Patents

Literature

31results about How to "Small gap width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

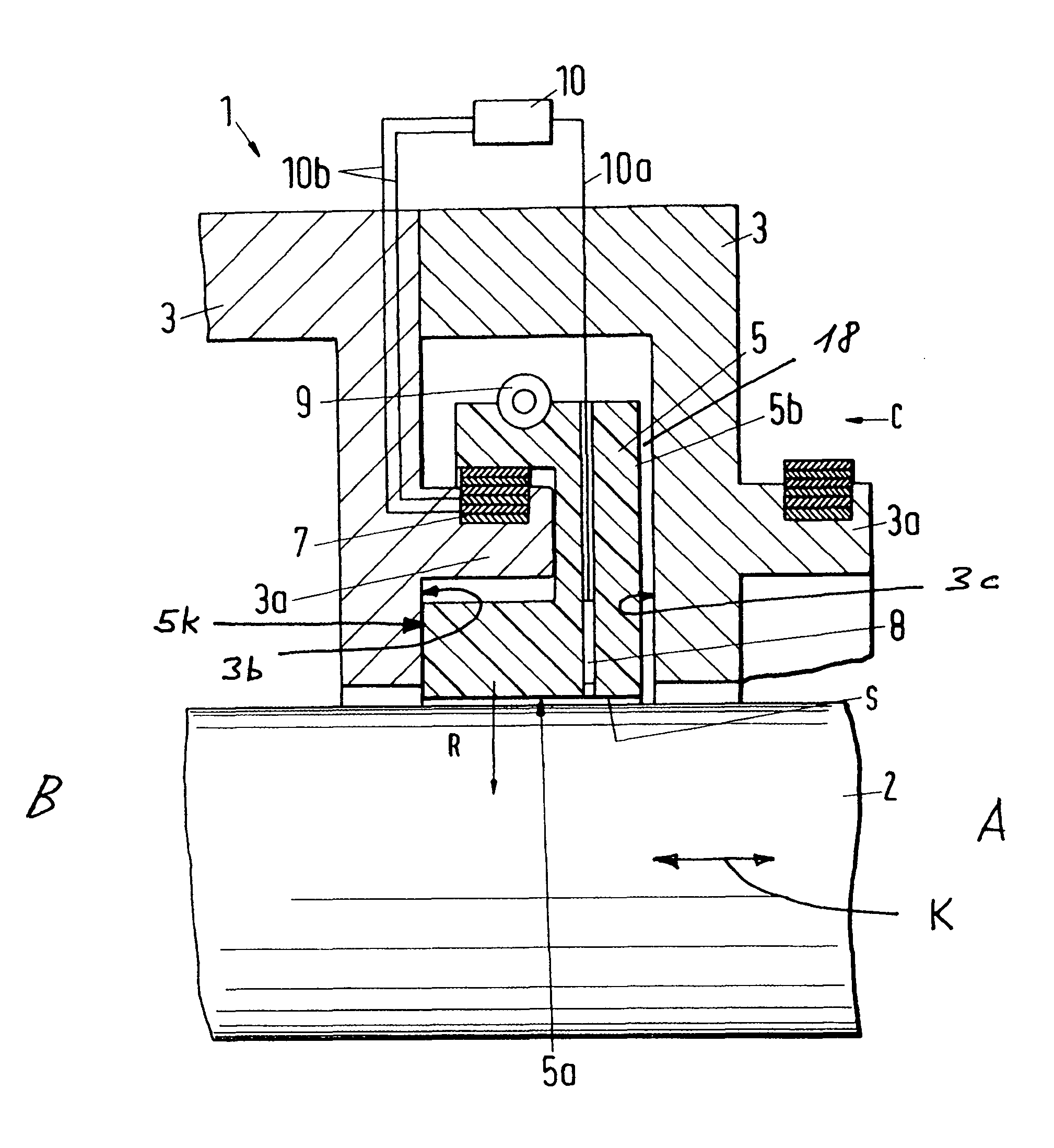

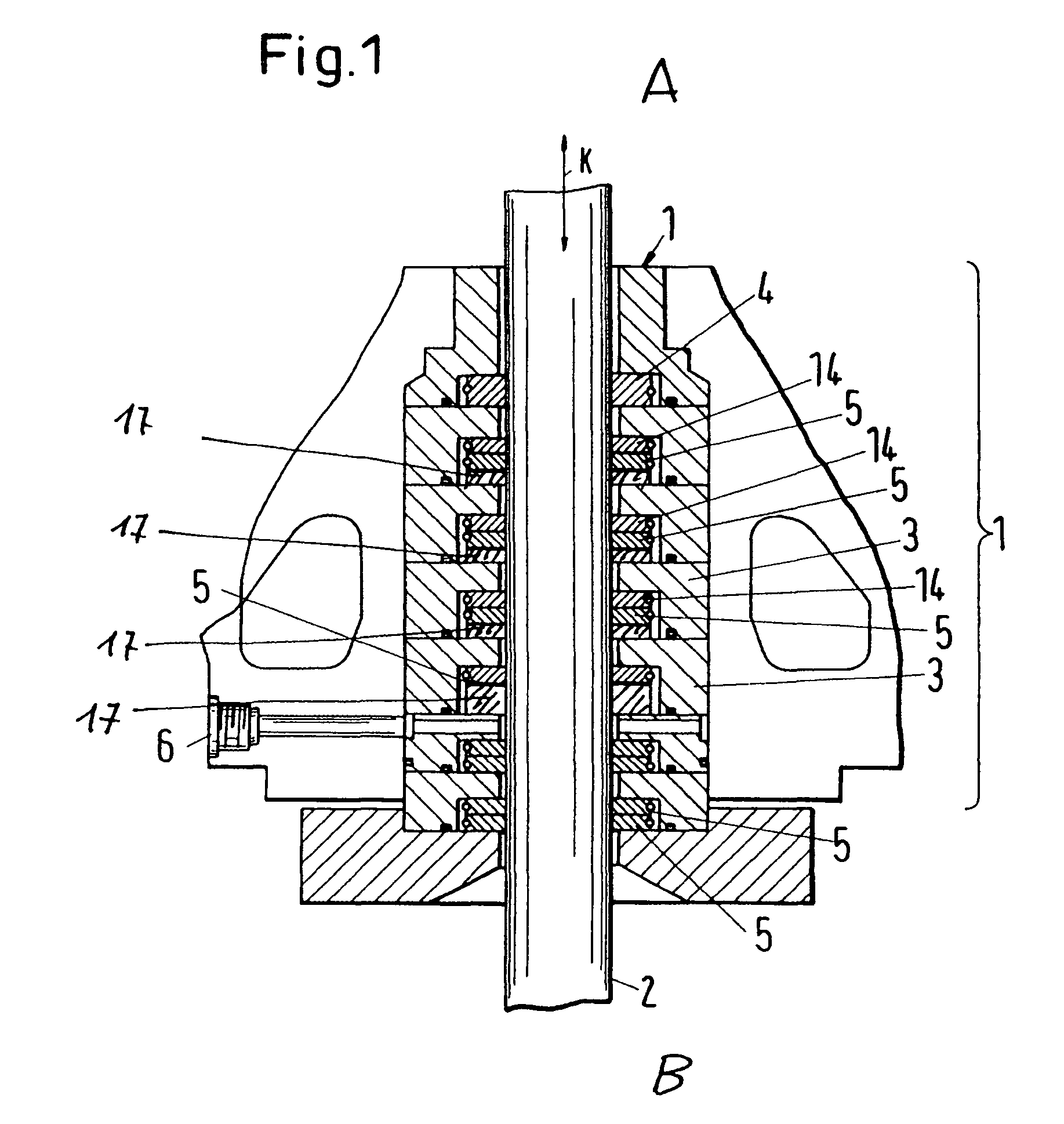

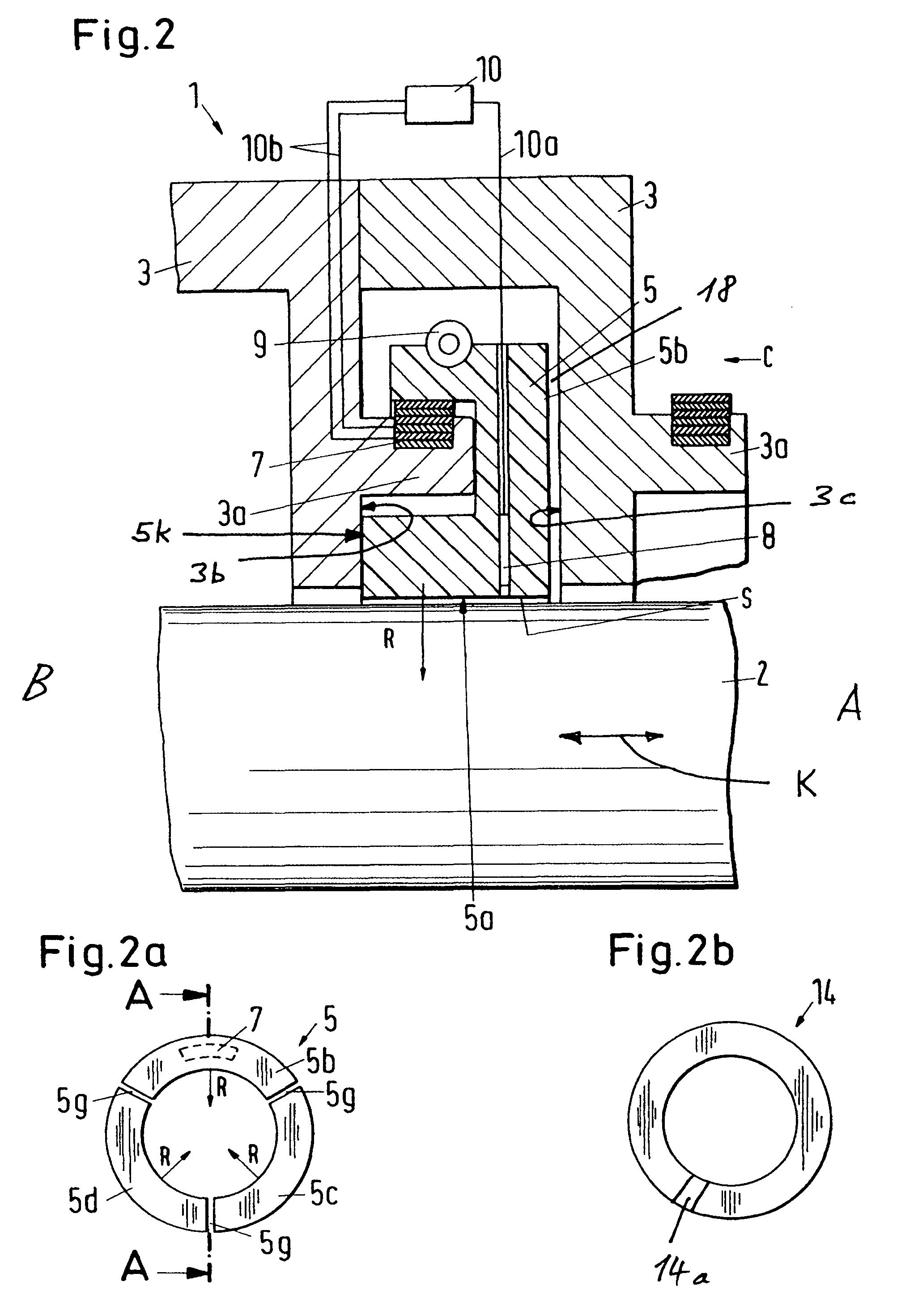

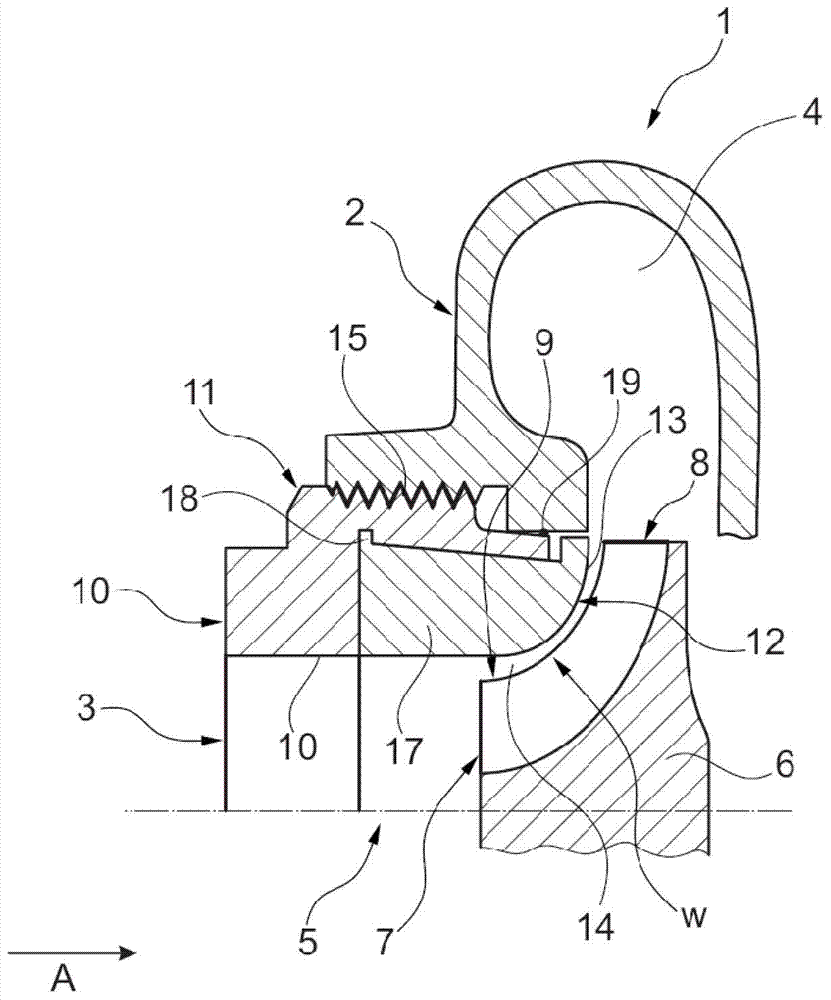

