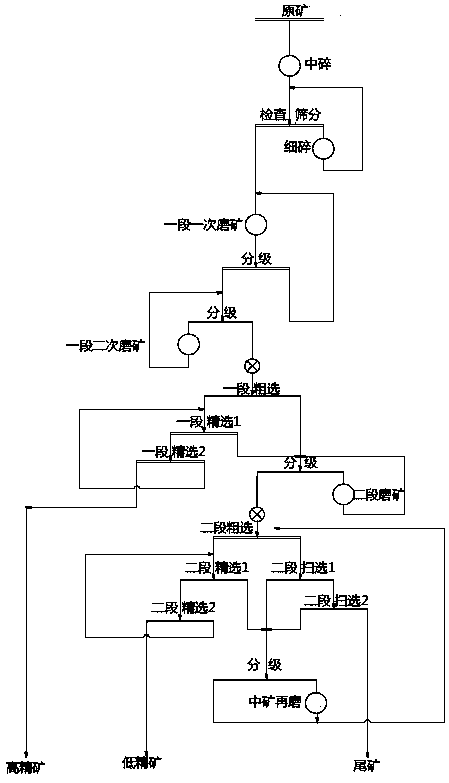

High copper-to-nickel-ratio mineral flotation method

ActiveCN107234006AMeet the requirements of Express Selection and Early HarvestImprove efficiencyFlotationWet separationMineral flotationSlurry

The invention discloses a high copper-to-nickel-ratio mineral flotation method. The high copper-to-nickel-ratio mineral flotation method comprises the following steps of A, pretreatment of raw materials, and A.2, mineral grinding for grading; A.2.1, primary mineral grinding; A.3, powder adding, slurry mixing and stirring; B.1, the primary rough concentration process; B.2, primary first-time concentrating; B.3, primary second-time concentrating; C, the secondary rough concentration process, and C.1, secondary mineral grinding; C.3, the secondary rough concentration process; C.4, secondary one-time concentrating; C.5, secondary second-time concentrating; C.6, secondary one-time scavenging; C.7, secondary second-time scavenging; and D.1, graded regrinding of part products in the secondary process. According to the high copper-to-nickel-ratio mineral flotation method, the mineral processing process is adopted, the fine grinding and concentrating operation efficiency is strengthened, and the requirement for quick selection and early collecting of copper nickel is met; after implementation, the copper recovering rate of high copper-to-nickel-ratio sulfide copper-nickel mineral is improved by about 1% or more, the copper concentrate grade is improved by about 0.5%, and the copper metal output amount is obviously improved. What's more, an economical and applicable beneficiation method is provided for sorting same-class joined and accompanied mineral, and the high application and popularization value is achieved.

