Patents

Literature

121results about How to "Small volume flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

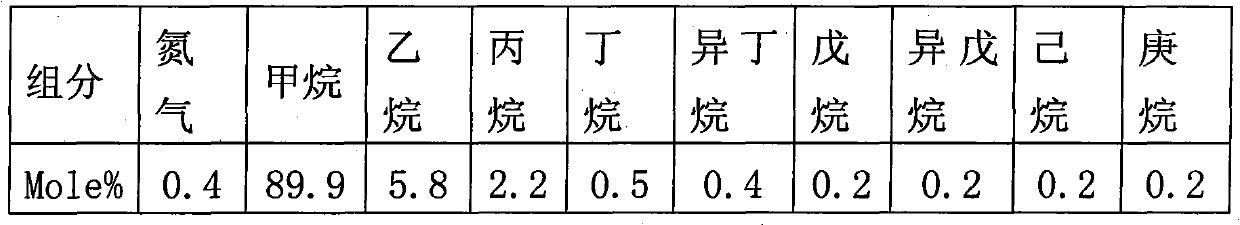

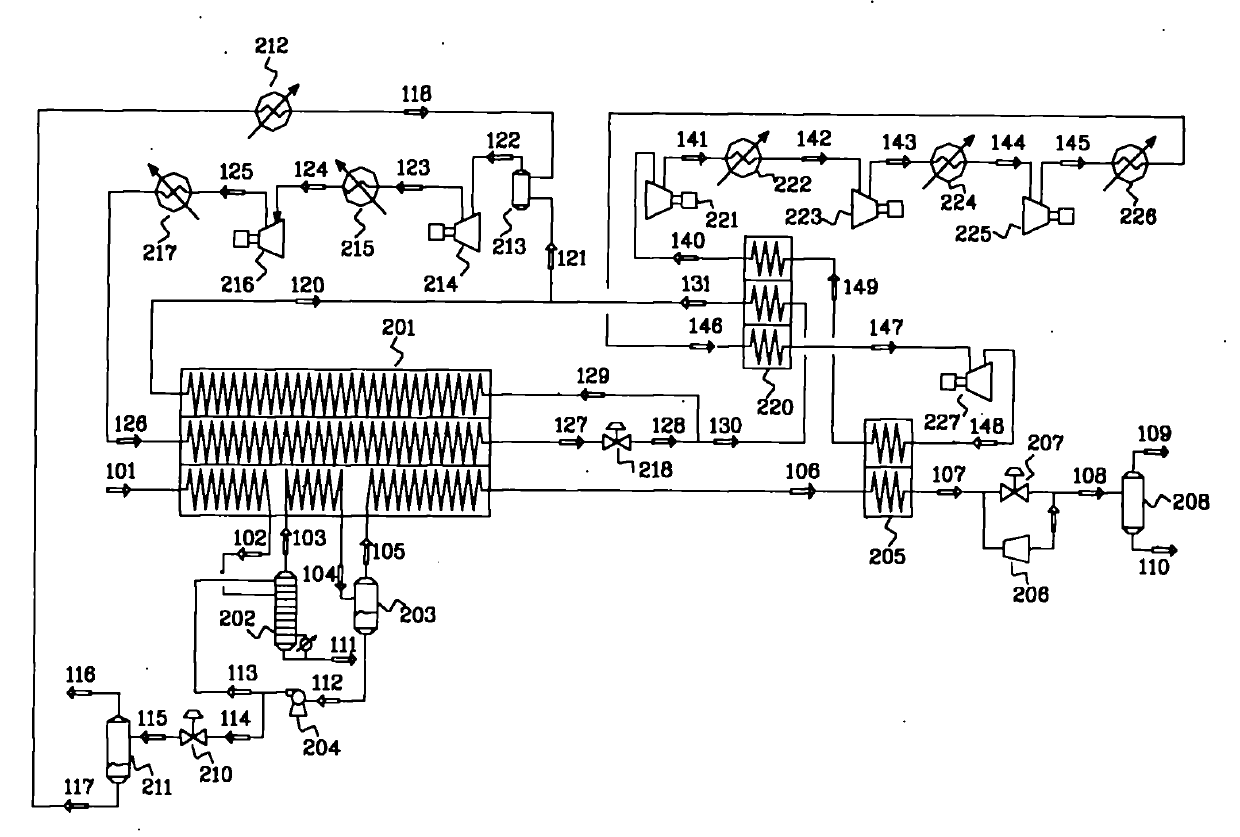

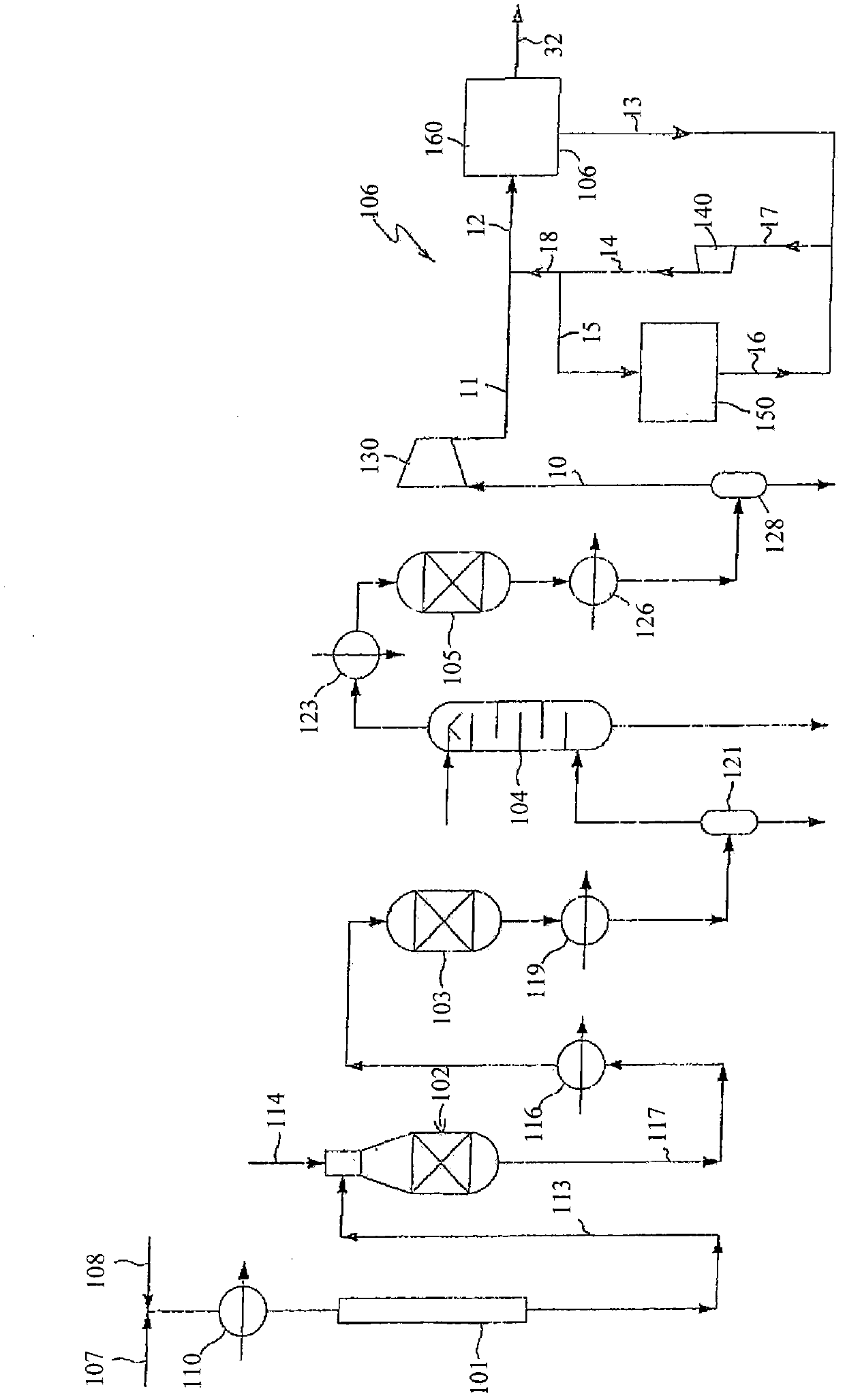

Mixed refrigerant and nitrogen expansion combinational refrigeration type natural gas liquefying method

ActiveCN101948706AImprove cycle efficiencySmall volume flowSolidificationLiquefactionRefrigerantLiquefied natural gas

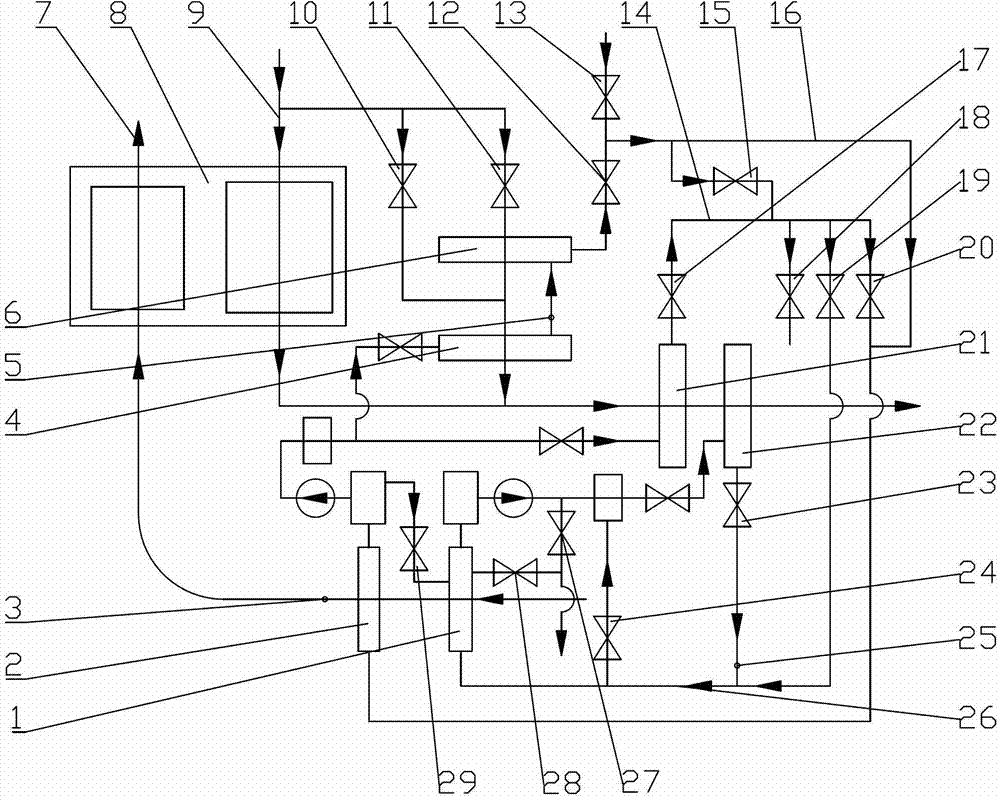

The invention belongs to the technical field of gas liquefaction and relates to a mixed refrigerant circulation and nitrogen expansion circulation combinational refrigeration type natural gas liquefying method. The method comprises the following steps of: allowing natural gas subjected to pretreatments such as acid gas removal, dehydration and the like to enter a natural gas liquefying section cooling box; performing refrigeration by vaporizing the mixed refrigerant in the liquefying section cooling box and controlling the pressure to be 4 to 10 Mpa so as to liquefy the natural gas under high pressure, wherein the temperature of the liquefied natural gas (LNG) departing from the liquefying section cooling box is between -75 and -110 DEG C; cooling the LNG to about -150 DEG C after the LNGenters a supercooling section cooling box; reducing pressure to be the pressure of a storage tank by using a liquid expander and further cooling to about -160 DEG C; and then compressing the LNG to serve as fuel gas. The method has the advantages of simple technical process, high reliability, high liquefaction rate and suitability for industrialized production.

Owner:CHINA NAT OFFSHORE OIL CORP +2

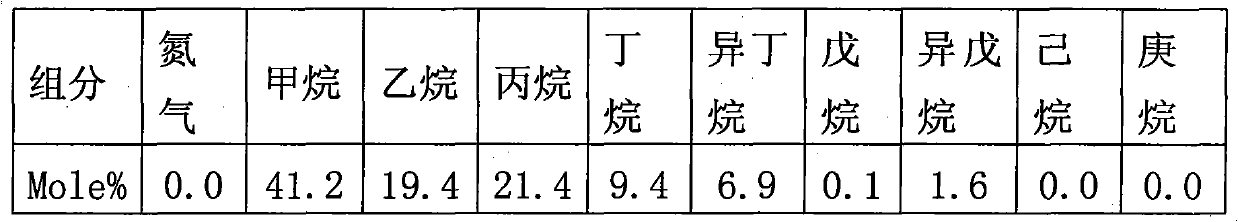

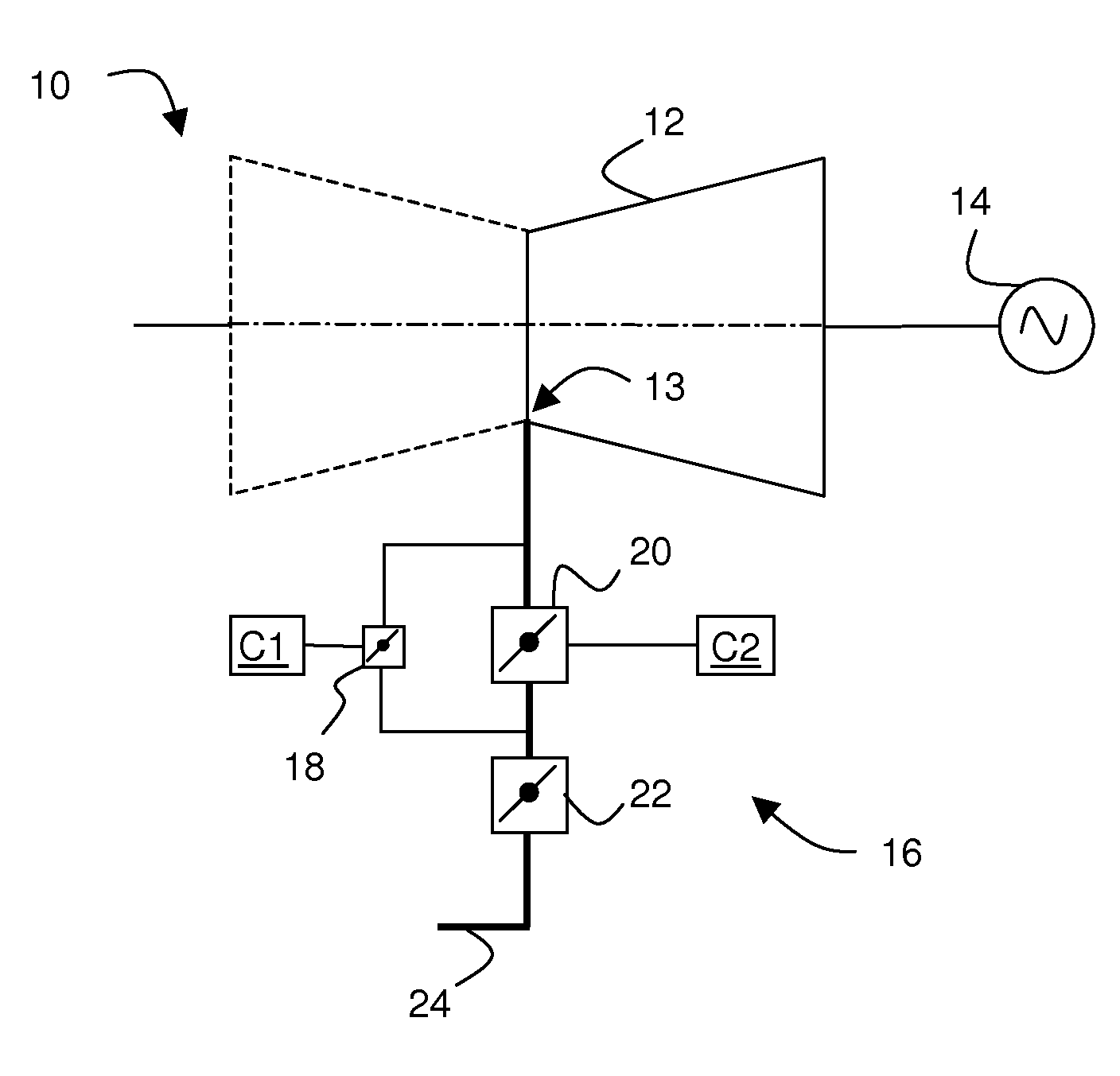

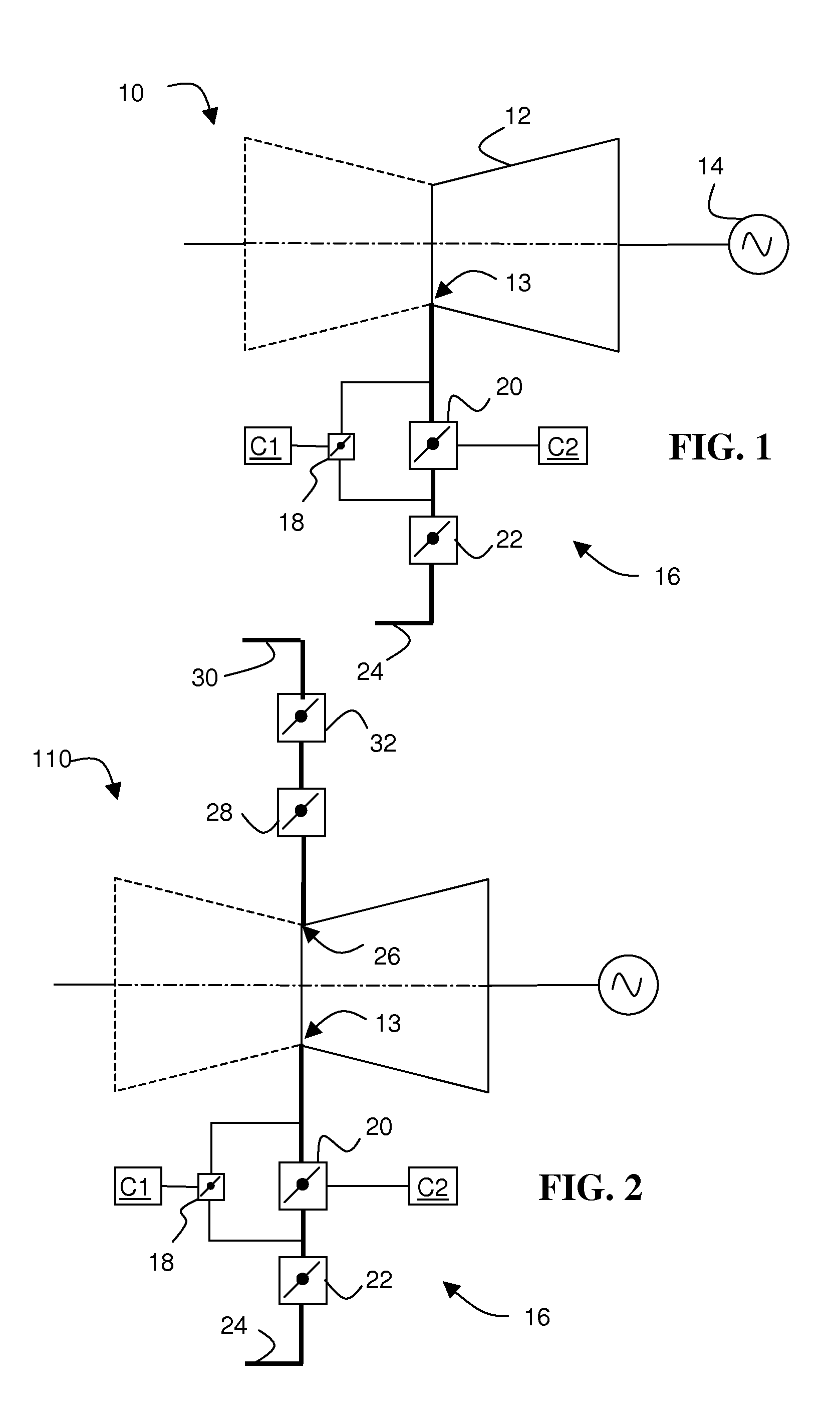

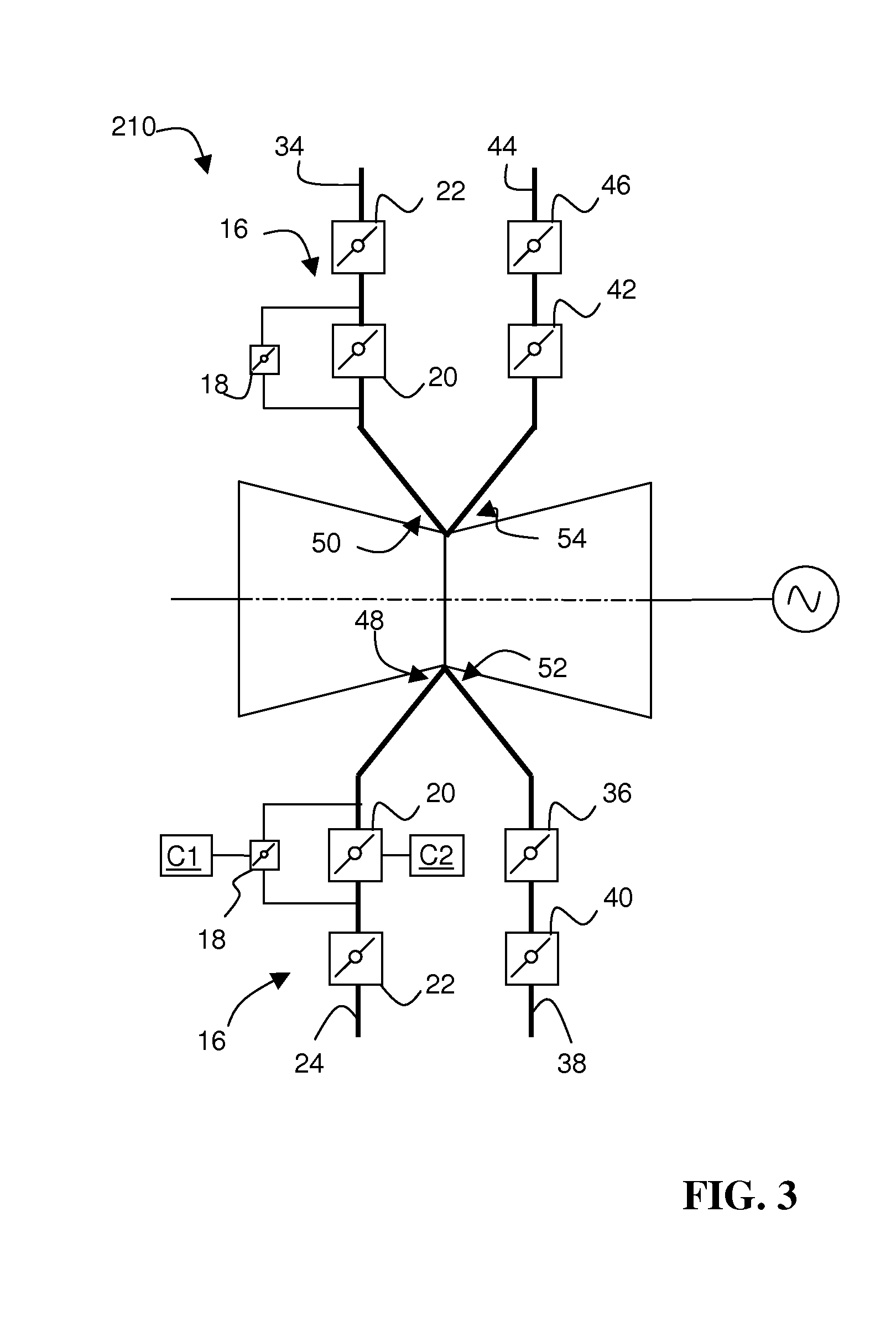

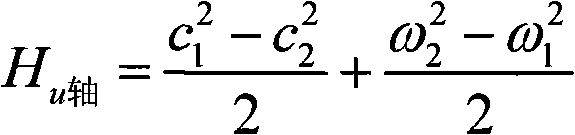

Geothermal power generation

InactiveUS20130247569A1Small volume flowSmall diameterEngine componentsSteam engine plantsEngineeringControl valves

A valve arrangement (16) for a geothermal steam turbine generator (10) comprises first and second steam control valves (18, 20) for regulating the supply of steam to the steam turbine generator (10). The first and second steam control valves are arranged in parallel in a steam supply line (24) and the first steam control valve (18) has a smaller fully-open diameter than the second steam control valve (20). The first steam control valve (18) is arranged to regulate the volume flow rate of steam supplied to the steam turbine generator (10) during a speed-control phase, until the steam turbine generator (10) attains a predetermined rotational speed at which it can be connected to an ac electrical system. The second steam control valve (20) is arranged to regulate the volume flow rate of steam supplied to the steam turbine generator (10) during a load-control phase, after the end of the speed-control phase, once the steam turbine generator (10) has attained the predetermined rotational speed and is connected to the ac electrical system.

Owner:ALSTOM TECH LTD

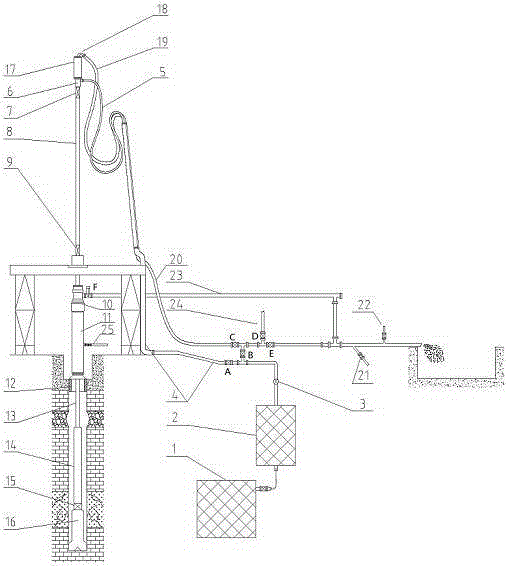

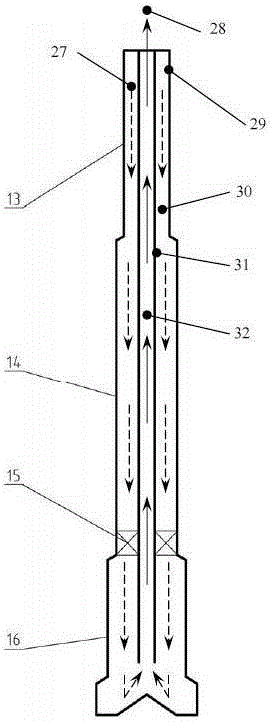

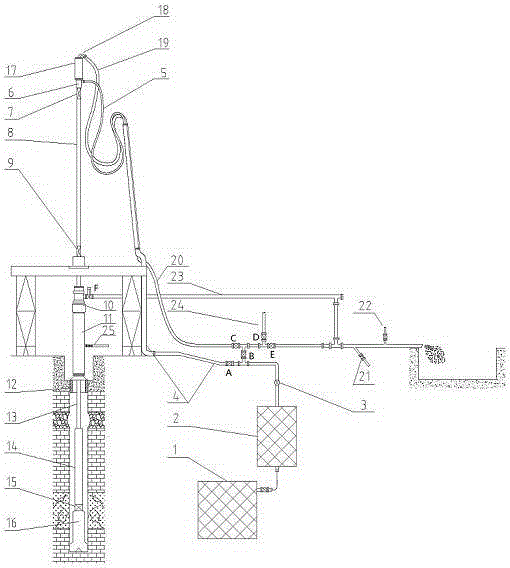

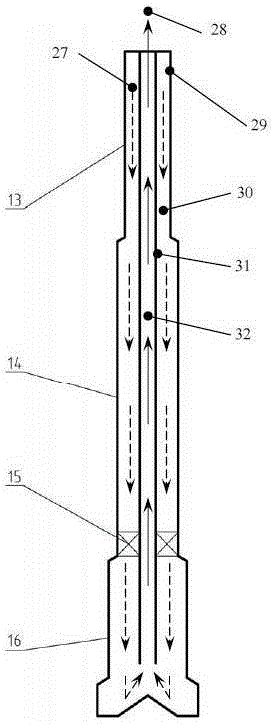

Full-well-section self-suction type reverse circulation gas drilling system for oil and gas drilling

ActiveCN105178859AImprove drilling efficiencySmall volumeLiquid/gas jet drillingFlushingGas liftDrilling system

The invention discloses a full-well-section self-suction type reverse circulation gas drilling system for oil and gas drilling. The full-well-section self-suction type reverse circulation gas drilling system for oil and gas drilling comprises a ground manifold connecting structure and a drilling assembly structure connected with the ground manifold connecting structure; and the ground manifold connecting structure comprises a gas injection unit, a pressure relief unit, a flowmeter, a ground gas injection manifold, a high-pressure gas injection hose, an erosion-resistant gooseneck, a high-pressure reverse circulation sand discharging hose, a ground reverse circulation sand discharging pipeline and a normal circulation gas drilling sand discharging pipeline. Double-wall drilling rigs are used in a full well section, conventional tools such as single-wall drilling rigs and gas and water mixing joints are omitted, air serves as a circulatory medium in the full well section, and reverse circulation can be implemented without mud or other drilling fluid. The full-well-section self-suction type reverse circulation gas drilling system for oil and gas drilling is particularly suitable for well sections with serious water shortage, serious well leakage or incapability of implementing air lift reverse circulation drilling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

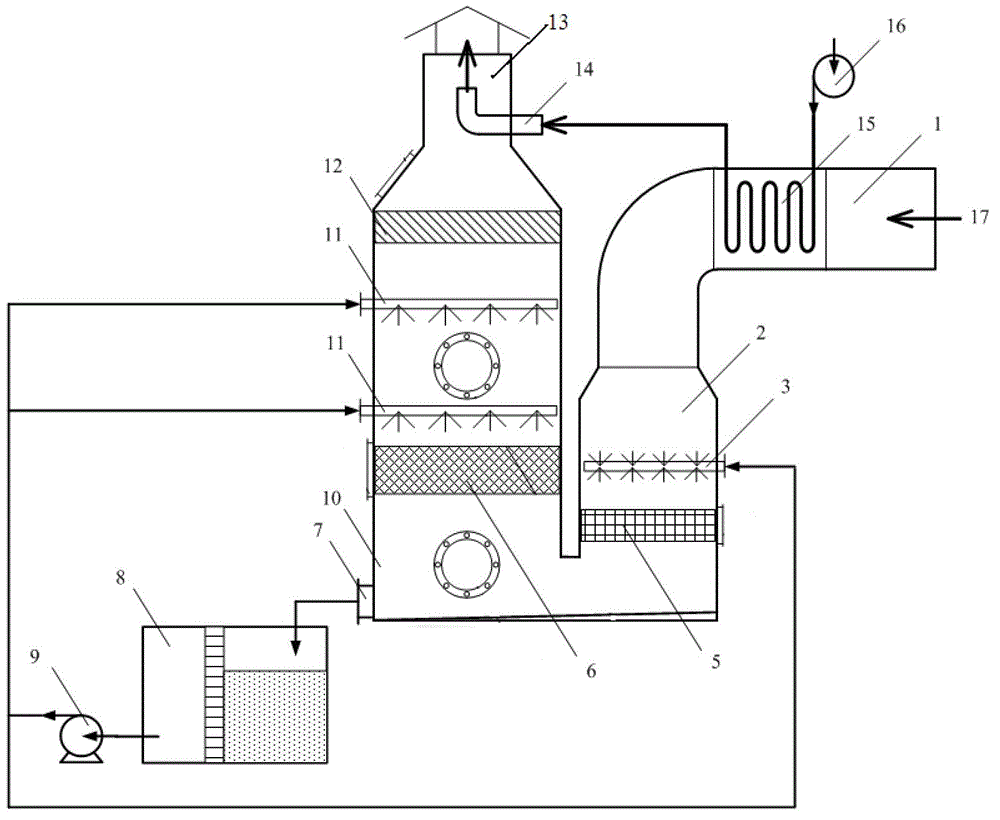

Smoke washing device

InactiveCN102716656AReduce the temperatureSmall volume flowUsing liquid separation agentFlue gasMiniaturization

The invention relates to a smoke washing device. A washing tower of the smoke washing device comprises a cooling adsorption washing area and an adverse current adsorption washing area. When smoke passes through the cooling adsorption washing area, partial pollutant such as smoke dust in the smoke can be removed, volume flow rate of the smoke is reduced simultaneously, and sectional area of the adverse current adsorption washing area is favorably reduced. In the adverse current adsorption washing area, the smoke dust in the smoke can be absorbed through sufficient contact between the smoke dust and a liquid film, and simultaneously pollutant such as sulfur dioxide can be sufficiently reacted. By means of the smoke washing device, high-efficient smoke dedusting desulfuration is achieved. In addition, washed smoke and heated air are mixed and then discharged out, smoke humidity is reduced, and rime fog at an air outlet of the smoke washing device is avoided. The smoke washing device is small in size, light in weight and applicable to flue gas treatment of a host machine and a boiler of an offshore platform or a traveling ship, and meets miniaturization requirements of on-land fume treatment equipment.