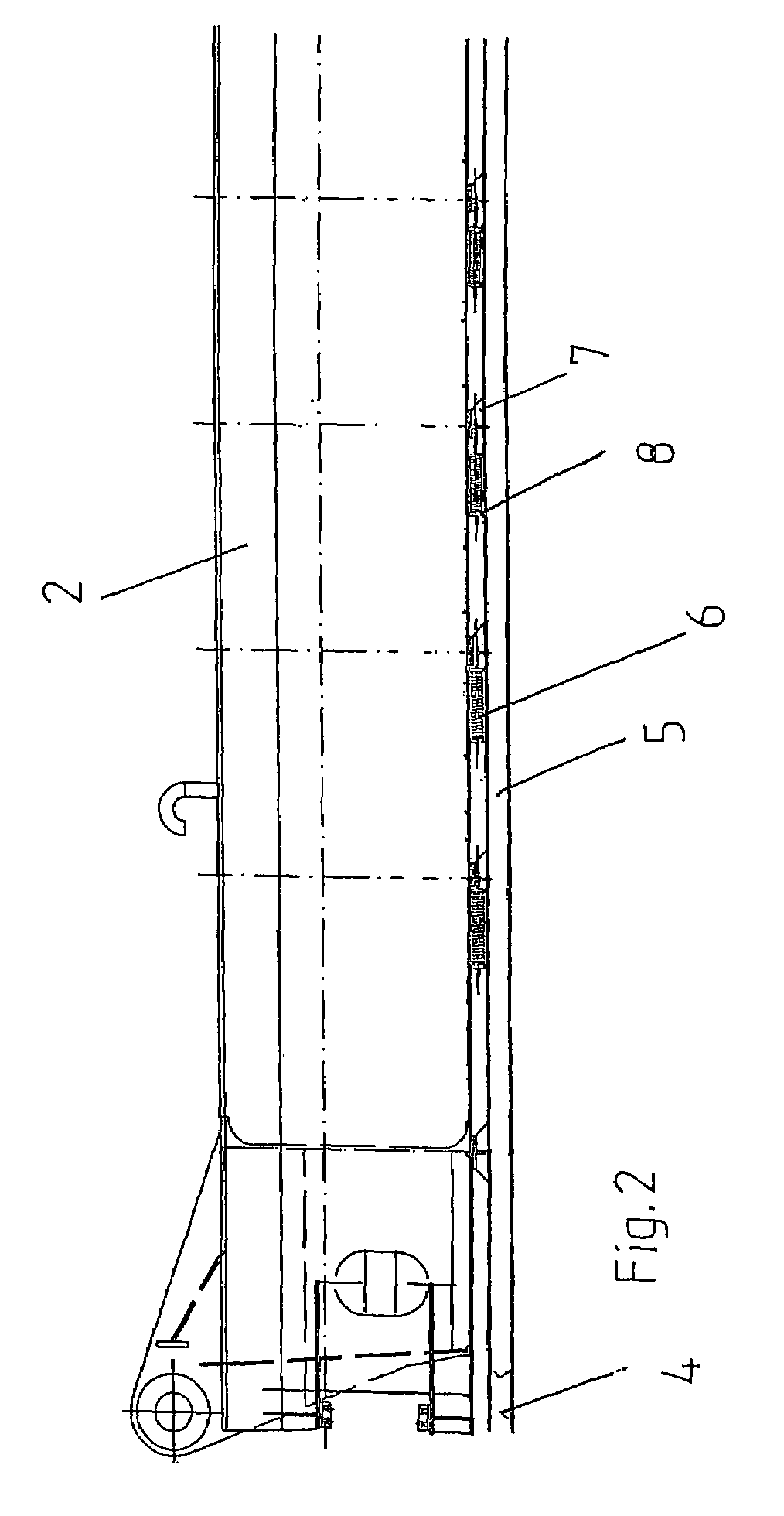

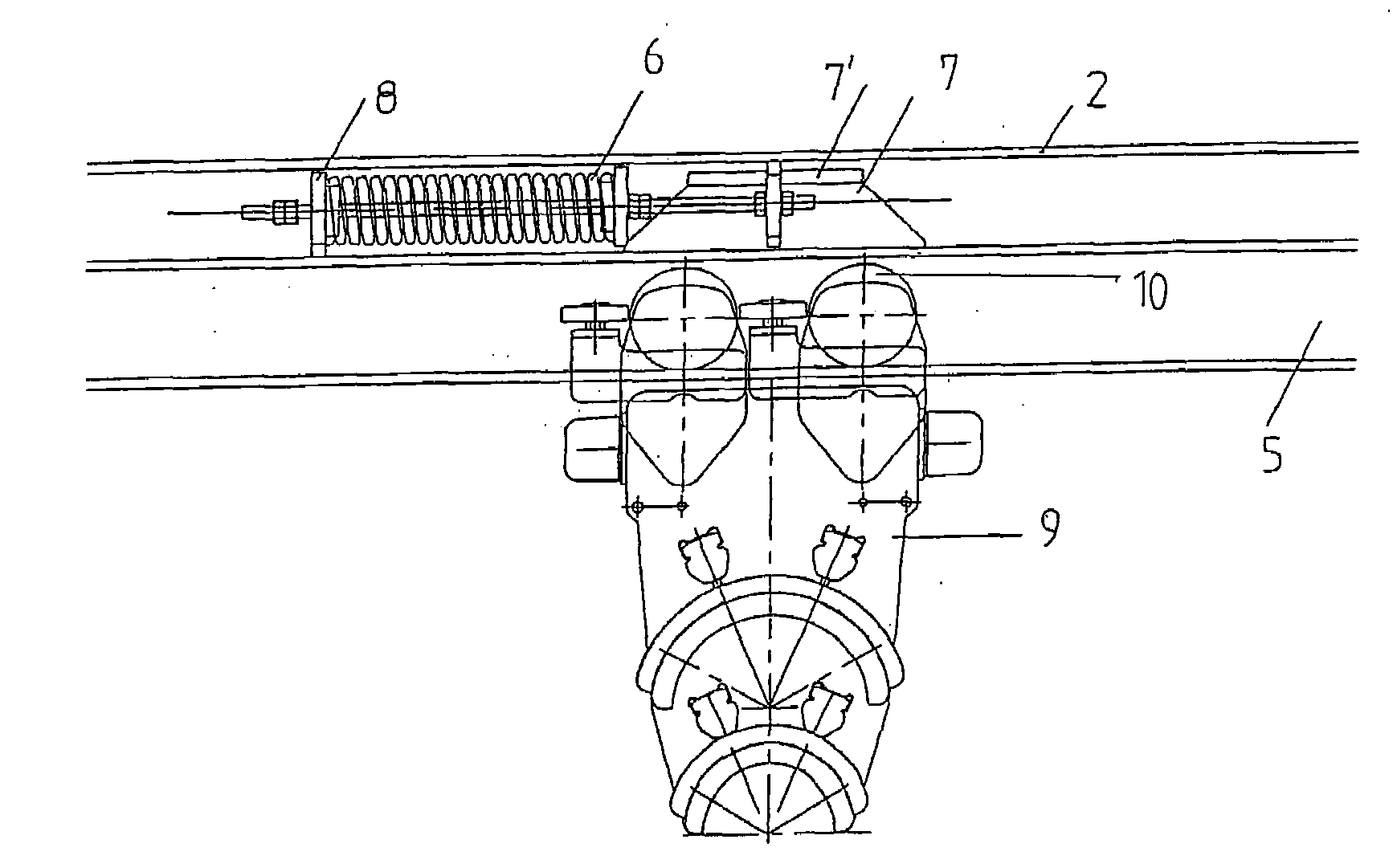

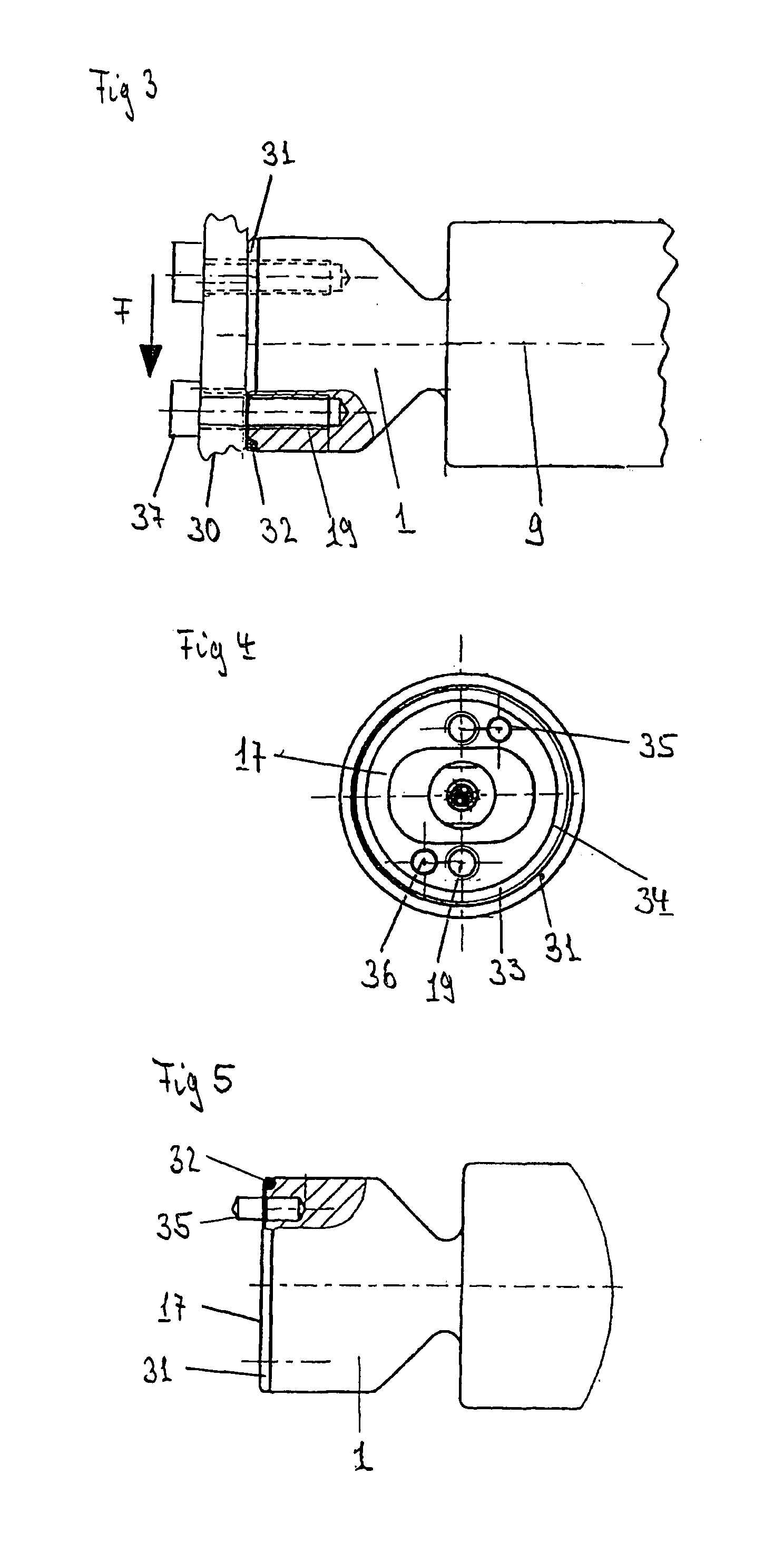

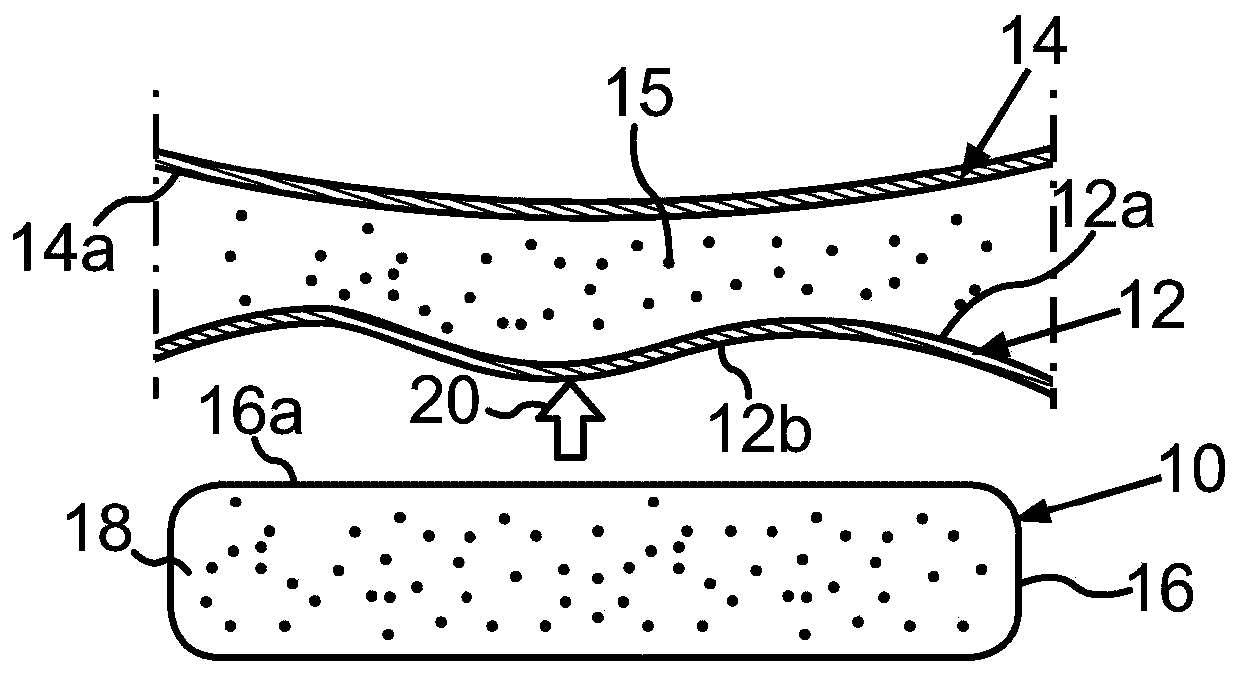

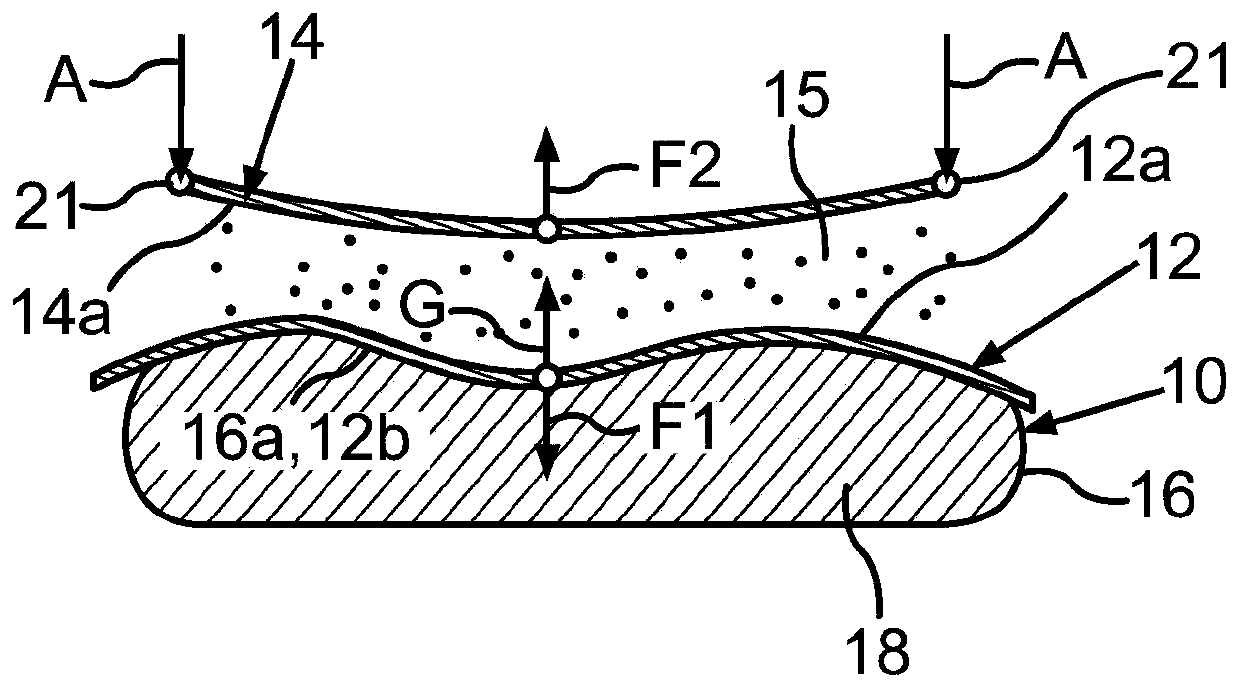

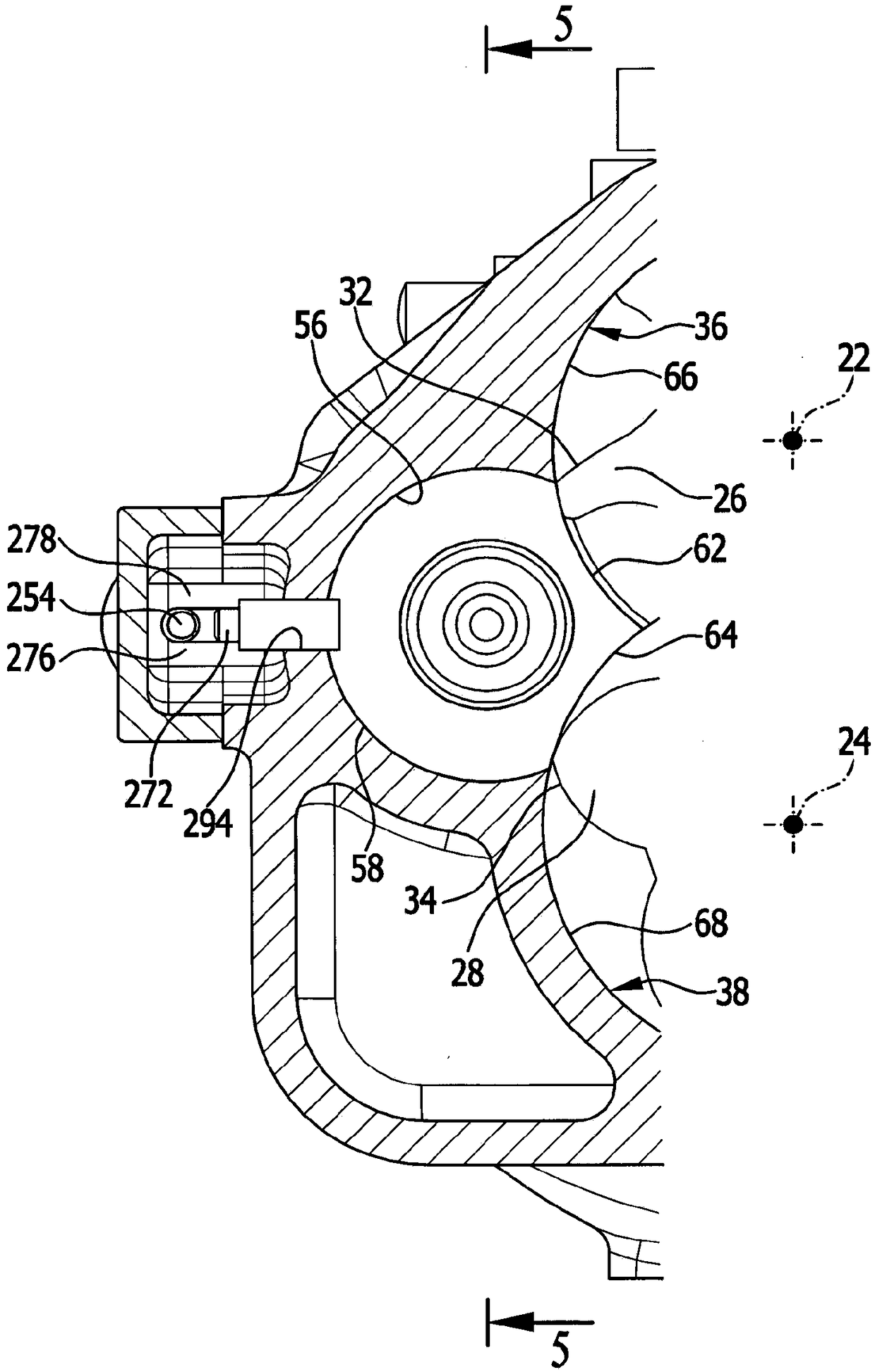

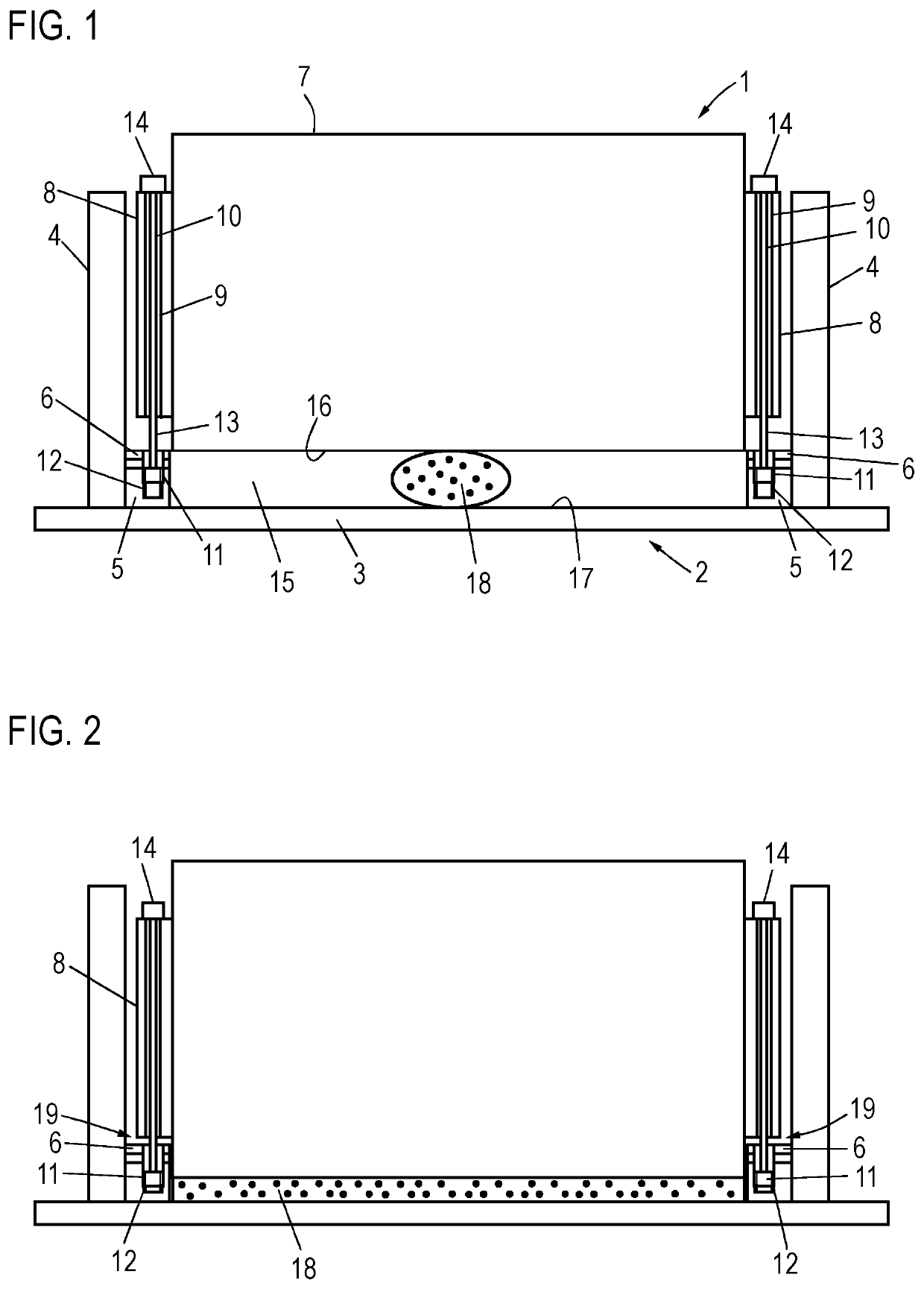

