High copper-to-nickel-ratio mineral flotation method

A technology of copper-nickel ore and beneficiation method, applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problem of low copper concentrate grade and recovery rate, recovery rate less than 30%, copper recovery rate is not high, etc. problems, to achieve the effect of increasing the effective utilization rate, improving the grade of copper concentrate, and improving the pharmaceutical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

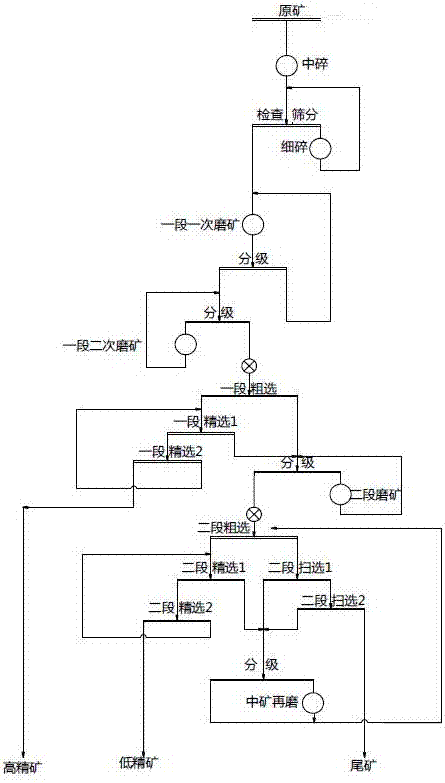

Image

Examples

example 1

[0043] Example 1: Taking the raw ore containing 1.32% copper, 1.48% nickel, and a copper-nickel ratio of 0.89 as an example, go through the following beneficiation methods:

[0044] A raw material pretreatment

[0045] A.1 Crushing and screening: crush the copper-nickel ore with a high copper-nickel ratio, and obtain a finely crushed product with a particle size of -10 mm through inspection and screening;

[0046] A.2 Grinding and classification

[0047] A.2.1 One-stage grinding: The finely crushed product obtained in step A.1 is subjected to one-stage grinding, and two-stage closed-circuit grinding operations are performed to obtain pulp A1 with a -200 mesh content > 65%, which is used as a raw material for one-stage flotation;

[0048] A.3 Dosing, mixing and stirring

[0049] A.3.1 Put the primary flotation raw material A1 obtained in step A.2.1 into the stirring tank, add ammonium sulfate 800g / t to make the pH value of the pulp reach 8.5; add water to adjust the concentra...

example 2

[0066] Example 2: The raw ore contains 1.136% copper, 1.316% nickel, and a copper-nickel ratio of 0.86, through the following beneficiation methods:

[0067] A raw material pretreatment

[0068] A.1 Crushing and screening: crush the copper-nickel ore with a high copper-nickel ratio, and obtain a finely crushed product with a particle size of -10 mm through inspection and screening;

[0069] A.2 Grinding and classification

[0070] A.2.1 One-stage grinding: The finely crushed product obtained in step A.1 is subjected to one-stage grinding, and two-stage closed-circuit grinding operations are performed to obtain pulp A1 with a -200 mesh content > 65%, which is used as a raw material for one-stage flotation;

[0071] A.3 Dosing, mixing and stirring

[0072] A.3.1 Put the primary flotation raw material A1 obtained in step A.2.1 into the stirring tank, add ammonium sulfate 1000g / t, and make the pH value of the pulp reach 9.0; add water to adjust the concentration of the pulp to 3...

example 3

[0089] Example 3: The raw ore contains 1.02% copper, 1.29% nickel, and a copper-nickel ratio of 0.79, through the following beneficiation methods:

[0090] A raw material pretreatment

[0091] A.1 Crushing and screening: crush the copper-nickel ore with a high copper-nickel ratio, and obtain a finely crushed product with a particle size of -10 mm through inspection and screening;

[0092] A.2 Grinding and classification

[0093] A.2.1 One-stage grinding: The finely crushed product obtained in step A.1 is subjected to one-stage grinding, and two-stage closed-circuit grinding operations are performed to obtain pulp A1 with a -200 mesh content > 65%, which is used as a raw material for one-stage flotation;

[0094] A.3 Dosing, mixing and stirring

[0095] A.3.1 Put the primary flotation raw material A1 obtained in step A.2.1 into the stirring tank, add ammonium sulfate 900g / t to make the pH value of the pulp reach 8.7; add water to adjust the concentration of the pulp to 35%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com