Rotational flow deoiling method for sulfur bearing sewage

A technology for sulfur sewage and sewage, which is applied in the field of dispersing oil and emulsified oil, and removing floating oil in sewage. It can solve the problems of increased pump energy consumption, unsatisfactory degreasing effect, and low degreasing efficiency, so as to improve efficiency and improve The recovery rate and the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

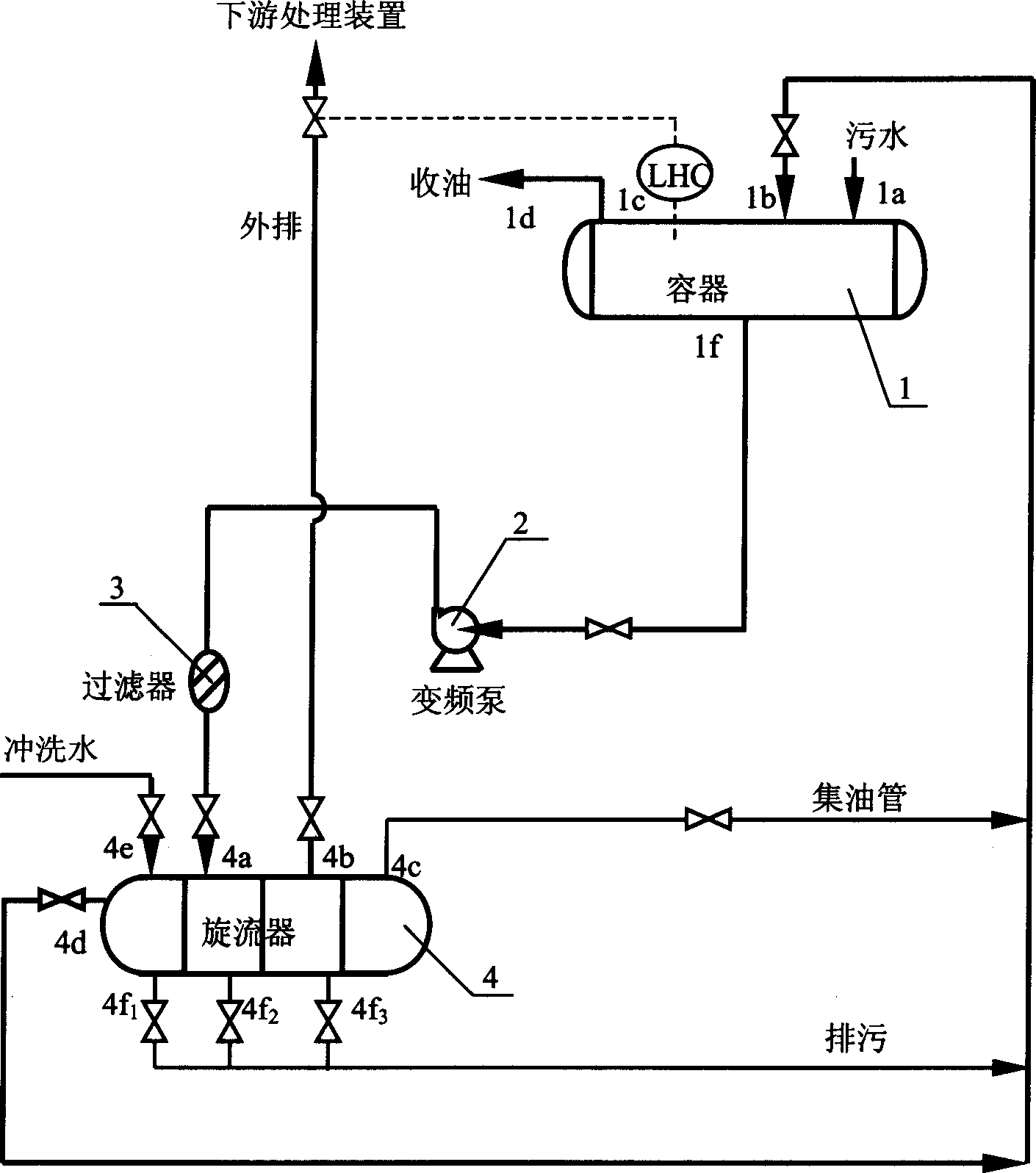

[0054] For the implementation plan of sulfur-containing sewage under atmospheric and vacuum pressure or the sulfur-containing sewage system whose pressure is lower than the working pressure of the cyclone, see figure 1 . exist figure 1 Among them, the pressure of the sulfur-containing sewage in the container is 0-0.02MPa, which is less than the minimum driving pressure of the cyclone, and the sulfur-containing sewage needs to be pressurized. The frequency conversion centrifugal pump is used to increase the pressure of the sulfur-containing sewage to 0.45-0.55MPa, and enter the cyclone through the basket filter, and the cyclone separates the sulfur-containing sewage into two parts, the oil phase and the water phase, and the pressure of the oil phase is 0.05 ~0.1MPa, water phase pressure is 0.25~0.30MPa, oil phase flow rate is 18% of water phase flow rate. The oil phase automatically returns to the container under its own pressure, and the water phase flows into the downstream...

