Piloted valve, particularly proportional throttle valve

A pilot control valve, pilot control technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as excess force of the magnet system, achieve stable operation characteristics, and eliminate the effect of sudden movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

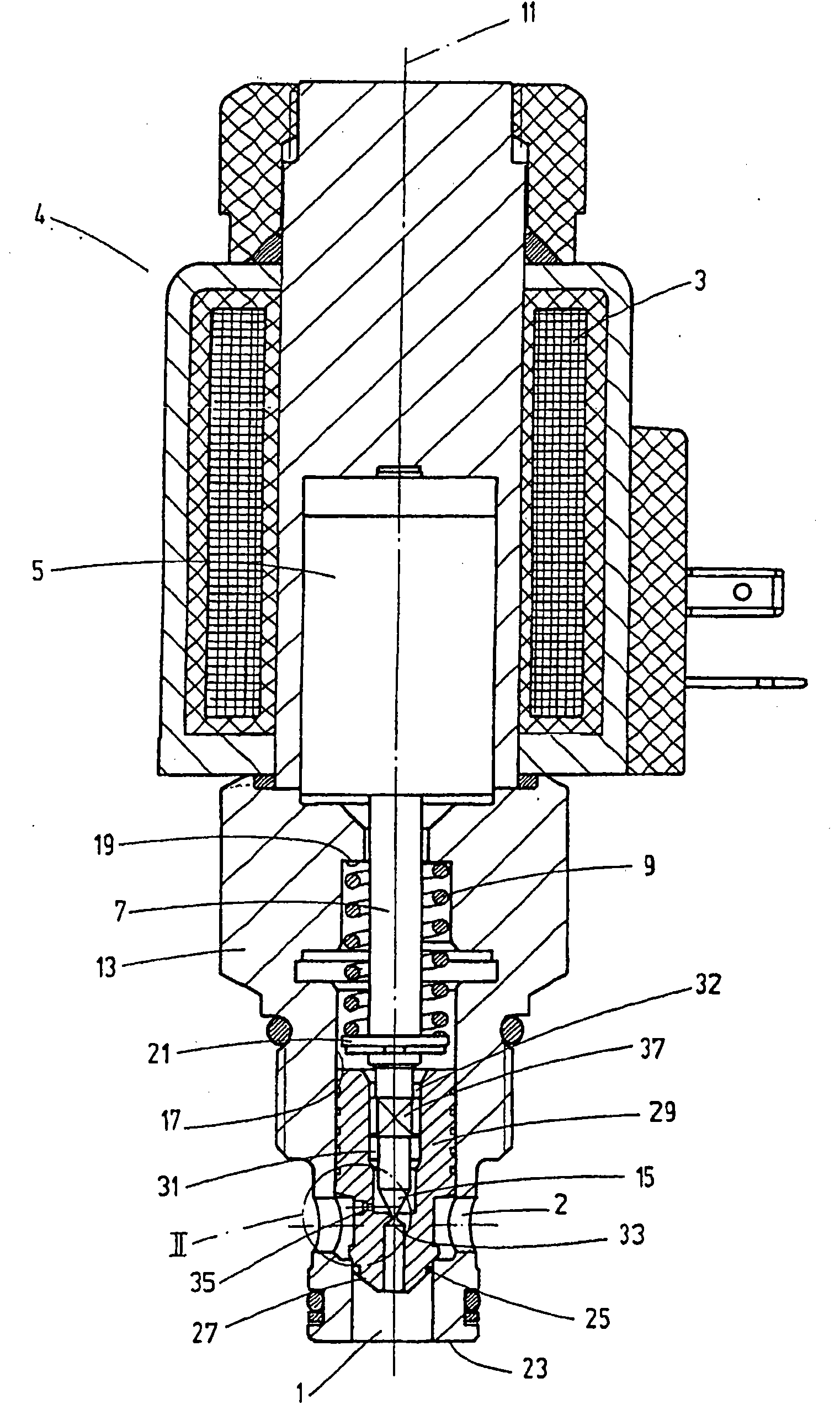

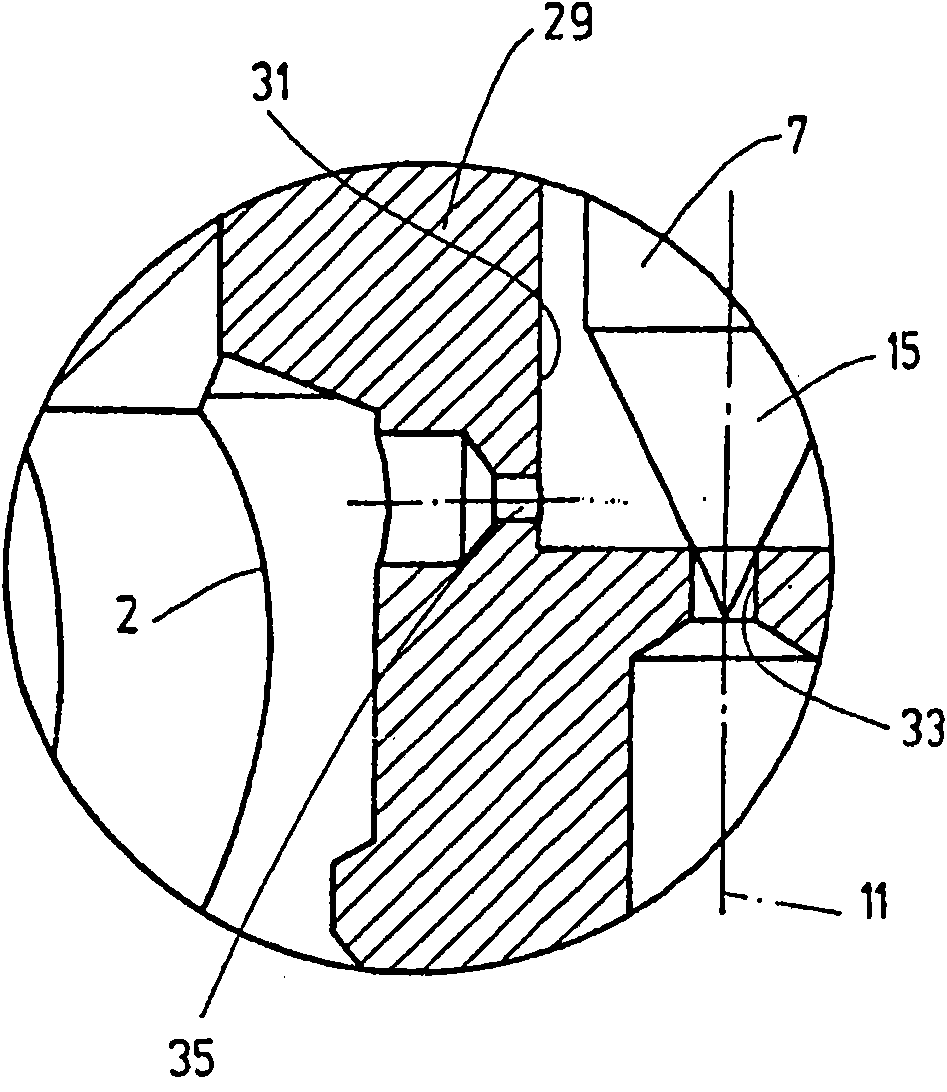

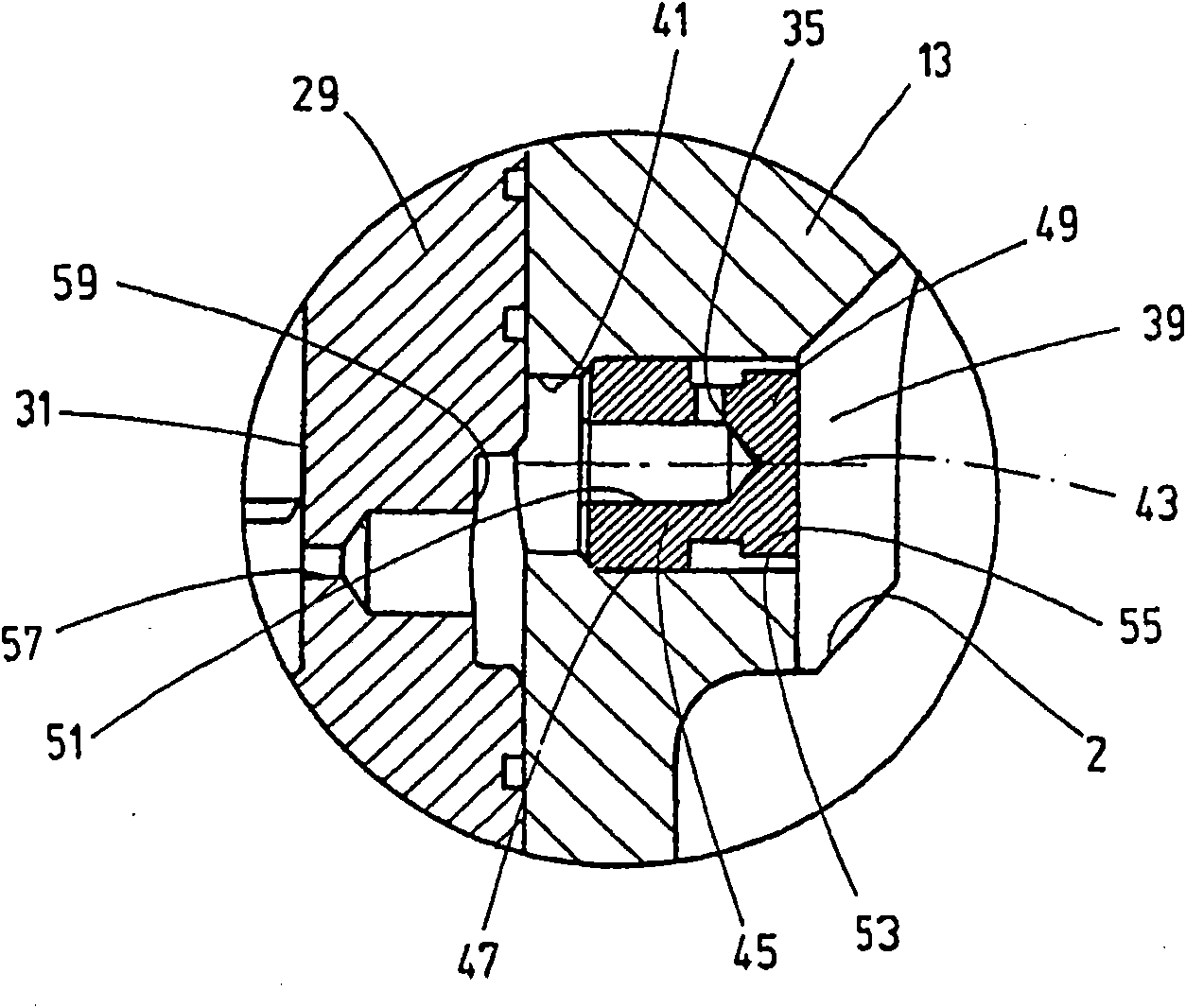

[0026] The known pilot-controlled proportional throttle valve in the form of cooperation according to FIG. 1 is provided with an electrically controllable magnet system 4 . Magnet systems of this type for controlling valves are well known in the prior art (DE 4416279 A1), wherein an armature 5 can be controlled by means of an actuating coil 3 of the magnet system 4 . In the embodiment shown, the magnet system 4 is designed as a so-called pull-in displacement-controlled proportional magnet, which, viewed in the direction of view in FIG. Element 7 moves from bottom to top. In the de-energized state, the armature 5 and thus the actuating element 7 are reset downwards via an energy store formed by a compression spring 9 , that is to say, with respect to the longitudinal axis 11 , are brought into a closed position with the throttle valve corresponding axial position.

[0027]The housing of the magnet system 4 is connected to a valve housing 13 in a sealed condition, the actuatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com