Mineral separation technology for recovering low-grade marmatite and cassiterite minerals from copper separation tailings

A technology for beneficiating copper tailings and sphalerite, which is applied in the field of mineral processing, can solve the problems of low economic benefit, poor recovery effect, loss of money, etc., and achieve the reduction of production cost, the reduction of equipment quantity and chemical dosage, and the reduction of production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

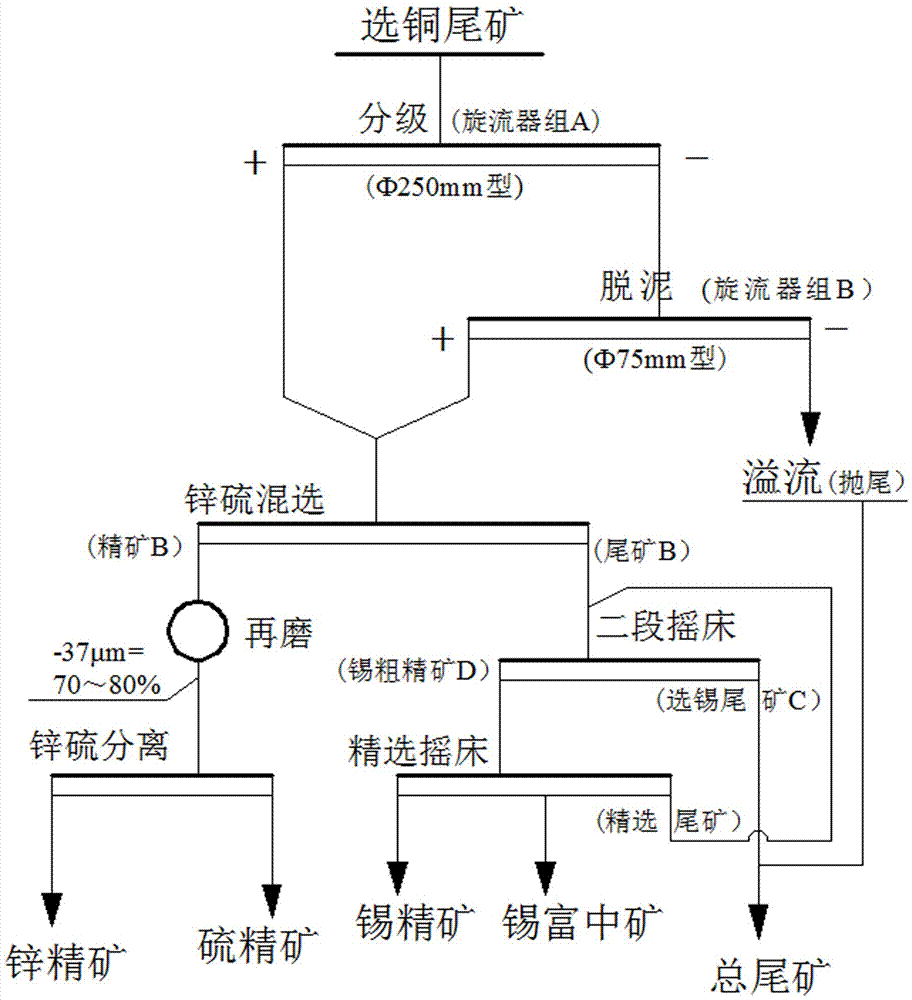

[0022] Embodiment 1: A process for recovering low-grade sphalerite and cassiterite minerals from copper beneficiation tailings, which mainly includes three processes of graded desliming, zinc-sulfur mixed separation-separation, and shaking table tin selection. The specific steps are as follows :