Owner:JINCHUAN GROUP LIMITED

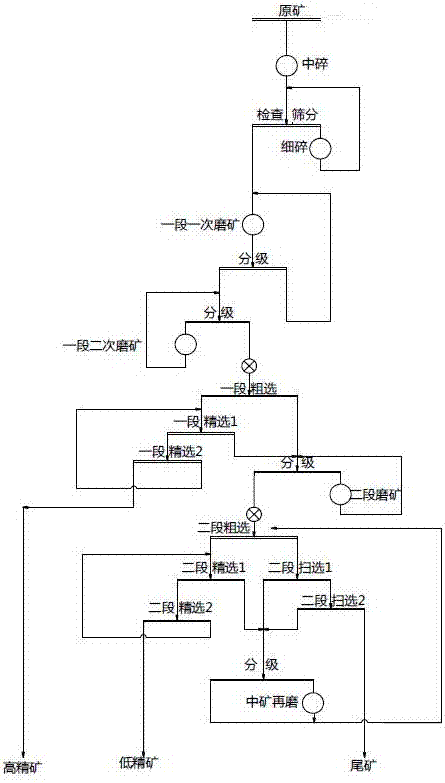

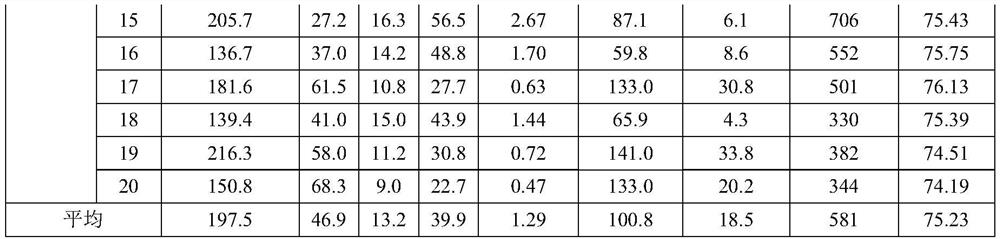

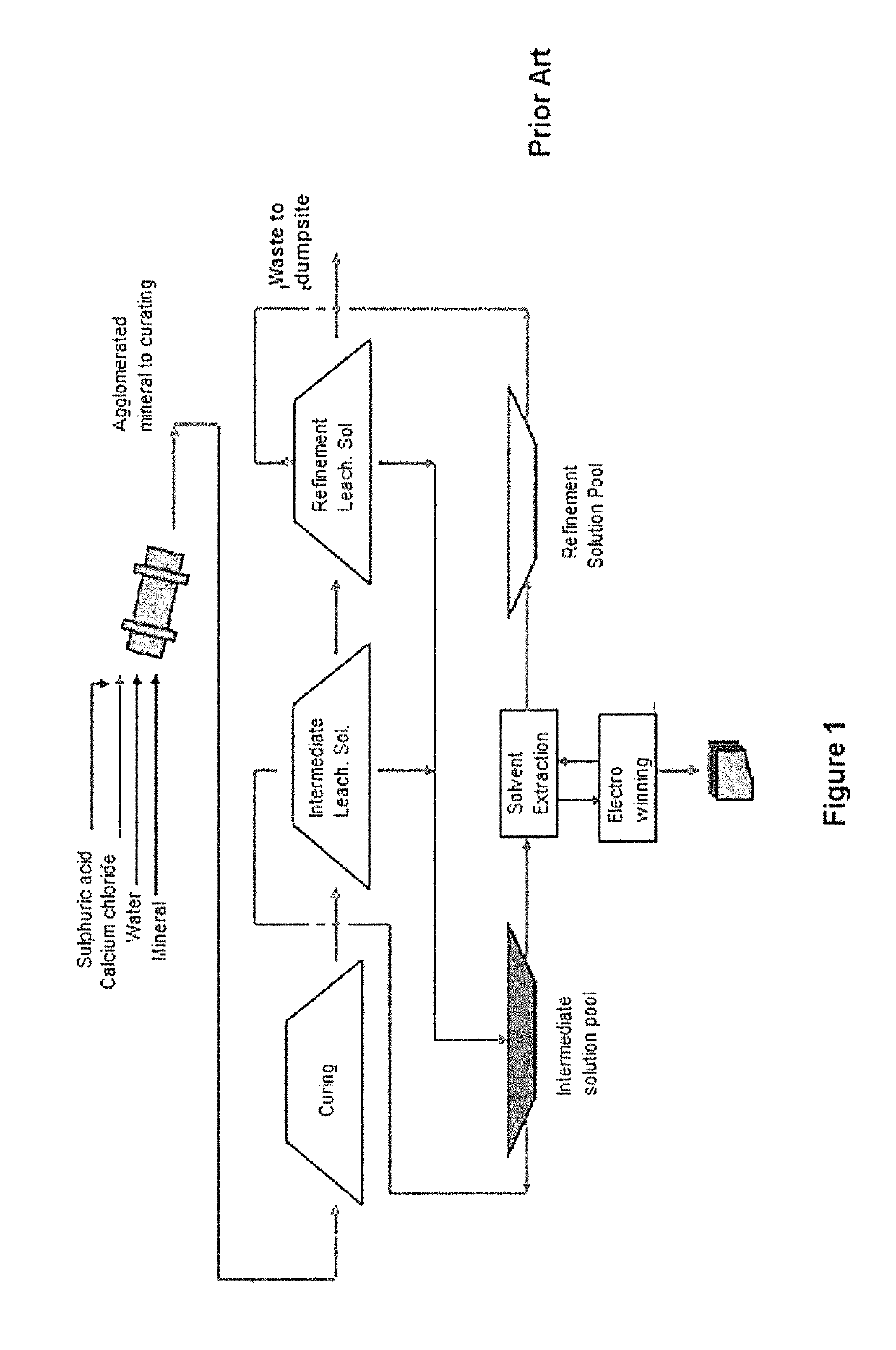

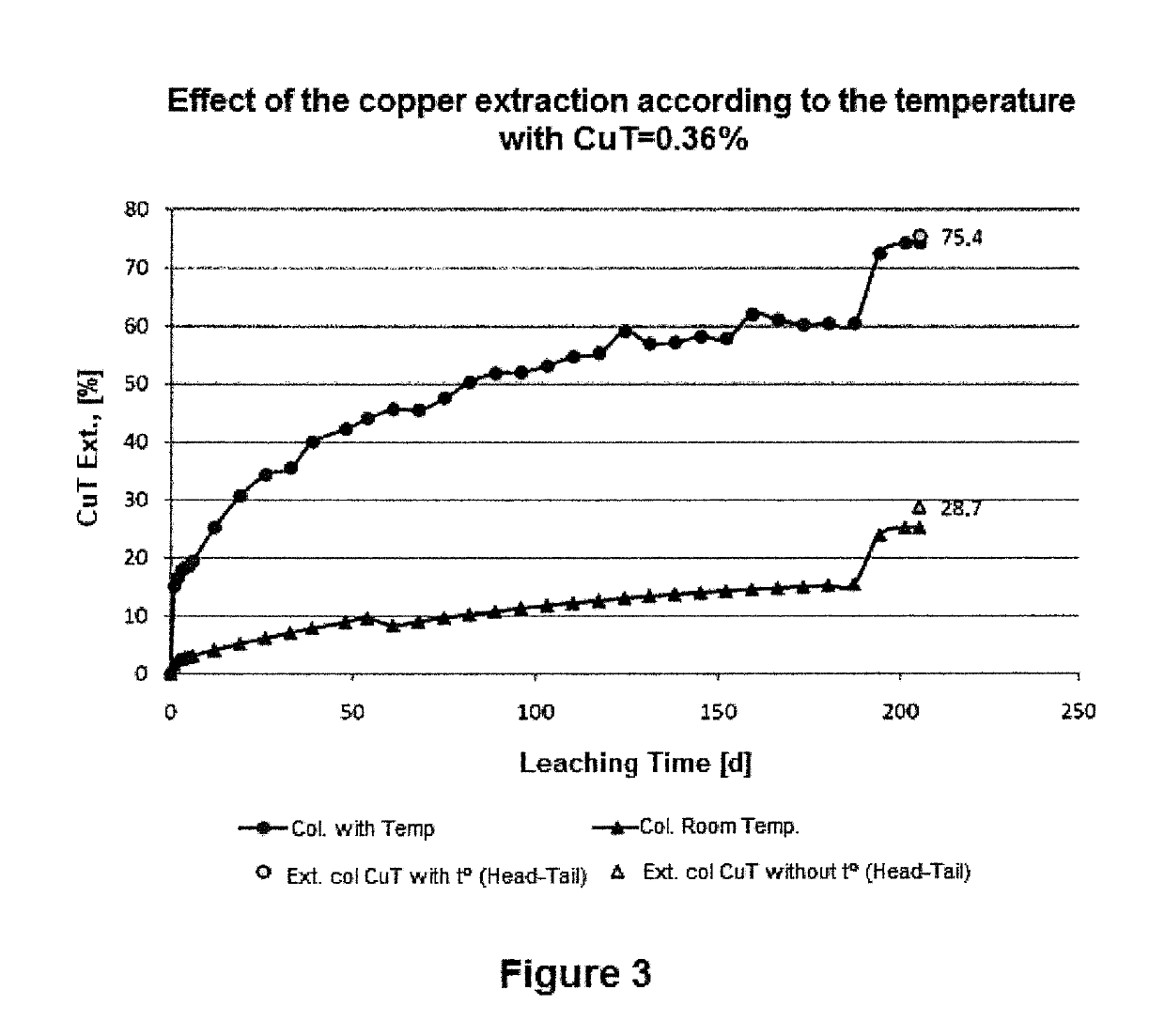

Process For the Improvement of Copper Leaching Processes Using Calcium Chloride

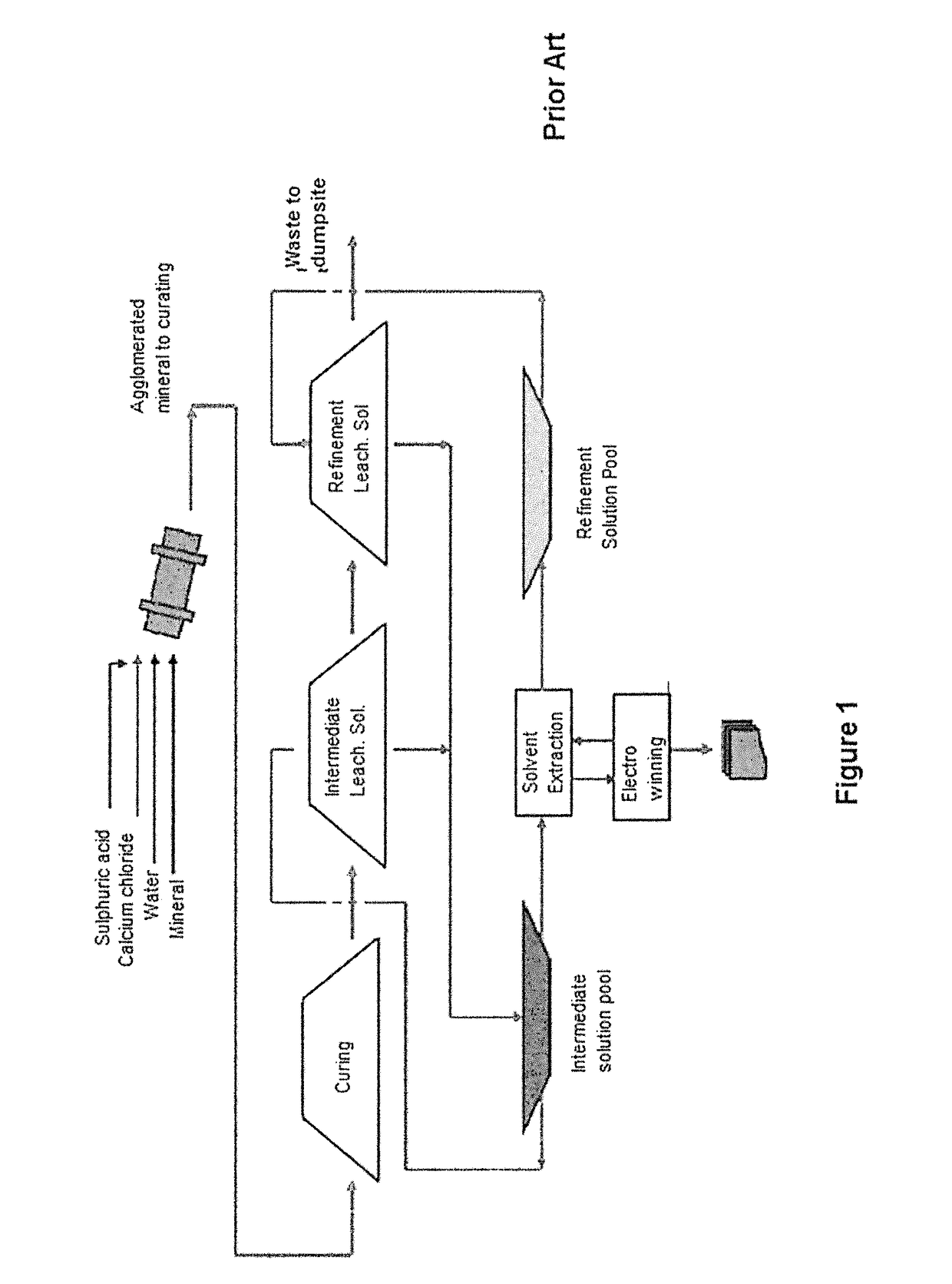

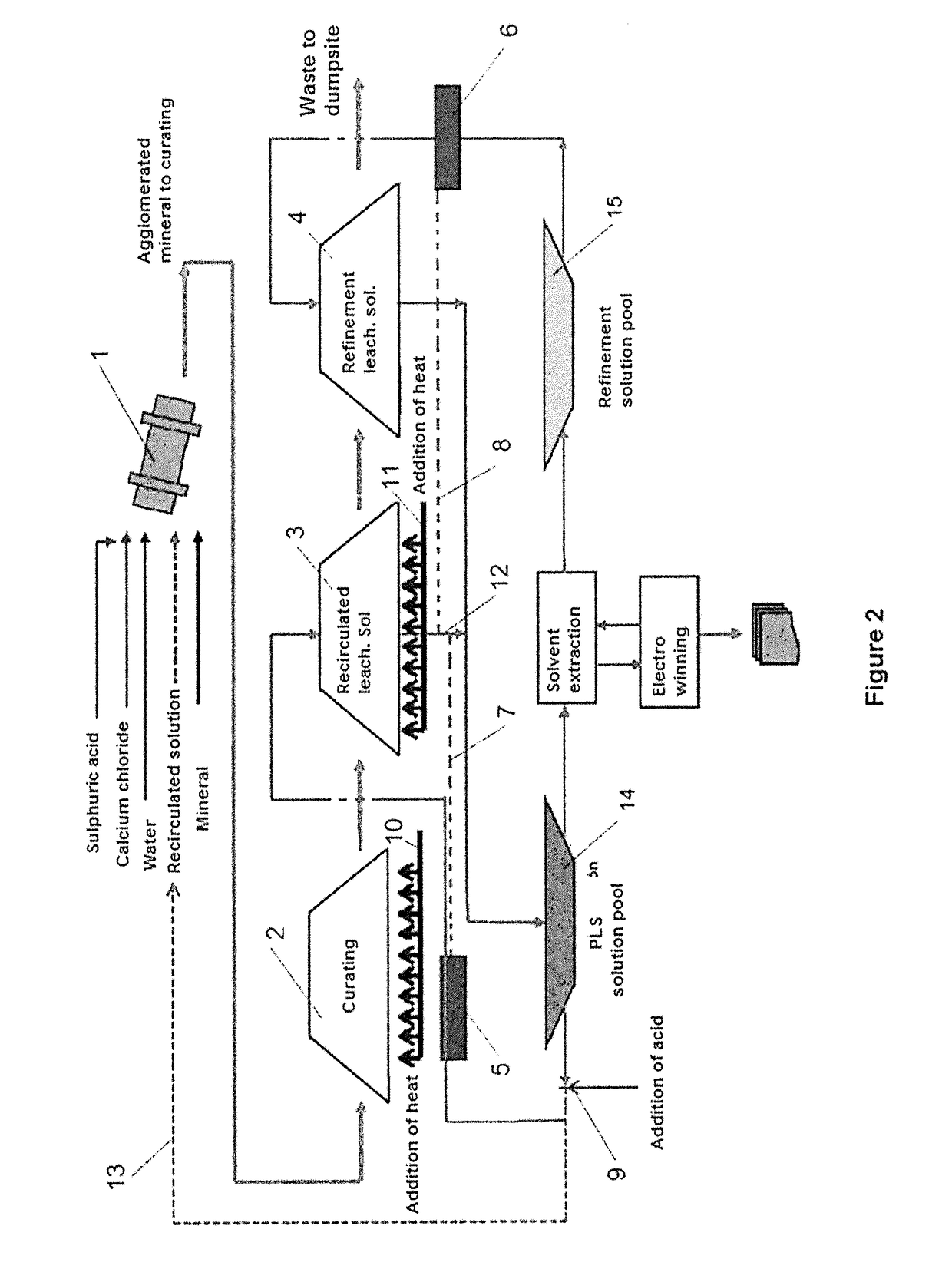

A process to significantly improve the copper chemical leaching process for primary and secondary minerals, using calcium chloride including the agglomeration, curing, and leaching with a high content of chloride, iron and copper stages. The mineral is then washed with a low concentration of copper and a high concentration of acid, where the impregnated copper is extracted from the pit and wherein a recirculated solution is used in the agglomeration stage.

Owner:ANTOFAGASTA MINERALS SA

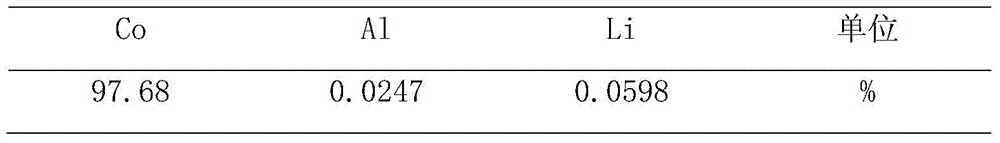

Recycling method of positive and negative electrode residues of waste lithium cobaltate lithium ion battery

ActiveCN104593606BNo secondary pollutionLow costWaste accumulators reclaimingProcess efficiency improvementFiltrationSecondary mineral

The invention discloses a method for recycling positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries. By combing technologies such as high-speed impact crushing, vibration screening, anaerobic atmospheric roasting, wet-type magnetic separation and temperature-variable filtration, products such as elemental cobalt, lithium carbonate and graphite powder are prepared from the positive-negative electrode defective materials of waste lithium waste lithium cobalt oxide lithium-ion batteries; the materials are separated and enriched in such manners as high-speed impact crushing, vibration screening and wet-type magnetic separation, the original physical properties of the materials are retained, the negative electrode graphite material is fully utilized, the in-situ preparation of resources is achieved and the cost is saved; the anaerobic atmospheric roasting is adopted, the reaction conditions are relatively loose, the graphite material loss is decreased, the flow is simplified, any chemical agent is not needed in the entire process, no secondary pollution is caused and the industrial application practice is facilitated. By the method, the problem of pollution-free treatment of leftover material generated in the manufacturing of the lithium-ion batteries for battery manufacturers is solved and meanwhile, a method for mining secondary mineral, namely, a cobalt resource is provided.

Owner:SHANGHAI JIAO TONG UNIV

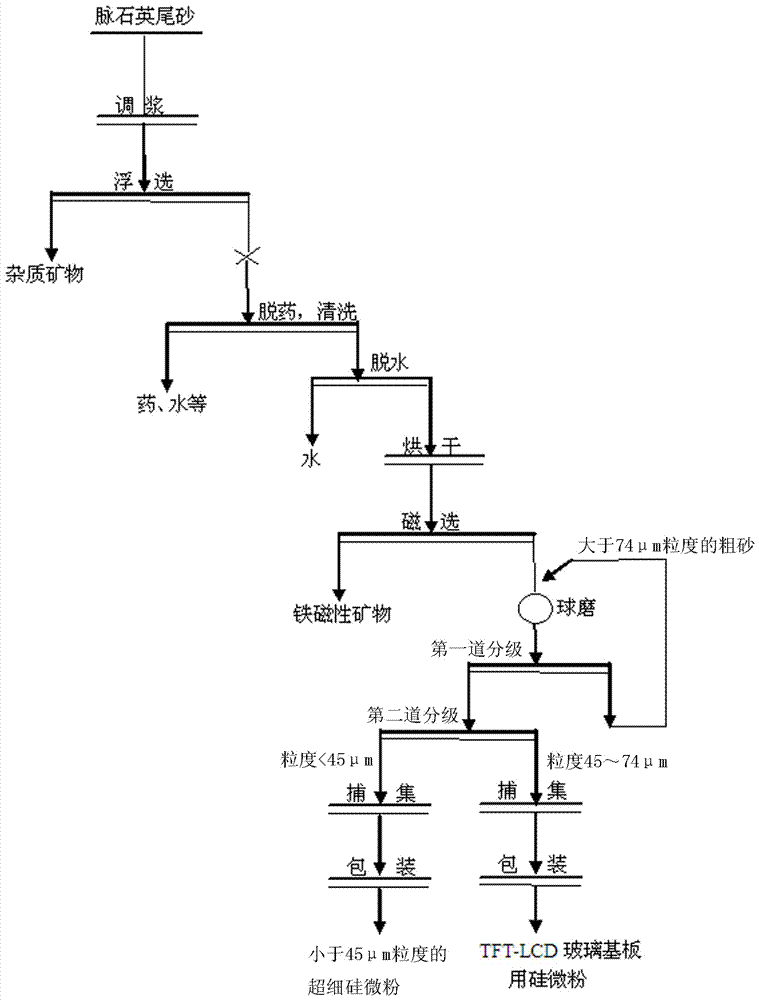

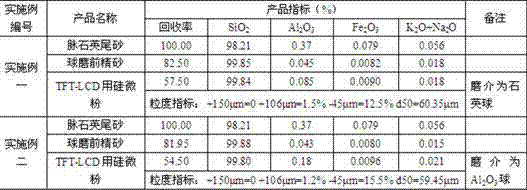

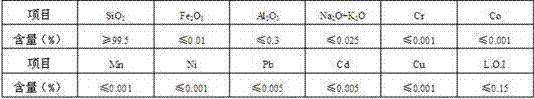

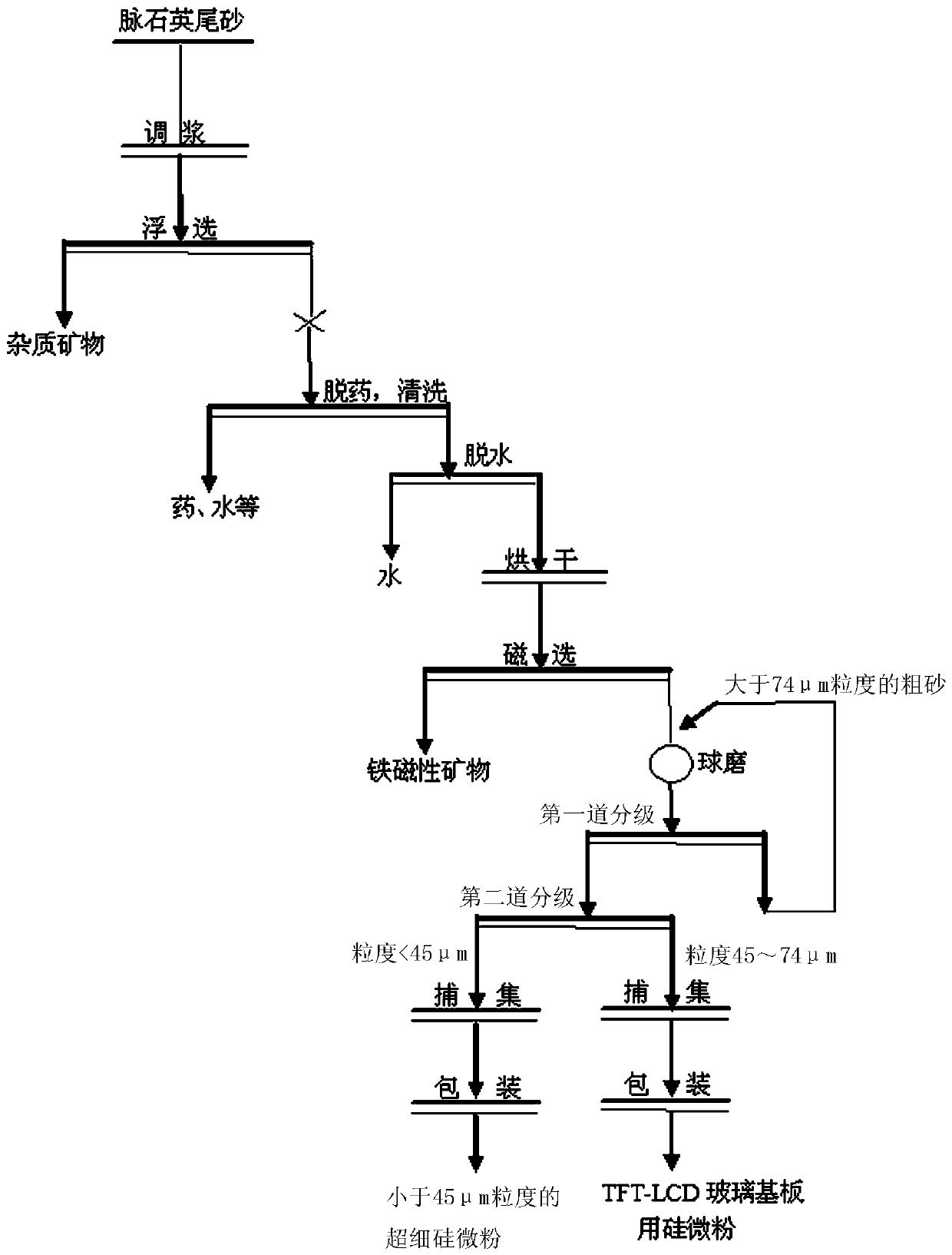

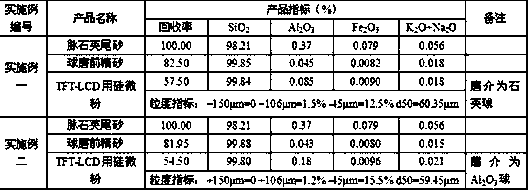

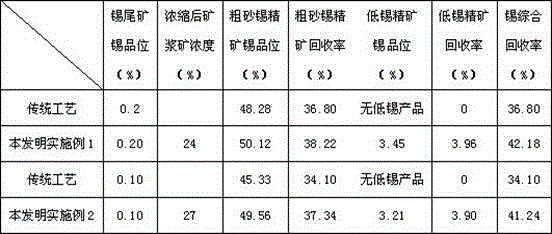

Method for preparing TFT-LCD silicon micro powder through vein quartz tailings

The invention discloses a method for preparing TFT-LCD silicon micro powder through vein quartz tailings. The method comprises the steps of S1, preparing pulp, wherein the quartz tailings are sent into a pulp preparing bucket, and an anion-cation mixed collecting agent and industrial grade H2SO4 are added into the pulp preparing bucket to prepare the pulp; S2, conducting flotation, wherein impurity minerals which floats in the form of foams are removed; S3, agent removing, wherein agent water in mortar after flotation is removed through a screw sand washer; S4, washing, wherein water is added into the mortar after agent removing to be cleaned; S5, dehydrating; S6, drying; S7, magnetic separation, wherein ferromagnetic minerals are further removed; S8, ball grinding and classification, wherein fine sand after treatment in the step S7 is sent into a non-mineral ball grinding machine for mineral grinding, meanwhile, two classifiers are adopted in sequence for classification, coarse sand which is classified by the first classifier and is bigger than 74 micrometers in particle size is returned to the non-mineral ball grinding machine for secondary mineral grinding, fine sand which is classified by the second classifier and is smaller than 45 micrometers in particle size is cut off, and therefore the TFT-LCD silicon micro powder of which the particle size is 45-74 micrometers is obtained.