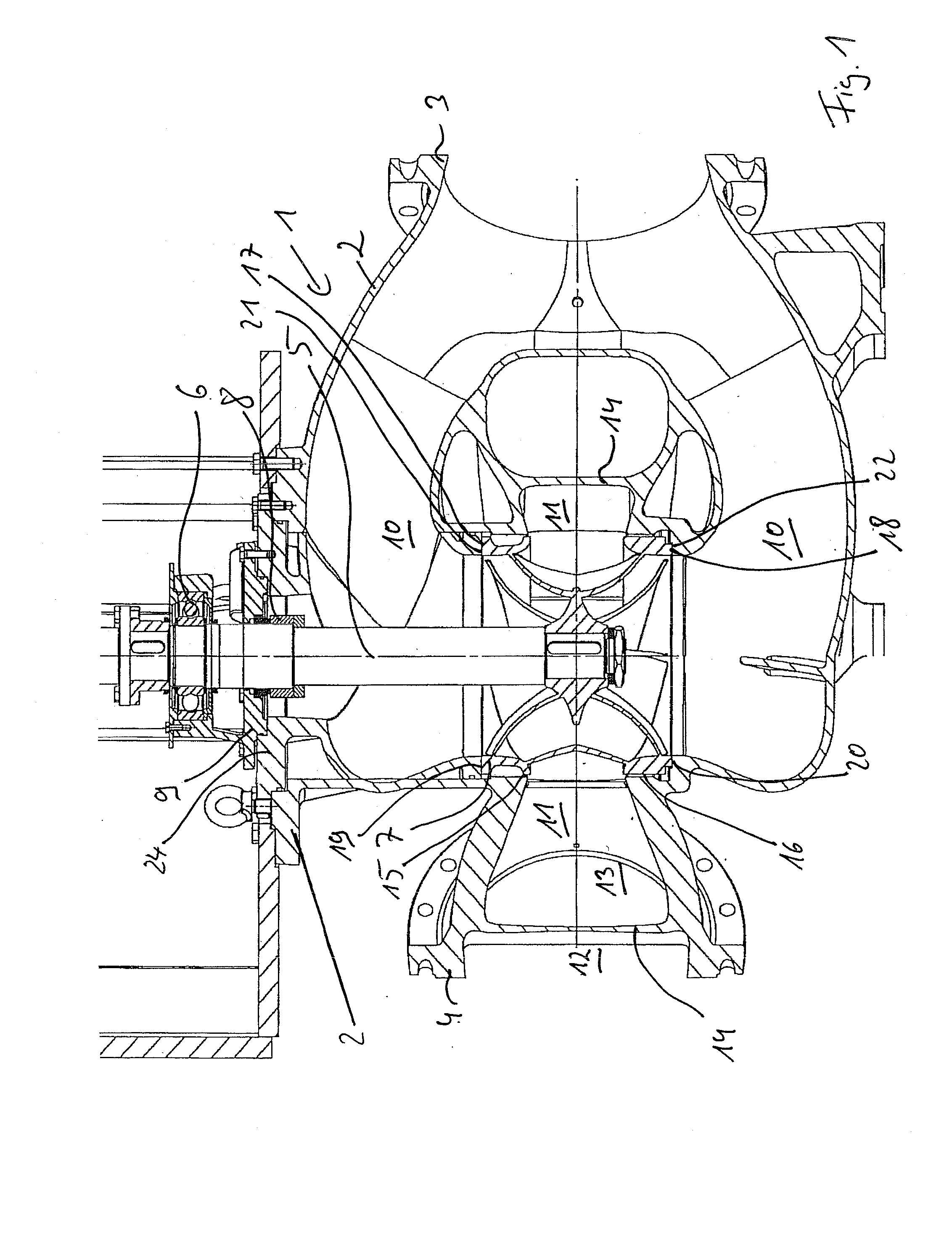

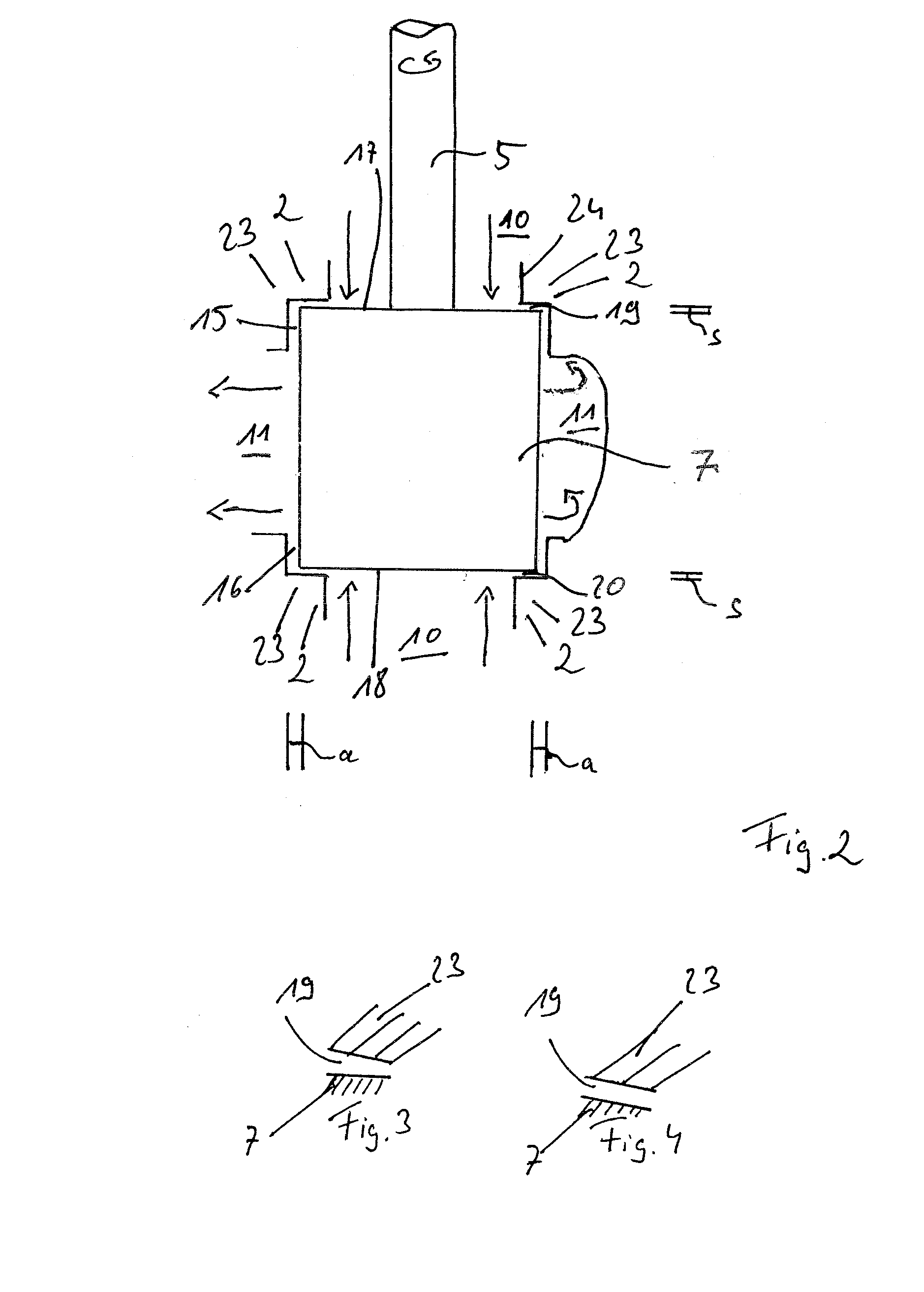

Dry-running piston rod sealing arrangement, and method for sealing a piston rod using one such arrangement

ActiveUS7815193B2Small gap widthVariable positionSleeve/socket jointsEngine sealsEngineeringActuator