Owner:BEIJING DONGZHAN KEBO ELECTRONICS

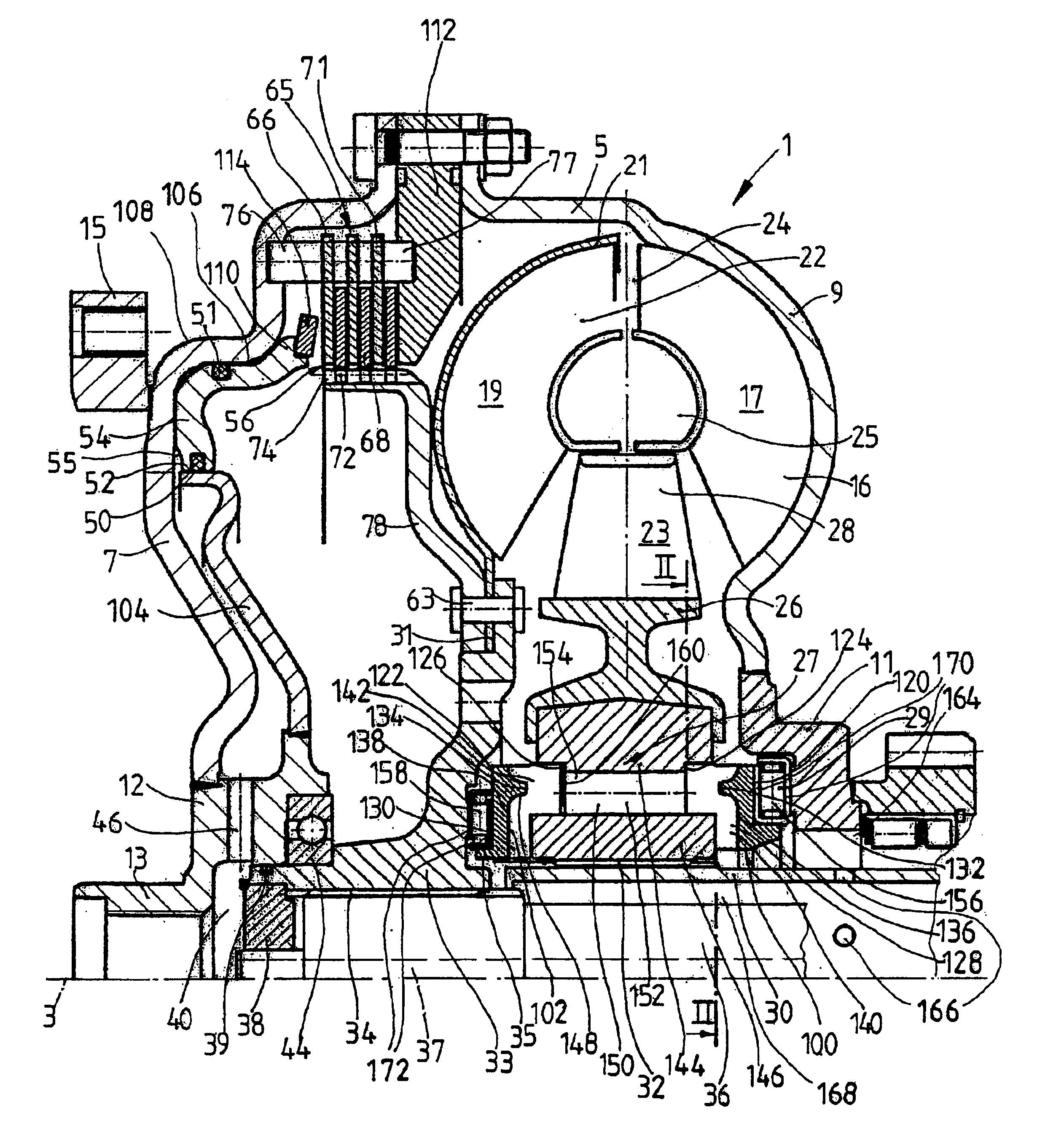

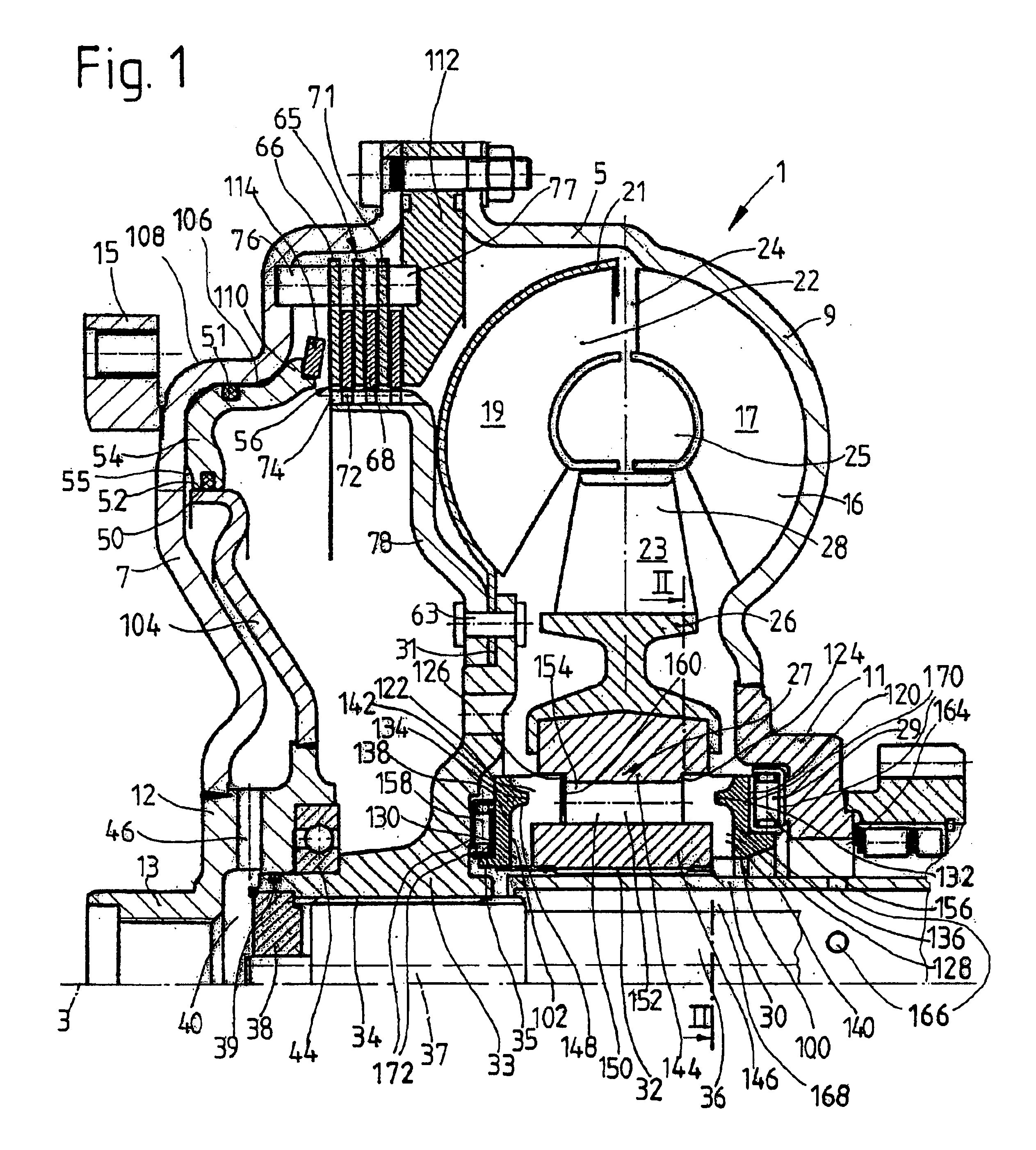

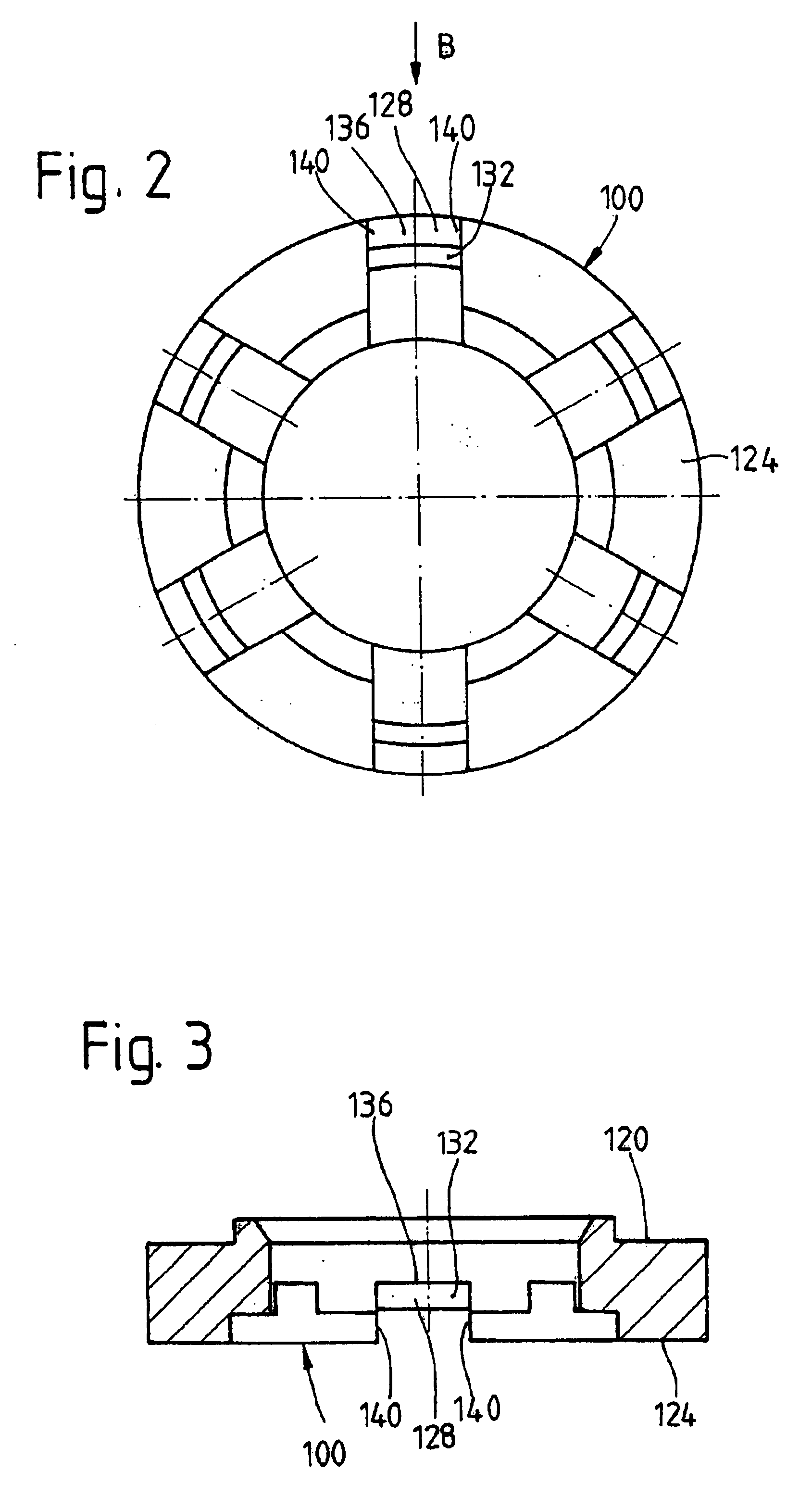

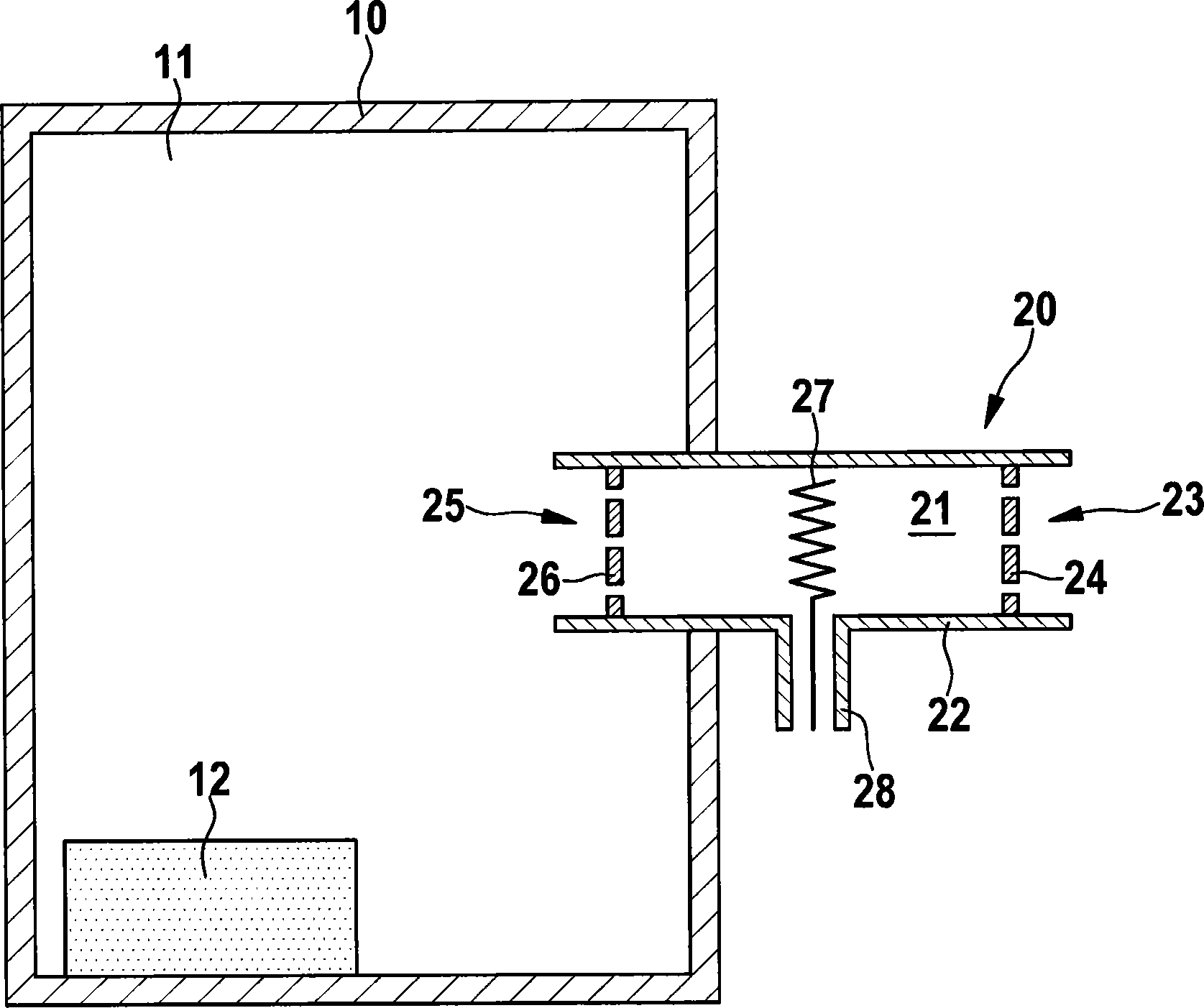

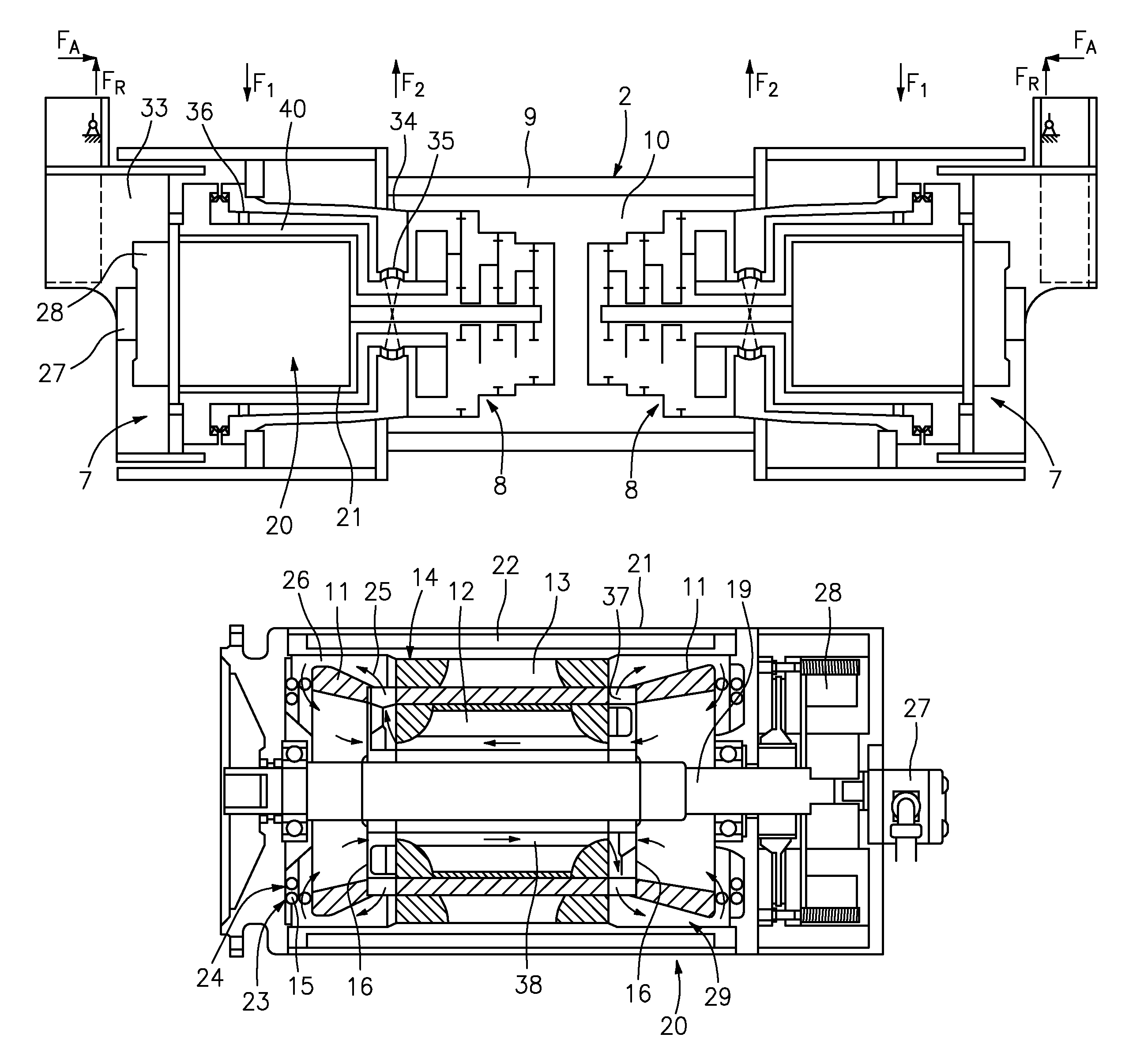

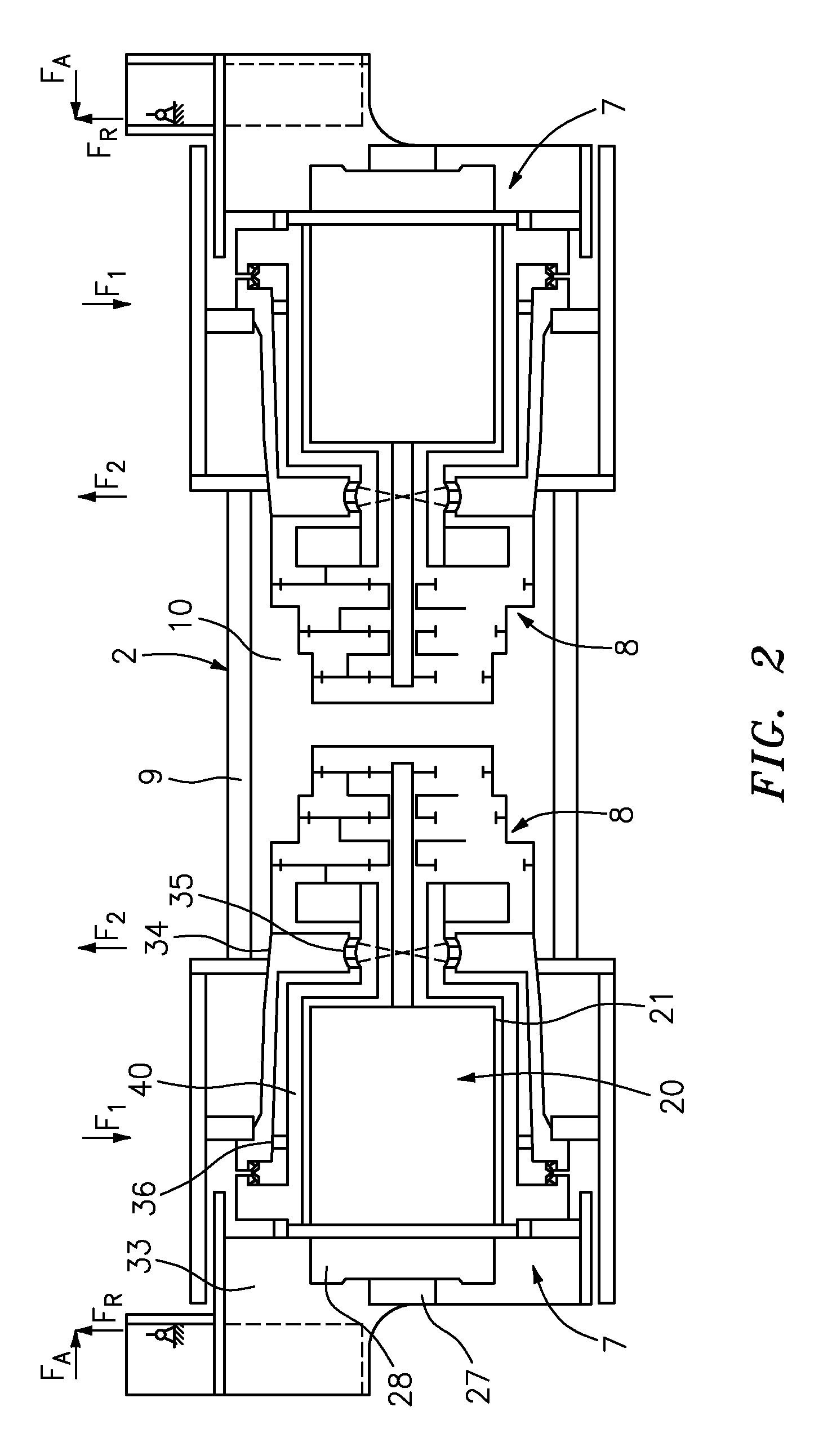

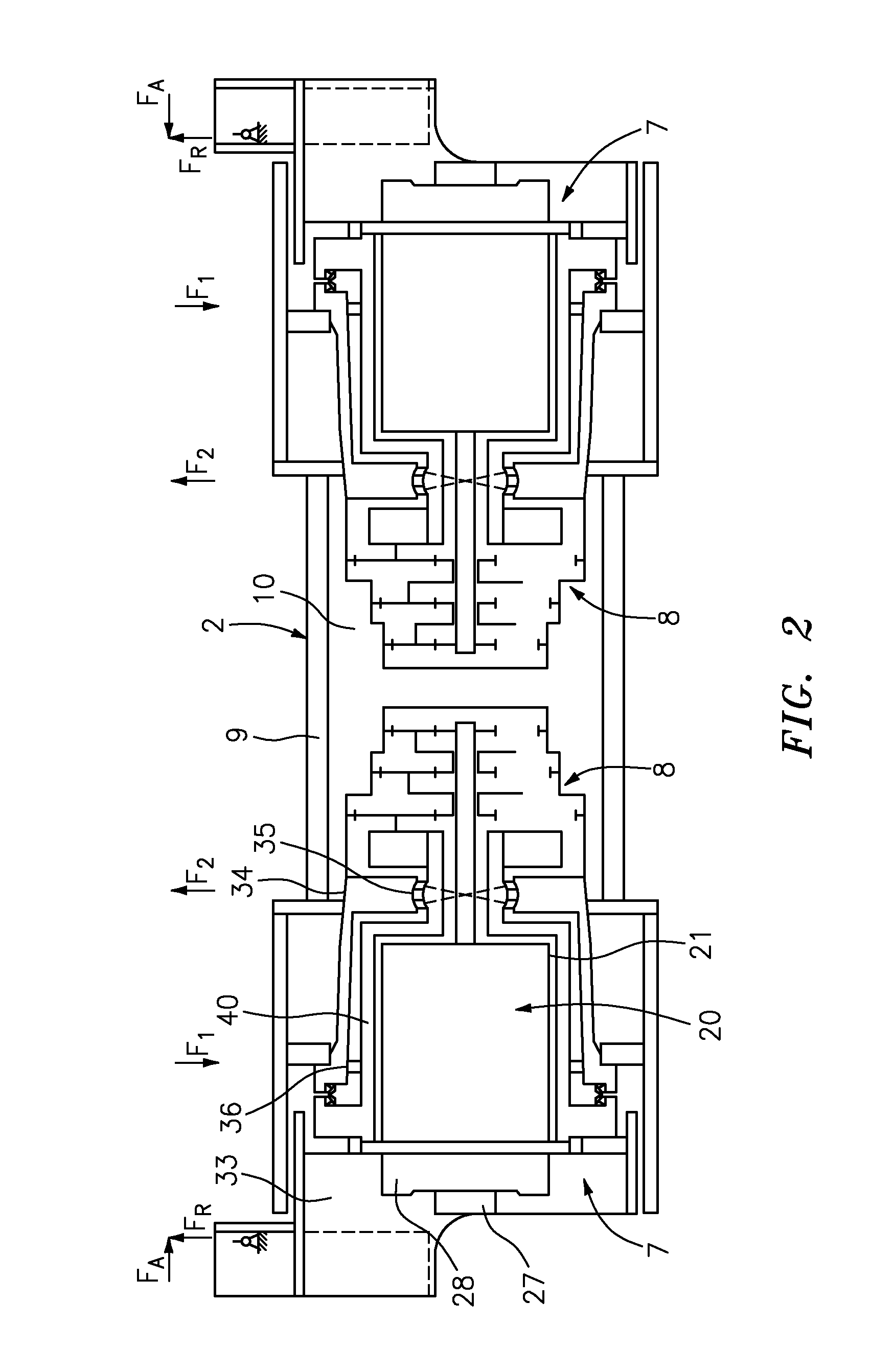

Hydrodynamic torque converter with at least one axial bearing arrangement for supporting the stator

InactiveUS6814202B1Excessive deformationSmall volume flowRotary clutchesFriction clutchesImpellerTurbine wheel

A hydrodynamic torque converter is provided with a converter housing to hold at least one pump wheel, one turbine wheel, and one stator to form a hydrodynamic circuit and with at least one axial bearing arrangement for supporting the stator. At least one support element has a bearing side which rests against the axial bearing arrangement, and a stator side which rests against a component of the stator and is designed with at least one flow passage for viscous medium, which forms a connection between at least one flow conduit and the hydrodynamic circuit. The flow passage has a flow bed and, contiguous with that, at least one boundary wall, which leads from the flow bed to the axial level of the corresponding support element side. The bearing side of the support element is essentially flat and the stator side is provided with at least one flow passage, in the extension area of which a stiffener is provided, which produces at least a partial connection between the flow bed of the flow passage and the at least one boundary wall.

