Patents

Literature

126results about How to "Guaranteed grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

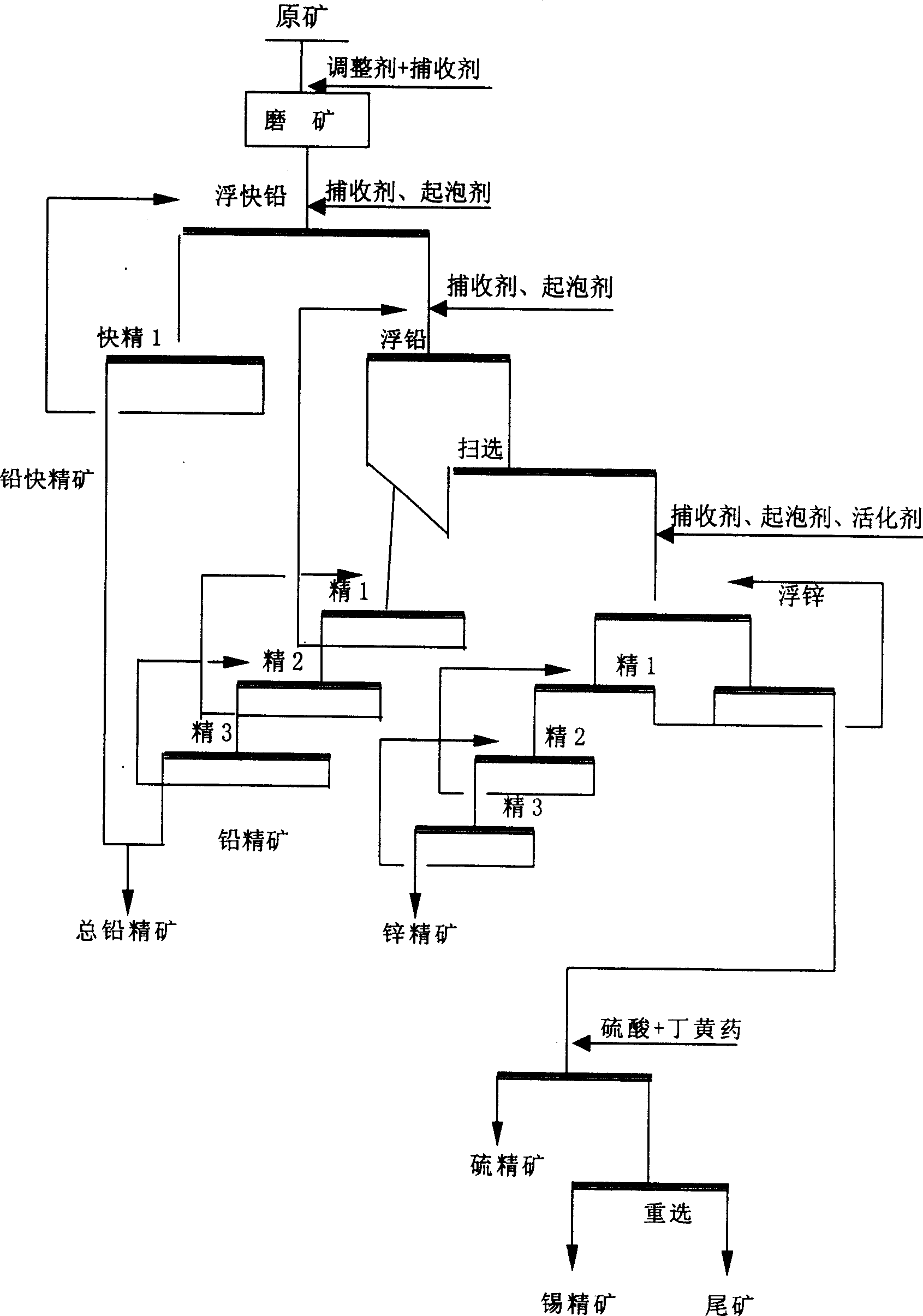

Stepped flotation of tin, lead and zinc sulfide mine

A step floatation technology for the tin-lead-zinc sulfide ore includes such steps as high-alkali high-speed floatation and separation of lead sulfide ore, high-alkali high-Ca floatation and separation of zinc sulfide ore, and floatation of zinc tailings. Its advantages are high grade and recovering rate of lead concentrate, no loss of Ag ore, and simple apparatus.

Owner:黎东明

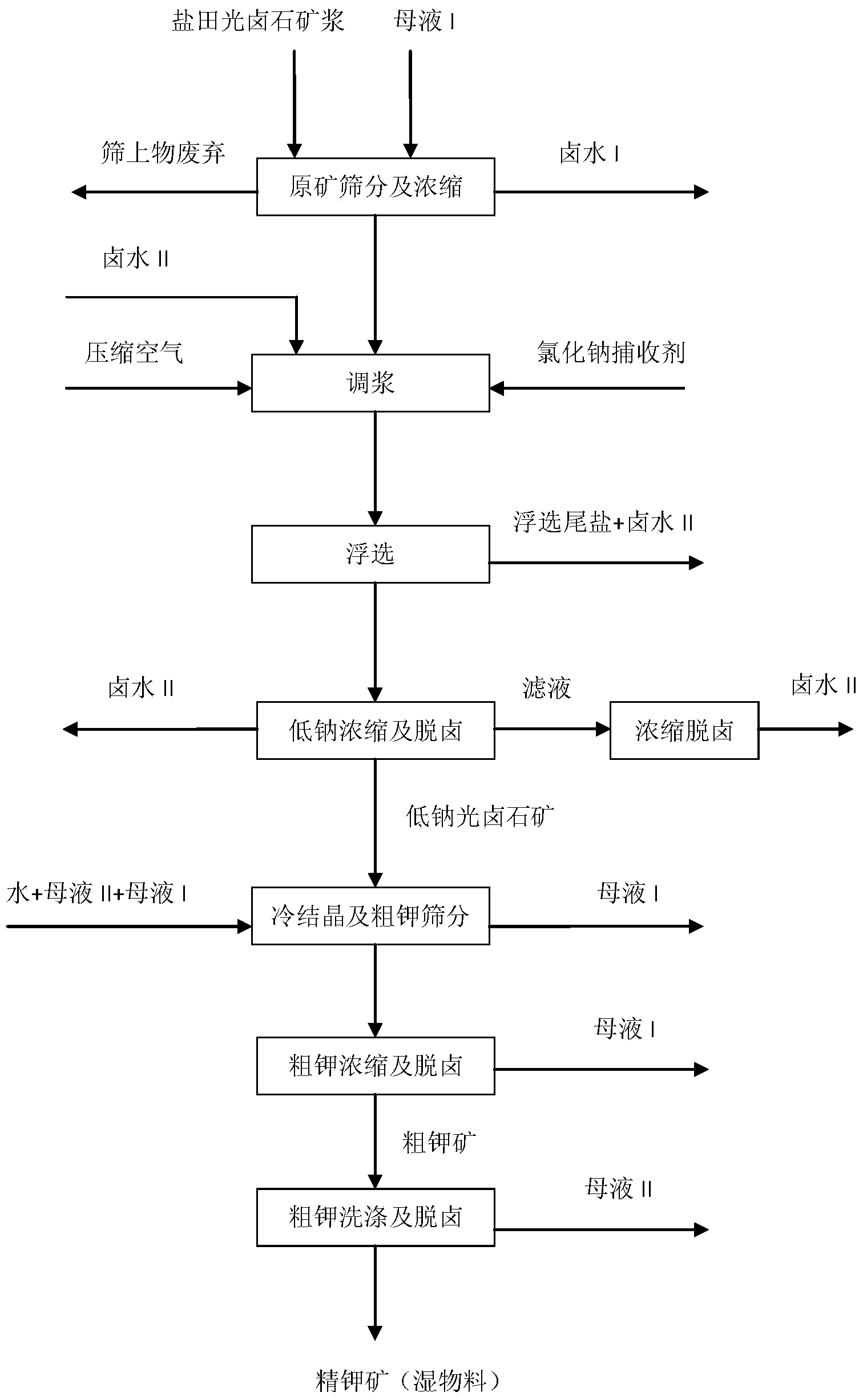

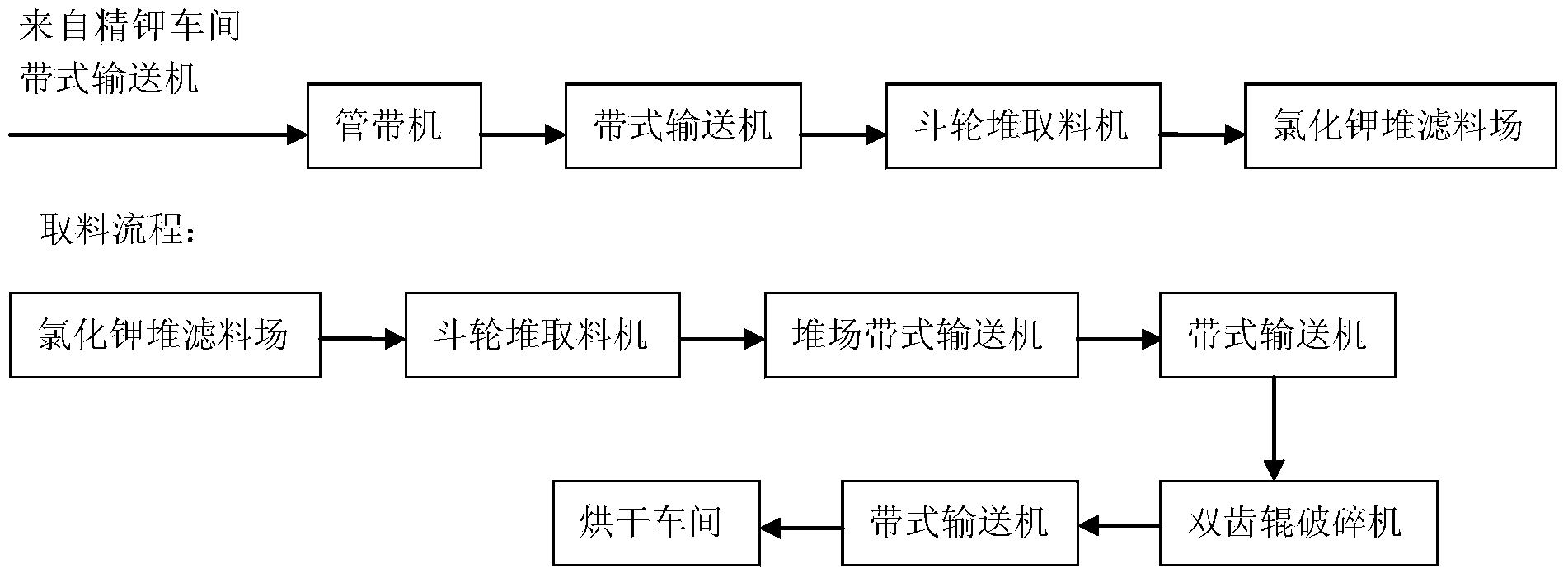

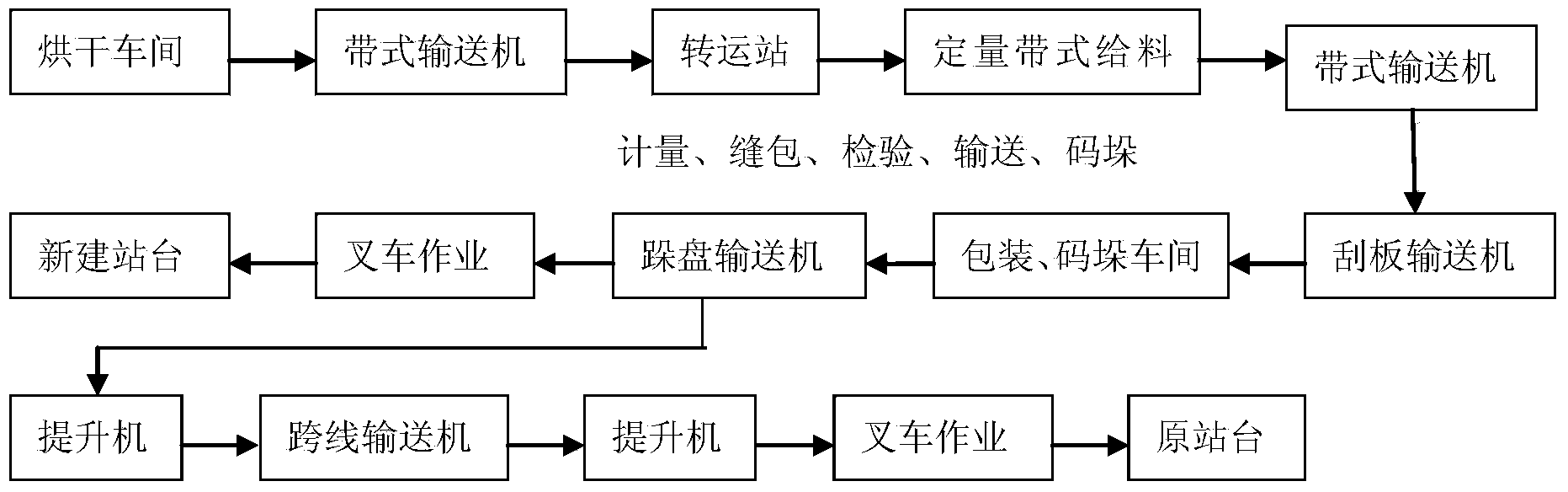

High-grade potassium chloride production system and method thereof

ActiveCN104058427ARaise the gradeReduce dosageAlkali metal chloridesAlkali metal halide purificationChemistryLow sodium

The invention discloses a high-grade potassium chloride production system and a method thereof. The system comprises a raw ore screening and concentrating system, a size mixing system, a floatation system, a low sodium concentration and dehalogenation system, a cold crystallization and thick potassium screening system, a thick potassium concentration and dehalogenation system, a refined potassium washing and dehalogenation system, a piling and filtering storage stock ground system, a breaking and conveying system and a drying cooling, packing, stacking and line crossing conveying system, and all the systems are sequentially connected and are arranged in a three-dimensional mode. Materials enter a next system in a self-flowing mode. An automatic dosing, automatic water adding and dehalogenation device is adopted, a spiral screen type centrifugal machine is used for replacing a horizontal belt type filter, and other technology improvements are adopted, so that the potassium chloride grade is improved to 98 percent from 95 percent, the piling and filtering technology is adopted in the system so that the natural gas using amount can be saved, production operation is convenient, and equipment operation is stable.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

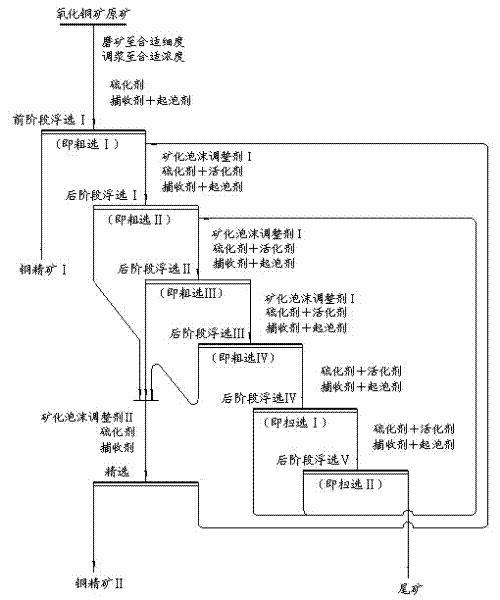

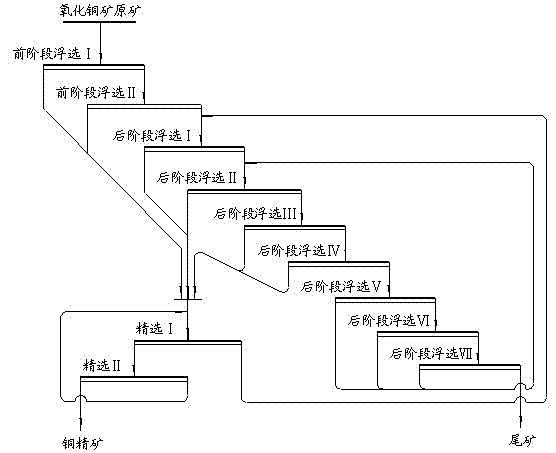

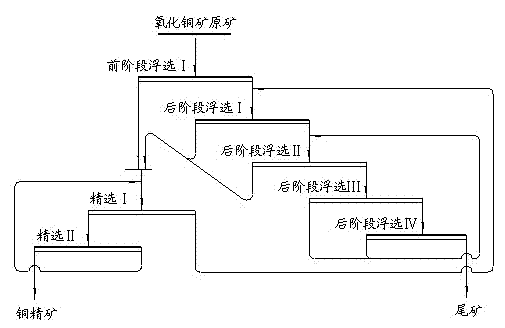

Method for activating and adjusting mineralized bubbles in vulcanizing flotation process of copper oxide ores

InactiveCN102366731AThe cumulative recovery rate is largeThe cumulative recovery rate increased greatlyFlotationFoaming agentCopper oxide

The invention provides a method for activating and adjusting mineralized bubbles in the vulcanizing flotation process of copper oxide ores. The method comprises pre-stage flotation, post-stage flotation and selection; after grinding and mixing, a vulcanizing agent, a collecting agent and a foaming agent are added in each sub-stage of the pre-stage flotation; the mineralized bubble adjusting agent I, a vulcanizing agent, an activating agent, a collecting agent and a foaming agent are added in each sub-stage of the post-stage flotation; and the mineralized bubble adjusting agent II, a vulcanizing agent and a collecting agent are added in each sub-stage of the selection so as to obtain copper concentrate and tailings. The method provided by the invention has the advantages that: the mineralized bubble adjusting agent is correspondingly added when the activating agent is added in the post-stage flotation so as to avoid excessively large bubbles caused by adding the activating agent only, and the production operation is convenient; and compared with the conventional vulcanizing flotation method and conventional activating flotation method, by adopting the medicine adding method and flow structure provided by the invention, the method can improve the recovery rate of copper concentrate by 8-14% while ensuring similar grades of the copper concentrate.

