Beneficiation method for recycling zinc from lead-floating tailings

A mineral processing method and tailings technology, which is applied in flotation, solid separation, etc., can solve the problems of unstable comprehensive index of mineral processing and poor separation effect, and achieve the effect of ensuring flotation recovery rate and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

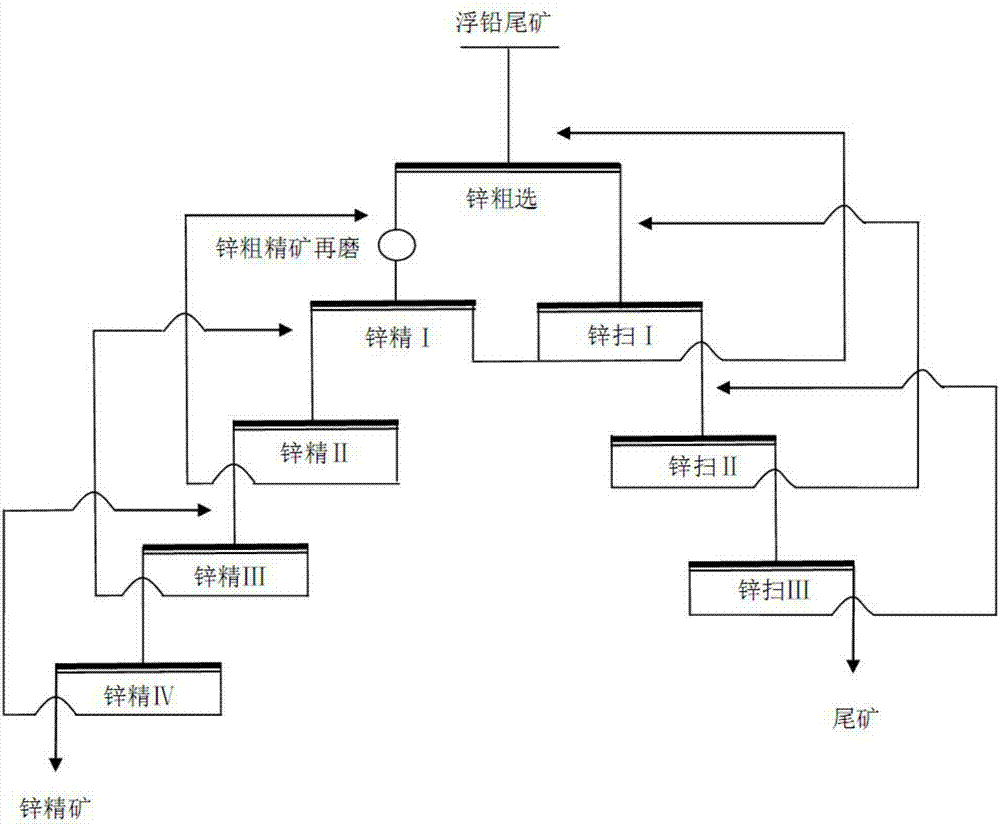

Image

Examples

Embodiment 1

[0020] A high pyrrhotite type complex lead-zinc sulfide ore in Inner Mongolia, the main metal minerals are galena, sphalerite and pyrrhotite, and the main gangue minerals are quartz, feldspar, muscovite, diopside, Tremolite, chlorite, epidote, calcite, etc., the multi-element results of the raw ore are shown in Table 1.

[0021] Table 1 Raw ore multi-element analysis unit g / t

[0022] element

Pb

Zn

Cu

Fe

S

As

C

content%

1.45

1.93

0.13

17.25

12.45

0.01

0.34

element

Au *

Ag *

CaO

MgO

Al 2 o 3

SiO 2

——

content%

0.18

21.32

4.82

2.51

9.32

39.07

—

[0023] The specific process is as follows:

[0024] (1) Perform zinc roughing on the lead-selected tailings, add lime to adjust the pH of the pulp to 10.5, and the concentration of the pulp to 38%, add copper sulfate at 300g / t, stir for 5min, and adjust the potential of the pulp to 220-280mV (rel...

Embodiment 2

[0033] A high pyrrhotite type complex lead-zinc-gold-silver sulfide polymetallic ore in Yunnan, the ore contains some carbonaceous, its main metal minerals are galena, sphalerite, pyrrhotite, part of sphalerite, mainly The gangue minerals are quartz, feldspar, calcite, etc. The multi-element results of the raw ore are shown in Table 2.

[0034] Table 2 Raw ore multi-element analysis unit g / t

[0035] element

Pb

Zn

Cu

Fe

S

As

C

content%

3.97

5.51

0.13

16.95

23.17

0.05

0.52

element

Au *

Ag *

CaO

MgO

Al 2 o 3

SiO 2

——

content%

0.52

90.62

1.42

1.73

4.13

23.84

—

[0036] The specific process is as follows:

[0037] (1) Perform zinc roughing on the lead-selected tailings, add lime to adjust the pulp pH to 11.0, pulp concentration to 40%, add copper sulfate to 400g / t, stir for 6min, and adjust the pulp potential to 220-280mV (relative to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com