Blast furnace ironmaking production process by cyclically utilizing steel slag and iron slag in metallurgy and chemical industry

A technology of blast furnace ironmaking and production technology, which is applied in the field of metallurgical technology to achieve the effect of satisfying air permeability, increasing the added value of resources, and improving the utilization factor

Inactive Publication Date: 2010-09-08

TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

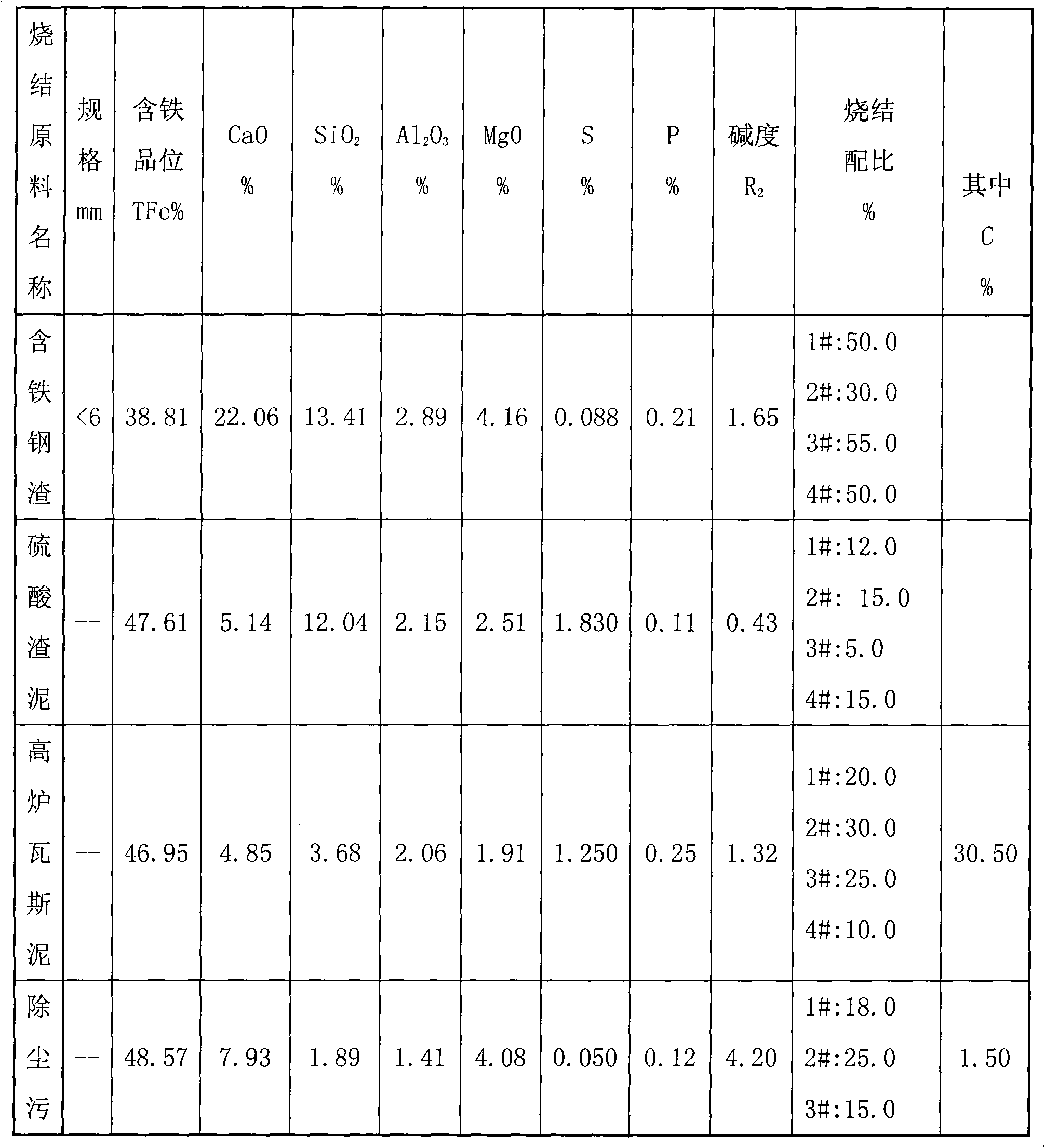

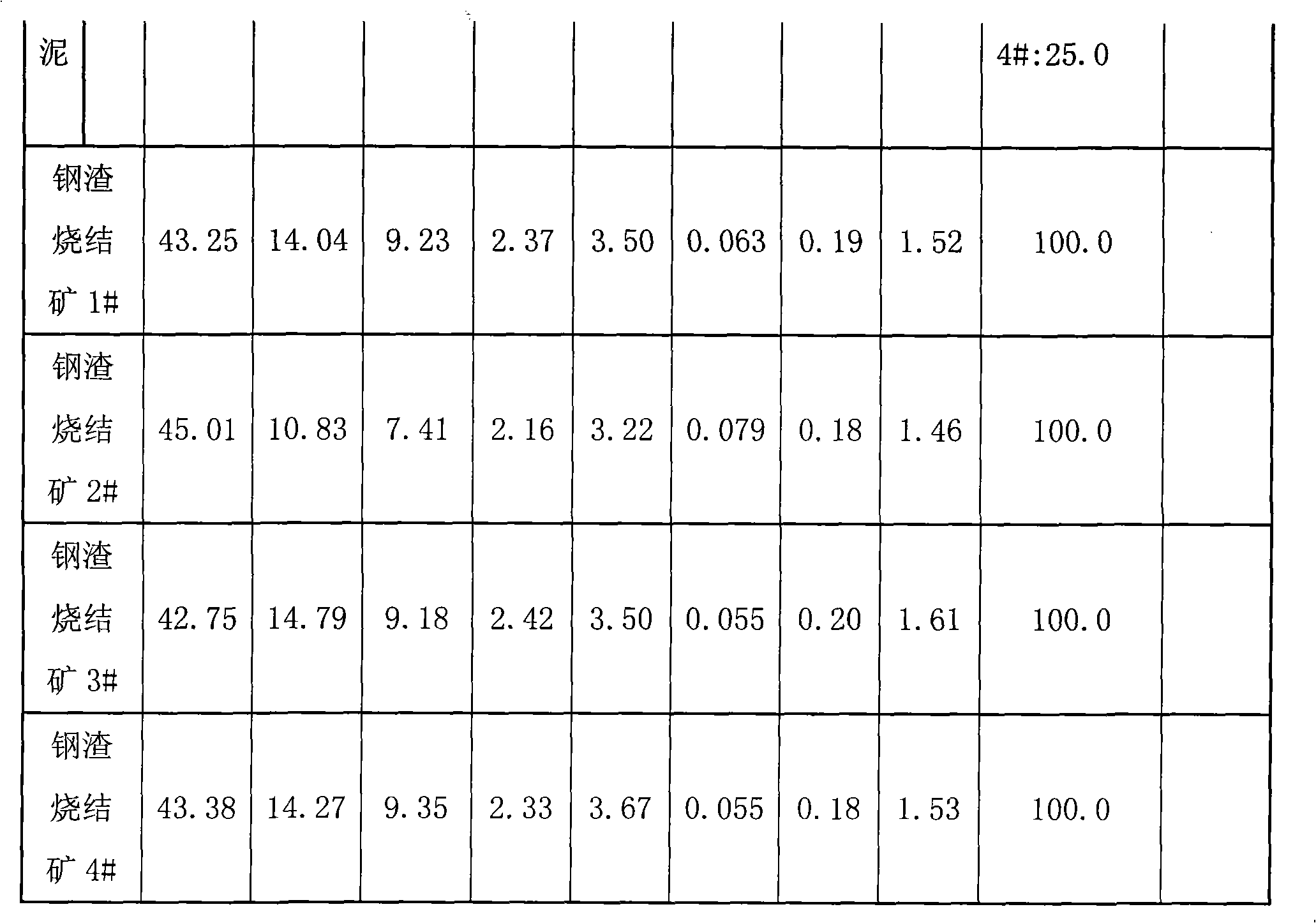

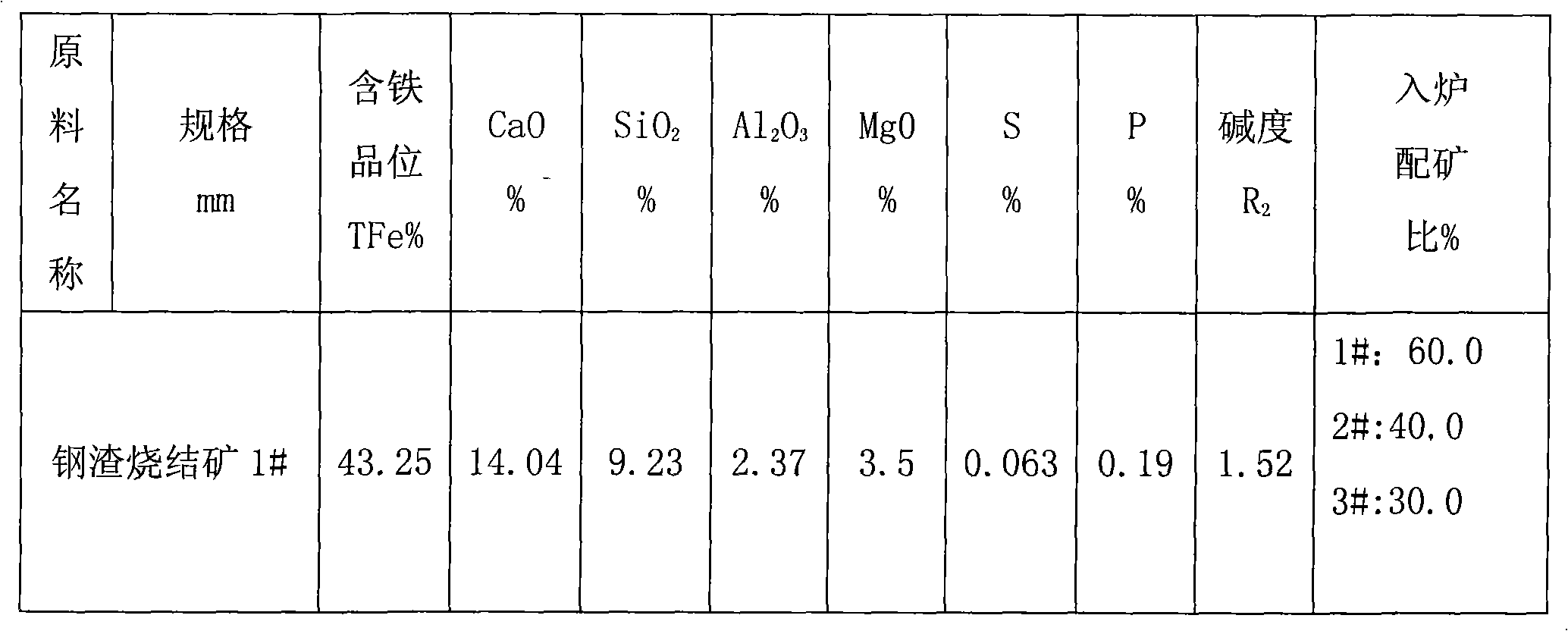

The purpose of the present invention is to solve the resource recycling problem of low-grade iron-containing waste slag, and provide a method of using low-grade iron-containing steel slag and metallurgical and chemical iron-containing slag as the main raw material for sintering and ore blending for blast furnace ironmaking. iron production process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to metallurgy process, and discloses a blast furnace ironmaking production process by cyclically utilizing steel slag