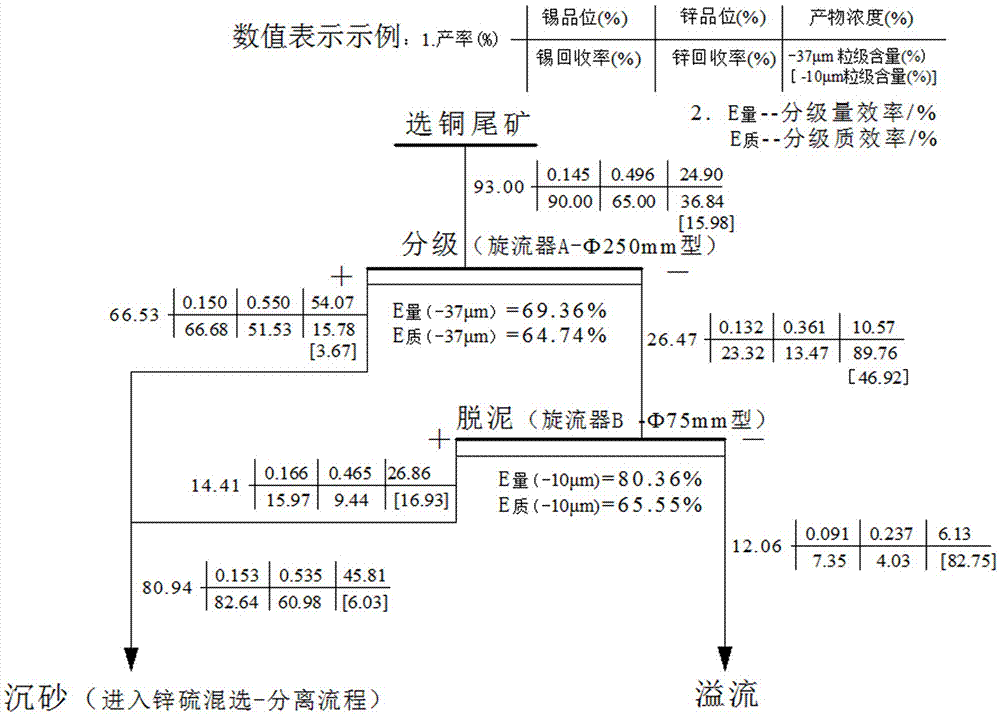

[0023] First, the staged desliming process (see image 3 ), transport the copper beneficiation tailings to the cyclone group A for grading, the type of the cyclone group A is Ф250mm, the ore feeding pressure is 0.06MPa, the ore feeding concentration is 20%, and the output of the cyclone group A is graded There are two products of sand settling and overflow; the overflow of cyclone group A is transported to cyclone group B for desliming. The model of cyclone group B is Ф75mm, the feeding pressure is 0.20MPa, and the feeding concentration is 8 %, to obtain two products of sand settling and overflow, the overflow is mainly -10μm grain size sludge, which can be thrown out, the sand sett...

Embodiment 2

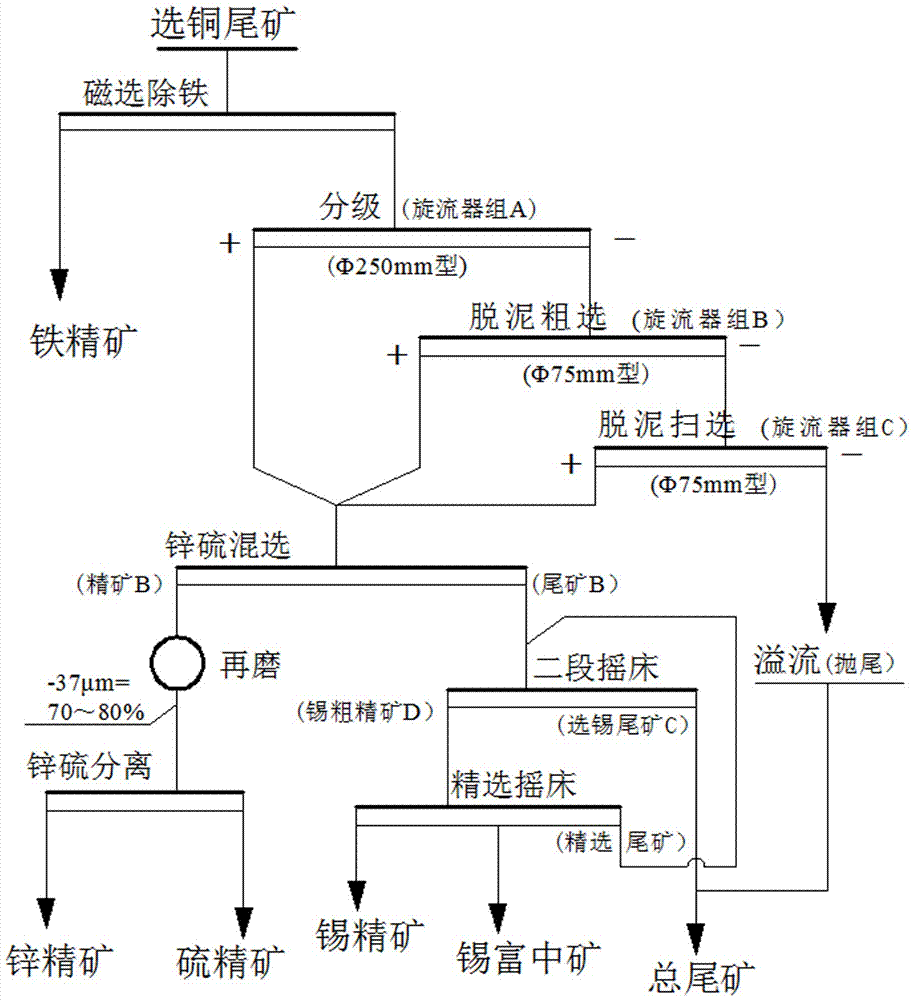

[0024] Embodiment 2: A process for recovering low-grade sphalerite and cassiterite minerals from copper beneficiation tailings, which mainly includes three processes of graded desliming, zinc-sulfur mixed separation-separation, and shaking table tin selection. The specific steps are as follows :

[0025] First, the staged desliming process (see image 3 ), transport the copper beneficiation tailings to the cyclone group A for grading, the type of the cyclone group A is Ф250mm, the ore feeding pressure is 0.10MPa, the ore feeding concentration is 30%, and the output of the cyclone group A is graded There are two products of sand settling and overflow; the overflow of cyclone group A is transported to cyclone group B for desliming. The model of cyclone group B is Ф75mm, the feeding pressure is 0.25MPa, and the feeding concentration is 13 %, to obtain two products of sand settling and overflow, the overflow is mainly -10μm grain size sludge, which can be thrown out, the sand set...

Embodiment 3

[0026] Embodiment 3: A process for recovering low-grade sphalerite and cassiterite minerals from copper beneficiation tailings, mainly including three processes of graded desliming, zinc-sulfur mixed separation-separation, and shaking table tin selection. The specific steps are as follows :

[0027] First, the staged desliming process (see image 3 ), transport the copper beneficiation tailings to the cyclone group A for grading, the type of the cyclone group A is Ф250mm, the feeding pressure is 0.08MPa, the feeding concentration is 25%, and the output of the cyclone group A is graded There are two products of sand settling and overflow; the overflow of cyclone group A is transported to cyclone group B for desliming. The model of cyclone group B is Ф75mm, the feeding pressure is 0.23MPa, and the feeding concentration is 10 %, to obtain two products of sand settling and overflow, the overflow is mainly -10μm grain size sludge, which can be thrown out, the sand settling of cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com