Owner:凯盛石英材料(黄山)有限公司 +1

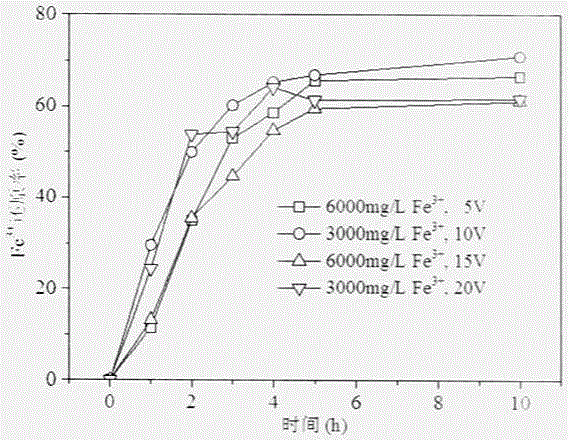

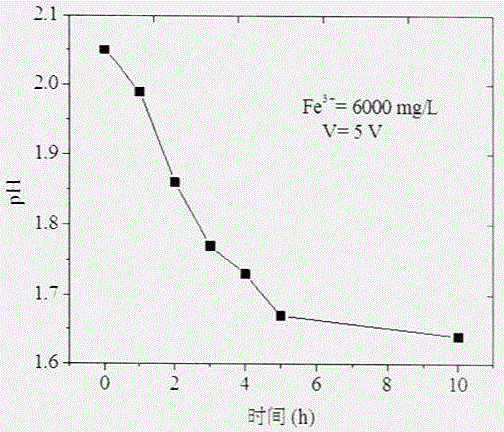

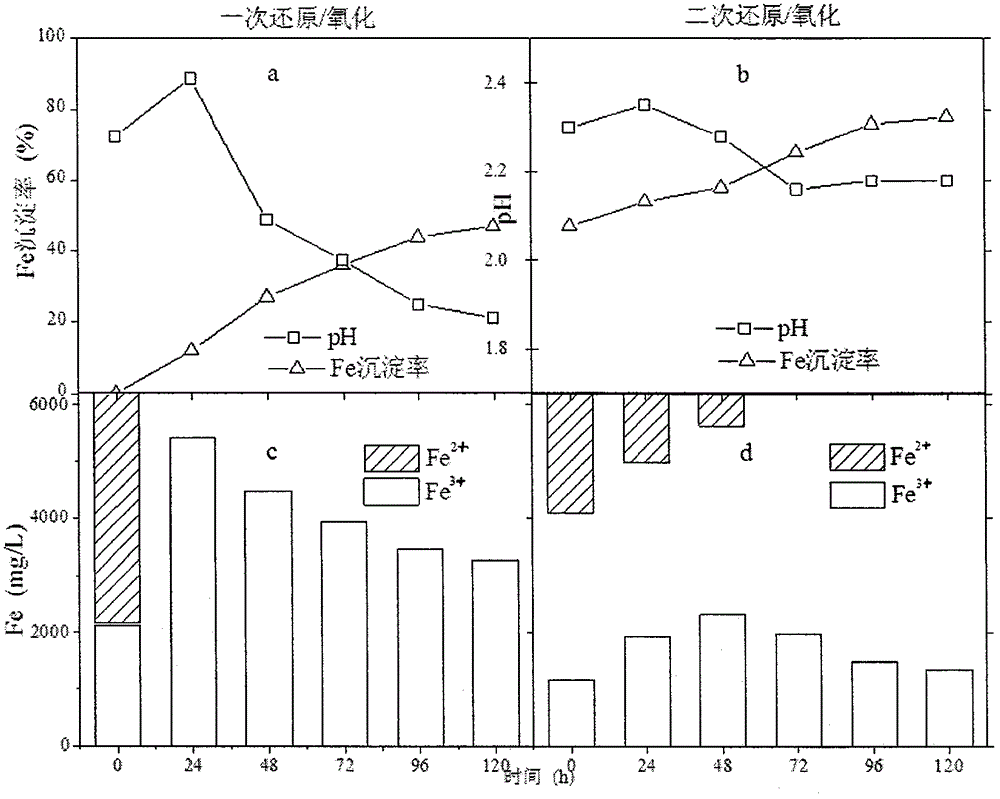

Method for high-efficiency precipitation of soluble iron in acid mine drainage

InactiveCN103910466ALow costLarge specific surface areaMultistage water/sewage treatmentLow voltageSecondary mineral

The invention relates to a method for high-efficiency precipitation of soluble iron in acid mine drainage, belonging to the field of environment engineering technology. The method comprises the following steps: electrolyzing acid mine drainage rich in iron ions at a low voltage and allowing most trivalent iron ions to be reduced into divalent iron ions through gain and loss of electrons; and then oxidizing divalent iron ions by using acidithiobacillus ferrooxidans so as to produce a ferric hydroxysulfate mineral with good settleability and compact particles. After secondary reduction and secondary mineral formation, the total iron precipitation rate is increased to almost 80%. The method promotes removal of soluble iron and does not introduce other chemical components, and the obtained secondary mineral has good settleability. Compared with technology of the same kind, the method provided by the invention is more superior and has the advantages of low cost, safety, reliability, energy conservation and environment friendliness, and moreover, the secondary mineral can be used as an adsorption material for resourceful utilization.

Owner:NANJING AGRICULTURAL UNIVERSITY

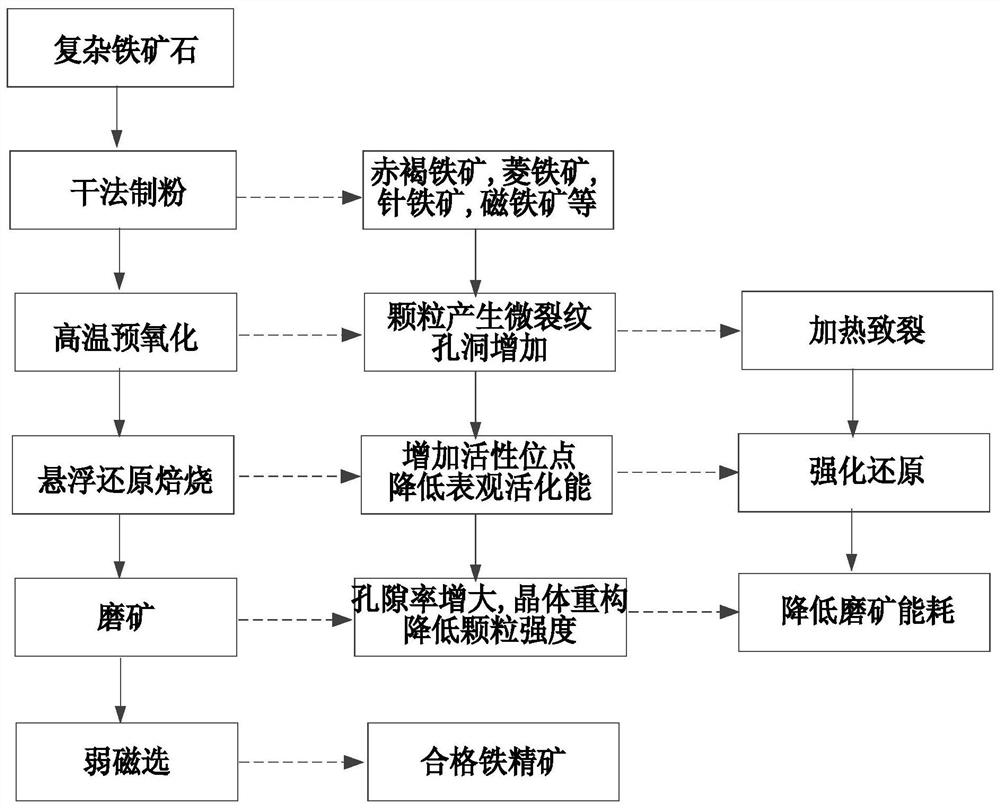

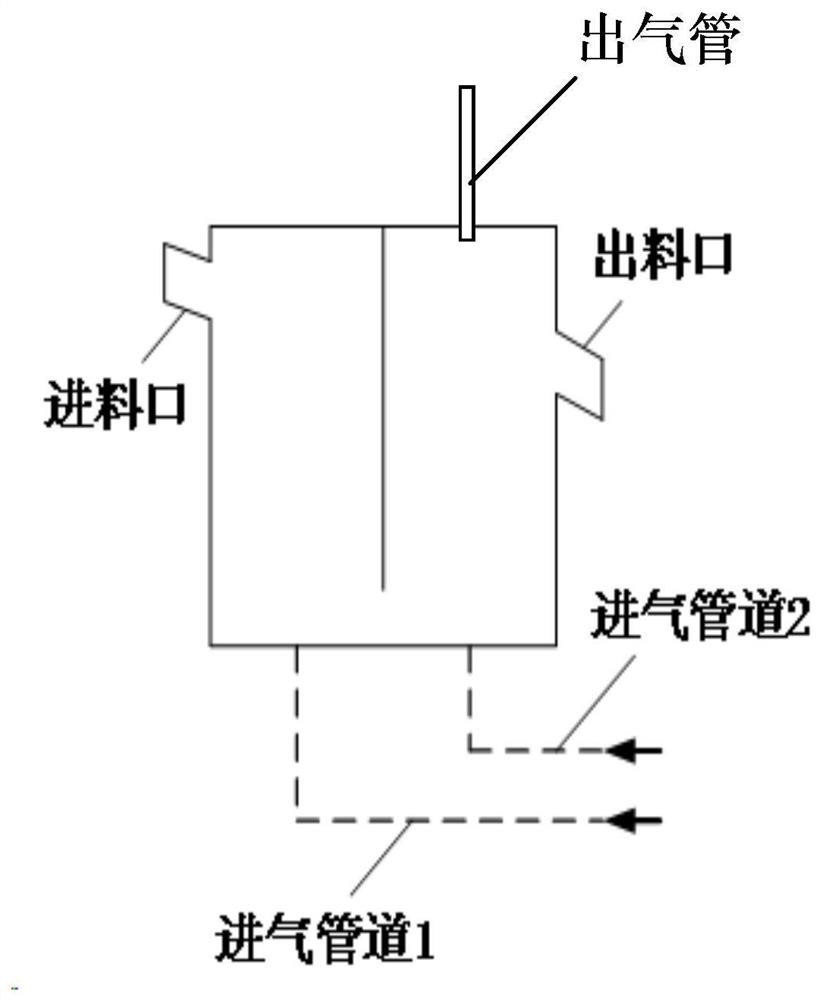

Method for strengthening reduction roasting based on heating cracking of iron-containing material

ActiveCN111632757AEfficient separationAdd reactive sitesMagnetic separationAir atmosphereReaction rate

The invention discloses a method for strengthening reduction roasting based on heating cracking of an iron-containing material. The method comprises the following steps of: (1) crushing and grinding the iron-containing material into mineral powder; (2) conveying the mineral powder to a pre-oxidation roasting furnace, heating the mineral powder in a suspension state for pre-oxidation roasting, andthen enabling the mineral powder to enter a cyclone separator; (3) performing discharging into a heat storage reduction roasting furnace through cyclone separation, and carrying out reduction roastingwith reducing gas in a suspension state; (4) conveying the reduced material to a primary cooling cyclone separator, carrying out cyclone separation under a nitrogen atmosphere condition, and performing cooling to 200-300DEG C; (5) feeding the cooled and reduced material into a secondary cooling cyclone separator through a flow sealing valve, carrying out cyclone separation in an air atmosphere, and carrying out reoxidation reaction; and (6) grinding the re-oxidized material to prepare secondary mineral powder; and performing low intensity magnetic separation. According to the method, the reaction active sites of iron minerals are increased, the reaction rate is increased, and the apparent activation energy of the reduction reaction is reduced, so that the reduction effect is enhanced.

Owner:NORTHEASTERN UNIV

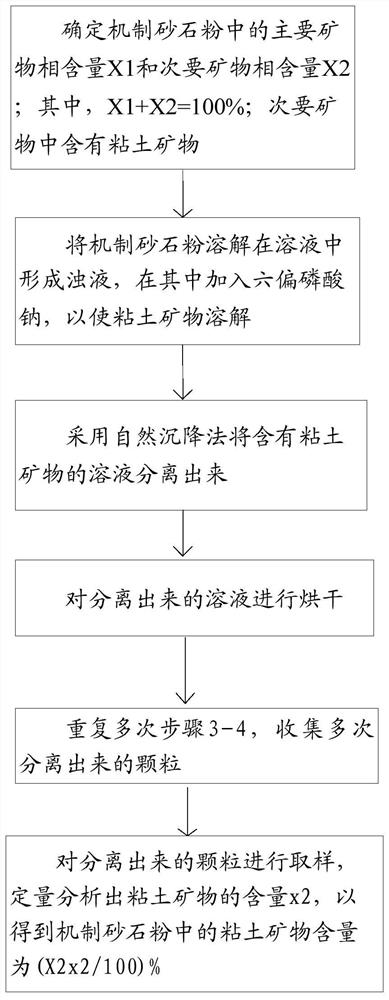

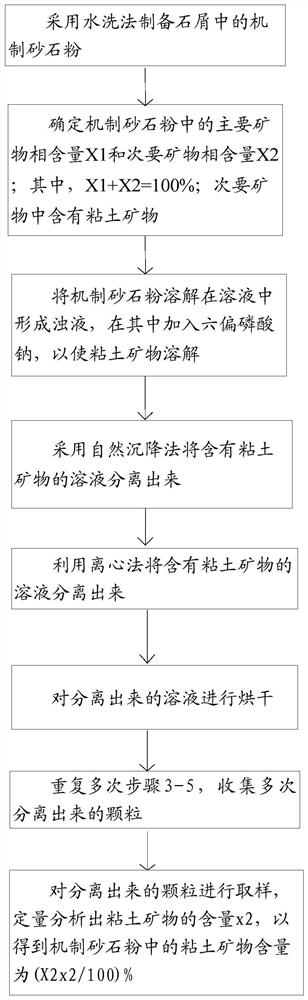

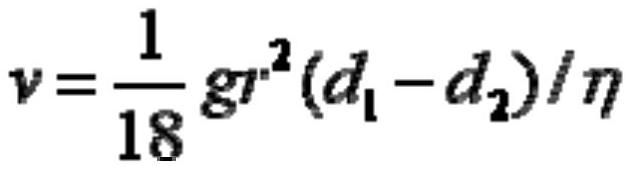

Method for separation and content determination of clay particles

PendingCN112284990ANot easy to cause misjudgmentIndividual particle analysisMaterial analysis using radiation diffractionClay mineralsPhysical chemistry

The invention provides a method for separation and content determination of clay particles, and relates to the technical field of particle number measurement. The method for separation and content determination of clay particles comprises the following steps of: determining the content X1 of a main mineral phase and the content X2 of a secondary mineral phase in machine-made sandstone powder; dissolving machine-made sandstone powder in the solution to form turbid liquid, and dissolving clay minerals; separating out a solution containing clay minerals by adopting a natural sedimentation method;drying the separated solution; repeating the separation steps for multiple times, and collecting particles separated for multiple times; and quantitatively analyzing the content x2 of the clay minerals, so as to obtain the content (X2x2 / 100)% of the clay minerals in the machine-made sandstone powder. According to the method, particles smaller than 5 micrometers can be extracted through adopting anatural sedimentation method, meanwhile, the content of the clay minerals processed through a quantitative analysis method is measured, the accuracy degree can reach 80%-90%, and therefore the content of the clay particles in the machine-made sand can be separated and measured more accurately, and misjudgment is not likely to be caused.