Embodiment 2

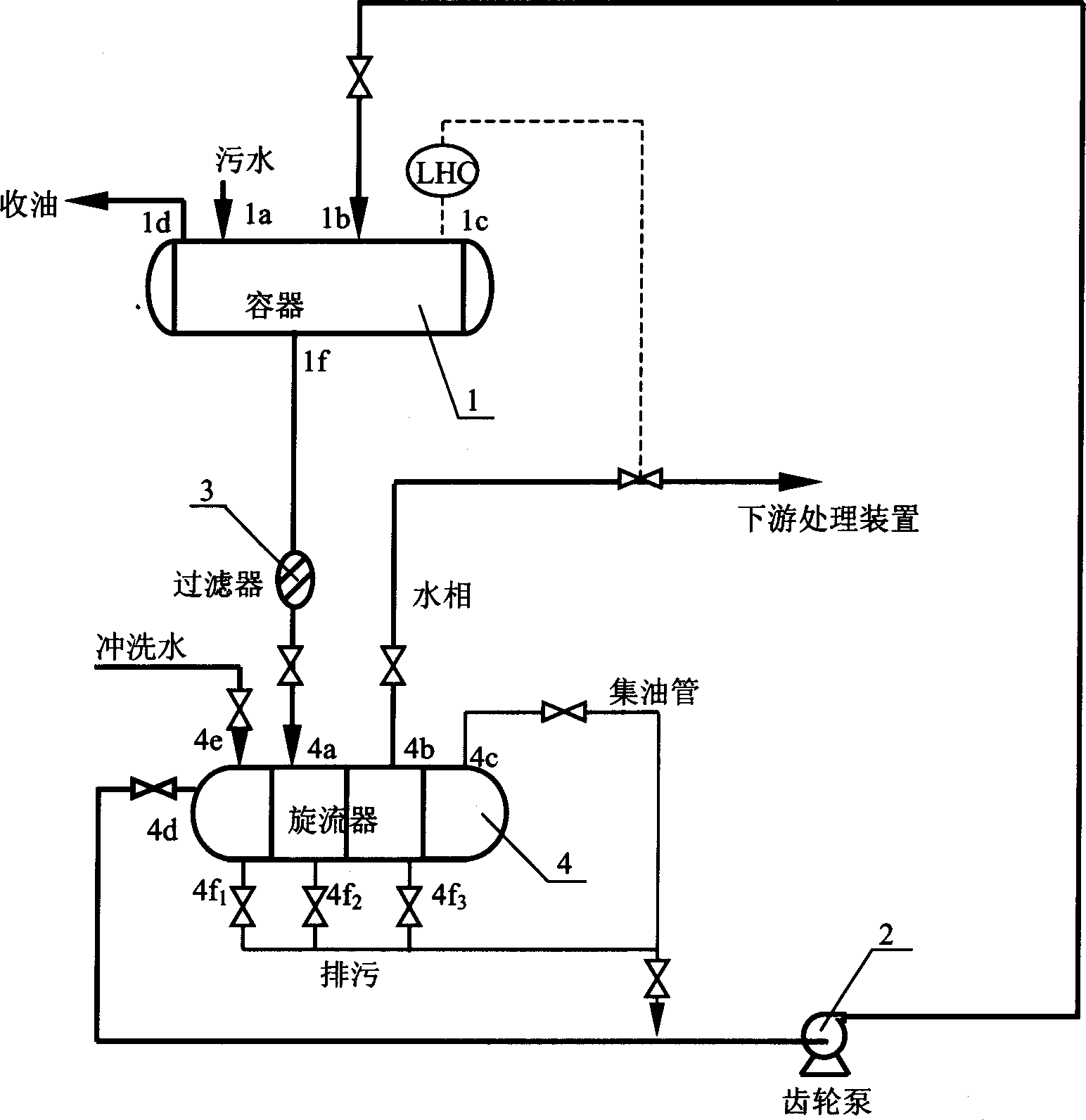

[0056] See figure 2 . exist figure 2 Among them, the pressure of the sulfur-containing sewage in the container is 0.75-0.8MPa, which is greater than the minimum driving pressure of the cyclone, so the sulfur-containing sewage does not need to be pressurized. The sulfur-containing sewage directly enters the cyclone through the basket filter, and the cyclone separates the sulfur-containing sewage into two parts: oil phase and water phase. 10% of the water phase flow. . The oil phase returns to the container after being pressurized by the gear pump, and the water phase flows into the downstream device through the liquid level control valve of the container. The oil accumulated in the inner cavity of the cyclone is discharged regularly through the oil collecting pipe. When the concentration of the sulfur-containing sewage is 860ppm, the oil concentration of the separated water phase is 200ppm, and the oil removal rate of the sulfur-containing sewage reaches more than 77%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com