Owner:ZF FRIEDRICHSHAFEN AG

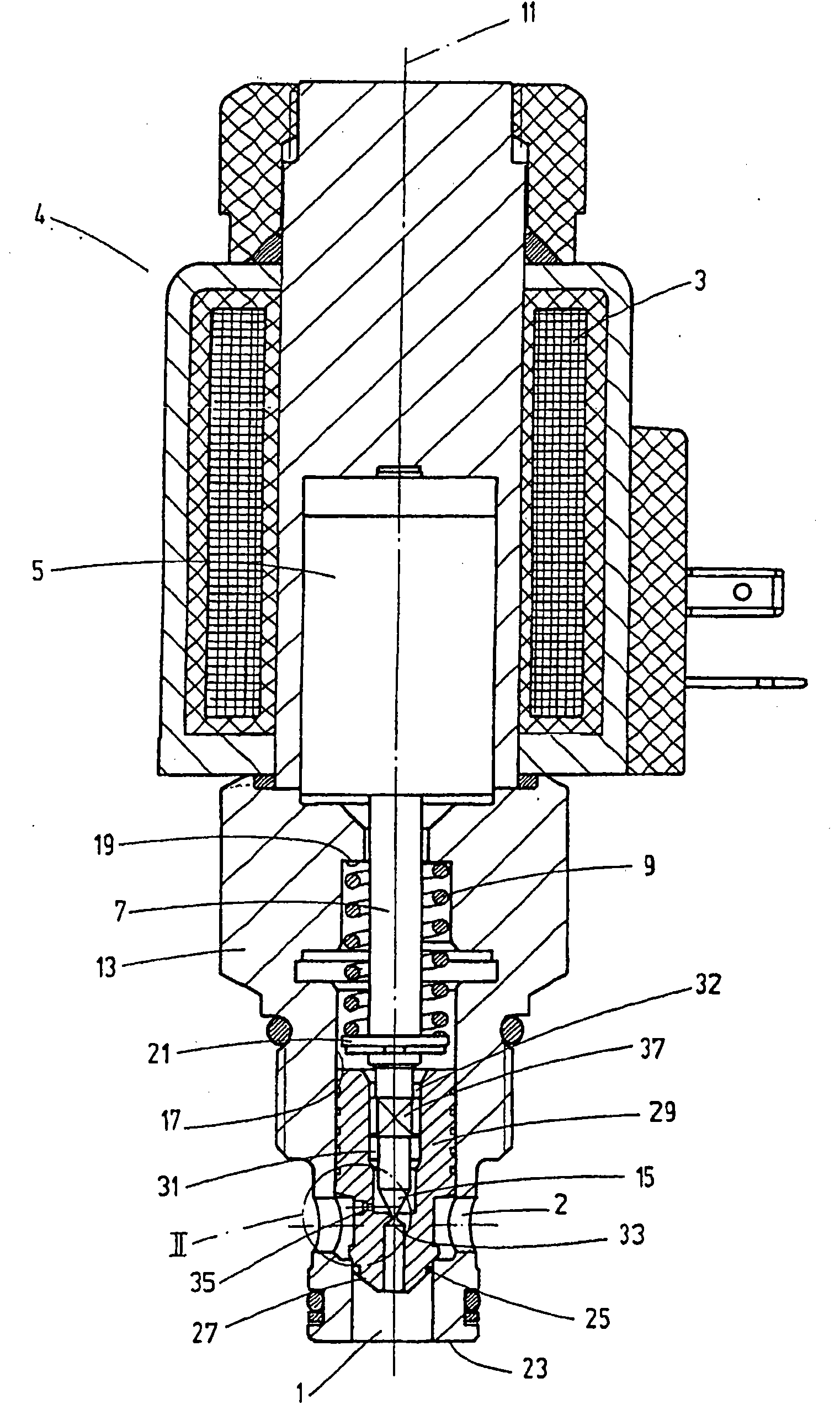

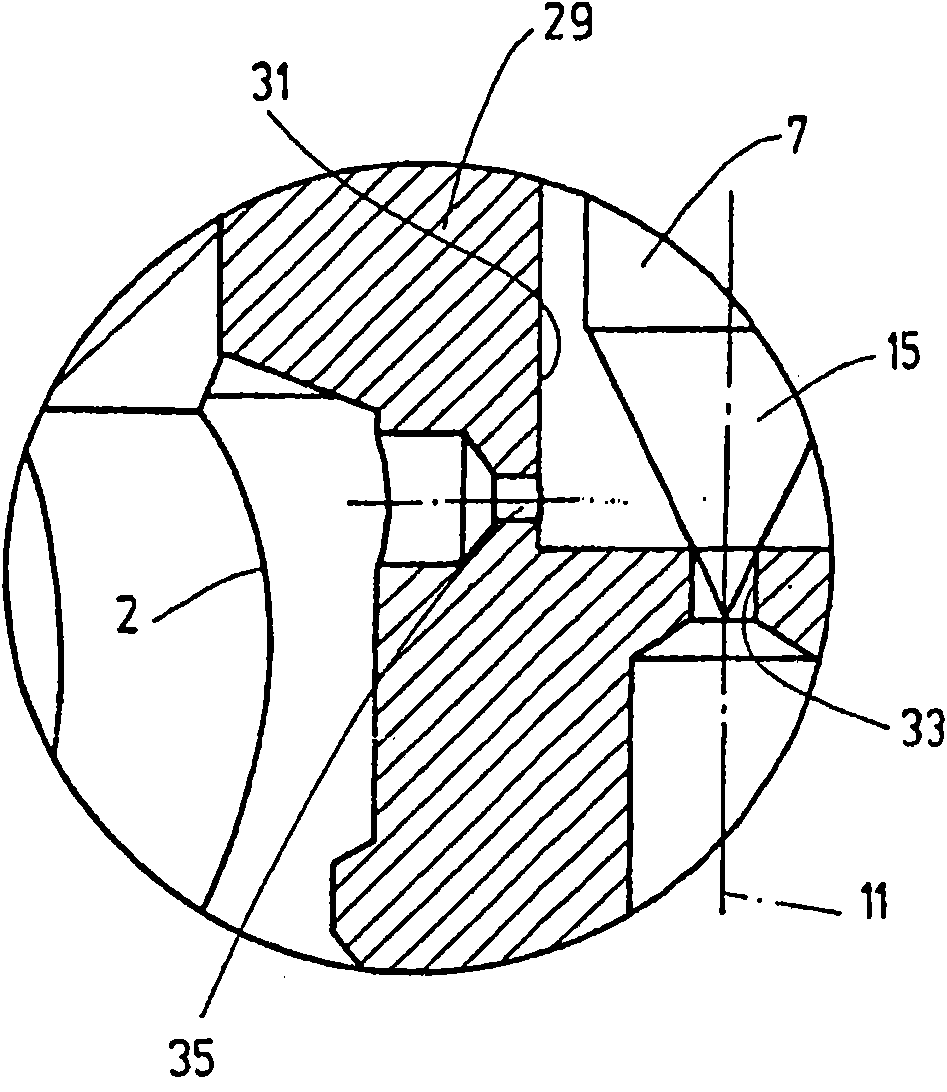

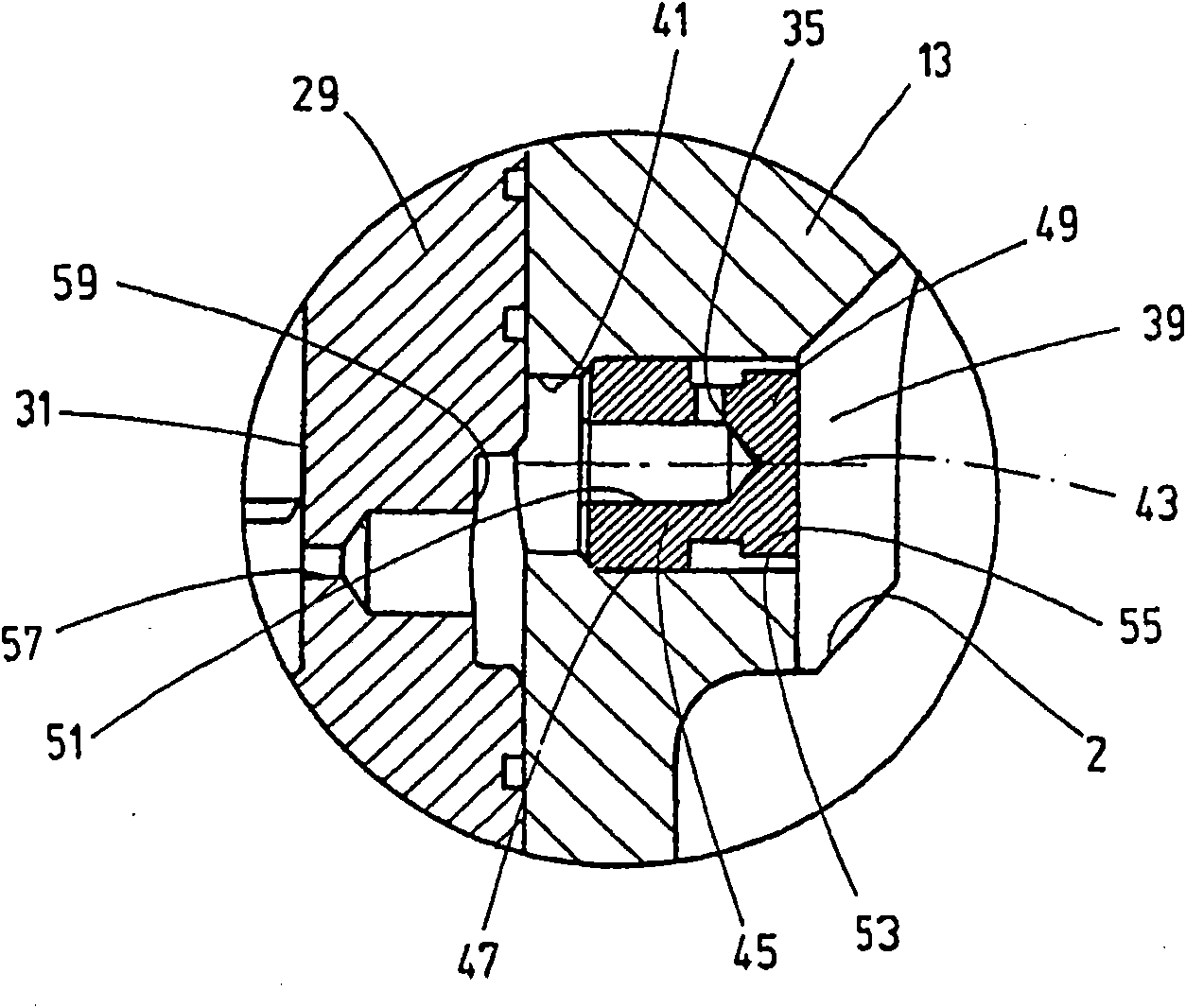

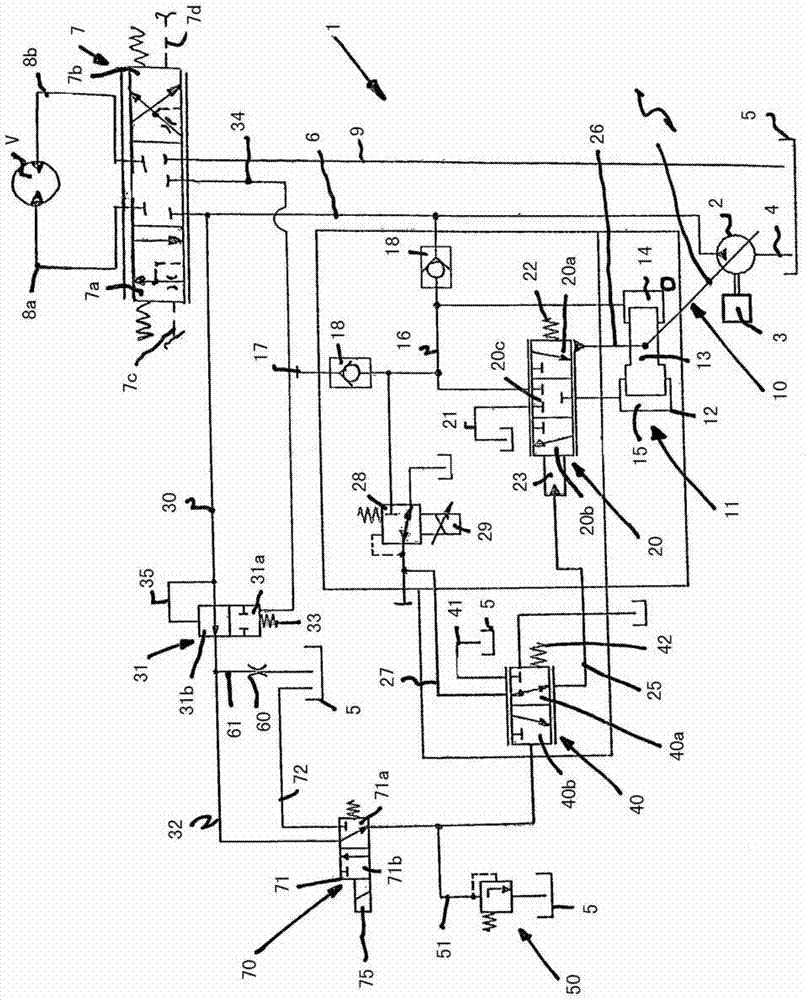

Piloted valve, particularly proportional throttle valve

InactiveCN101925768AAvoid contamination riskPilot control volume flow reductionOperating means/releasing devices for valvesThin material handlingMarine engineeringControl valves

Owner:HYDAC FLUITECHNIK GMBH

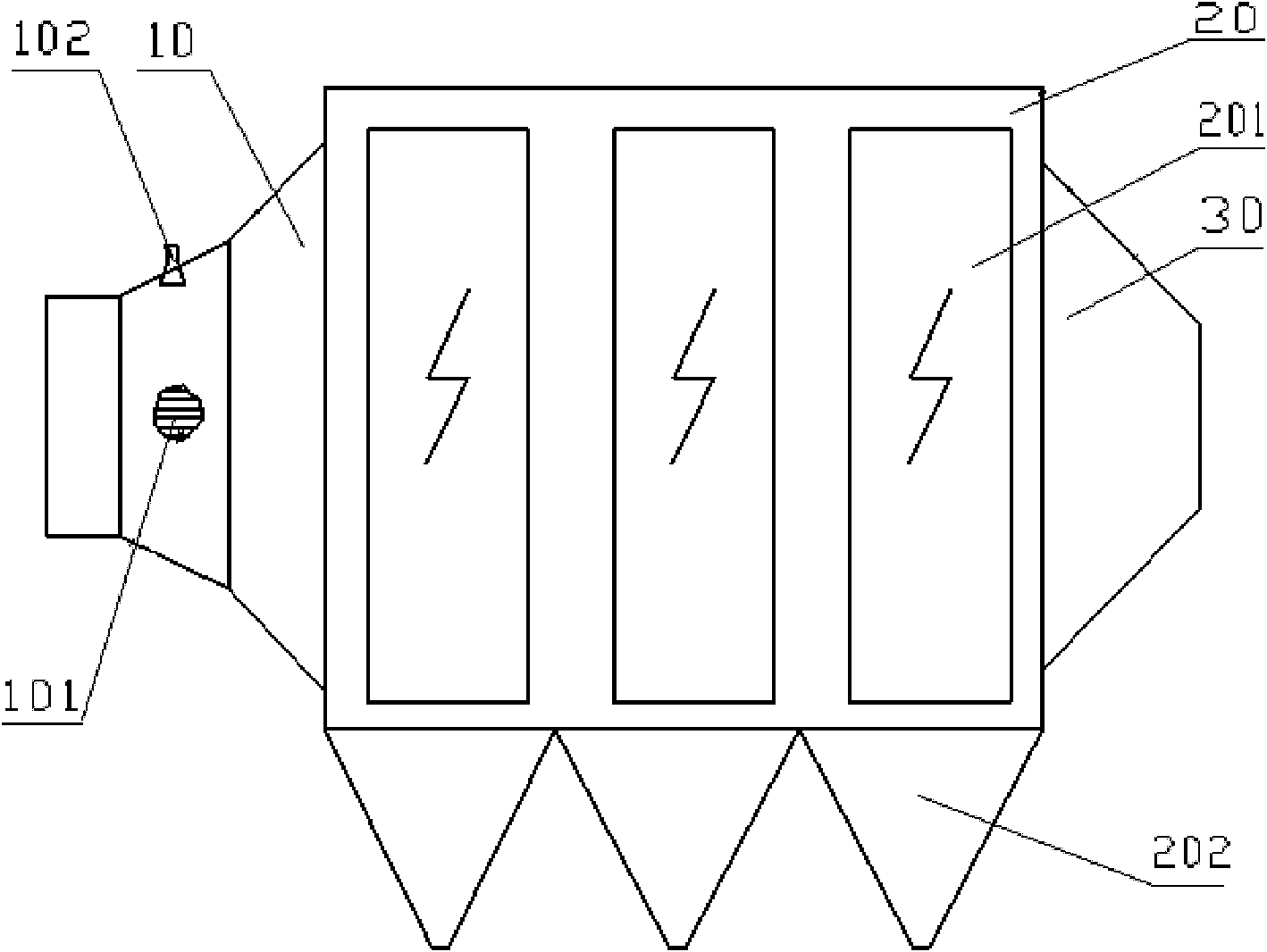

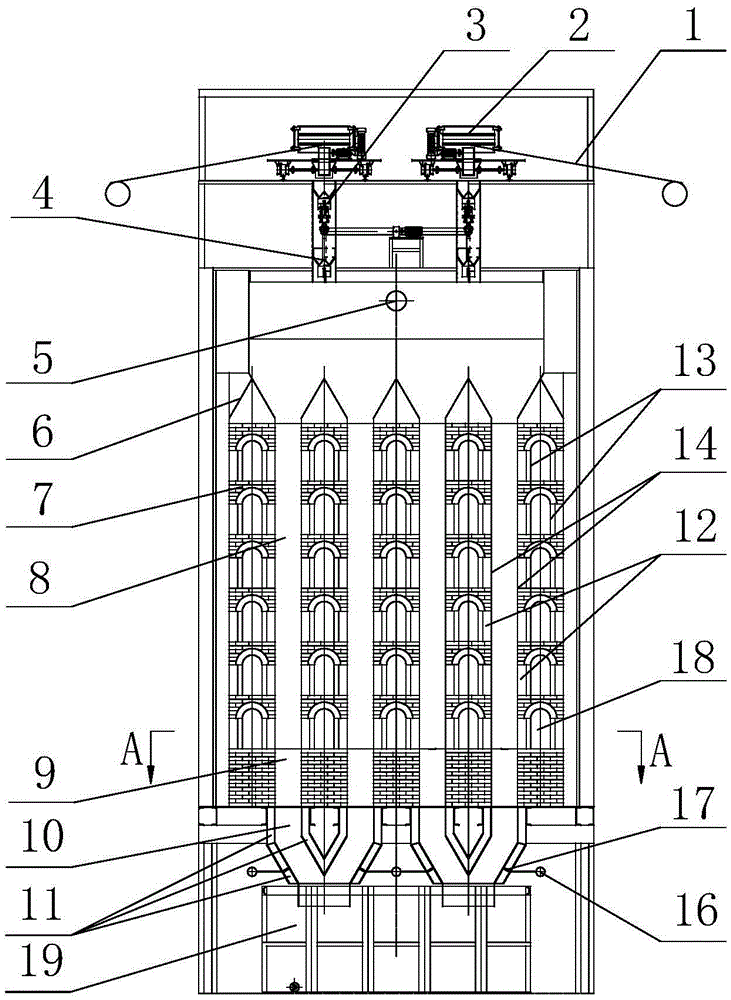

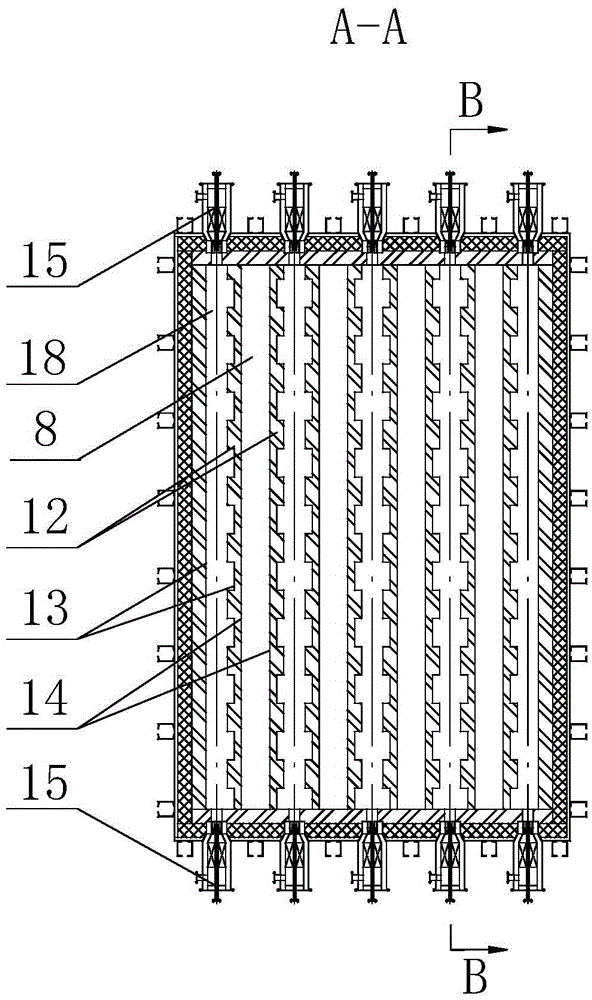

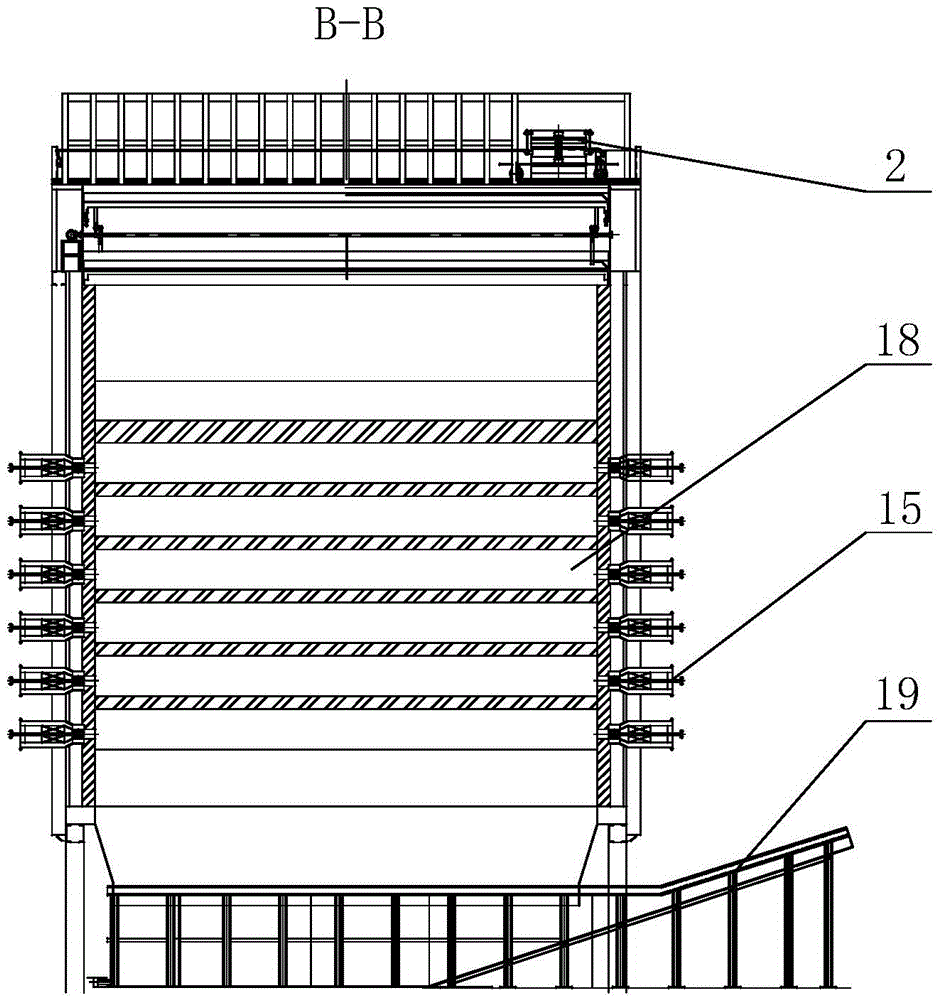

A flue gas dedusting system and its electric precipitator

ActiveCN102284361AImprove dust removal efficiencyCompact structureElectrostatic separationFlue gasProcess engineering

The invention discloses a flue gas electric dust remover. The flue gas electric dust remover comprises an inlet flue gas box, an outlet flue gas box, a high-pressure electrostatic dust collection electric field positioned between the inlet flue gas box and the outlet flue gas box, and a heat exchange device arranged in the inlet flue gas box. The flue gas electric dust remover can reduce the temperature of flue gas before the flue gas enters the high-pressure electrostatic dust collection electric field, so the volume flow rate of the flue gas to be treated which enters the electric field is reduced, and the flow velocity of the flue gas in a flue gas channel of the electric field is correspondingly reduced; meanwhile, the flue gas temperature is reduced, so the dust specific resistance of the flue gas is reduced, and the dust removal efficiency of the electric dust remover is improved; in addition, the heat exchange device is arranged at the inlet flue gas box, so the inner space of the inlet flue gas box on the conventional electric dust remover can be fully utilized, and additional occupied space is not increased while the dust removal efficiency is improved, namely the flue gas electric dust remover has the advantages of compact structure and contribution to system and process arrangement. The invention also discloses a flue gas dust removal system with the flue gas electric dust remover.