Owner:CHINA FIRST HIGHWAY ENG +1

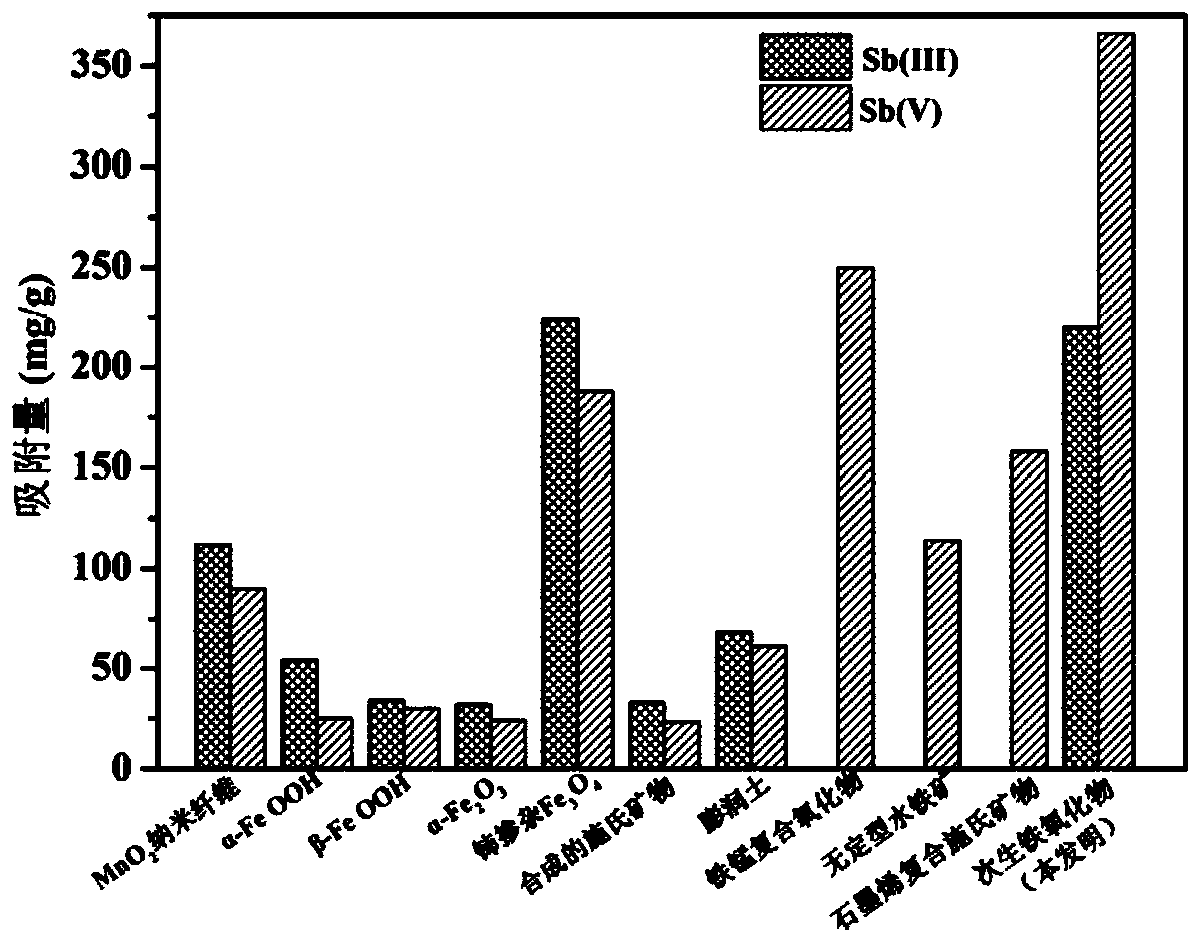

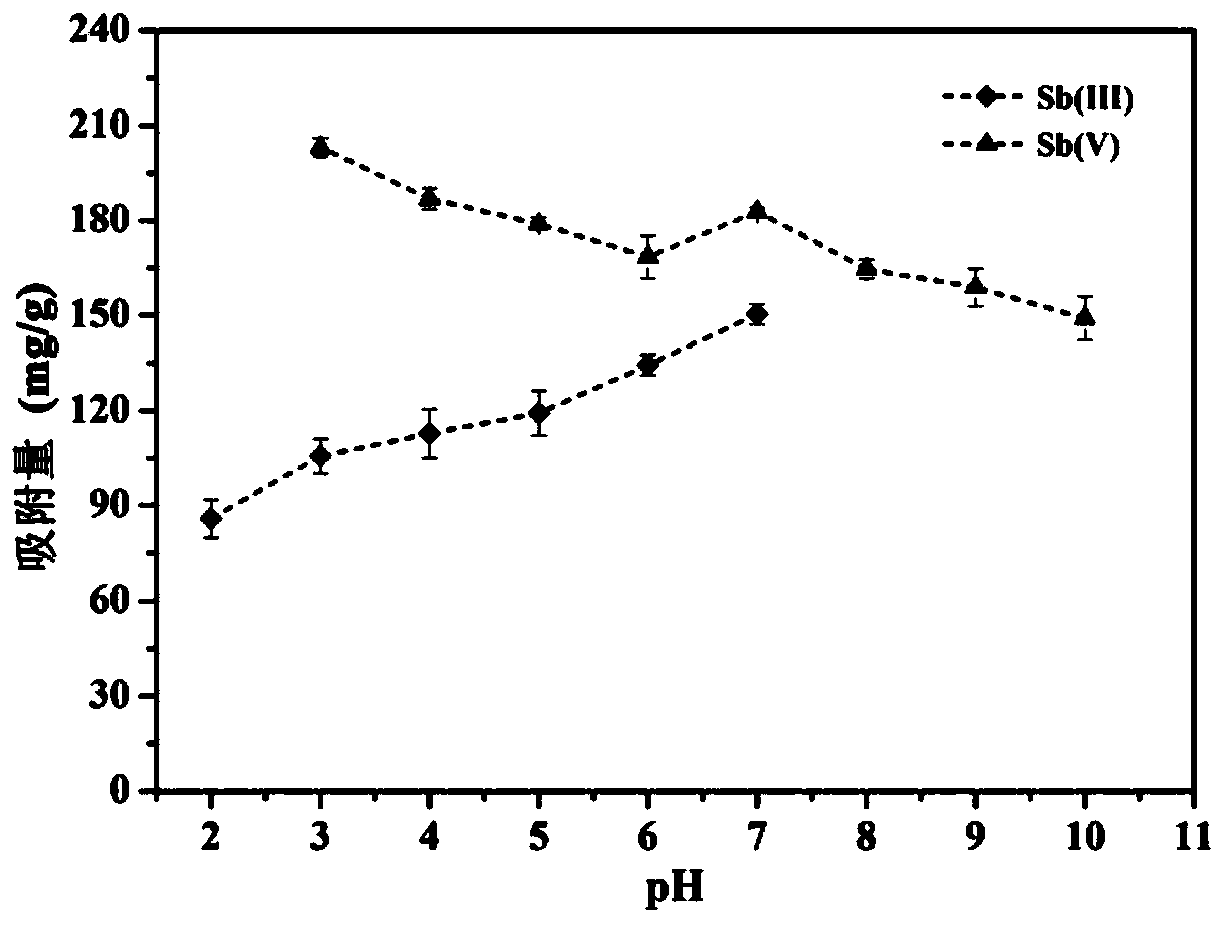

Method for removing antimony in wastewater

ActiveCN110642324AEfficient removalImprove adsorption capacityWater contaminantsWater/sewage treatment by sorptionIron sulfateSorbent

The invention provides a method for removing antimony in wastewater, and belongs to the field of water treatment. According to the method for removing antimony from waste water, an initially generatedsecondary iron oxide is used as an adsorbent to remove antimony. The initially generated secondary iron oxide is an iron oxide generated from acid waste water of coal mine, is shaped like yellow-brown grains, and has a pore structure inside, and main composition elements of the initially generated secondary iron oxide are Fe, S, O and H. The initially generated secondary iron oxide is an iron sulfate secondary mineral with not toxicity or harm, so that secondary pollution caused by an adsorbent is avoided. The adsorption quantity of the initially generated secondary iron oxide on Sb (III) canbe up to 219.78 mg / g, and the adsorption quantity of the initially generated secondary iron oxide on Sb (V) can be up to 366.30 mg / g, so that antimony ions in the wastewater can be effectively removed. In addition, the method is low in cost, waste is changed into treasure, and the method accords with the environment protection strategy of treating waste by waste, and has important social and economic significance.