Owner:KUNMING UNIV OF SCI & TECH

Flotation method of brass ore-containing complex lead-zinc sulphide ore

The invention discloses a flotation method of a brass ore-containing complex lead-zinc sulphide ore, which comprises the steps of: adjusting the pH value to be 10-11 in the process of ore grinding; adding ore pulp electric potential regulating agent-sodium pyrosulfite to adjust the electric potential of the ore pulp to be at 220-260mV (relative to hydrogen standard potential); adding zinc sulfate, ethoxy-dithioformicacid ethyl formate and ethyl thio carbamate grinding ore; performing one roughing, one scavenging and two selecting to enrich copper-lead mineral by means of mixing and floating and to form into copper-lead mixed concentrate; performing reagent desorption to the copper-lead mixed concentrate by adding active carbon; adding potassium peroxydisulfate and carboxymethyl starch to restrain lead-containing mineral in the copper-lead mixed concentrate such as galena and the like; performing one roughing, one scavenging and three selecting to obtain copper concentrate; adjusting the pH value of tailings after recovering copper mineral by floating the copper-lead mixed concentrate to be 9.0; adding sodium pyrosulfite, ethyl thio carbamate and butyl ether alcohol; and performing one roughing, one scavenging and two selecting to obtain lead concentrate. The method guarantees the grade of the copper and the lead concentrate, and reduces the environmental pollution.

Owner:CENT SOUTH UNIV +1

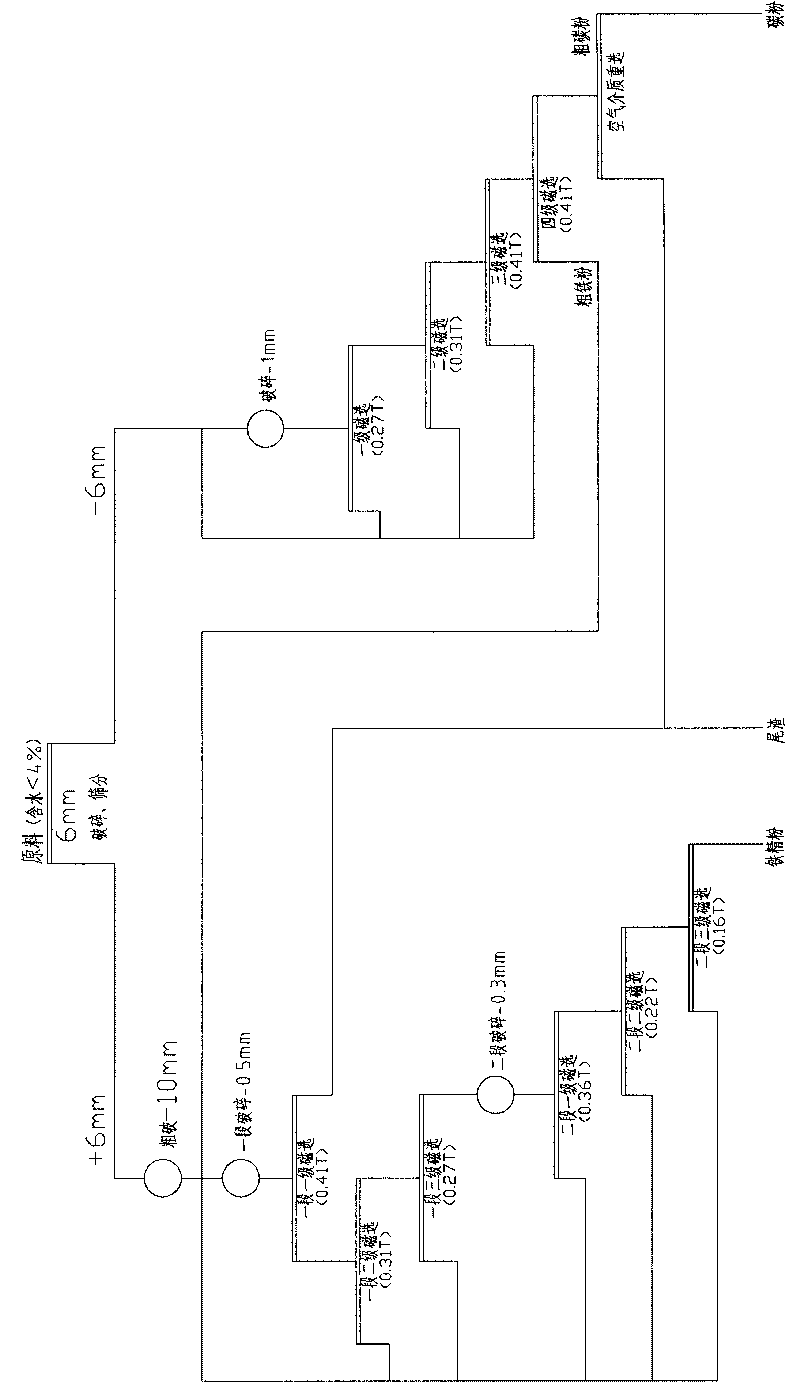

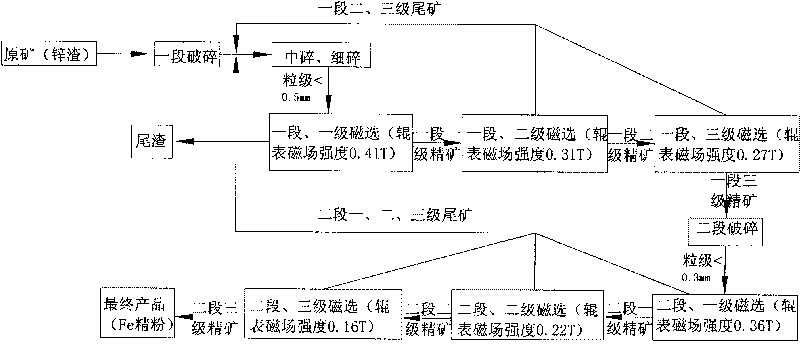

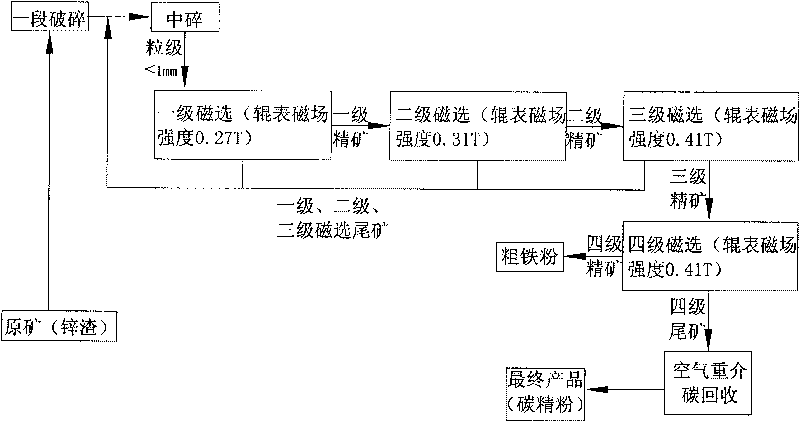

Kiln slag processing technology of zinc volatilizing kiln

The invention relates to a kiln slag processing technology of a zinc volatilizing kiln, which is characterized by comprising the technological steps of crude crushing and prescreening, medium crushing and fine crushing, two-section and three-stage magnetic separating Fe fined powder, four-stage magnetic separating and re-separating carbon refined powder by an air medium. The invention has the advantages of simple technology, high production efficiency, stable product quality and low energy consumption and enhances the utilization rate of resources, the Fe content of the finally separated Fe refined powder can be about 60%, and the Fe refined powder according with the national requirements can be separated without secondary processing.

Owner:HENAN POLYTECHNIC UNIV

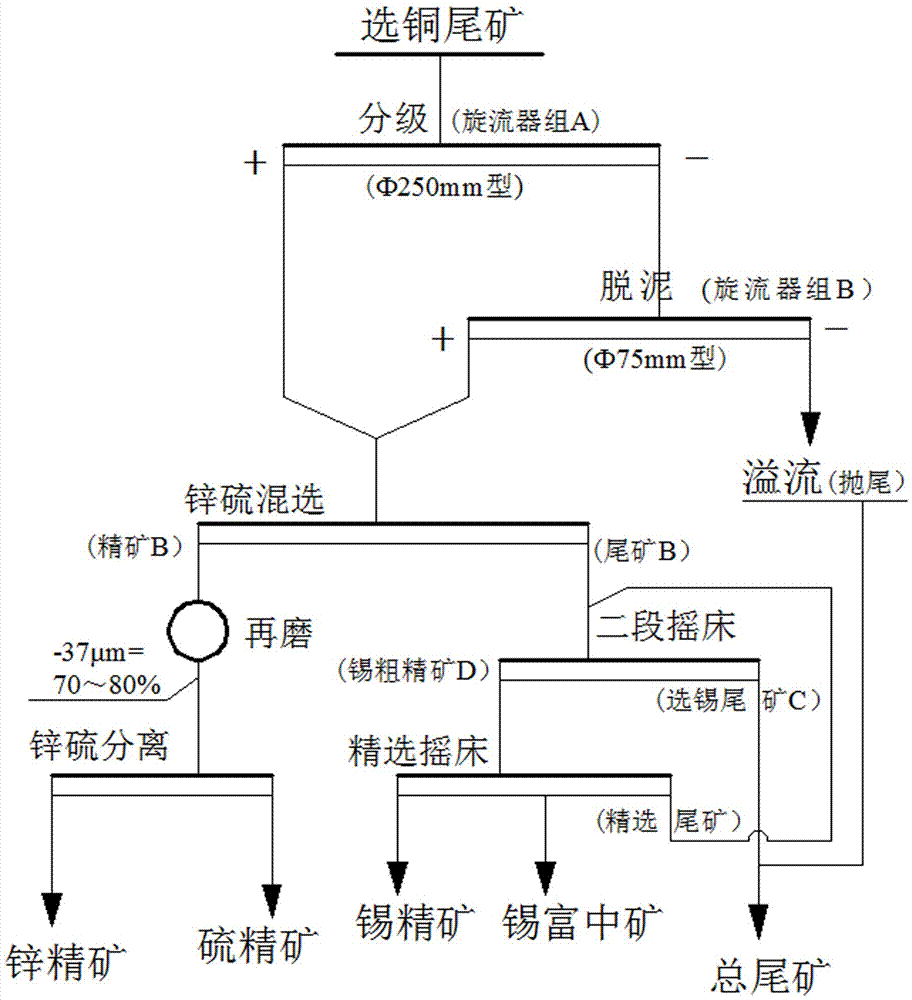

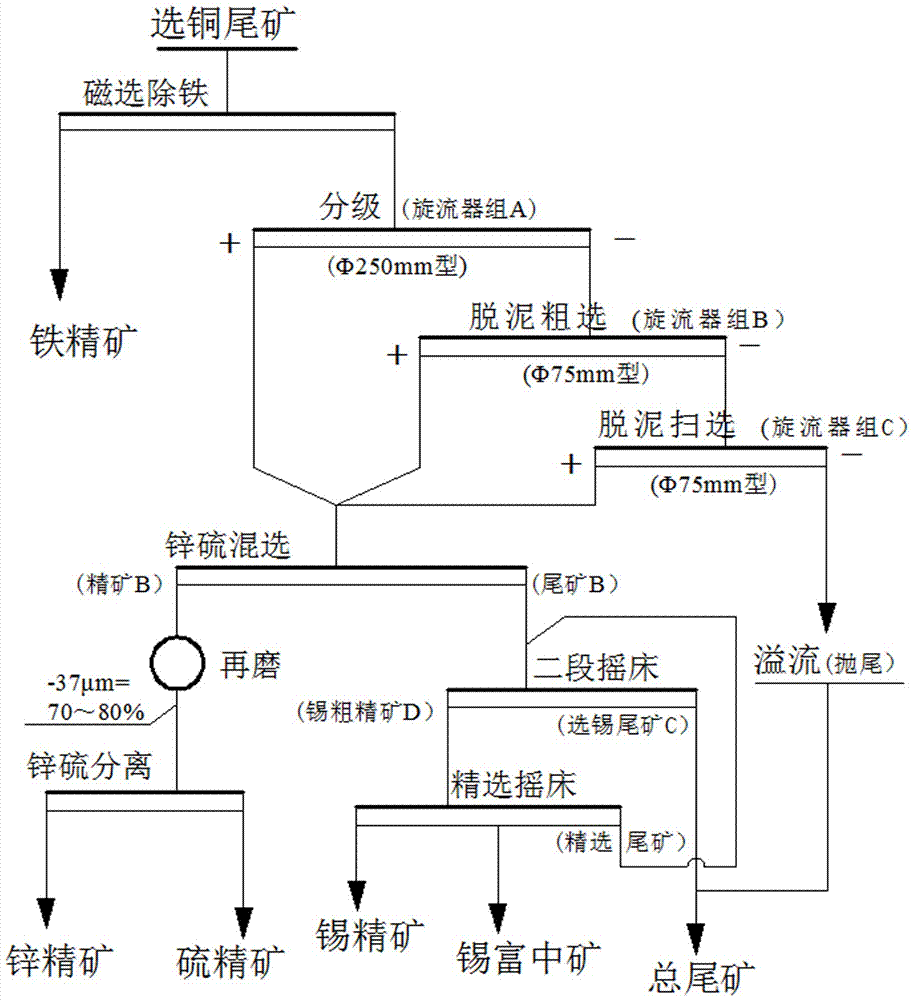

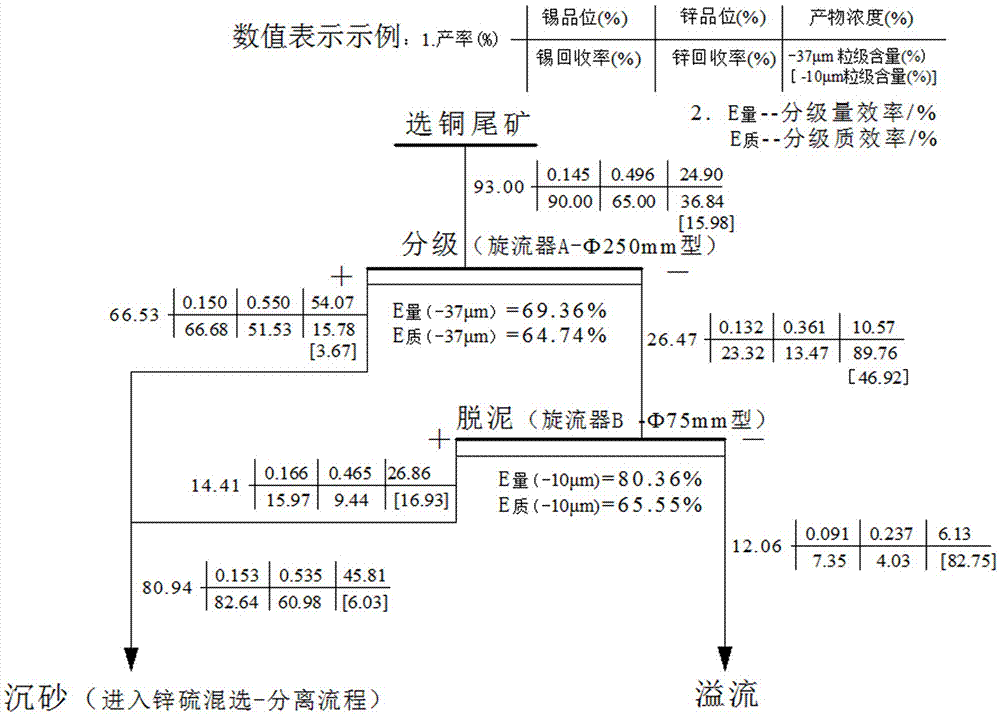

Mineral separation technology for recovering low-grade marmatite and cassiterite minerals from copper separation tailings

The invention relates to the field of mineral separation, in particular to a mineral separation technology for economically and efficiently recovering low-grade marmatite and cassiterite minerals from copper separation tailings. The mineral separation technology mainly comprises the three steps of classification desliming, zinc and sulfur mix-floatation and separation, and tin separation with a shaking table. The effect of economically and efficiently recovering the low-grade marmatite and cassiterite minerals in the copper separation tailings can be realized.