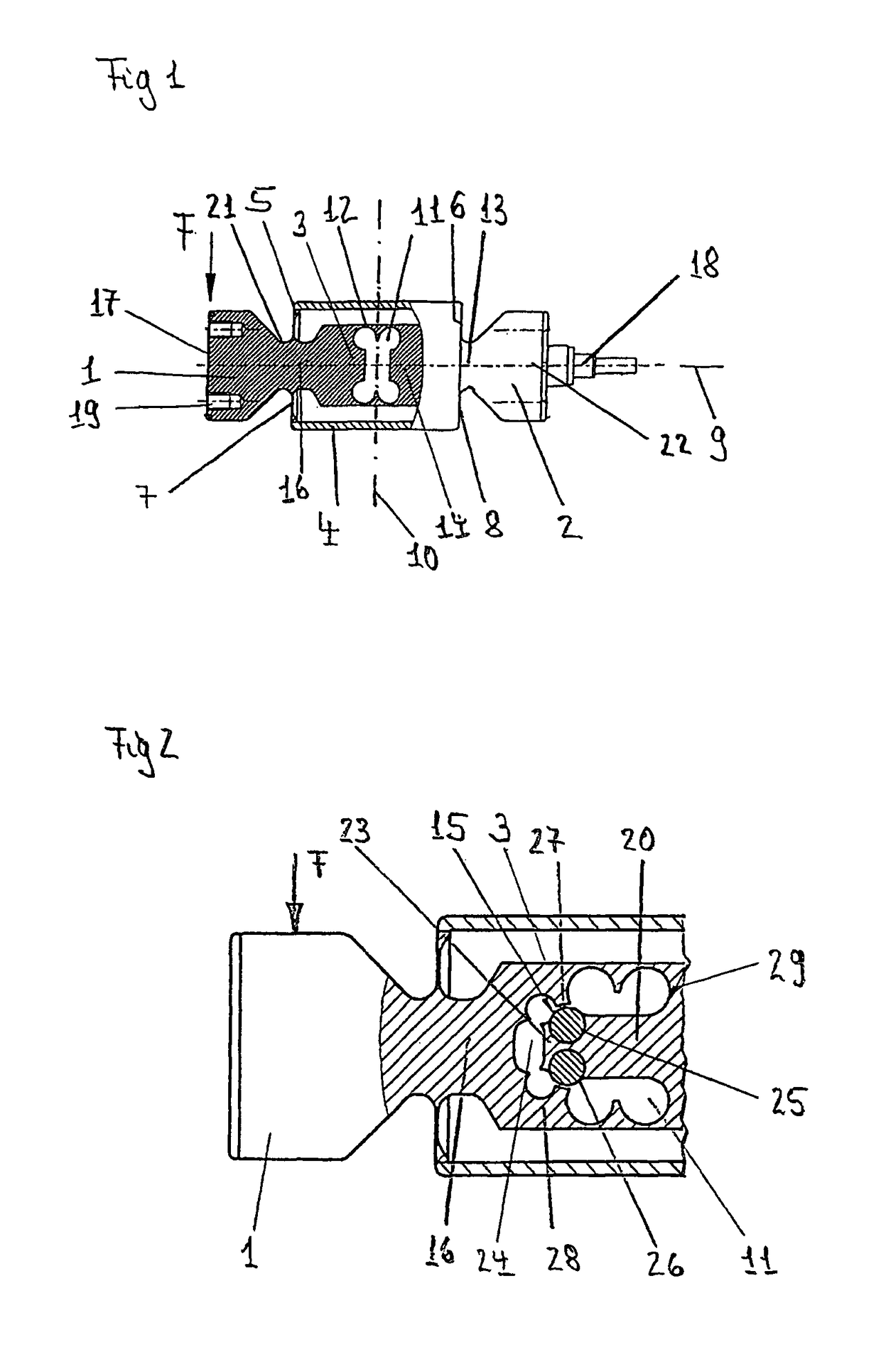

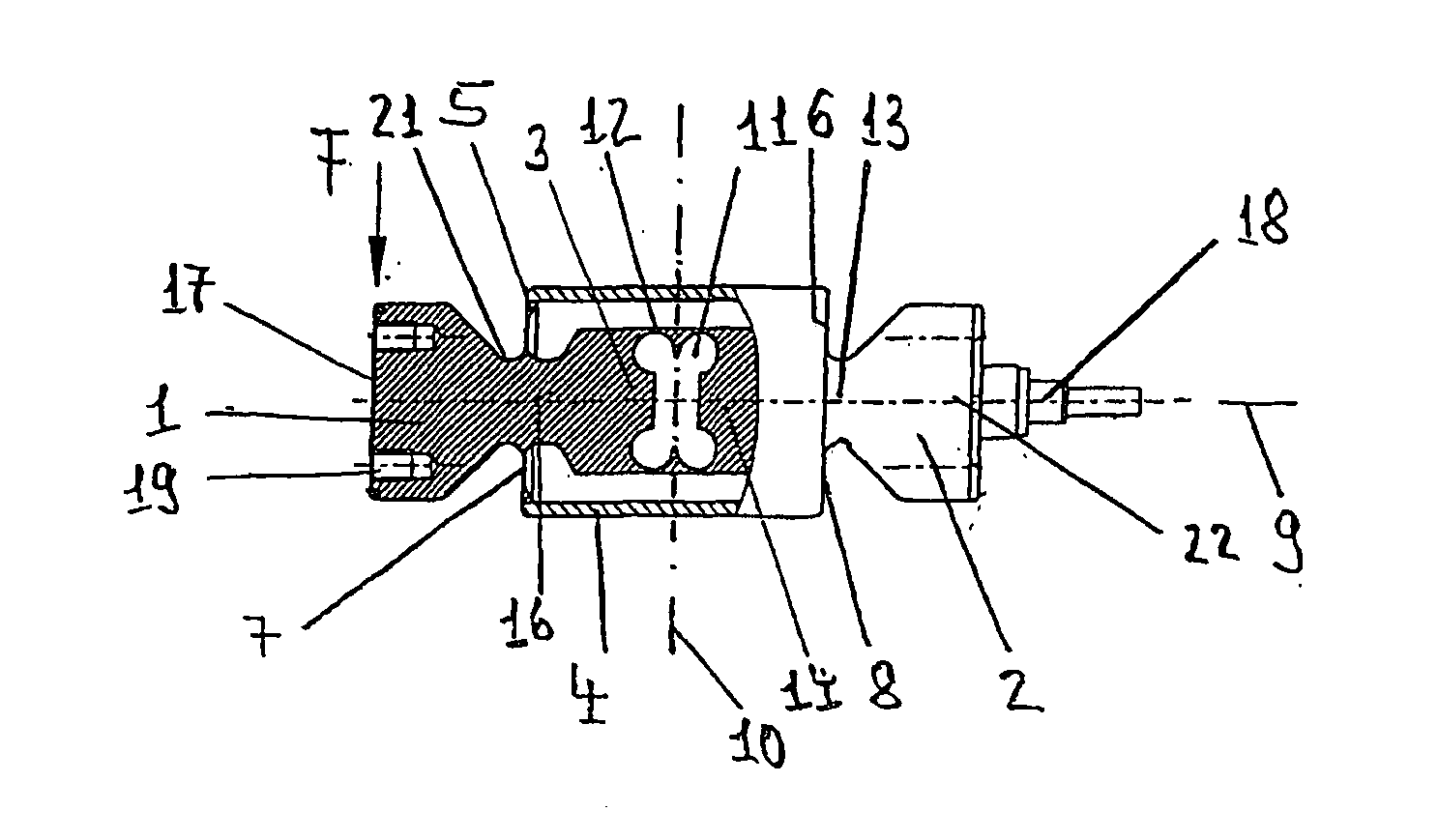

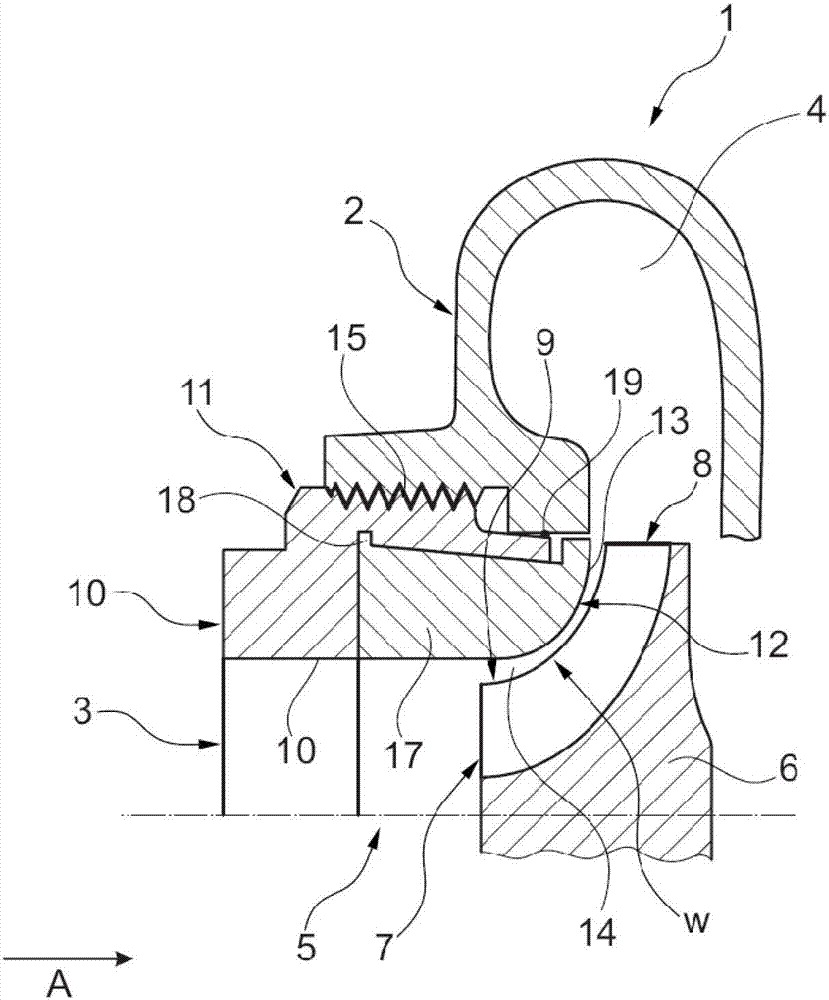

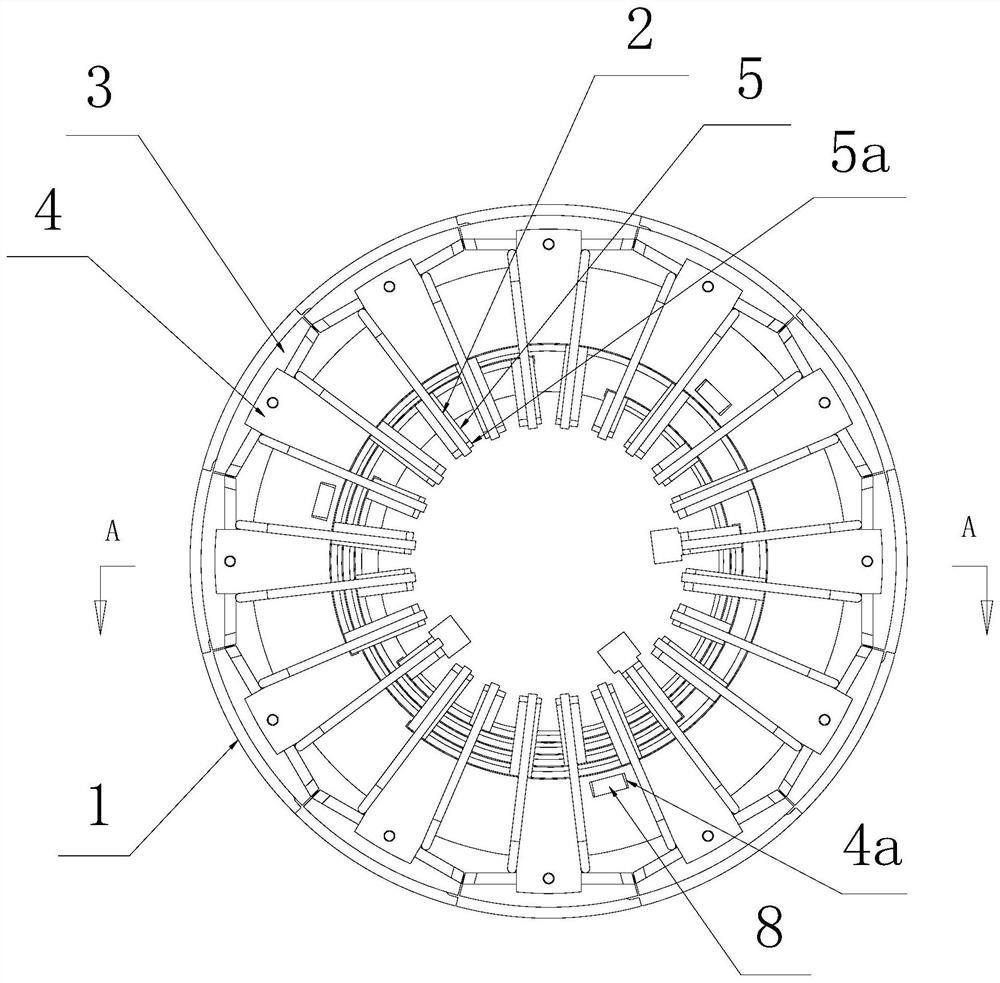

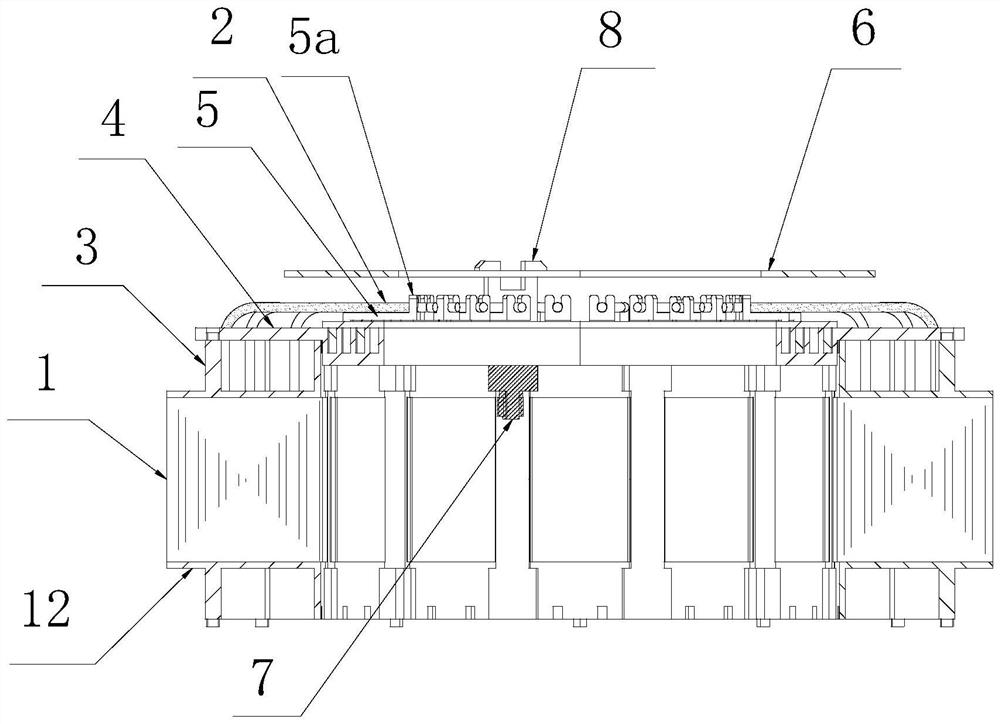

The invention relates to a dry-running piston rod sealing arrangement (1) for sealing a piston rod (2) mounted in a longitudinally displaceable manner. The sealing arrangement comprises at least one sealing ring (5) having a sealing surface (5a), an actuator (7), a sensor (8), and a chamber ring (3) containing the sealing ring (5). The actuator (7) comprises an active connection in relation to the sealing ring (5), such that the sealing surface (5a) can be radially displaced in relation to the piston rod (2). The actuator (7) can be controlled according to a measuring value detected by the sensor (8).