Owner:GUANGZHOU UNIVERSITY

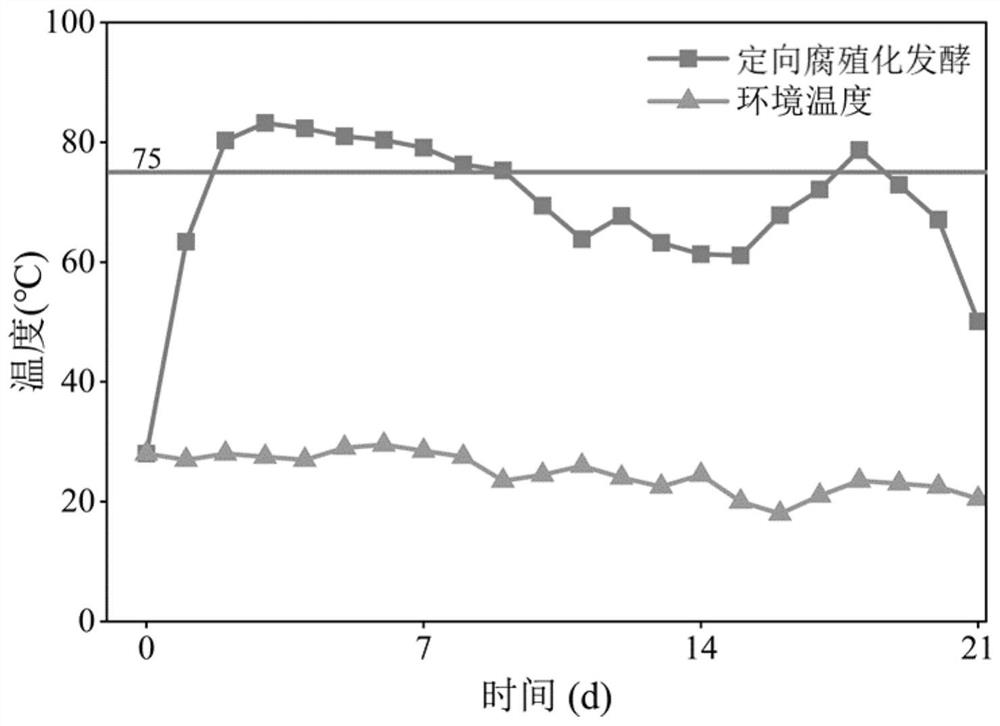

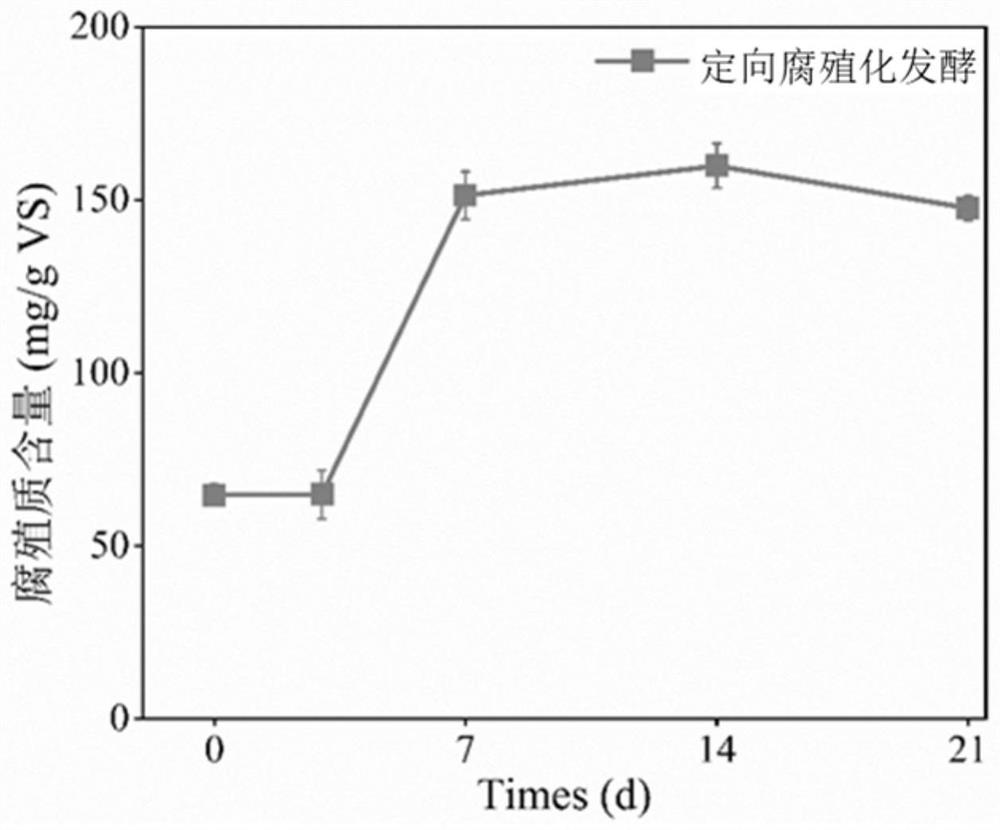

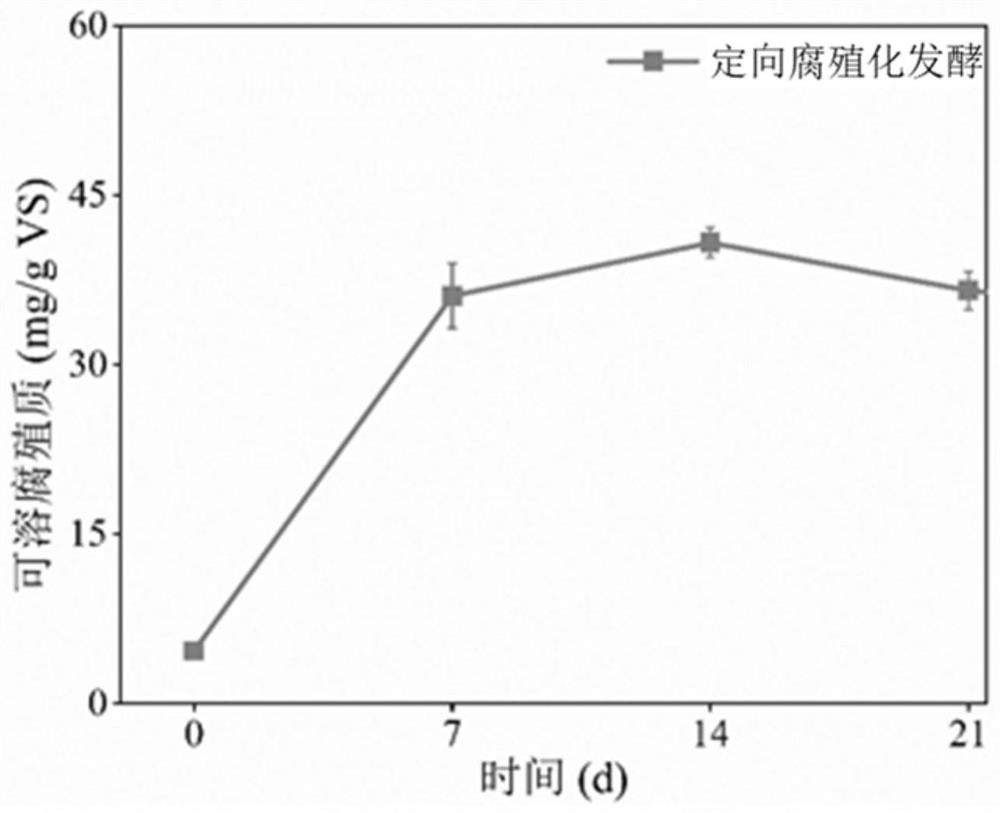

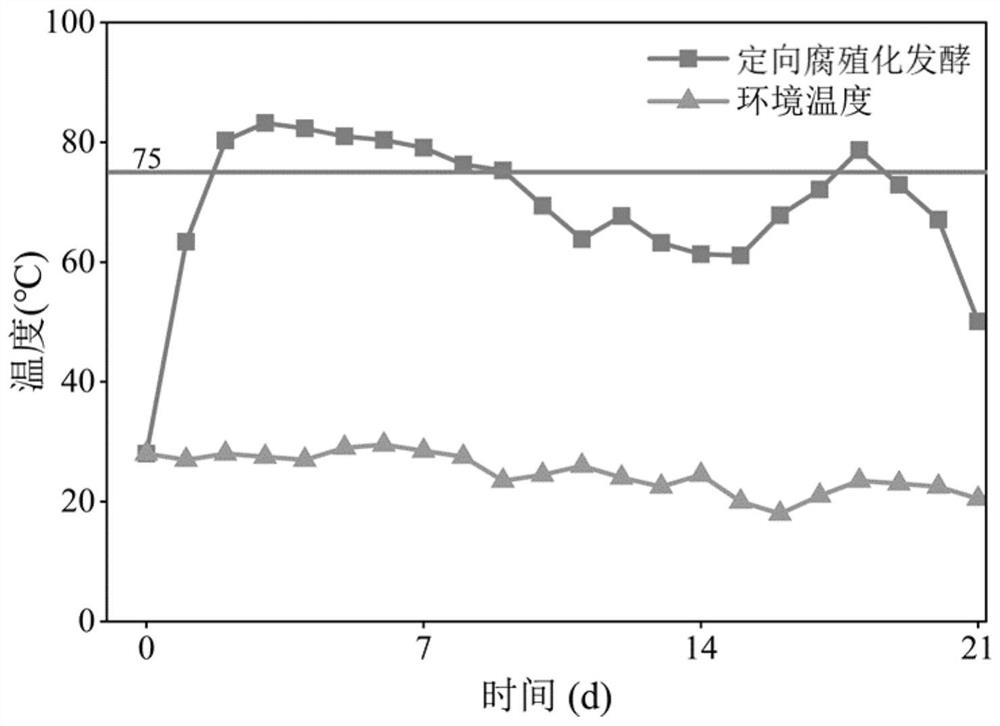

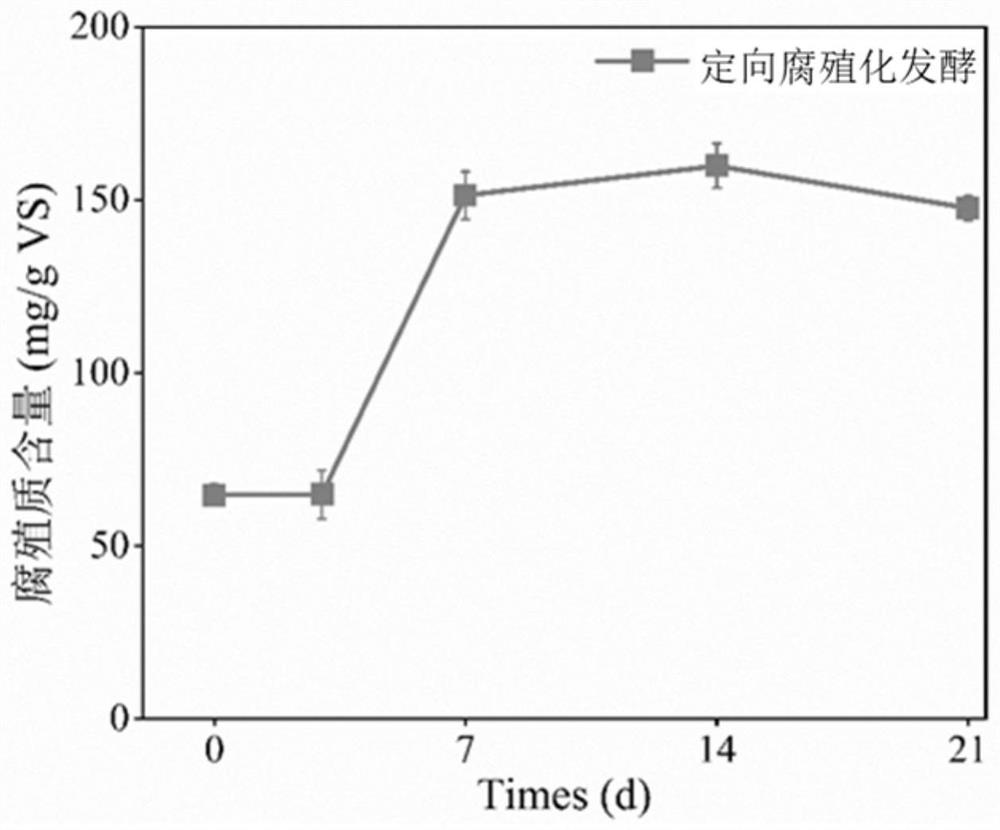

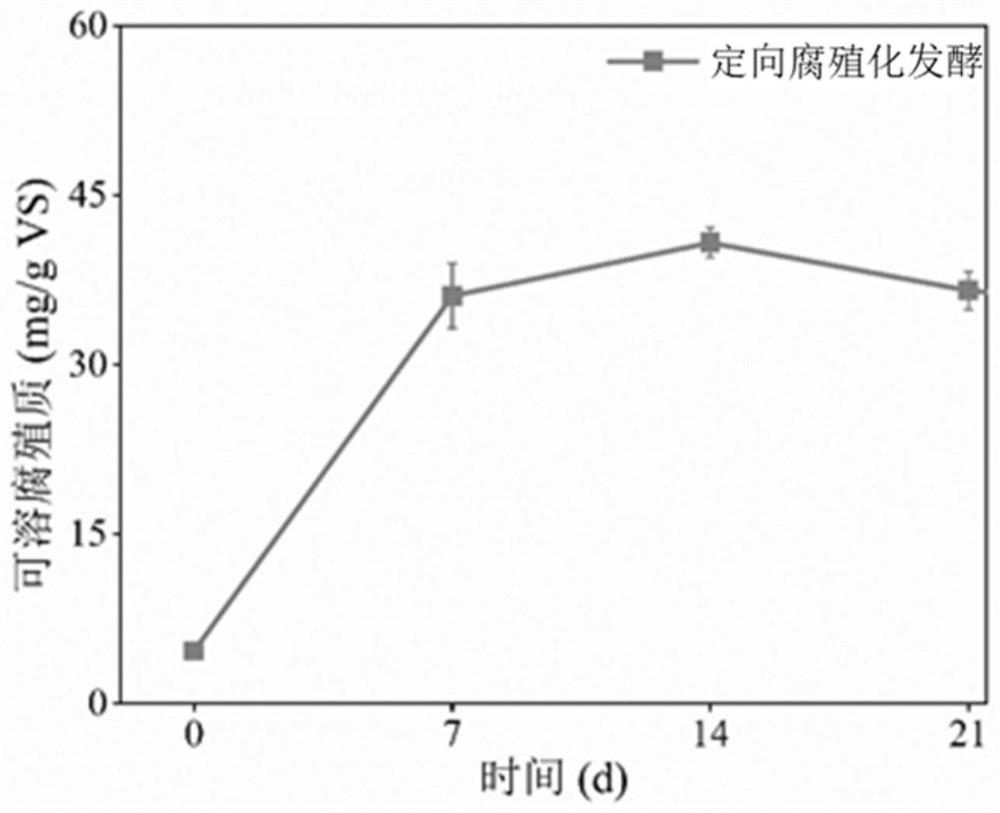

Method for controlling mine heavy metal flushing pollution by using humification product

ActiveCN113578954AHarmlessAchieve reductionWaste water treatment from quariesBio-organic fraction processingSludgeHumin

The invention discloses a method for controlling mine heavy metal flushing pollution by using a humification product, which comprises the steps of (1) carrying out mixed fermentation on sludge and extreme thermophilic strains to promote generation of polar humification groups, and then carrying out mixed fermentation on the fermented materials and primary substances of humus precursors to induce generation of a large amount of humus, until the humus content reaches the standard requirement; and (2) mixing and maintaining the sludge humification product reaching the standard and the heavy metal polluted mine soil, and repairing the polluted mine. According to the invention, the humification product is used for absorbing and enriching heavy metal polluted on the surface layer of the mine, complexing of copper, cadmium, chromium, lead, nickel, arsenic and zinc can be increased by 20-85%, the remarkable heavy metal absorbing and enriching effect is achieved, after the humification product enriches the heavy metal, the heavy metal is induced to migrate on primary mineral of the mine and mineralized to generate secondary mineral, and free heavy metals are fixed on the primary mineral, so that the problem of heavy metal flushing pollution of the mine is effectively solved.

Owner:TONGJI UNIV

A kind of method utilizing vein quartz tailings to prepare tft-lcd silica powder

The invention discloses a method for preparing TFT-LCD silicon micro powder through vein quartz tailings. The method comprises the steps of S1, preparing pulp, wherein the quartz tailings are sent into a pulp preparing bucket, and an anion-cation mixed collecting agent and industrial grade H2SO4 are added into the pulp preparing bucket to prepare the pulp; S2, conducting flotation, wherein impurity minerals which floats in the form of foams are removed; S3, agent removing, wherein agent water in mortar after flotation is removed through a screw sand washer; S4, washing, wherein water is added into the mortar after agent removing to be cleaned; S5, dehydrating; S6, drying; S7, magnetic separation, wherein ferromagnetic minerals are further removed; S8, ball grinding and classification, wherein fine sand after treatment in the step S7 is sent into a non-mineral ball grinding machine for mineral grinding, meanwhile, two classifiers are adopted in sequence for classification, coarse sand which is classified by the first classifier and is bigger than 74 micrometers in particle size is returned to the non-mineral ball grinding machine for secondary mineral grinding, fine sand which is classified by the second classifier and is smaller than 45 micrometers in particle size is cut off, and therefore the TFT-LCD silicon micro powder of which the particle size is 45-74 micrometers is obtained.

Owner:凯盛石英材料(黄山)有限公司 +1

A method for recovering tin from fine-grained low-grade secondary tailings

The invention discloses a tin reclaiming method for fine-grain and low-grade secondary mineral tailings. The tin reclaiming method comprises the procedures including front hoisting and tailings throwing, fine silt separating, and the like, wherein the procedure of front hoisting and tailings throwing of secondary mineral tailings comprises the steps of primary screening and classification, primary ore grinding and secondary screening and classification; the procedure of fine silt separating comprises the steps of classification and swirler treatment. According to the invention, separated mineral tailings are classified again, and a swirler is used for desliming, so that the equilibrium quantity and the concentration of ore slurry flowing into a fine silt yun tin shaking bed are ensured, separation of tin and silt slag is improved, the defect that in the traditional process, tin separation is complicated and difficult, the degree of dissociation of tin monomer is poor and the recovery rate is low due to low grade of mineral tailings can be overcome, the separating capability of tin separation is improved, the tin concentrate recovery rate of the shaking bed is improved, and reclaiming and cyclic utilization of waste material are realized.

Owner:广西华锡矿业有限公司再生资源分公司

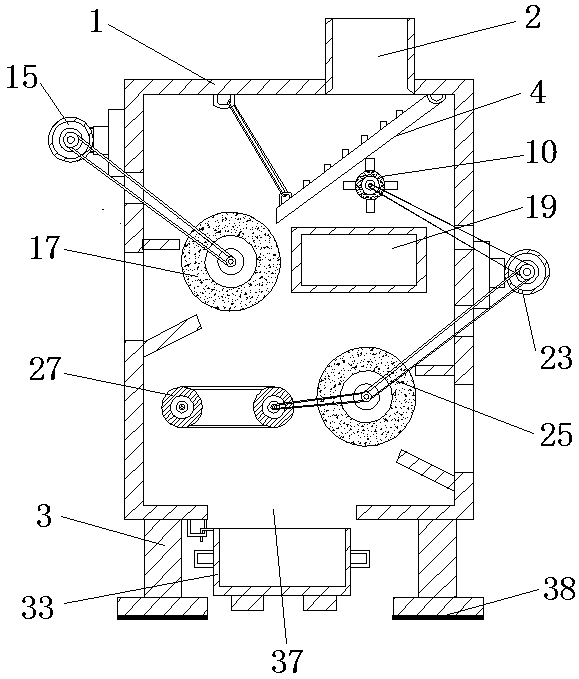

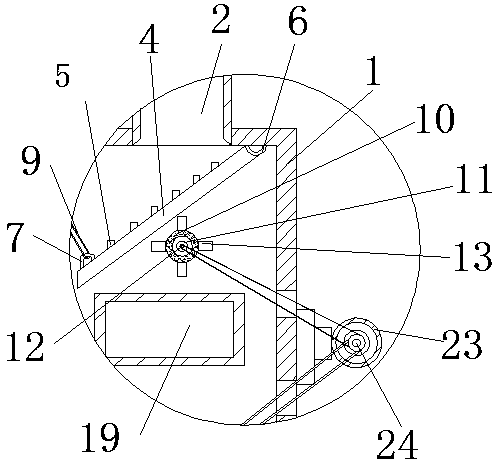

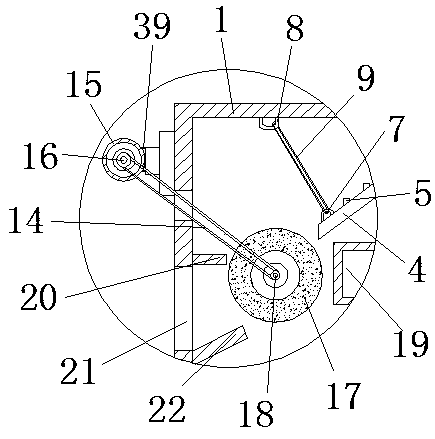

Concentrating machine

InactiveCN109225618ASolve the disadvantages of the need for secondary beneficiationWhereabouts fineMagnetic separationSurface mountingMagnetic separator

The invention discloses a concentrating machine which comprises a box and a feeding port; the feeding port is formed on the top on the right side of the box; a baffle plate is connected with the box through a connecting shaft; a plurality of baffle blocks are arranged on the surface of the baffle plate; a spring is arranged on the bottom of a gasket; a gear rack is arranged on the left side of thebaffle plate; a gear is arranged on the left side of the baffle plate; a rotating rod is arranged on the left side of the gear; a bolt is penetrated through the rotating rod; a slide rail is arrangedon the right side of the baffle plate. In the concentrating machine, the baffle plate and the adjustable baffle blocks are arranged at the feeding port, so that a first magnetic separator is capableof more finely screening ores; a conveyor belt is arranged in the box, is used for conveying the waste ores after primary filtering to a second magnetic separation wheel and is capable of achieving the effect of secondary filtering; the baffle plate and the adjustable baffle blocks in the box can solve the problems of inaccurate sorting and serious waste of ores of other concentrating machines; the second magnetic separation wheel is used for performing secondary filtering, so that the defect of secondary mineral separation required by other concentrating machines can be overcome.

Owner:高伟

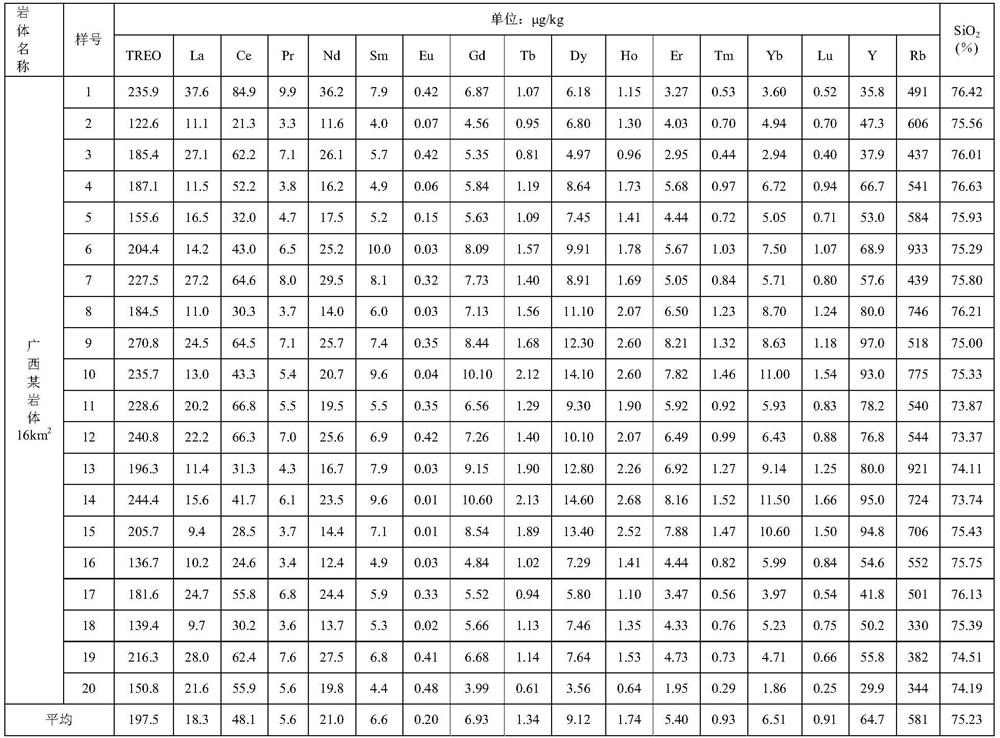

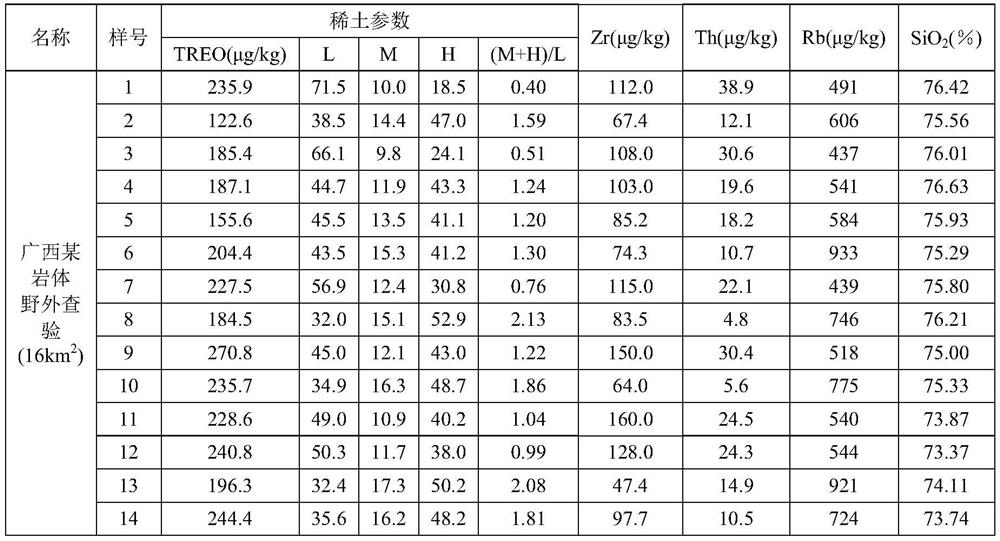

Method for rapidly delineating medium and heavy rare earth prospecting target area in weathering crust model based on geologic body rare earth partition