Owner:YUNNAN HUALIAN ZINC & INDIUM

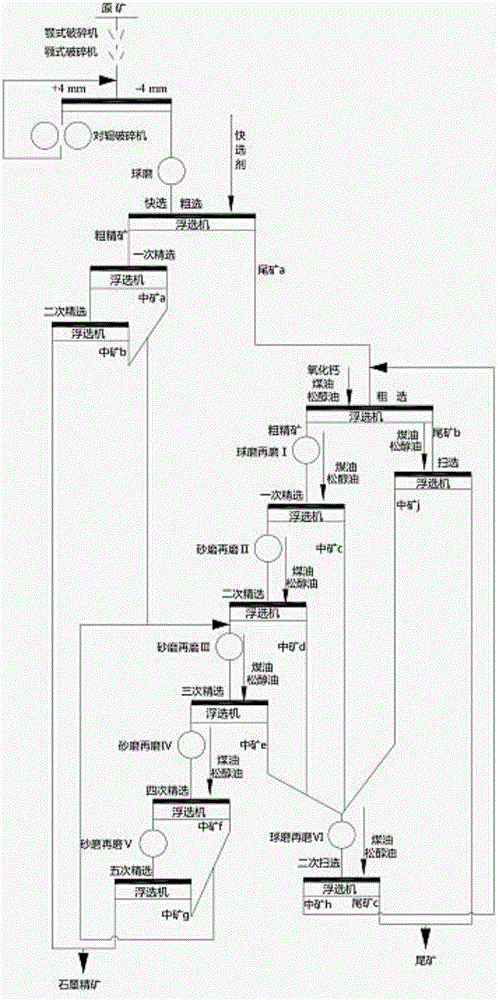

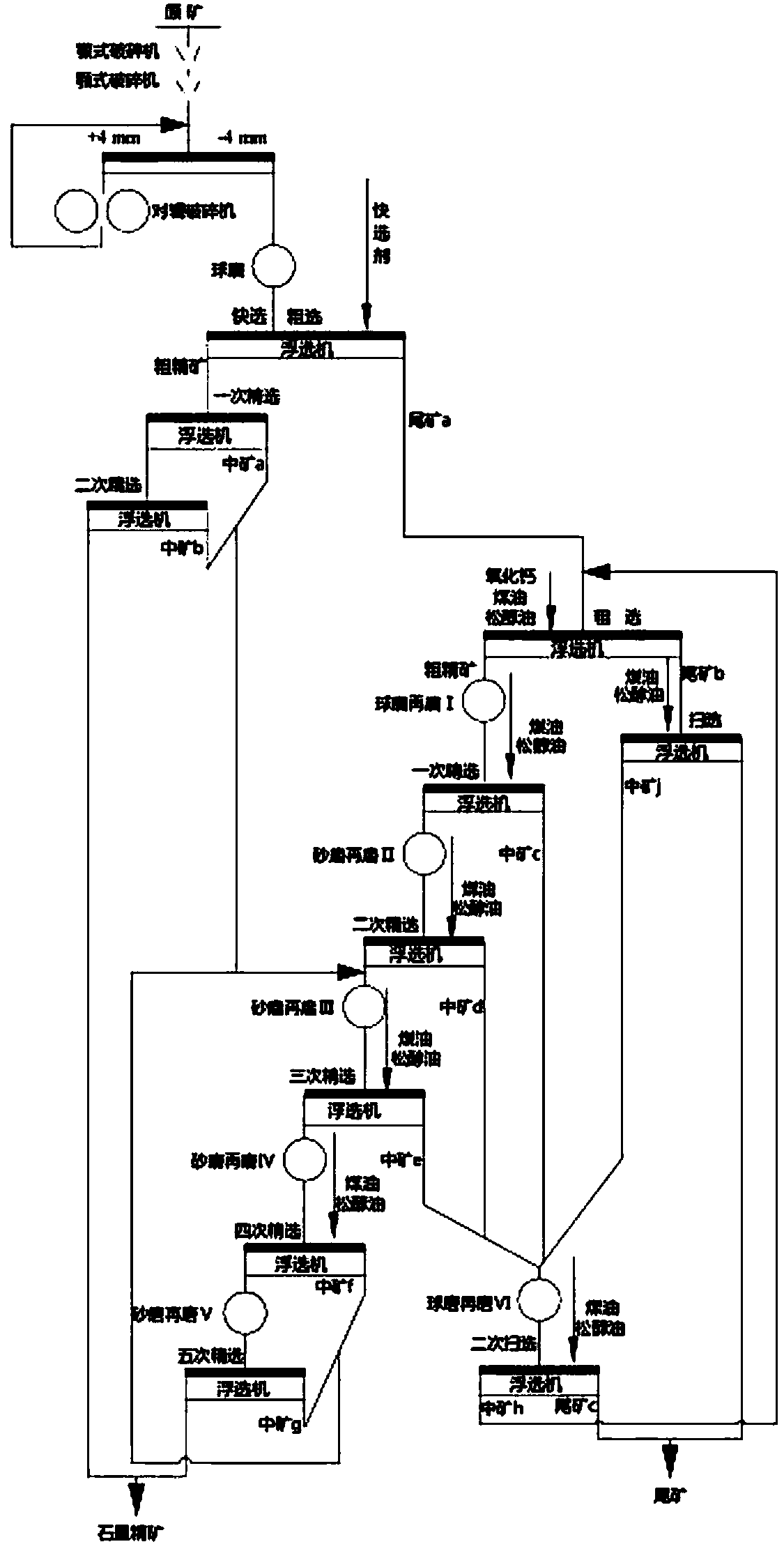

Large-scale crystalline graphite ore flotation fast selecting agent and flotation technology

ActiveCN106513164AReduce consumptionReduce manufacturing costFlotationWet separationMethanolGraphite

The invention relates to a large-scale crystalline graphite ore flotation fast selecting agent and a flotation technology. The agent comprises following components including, by weight, 50% to 65% of methyl isobutyl carbinol, 20% to 30% of petroleum ether and 10% to 25% of acetone. The graphite ore flotation fast selecting agent can rapidly select high-quality large-scale graphite ore from neutral pulp, and high-grade large-scale crystalline graphite concentrate can be obtained through the short selection technology free of regrinding; compared with a traditional large-scale crystalline graphite ore flotation technology, graphite scales can be effectively protected, meanwhile, the consumption amount of the floatation agent can be reduced, and the production cost is reduced.

Owner:金建工程设计有限公司

Flotation desilication method for bauxite

Disclosed is a floatation desilication process for bauxite, comprising grinding, classifying and floatation, wherein the raw materials are pre-separated to give fine products and coarse products on condition that -0.074mm grinding fineness is 30 to 95%, and fine products react with floatation agent by floatation process to yield refined foam; coarse products are reground to give the reground products which react with floatation agent, and then are processed in refining process, the mixture of reground coarse products and fine products are refined to give final concentrate, refined underflow returns in sequence and the scavenging underflow becomes the final mine tailing. Quick floatation of coarse particles and high recovery rate and quality of concentrate can be realized, and as a result, the level of resources utilization and economic benefit can be improved remarkably.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

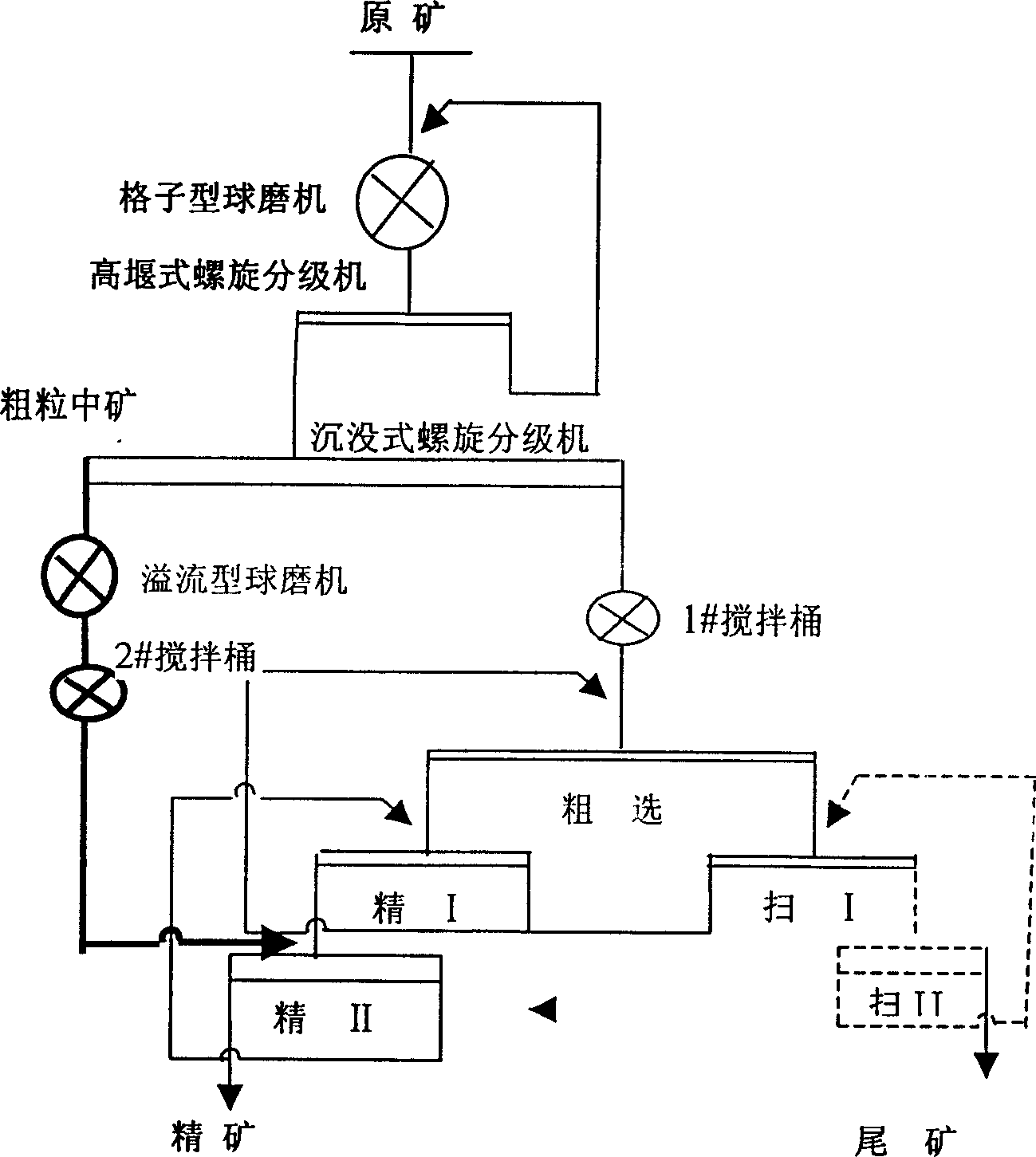

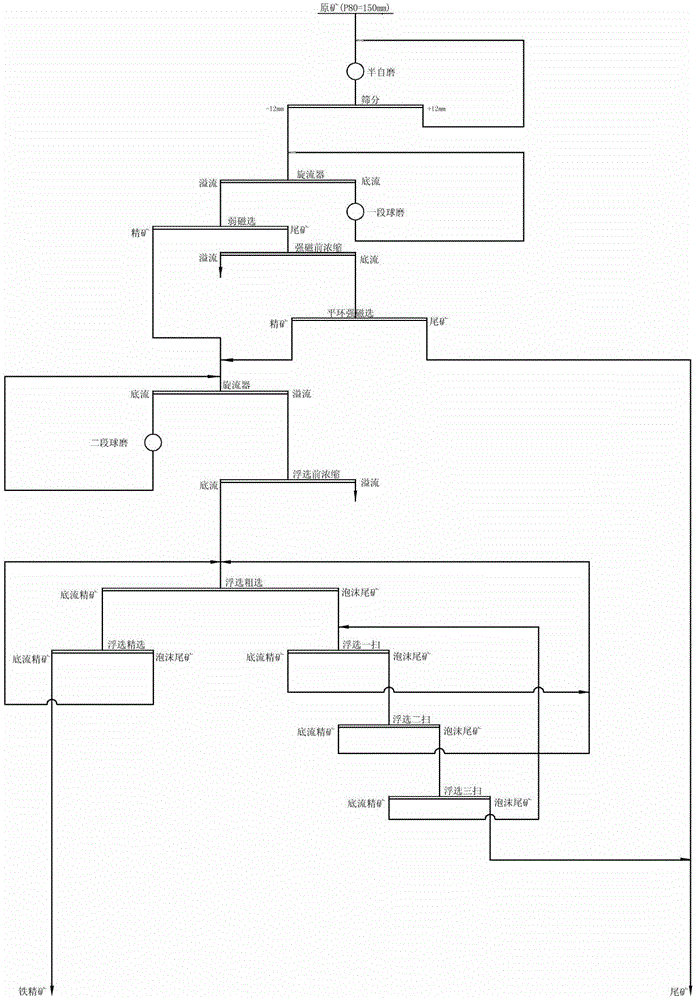

Micro-fine particle red magnetic mixed iron ore sorting process

The invention relates to a micro-fine particle red magnetic mixed iron ore sorting process characterized by including stage grinding-classification-weak magnetic operation-strong magnetic operation-anionic reverse flotation operation, the anionic reverse flotation is performed by use of a one-coarse, one-fine and large circulation mine returning three-scavenging system. According to the micro-fine particle red magnetic mixed iron ore sorting process, first stage ball-milling is performed, then weak magnetic-strong magnetic separation is performed, excess-grinding is effectively prevented, the effect of the magnetic separation can be ensured; after secondary stage ball-milling, anionic reverse flotation operation is directly performed, the advantage of good micro-fine particle iron ore sorting effect of reverse flotation is full used, by use of the technological process, iron concentrate with the iron grade of 65% and the iron recovery rate of more than 73% can be obtained, the final sorting indicators can be further optimized, and the high recovery rate of the iron concentrate can be ensured.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