Owner:FUJIAN LONGKING

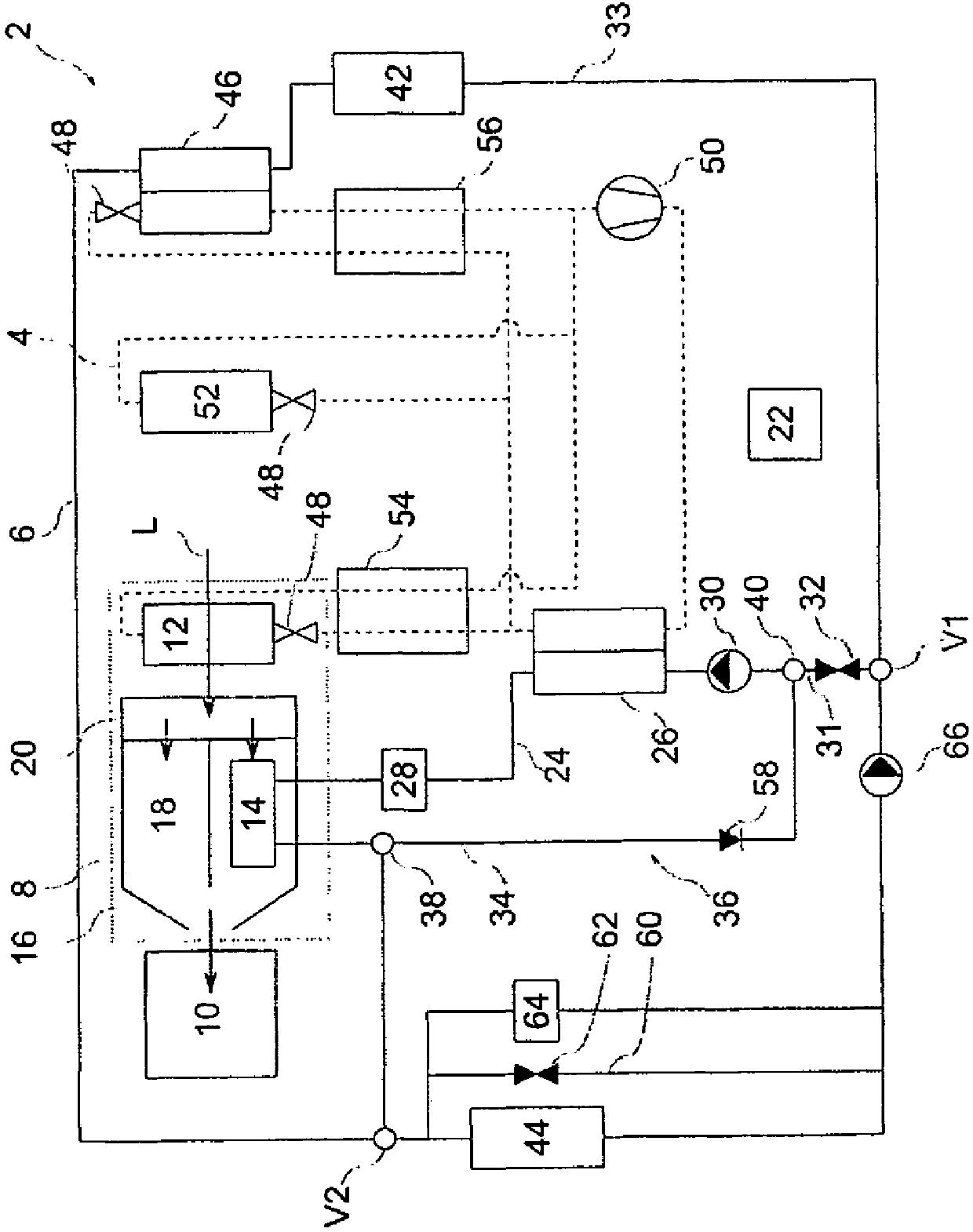

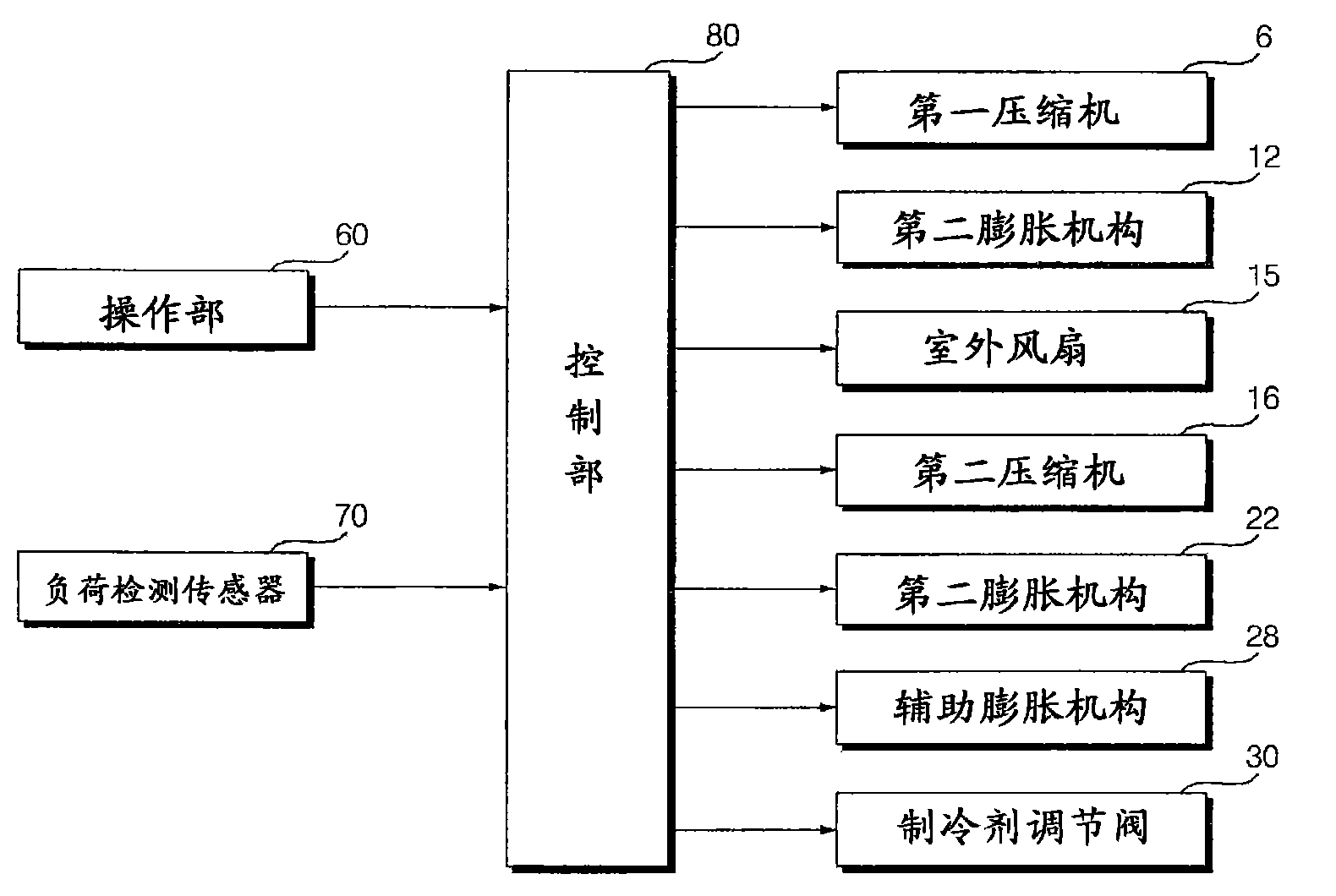

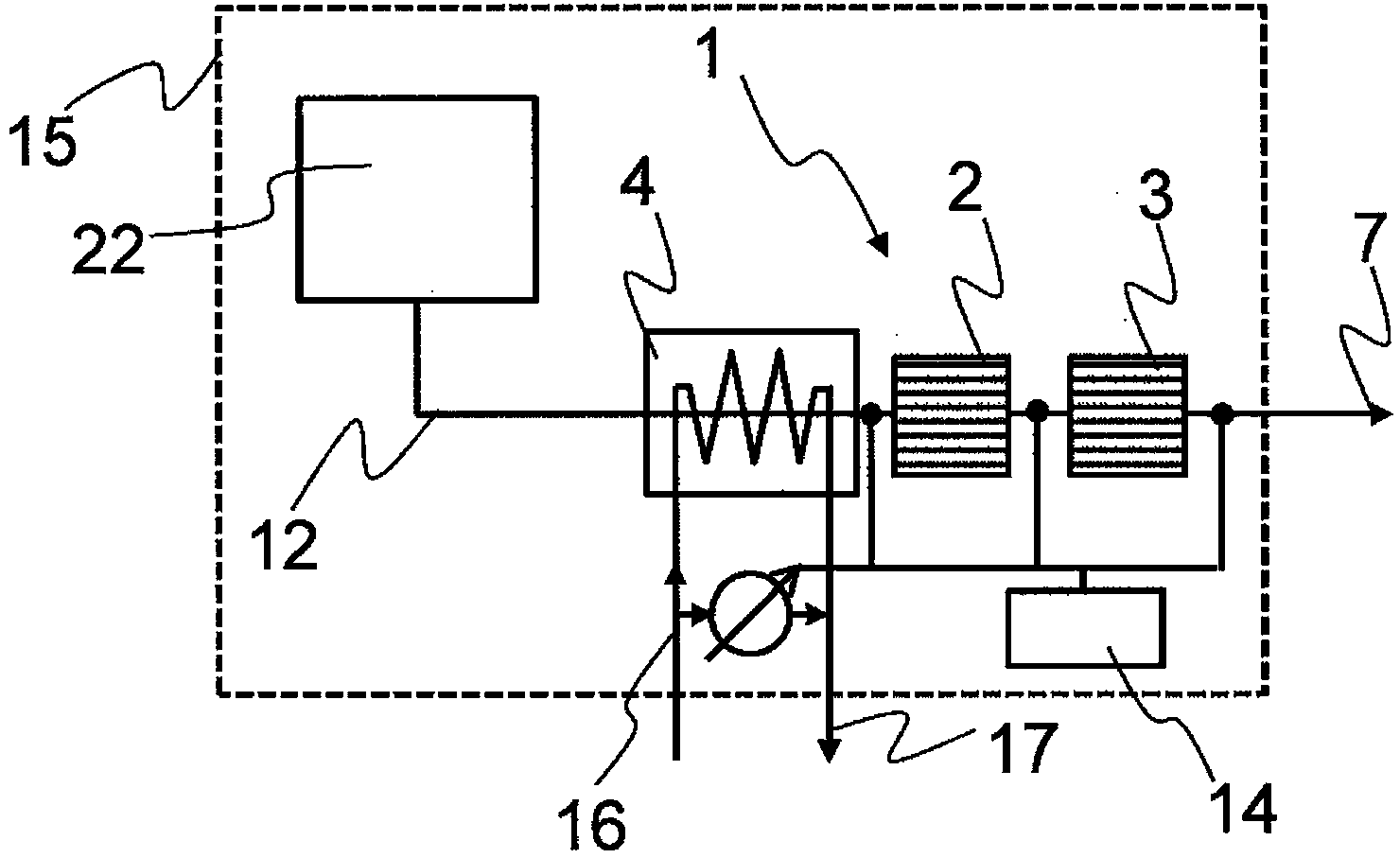

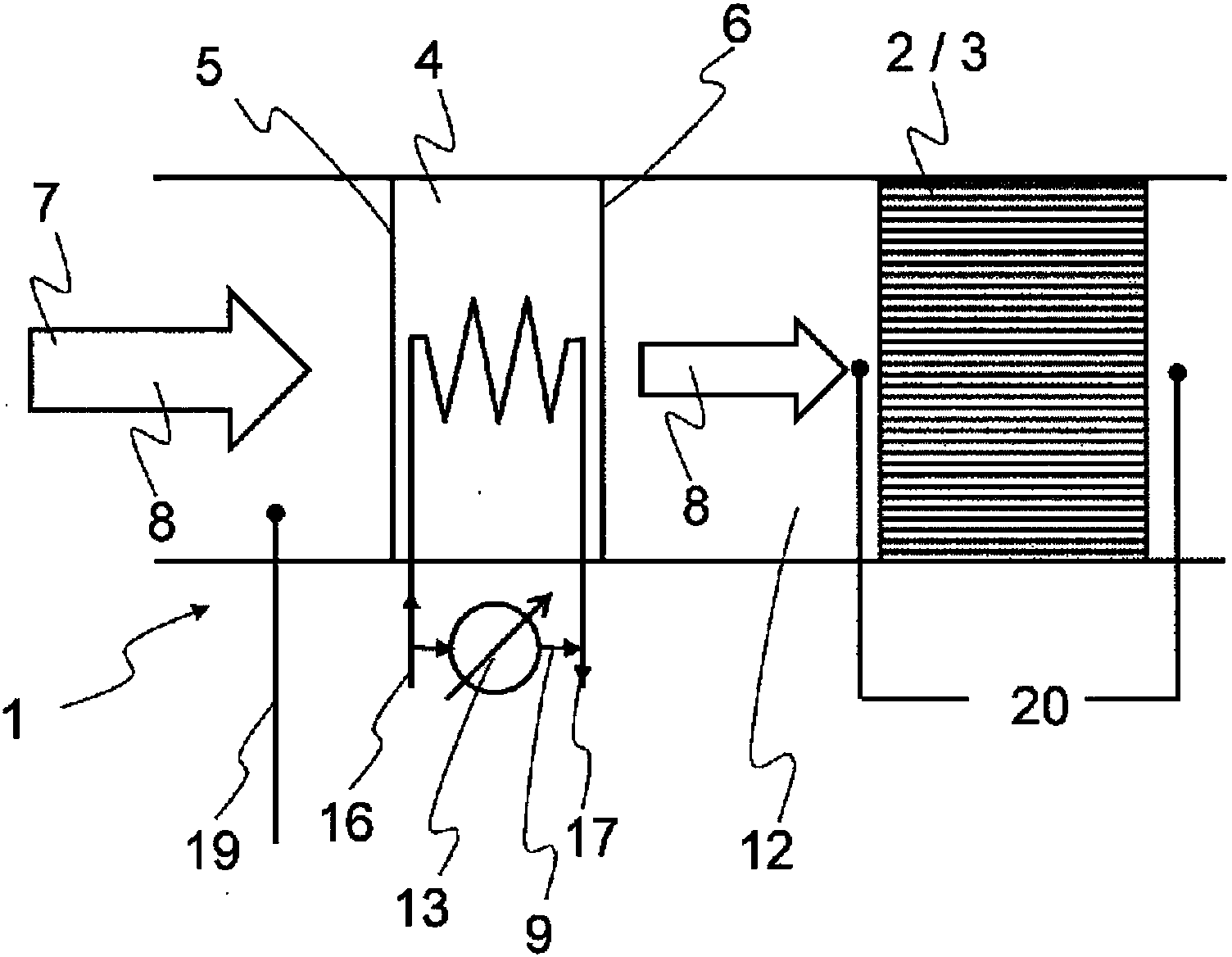

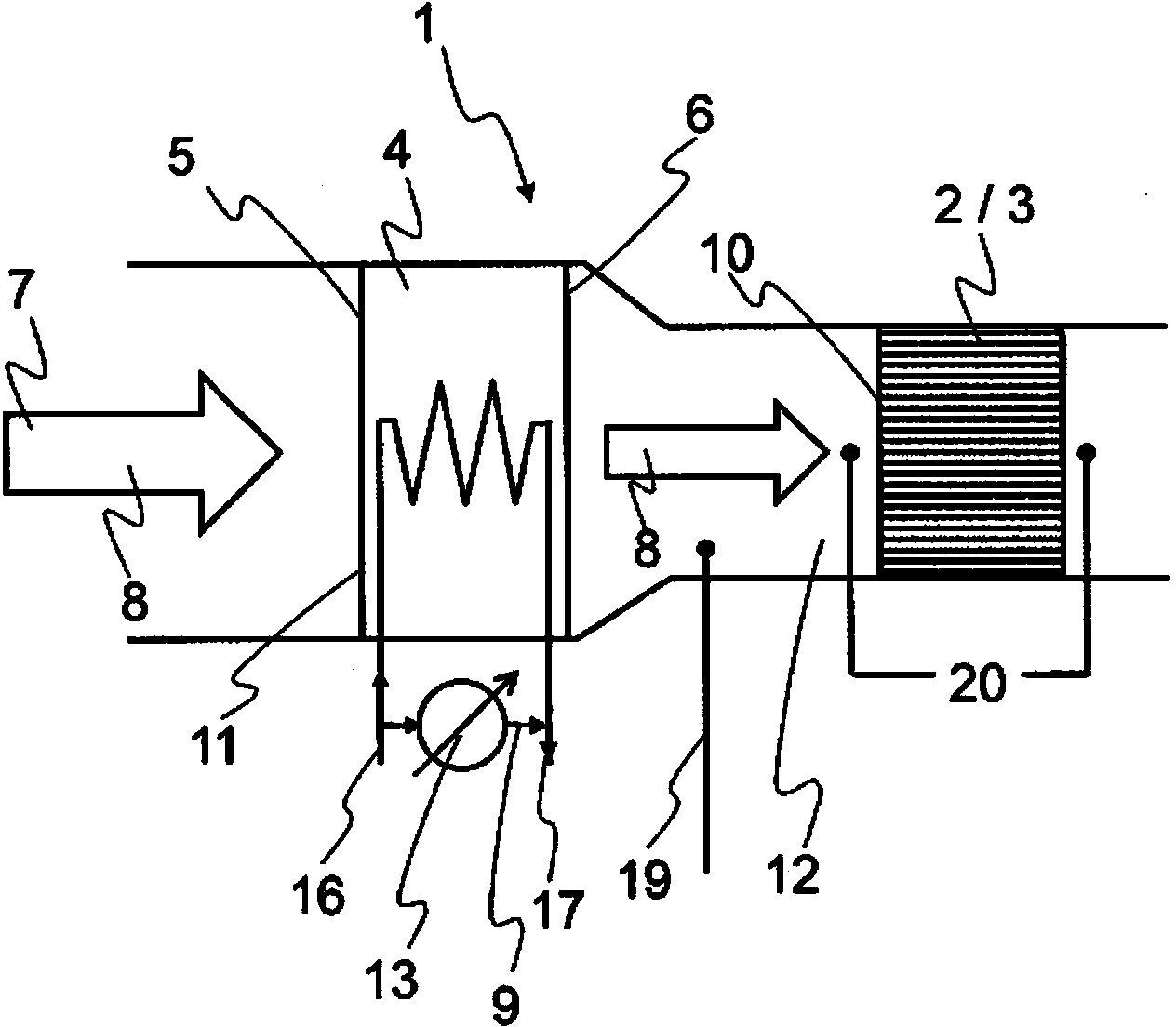

Heat pump system and method for operating it

ActiveCN107709063ACompact structureReduce plumbing costsAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

The invention relates to a heat pump system (2) for air conditioning a vehicle, in particular an electric or hybrid vehicle, having an air conditioning unit (8) which has an air conditioning evaporator (12) and a heating heat exchanger (14), for air conditioning a passenger compartment (10) of the vehicle, having a condenser (26), for transmitting heat from a refrigeration circuit (4) into a coolant circuit (6), having a chiller (46), for transmitting heat from the coolant circuit (6) into the refrigeration circuit (4), wherein the coolant circuit (6) has two branches (24, 33) which are parallel to one another downstream of a low temperature cooler (44), namely a heating branch (24) which can be shut off and in which the condenser (26) and the heating heat exchanger (14) are arranged, anda cooling branch (33), in which the chiller (46) and a low temperature heat exchanger (42) for cooling a vehicle component are arranged. The heat pump system (2) is characterized in that the low temperature cooler (44), the condenser (26) and the heating heat exchanger (14) are connected in series with respect to one another. In addition, the heat pump system (2) has a plurality of operating modes. Particularly flexible, inexpensive, robust and, above all, efficient air conditioning is realised on the basis of the special connection. Furthermore, the invention relates to a method for operatingthe heat pump system (2).

Owner:BAYERISCHE MOTOREN WERKE AG

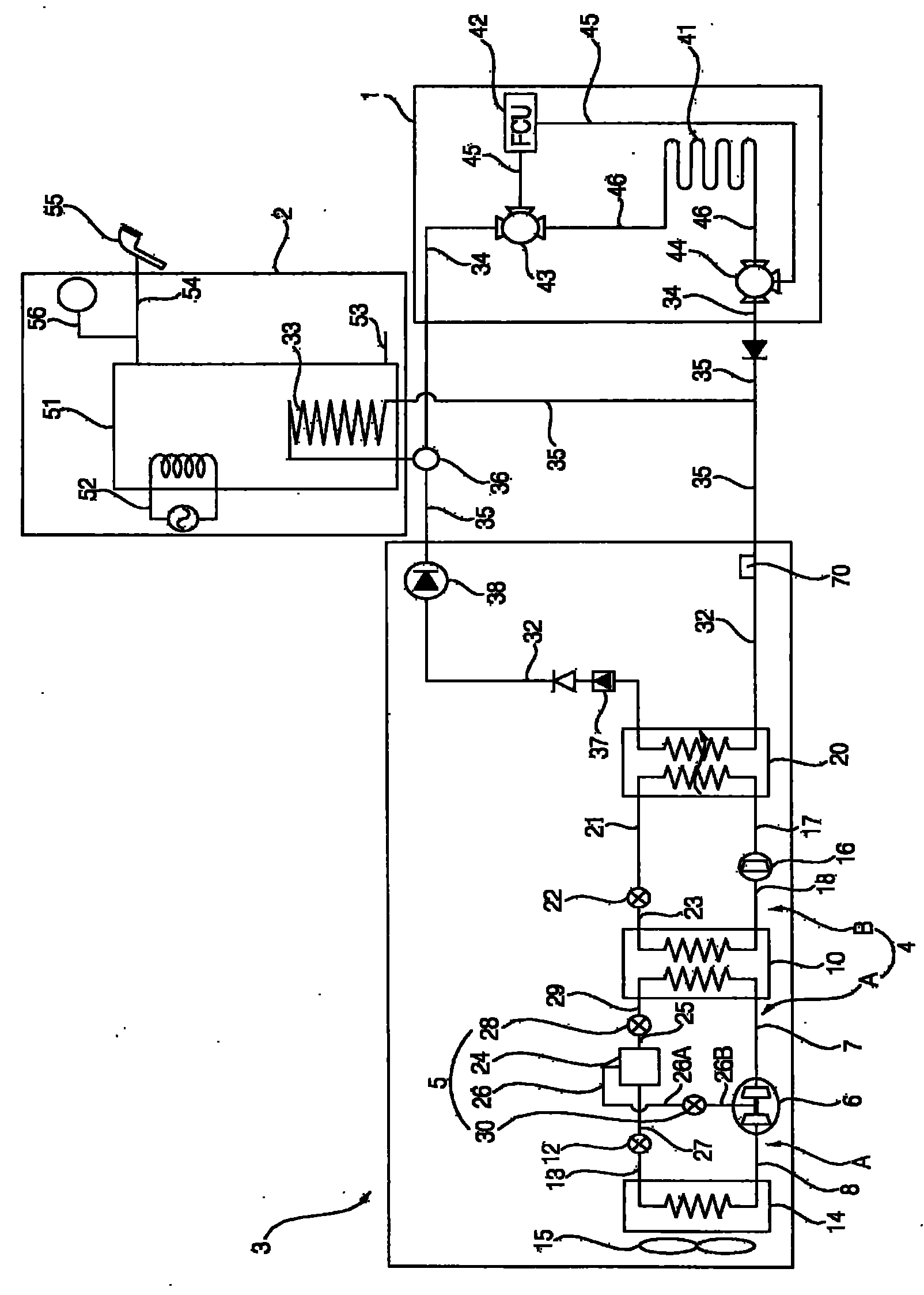

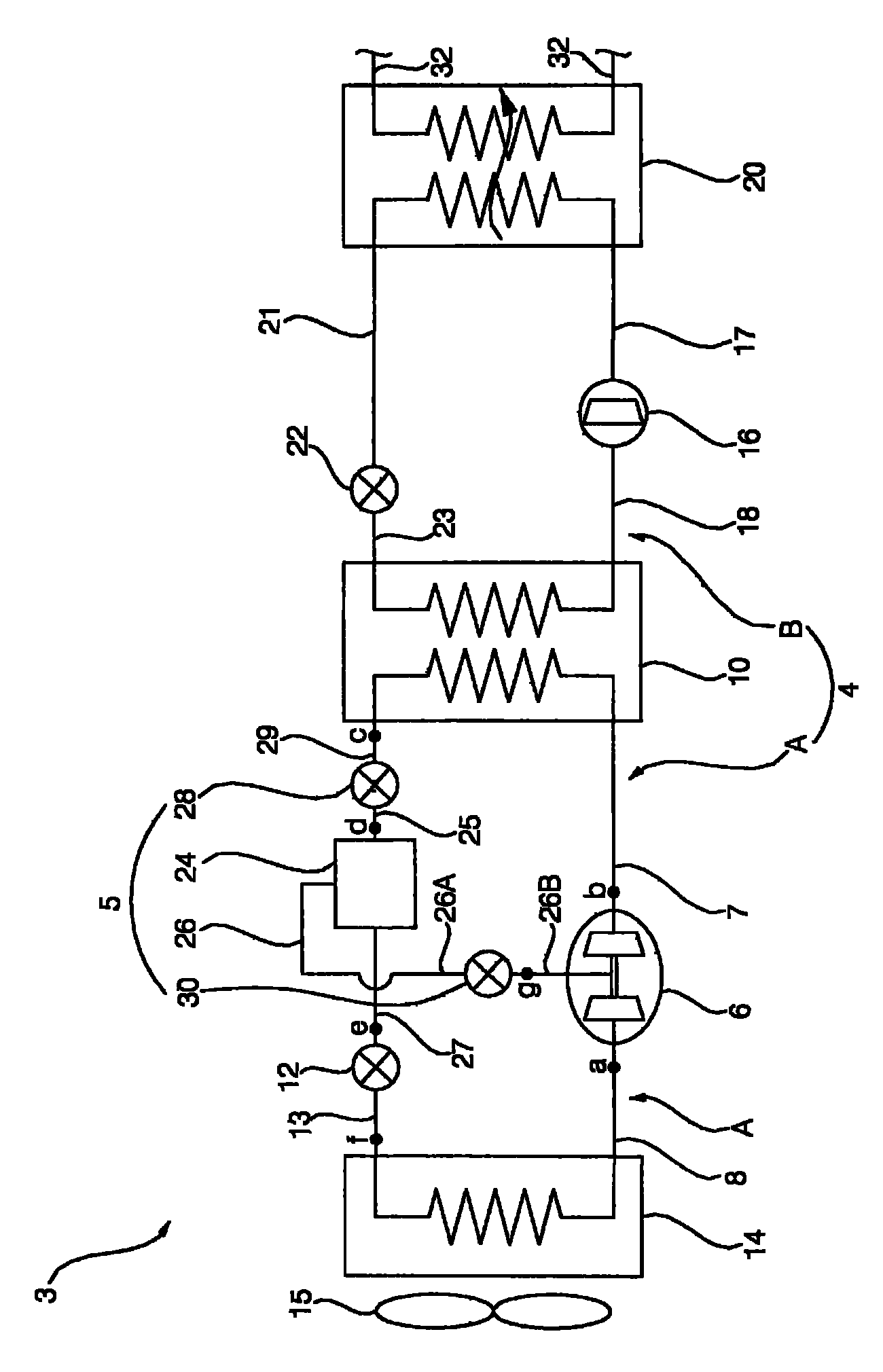

Heat pump type hot water supply apparatus

ActiveCN102072559AImprove heating performanceIncrease condensation capacityMechanical apparatusHeat pumpsRefrigerantEvaporator

The invention provides a heat pump type hot water supply apparatus, comprising a cascade circulation unit, comprising: a cascade circulation heat exchanger making a first coolant of a low temperature refrigeration circulation perform heat exchange with a second coolant of a high temperature refrigeration circulation, the water coolant heat exchanger heating water during condensation of the secondcoolant of the high temperature refrigeration circulation is connected with a position requiring heat supply and a water circulating path. The heat pump type hot water supply apparatus comprises a coolant injection path and a gaseous coolant adjustment valve. The coolant injection path may be split between a cascade heat exchanger and an evaporator of a low temperature refrigeration cycle to inject coolant into a low pressure side compressor, or between a water coolant heat exchanger and a cascade heat exchanger to inject coolant into a high pressure side compressor of a high temperature refrigeration cycle. The gaseous coolant adjustment valve may be provided in the coolant injection path and is adjusted to correspond to a load of a destination. Via the above structure, high temperature water can be effectively supplied to places requiring hot water supply, reduction of heating efficiency due to outdoor low temperature in cold zones can also be effectively prevented.