PendingCN114002410AQuick and easy collectionAvoid composition problemsEarth material testingGeological measurementsMetallogenyRare-earth element

The invention discloses a method for rapidly delineating a medium and heavy rare earth prospecting target area in a weathering crust model based on geologic body rare earth partition, and belongs to the technical field of mineral resource exploration. By collecting and analyzing the rare earth element content of the geologic body, the partition rule of the rare earth elements and the main rare earth carrier secondary mineral characteristics, the medium and heavy rare earth prospecting target area is rapidly determined. According to the method, the occurrence state of the rare earth in the weathering crust and the mineralization potential of the medium and heavy rare earth can be rapidly evaluated only by carrying out a small amount of field verification, a large amount of prospecting cost and manpower investment are saved compared with an existing medium and heavy rare earth target area delineation method, and the method has the advantages of being low in cost, accurate in result, high in efficiency and the like.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Process for recovering plumbum and silver from waste slag of metal smelting

InactiveCN102925922ATake advantage ofReduce wastePhotography auxillary processesProcess efficiency improvementSlagReverberatory furnace

The invention discloses a process for recovering plumbum and silver from waste slag of metal smelting. The smelting waste slag containing the plumbum and the silver is firstly placed into a combustion furnace for high-temperature combustion, smelted plumbum after purified is cast into an anode, dross generated in the furnace is conveyed into a blast furnace, the anode cast by the plumbum is conveyed into an electrolytic bath for further purification, cathodic plumbum is generated in the electrolytic bath, the cathodic plumbum is refined through an electric plumbum pot, and anode mud generated by the electrolytic bath and added bismuth and antimony are together conveyed into a reverberatory furnace for treatment, waste slag containing silver and zinc is conveyed into a cupellation furnace for smelting, the separation of the silver form other impurities is achieved, and obtained coarse silver or alloy containing the silver flows to the bottom of the cupellation furnace. The process for recovering the plumbum and the silver from the waste slag of metal smelting fully utilizes secondary mineral resources, reduces the waste of resources, improves the comprehensive recovery capacity of valuable metal, and ensures environment protection.

Owner:永兴县庚仁银业有限责任公司

Process for the improvement of copper leaching processes using calcium chloride

A process to significantly improve the copper chemical leaching process for primary and secondary minerals, using calcium chloride including the agglomeration, curing, and leaching with a high content of chloride, iron and copper stages. The mineral is then washed with a low concentration of copper and a high concentration of acid, where the impregnated copper is extracted from the pit and wherein a recirculated solution is used in the agglomeration stage.

Owner:ANTOFAGASTA MINERALS SA

Production of magnetic refrigerant material by ferro-manganese mixture

InactiveCN101074358ARich sourcesRaise the possibilityHeat-exchange elementsManganeseSecondary mineral

Production of magnetic refrigerating material by ferro-manganese mixture is carried out by taking nano-secondary mineral with nitrate replacement ferro-manganese structure and mixture of Gd3Ga5012, mixing with excess tartaric acid solution, dewatering, heating by high-temperature air and cooling to obtain final product. It's simple, has various raw material sources and no environmental pollution. It can be used as low-yield filed microelement fertilizer and for modifying sand soil.

Owner:林勋

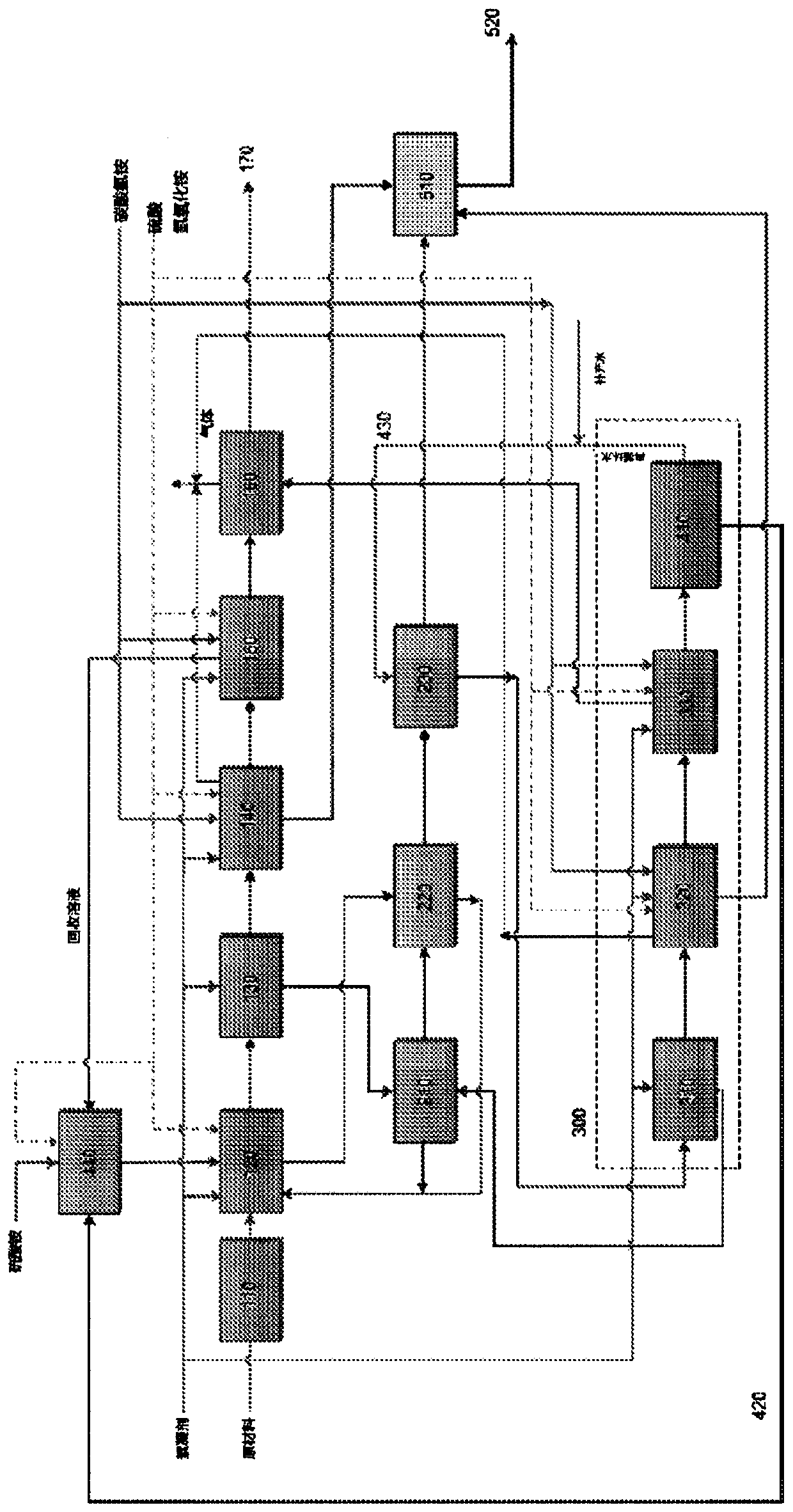

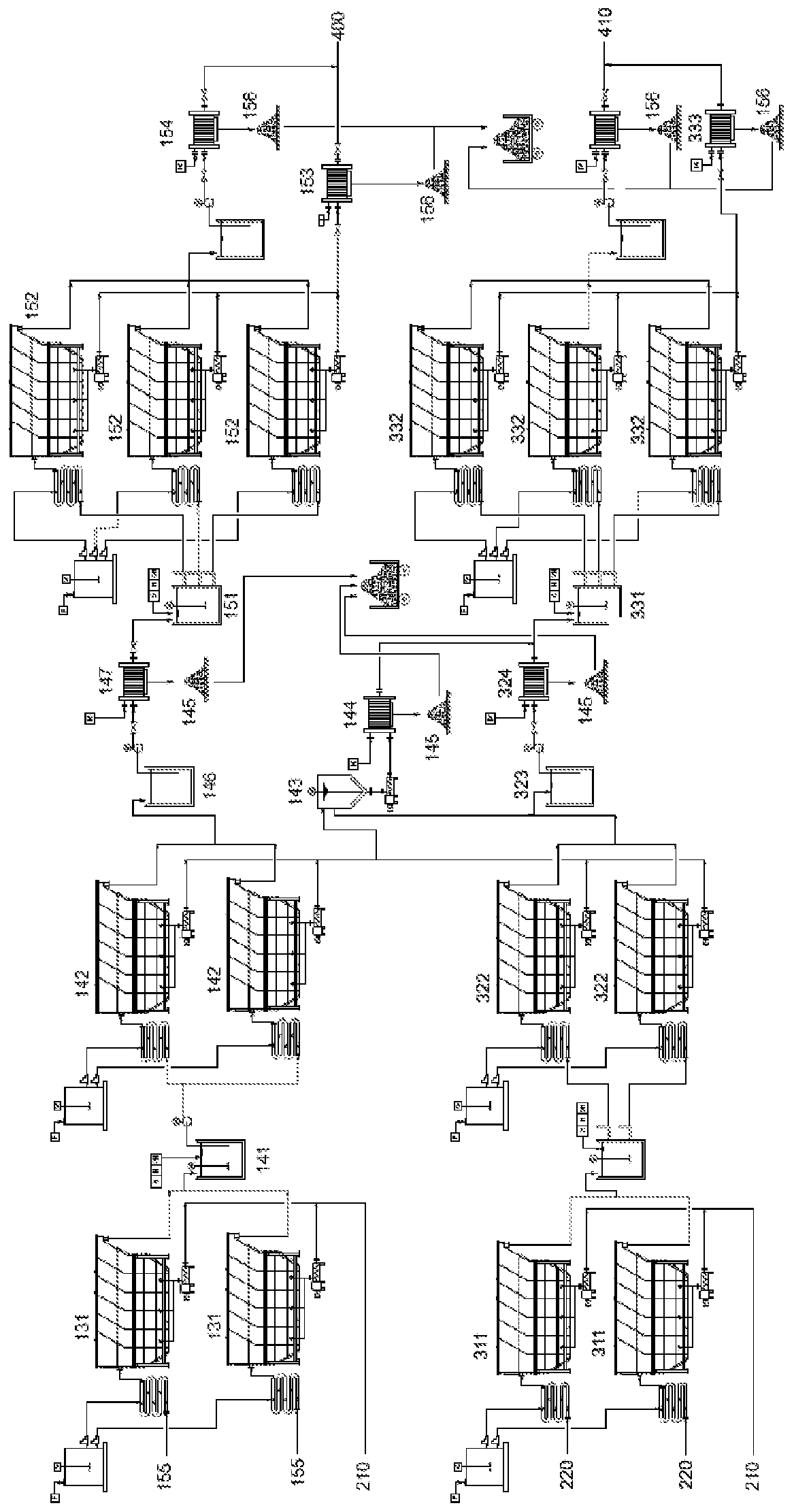

System and method for processing of minerals containing the lanthanide series and production of rare earth oxides

ActiveCN110382109AReduce riskImprove extraction efficiencyRare earth metal oxides/hydroxidesProcess efficiency improvementDesorptionLanthanide

The invention relates to a system and a method for the processing of minerals containing the lanthanide series and the production of rare earth oxides, which allow a completely closed and continuous treatment of the different materials and desorbent agents involved in the process, thus improving the efficiency in the extraction and avoiding environmental risks associated. The method comprising thesteps of: reception and conditioning of the raw material; desorption of valuable product through a plurality of mixing and reaction stages in which the raw material is contacted in countercurrent with a stream of desorbent solution; separation of fine solids; precipitation of secondary minerals through the use of a first reactive solution; precipitation of rare earth carbonates through the use ofa second reactive solution; and drying and roasting of the rare earth carbonates to obtain rare earth oxides; wherein the method further comprises a secondary process that allows further processing of the residual mineral, and a dewatering and washing step wherein the residual mineral from the desorption step is washed and a lanthanide-containing liquid is recovered.