Owner:BURCKHARDT COMPRESSION AG

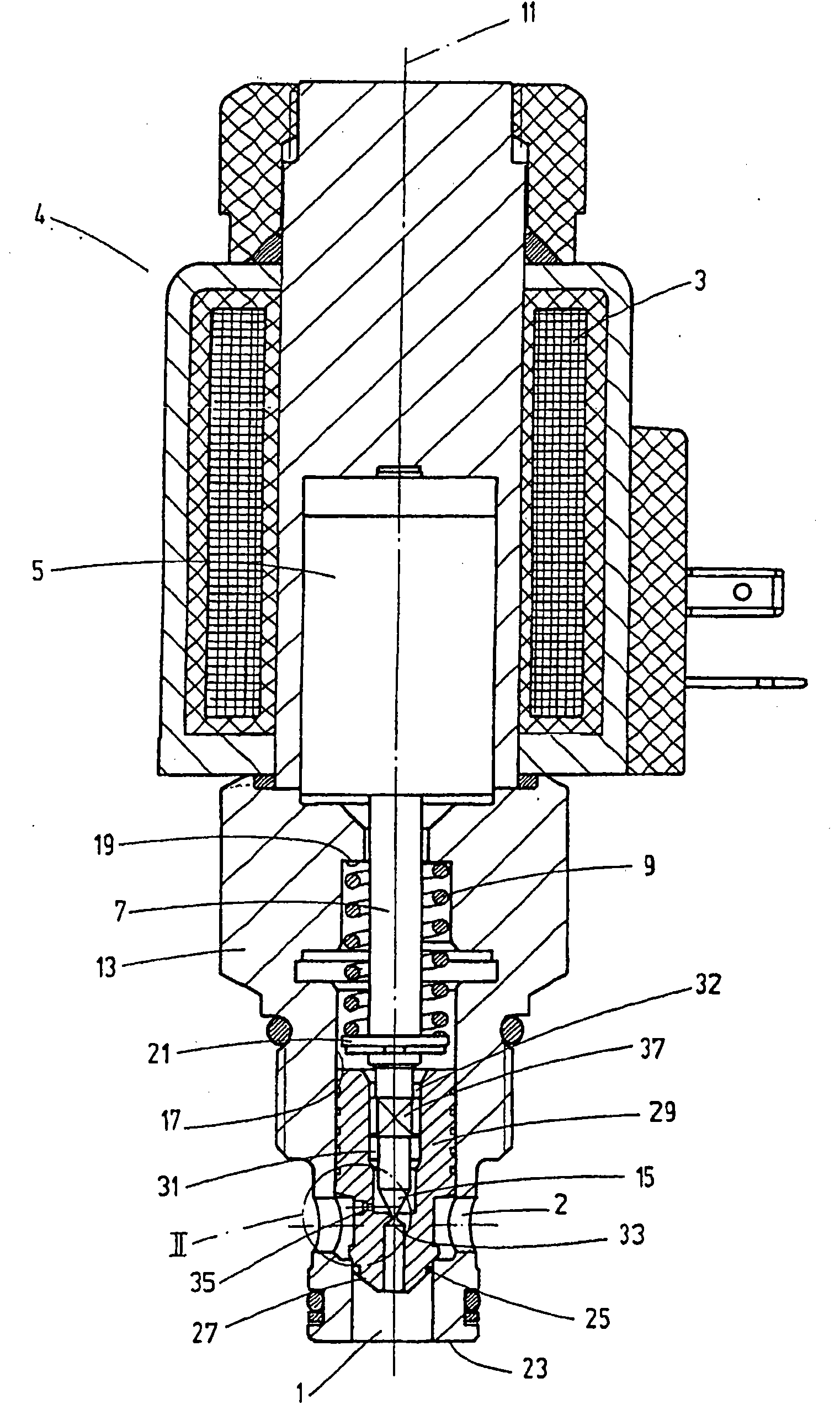

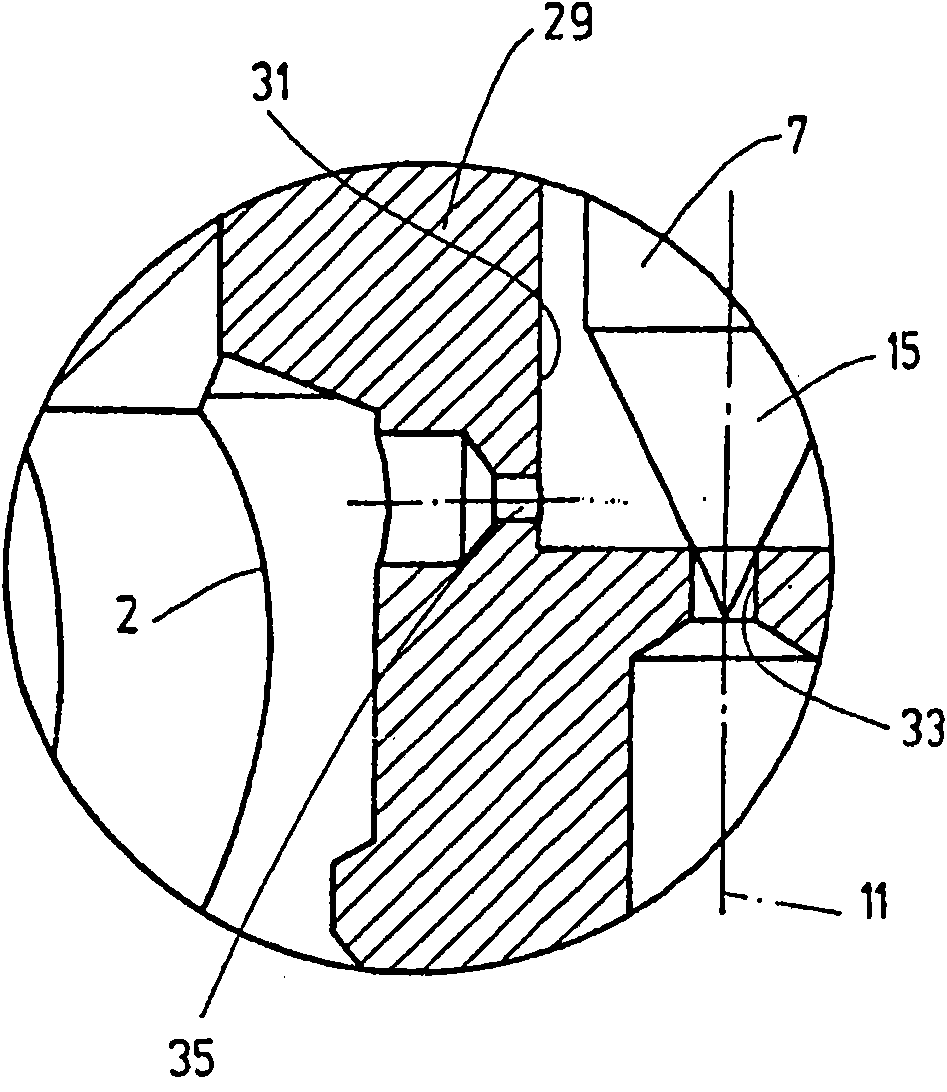

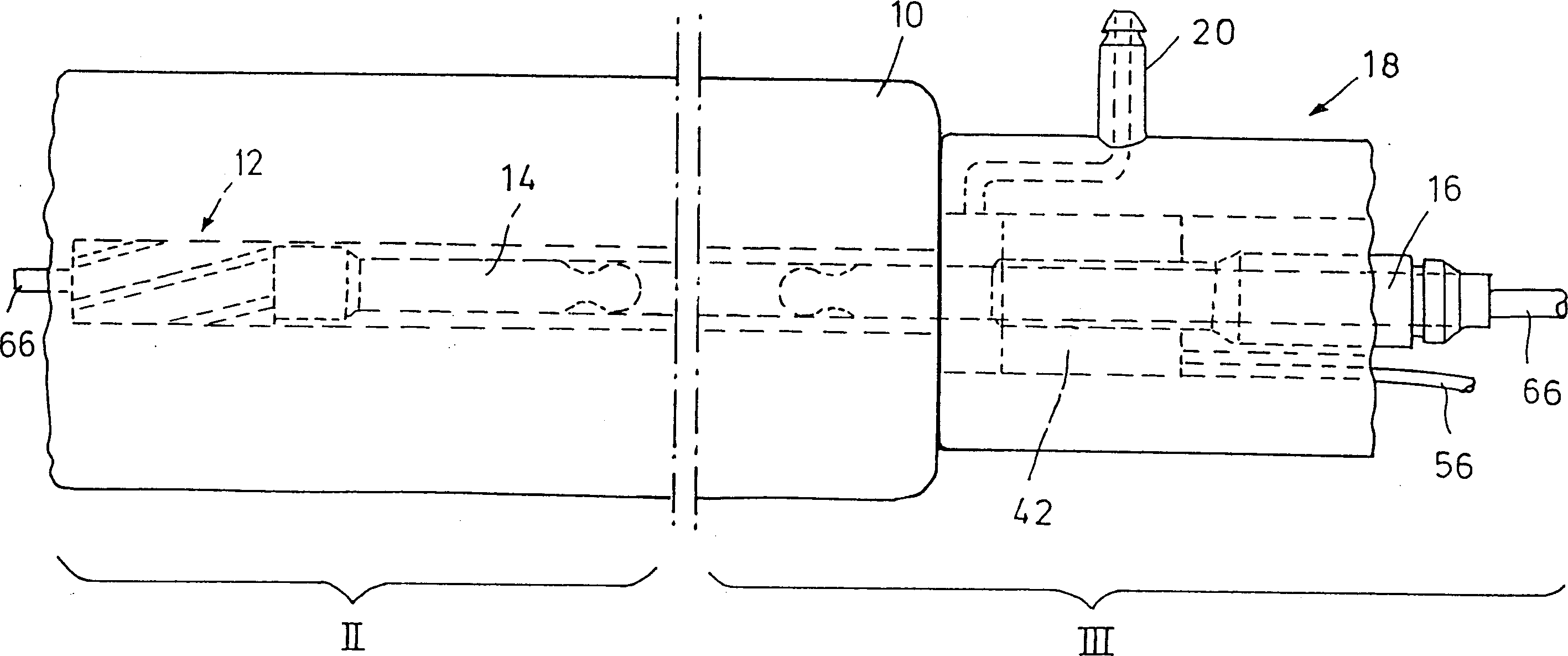

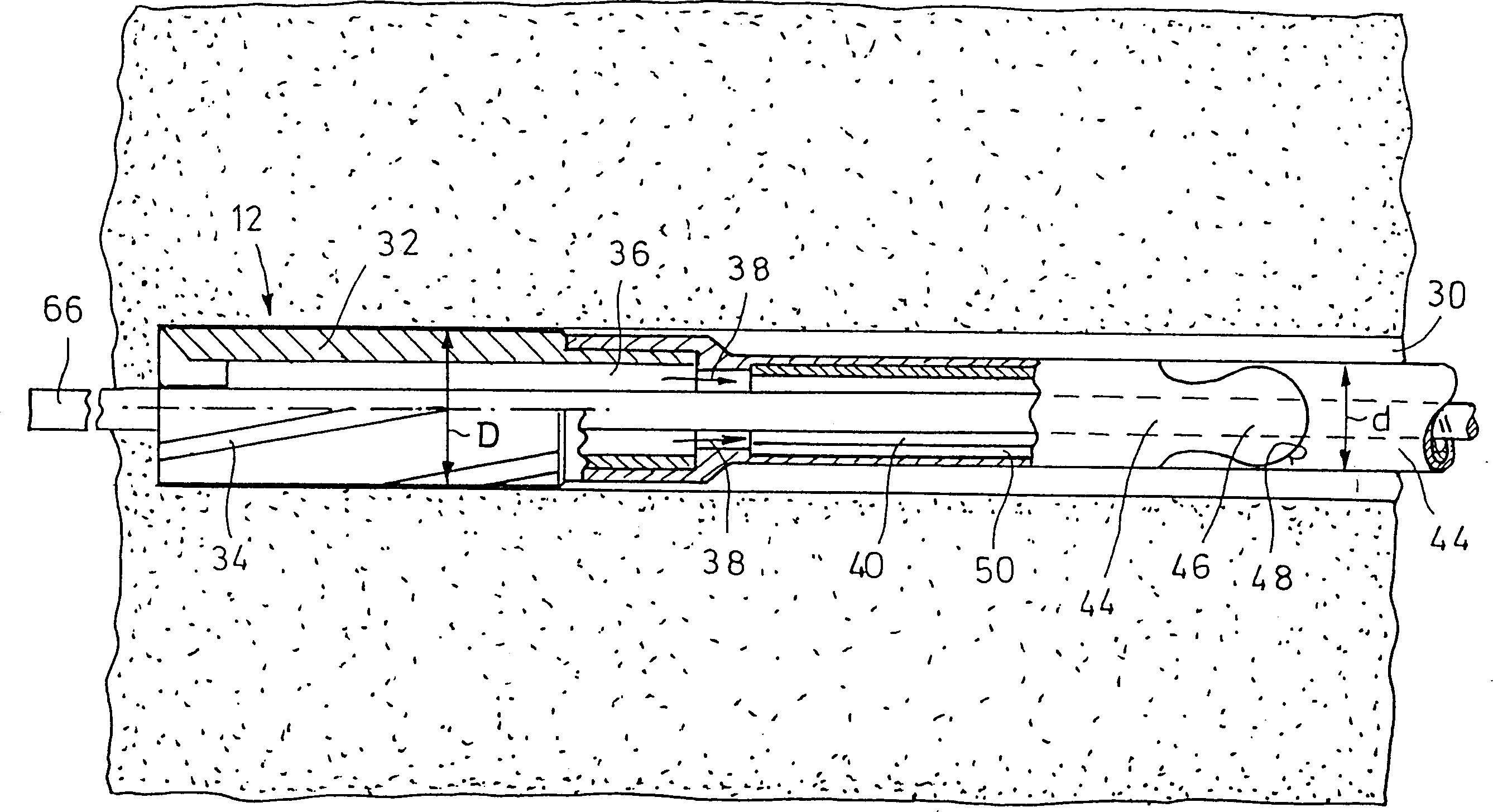

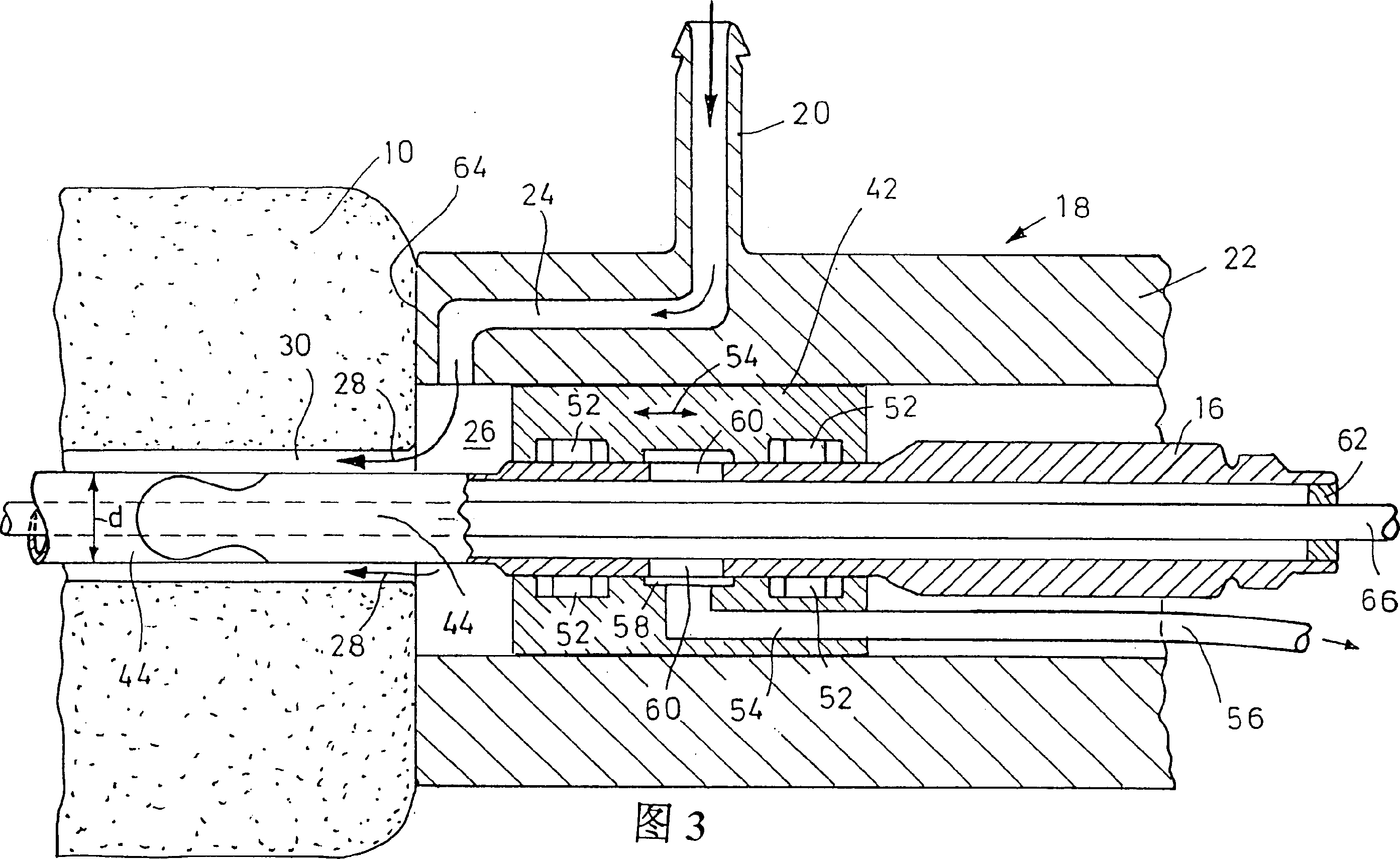

Piloted valve, particularly proportional throttle valve

InactiveCN101925768AAvoid contamination riskPilot control volume flow reductionOperating means/releasing devices for valvesThin material handlingMarine engineeringControl valves

