Oil shale external heat radiation type retort

A technology for oil shale and retort furnaces, which is applied in special forms of retorts, indirect heating retorts, combustible gas heating coke ovens, etc. It can solve the problems of low thermal efficiency, complex process flow, large investment, etc., and achieve temperature stability and reduce volume flow , load reduction and the effect of public auxiliary facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

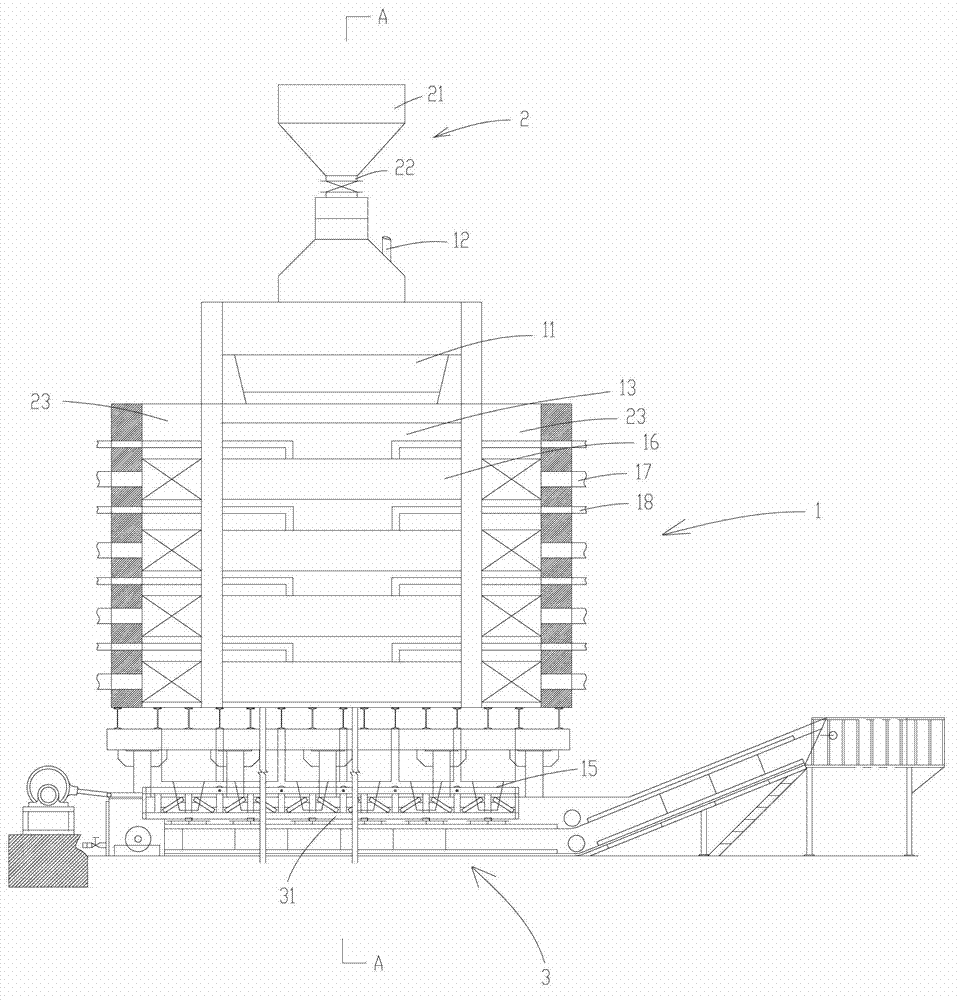

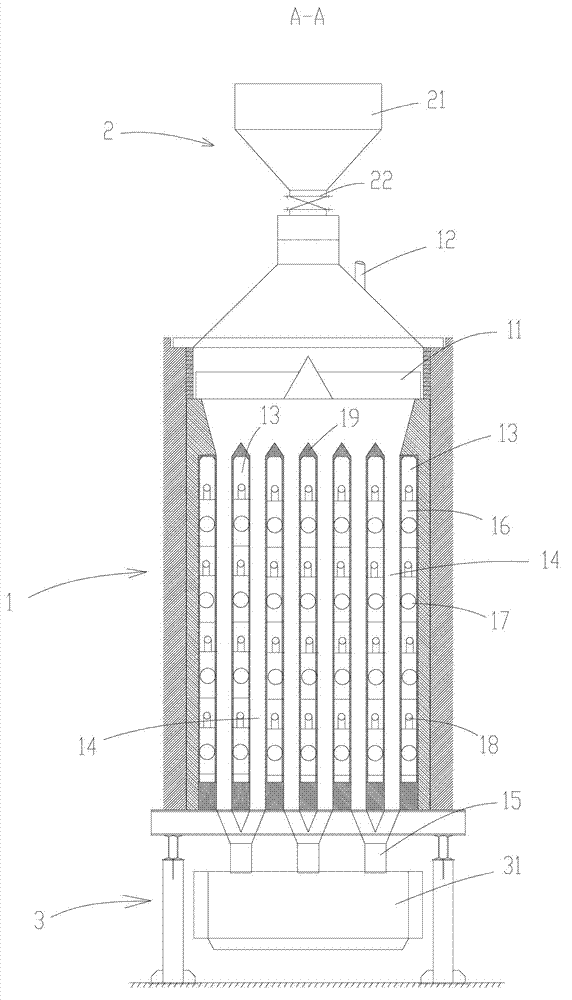

[0032] As shown in the figure: an oil shale external heat radiation retort furnace, mainly including: breaking the oil shale raw material into granular rock materials, and a feeding mechanism 2 for controlling the amount of feeding, which is set on the feeding mechanism 2 The furnace body 1 at the bottom, the furnace body 1 performs external heat radiation dry distillation on the rock material, and the coke discharge machine 3 arranged under the furnace body 1 is used to process the semi-coke generated after the rock material carbonization.

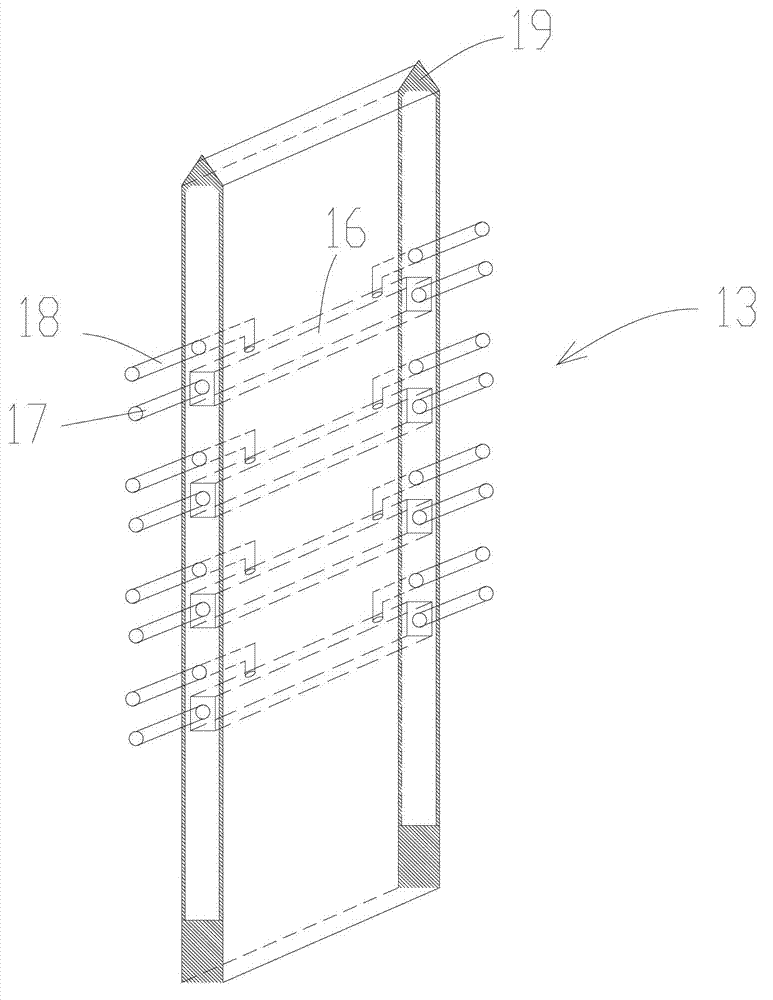

[0033] As the main equipment for radiative carbonization of oil shale rock materials, the interior of the furnace body 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com