Owner:REE UNO SPA

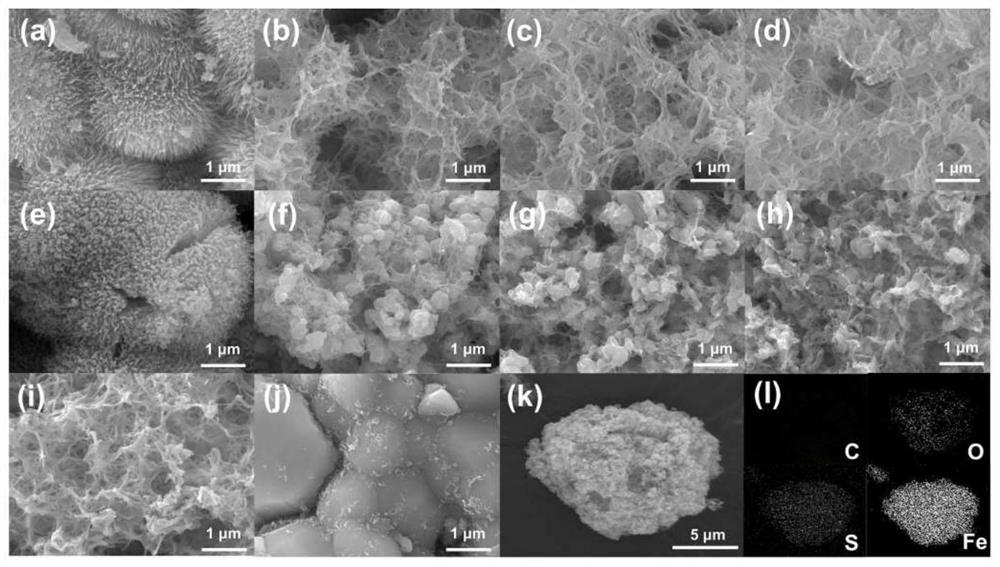

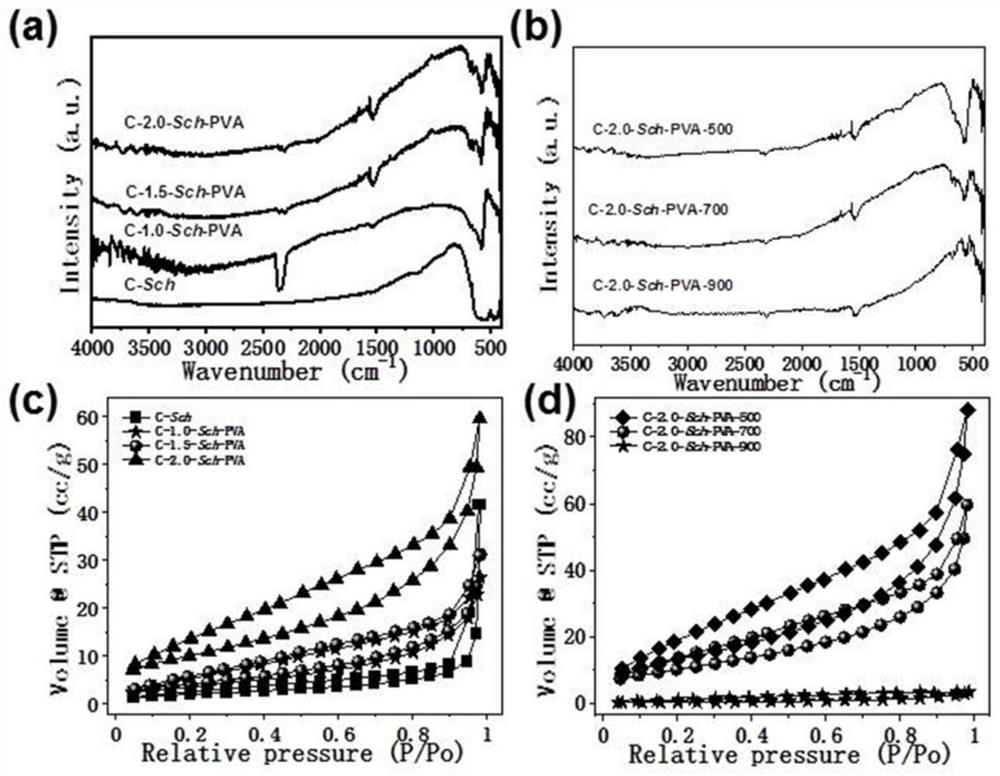

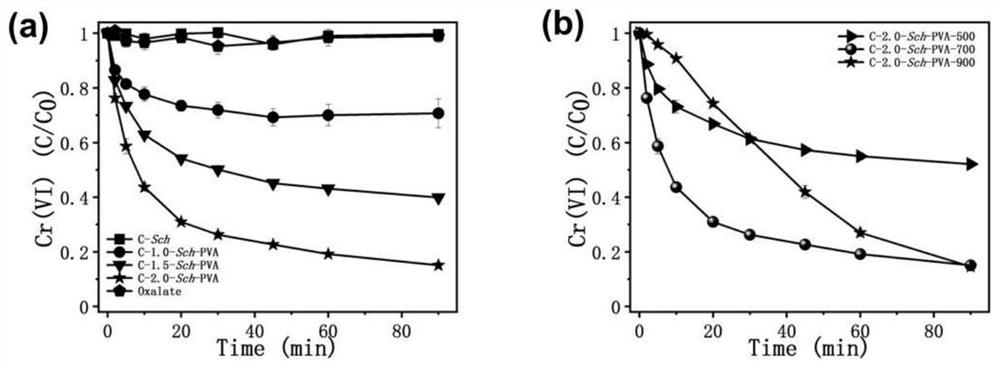

Preparation and application of carbon-coated iron oxide of high-mediation oxalic acid reduced chromium

PendingCN114308038ALow costWide variety of sourcesWater contaminantsCatalyst activation/preparationOXALIC ACID DIHYDRATEPolyvinyl alcohol

The invention relates to preparation and application of carbon-coated iron oxide of high-mediation oxalic acid reduced chromium, and belongs to the technical field of environmental materials. The material is prepared by adding polyvinyl alcohol (PVA) for modification on the basis of synthesizing iron-based secondary minerals through iron-oxidizing bacteria, culturing for a period of time, filtering, drying, grinding into powder, finally calcining for 2 hours in an inert gas atmosphere of 700 DEG C, cooling to room temperature, taking out, and introducing nitrogen for sealing. The carbon-coated iron oxide can efficiently mediate oxalic acid (4mM) to realize nearly 100% removal of hexavalent chromium (Cr (VI), 40mg / L) within 90 minutes under the dosage of 0.75 g / L, and shows an excellent Cr (VI) removal effect in a relatively wide pH range, different salt ion concentrations and different water bodies. The carbon-coated iron oxide is wide in raw material source, simple to synthesize, low in cost and capable of being industrially prepared on a large scale, and has the main characteristic that the removal of Cr (VI) can be realized by efficiently mediating oxalic acid within a short time. Therefore, the carbon-coated iron oxide material has a wide application prospect in removal of heavy metal polluted water.