and metallurgic and chemical slag containing iron. The process comprises the following steps: low grade steel slag containing iron and metallurgic and chemical slag containing iron are classified and selected; the low grade steel slag containing iron with grain diameter more than or equal to 6mm, and low grade steel slag containing iron with grain diameter less than 6mm are selected from the low grade steel slag containing iron; the low grade steel slag containing iron with grain diameter less than 6mm and metallurgic and chemical slag containing iron are combined and sintered to prepare a steel slag sintering ore; the low grade steel slag containing iron with grain diameter more than or equal to 6mm and the steel slag sintering ore obtained on the step 2 are used as raw materials of blast furnace ironmaking, silica is used as a smelting additive,and coke is used as fuel to carry out blast furnace ironmaking. The process achieves modification of slag resource while sufficiently and cyclically utilizing ferritic resource, thereby realizing theaim of slag resource comprehensive utilization.

Description

technical field The invention relates to a metallurgical process, in particular to a blast furnace ironmaking production process for energy saving, emission reduction and resource comprehensive utilization. Background technique Steel slag is a large amount of industrial waste discharged from steelmaking converters or electric furnaces, accounting for about 15% of steel production. Generally, it also contains about 10% scrap steel and more than 15% iron oxide components, and is rich in Ca and Mg-rich alkaline oxide compound mineral clinker, and most of them are slag-coated iron and iron-coated slag solids. In the state of compound, it is difficult to break and grind. It is a waste of work and energy to achieve crushing, sorting and purification for reuse. Therefore, most of the low-grade iron-containing steel slags are not effectively recycled, and the recyclable ferrite resources are seriously wasted. At the same time, with the rapid development of my country's heavy chemi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B1/248C22B1/16C21B5/00

Inventor 崔四荣

Owner TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com