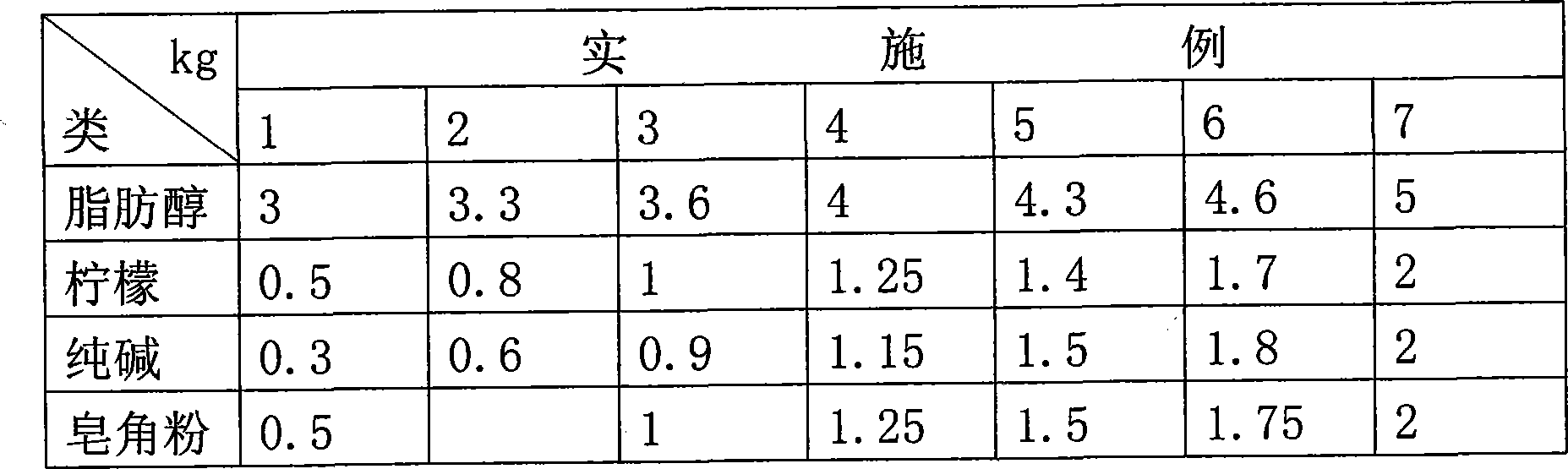

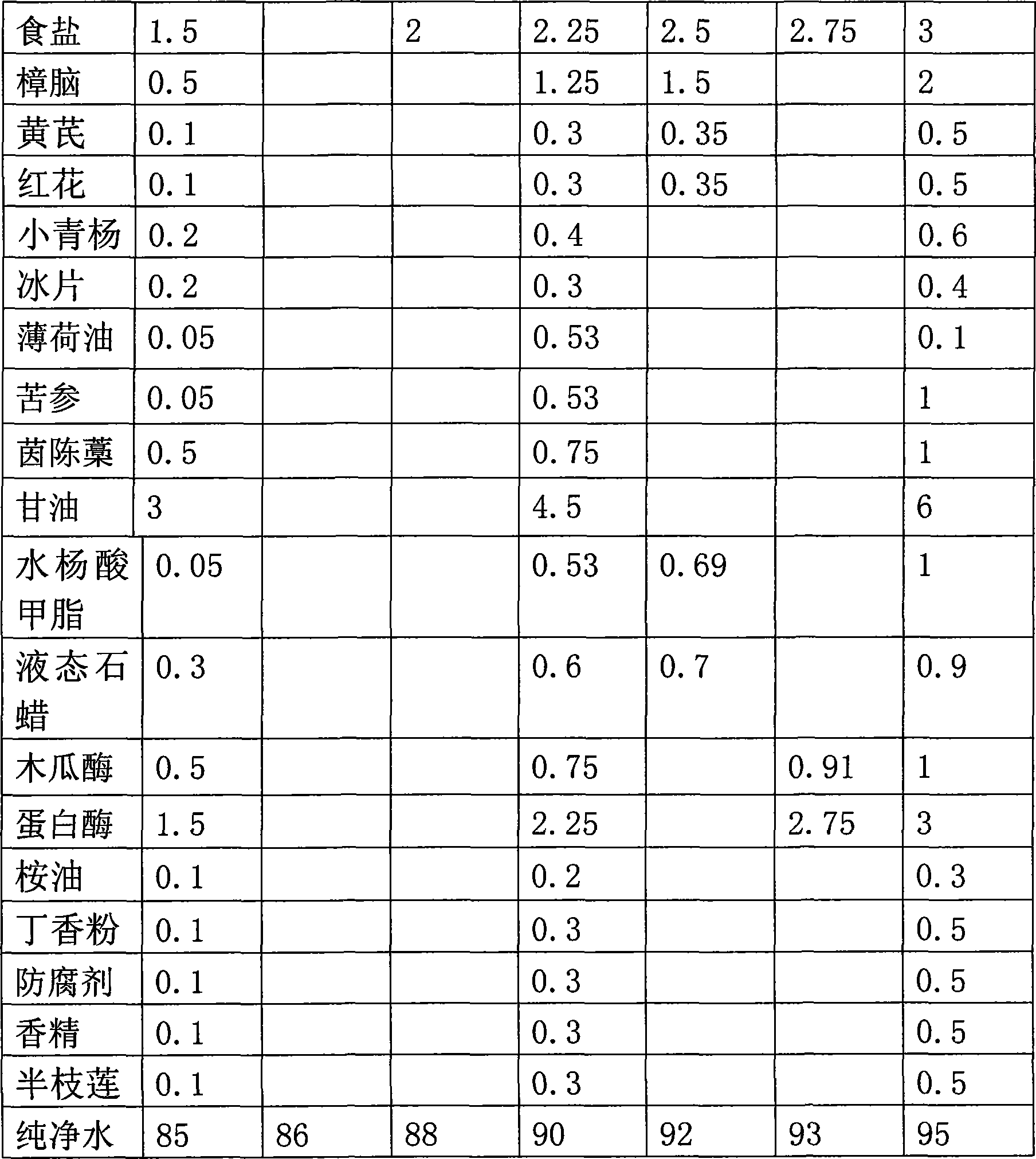

Health-care multipurpose washing liquor and method for making same

InactiveCN101182430AImprove immunityNo side effectsAntibacterial agentsPeptide/protein ingredientsDiseaseAdjuvant

The invention relates to health-care multi-functional lotion and a preparation method thereof, and relates to the technological field of detergent, sterilizing agent, disinfectant and pharmaceutical preparation. The invention is preparation made according to the following weight portions: 3 portions to 5 portions of fatty alcohol, 0.5 portions to 2 portions of lemon, 0.3 portions to 2 portions of soda, 85 portions to 95 portions of purified water, 0.5 portion to 2 portions of soap powder, and 1.5 portions to 3 portions of salt. The method only requires the respective dissolution and direct mixing of the materials. The invention has significant effects; the invention not only can significantly remove pesticide residue in fruits and vegetables and decontaminate, but also has better health-care functions of sterilization, microbial inhibition, disinfection, anti-inflammation, pain easing, itch prevention, promotion of blood circulation, promotion of menstruation, activation and other functions for human bodies through external washing (or oral taking); the invention has better health-care and adjuvant therapeutic effects for treatment of various types of inflammation, bacteria, virus and other diseases; and the invention has beautifying and slimming effects. The formula is unique and scientific; the preparation method is simple and easy; the cost is low and economic; and the social benefits are good.

Owner:平风智

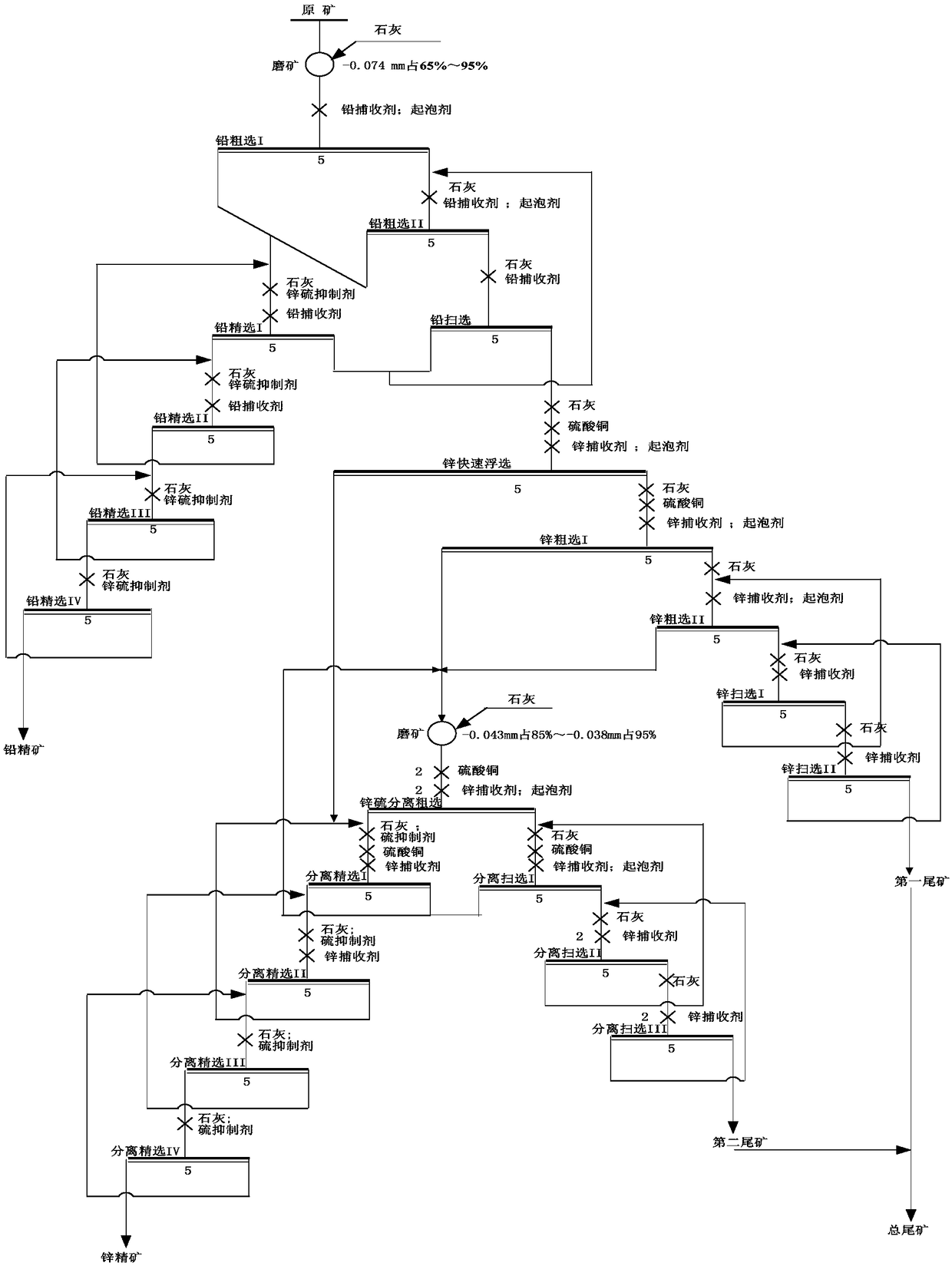

Beneficiation method of high-sulfur lead zinc ores under high-temperature environment

The invention discloses a beneficiation method of high-sulfur lead zinc ores under high-temperature environment. After raw ore pulp with a pH value above 12 is prepared, the lead roughing and the leadscavenging are performed to obtain lead roughing concentrates and lead scavenging tailing pulp; zinc sulfur inhibitors are added in the lead roughing concentrates for lead refining to obtain lead concentrates; the zinc quick flotation, the zinc roughing and the zinc scavenging are performed on the lead scavenging tailing pulp to obtain zinc quick flotation roughing concentrates and zinc roughingcrude concentrates; the zinc roughing crude concentrates are grinded again; then, the zinc sulfur separation roughing and the zinc sulfur separation scavenging are performed; and after the zinc quickflotation roughing concentrates and the zinc sulfur separation flotation roughing concentrates are merged, high-sulfur inhibitors are added for refining zinc sulfur separation zinc to obtain zinc concentrates. The pH value of the pulp is always kept above 13 in each flotation procedure. The beneficiation method can realize efficient recovery of the high-sulfur lead zinc ores under high-temperatureenvironment, and effectively guarantees the beneficiation process technical index of lead and zinc minerals.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

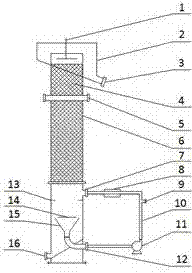

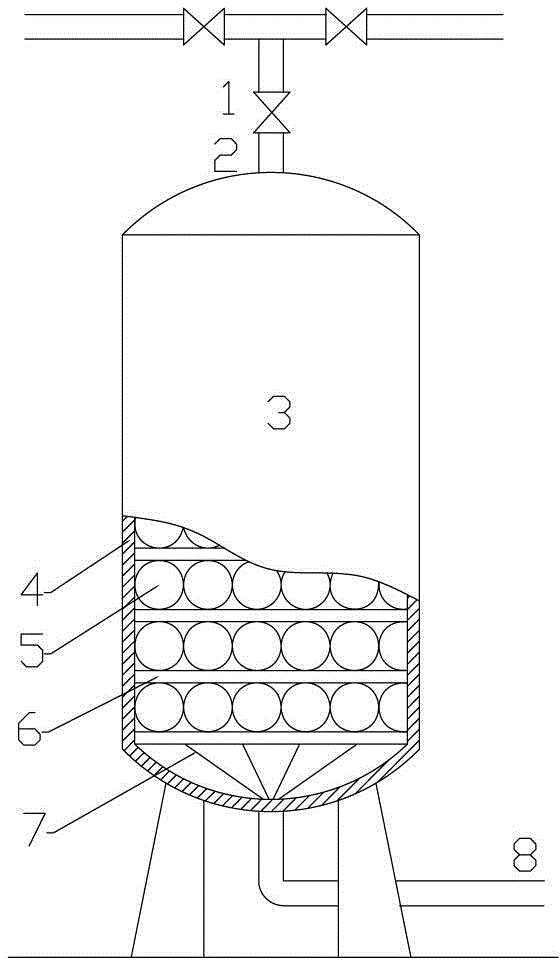

Novel flotation column

The invention relates to a novel flotation column. A main body of the novel flotation column is a column body; two-section type pore plate rolling padding is arranged in the column body; a middling circulating device is arranged on the lower portion of the column body and comprises an inverted-cone-shaped barrel, a circulating pump and an air bubble generator which are sequentially connected to one another through a pipe; the inverted-cone-shaped barrel is arranged in the column body; an opening of the inverted-cone-shaped barrel is upward; the circulating pump and the air bubble generator are arranged on the outside of the column body; the inverted-cone-shaped barrel is connected with the circulating pump through a liquid inlet pipe; and the air bubble generator is connected with the inside of the column body through a liquid outlet pipe. The novel flotation column is simple in structure and cannot be blocked easily; rising air bubbles are in contact with descending ore pulp sufficiently; and the flow state of the ore pulp is stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

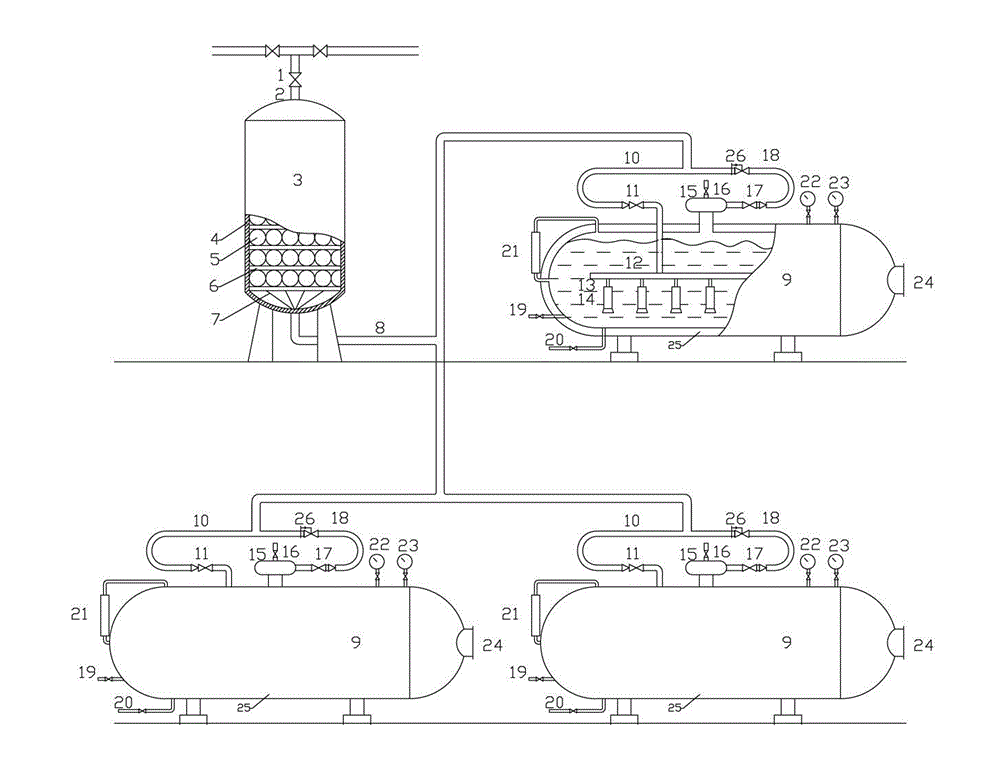

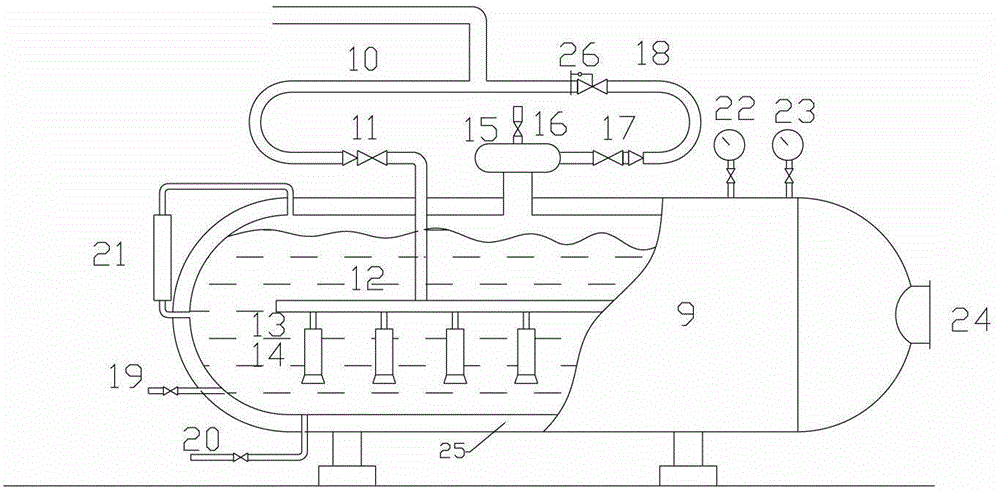

Novel superheated steam storing device and method

The invention discloses a novel superheated steam storing device and a method. The device comprises a packed bed heat accumulator, a steam heat accumulator, a pressure regulating valve group and relevant pipelines and valves, wherein a hot end pipeline of the packed bed heat accumulator is connected with a main steam pipeline of a solar thermal power generation system, a cold end pipeline of the packed bed heat accumulator is provided with two ways of branched pipes, the two ways of branched pipes are connected with a steam inlet pipeline and an exhaust steam pipeline of the steam heat accumulator respectively, and the pressure regulating valve group is arranged on the exhaust steam pipeline of the steam heat accumulator. By means of the device, heat of superheat and latent heat of vaporization of the superheated steam can be stored respectively, high quality storing of energy is achieved, heat and steam can be stored in the same device, the system structure is remarkably simplified, and equipment investment and operating maintenance costs are saved.

Owner:中科中蓝能源科技(北京)有限公司

Preparation method of low-temperature solidified metallurgical pellets

The invention belongs to the field of comprehensive utilization of metallurgical residue resources and specifically relates to a preparation method of low-temperature solidified metallurgical pellets.In order to solve the problems that when steel and iron scrap powder are adopted for making pellets, the generated pellets are poor in forming performance, low in sintering intensity, likely to be pulverized and the like. The provided preparation method of the low-temperature solidified metallurgical pellets includes the following steps of a, taking and weighing vanadium titano-magnetite concentrates, steel and iron scraps and a compound bonding agent according to a mass ratio of (28-65):(34-68):(2-4), adding water, uniformly mixing the mixture, and conducting pelleting to obtain raw pellets;b, drying the raw pellets obtained in step a until the moisture content is lower than or equal to 1%, and obtaining dry pellets; c, preheating the dry pellets and conducting sintering to obtain finished pellet products. The preparation method is simple in operation, the prepared pellet products are high in strength, MFe of the finished pellet products is 55-58%, the compressive strength of each pellet is 2,600-3,100 N, the drum index is 90.0-93.5%, and the production cost is low. The new method is provided for comprehensive utilization of the steel and iron scrap powder, and obvious economicbenefits are obtained.

