A Flotation Technology of Large Scale Crystalline Graphite Ore

A technology of crystalline graphite and large scales, which is applied in the field of flotation quick separation agent and flotation process, can solve the problems of high mineral processing cost, low equipment efficiency, and unstable indicators, so as to reduce production cost, ensure grade and recovery rate , the effect of increasing the level of profitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

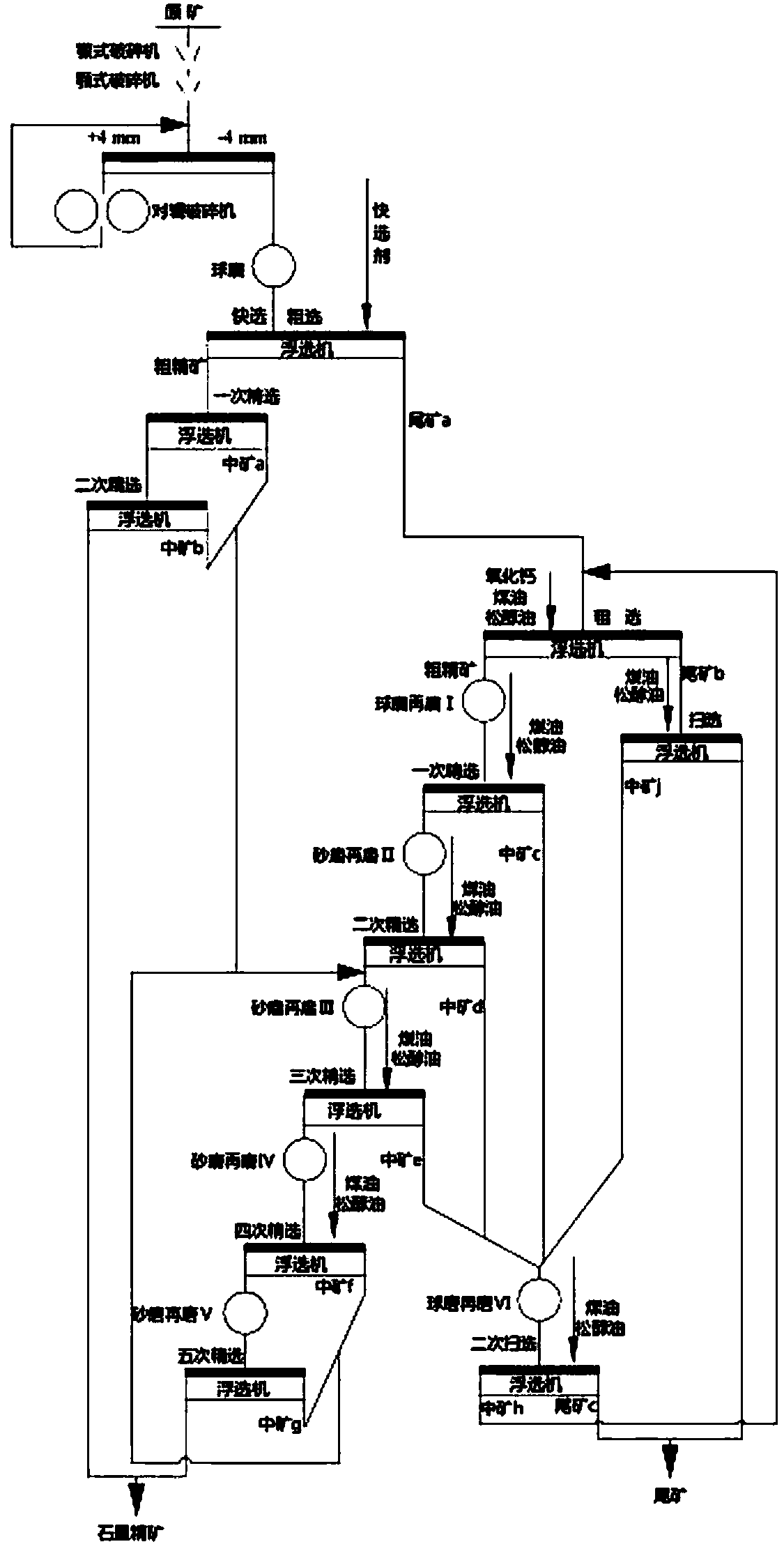

Image

Examples

Embodiment 1

[0024] A rapid separation agent for flotation of large-scale crystalline graphite ore, comprising the following components: 50% by weight of methyl isobutyl carbinol, 30% by weight of petroleum ether and 20% by weight of acetone.

[0025] A kind of flotation process of large scale crystalline graphite ore, comprises the steps:

[0026] The raw ore is a large scale crystalline graphite ore, the fixed carbon content is 15.28%, and the graphite scale diameter is greater than 0.5mm. The kerosene used in this embodiment is through 60wt% sodium lauryl sulfate, 40wt% sulfated monoglyceride It is emulsified by the emulsifier composed.

[0027] A. Crush the above raw ore to -4mm, and then use a ball mill for grinding, the grinding concentration is 60%, the grinding time is 6min, the grinding fineness is -0.15mm and the content is 55%; the grinding product is added with the above-mentioned graphite After the quick-selection agent, put into a flotation machine and carry out quick-select...

Embodiment 2

[0036] A rapid separation agent for flotation of large scale crystalline graphite ore, comprising the following components: 65% by weight of methyl isobutyl carbinol, 20% by weight of petroleum ether and 15% by weight of acetone.

[0037] The difference between this embodiment and embodiment 1 is: 1) the flotation fast separation agent used is different; emulsified by emulsifiers.

[0038] The grade of the graphite concentrate finally obtained in this embodiment is 99.83%, the recovery rate is 88.36%, and the scale particle size of the graphite concentrate is +0.282mm, and the content accounts for 85.28%.

Embodiment 3

[0040] A rapid separation agent for flotation of large scale crystalline graphite ore, comprising the following components: 50% by weight of methyl isobutyl carbinol, 25% by weight of petroleum ether and 25% by weight of acetone.

[0041] The difference between this embodiment and embodiment 1 is: 1) the flotation fast separation agent used is different; emulsified by emulsifiers.

[0042] The grade of the graphite concentrate finally obtained in this embodiment is 99.93%, the recovery rate is 85.37%, and the scale particle size of the graphite concentrate is +0.282mm, and the content accounts for 80.36%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com