Owner:LG ELECTRONICS INC

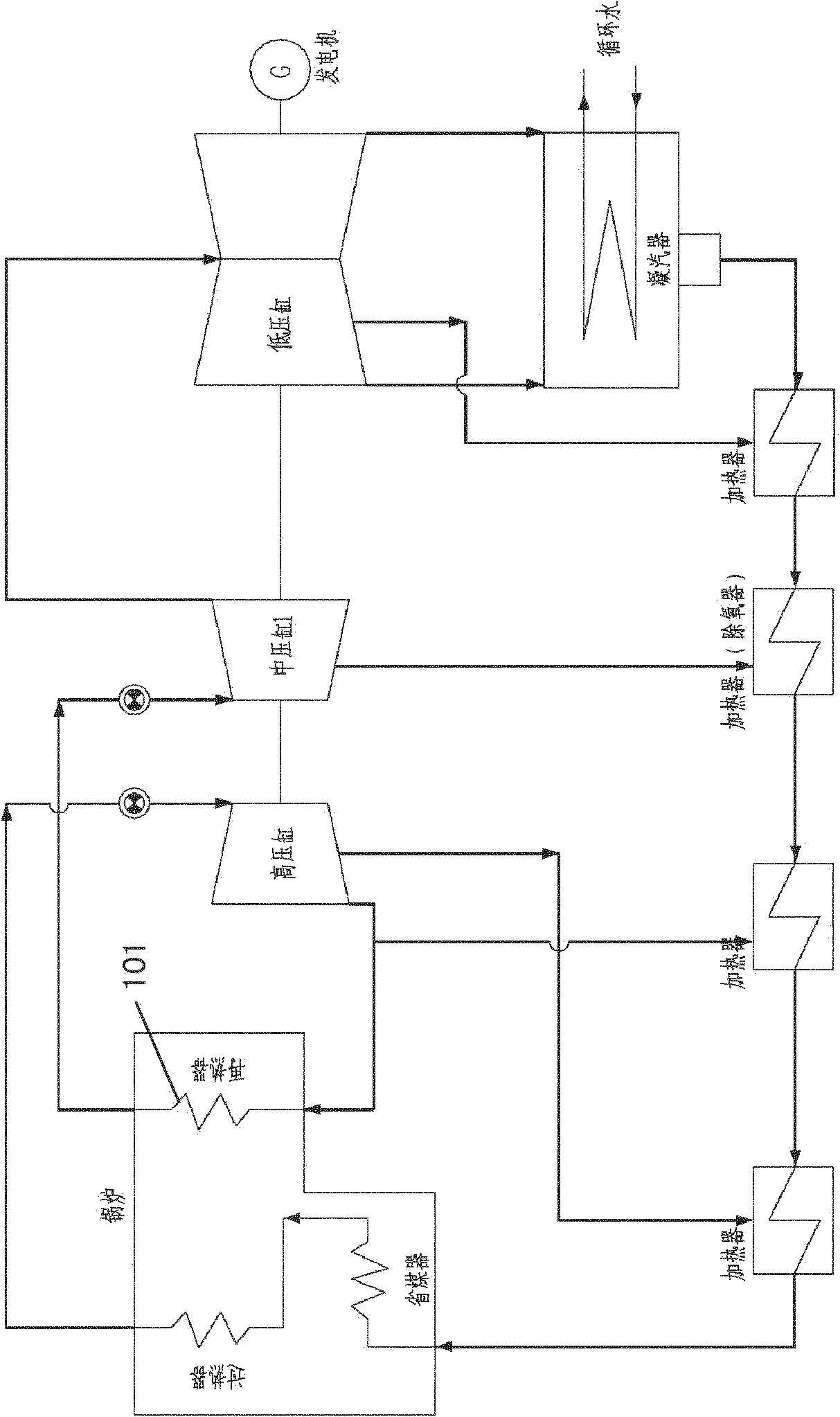

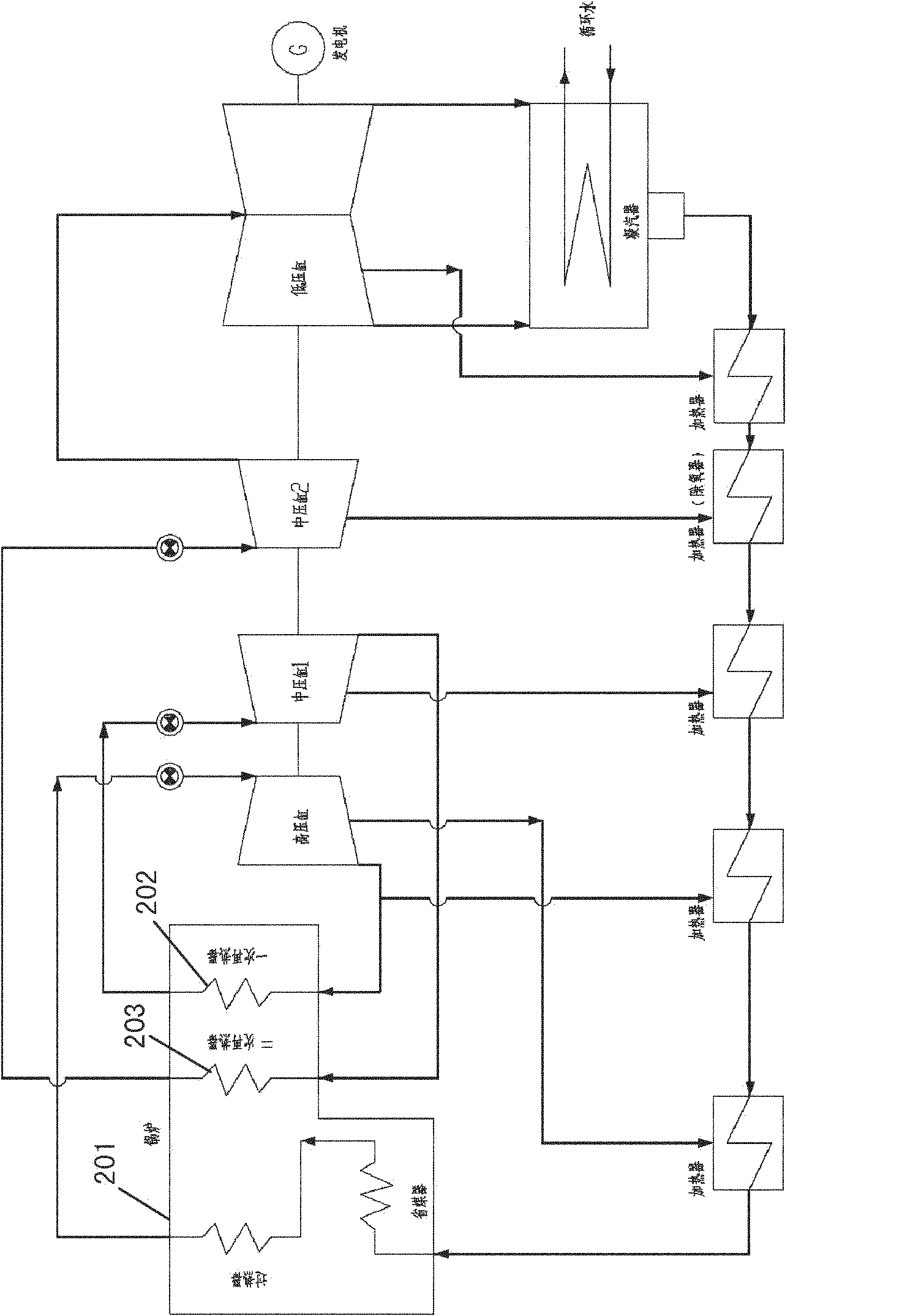

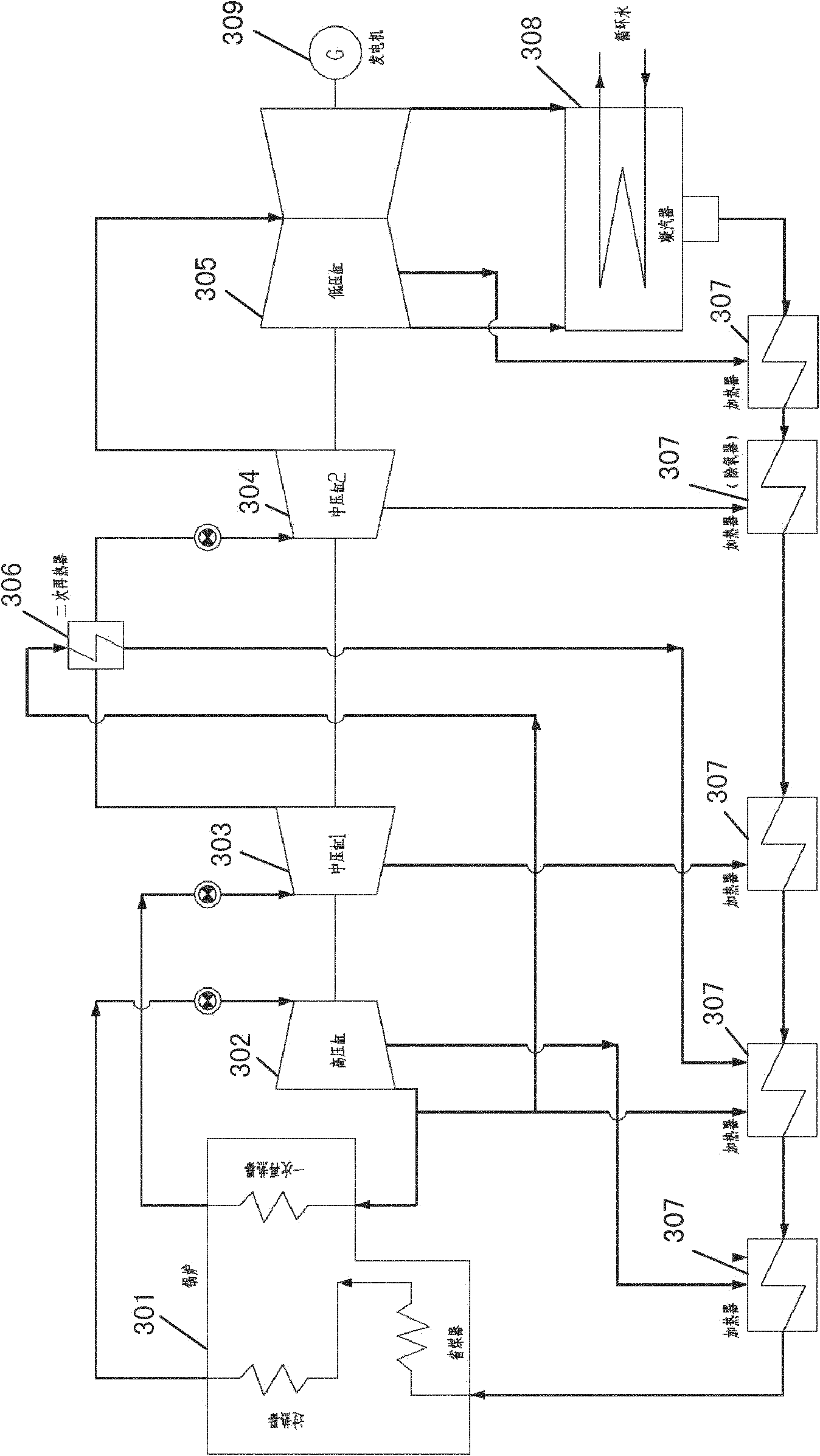

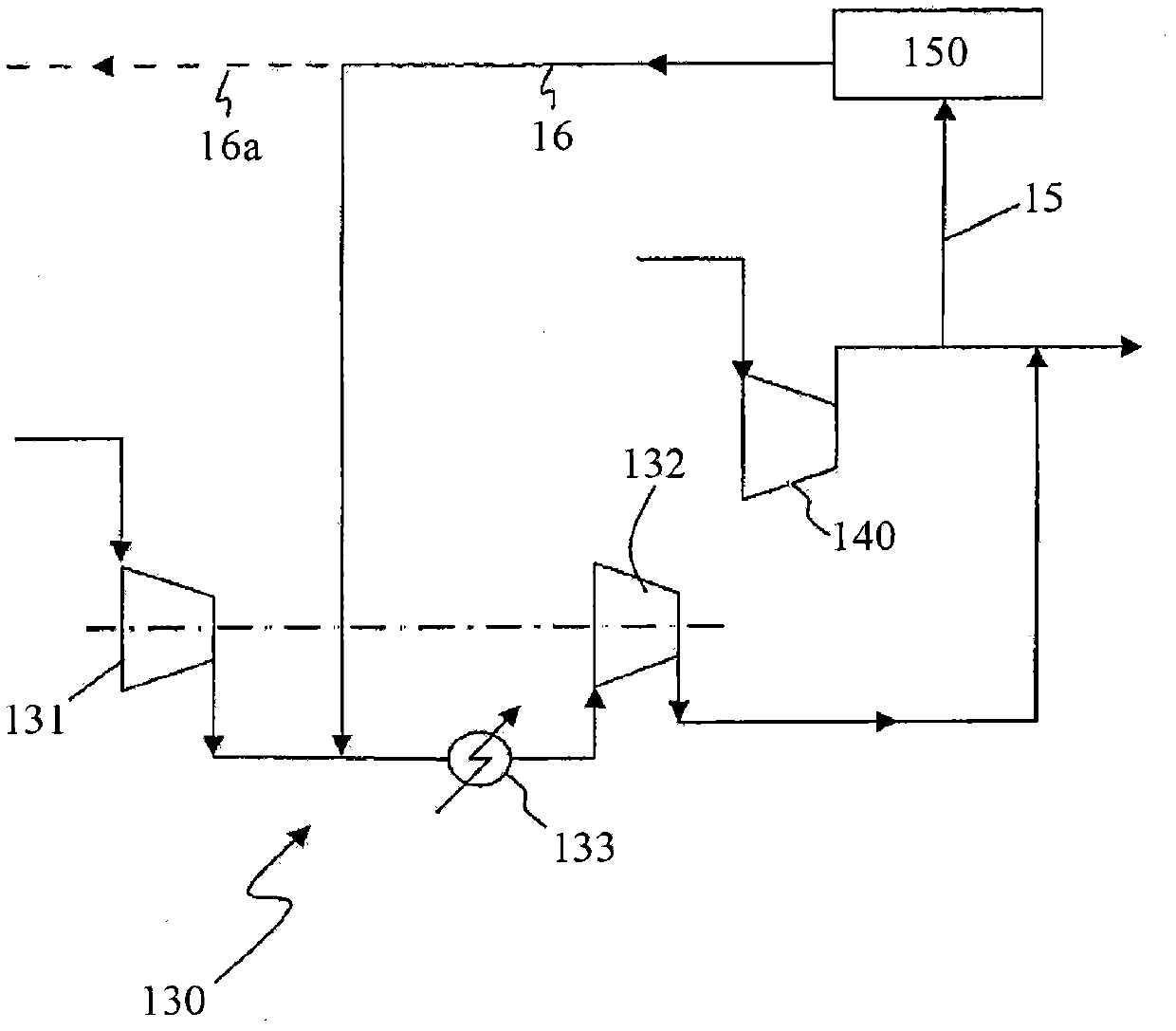

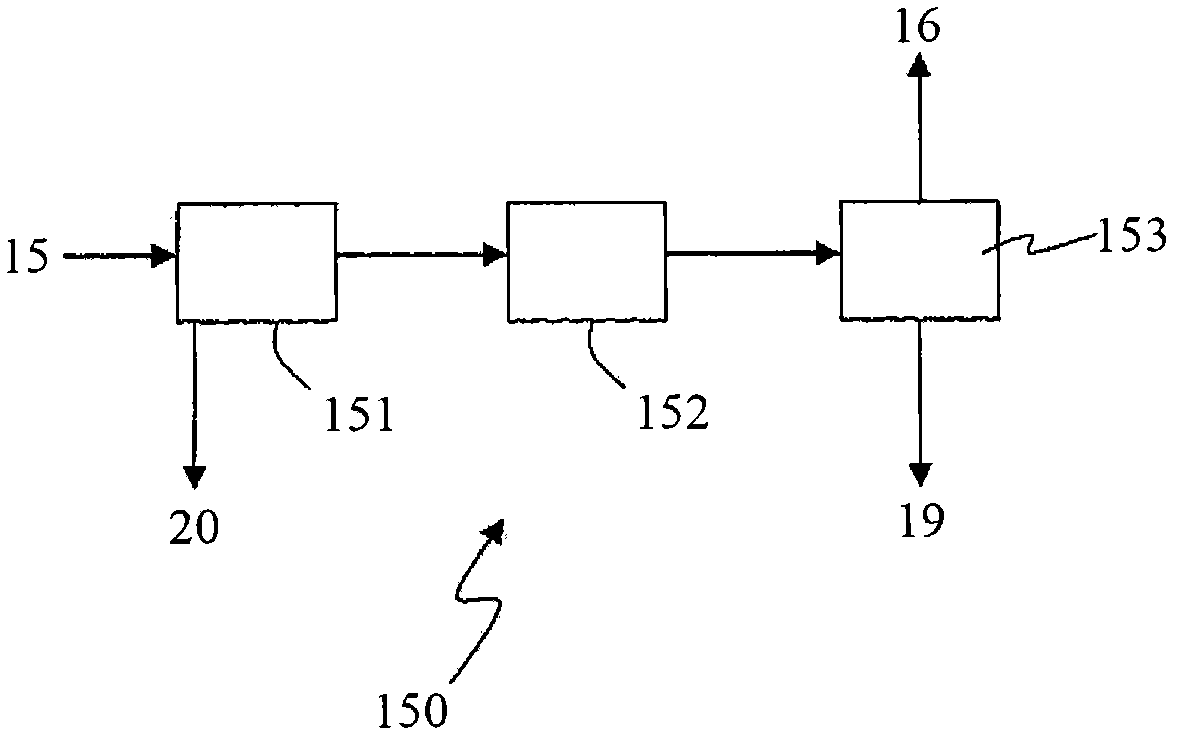

Steam secondary reheating system

InactiveCN102486308AImprove thermal cycle efficiencySmall flow resistanceMachines/enginesSteam superheatersEngineeringHeating system

The invention provides a steam secondary heating system. The system comprises a steam turbine and a secondary reheater, wherein the steam turbine comprises a high-pressure cylinder, intermediate-pressure cylinders and a low-pressure cylinder which are connected in sequence; the secondary reheater is arranged on the exterior of a boiler, and is connected with the exhaust port of one intermediate-pressure cylinder of the steam turbine and the air inlet of the other intermediate-pressure cylinder or the low-pressure cylinder of the steam turbine; the secondary reheater produces high-temperature reheated steam, and introduces the high-temperature reheated steam into the other intermediate-pressure cylinder or the low-pressure cylinder. According to the steam secondary reheating system provided by the invention, the investment on the secondary reheating system is greatly reduced while the efficiency is improved, so that the steam secondary reheating system has the advantages of excellent investment income and technique economical efficiency.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

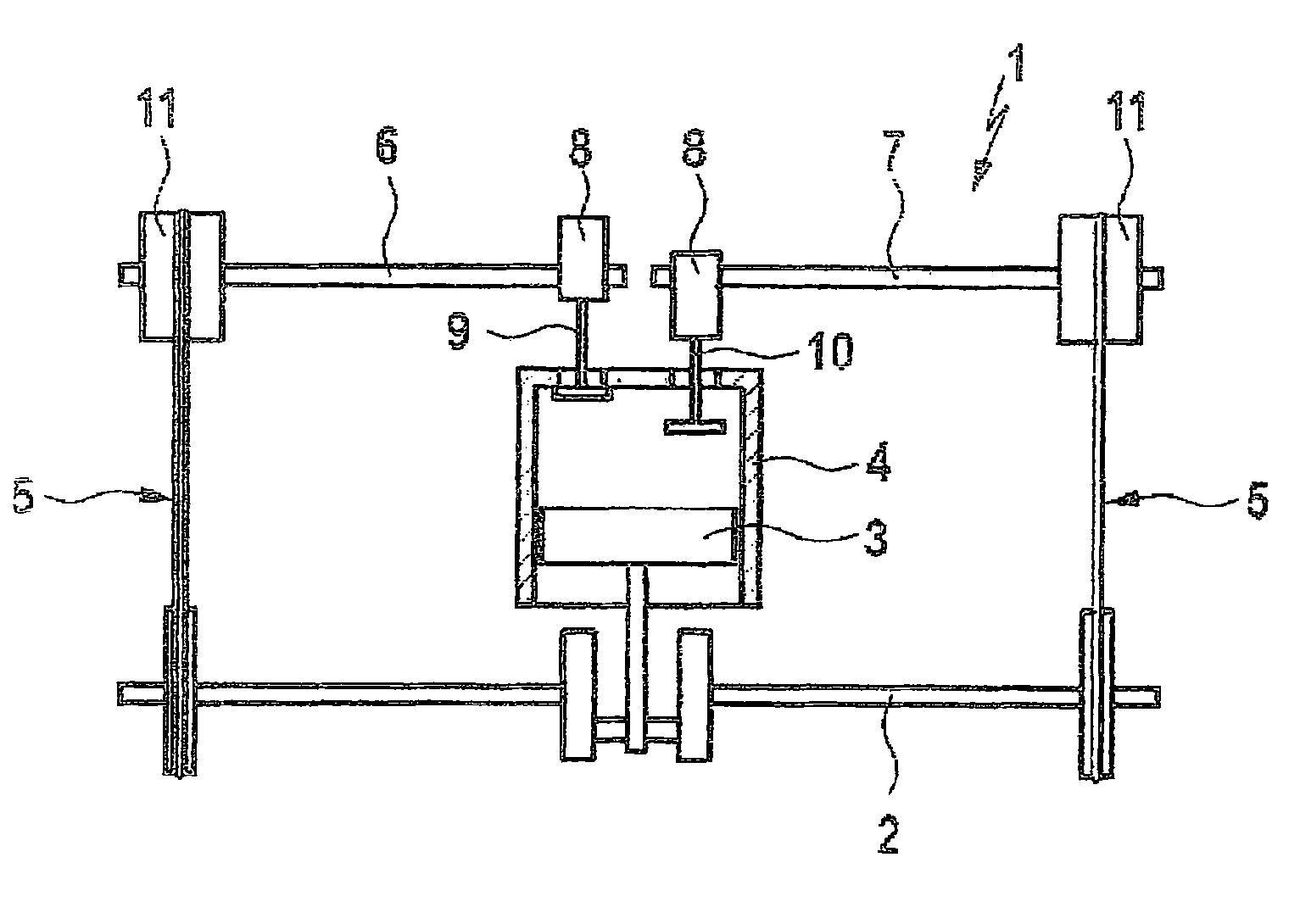

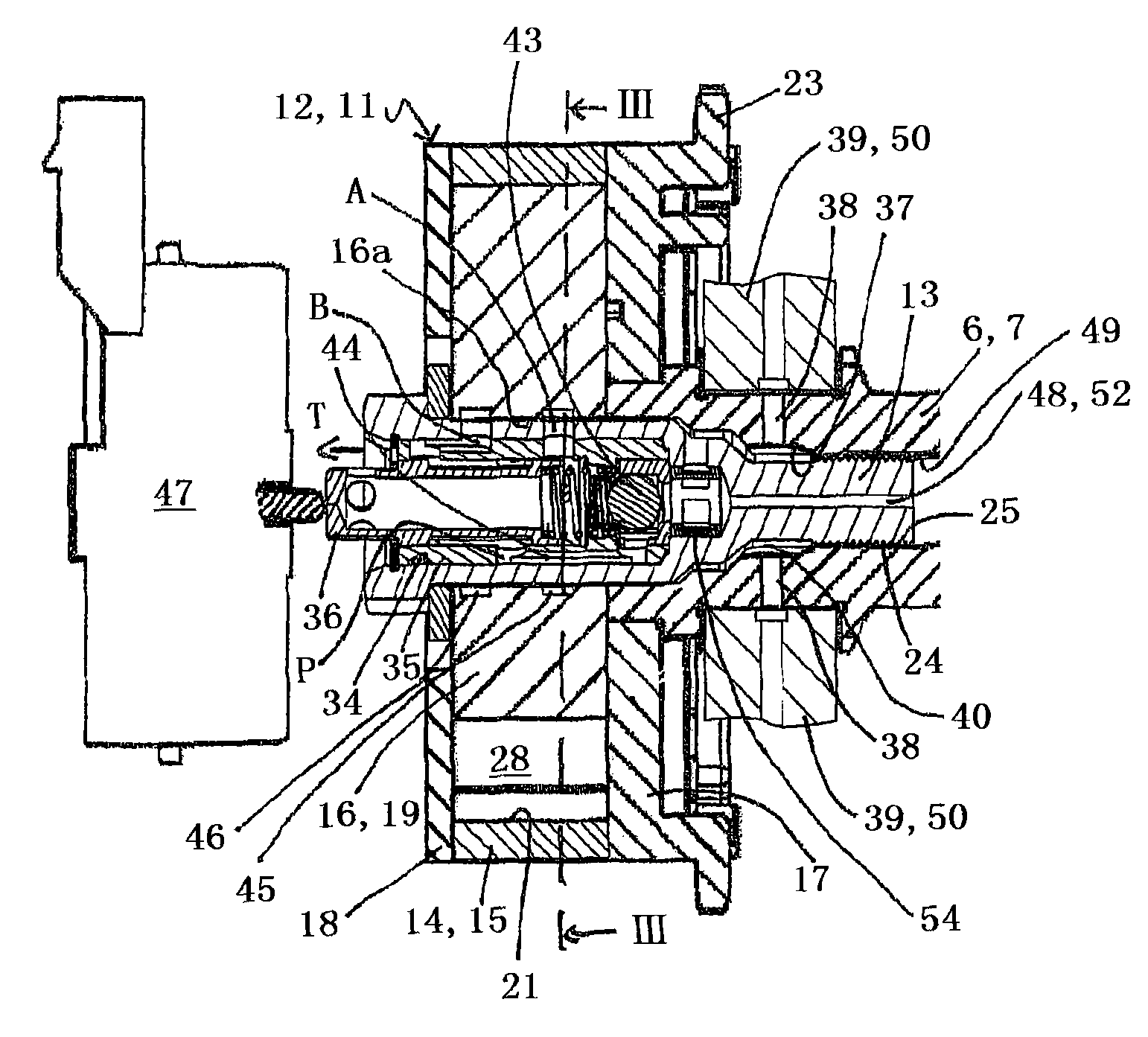

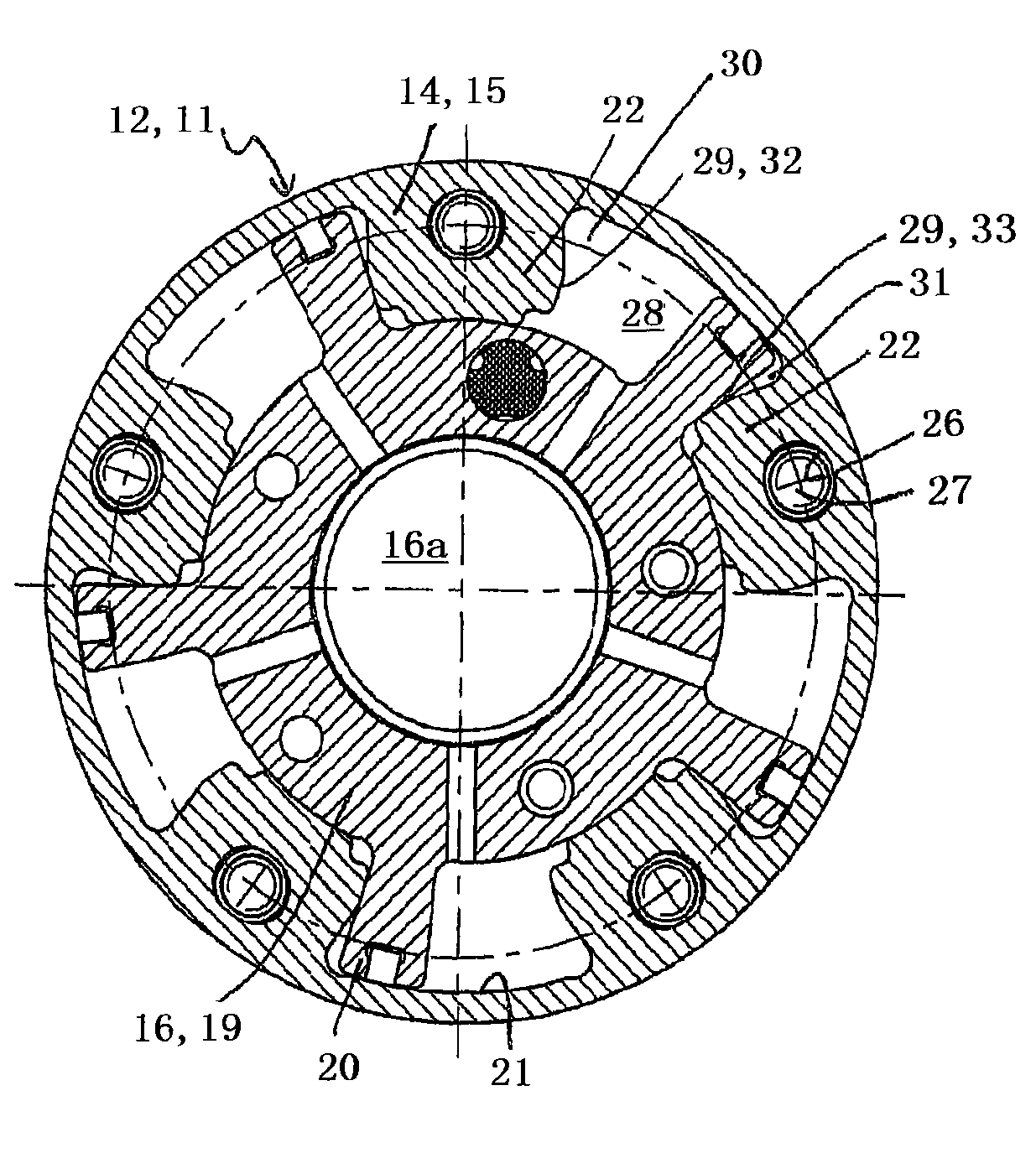

Device for variable adjustment of timing of gas exchange valves of internal combustion engine

InactiveCN102112707AReduced flow areaReduce loadValve arrangementsMachines/enginesPhase shiftedExternal combustion engine

The invention relates to a device (11) for the variable adjustment of the timing of gas exchange valves (9, 10) of an internal combustion engine (1), comprising a hydraulic phase shifting device (12), a camshaft (6, 7) and a pressurizing means distributor (13), wherein the phase shift device (12) can be caused to come into drive linkage with a crankshaft (2) and is rigidly connected to the camshaft (6, 7), wherein a phase position of the camshaft (6, 7) relative to the crankshaft (2) can be variably adjusted by way of the phase shift device (12), wherein the interior of the camshaft (6, 7) comprises a cavity (49) that communicates with one or more camshaft bearings (50) designed to be separate from a rotating pressurizing means conveyor (39), wherein the pressurizing means distributor (13) is disposed in a receiving area (37) of the camshaft (6, 7), wherein the camshaft (6, 7); comprises an opening (38) in the area of the pressurizing means distributor (13), said opening communicatingon the one hand with the interior of the camshaft (6, 7) and on the other hand with the rotating pressurizing means conveyor (39), wherein a pressurizing means path (40) is designed inside the camshaft (6, 7), said path communicating on the one hand with the opening (38) and on the other hand with the hydraulic phase shift device (12).

Owner:SCHAEFFLER TECH AG & CO KG

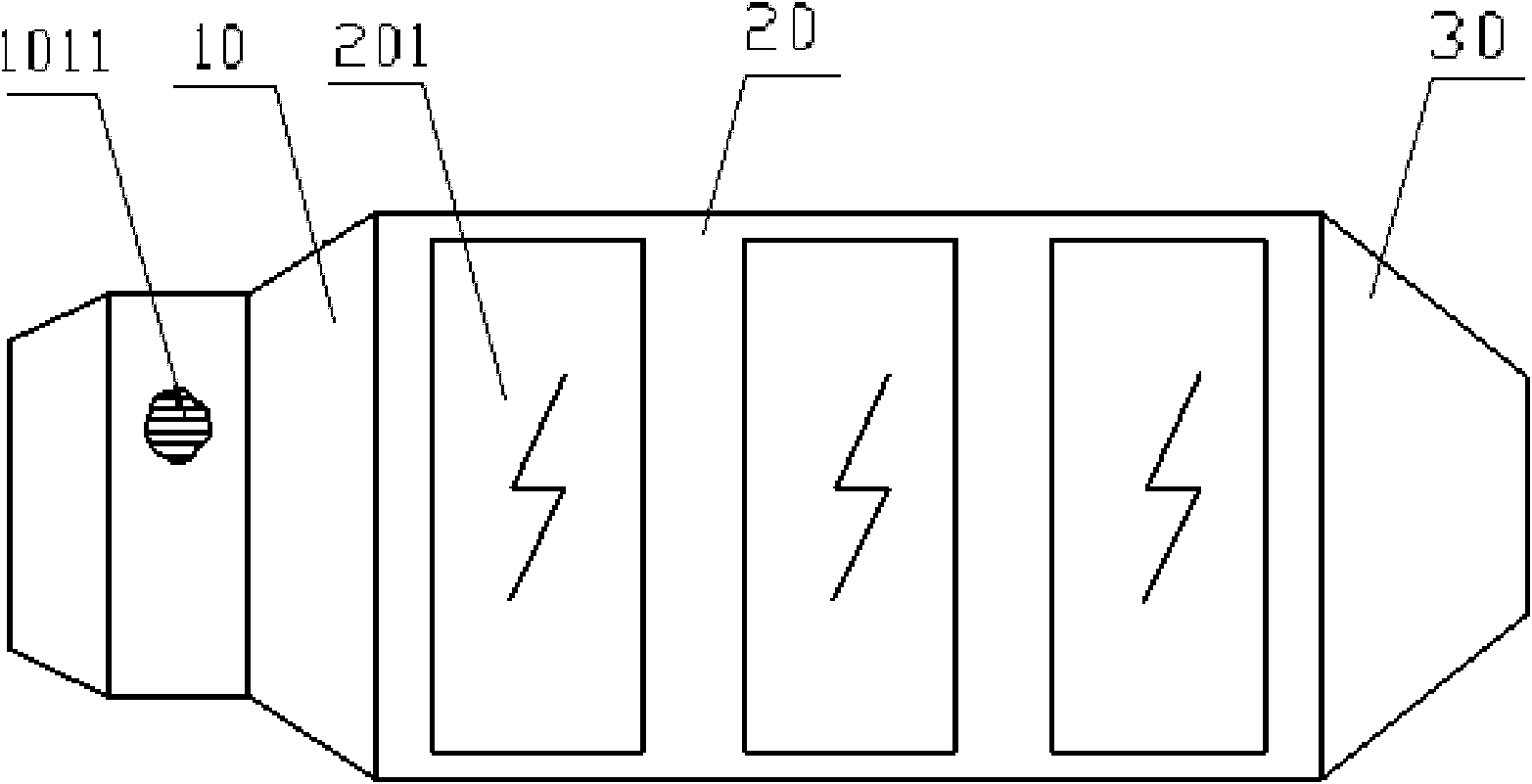

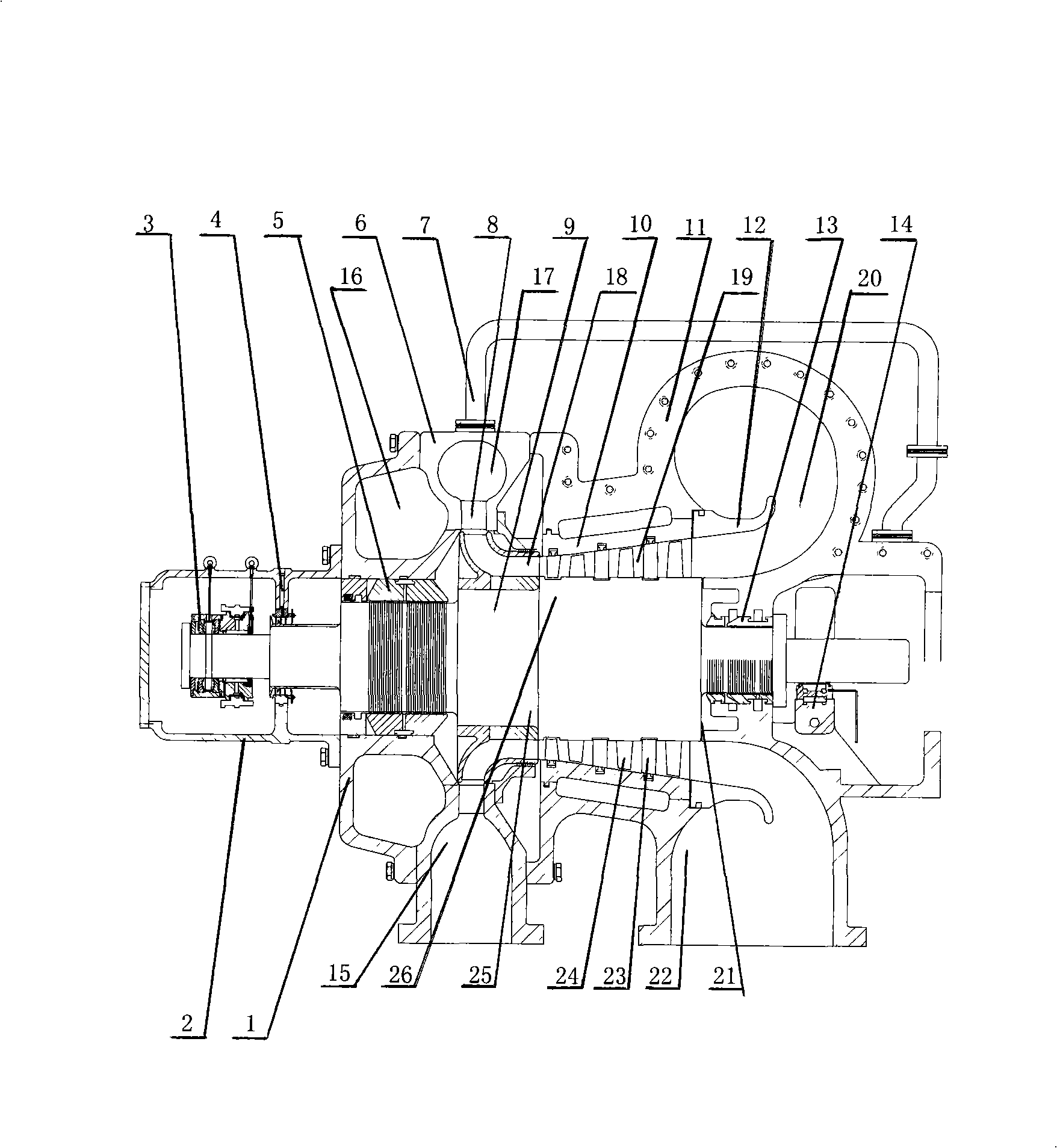

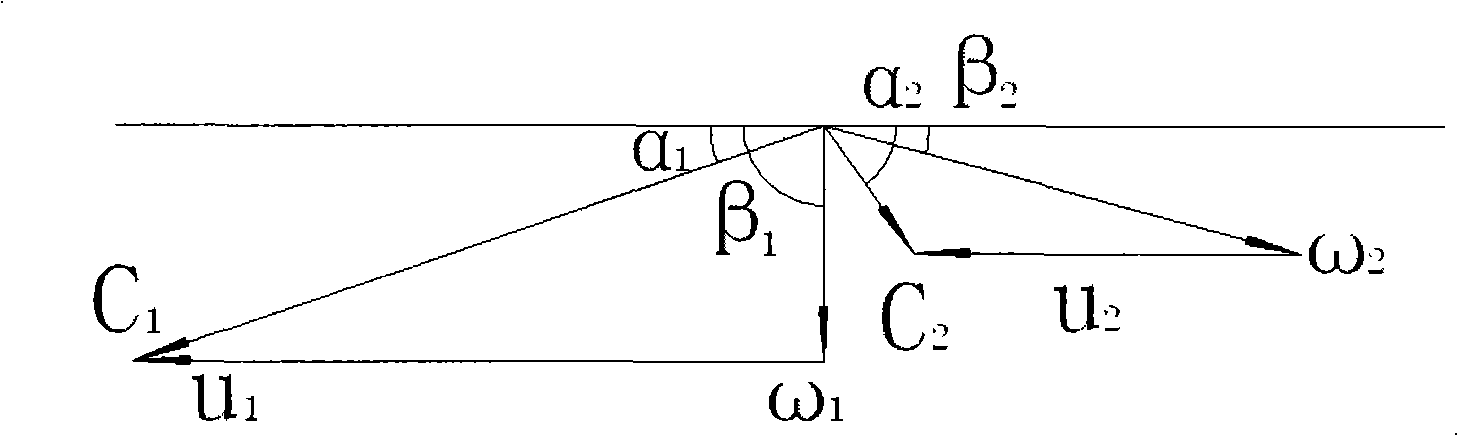

Combined turbine expansion machine

InactiveCN101265814AIncreased volume flowIncrease the expansion ratioBlade accessoriesNon-positive displacement enginesImpellerEngineering

The invention provides a composite turboexpander, which comprises a rotor. The rotor is arranged in a shell consisting of a high-pressure section casing and a low-pressure section casing; the high-pressure section casing is provided with an inlet pipe, and the inlet pipe communicates with an adjustable nozzle through a volute chamber; the high-pressure section of the rotor is provided with a radial impeller that communicates with the adjustable nozzle; the low-pressure section casing is provided with a blade carrier cylinder; the outlet of the blade carrier cylinder is provided with a flow deflecting ring, and the blade carrier cylinder is provided with a static blade; the low-pressure section casing is also provided with a volute chamber for exhausting and a vent-pipe; the low-pressure section of the rotor is provided with a moving blade; an axial flow stage comprises a first-stage static blade and a first-stage moving blade and communicates with the radial impeller and the flow deflecting ring; the pressure of the working medium decreases after going through the first-stage endocentric grade, the circumferential direction is changed into axial direction after the volume flow rate increases, and the axial flow stage is finally reached. The composite turboexpander has the advantages of simple structure, small volume flow rate for first-stage entry, high expansion rate, high expanding efficiency, convenient installation and maintenance, steady operation, etc.