Owner:PANZHIHUA UNIV +1

Iron-rich metallurgy dust mud and high-calcium garbage incineration fly ash collaborative fusion treatment method

ActiveCN110373546AHigh economic valueReduce energy consumptionProcess efficiency improvementSlagPre treatment

The invention discloses an iron-rich metallurgy dust mud and high-calcium garbage incineration fly ash collaborative fusion treatment method. According to the method, high-calcium garbage incinerationfly ash is subjected to washing pretreatment and then is mixed with iron-rich metallurgy dust mud and a carbonaceous reducing agent, clusters are formed through pressing, drying is conducted, and block masses are obtained; carbon-based backing materials are distributed at the bottom of a rotary hearth furnace, then, the block masses are distributed on the surface layers of the carbon-based backing materials, fusion reducing is conducted, grained iron and CaO-SiO2-MgO-FeO slag is obtained, and zinc-rich raw materials are recycled from smoke. According to the method, through iron-rich metallurgy dust mud and high-calcium garbage incineration fly ash collaborative treatment, the garbage incineration fly ash is harmlessly treated, and meanwhile valuable utilization of metallurgy dust mud is achieved.

Owner:CENT SOUTH UNIV +1

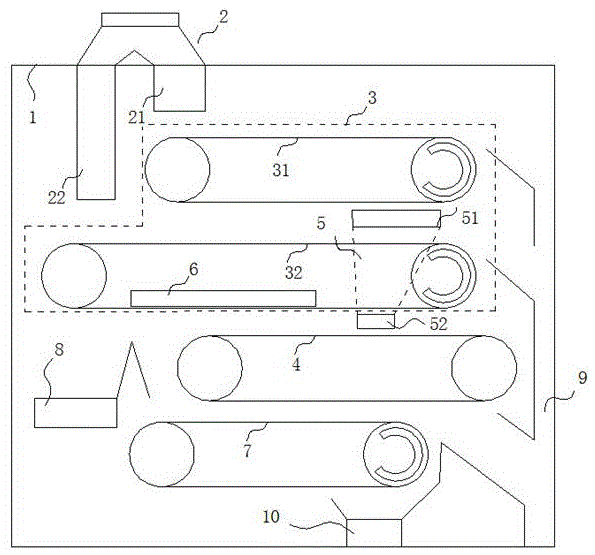

Multi-feeding-belt magnetic separator

ActiveCN105562200AAdjust the size of the forcePromote stratificationMagnetic separationChemical industryMagnetic separator

The invention relates to a device for separating magnetic minerals milled by milling equipment in the industries of metallurgy, mine, chemical industry and the like, in particular relates to a device for magnetic separation of mineral powder extruded by a high-pressure roller mill, and concretely relates to a multi-feeding-belt magnetic separator. The multi-feeding-belt magnetic separator comprises a belt pre-separation mechanism, a belt conveying mechanism and a belt tail-separation mechanism which are arranged from top to bottom, wherein the belt pre-separation mechanism comprises more than two stages of belt magnetic separation mechanisms which are arranged in an overlapped mode; each belt magnetic separation mechanism comprises a transmission wheel, a magnetic roller and a magnetic separation belt sleeving the transmission wheel and the magnetic roller; a magnetic system is arranged inside a lower belt of the magnetic separation belt adjacent to the belt conveying mechanism; and the magnetic field of the magnetic system covers the discharge end of the belt conveying mechanism. The multi-feeding-belt magnetic separator is simple in structure, large in treatment amount and capable of simultaneously considering the separated ore grade and tailing rate; the magnetic system structure of each part can be sufficiently and reasonably utilized through a reasonable structure layout; and under the condition of guaranteeing the magnetic separation effect, the treatment capability is high, and the equipment is compact in shape and small in occupation area.

Owner:CHENGDU LEEJUN IND

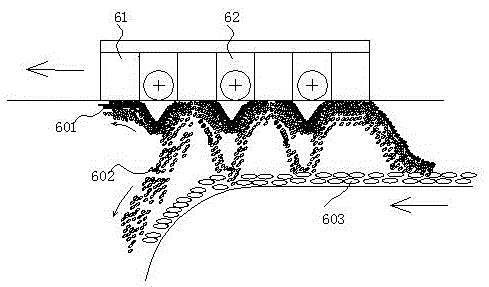

Interference-free middle-deep-stratum geothermal resource gradient utilization heating system

PendingCN109931651AImprove energy efficiency ratio and heating loadSmall heat transfer temperature differenceHeat pumpsGeothermal energy generationThree levelHeating system

The invention discloses an interference-free middle-deep-stratum geothermal resource gradient utilization heating system. The interference-free middle-deep-stratum geothermal resource gradient utilization heating system comprises a casing pipe (1), a heat insulation pipe (2), a heat exchanger (7), a high-temperature heat pump (8) and a low-temperature heat pump (9). According to the interference-free middle-deep-stratum geothermal resource gradient utilization heating system, through a three-level system including the heat exchanger, the high-temperature heat pump and the low-temperature heatpump, the high-grade portion, the middle-grade portion and the low-grade portion in geothermal energy can be sequentially absorbed and utilized, the middle-deep-stratum geothermal resource gradient utilization heating purpose is finally achieved, and the energy efficiency ratio and the heating load of the heating system are significantly increased. The heat insulation pipe (especially a vacuum heat insulation pipe) is taken as a central pipe, therefore, the heat dissipation capacity of water in the central pipe can be effectively reduced, and the grade of the geothermal energy can be effectively kept. Meanwhile, the advantages of an interference-free geothermal exploitation mode adopting the vacuum heat insulation pipe and the geothermal resource gradient utilization heating system are combined, and therefore the characteristics of being efficient, environmentally friendly and capable of achieving sustainable utilization are achieved.

Owner:XI'AN PETROLEUM UNIVERSITY +1

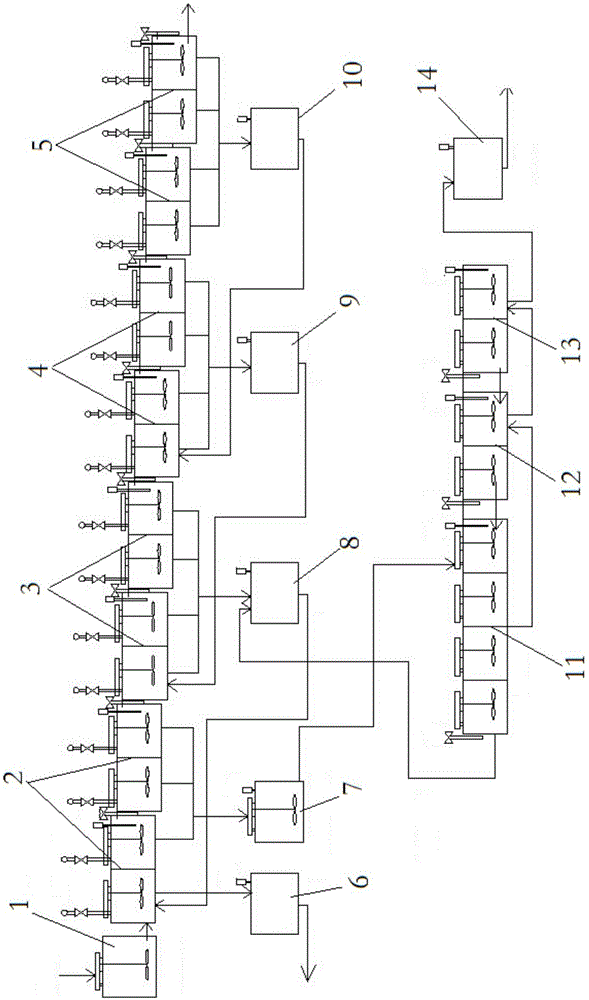

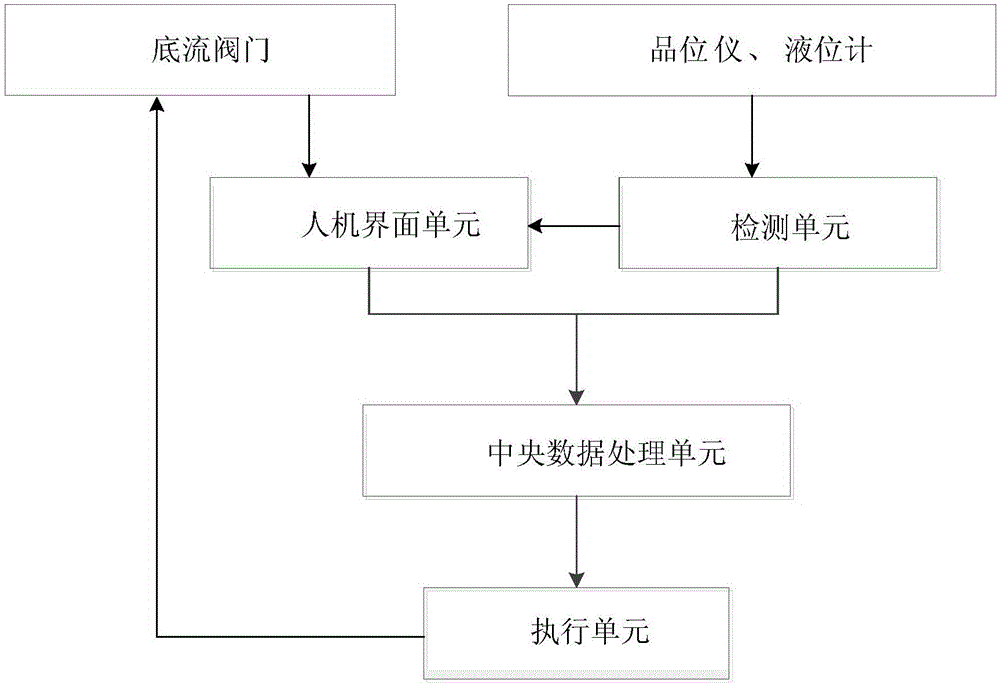

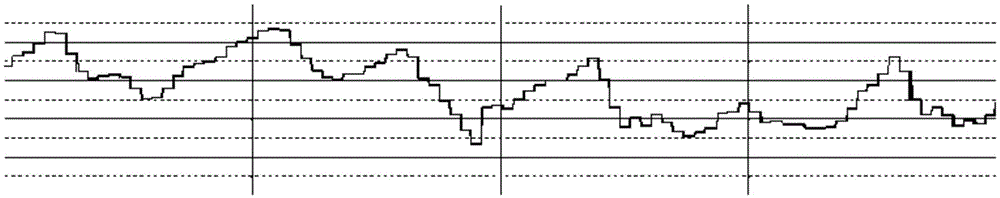

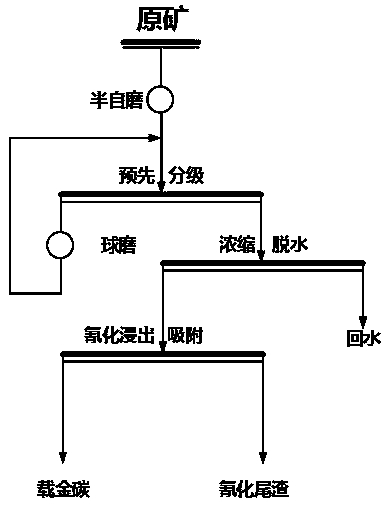

Mixed concentration grade control system and control method

ActiveCN105022302AGuaranteed qualifiedIncrease the amount of scrapingProgramme control in sequence/logic controllersLower limitHuman–machine interface

The invention relates to the technical field of ore dressing, especially to a mixed concentration grade control system and control method. The mixed concentration grade control system comprises a human-machine interface unit, a detection unit, a central data processing unit and an execution unit. Setting parameters related to mixed concentration grades are set in the human-machine interface unit; the detection unit detects actual parameters related to the mixed concentration grades in real time; the central data processing unit carries out intelligent analyses and determination on the actual parameters and the set parameters directly; and according to the analysis and determination result, the execution unit controls correlated motion and adjusts the set parameter values, so that all actual parameters are kept in a set parameter range. According to the invention, on the basis of automatic control, the concentration grade can be controlled between a set upper limit and a set lower limit stably, thereby guaranteeing the good concentration product quality.

Owner:CHINA GOLD INNER MONGOLIA MINING

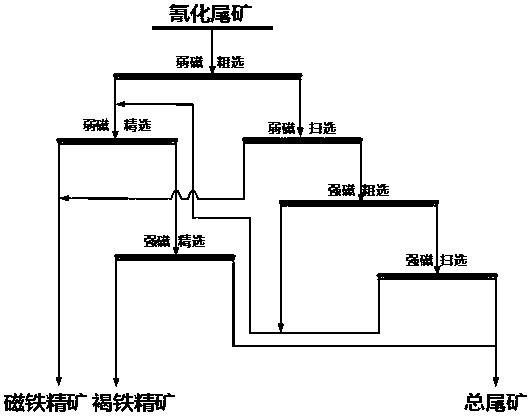

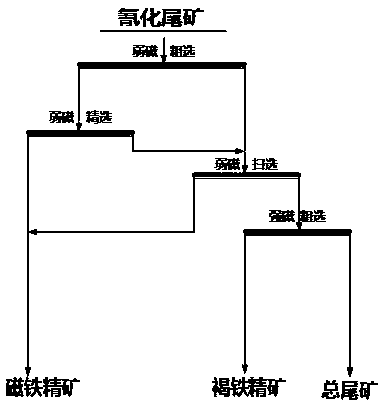

Beneficiation method for comprehensively recovering magnetite from cyanide tailings

The invention discloses a beneficiation method for comprehensively recovering magnetite from cyanide tailings. The method includes steps of weak magnetic roughing, weak magnetic scavenging, strong magnetic roughing, strong magnetic scavenging, weak magnetic concentration, and strong magnetic concentration. The method, under the condition of less modifying a conventional beneficiation plant and achieving a low modification cost, avoids calcinations of magnetic separation tailings by means of the prior and subsequent grading and matching design of the reasonable strong and weak magnetic field, and on the premise of recovering the gold to the utmost extent, not only can ensure an iron grade, but also can greatly improve the yield and recovery rate of the magnetite, maximizes a resource value,and achieves a high commercial promotional value. The method solves the technical problem that gold and iron are simultaneously present in the ore and the cyanide leaching of gold and silver requiresvery fine feed particle size which may seriously affect the magnetic separation and recovery of iron if the feed particle size is fine to a certain extent, which makes it difficult to separate the magnetite in physical beneficiation and difficult to obtain a magnetite concentrate and a brown iron concentrate with high recovery rates and qualified iron grade contents.

Owner:鹤庆北衙矿业有限公司 +1

Method for preparing reduction chromium powder through microwave heating

The invention relates to a method for preparing reduction chromium powder through microwave heating and belongs to the technical field of microwave metallurgy. The method comprises the steps that firstly, Cr2O3, charcoal and coal are smashed, and then the Cr2O3 and the charcoal are evenly mixed to obtained a mixed material; secondly, materials are distributed in a layered mode, wherein the mixed material obtained in the first step is distributed and arranged on the bottom layer, and the smashed coal powder which is prepared in the first step and accounts for, by mass, three to four percent of the mixed material is distributed and arranged on the upper layer; thirdly, the materials arranged in second step are put in a microwave reactor to be heated to 1300 DEG C to 1400 DEG C with heat preservation carried out for 30 min to 60 min, the reduced and heated furnace charge is cooled, smashed and screened, and thus the reduction chromium powder is obtained. According to the method, due to the fact that microwaves are taken as a heating source, the temperature increasing speed and the heating efficiency are improved, the obtained product is made to be in a fluffy state, and meanwhile the rawish phenomenon is avoided.

