Flotation desilication method for bauxite

A bauxite and flotation technology, applied in flotation, solid separation, etc., can solve problems such as complex process flow, difficulty in floating coarse grains, and poor process indicators, and achieve good process stability, significant economic benefits, and high efficiency. The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

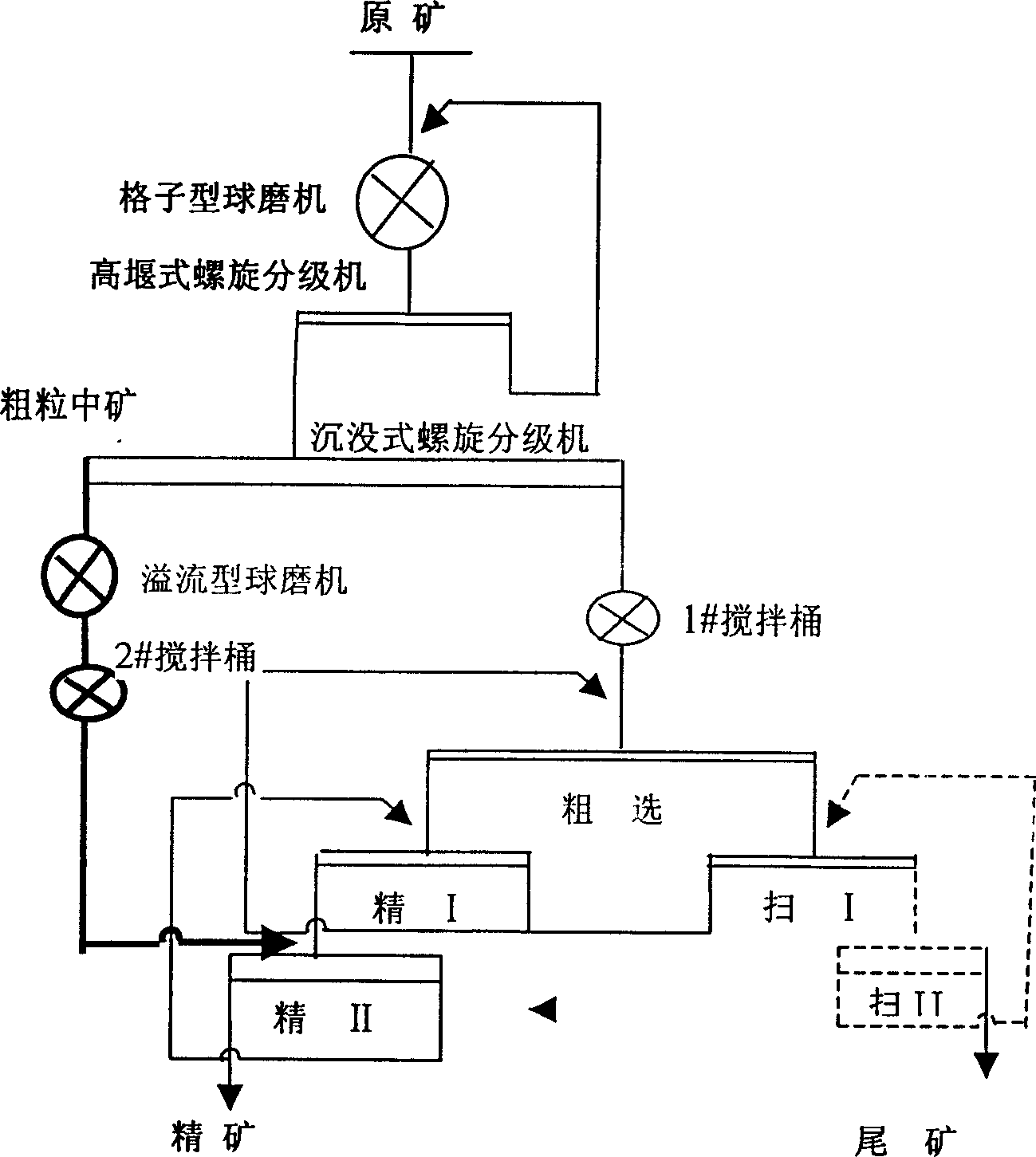

[0015] A bauxite flotation desiliconization method, including grinding, grading and flotation processes, when the grinding fineness is -0.074mm and accounts for 30%-95%, after pre-classification, fine-grained products and coarse-grained products are obtained The fine-grained product directly enters the flotation process through the action of the flotation agent, and produces selected foam; Grinding products and fine-grained flotation foam products enter the beneficiation operation at the same time, and the final concentrate is obtained after flotation. After the raw ore undergoes a stage of closed-circuit grinding and grading, it enters the second stage of pre-grading, and the fine-grained grades obtained enter the roughing operation after being interacted with the flotation agent in the mixing tank. Concentration II operation, foam as the final concentrate; the second-stage pre-graded coarse-grained medium ore is subjected to the second-stage open-circuit grinding, and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com