Owner:冀江 +1

Method and device for reducing the humidity of a gas in a housing interior

ActiveCN102656738AAvoid introducingReduce humidityGas treatmentDispersed particle separationInterior spaceElectrical battery

Owner:ROBERT BOSCH GMBH +1

Ammonia production process

InactiveCN102596808AHigh hydrogen contentImprove conversion efficiencyEnergy inputBulk chemical productionSyngasMolecular sieve

Owner:AMMONIA CASALE SA

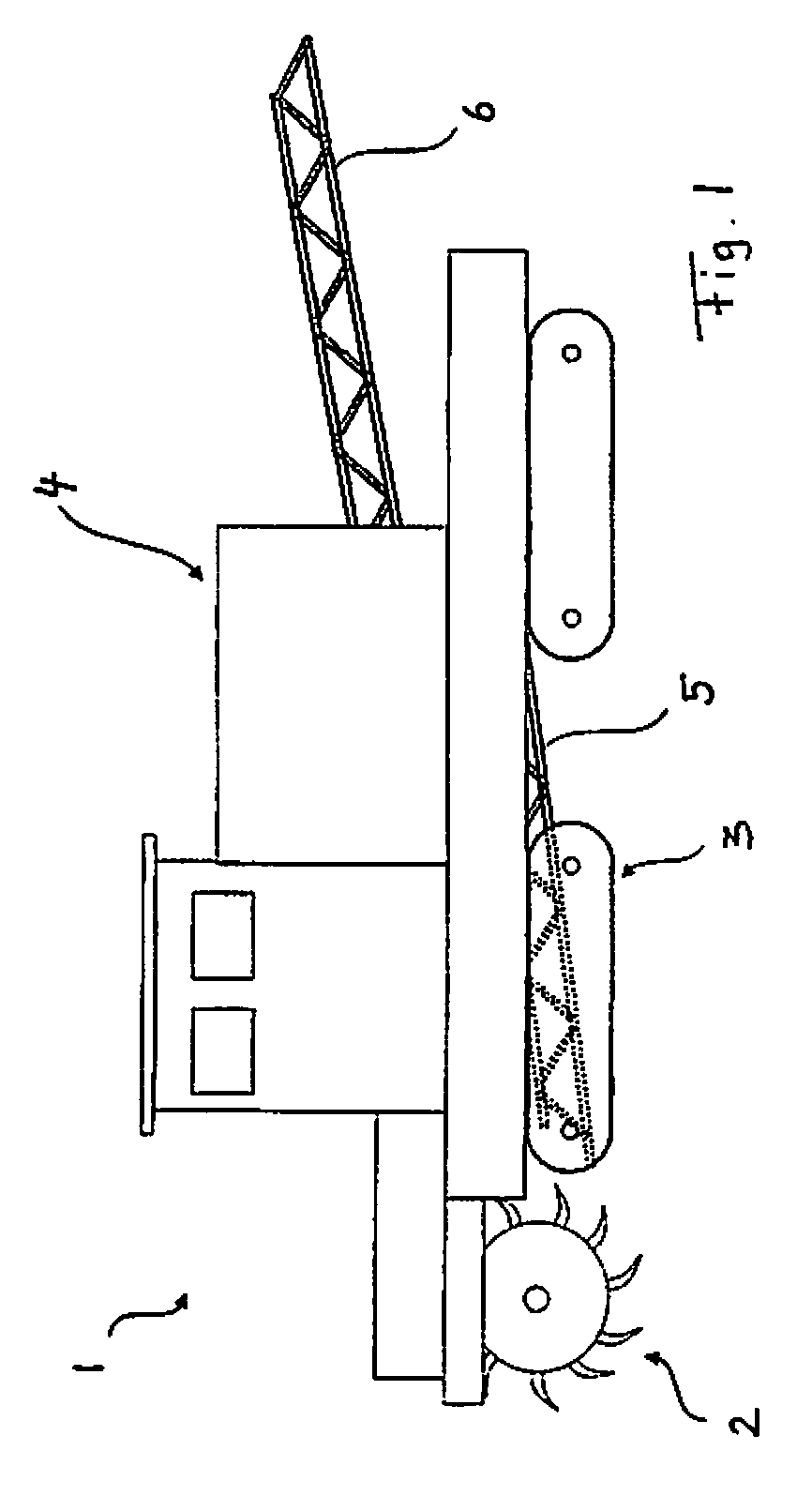

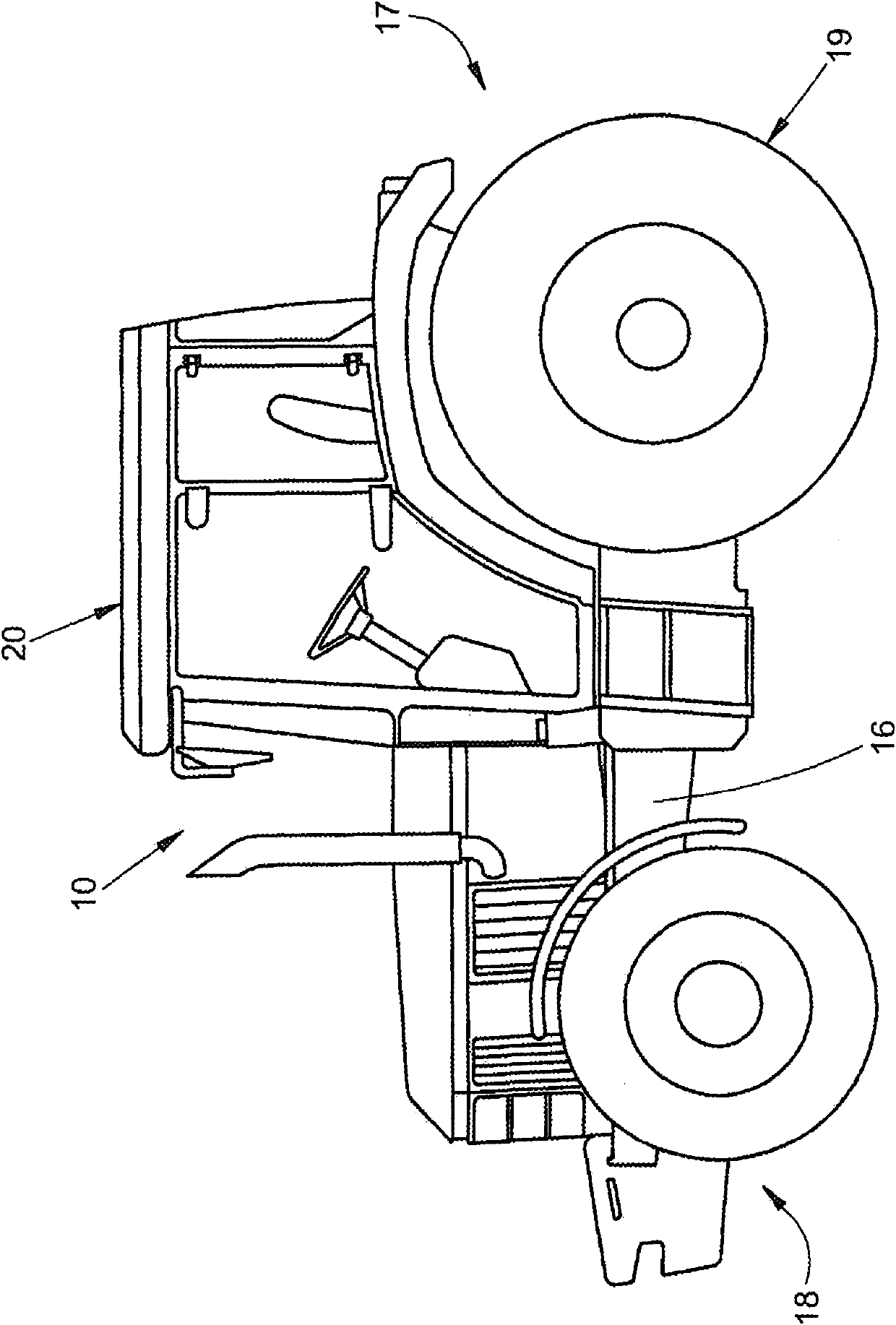

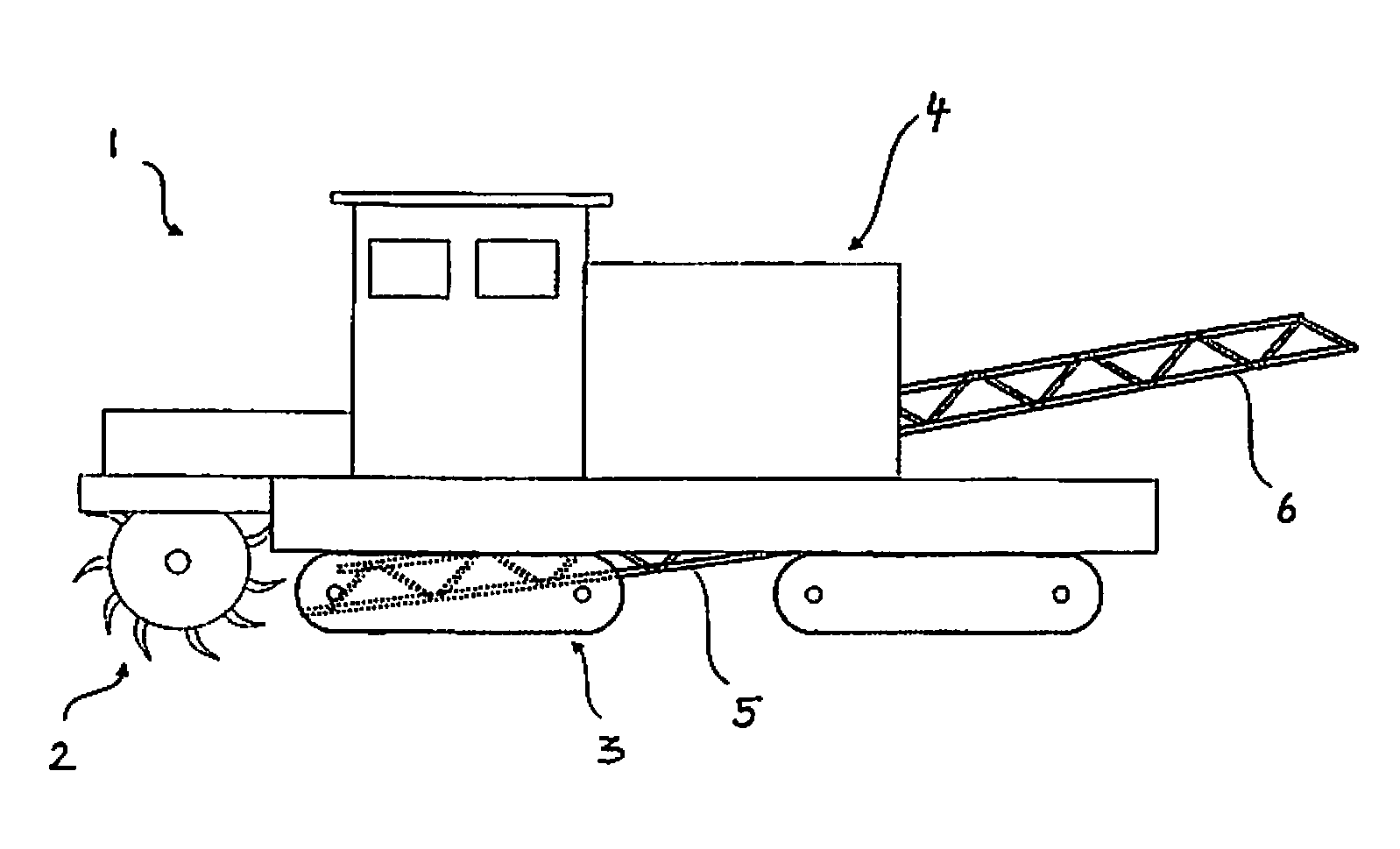

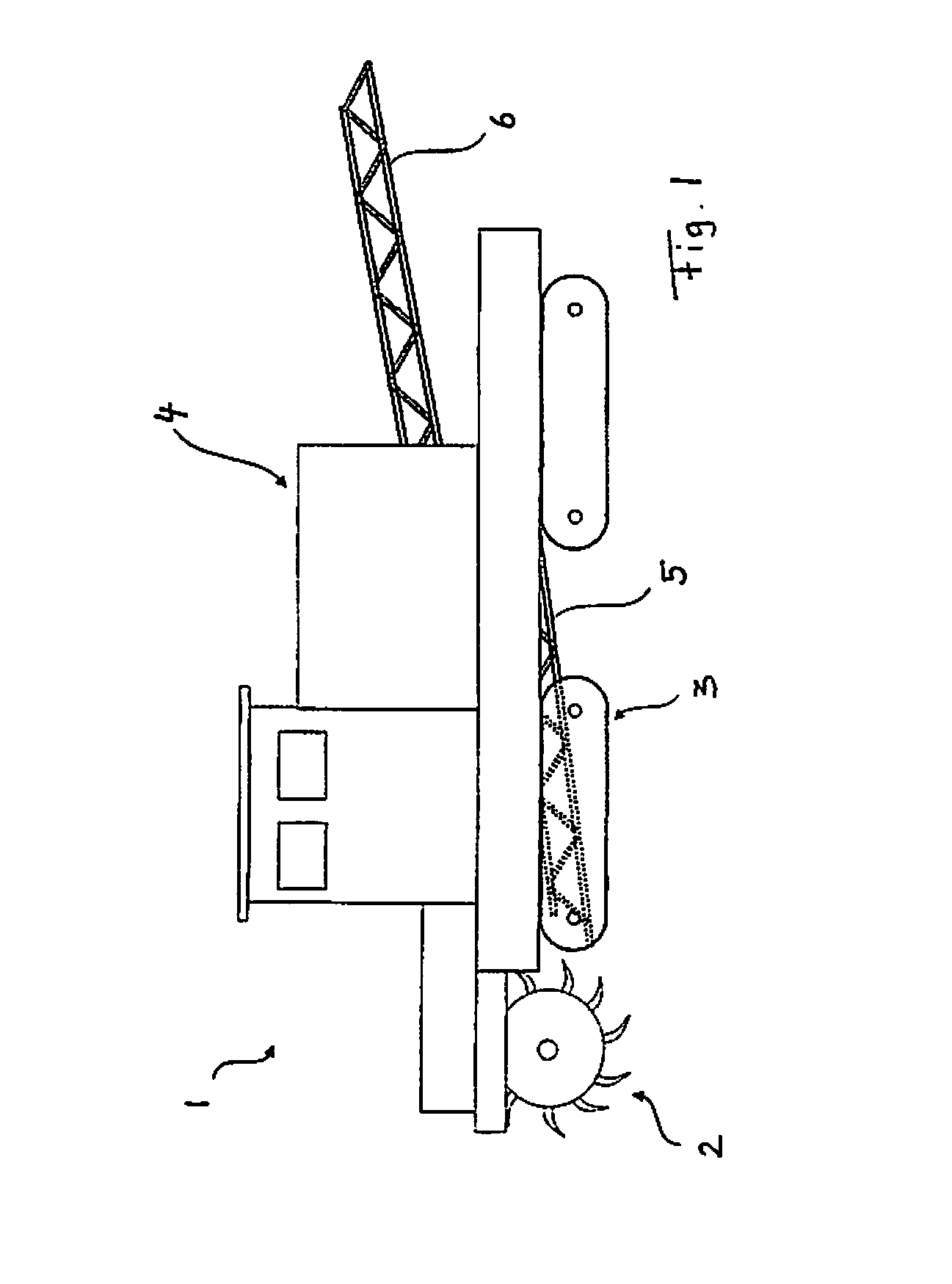

Self-propelled surface milling machine with electrical mill roll drive

InactiveUS9080293B2Reduce thermal stressIncrease loadRoads maintainenceSnow cleaningRotational axisLiquid cooling system

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

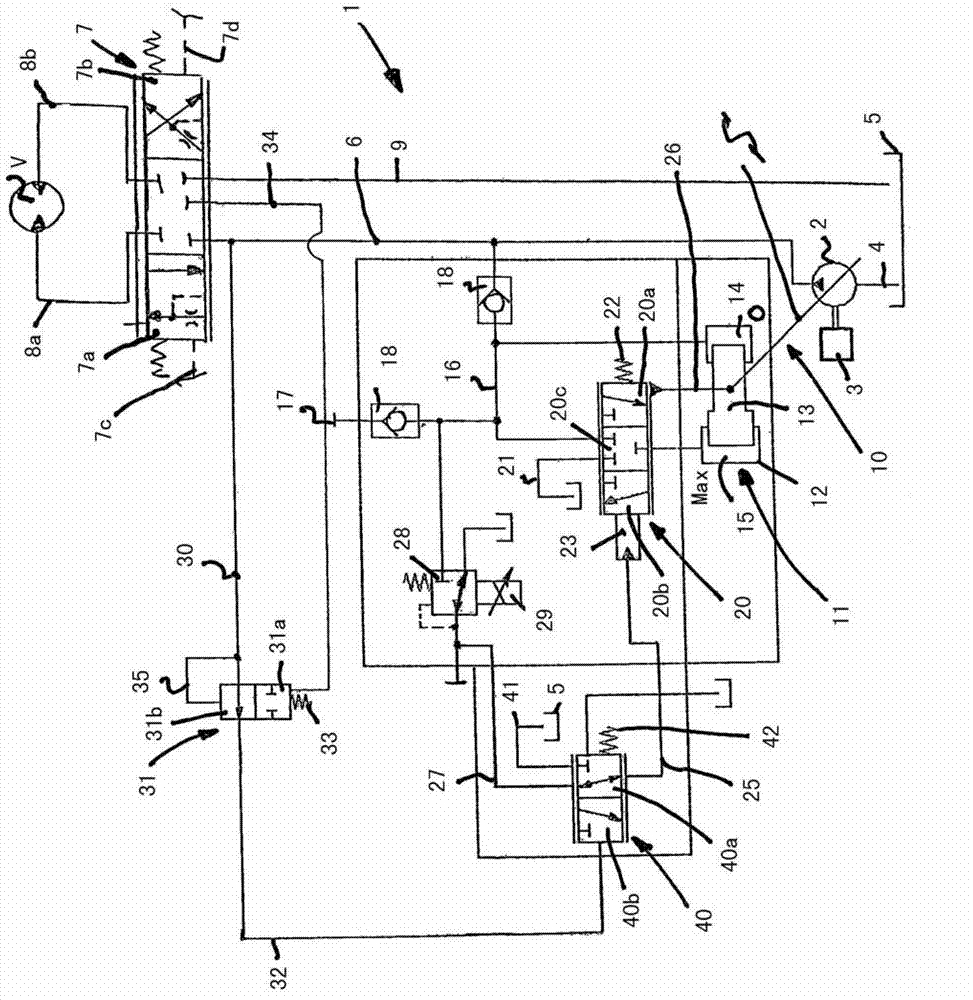

Hydrostatic drive system

InactiveCN102878126AReduce loadLimit heightServomotor componentsServomotorsEngineeringPressure balance

The invention relates to a hydrostatic drive system, having a conveying volume flow adjustable pump, wherein the pump is set to supply for at least one consumption unit; a conveying volume flow adjusting device for the pump controls toward the direction of increasing the conveying volume flow by means of the preset signal and controls towards the direction of reducing the conveying volume flow according to the hydraulic reset signal of the volume flow which is conveyed excessively; a circulating pressure balance is set to generate a reset signal at the reset signal generating position; a pressure adjusting valve is set to control the conveying volume flow adjusting device of the pump, and can be loaded by a preset signal. The pressure adjusting valve is made as a pre-control pressure adjusting valve, and is provided with a first control position towards the direction of reducing the conveying volume flow and a second control position towards the direction of increasing the conveying volume flow; and a pre-control valve is set and is controlled by a hydraulic pressure reset signal, and can excessively control the load of the preset signal through the pressure adjusting valve according to the hydraulic reset signal.

Owner:LINDE HYDRAULICS

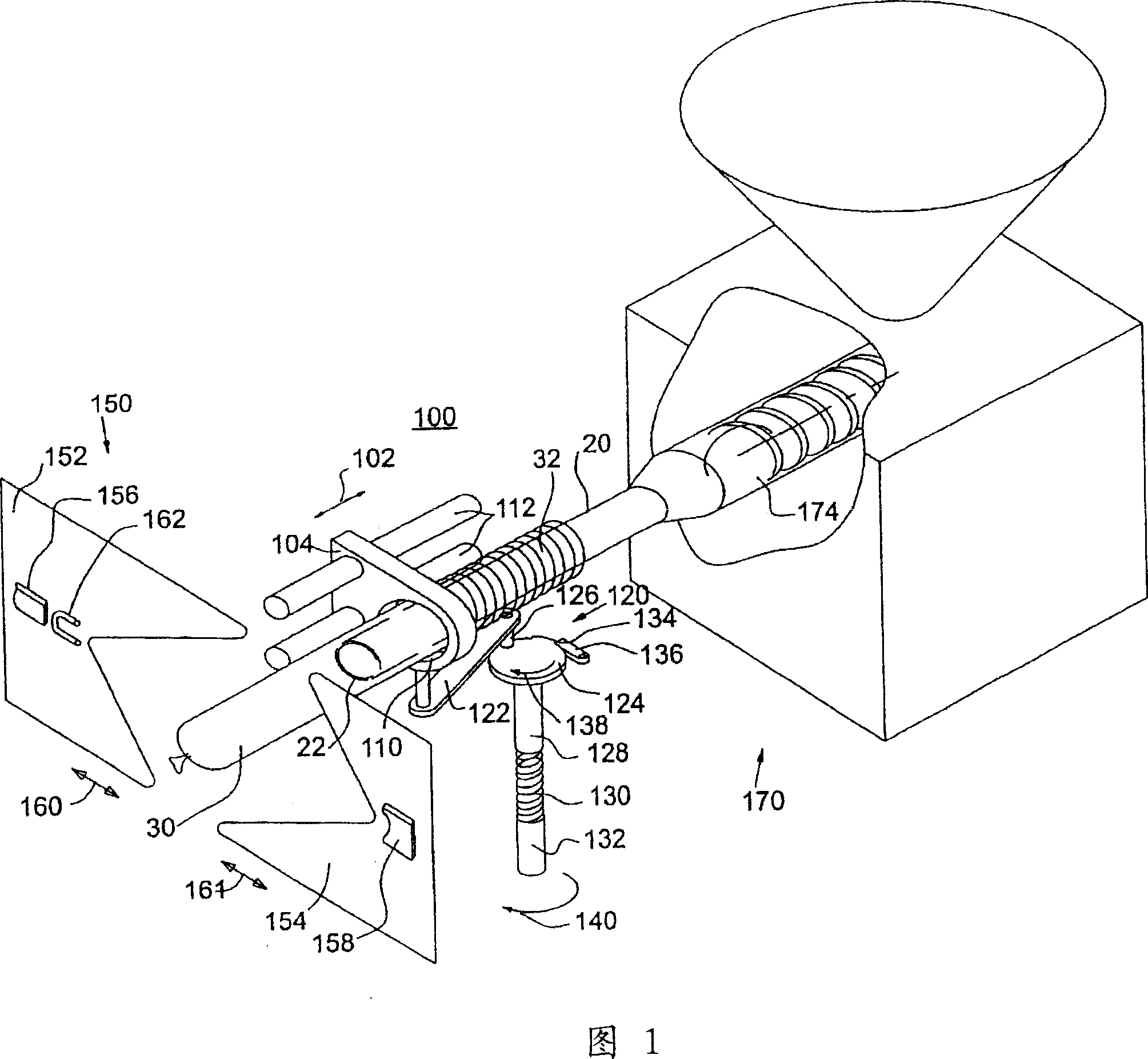

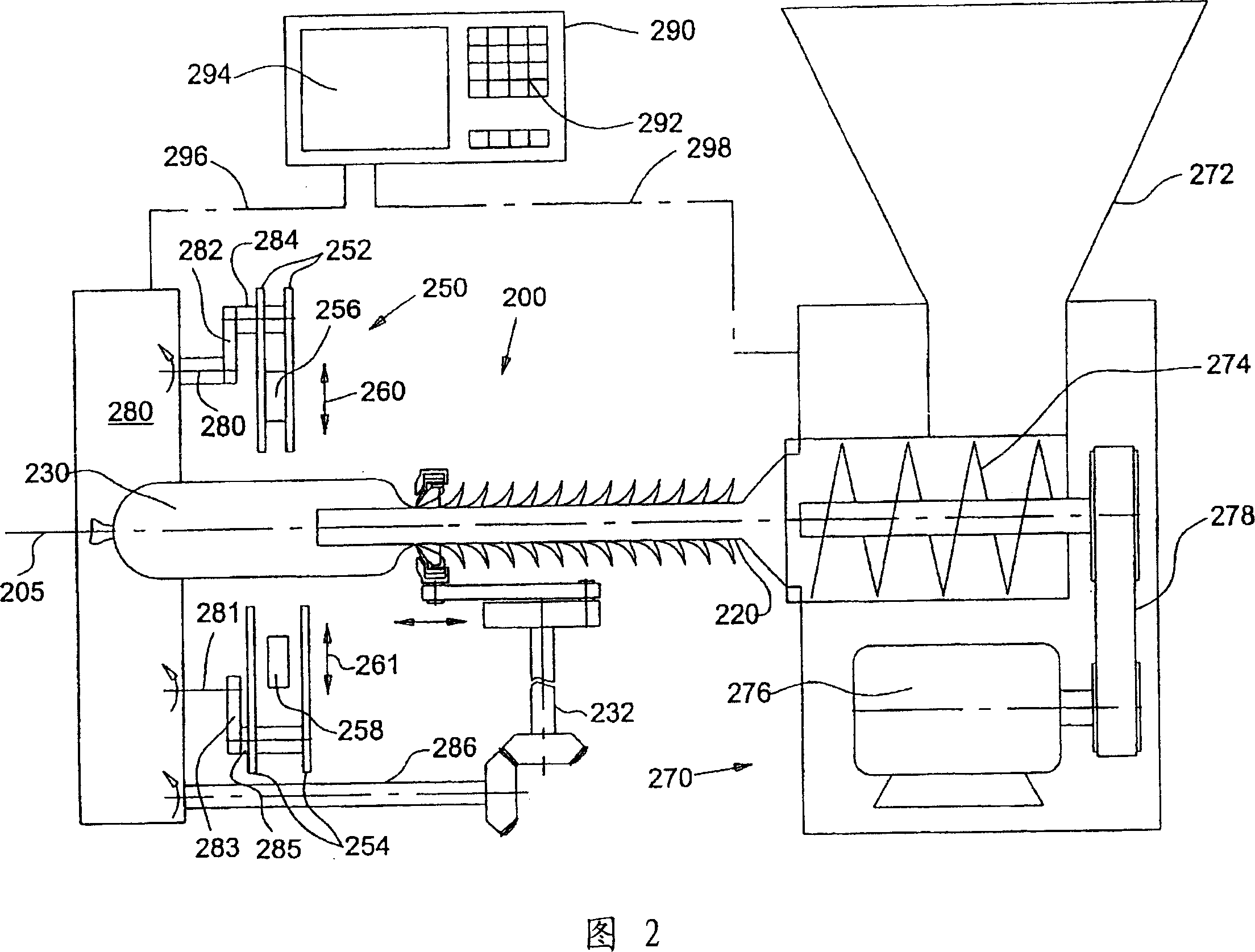

Device and method for portioning and packaging

InactiveCN1934961ASimplified actuationAllows for increased efficiencySausage skin tying apparatusSausage filling/stuffing machinesPortion sizeFilling materials

Portioning and packaging device comprises a conveying device (170, 270) for filling material that has a pump for generating a continuous volume and is connected to a filling pipe (20, 220) supplying a reservoir of a tube-shaped packing sleeve (30, 230) so that this can be removed with filling material from the filling tube, and a sealing device (150, 250) that ties the end of the filled tube and seals it with a sealing element(162). The sealing device has a control device (290) that generates a control signal during the tying and sealing step based on a selected portion size and the continuous volume flow and sends it to a drive of the sealing device. An independent claim is also included for a portioning and packaging process.

Owner:POLY CLIP SYST

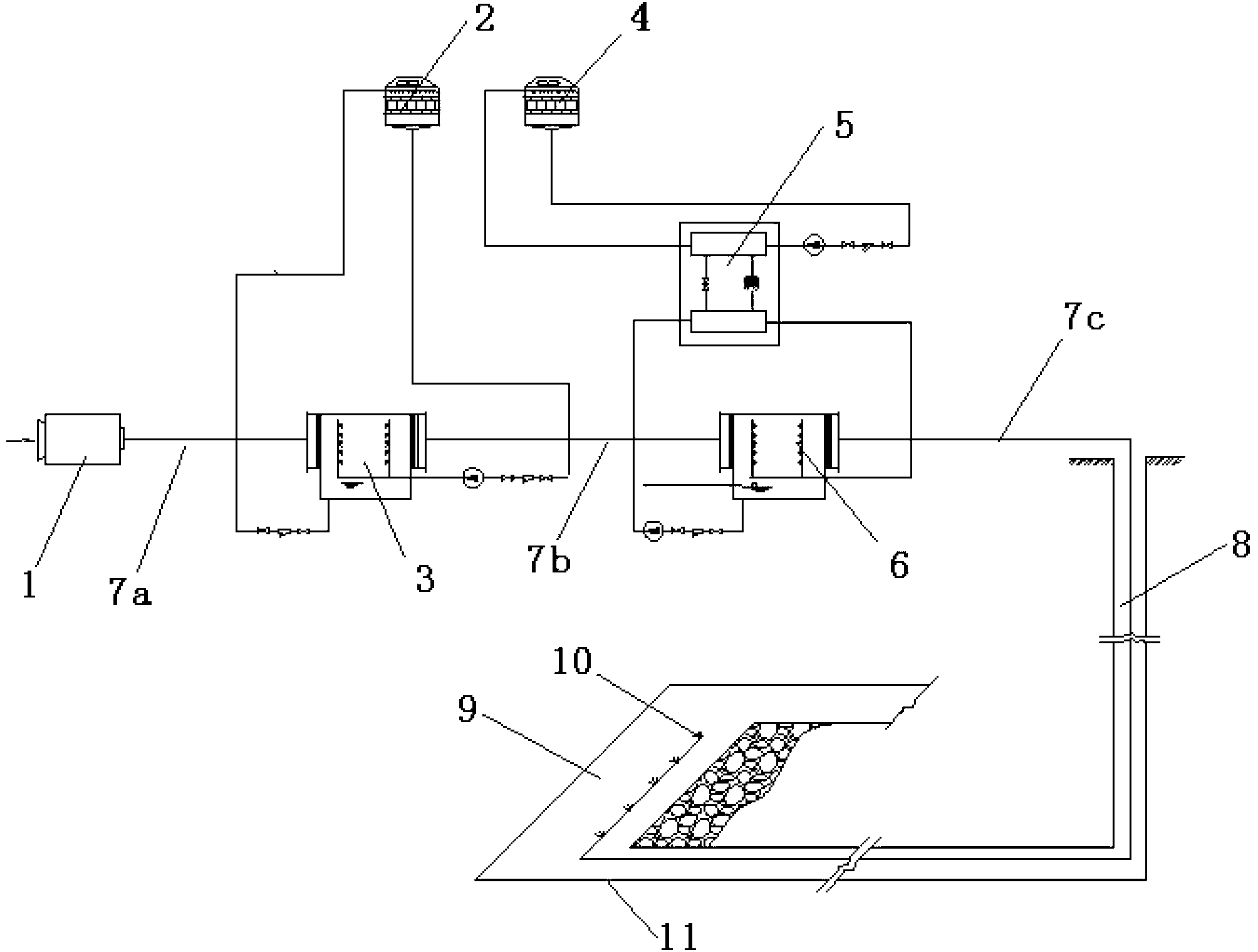

Compressed air cold conveying cooling system for mine and cooling method thereof

InactiveCN103216255AReduce cooling loadLow running costTunnel/mines ventillationCooling towerEngineering

The invention discloses a compressed air cold conveying cooling system for a mine and a compressed air cold conveying cooling method. The compressed air cold conveying cooling system is formed by sequentially connecting an air compressor, a natural cold source subsystem, a manual cold source subsystem, a compressed air injection and air supply device through a compressed air conveying pipeline, wherein the air compressor, the natural cold source subsystem and the manual cold source subsystem are arranged on the ground, and the compressed air injection and air supply device is arranged on an underground mine working surface. The natural cold source subsystem is a water cycle cooling passage connected by a first level cooling tower and a first level cooling sprinkling chamber through a pipeline for pre-cooling compressed air. The manual cold source subsystem is water cycle cooling passage sequentially connected by a second level cooling tower, a second level sprinkling chamber and a refrigerating unit through the pipeline through the pipeline for manually cooling the compressed air. Due to the fact that natural cold source is utilized to conduct pre-cooling on the compressed air, refrigeration load of manual refrigeration equipment is greatly reduced, in winter or a transition season, the manual cooling system does not even need to be operated, and then operating cost of the compressed air cold conveying cooling system is greatly reduced.