Owner:KUNMING UNIV OF SCI & TECH

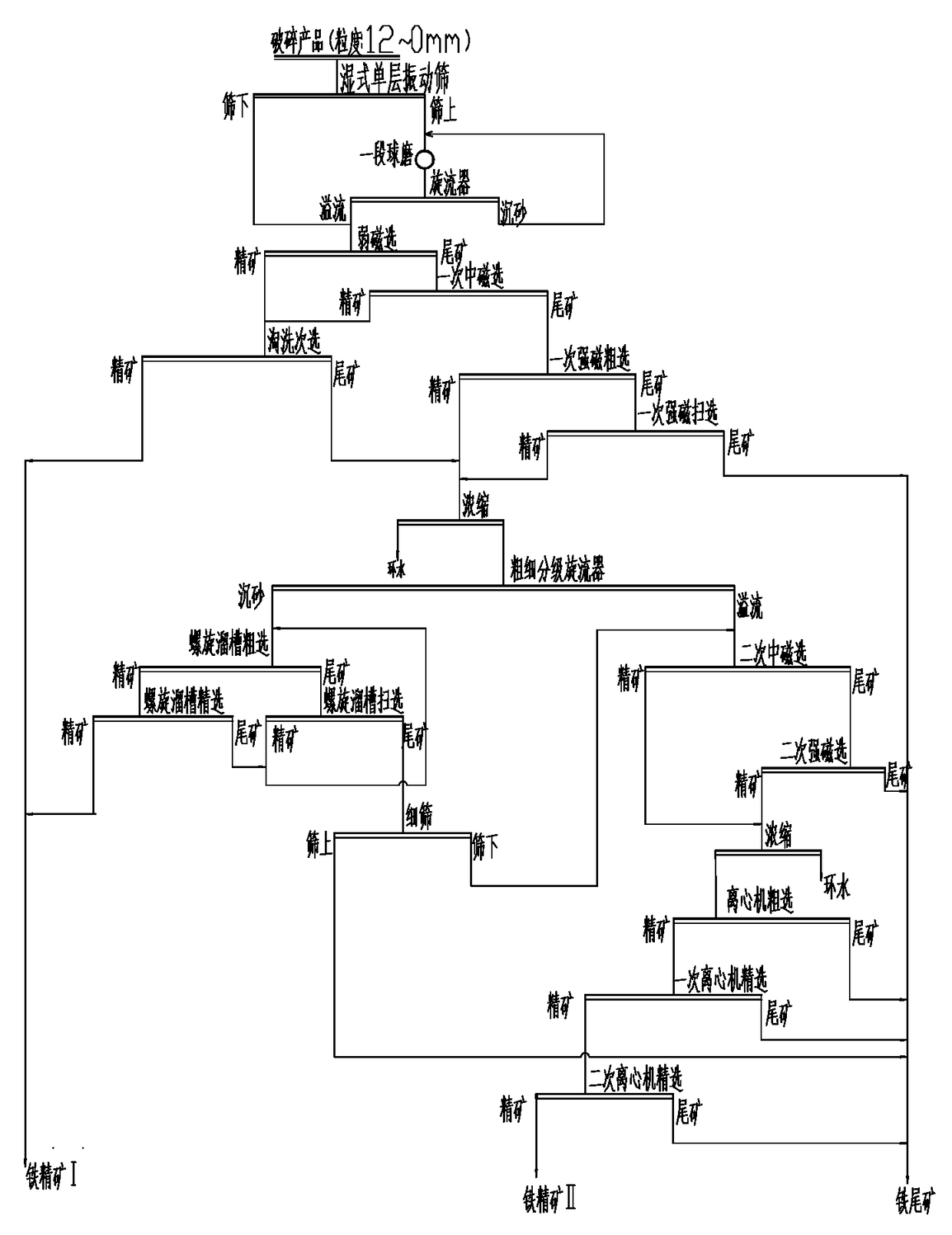

High-yield two-product mixed maghemite beneficiation process

The invention relates to a high-yield two-product mixed maghemite beneficiation process. The high-yield two-product mixed maghemite beneficiation process comprises three-section breakage including coarse breaking, medium breaking and fine breaking on mixed maghemite, and is characterized by further comprising the following steps: sieving operation, a one-section closed circuit grinding operation implemented by a one-section ball-milling-cyclone, primary beneficiation operation, coarse and fine classification operation, reselection operation, secondary magnetic separation operation and centrifuging operation; a primary magnetic separation operation sieve treats overflow products of one-section closed circuit grinding operation, sieving operation and undersizes, the coarse and fine classification operation treats bulk concentrate obtained by primary beneficiation, the reselection operation treats coarse grain products of the coarse and fine classification operation, the secondary beneficiation operation treats coarse particle products of the coarse and fine classification operation, and the centrifuging operation treats bulk concentrates of secondary weak magnetic separation. The high-yield two-product mixed maghemite beneficiation process has the advantages that iron ore concentrates I with grade being 62% for pelletizing raw materials and iron ore concentrates II with grade being 58% for sintered raw materials can be selected out.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

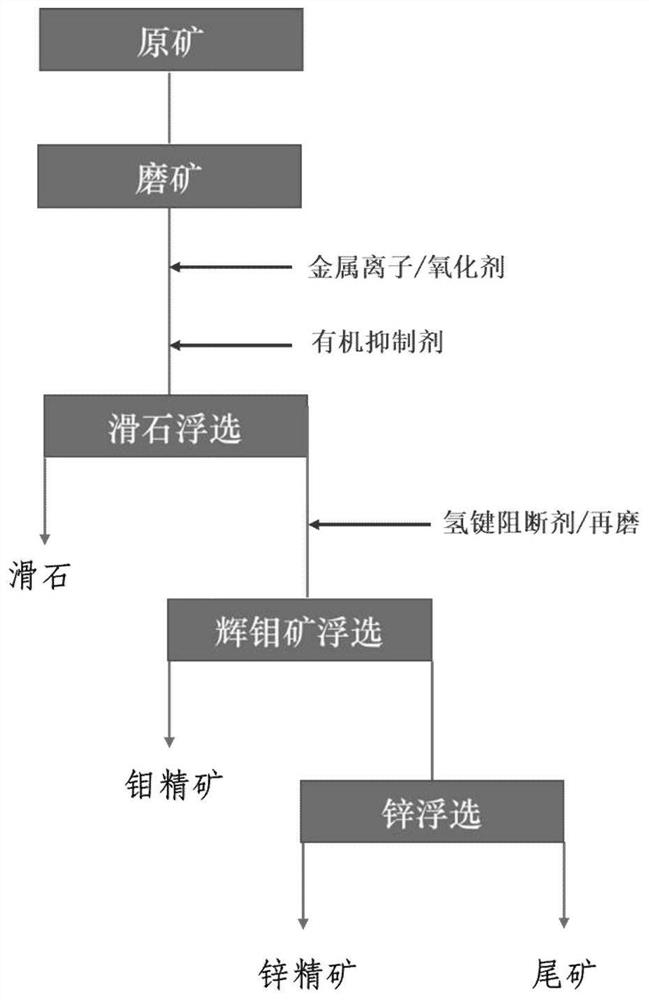

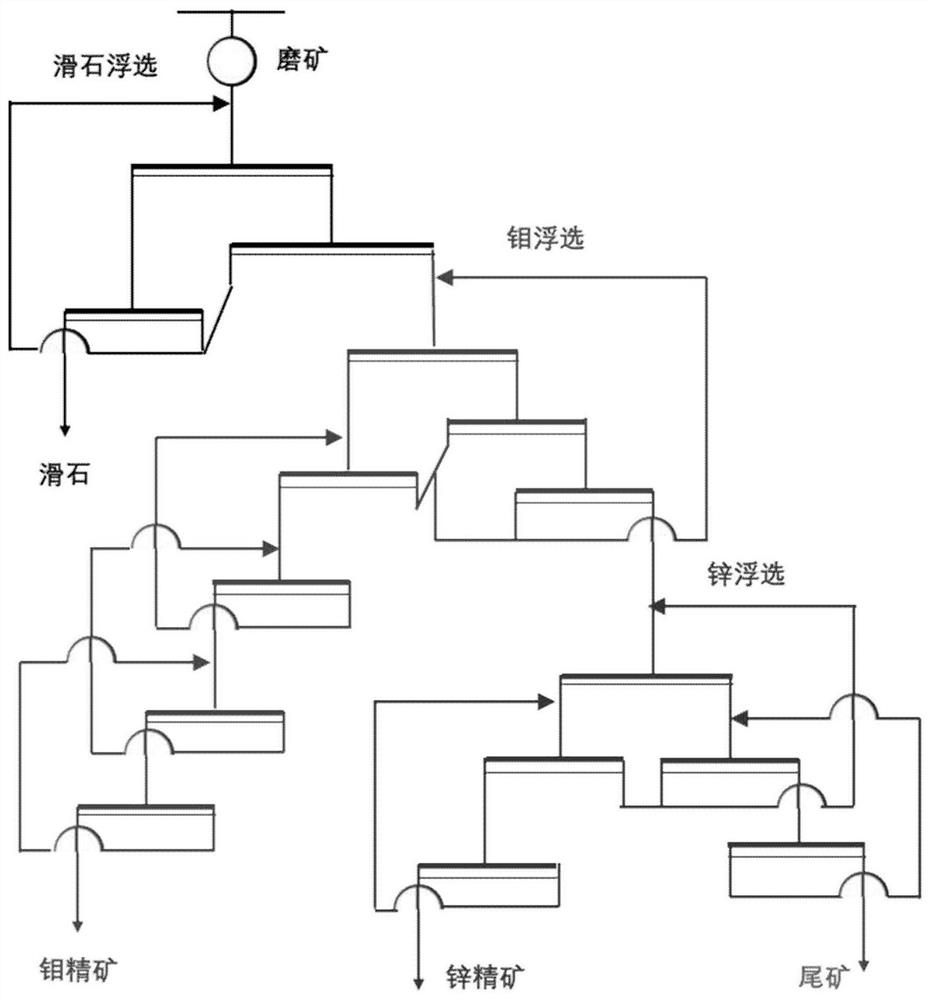

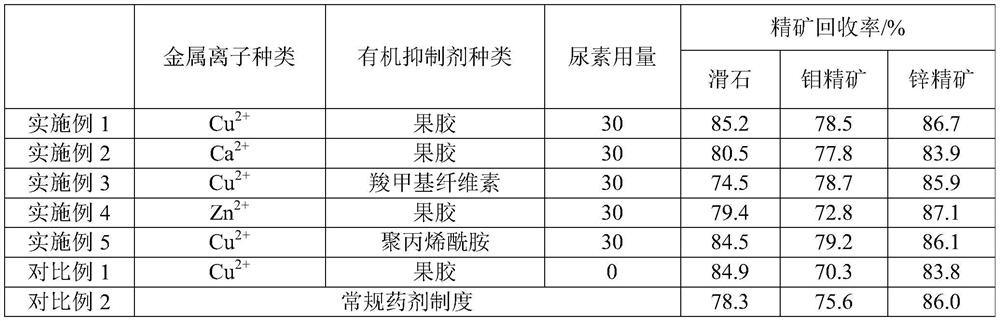

Flotation method for talc-containing molybdenum-zinc ore

The invention discloses a flotation method for talc-containing molybdenum-zinc ore. The flotation method comprises the following steps: (1) grinding ore; (2) with metal ions and an organic inhibitor or an oxidant and an organic inhibitor as a combined inhibitor for molybdenite and sphalerite, carrying out talc flotation operation; (3) carrying out regrinding and reagent removal treatment on talc flotation tailings or desorbing the adsorbed organic inhibitor by using urea and derivatives thereof as hydrogen bond blockers, and carrying out molybdenite flotation operation to obtain a molybdenum concentrate and molybdenum flotation tailings; and (4) conductingzinc flotation operation on the molybdenum flotation tailings so as to obtain a zinc concentrate and tailings. According to the method,the metal ions and the organic inhibitor or the oxidizing agent and the organic inhibitor are adopted as the combined inhibitor for molybdenite and sphalerite; and before molybdenite flotation operation, the organic inhibitor is desorbed through regrinding reagent removal or urea and derivatives thereof are used as hydrogen bond blockers, so cleanness and mineral dispersion on mineral surfaces arepromoted, and subsequent adsorption of a collecting agent is facilitated.

