Beneficiation method for comprehensively recovering magnetite from cyanide tailings

A mineral processing method and a technology of cyaniding tailings, which are applied in the mineral processing field of magnetite recovery and comprehensive recovery of magnetite, can solve the problems of damage to the mine's due interests and poor magnetite recovery effect, and achieve the benefits of Effects of large-scale promotion, improvement of yield and recovery rate, and improvement of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A kind of beneficiation method of comprehensively recovering magnetite from cyanide tailings

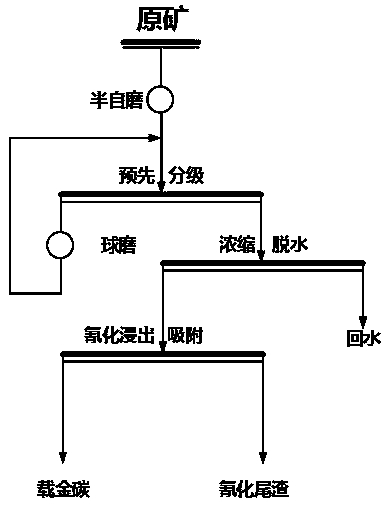

[0040] 1. Mineral processing method

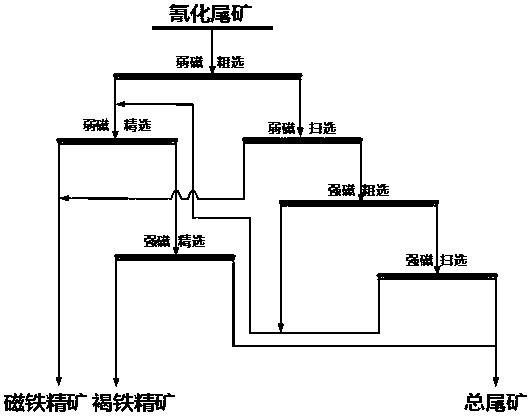

[0041] The ore in this embodiment is the cyanidation tailings of oxidized ore-type gold mines in a certain place of Yunnan Gold Group, wherein the iron grade in the cyanide tailings is 32.61%. Such as figure 2 Shown, adopt the method for following steps to carry out the recovery of magnetite:

[0042] S1. Weak magnetic roughing: Grind the cyanide tailings obtained after cyanide leaching until the ore fineness is -0.043mm, accounting for 82.36%, and then directly carry out weak magnetic roughing through a 0.22T weak magnetic field to obtain weak Magnetic rougher concentrate and weak magnetic rougher tailings;

[0043] S2. Weak magnetic scavenging: performing weak magnetic scavenging operation on the weak magnetic roughing tailings obtained in step S1 in a 0.33T weak magnetic field to obtain weak magnetic scavenging concentr...

Embodiment 2

[0050] Embodiment 2 A kind of beneficiation method of comprehensively recovering magnetite from cyanide tailings

[0051] 1. Mineral processing method

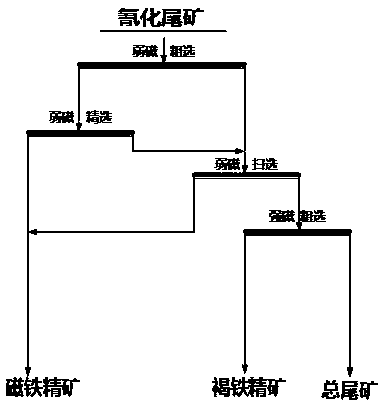

[0052] The ore in this embodiment is the cyanidation tailings of oxidized ore-type gold mines in a certain place of Yunnan Gold Group, wherein the iron grade in the cyanide tailings is 37.81%. Such as figure 2 Shown, adopt the method for following steps to carry out the recovery of magnetite:

[0053] S1. Weak magnetic roughing: Grind the cyanide tailings obtained after cyanide leaching until the ore fineness is -0.043mm, accounting for 91.56%, and then directly carry out weak magnetic roughing through a 0.3T weak magnetic field to obtain weak Magnetic rougher concentrate and weak magnetic rougher tailings;

[0054] S2. Weak magnetic scavenging: the weak magnetic roughing tailings obtained in step S1 are subjected to weak magnetic scavenging operations in a 0.4T weak magnetic field to obtain weak magnetic scavenging concen...

Embodiment 3

[0072] Embodiment 3 different magnetic field strength magnetic separation test

[0073] 1. The influence of different magnetic field strengths on the magnetic separation of cyanide tailings

[0074] Weak magnetic separation tests were carried out on cyanide tailings under the conditions of magnetic field strengths of 0.3T, 0.35T, and 0.4T, and the test results are shown in Table 2.

[0075] Table 2 Magnetic separation test results under different magnetic field strengths

[0076]

[0077] As can be seen from the test results in Table 2, increasing the magnetic field strength increases the magnetite concentrate production rate and recovery rate to a certain extent, but the increase is small, indicating that for the finer cyanide tailings of the grinding, the method of increasing the magnetic field strength is also more effective. It is difficult to achieve better recovery of magnetite.

[0078] 2. The influence of different magnetic field strengths on the magnetic separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com