Owner:HENAN POLYTECHNIC UNIV

Part control phase change air preheating system and air preheating method

InactiveCN103115377AImprove securityImprove adaptabilityCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a part control phase change air preheating system and an air preheating method. The part control phase change air preheating system and the air preheating method well solve the coupling problem of traditional air preheater low temperature corrosion and heat efficiency, an operating method of the air preheating system can be timely adjusted according to actual operation parameters, adjusting capability is greatly increased, and not only is economy and high efficiency of a thermal circulation system guaranteed, but also security and adaptability of the air preheating system can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

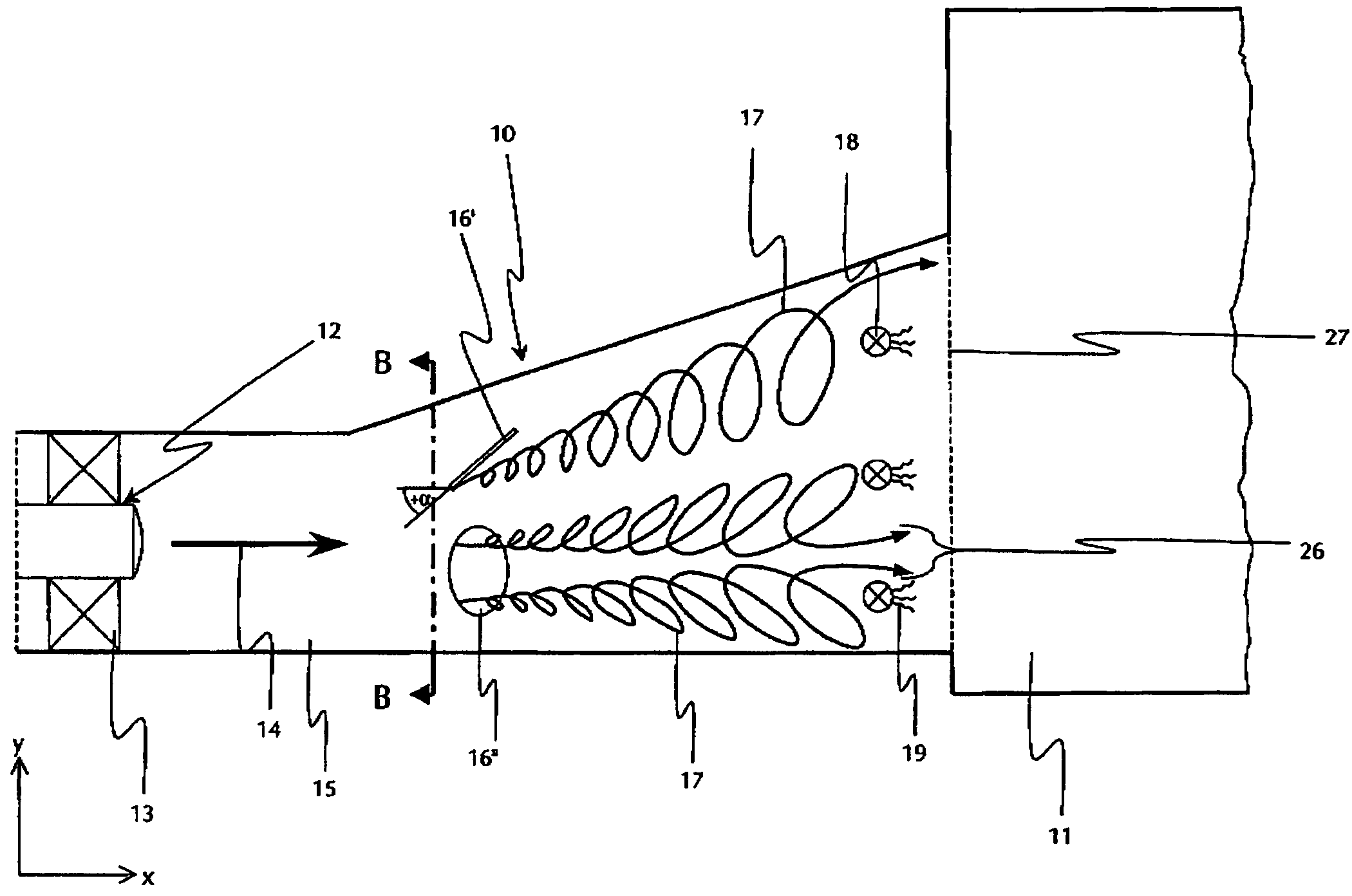

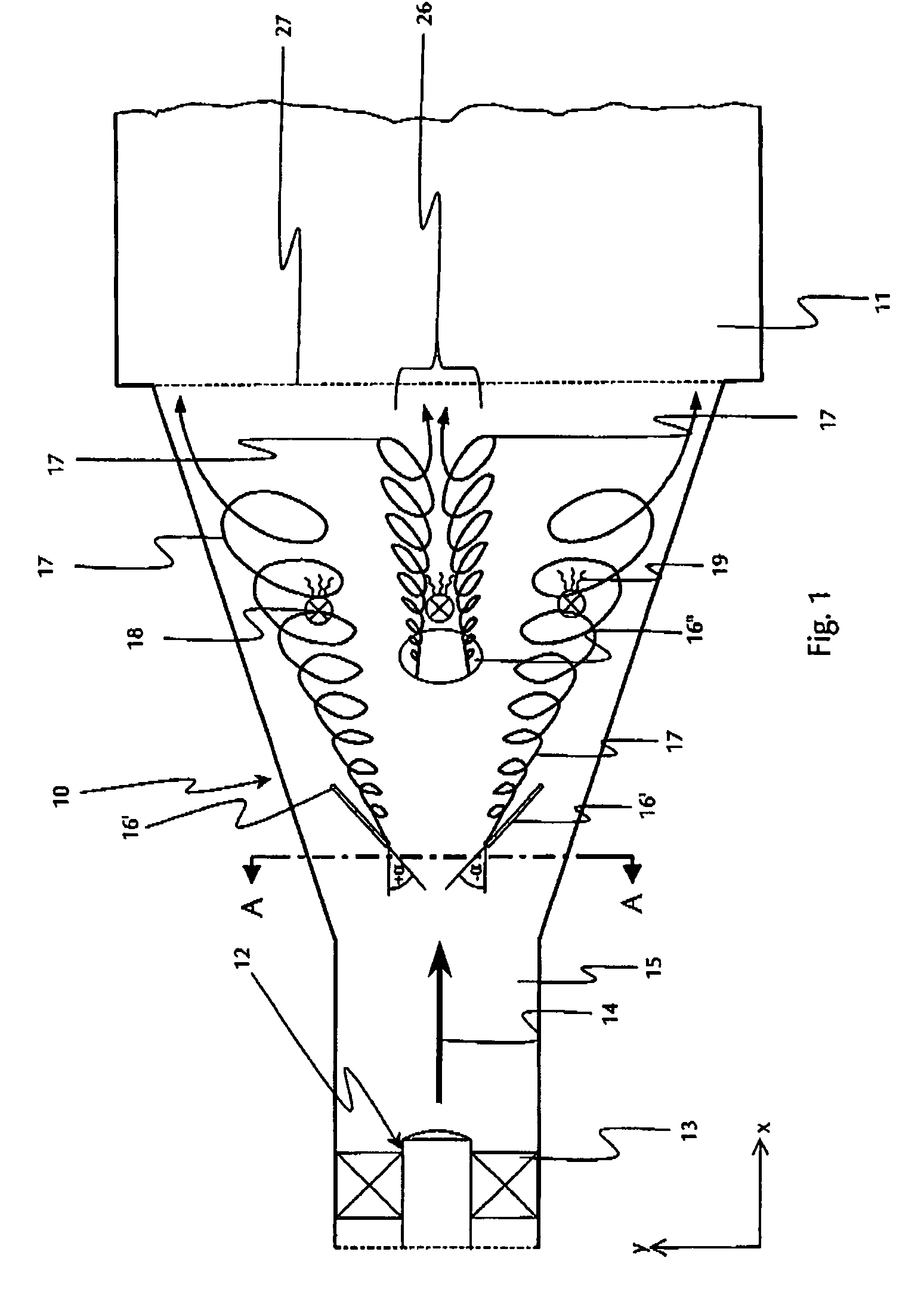

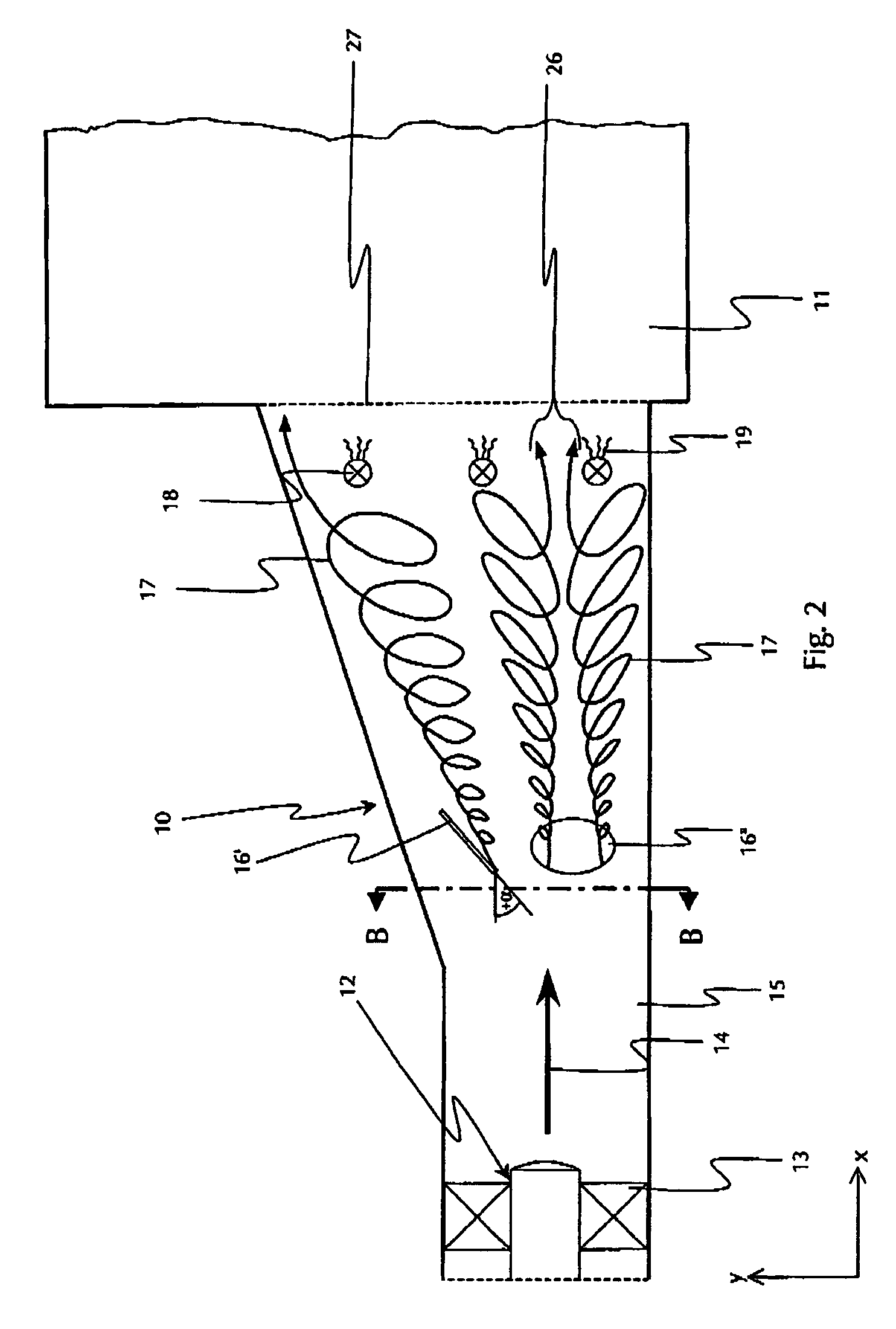

Exhaust gas guide of a gas turbine and method for mixing the exhaust gas of the gas turbine

ActiveUS7784262B2Efficient powerImprove efficiencyBurnersContinuous combustion chamberLeading edgeCombustor

The present invention relates to an exhaust gas guide of a gas turbine, which is situated between the gas turbine and a downstream waste heat boiler or a downstream gas diverter and which comprises a flow channel which has a cross-section expanding in at least some areas in the main flow direction, having installed surfaces influencing the flow. In order to achieve a more compact implementation of the exhaust gas guide and simultaneously avoid or reduce pressure losses, the installed surfaces are implemented as a swirl device generating a leading edge swirl, which is situated in the diverging area of the flow channel and is implemented to distribute the exhaust gas flow uniformly over the flow cross-sectional area upon entry into the waste heat boiler or the gas diverter. Furthermore, the present invention relates to a method for mixing the exhaust gas of a gas turbine with hot exhaust gas streams generated in an auxiliary firing of at least one burner. This thorough mixing is achieved by generating at least one leading edge swirl system in the flow channel.

Owner:HOWDEN ROTHEMUHLE GMBH

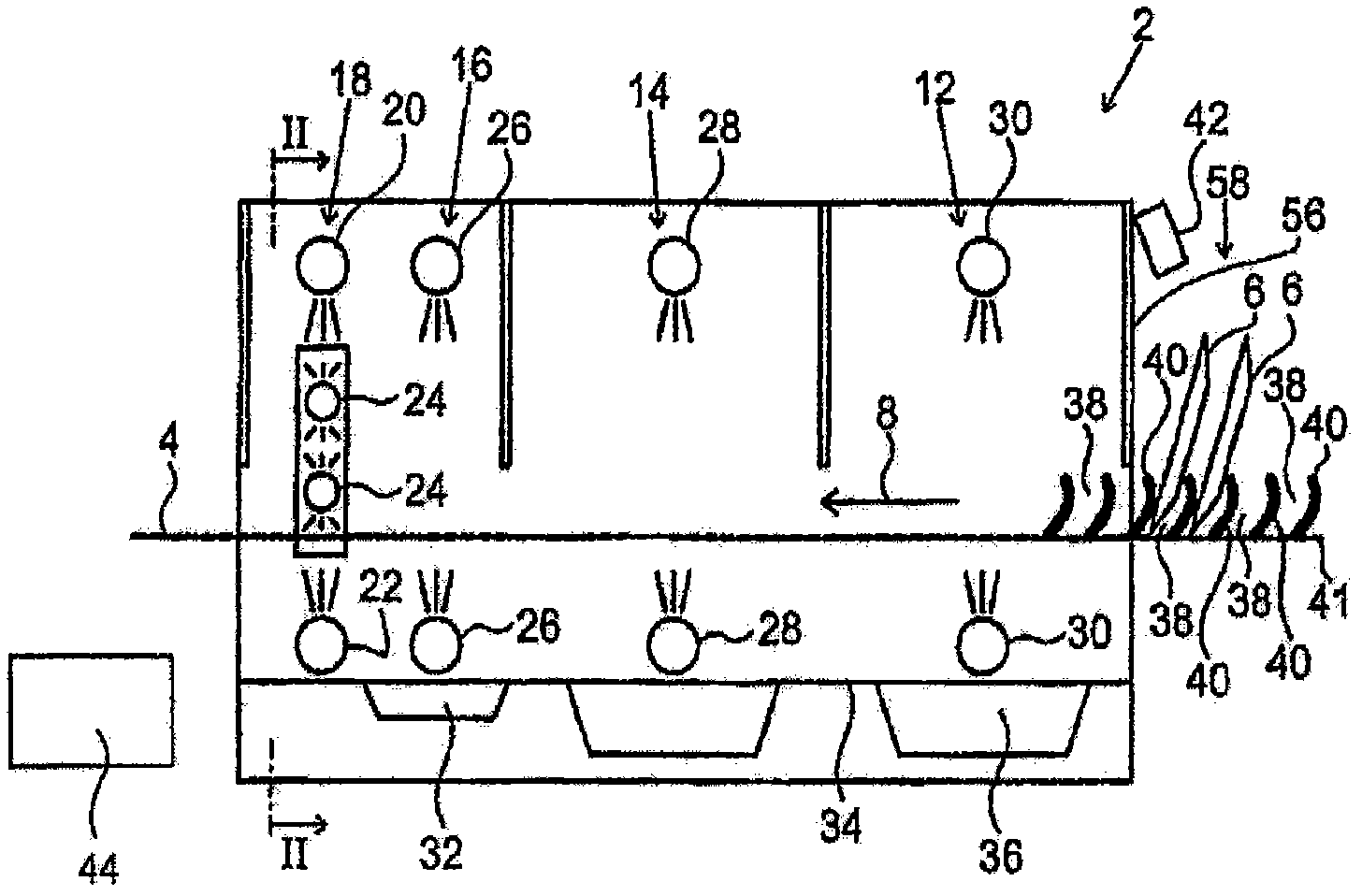

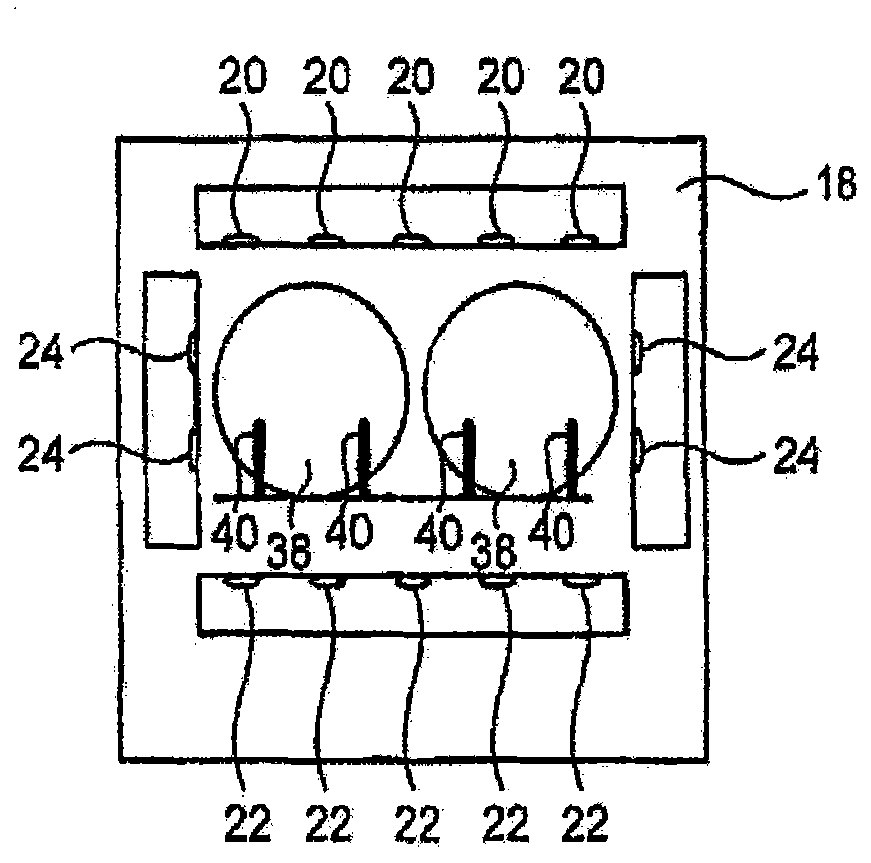

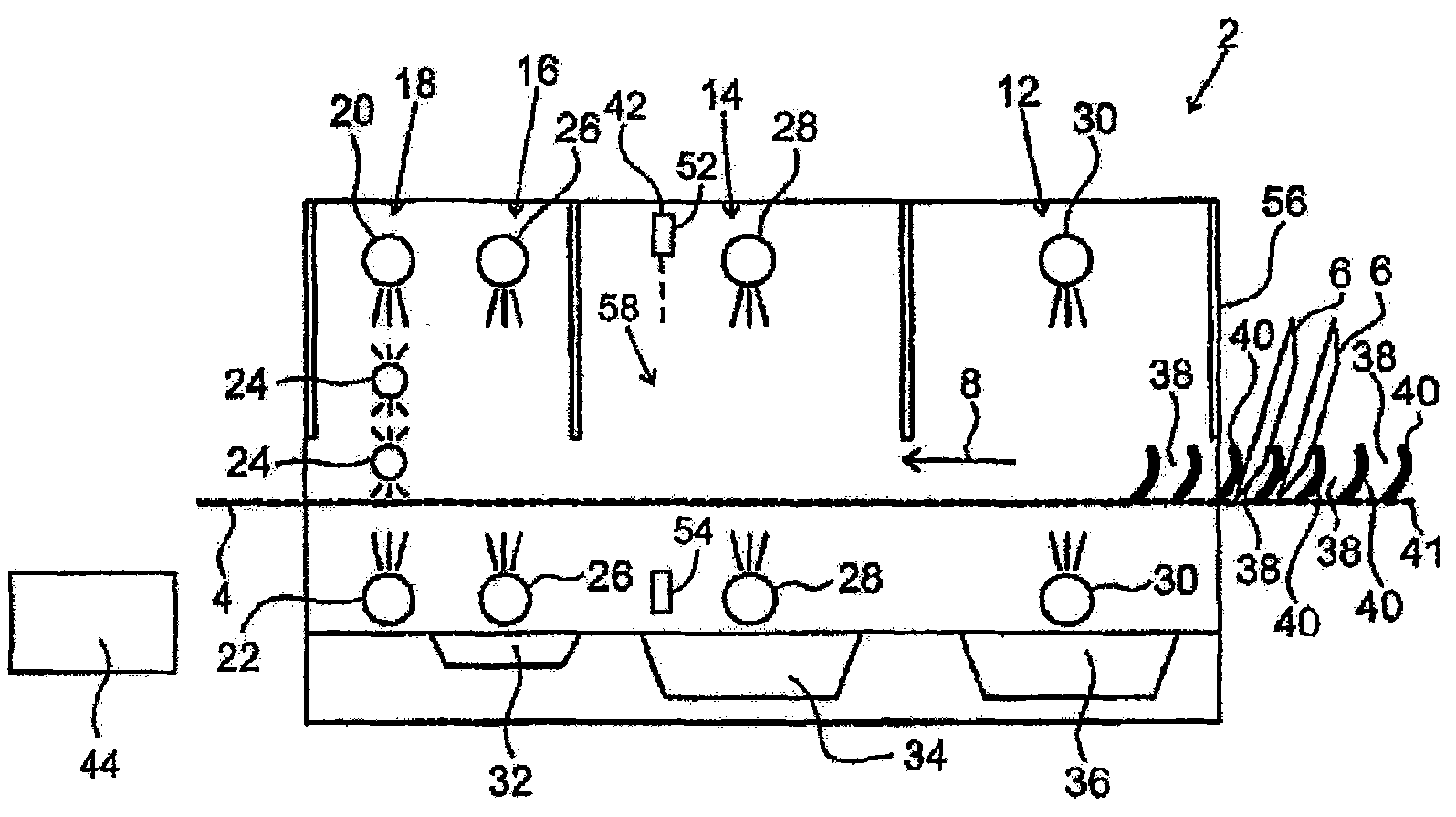

Conveyor dishwasher and method for operating a conveyor dishwasher

ActiveCN102119059AReduce consumptionSmall volume flowAutomatic washing/rinsing machine detectionCleaning equipmentSpray nozzleProcess engineering

The invention relates to a conveyor dishwasher (2) comprising a conveyor apparatus (4) for conveying washware (6) through a final rinse zone (18), with the conveyor apparatus (4) having a large number of compartments (38) for accommodating washware (6). A washware sensor apparatus (42) is provided in order to detect empty compartments (38). In order to be able to reduce the consumption of fresh water, chemicals and energy during operation of the conveyor dishwasher (2), the invention provides a control apparatus (44) which is designed to automatically set the quantity of final rinse liquid supplied to the spray nozzles (20, 22, 24) of the final rinse zone (18) per unit time as a function of the detection of empty compartments (38). The invention also relates to a method for operating a conveyor dishwasher (2) of this type.

Owner:PREMARK FEG L L C

Gas drilling ground manifold connecting structure

The invention discloses a gas drilling ground manifold connecting structure. The gas drilling ground manifold connecting structure comprises a gas injection unit, a pressure relief unit, a flowmeter, a ground gas injection manifold, a high-pressure gas injection hose, an erosion-resistant gooseneck tube, a high-pressure reverse circulation sand discharging hose, a ground reverse circulation sand discharging pipeline and a normal circulation gas drilling sand discharging pipeline. The ground manifold connecting structure is used in a full-well-section self-suction type reverse circulation gas drilling system, conventional tools such as single-wall drilling tools and gas and water mixing joints are omitted, air serves as a circulatory medium in a full well section, and reverse circulation can be implemented without mud or other drilling fluid. The gas drilling ground manifold connecting structure is particularly suitable for well sections with serious water shortage, serious well leakage or incapability of implementing air lift reverse circulation drilling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

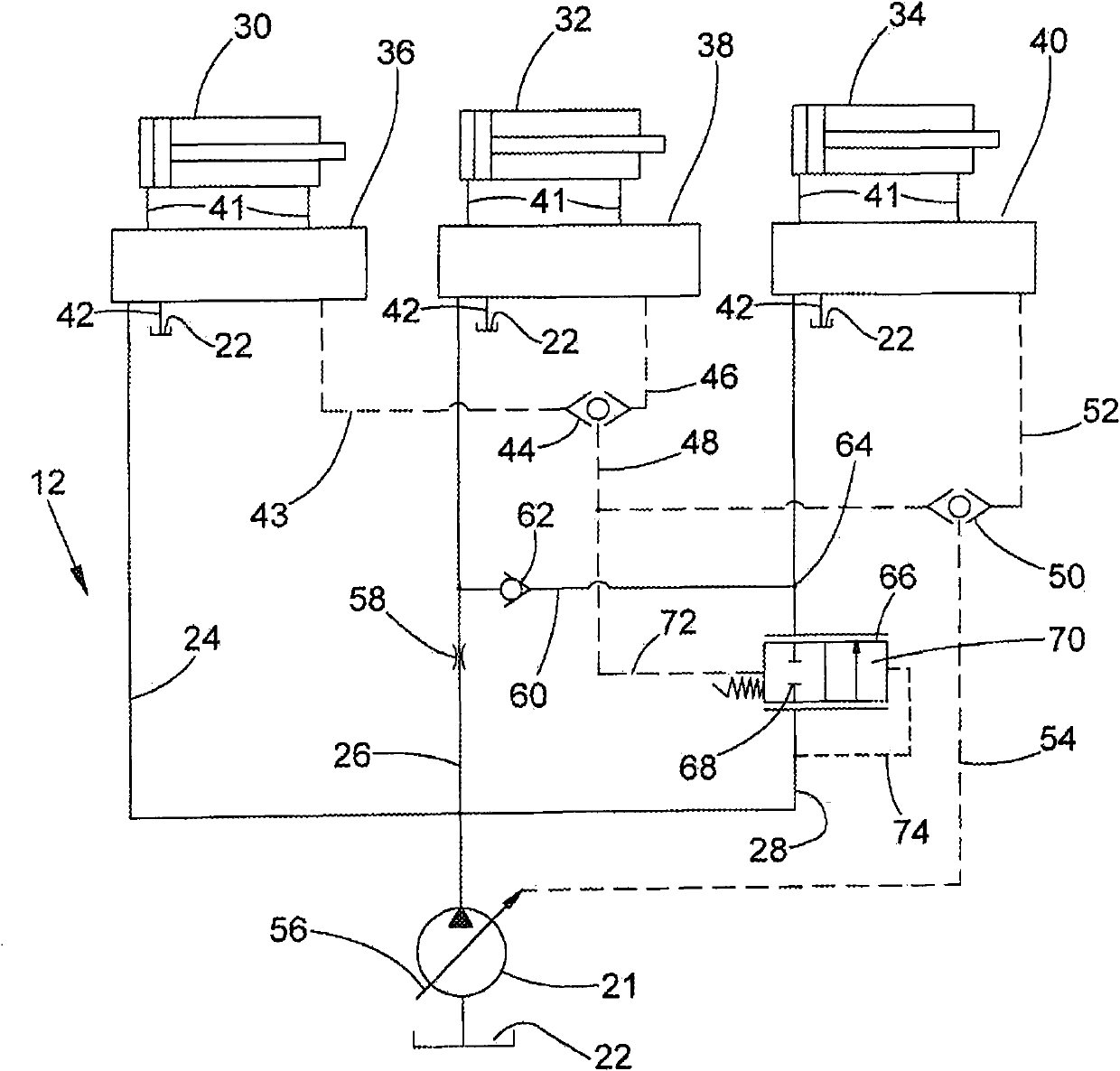

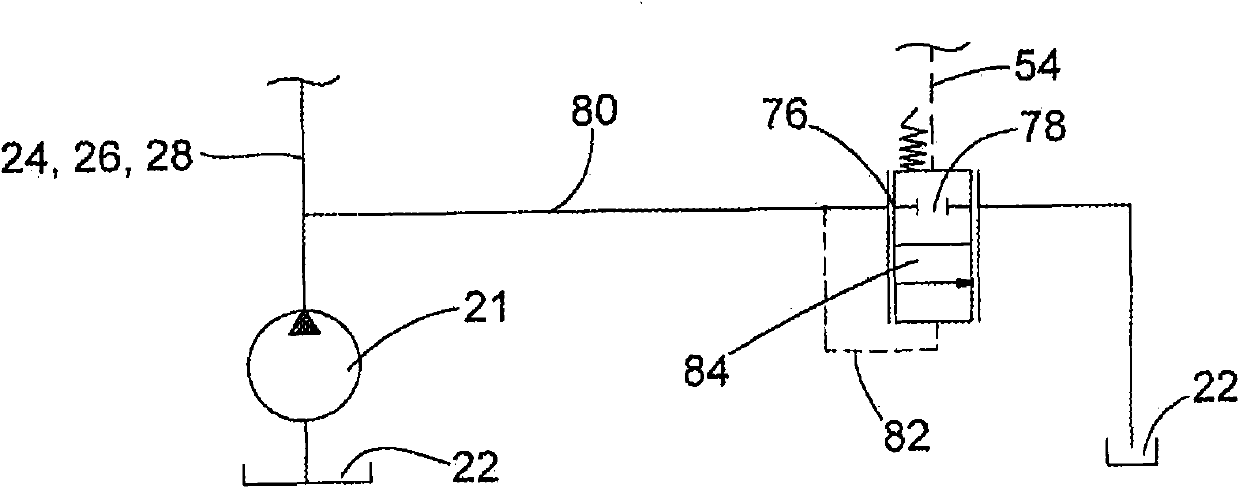

Hydraulic assembly

InactiveCN101994725ASmall volume flowVolume flow suppression or reductionAgricultural machinesServomotorsPriority callHydraulic pump

The present invention relates to a hydraulic assembly, including a hydraulic pump and at least a first, second and third consumption devices, each of which is hydraulically connected with a hydraulic pump in parallel through its supply line by at least one control valve, the first consumption device is endowed with a first priority level, the second consumption device is endowed with a second priority level following the first priority level, and the third consumption device is endowed with a third priority level following the second priority level. In order to provide low-cost priorities for the consumption devices, supply lines of the second and third consumption devices are connected through a connection line for controlling supply priority levels assigned to controls, a load pressure-controlled priority valve is arranged between the hydraulic pump and the connection line in the supply line of the third consumption device, and a volume flow reducing element is arranged in the supply line of the second consumption device, furthermore, the connection line is provided with a blocking unit for blocking volume flow from the second supply line to the third supply line.