Owner:CENT SOUTH UNIV

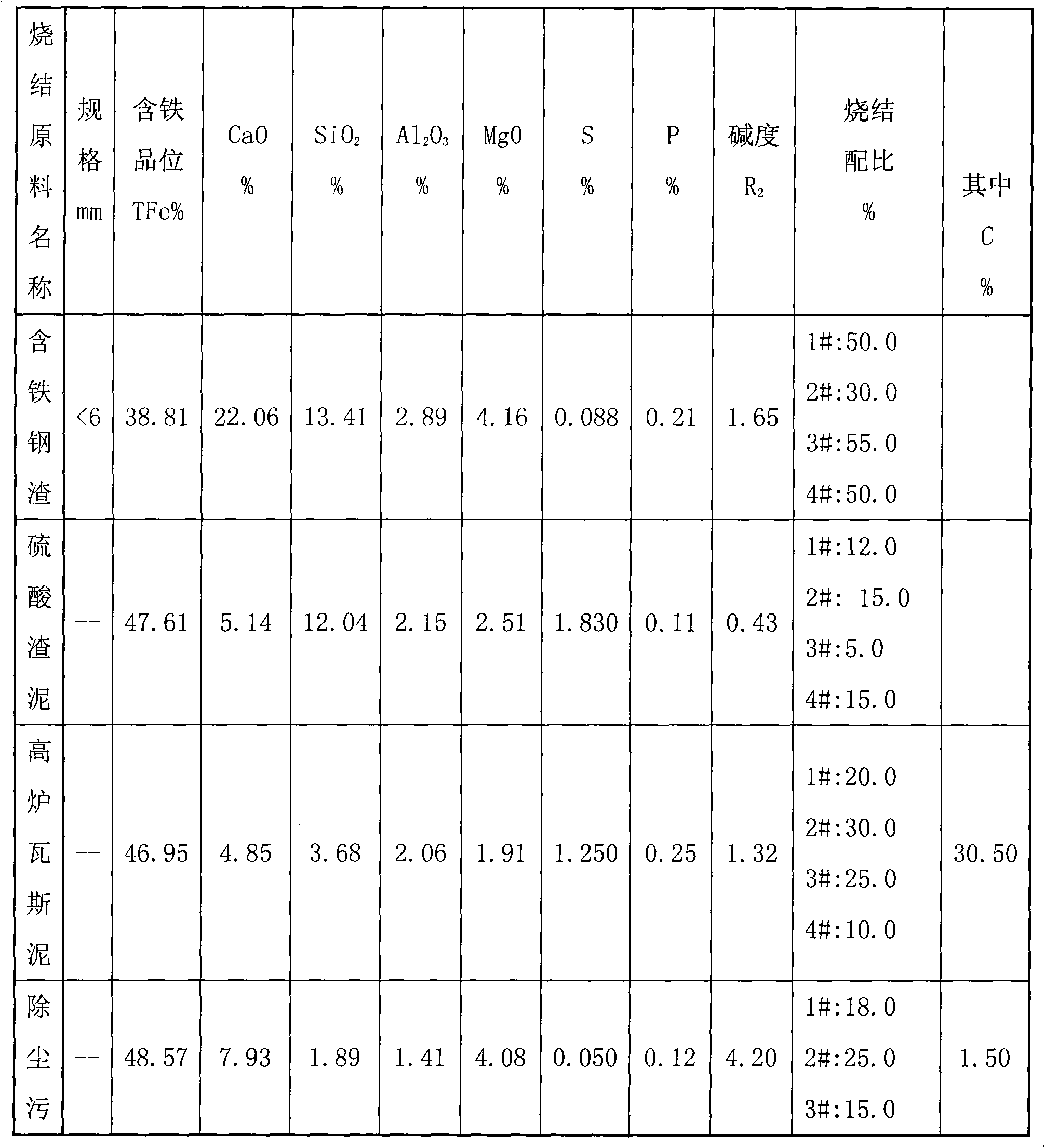

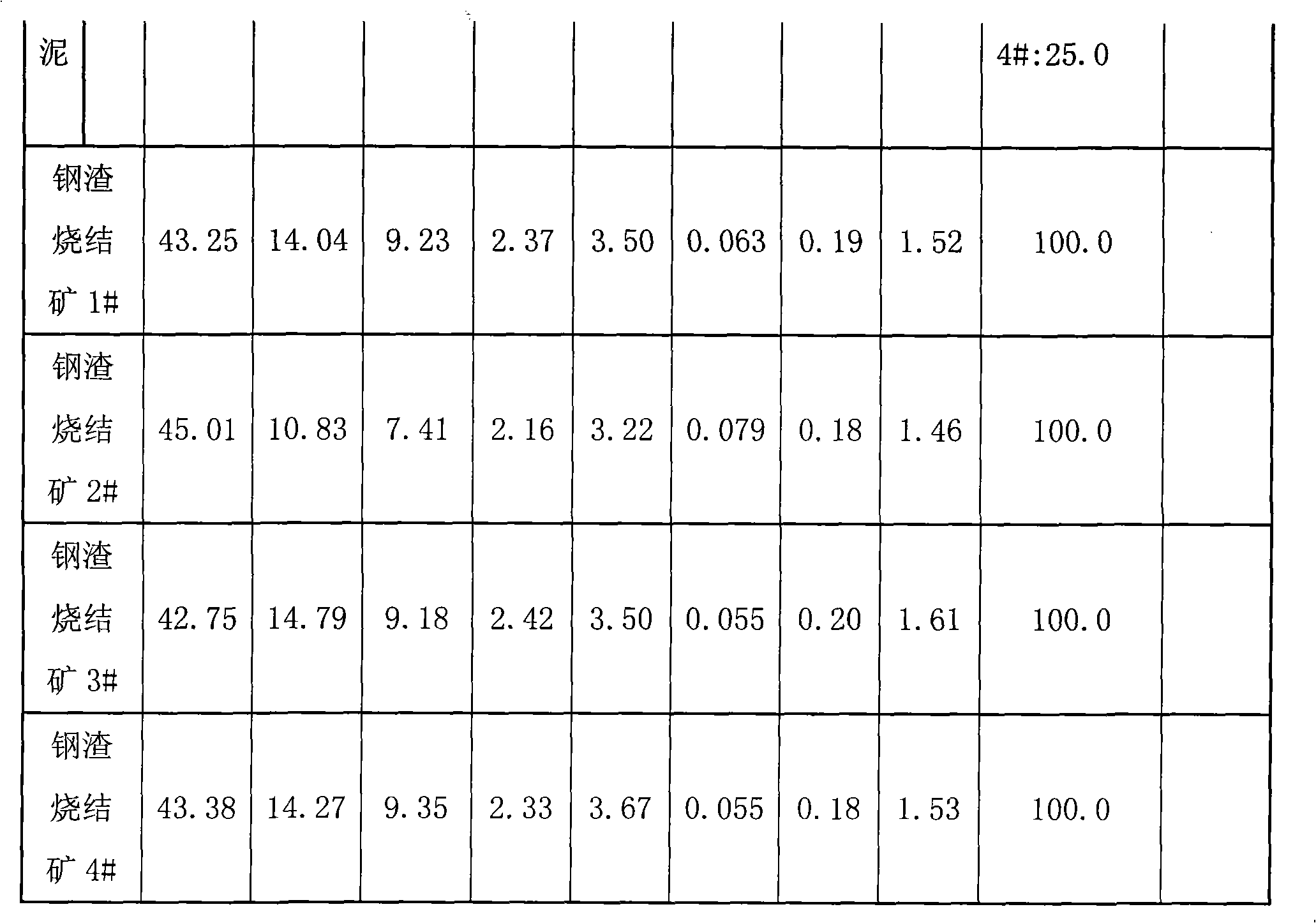

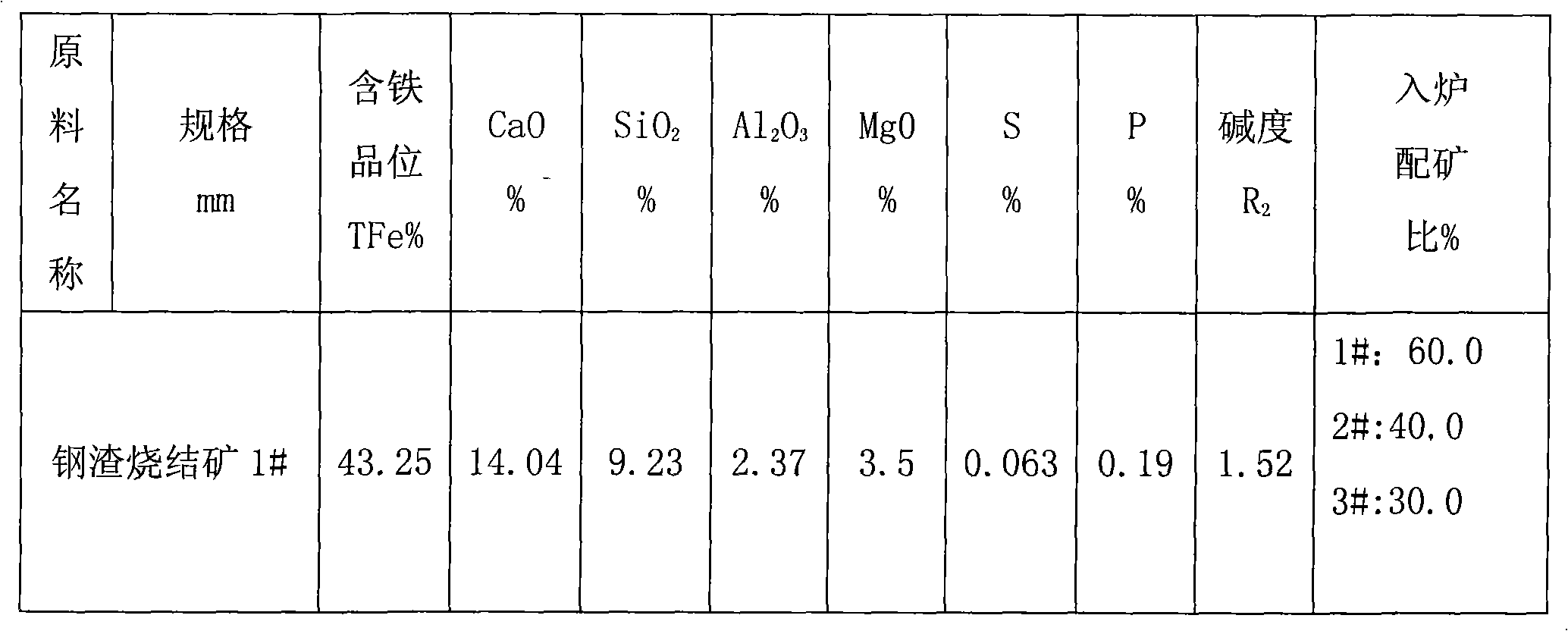

Blast furnace ironmaking production process by cyclically utilizing steel slag and iron slag in metallurgy and chemical industry

The invention relates to metallurgy process, and discloses a blast furnace ironmaking production process by cyclically utilizing steel slag and metallurgic and chemical slag containing iron. The process comprises the following steps: low grade steel slag containing iron and metallurgic and chemical slag containing iron are classified and selected; the low grade steel slag containing iron with grain diameter more than or equal to 6mm, and low grade steel slag containing iron with grain diameter less than 6mm are selected from the low grade steel slag containing iron; the low grade steel slag containing iron with grain diameter less than 6mm and metallurgic and chemical slag containing iron are combined and sintered to prepare a steel slag sintering ore; the low grade steel slag containing iron with grain diameter more than or equal to 6mm and the steel slag sintering ore obtained on the step 2 are used as raw materials of blast furnace ironmaking, silica is used as a smelting additive,and coke is used as fuel to carry out blast furnace ironmaking. The process achieves modification of slag resource while sufficiently and cyclically utilizing ferritic resource, thereby realizing theaim of slag resource comprehensive utilization.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION

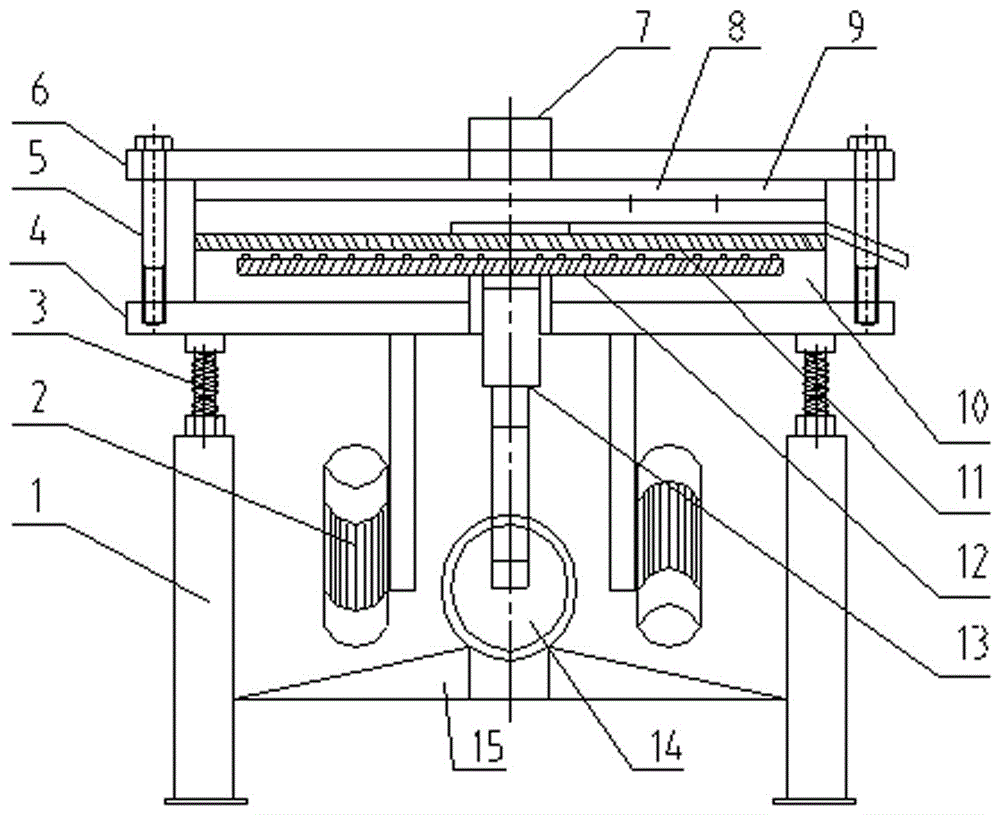

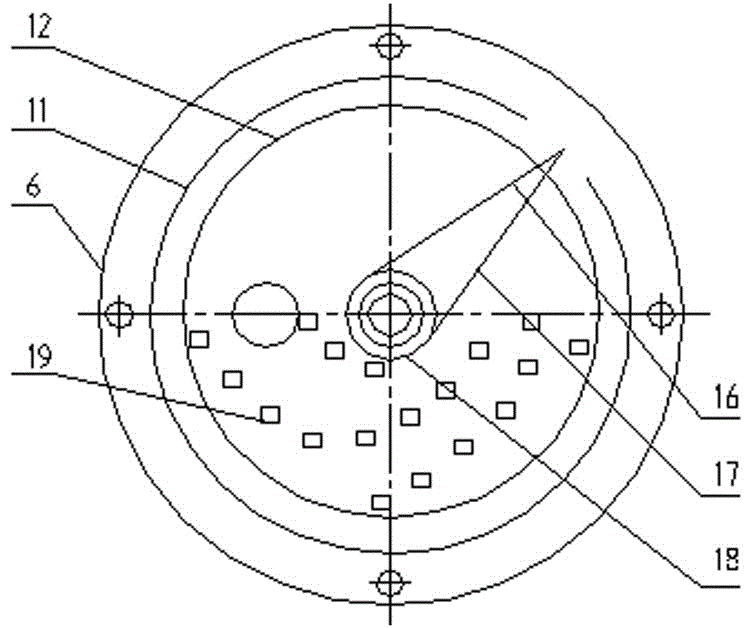

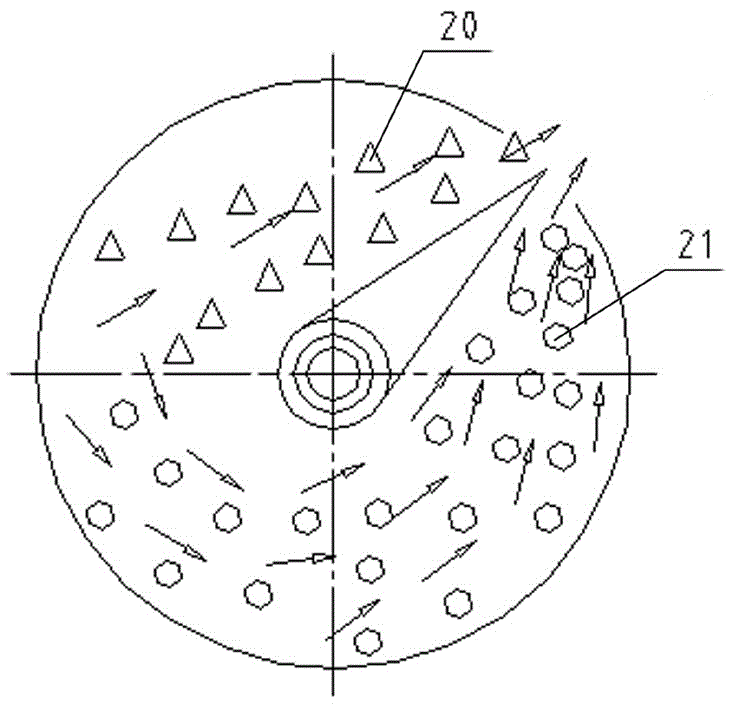

Weak-magnetic-field dry-type magnetic separating device with involute-arranged permanent magnet system

InactiveCN105665127AGuaranteed Scattered EntryGuaranteed gradeMagnetic separationElastic vibrationNon magnetic

The invention discloses a weak-magnetic-field dry-type magnetic separating device with an involute-arranged permanent magnet system. The weak-magnetic-field dry-type magnetic separating device comprises a body base installed at the upper ends of supports through elastic vibration pieces and vibration motors installed at the bottom of the body base. A top cover is installed above the body base, and a closed cavity is jointly formed by the body base and the top cover; a first feeding hole is formed in the center of the top cover; the closed cavity is divided by a disc support arranged in the cavity into an upper cavity body and a lower cavity body, a partition plate is arranged in the upper cavity body on the disc support, a second feeding hole is formed in the portion, bias arranged on one side of the center, of the partition plate, and a magnetic disc is arranged in the lower cavity body below the disc support, and is composed of a magnetic disc body and a plurality of pieces of permanent magnet steel arranged in an involute mode in the circumferential direction of the magnetic disc body; a discharging opening is formed in the side wall of the upper cavity body on the disc support, and a non-magnetic material baffle and a magnetic material baffle are arranged in the center of the upper plane of the disc support, wherein the tail end of the non-magnetic material baffle and the tail end of the magnetic material baffle extend to the discharging opening. By means of the weak-magnetic-field dry-type magnetic separating device, high-grade recycling of magnetic-mineral ore concentrate is achieved.

Owner:HENAN POLYTECHNIC UNIV

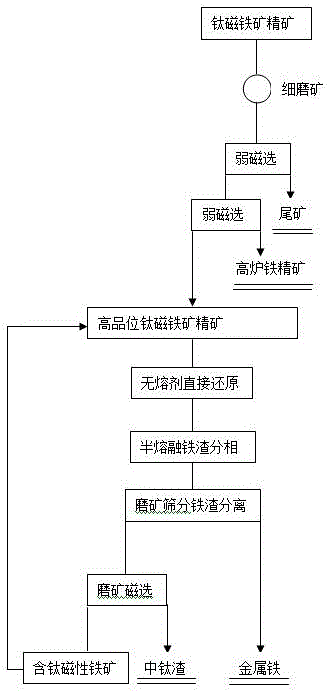

Method of using vanadium-titanium magnetite concentrate to produce middle-grade titanium slag

ActiveCN106498109ARaise the gradeLow flotation efficiencyShaft furnaceProcess efficiency improvementResource utilizationMagnetite

The invention relates to a method of using vanadium-titanium magnetite concentrate to produce middle-grade titanium slag, belongs to the field of combined concentration and smelting process comprehensive resource utilization, and aims to solve the problem that the titanium resources of Panzhihua vanadium-titanium magnetite ore cannot be effectively utilized so far. The method includes that the vanadium-titanium magnetite concentrate is used as the raw material, high-purity preparation is used to remove impurities such as calcium, aluminum and silicon, direct reduction without flux is performed, half-melting iron slag phase splitting is performed, coarse grinding and sieving is performed on iron slag, fine grinding and magnetic separating are performed to obtain direct reduction iron, magnetic-separating concentrate is returned to continue reduction, and a separation-metallurgy-separation closed loop flow is formed to obtain the middle-grade titanium slag with the grade of titanium dioxide being larger than 60%. The method has the advantages that the technical requirements of titanium resource recycling using sulfate process titanium dioxide and other methods are satisfied, the titanium resources, which is hard to utilize currently, the vanadium-titanium magnetite concentrate can be recycled efficiently, and the comprehensive utilization rate of the titanium resources of the Panzhihua area is increased.

Owner:KUNMING UNIV OF SCI & TECH

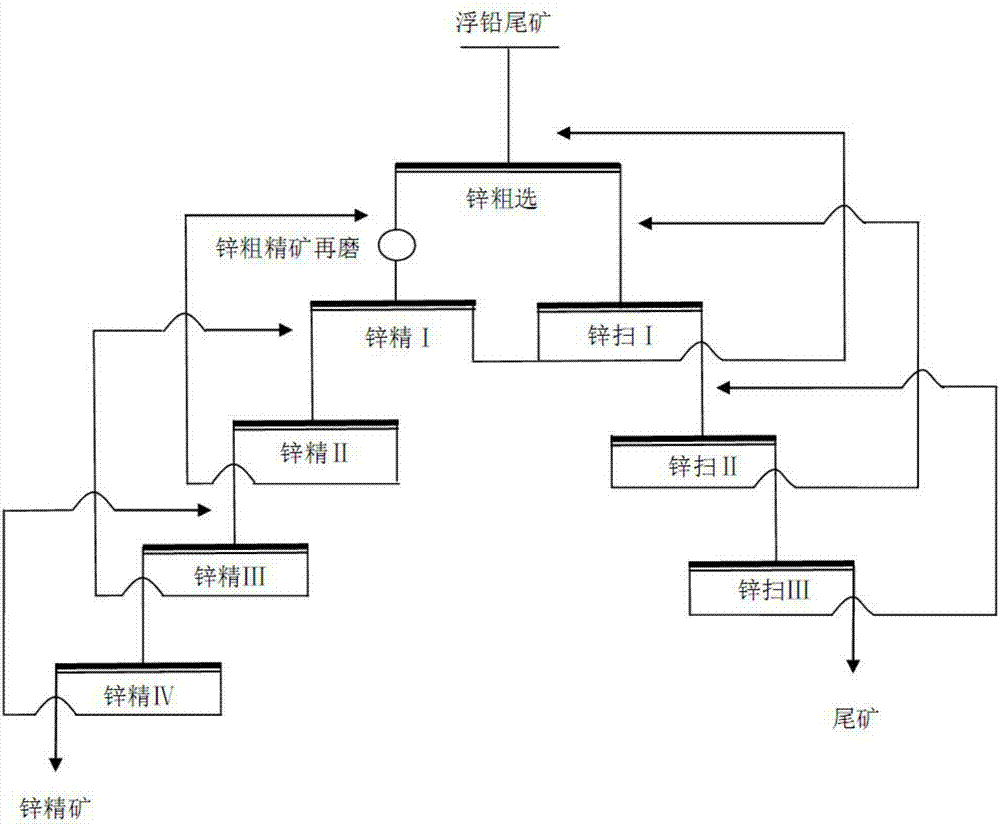

Beneficiation method for recycling zinc from lead-floating tailings

InactiveCN107971141AAvoid "dropping"Avoid "dropping the trough"FlotationMineral flotationElectrochemistry

The invention discloses a beneficiation method for recycling zinc from lead-floating tailings. The beneficiation method is characterized in that a floating method of distributed activated zinc at a zinc concentration stage is adopted, an activating agent copper sulfate is supplemented during zinc concentration operation for distributed activated zinc floating, dosage of a collecting agent is reduced, environmental pollution is reduced, beneficiation cost is reduced, a zinc concentration off-slot phenomenon is avoided, pulp potential is regulated according to electrochemical behaviors of different minerals, and the grade and the relatively high recovery rate of zinc concentrate are guaranteed. Compared with the prior art, the beneficiation method has the advantages that: firstly, distributed activated zinc concentration operation is creatively disclosed, and electrochemical behaviors of different minerals are controlled, so that zinc blende or marmatite is efficiently separated from pyrrhotite; and copper sulfate is supplemented during zinc concentration operation for pyrrhotite with strong reducibility, so that pulp is guaranteed to have enough copper irons, and therefore, the floating recovery rate of zinc concentrate is guaranteed.