Owner:HYDAC FLUITECHNIK GMBH

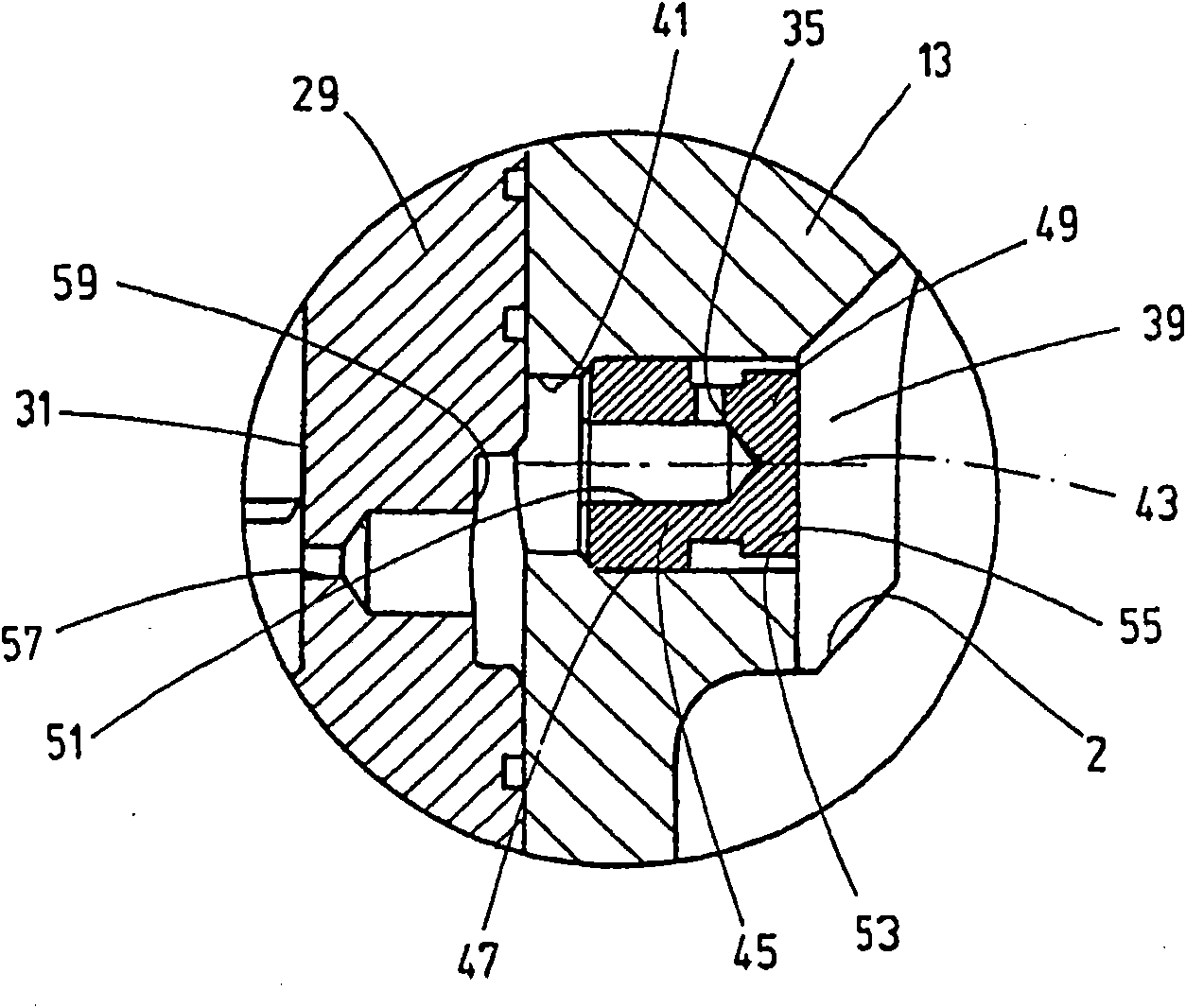

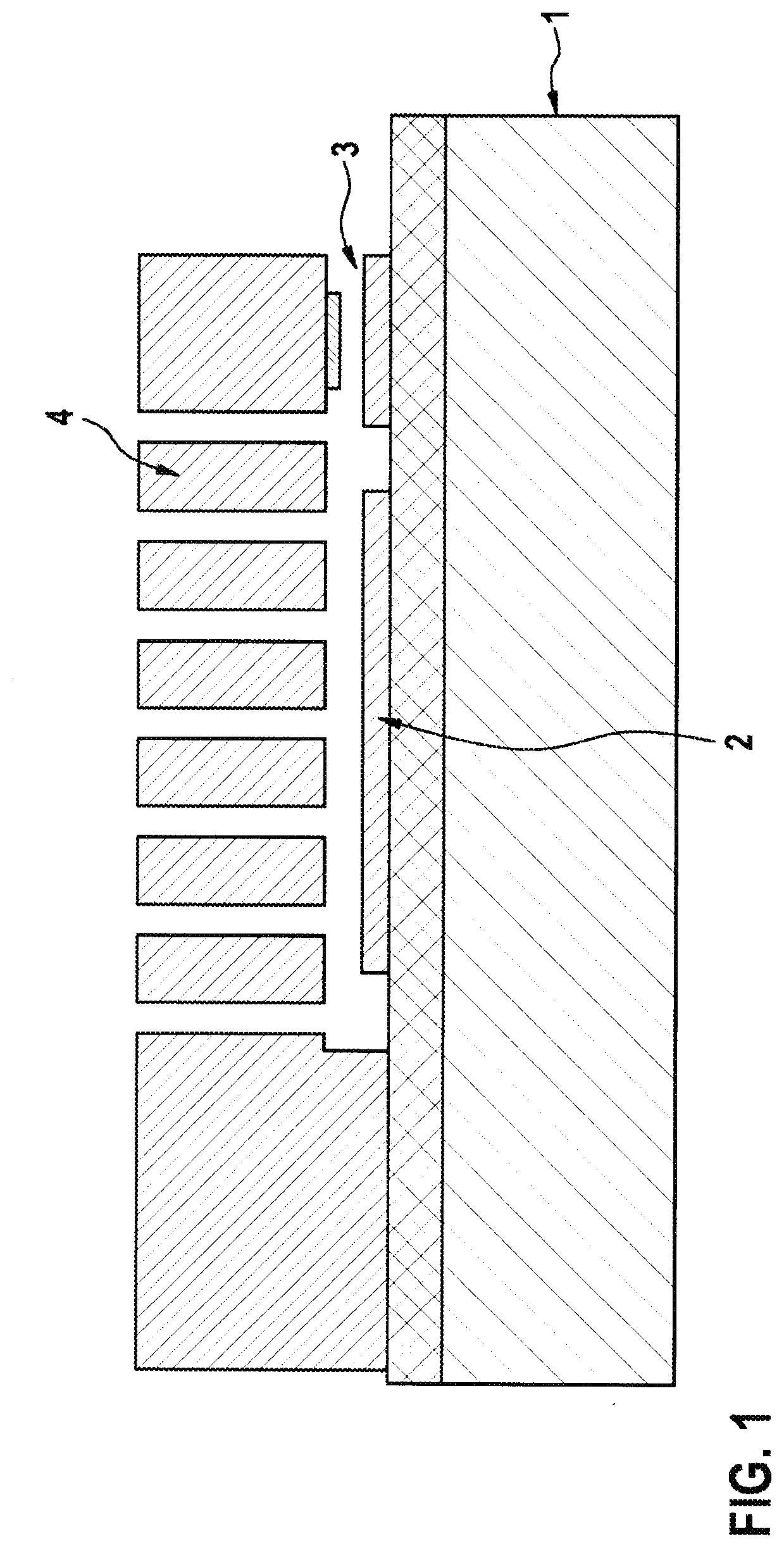

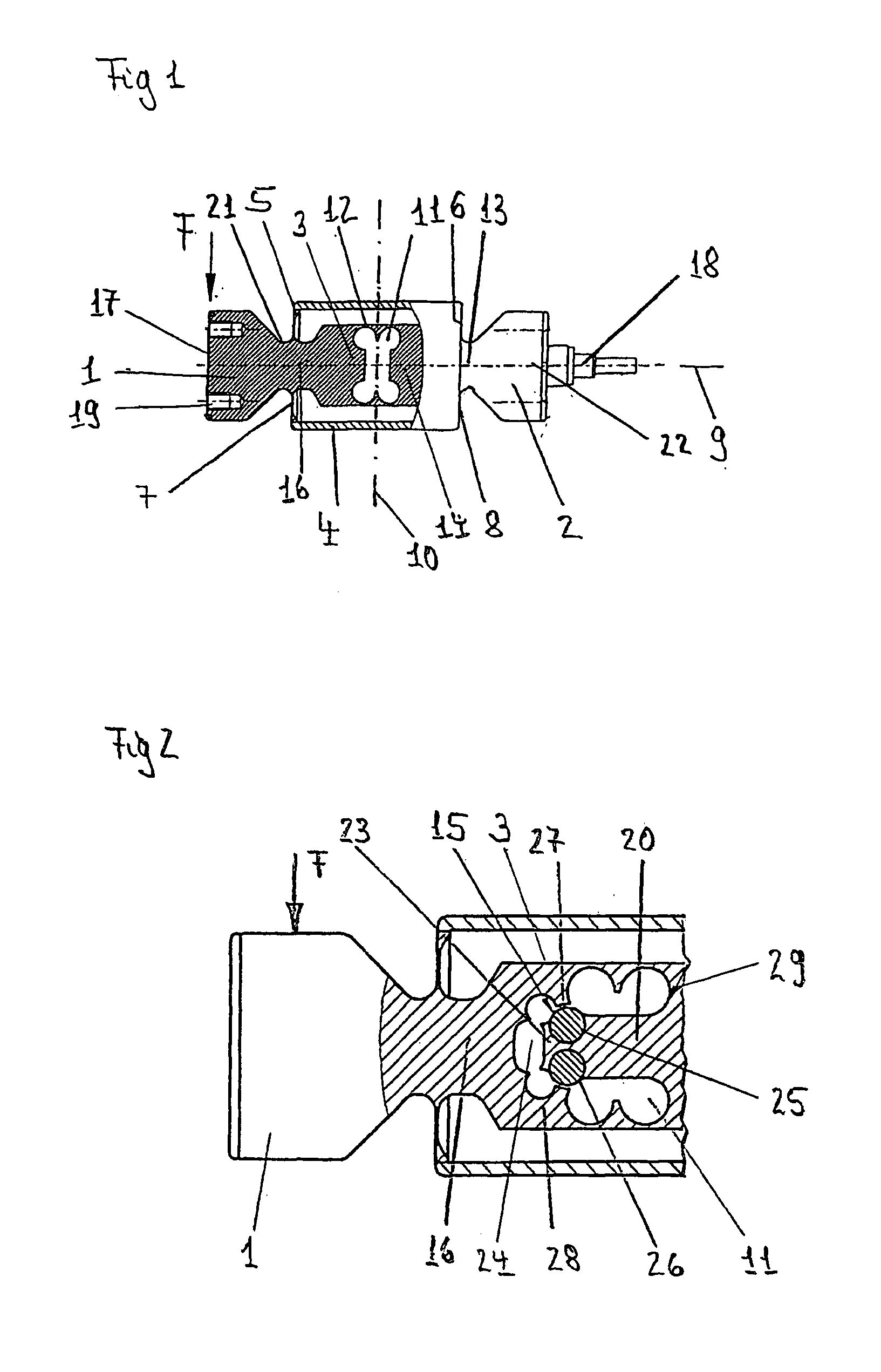

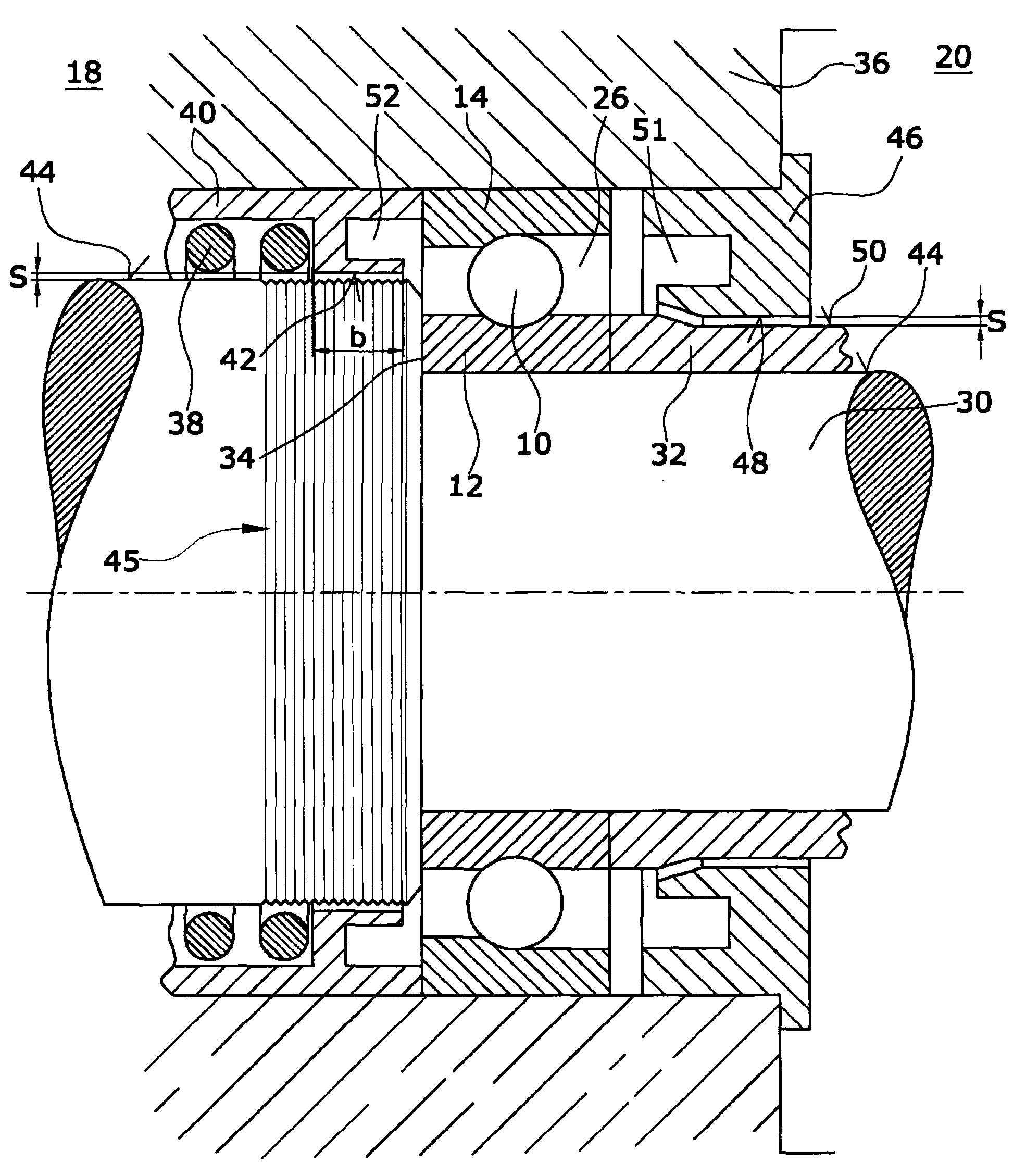

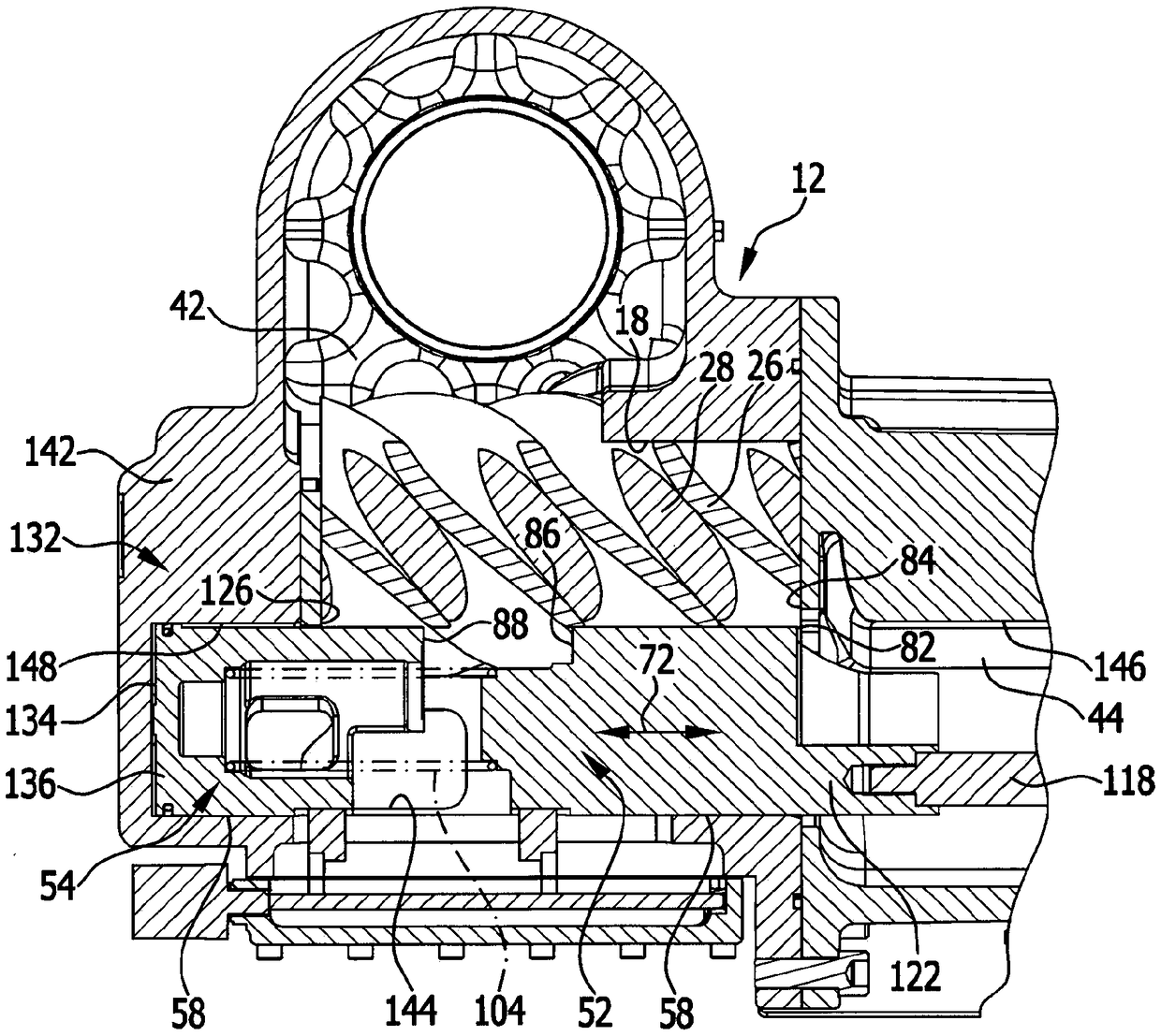

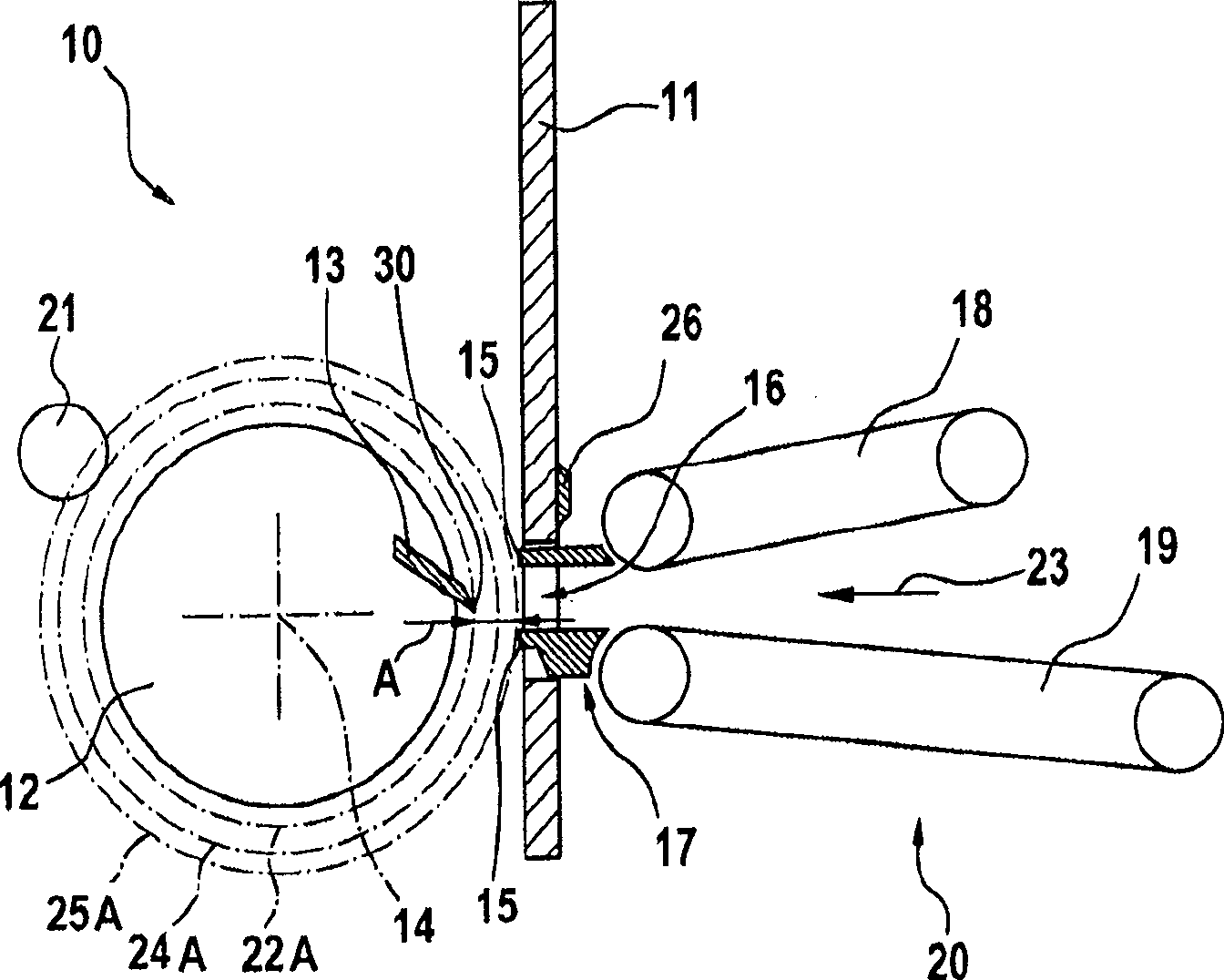

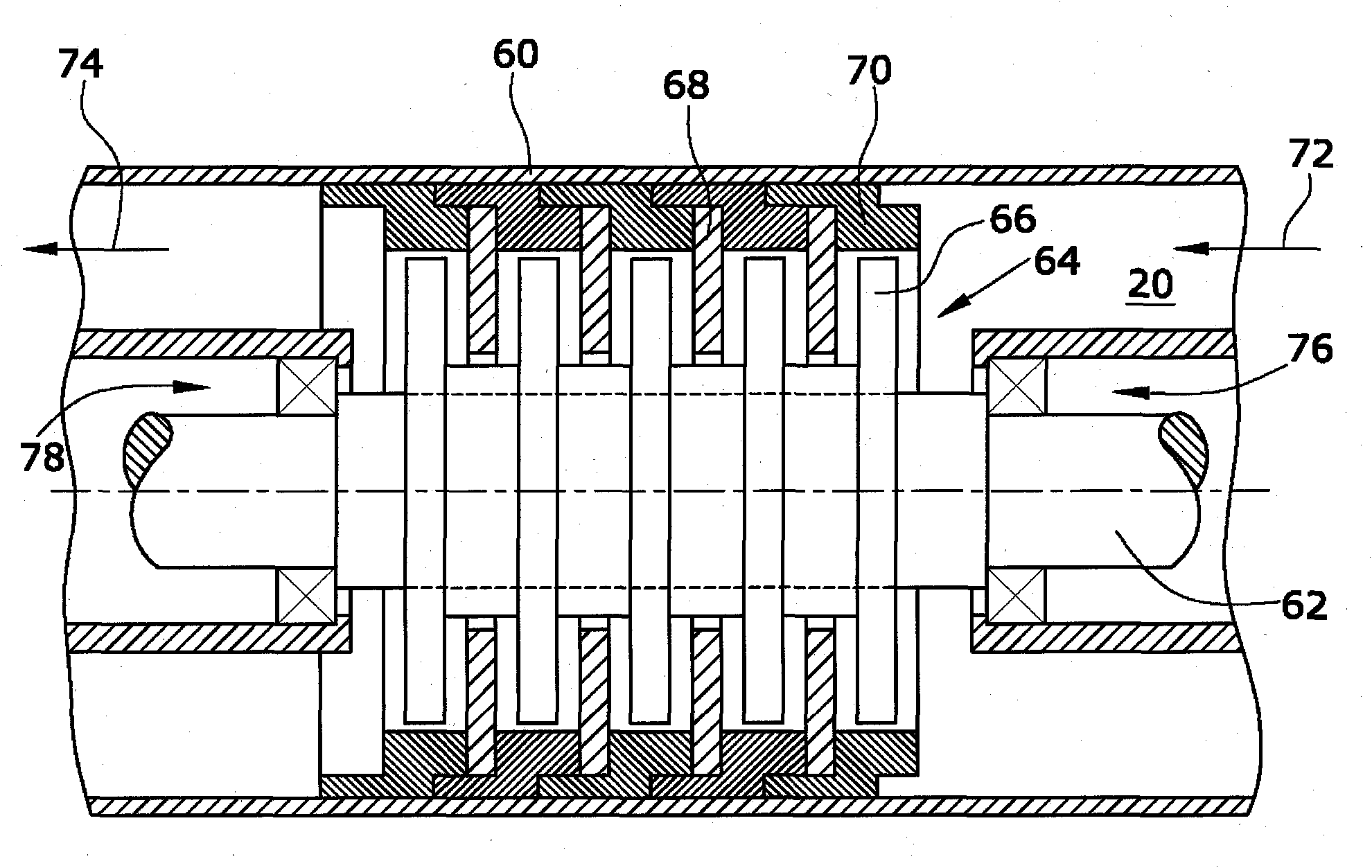

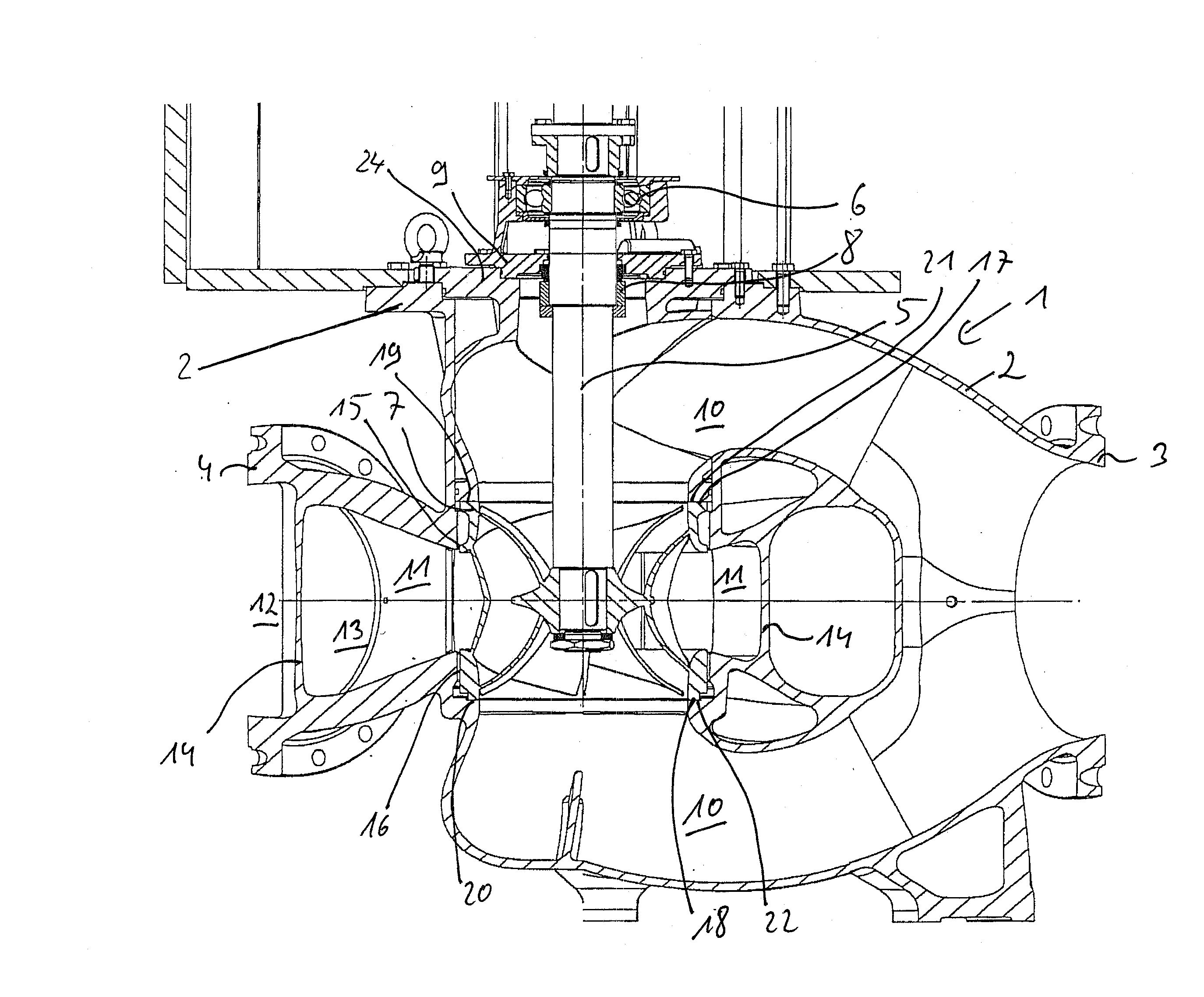

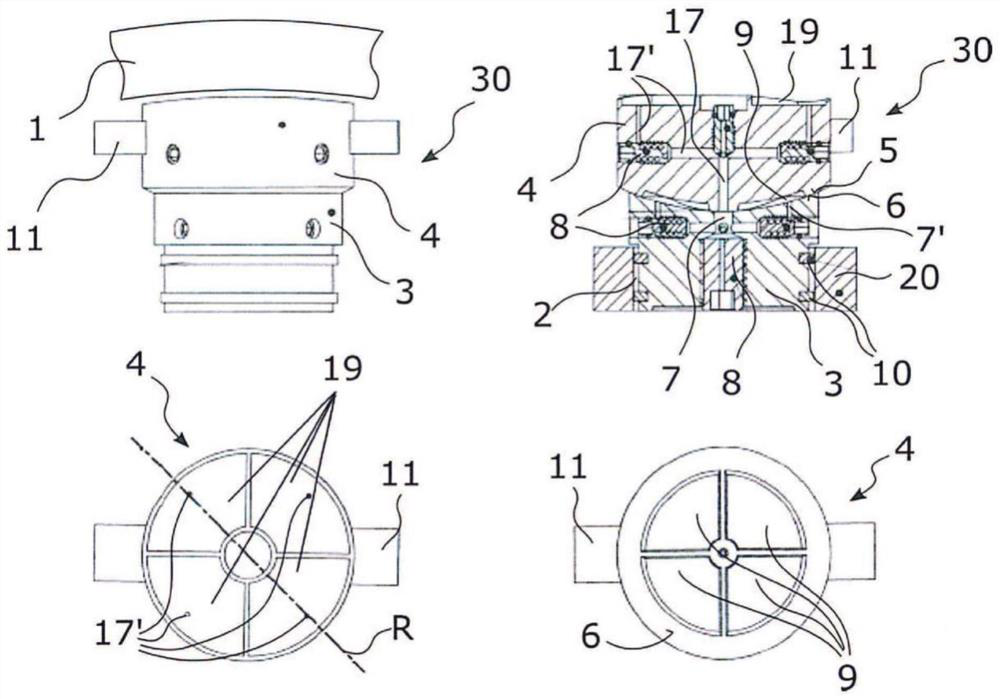

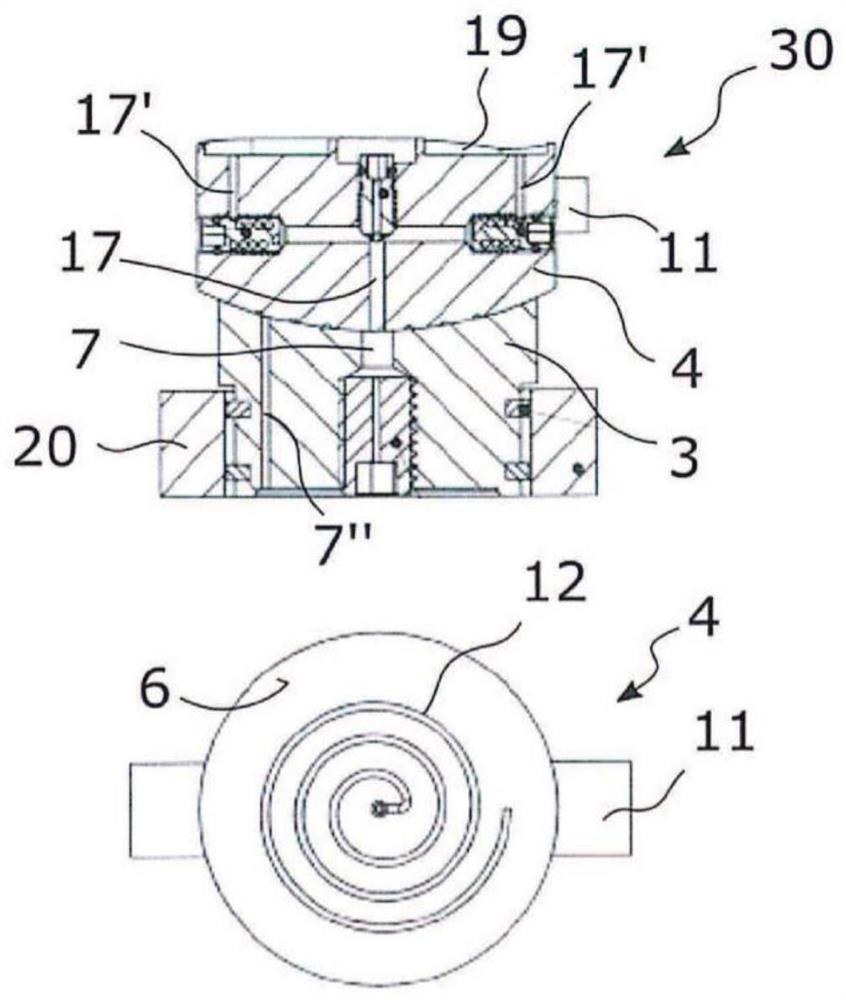

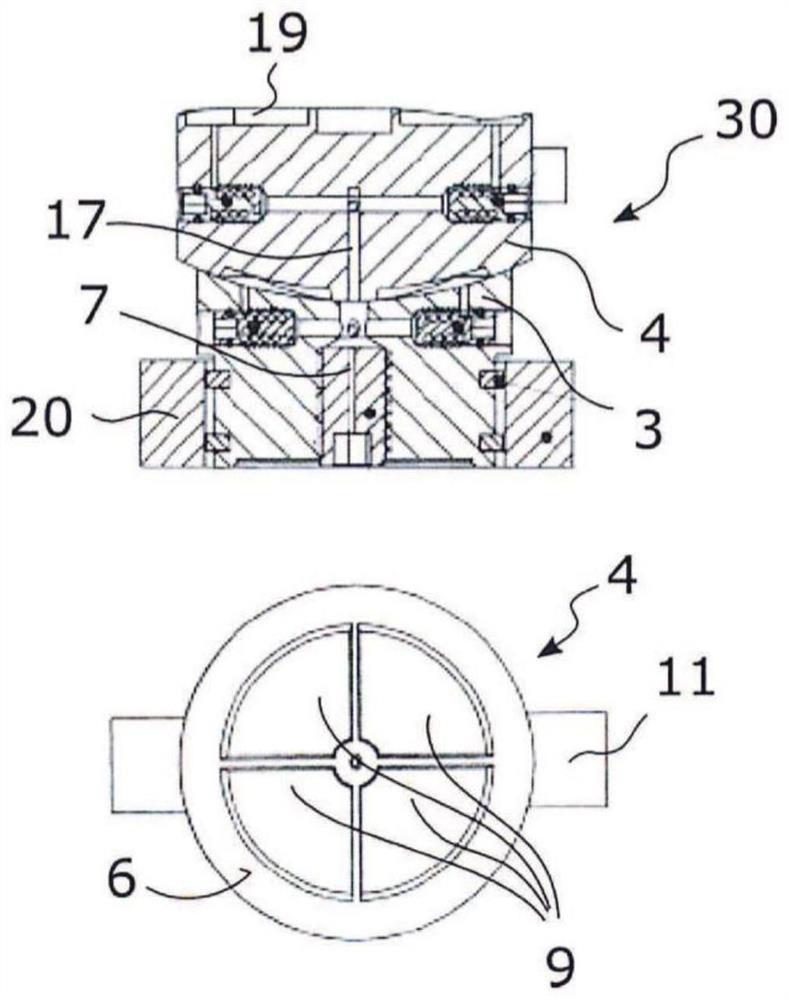

Centrifugal compressor for an exhaust gas turbocharger

ActiveCN103671265AIncrease air flow rateSmall gap widthPump componentsEngine fuctionsInlet channelTurbocharger

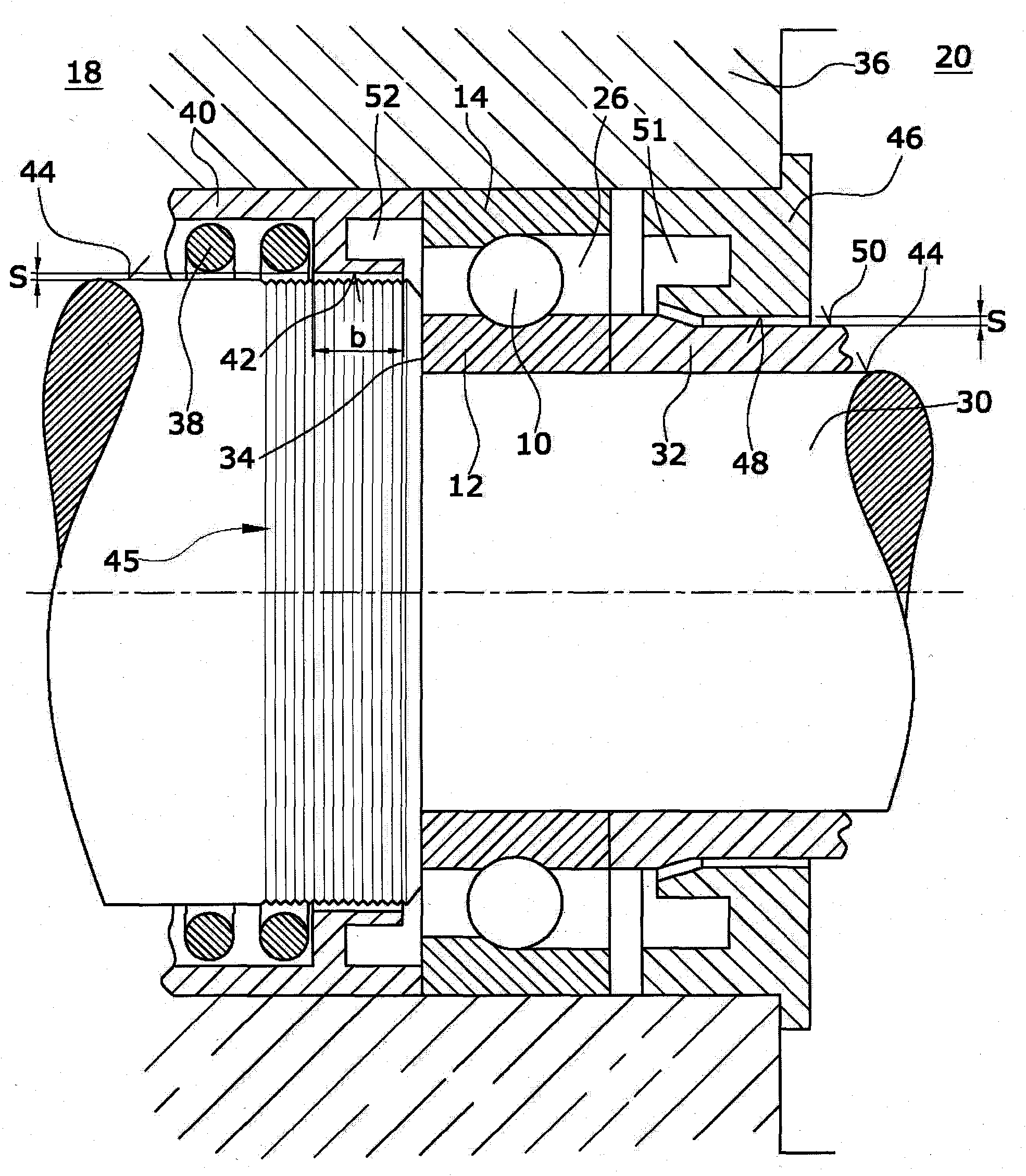

The invention relates to a centrifugal compressor (1) for an exhaust gas turbocharger, in particular an internal combustion engine. The centrifugal compressor has a compressor housing (2) comprising an axial inlet channel (3) and a centrifugal outlet channel (4); with a compressor impeller (6) for circulating and compressing a gas, wherein the compressor impeller (6) has an axial inlet side (7) facing towards an inlet passage (3), a centrifugal outlet side (8) facing an outlet channel (4), and an axial wheel surface contour (9) extending from the inlet side (7) extends up to the outlet side (8); a substantially sleeve-like adapter element (10) which may be axially inserted into an attachment portion (11) disposed at the compressor housing (2); wherein the adapter element (10) comprises, at least in sections, a surface contour (13) which is attached to the axial wheel surface contour (9), such that a gap width (W) between the adapter element (10) and the compressor impeller (6) can be adjusted along mutually facing surface contours (9, 13) through axial movement of the adapter member (10) in a fastening portion (11).