Owner:CENT SOUTH UNIV

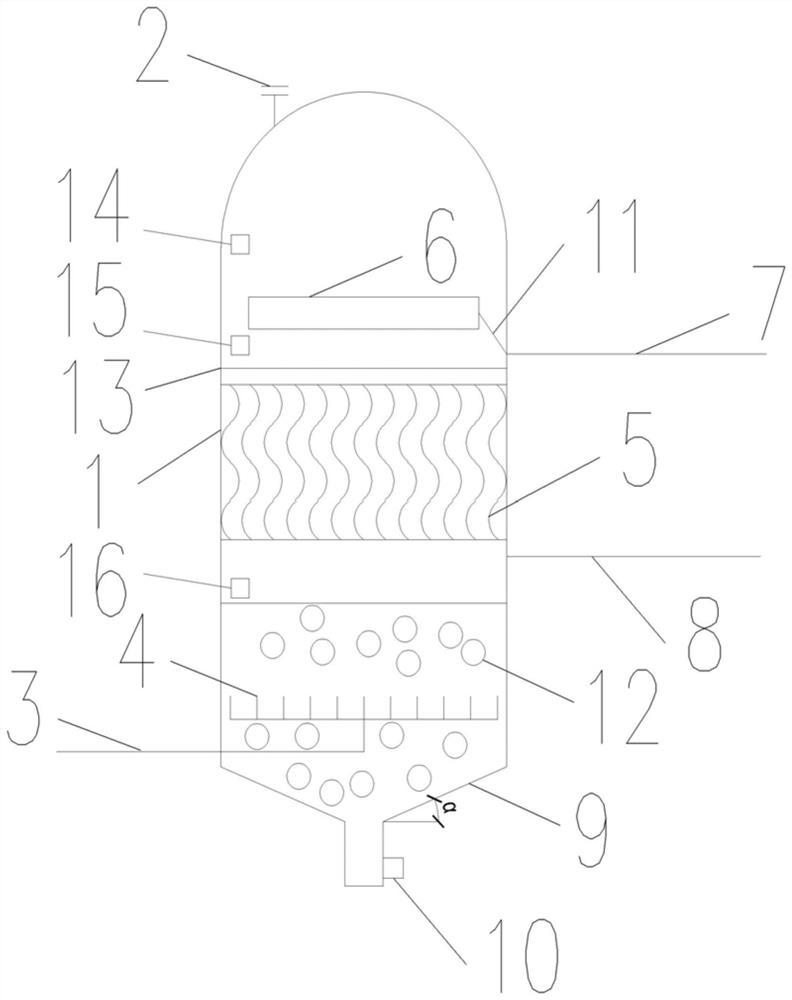

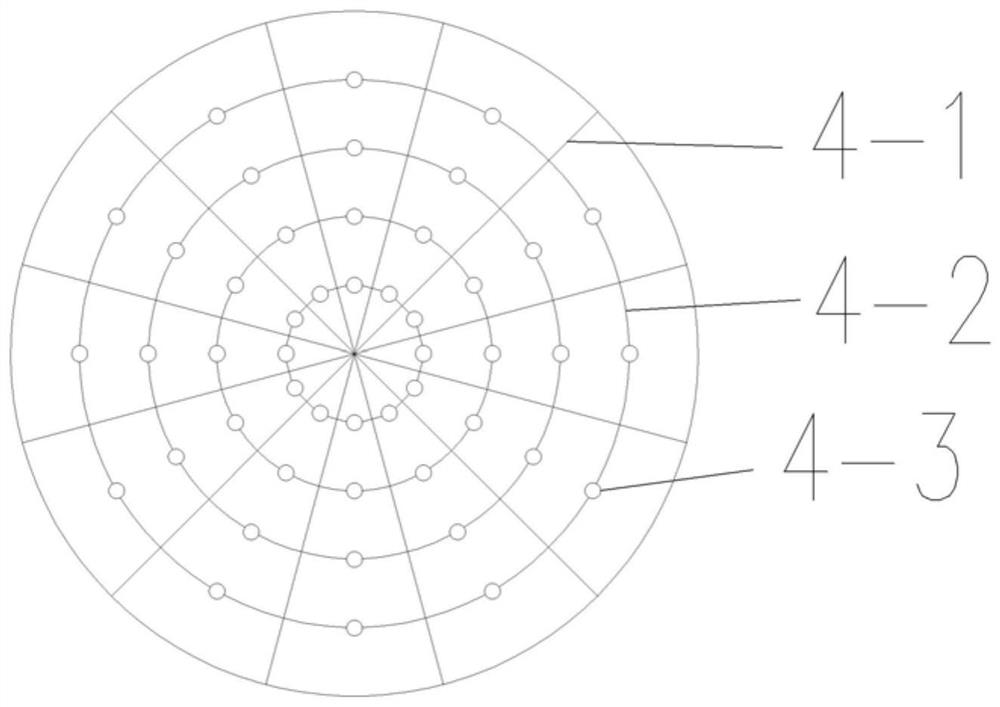

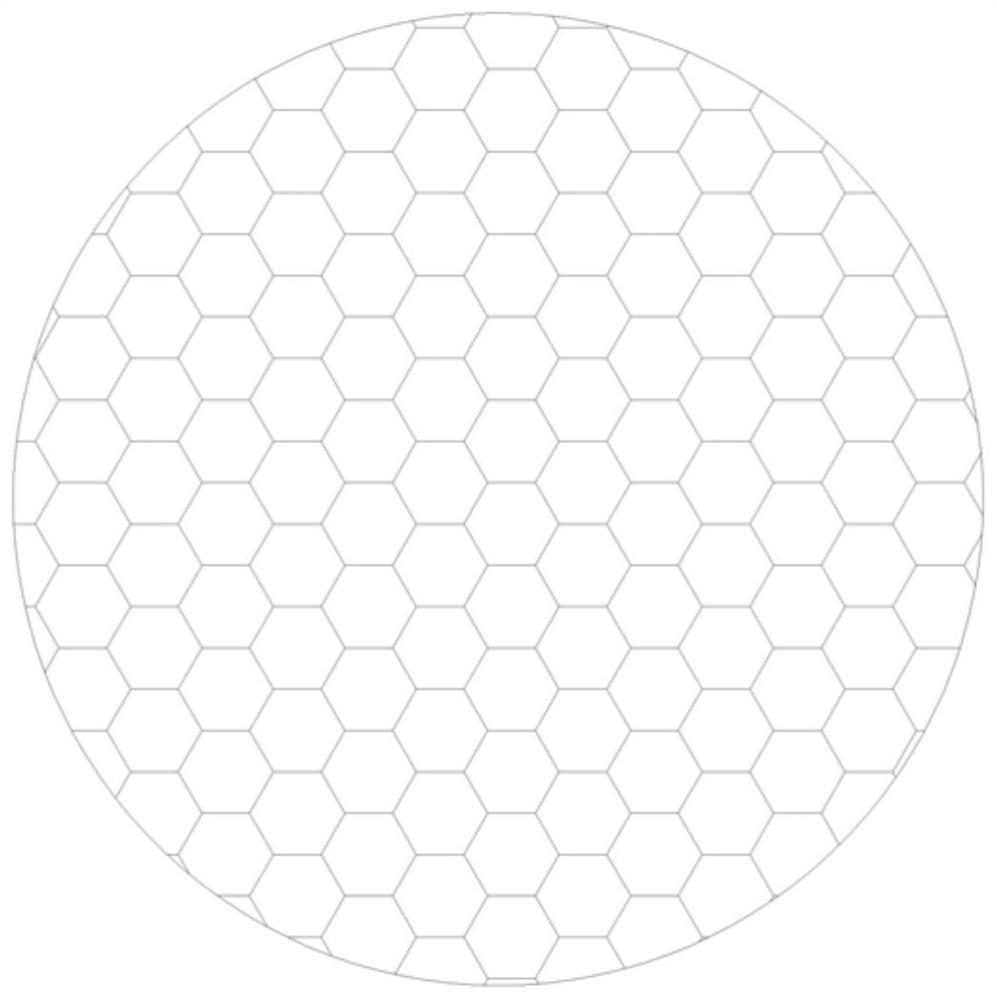

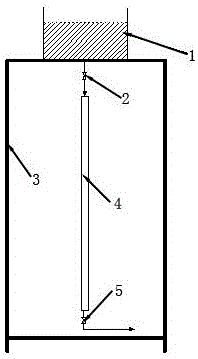

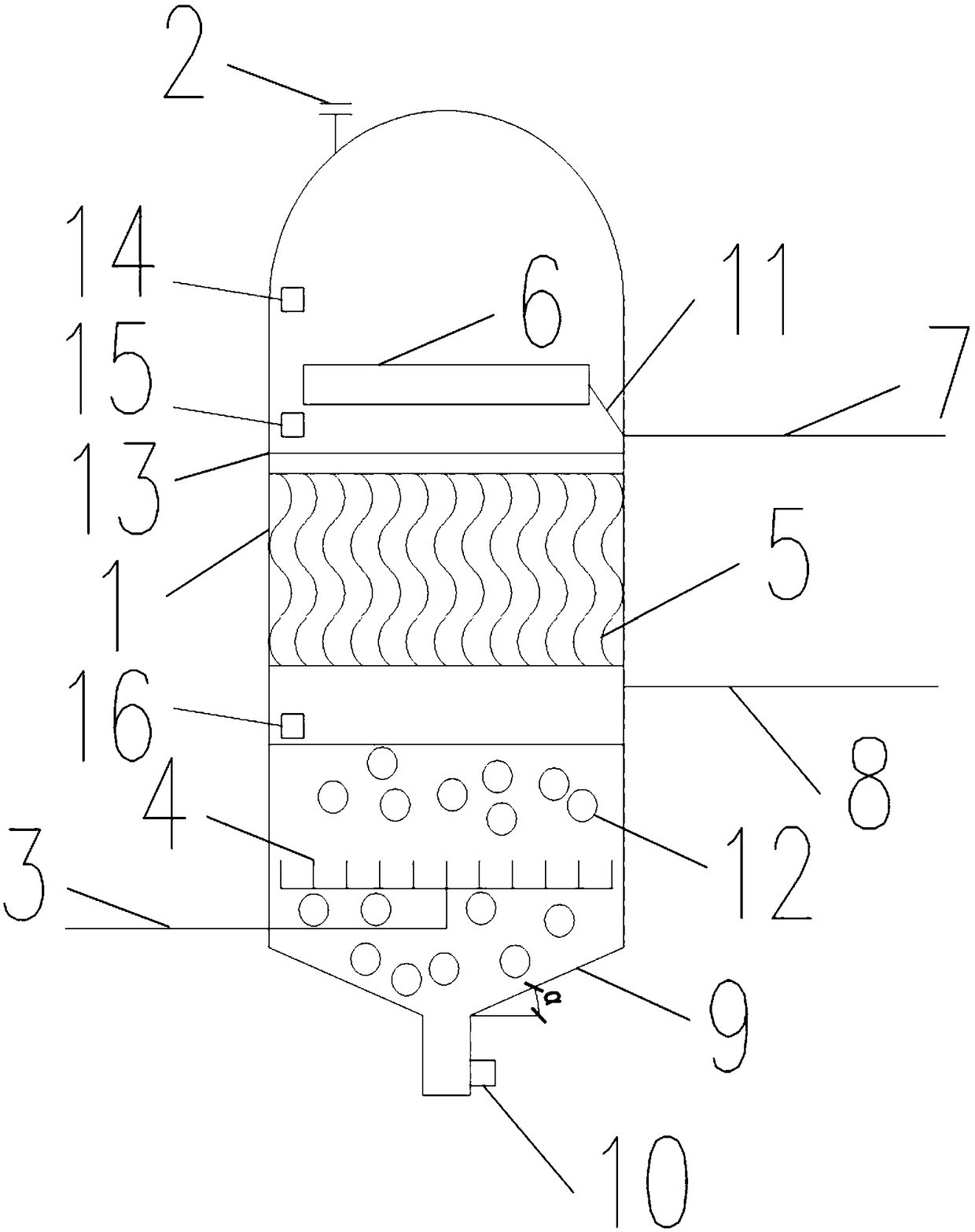

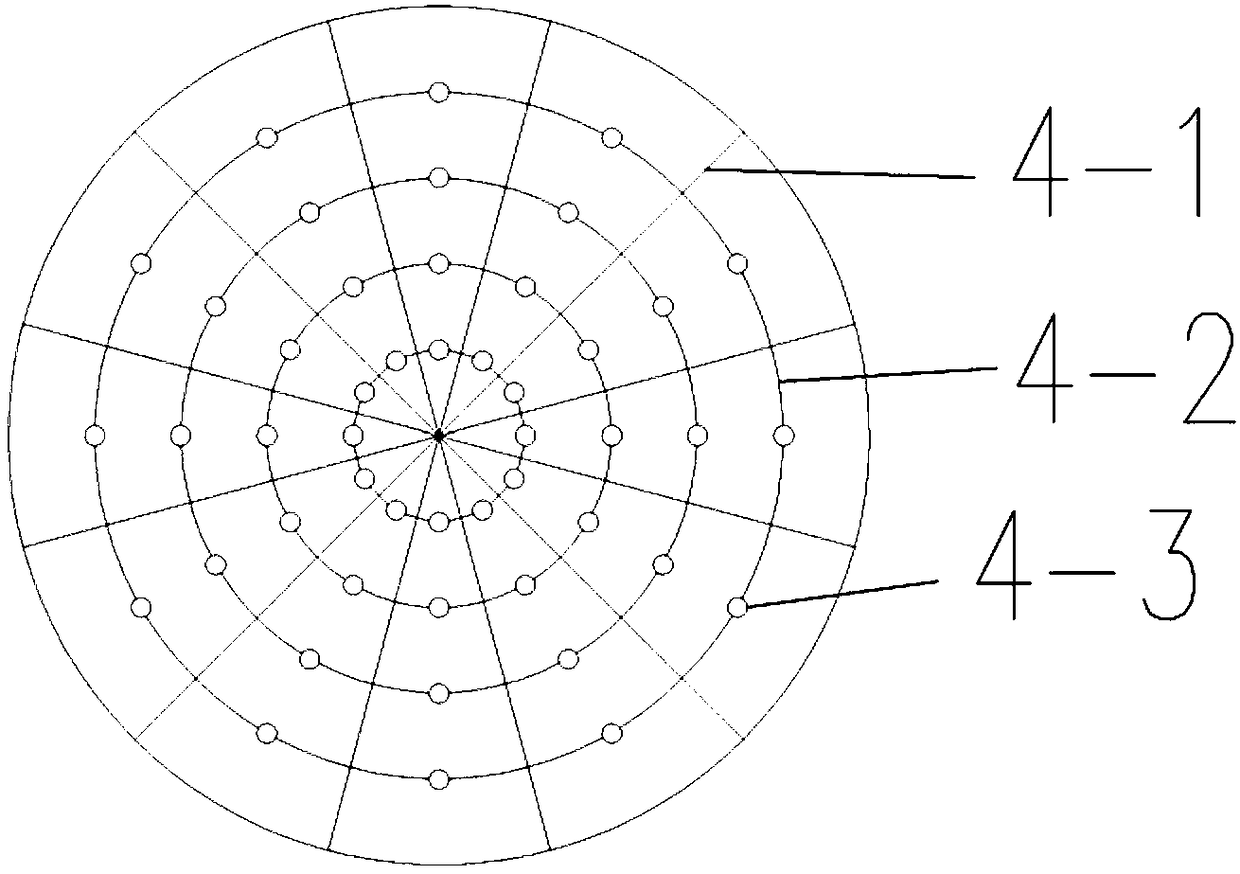

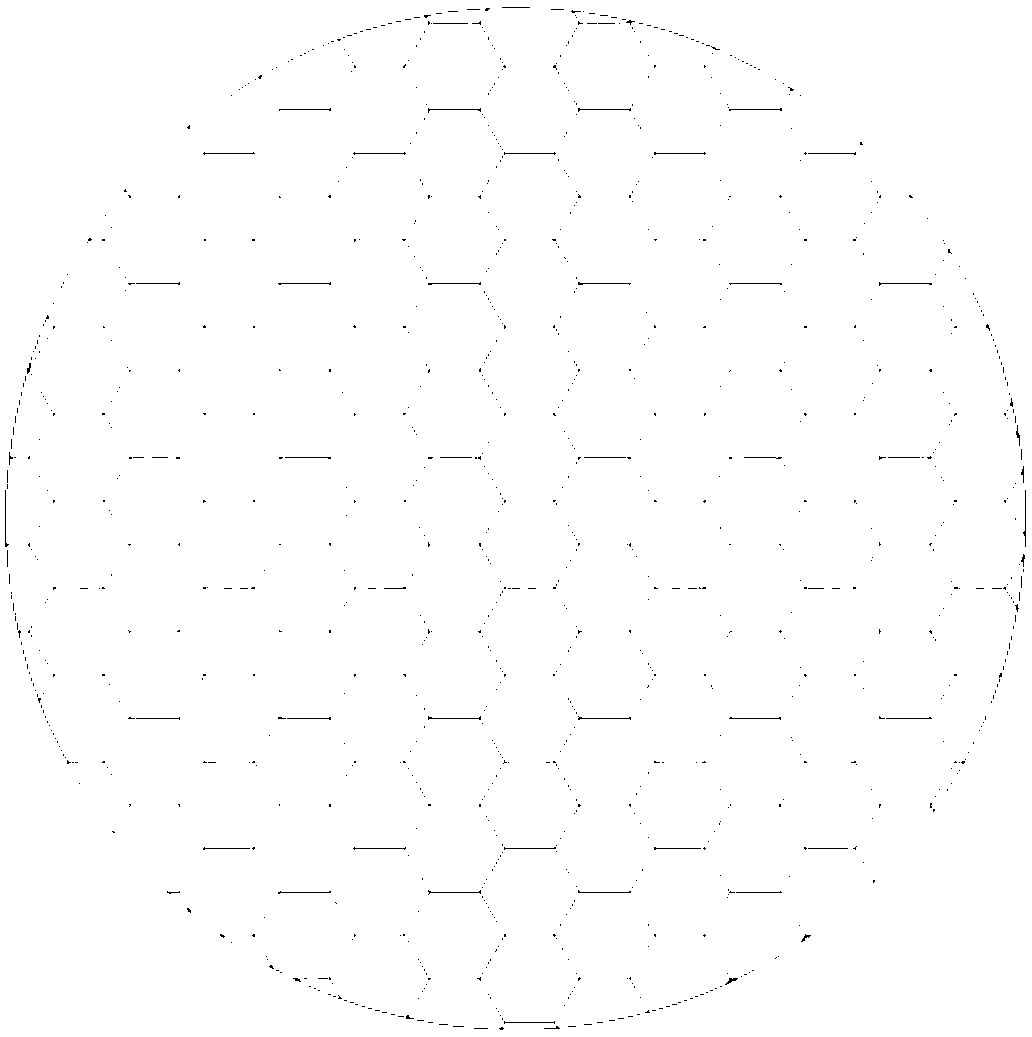

A high-efficiency filter device and wastewater treatment method for mineral processing wastewater treatment

ActiveCN108992980BCompact structureUniform structureLoose filtering material filtersGravity filtersWater dischargeFiltration

Owner:江苏卓燃高新科技有限公司

Polymetallic sulphide ore flotation process capable of increasing zinc index

ActiveCN103433149BReduce lossesImprove production indicatorsFlotationCleaning using liquidsSecondary mineralImpurity

The invention provides a polymetallic sulphide ore flotation process capable of increasing a zinc index, belonging to the technical field of ore dressing. Aiming at the disturbing influence of excess reagents and other minerals in a polymetallic sulphide ore flotation system on a zinc flotation index, the polymetallic sulphide ore flotation process adopts the process steps including sulphide ore mixed flotation, reagent removal and impurity removal, zinc-sulphur mixed flotation, zinc-sulphur separation and the like, other sulphide ores with good flotability relative to zinc are preferably floated, and then zinc flotation is carried out, so that the quality and recovery rate of zinc concentrate are significantly improved. Meanwhile, the comprehensive recovery of lead, antimony, sulphur, copper and other metals is realized, and the emission of heavy metals is reduced. The polymetallic sulphide ore flotation process also can be used for increasing the utilization rate of mineral resources, and has great significance for the exploitation and utilization of low-grade or secondary mineral resources.

Owner:广西华锡矿业有限公司铜坑矿业分公司 +1

A method of using key organic matter to induce the stabilization of active heavy metals

ActiveCN113603316BLower Stabilization CostsAvoid generatingWater contaminantsSludge detoxificationSoil scienceNitrogenous heterocyclic compound

The invention relates to a method for using key organic matter to induce the stabilization of activated heavy metals. Materials containing activated heavy metals are mixed with key organic matter containing nitrogen-containing heterocyclic compounds; activated heavy metals form organically bound heavy metals under the action of key organic matter ; Add primary minerals, organically bound heavy metals are induced secondary mineralization, new minerals are formed on the surface of primary minerals, and transformed into stable residue heavy metals. The present invention can stabilize activated heavy metals in situ without changing soil or washing, greatly reducing the cost of heavy metal stabilization and avoiding the generation of washing wastewater. Compared with heavy metal biological immobilization technology, the cycle is shorter, the operation is simple, and it is less affected by the climate. , and the addition of key organic matter is conducive to the subsequent restoration of fertilizer efficiency and regreening of the utilization scene.

Owner:TONGJI UNIV

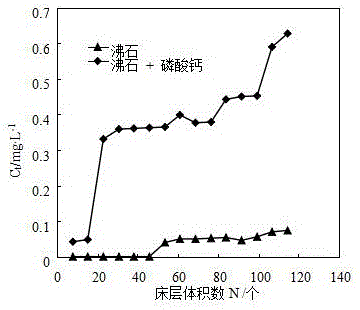

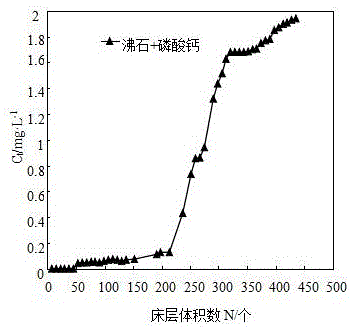

Detergent for uranium-containing wastewater and method for treating uranium-containing wastewater

ActiveCN104998612BProcessing speedGood choiceOther chemical processesWater/sewage treatment by sorptionPhosphateWastewater

The invention relates to a decontamination agent for uranium-containing wastewater. The decontamination agent for uranium-containing wastewater is composed of zeolite with a particle size of 40-150 mesh and phosphate with a particle size of less than 60 mesh. The volume ratio of the zeolite to phosphate is 50-75 : 1, the zeolite includes natural green zeolite and artificial zeolite; when the uranium-containing radioactive waste water with certain conditions flows through the reaction bed filled with the detergent at an appropriate flow rate, the uranium ion in the waste water is promptly removed, Thereby, the water body whose uranium content can meet the national discharge standard is obtained; the removed uranium is trapped in the reaction bed and forms a certain form of secondary uranium-containing minerals, which can be leached by acid Refining and utilization; the invention can achieve the purpose of both removing pollution and recovering uranium element at the same time, and has great popularization and application value.

Owner:GUANGZHOU UNIVERSITY

A kind of flotation method of mineral with high copper-nickel ratio

ActiveCN107234006BMeet the requirements of Express Selection and Early HarvestImprove efficiencyFlotationWet separationMineral flotationSlurry

The invention discloses a high copper-to-nickel-ratio mineral flotation method. The high copper-to-nickel-ratio mineral flotation method comprises the following steps of A, pretreatment of raw materials, and A.2, mineral grinding for grading; A.2.1, primary mineral grinding; A.3, powder adding, slurry mixing and stirring; B.1, the primary rough concentration process; B.2, primary first-time concentrating; B.3, primary second-time concentrating; C, the secondary rough concentration process, and C.1, secondary mineral grinding; C.3, the secondary rough concentration process; C.4, secondary one-time concentrating; C.5, secondary second-time concentrating; C.6, secondary one-time scavenging; C.7, secondary second-time scavenging; and D.1, graded regrinding of part products in the secondary process. According to the high copper-to-nickel-ratio mineral flotation method, the mineral processing process is adopted, the fine grinding and concentrating operation efficiency is strengthened, and the requirement for quick selection and early collecting of copper nickel is met; after implementation, the copper recovering rate of high copper-to-nickel-ratio sulfide copper-nickel mineral is improved by about 1% or more, the copper concentrate grade is improved by about 0.5%, and the copper metal output amount is obviously improved. What's more, an economical and applicable beneficiation method is provided for sorting same-class joined and accompanied mineral, and the high application and popularization value is achieved.

Owner:JINCHUAN GROUP LIMITED

A method for humification product used in mine heavy metal washout pollution control

ActiveCN113578954BHarmlessAchieve reductionWaste water treatment from quariesBio-organic fraction processingSludgeHumin

The invention discloses a method for controlling the pollution of heavy metal washing in mines by humification products, comprising the following steps: (1) mixing and fermenting sludge with extreme thermophilic bacteria to induce polar humification groups; The fermented material is mixed with the original material of humus precursors for fermentation to induce mass production of humus until the humus content reaches the standard requirements; (2) The sludge humification products that meet the standard are mixed with heavy metal-contaminated mine soil for conservation , to repair polluted mines. The method absorbs and enriches the heavy metals polluted on the mine surface by using the humification products, and can increase the complexation of copper, cadmium, chromium, lead, nickel, arsenic and zinc by 20-85%, and has significant absorption and enrichment of heavy metals. After the humification product is enriched with heavy metals, the heavy metals are induced to migrate on the primary minerals of the mine and mineralized to produce secondary minerals, so that the free heavy metals are fixed on the primary minerals, thereby effectively solving the washout pollution of heavy metals in the mine.

Owner:TONGJI UNIV

Production of magnetic refrigerant material by ferro-manganese mixture

The invention discloses a method for preparing a magnetic refrigeration material from a mixture of iron and manganese nodules. Iron-manganese concretion placer is a secondary ore produced by long-term biological bacteria action, with a hidden nano-transition structure. The present invention uses nitric acid to double-decompose nano-scale secondary ore with iron-manganese structure and gadolinium-gallium garnet (Gd3Ga5O12) in equal proportions, then fully mixes with excess tartaric acid water-soluble wine, dehydrates, heats and cools with high-temperature air. That is, the magnetic refrigeration material that constitutes the magnetic nano-cluster substance. The invention develops and utilizes the ferromanganese nodule secondary ore with abundant reserves in my country, which not only enriches the source of raw materials for preparing magnetic refrigeration materials, but also broadens the possibility of applying the secondary ore to other nanotechnology fields; When the magnetic refrigeration material loses its refrigeration effect after repeated use, it can also be used as a fertilizer for trace elements in fly sand soil improvement and low-yield fields. The magnetic refrigeration material is a slag-free, pollution-free, energy-saving and environment-friendly material, and has a simple preparation process.

Owner:林勋

High-efficiency filter device and wastewater treatment method for beneficiation wastewater treatment

ActiveCN108992980ACompact structureUniform structureLoose filtering material filtersGravity filtersWater dischargeSecondary mineral

Provided are a high-efficiency filter device and wastewater treatment method for beneficiation wastewater treatment. The filter device comprises a tank body, wherein a material discharge hopper is formed in the lower part of the tank body, a wastewater supply device is arranged at the upper part of the material discharge hopper, and an anti-blocking device is arranged in the middle of the tank body; and the parts, under the anti-blocking device, in the tank body are filled with filter filler composed of secondary mineral, weak soil, collapsible soil and sandy soil, a floating water discharge device is arranged under the anti-blocking device, and the tank body is provided with water drainage pipes, waste liquid discharge pipes and liquid level sensing contacts corresponding to different liquid level positions. When beneficiation wastewater treatment is conducted through the high-efficiency filter device, wastewater is mixed with the filter filler through a water distribution device under the pressure of inlet water, the obtained mixed liquid is raised to the top from bottom to top through the anti-blocking device, and then purified water is discharged through the floating water discharge device; the filtered waste liquid is returned to an adjustment tank, and when the suspended solid content in the discharged purified water does not meet the requirements, filtration stopping andreplacement of the filter filler are conducted; the filter device has even water distribution, and no additional arrangement of a stirring device is needed; and no agglomeration of the filter filleroccurs, the filter filler is not stirred by the water discharge device, and the filter device has a high speed and a good filter effect.

Owner:江苏卓燃高新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com