Dyeing treatment process for pure cotton fabrics based on pure natural biological preparations

A technology of pure cotton fabrics and biological agents, which is applied in the field of dyeing process of pure cotton fabrics. the destructive effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The dyeing process of pure cotton fabrics based on pure natural biological agents includes singeing, desizing, scouring, bleaching, dyeing, soft treatment, and preshrinking treatment. The key is: said desizing, scouring, bleaching, and dyeing The preparations used in the treatment process are biological preparations, which are respectively desizing enzyme solution, scouring enzyme solution, glucose oxidase solution, and vegetable dyes. On this basis, the dyeing process includes the following steps:

[0016] a. Singeing: Pass the pure cotton fabric quickly through the flame or rub it on the surface of the hot metal plate to burn off the surface hair. The flame temperature is 900-1000°C, and the surface temperature of the metal plate is 790-810°C;

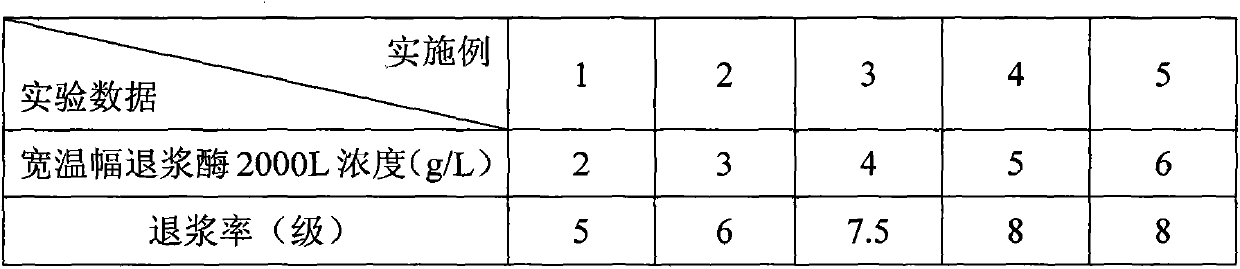

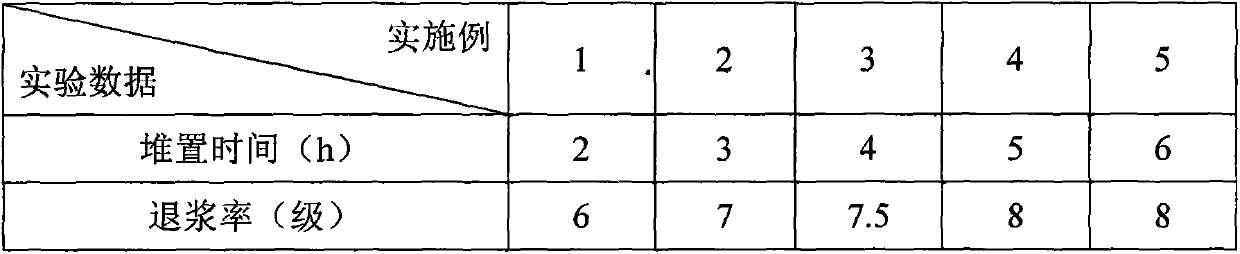

[0017] b. Desizing: Under the condition of 85-95°C, pad the pure cotton fabric in the desizing enzyme solution with a concentration of 4-6g / L. Stacked for 3-6 hours under certain conditions;

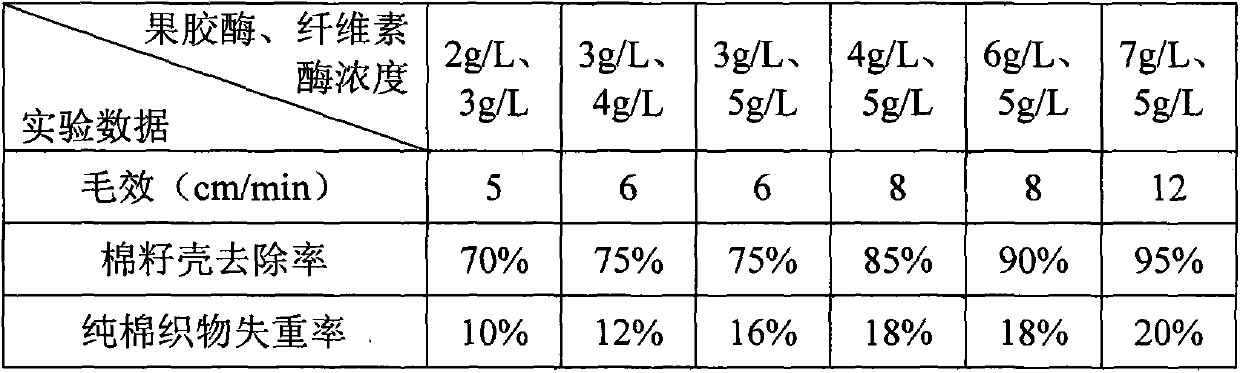

[0018] c. Scouring: Under the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com