Multi-feeding-belt magnetic separator

A magnetic separator, multi-feed technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increased energy consumption, large maintenance, small selection, etc., to promote stratification, reduce The effect of power loss and interference avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

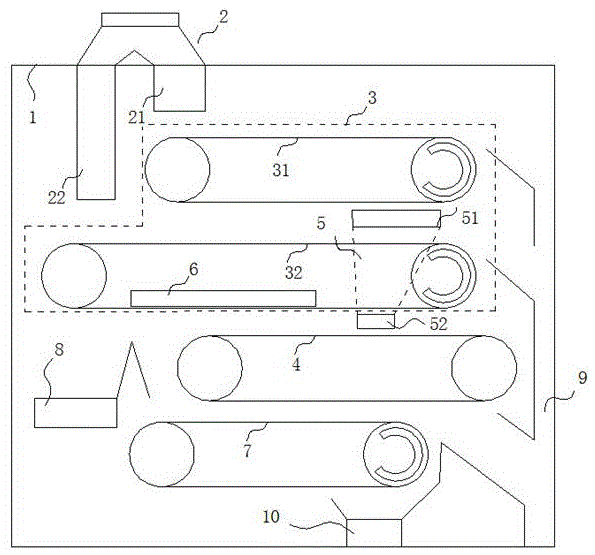

[0037] On the basis of the embodiment, the belt pre-selection mechanism 3 can also be three or more stages of belt magnetic separation mechanisms, and the feeding ends of adjacent belt magnetic separation mechanisms are arranged in steps.

[0038] The belt magnetic separation mechanism on the lowest layer may not be provided with an inlet, and an outlet is provided above the belt conveying mechanism 4 for the output of mineral materials in the ore collecting device 5, and the magnetic ore magnetically separated by the belt conveying mechanism 4 on each level is collected. onto the conveyor belt.

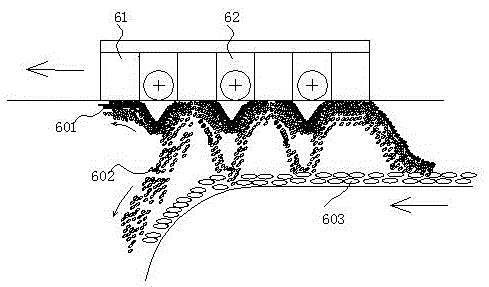

[0039] The magnetic separation belt adjacent to the belt conveying mechanism 4 (that is, the magnetic separation belt of the lowest layer) is divided into the magnetic roller magnetic area, the first non-magnetic area, the magnetic system 6 magnetic area, and the second non-magnetic area along the magnetic separation direction; the second non-magnetic area The magnetic area correspon...

Embodiment 1

[0042] In the magnetic separation method of the magnetic separator of embodiment 1 or embodiment 2 in use, the feeding device 2 passes through the ore inlet respectively such as the first ore inlet 21 and the second ore inlet 22 to spread the ore powder evenly and equally Sprinkle on the belt magnetic separation mechanism of all levels of independent transportation; the material is thrown at the magnetic roller, and the non-magnetic mineral material enters the tailing port under the action of inertia, and the strong magnetic ore and weak magnetic ore are separated by the magnetic force of the magnetic roller Under the action of the magnetic separation belt, it is attached to the magnetic separation belt and brought to the lower belt of the magnetic separation belt. When the magnetic force of the magnetic roller disappears, the strong magnetic ore powder and weak magnetic ore powder fall into the coarse ore inlet 51 of the collecting device. And drop from the coarse material out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com