Owner:WESTERN MINING CO LTD +1

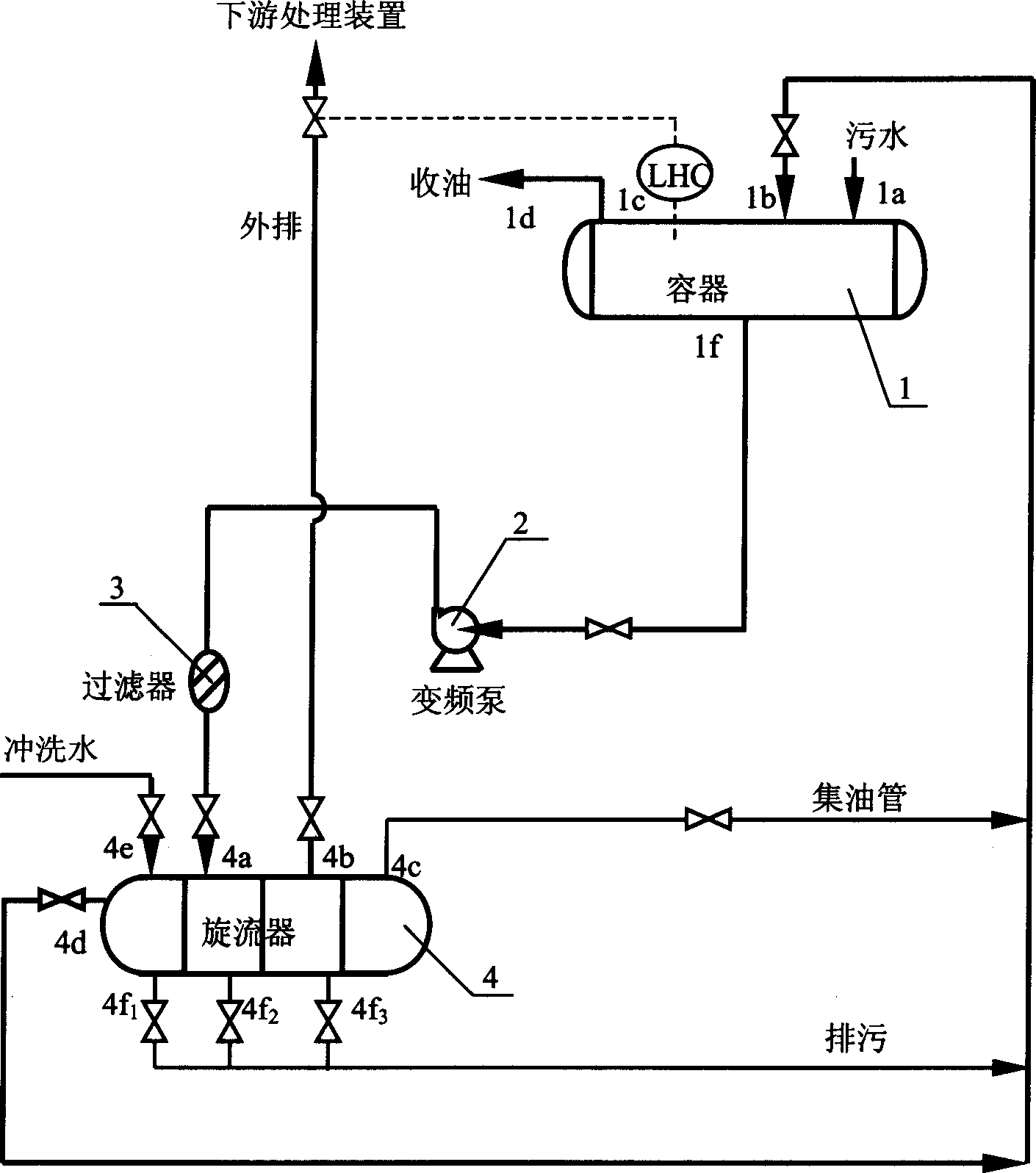

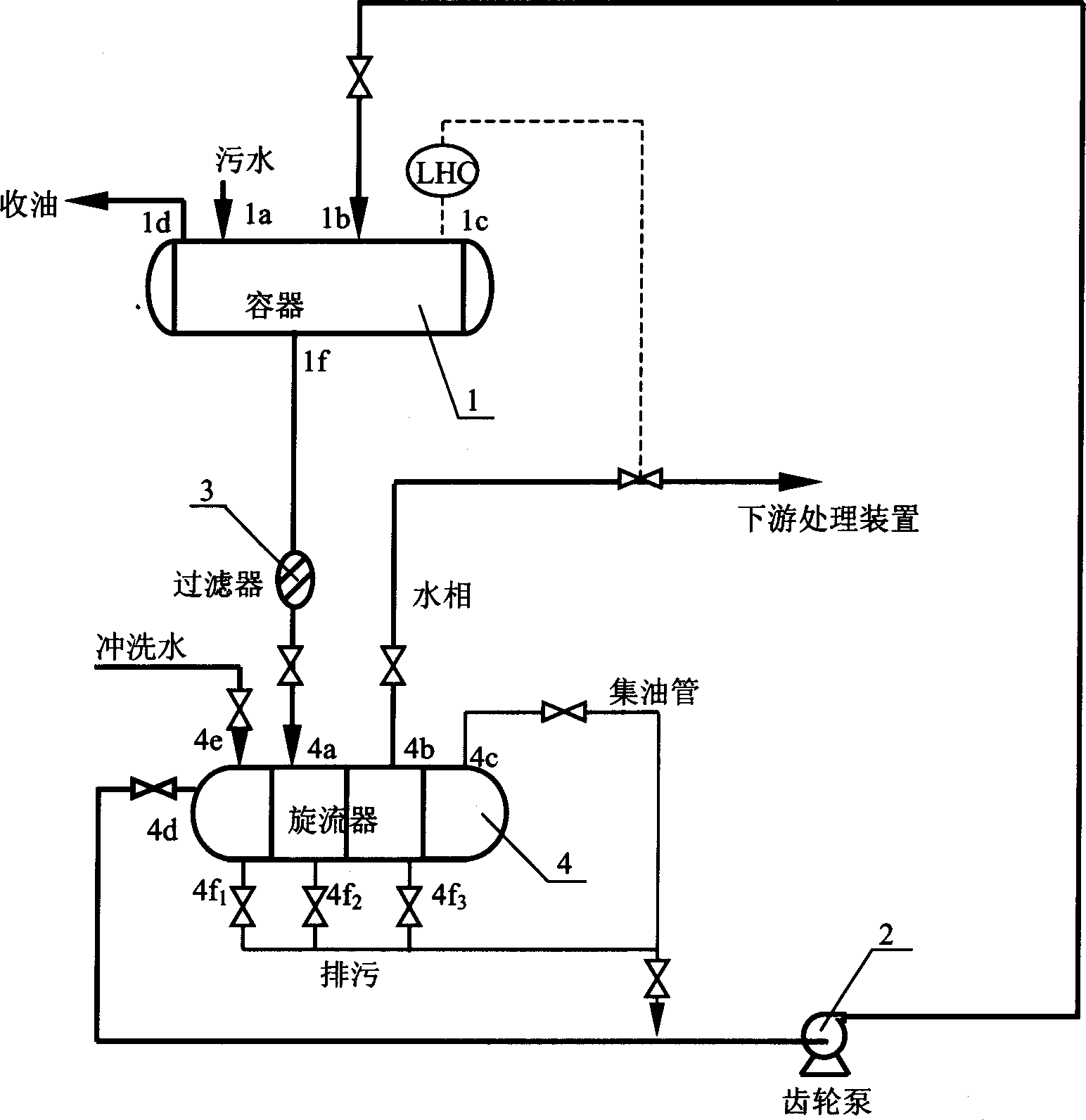

Rotational flow deoiling method for sulfur bearing sewage

InactiveCN1541948AImprove separation efficiencyHigh recovery rateFatty/oily/floating substances removal devicesLiquid separationCycloneSewage

The vortex oil eliminating method can eliminate dispersed oil, emulsified oil and floated oil effectively from sulfur containing sewage. It features the effective combination of liquid-liquid separating cyclone, container, control valve, frequency varying pump, filter and pipeline and the optimized operation conditions. The booster pump is made to operate always near designed flow rate by means of frequency varying speed regulating technology, and this can reduce the leakage of liquid from the pump and the breaking of oil drop obviously. For sewage with oil concentration less than 1000 ppm, the ratio between oil phase flow rate and the water phase flow rate in the cyclone is controlled in 8-18 % to avoid jamming in the oil phase outlet and raise the operation reliability. The said method has high separation efficiency, low cost, high oil recovering rate and other advantages.

Owner:EAST CHINA UNIV OF SCI & TECH

A Flotation Technology of Large Scale Crystalline Graphite Ore

The invention relates to a large-scale crystalline graphite ore flotation fast selecting agent and a flotation technology. The agent comprises following components including, by weight, 50% to 65% of methyl isobutyl carbinol, 20% to 30% of petroleum ether and 10% to 25% of acetone. The graphite ore flotation fast selecting agent can rapidly select high-quality large-scale graphite ore from neutral pulp, and high-grade large-scale crystalline graphite concentrate can be obtained through the short selection technology free of regrinding; compared with a traditional large-scale crystalline graphite ore flotation technology, graphite scales can be effectively protected, meanwhile, the consumption amount of the floatation agent can be reduced, and the production cost is reduced.

Owner:金建工程设计有限公司

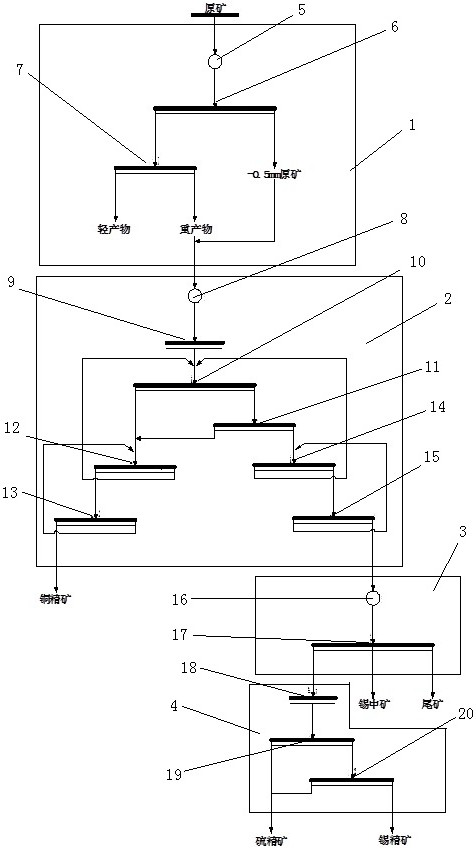

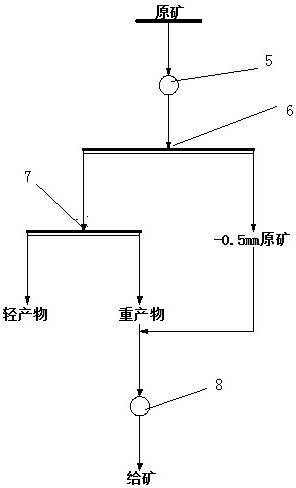

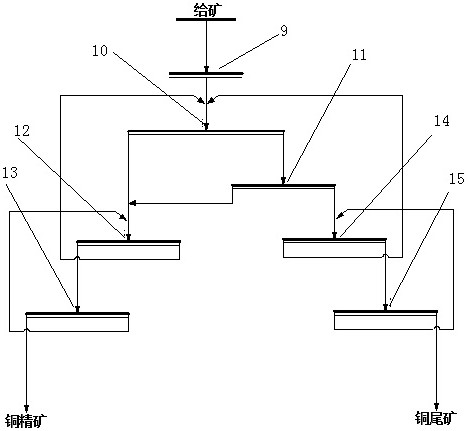

Copper-tin ore separation process

ActiveCN114308368AImprove the quality of selectionReduce storage capacityProcess efficiency improvementWet separationCassiteriteCopper

The invention relates to the technical field of copper-tin ore beneficiation, in particular to a copper-tin ore separation process which is characterized by comprising the following separation steps: (1) dense medium separation: crushing raw ore of copper-tin ore, and sequentially removing light-specific-gravity minerals with the specific gravity lower than that of copper minerals and tin minerals in the ores; (2) copper recovery: carrying out copper flotation on the ore pulp subjected to ore grinding treatment to obtain copper concentrate and copper tailings; (3) tin recovery: regrinding the copper tailings, feeding the copper tailings into a table concentrator, and separating to obtain tin rough concentrate, tin middlings and tailings; and (4) tin rough concentrate desulfurization: carrying out desulfurization flotation on the obtained tin rough concentrate, and separating to obtain tin concentrate and sulfur concentrate. The method has the advantages that the selected grade is high, the concentrate index is ensured, the production cost is reduced, the economic benefit is improved and the like.

Owner:CENT SOUTH UNIV +1

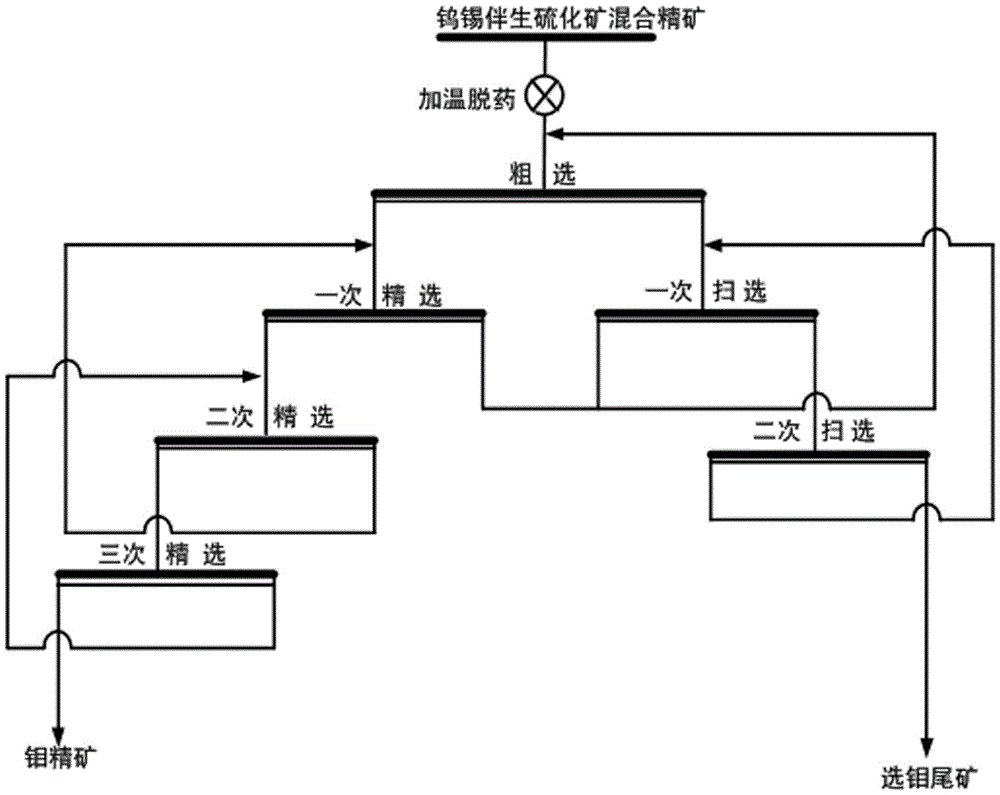

Beneficiation method for recovering molybdenum from tungsten tin associated sulfide ore bulk concentrate

InactiveCN105537005AIncrease floatability differenceGood hydrophobicityFlotationOre concentrateTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com