Owner:DEERE & CO

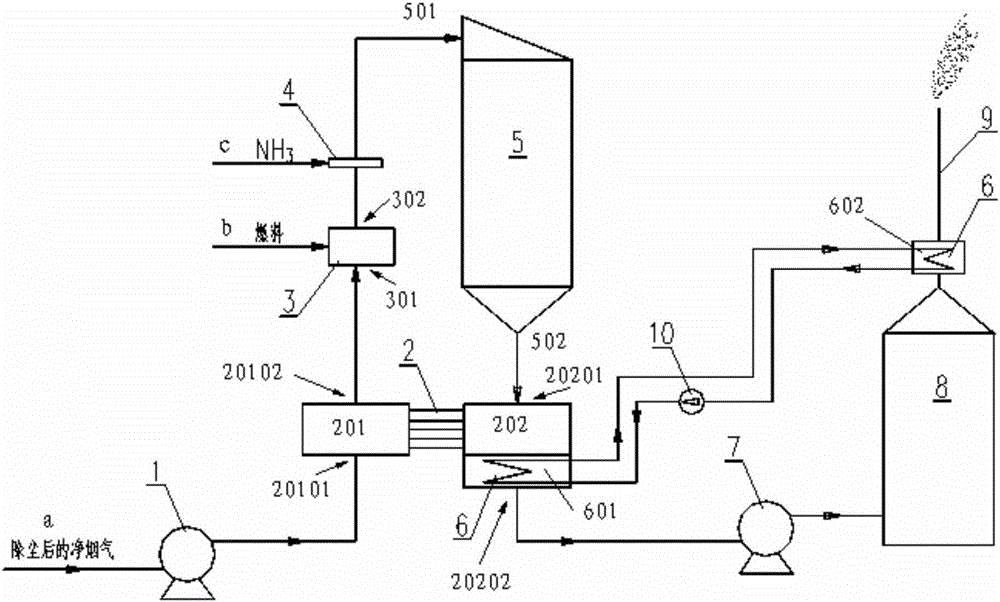

Device and method for comprehensively carrying out desulfurization, denitration and dioxin removing on steel sintering flue gas

PendingCN106669418AReduce consumptionSmall volume flowDispersed particle separationIncreasing energy efficiencyGas heaterHeat energy

The invention discloses a device and a method for comprehensively carrying out desulfurization, denitration and dioxin removing on steel sintering flue gas. The device mainly comprises a GGH (Gas Gas Heater), a flue gas heating furnace, an ammonia injection grid, an SCR (Selective Catalytic Reduction) reactor, a flue gas-water heat exchanger, a booster fan, a circulating water pump, a desulfurization tower, a chimney and the like. The method adopts a technology of desulfurizing after denitrating and is characterized by firstly accessing sintering flue gas after dust removing to an SCR flue gas denitration device after passing through a main exhaust fan, thus removing NOX and the dioxin; then enabling the sintering flue gas to enter a wet desulfurization tower to desulfurizing, and finally enabling the sintering flue gas to be subjected to standardized emission through the chimney. According to the device and the method, disclosed by the invention, in one hand, the sintering flue gas can be subjected to standardized emission, and the phenomenon that white smoke is discharged by the chimney is removed; meanwhile, on the other hand, the heating energy consumption of the flue gas is reduced, and the energy source is saved.

Owner:HUNAN ZHONGYE CHANGTIAN ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

External heat radiation regenerative oil shale dry distillation furnace

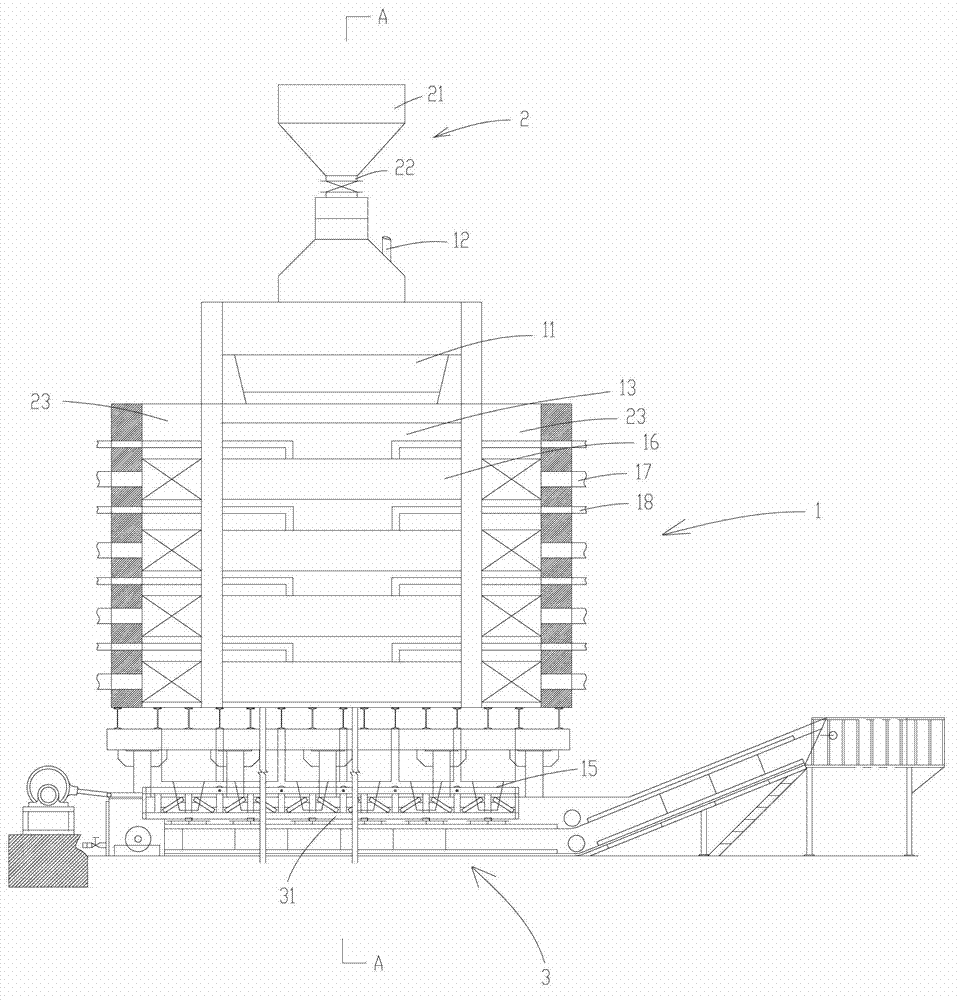

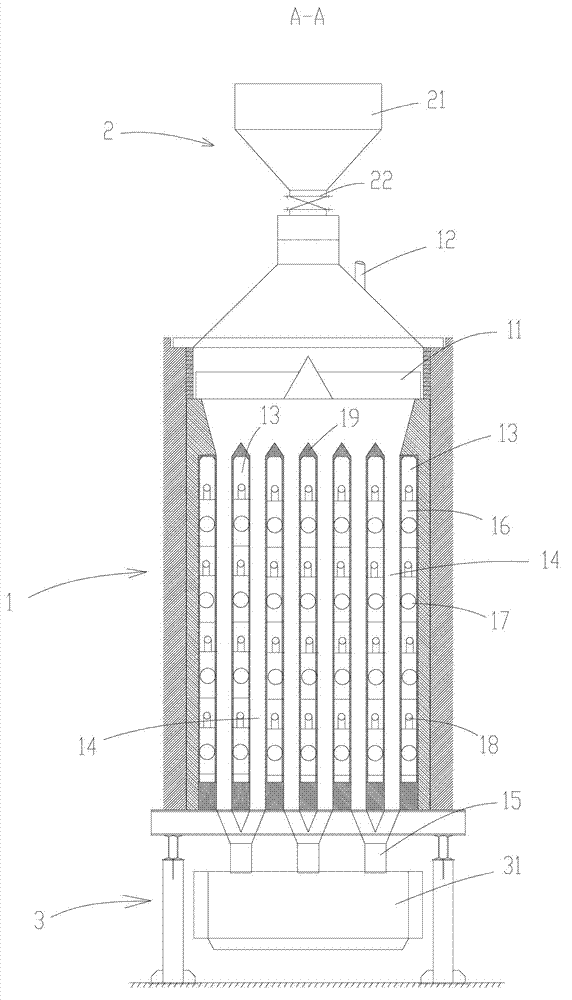

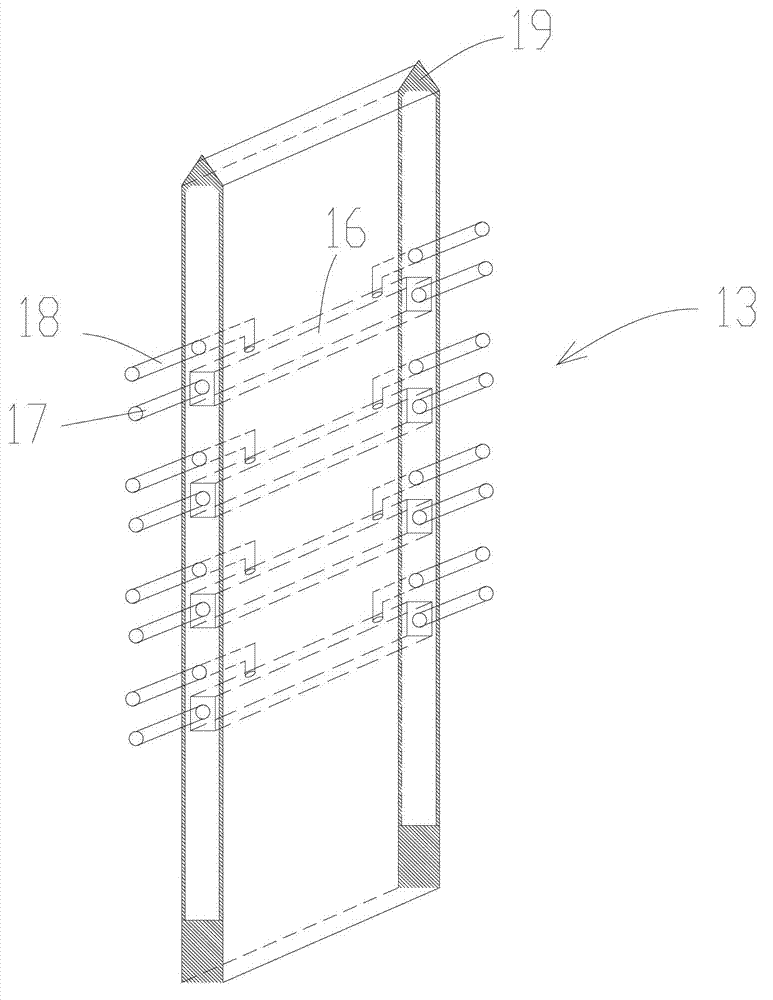

ActiveCN105542863AHigh strengthRun smoothlyGasification processes detailsCombustible gas productionCombustion chamberThermal efficiency

The invention relates to an external heat radiation regenerative oil shale dry distillation furnace. The furnace is provided with a plurality rows of alternately arranged dry distillation chambers and combustion chambers; each row of combustion chambers is formed by a plurality layers of independent combustion channels; heat generated by combustion is transferred to oil shale in the dry distillation chambers with heat radiation and heat conduction manners with lattice-wall-structured heat conduction walls. With a gasification section, a cooling section, cooling water jackets and steam nozzle devices on the lower part of the dry distillation furnace, carbon residue in semicoke can be fully recycled, and semicoke and ash residual heat can be recycled. Water gas generated by the reaction of semicoke and steam is used as a medium for bringing out oil shale pyrolysis oil gas, such that outlet gas amount is low, dry distillation gas purity is high, and dry distillation gas heat value is high. The daily processing capacity of the dry distillation furnace can by higher tan 500t, and an oil yield can be higher than 90%. Water and electricity consumptions are low, and an auxiliary recovery system is small. With existing external heat dry distillation technologies, semicoke carbon residue cannot be utilized, thermal efficiency is low, maintenance is difficult, and yield is low. With the dry distillation furnace, the above problems are solved. The dry distillation furnace is especially suitable for water-deficient areas.

Owner:WUHAN UNIV OF SCI & TECH

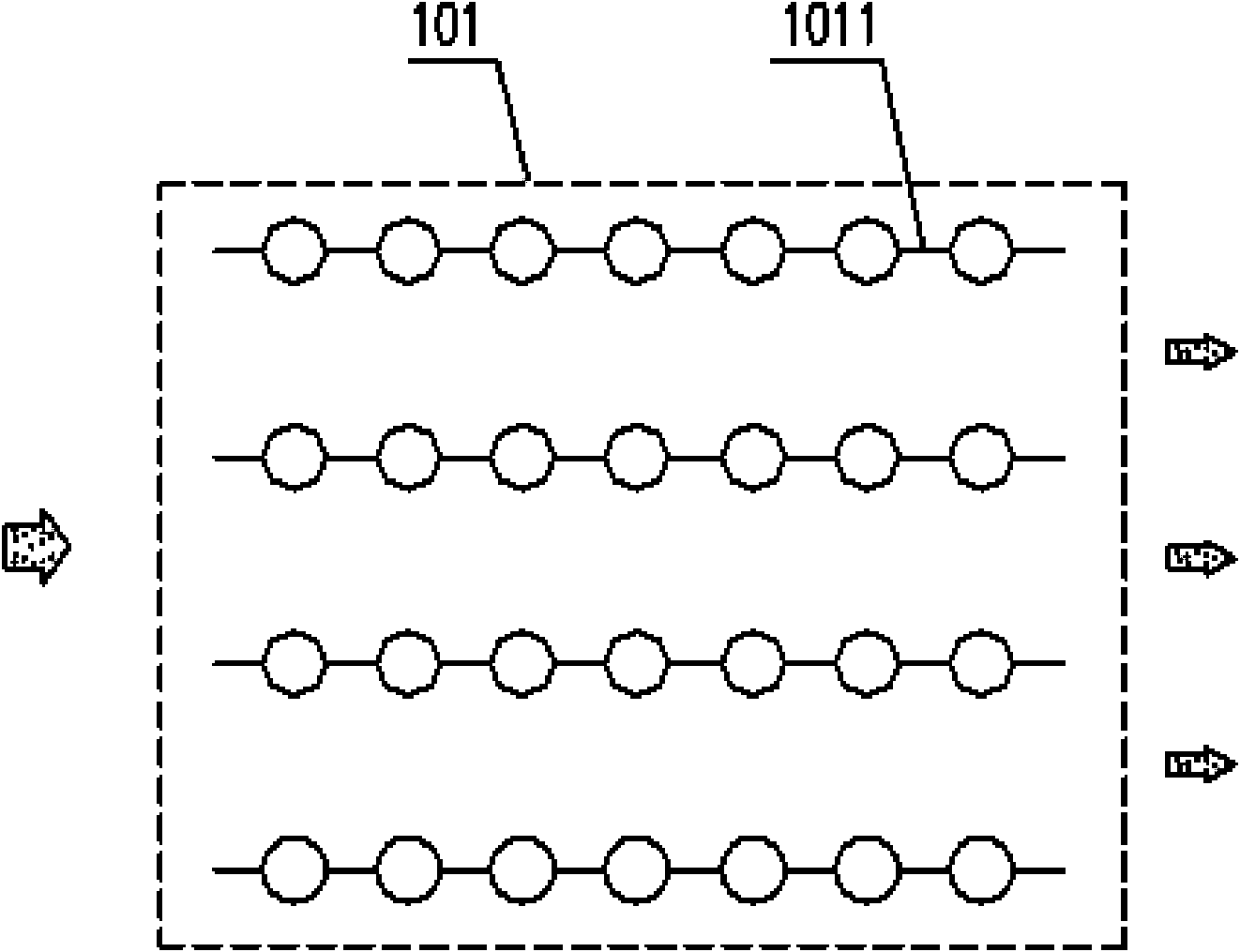

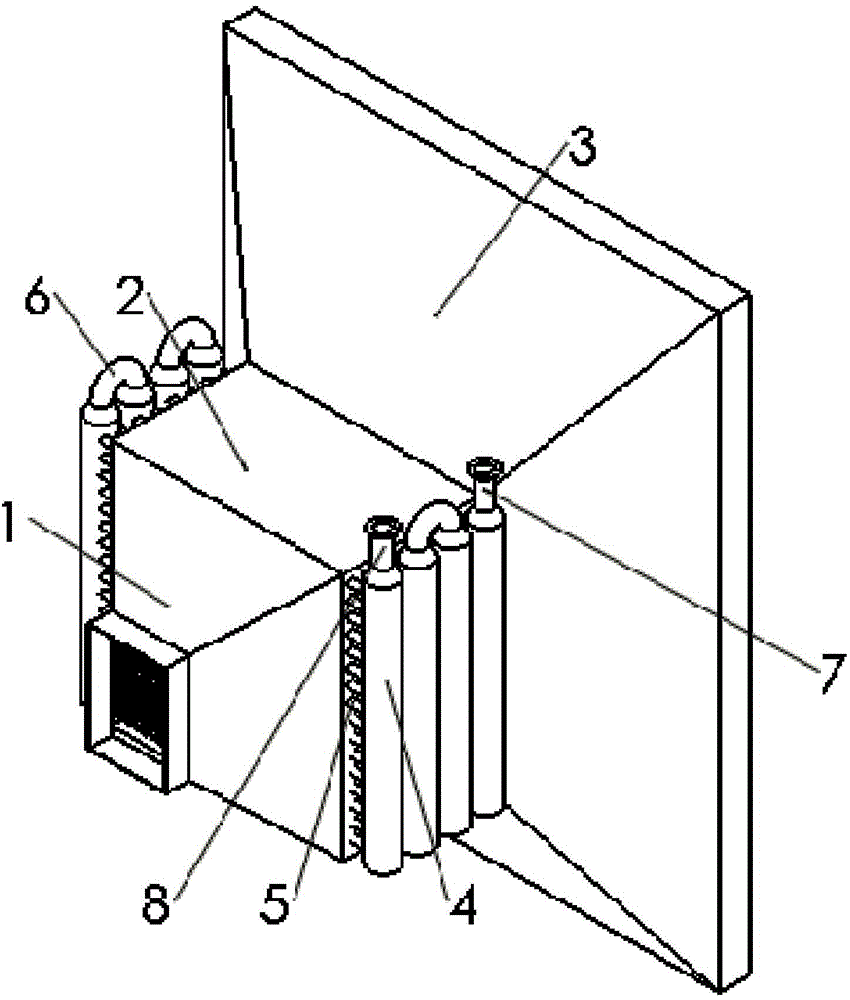

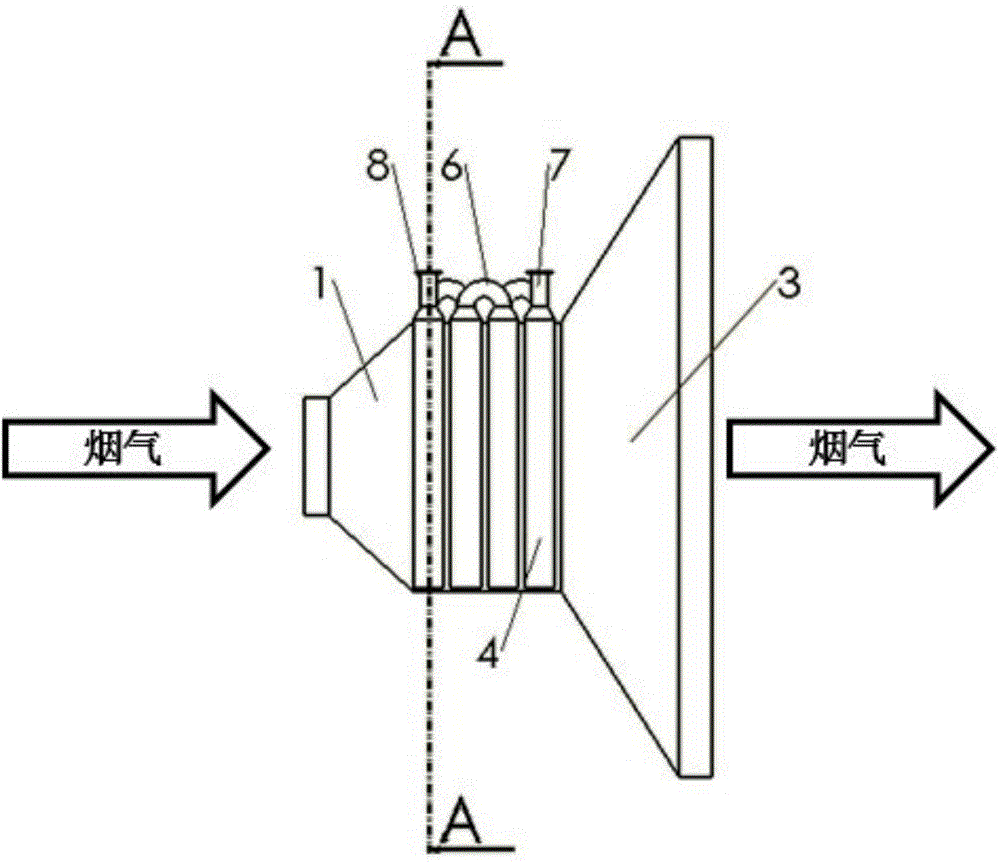

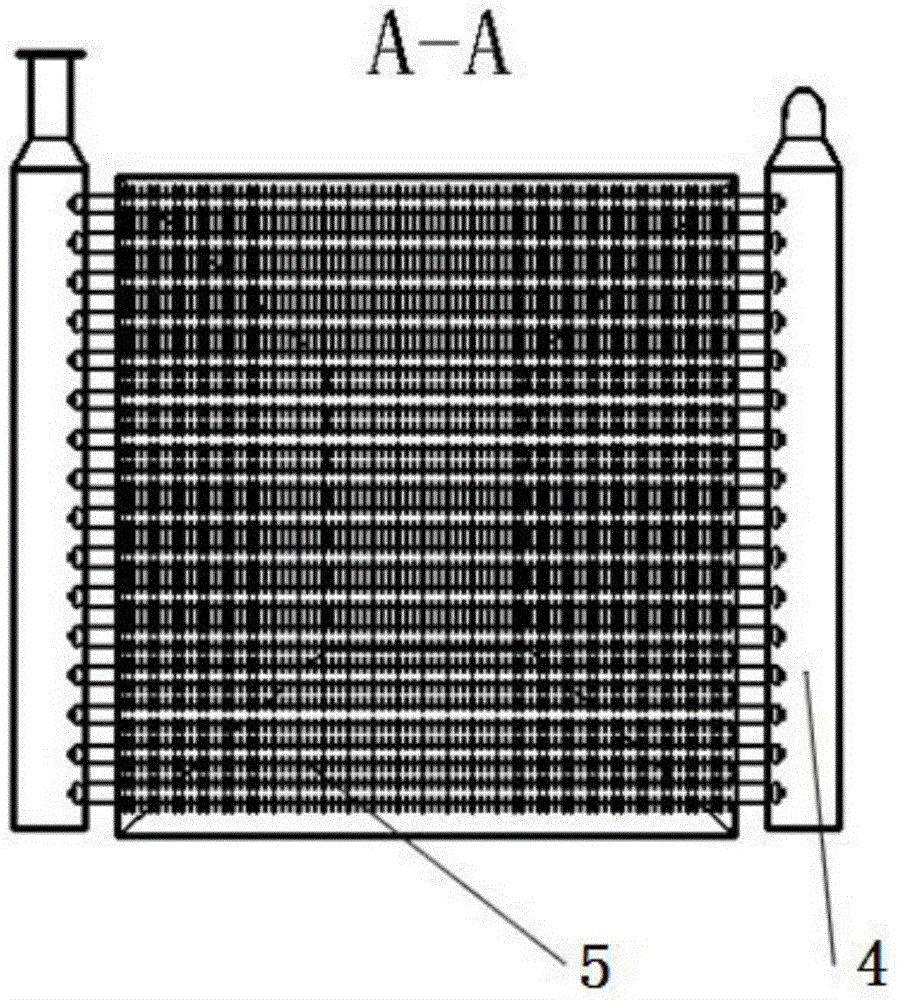

Novel tube panel type water tube heat exchanger integrated with electrostatic precipitator

ActiveCN103604113AMake full use of the flue spaceSmall footprintCombustion technology mitigationFeed-water heatersElectrical resistance and conductancePlate heat exchanger

A novel tube panel type water tube heat exchanger integrated with an electrostatic precipitator consists of a plurality of rows of tube panels, wherein each row of tube panels consists of heat exchanger headers at two ends and a plurality of heat exchanging tube bundles which are connected with the heat exchanger headers at the two ends; tube ends of the heat exchanger heads at the two ends of each of the adjacent tube panels are connected to one another through large-diameter elbows, so that working media of the adjacent tube panels are connected to one another; and heat exchanging tube bundles of each tube panel are arranged in a flue structure in a middle section of an extension section of an inlet of the precipitator. The heat exchanger does not occupy the other effective space in front of the inlet of the electrostatic precipitator; the waste heat of the smoke can be reasonably used; and the specific resistance of the soot is reduced, so that the efficiency of the electrostatic precipitator is improved. The novel tube panel type water tube heat exchanger integrated with the electrostatic precipitator has the advantages that the structure is simple and compact, modular production and modular assembly can be realized, and field installation is quite convenient.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP +1

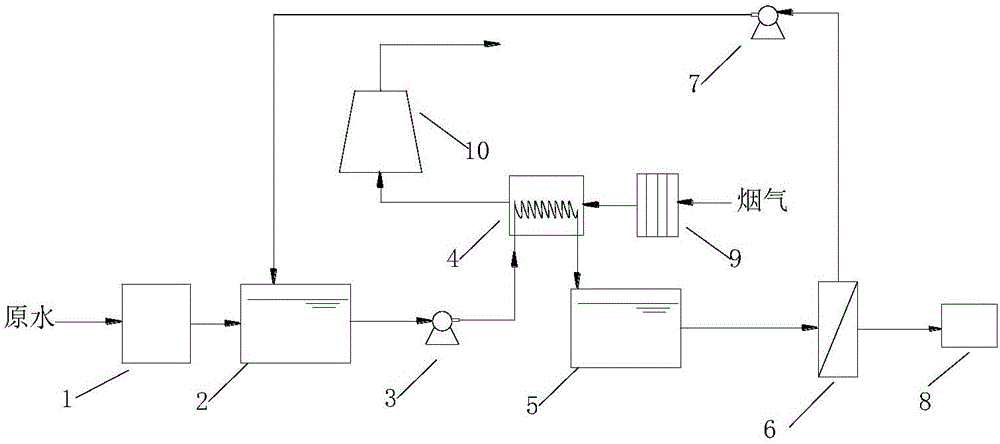

Water treatment device and water treatment method utilizing flue gas waste heat

InactiveCN106219895ALow running costReduce the temperatureSeawater treatmentEmission preventionWater treatment systemFlue gas

The invention discloses a water treatment device utilizing flue gas waste heat. Raw water enters a pretreatment device, the water outlet end of the pretreatment device is connected with the water inlet end of a regulation tank, the water outlet end of the regulation tank is connected with the water inlet end of a heat exchanger, and the water outlet end of the heat exchanger is connected with the water inlet end of a middle water tank. The heat exchanger is located in front of a flue gas inlet of a desulfurizing tower, flue gas enters a flue gas inlet of a dust remover, a flue gas outlet of the dust remover is connected with a flue gas inlet of the heat exchanger, and a flue gas outlet of the heat exchanger is connected with the flue gas inlet of the desulfurizing tower. The water inlet end of a second water pump is connected with the water outlet end of the middle water tank, the water outlet end is connected with the water inlet end of a membrane distillation device, and the water producing end of the membrane distillation device is connected with a produced water tank. The invention further provides a water treatment method utilizing flue gas waste heat. The water treatment device has the advantages that power plant waste heat utilization and a membrane distillation process are combined, the flue gas before desulfurizing is adopted as a heat source of a membrane distillation water treatment system, the flue gas waste heat is fully utilized while the membrane distillation water treatment process is completed, the flue gas temperature of a desulfurizing system is reduced, and the water consumption for desulfurizing can be remarkably decreased.

Owner:DATANG ENVIRONMENT IND GRP

Oil shale external heat radiation type retort

InactiveCN102925180AStable temperatureSmall volume flowCombustible gas coke oven heatingIndirect heating destructive distillationHeat carrierCombustion chamber

The invention discloses an oil shale external heat radiation type retort. Under the condition that the cost is not increased remarkably, a combustion chamber is added on a retort body, a combustion gas pipe and a combustion-supporting air pipe are connected onto the combustion chamber, gas and air are combusted in the combustion chamber through a combustor, and heat is transferred to an oil shale in a destructive distillation chamber through a combustion chamber furnace wall in a heat radiation mode, namely the heat required by oil shale temperature destructive distillation is provided by the external heat radiation instead of an original gas heat carrier. Therefore, the temperature in the combustion chamber is ensured to be stable, and heat quantity is utilized fully. Produced net retorting gas is high-calorific-value retorting gas produced through shale low-temperature destructive distillation, retorting gas amount of a furnace outlet per ton of shale is about 40Nm<3>, and the volume ratio of H2 content in the retorting gas is not smaller than 50%. The volume flow rate of the retorting gas is reduced, accordingly the load of a follow-up oil recovery workshop section is lightened, and public and auxiliary facilities are decreased.

Owner:新疆宝明矿业有限公司

Exhaust emission control device for a water vehicle and method for operating an exhaust emission control device

ActiveCN103547773AReduced flow cross-sectionEfficient purificationInternal combustion piston enginesExhaust apparatusExhaust fumesProcess engineering

An exhaust gas cleaning device for a watercraft includes at least a particle filter and / or an SCR catalytic converter and a heat exchanger disposed upstream thereof. The heat exchanger is operated with seawater as a cooling medium. The heat exchanger has an exhaust gas inlet side and an exhaust gas outlet side and is suitable for reducing a volumetric flow rate of an exhaust gas between the exhaust gas inlet side and the exhaust gas outlet side by a certain value in a certain temperature range of the exhaust gas at the exhaust gas inlet side. A watercraft and a method for operating an exhaust gas cleaning device for a watercraft are also provided.

Owner:VTESCO TECH GMBH

Self-Propelled Surface Milling Machine with Electrical Mill Roll Drive

InactiveUS20110248110A1No intensive coolingReduce thermal stressRoads maintainenceSnow cleaningRotational axisHermetic seal

The present invention relates to a self-propelled surface milling machine, preferably in the form of an asphalt-milling machine, snow-milling machine or Surface Miner, having a mill roll which is drivable about a rotational axis, and a mill roll drive comprising an electrical motor which is accommodated within the mill roll, wherein stator and rotor of the electrical motor are accommodated within a dust and air-tightly sealed motor housing. It will be suggested to associate a cooling device comprising a closed circuit liquid cooling system to the electrical motor located within the milling roll body. Due to the high heat capacity of a suitable coolant, such as oil or mixed water and glycol small volume flows and hence small conduit cross sections will be sufficient. On the other hand, any incorporation of dust into the mill-roll drive as well as any formation of dust by discharge air can be avoided by the closed form of the circuit liquid cooling system.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com