Method of using vanadium-titanium magnetite concentrate to produce middle-grade titanium slag

A technology for titanomagnetite and concentrate is applied in the field of comprehensive utilization of combined resources in beneficiation and smelting, which can solve problems such as ineffective utilization of titanium resources, and achieve the effects of high grinding cost, efficient separation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

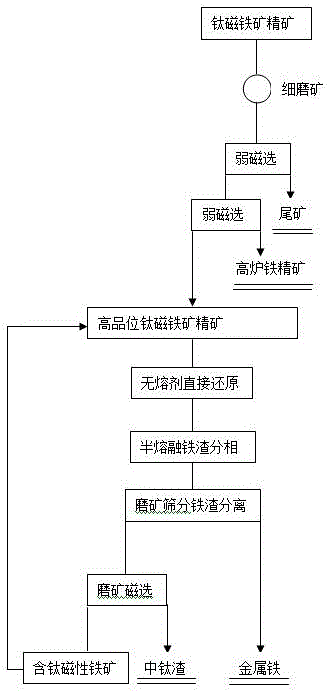

Image

Examples

Embodiment 1

[0024] (1) High-purification preparation of titanium-magnetite concentrate: Grinding the titanium-magnetite blast furnace concentrate with a particle size percentage of -74 μm greater than 80% and an iron grade of 54.5%~55.5% to a particle size percentage of -45 μm 85%~90%, using a magnetic separator with a magnetic field strength of 90KA / m to obtain a concentrate, and then using a magnetic separator with a magnetic field strength of 80KA / m / m to obtain iron grades of TFe 57%~58%, TiO 2 The grade is 14%~14.3% high-grade titanium magnetite concentrate. The magnetic separation tailings are combined for a beneficiation, the tailings are discarded, and the beneficiation concentrate becomes a common iron concentrate containing 52.5% to 53% iron, which is used as a raw material for blast furnace ironmaking.

[0025] (2) Direct reduction without flux: the high-grade titano-magnetite concentrate prepared by high-purification in step (1) is pelletized with 1% by mass of water-soluble o...

Embodiment 2

[0030] (1) High-purification preparation of titanium-magnetite concentrate: Grinding the titanium-magnetite blast furnace concentrate with a particle size percentage of -74 μm greater than 80% and an iron grade of 55.0%~56.0% to a particle size percentage of -45 μm 90%~95%, using a magnetic separator with a magnetic field strength of 80KA / m to obtain a concentrate, and then using a magnetic separator with a magnetic field strength of 70KA / m to obtain iron grades of TFe 58%~59%, TiO 2 The grade is 14.3%~14.8% high-grade titano-magnetite concentrate. The magnetic separation tailings are combined for a beneficiation, the tailings are discarded, and the beneficiation concentrate becomes a common iron concentrate containing 52% to 52.5% iron, which is used as a raw material for blast furnace ironmaking.

[0031] (2) Direct reduction without flux: the high-grade titano-magnetite concentrate prepared by high-purification in step (1) is pelletized with 0.8% by mass of water-soluble o...

Embodiment 3

[0036] (1) High-purification preparation of titano-magnetite concentrate: Grinding the blast furnace concentrate of titano-magnetite with a particle fraction percentage of -74 μm greater than 80% and an iron grade of 55.5%~56.5% to a fraction percentage of -45 μm 90%~95%, using a magnetic separator with a magnetic field strength of 70KA / m / m to obtain a concentrate, and then using a magnetic separator with a magnetic field strength of 60KA / m to obtain iron grades of TFe 59%~60%, TiO 2 The grade is 14.5%~15% high-grade titanium magnetite concentrate. The magnetic separation tailings are combined for a beneficiation, the tailings are discarded, and the beneficiation concentrate becomes a common iron concentrate containing 52.5% to 53% iron, which is used as a raw material for blast furnace ironmaking.

[0037] (2) Direct reduction without flux: the high-grade titano-magnetite concentrate prepared by high-purification in step (1) is pelletized with 0.6% by mass of water-soluble o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com