Owner:BMTS TECH SHANGHAI CO LTD

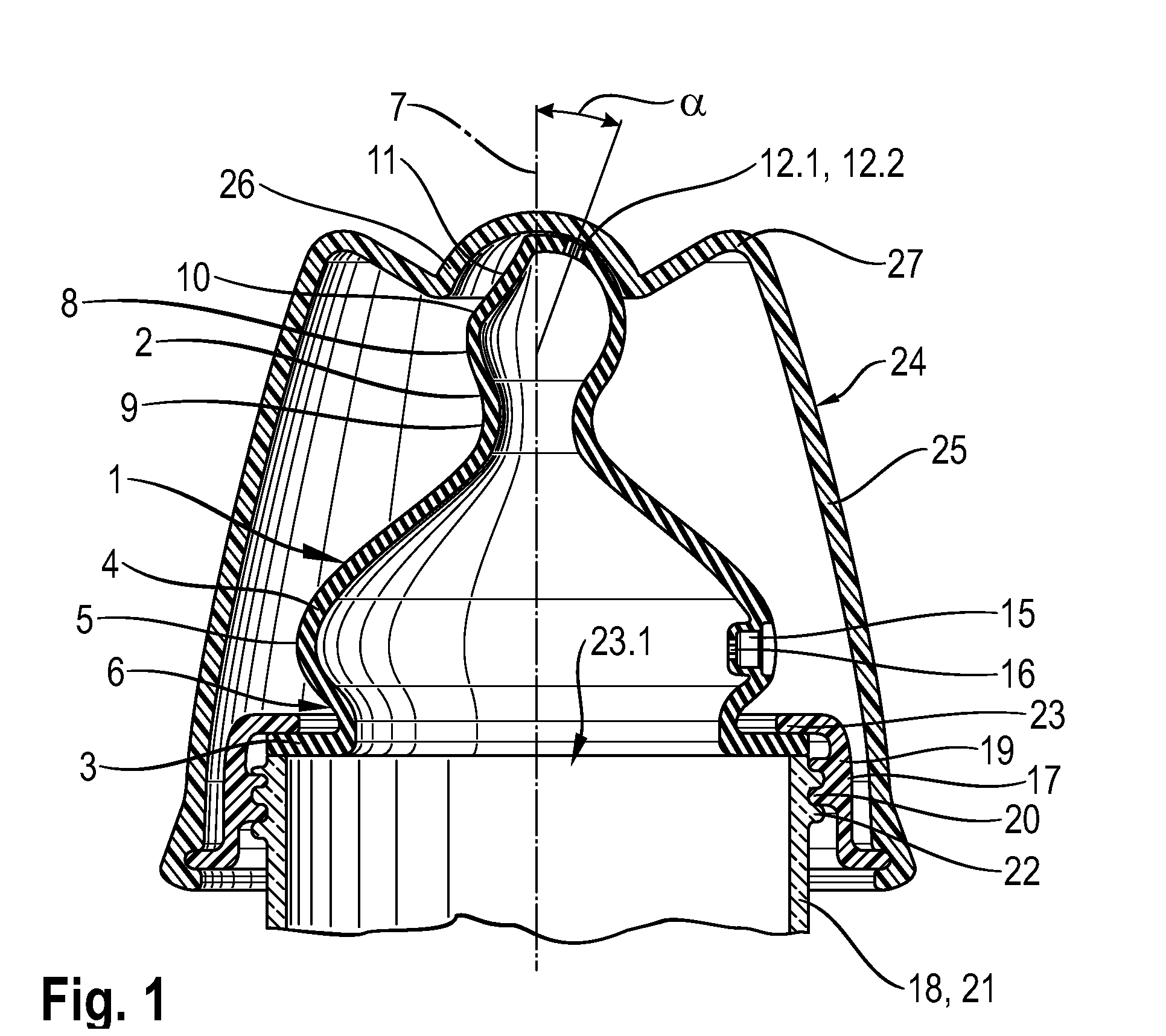

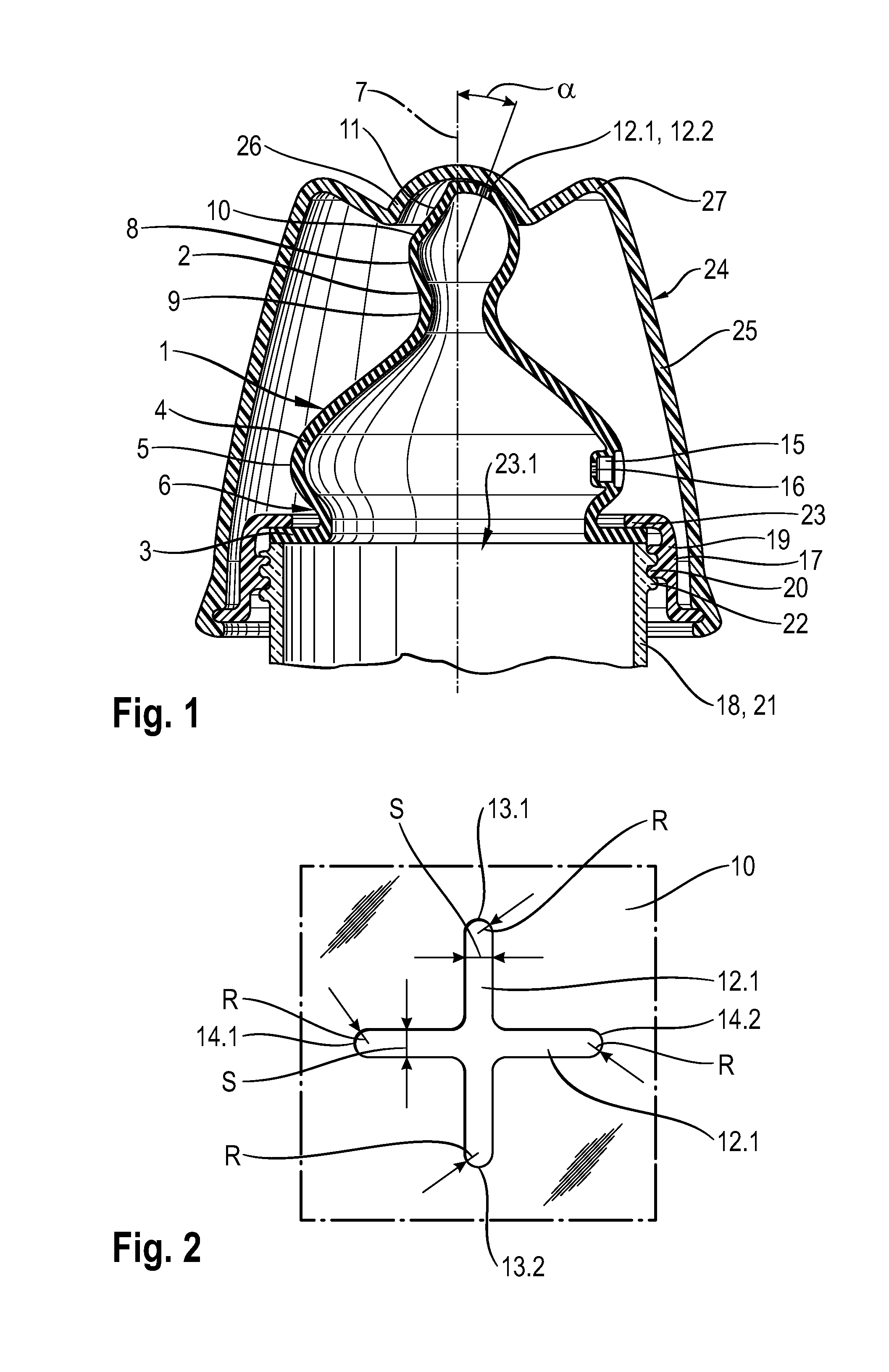

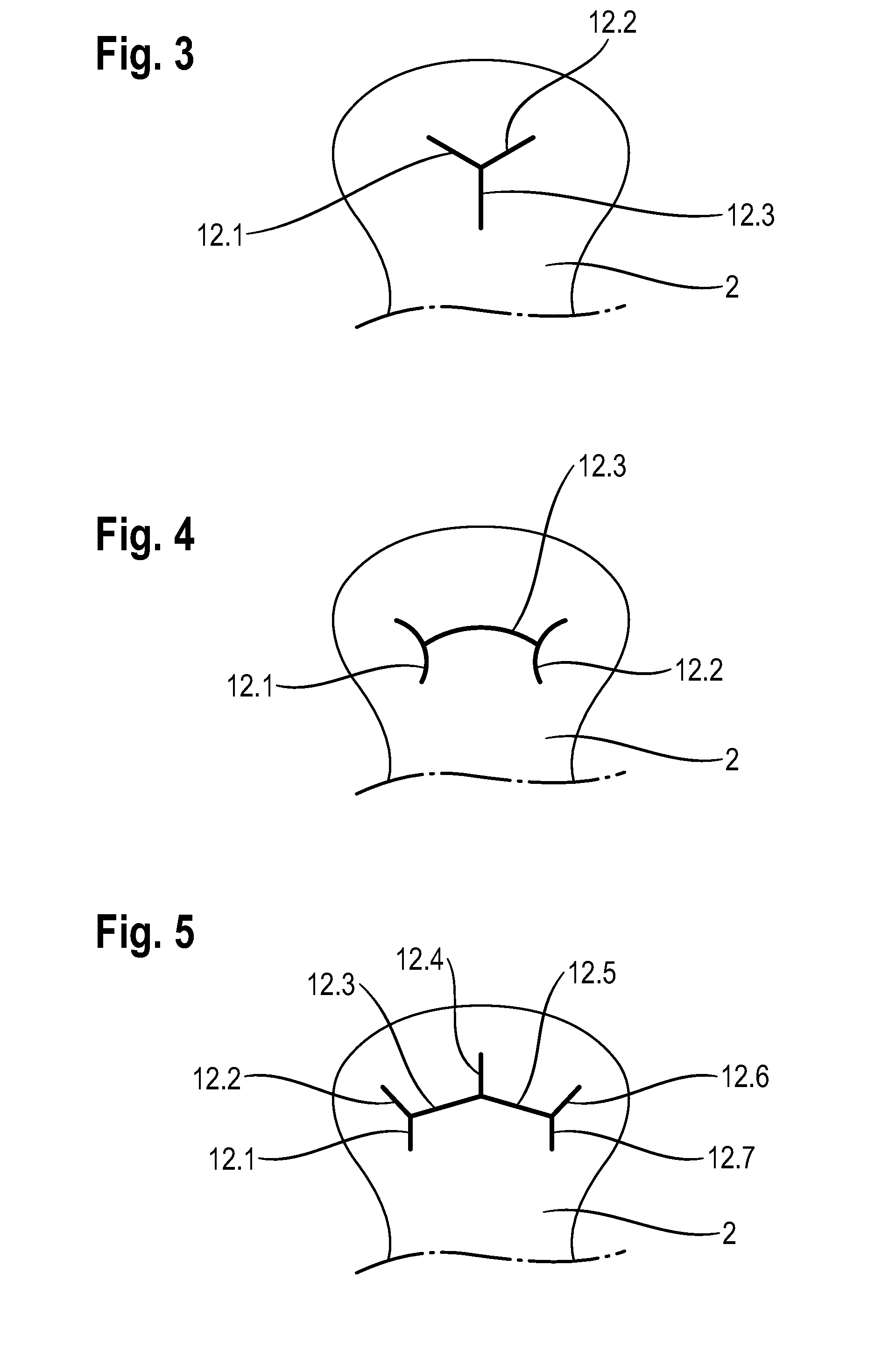

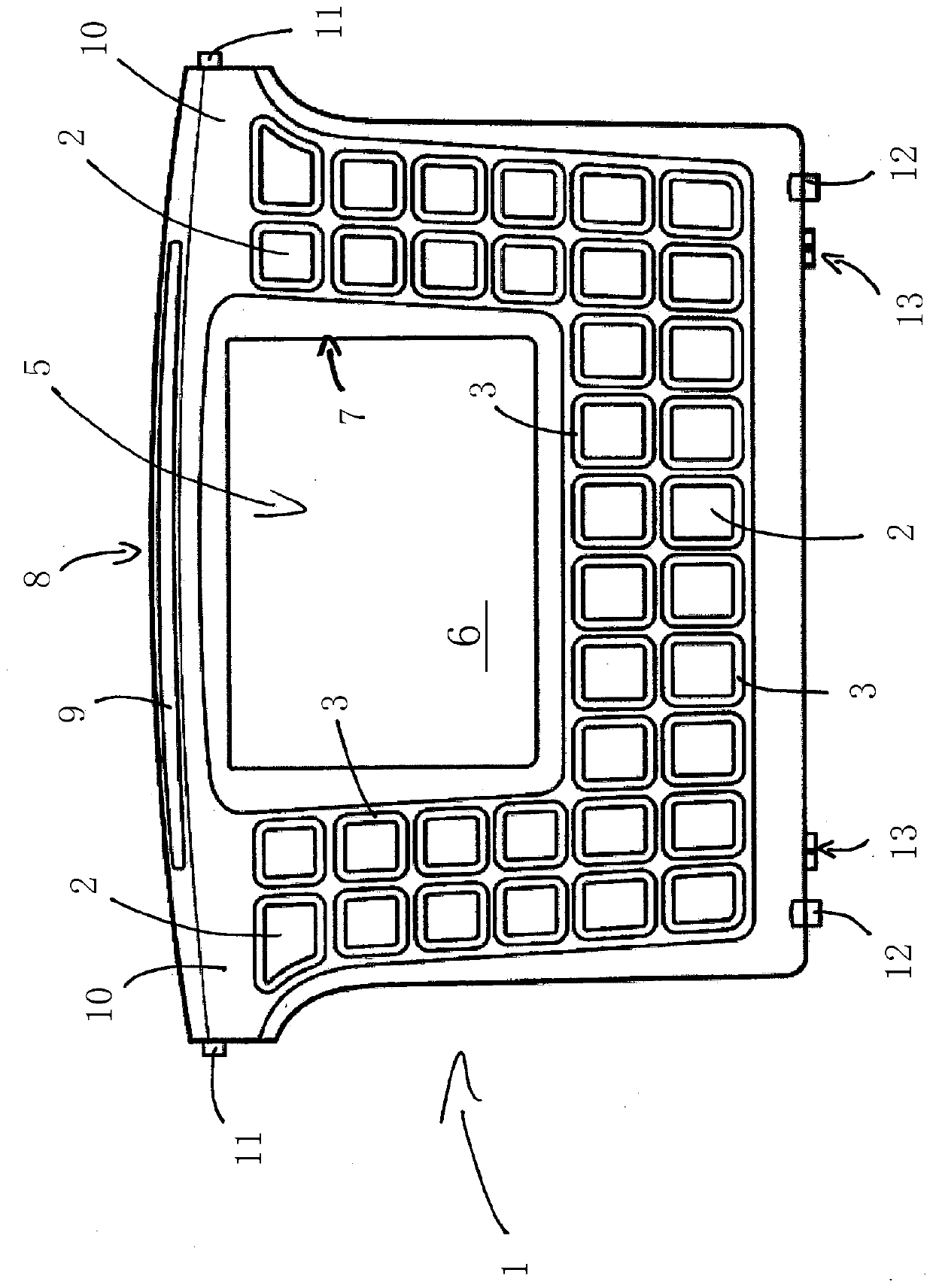

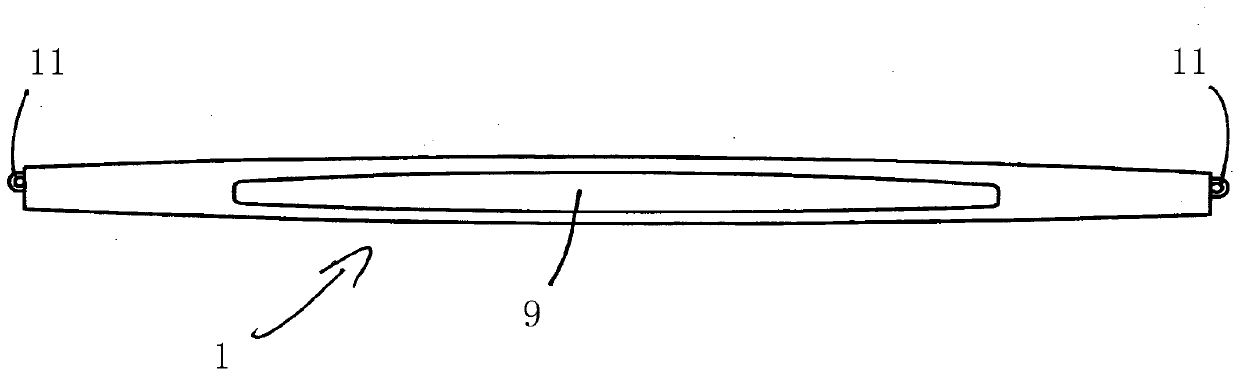

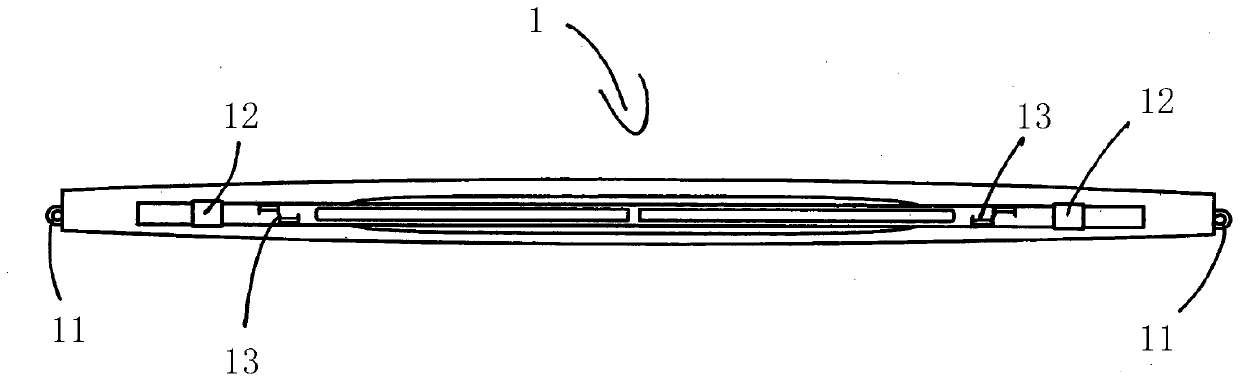

Bottle Teat

A bottle teat, in particular for infants and small children, having a suction part with at least one drinking slit, and a teat flange connected to the bottom end of the suction part for fastening to the front edge of a mouth of a container, wherein the drinking slit is cut by a laser beam in the suction part, and is opened a small gap when the bottle teat is in an unstressed state.

Owner:MAPA

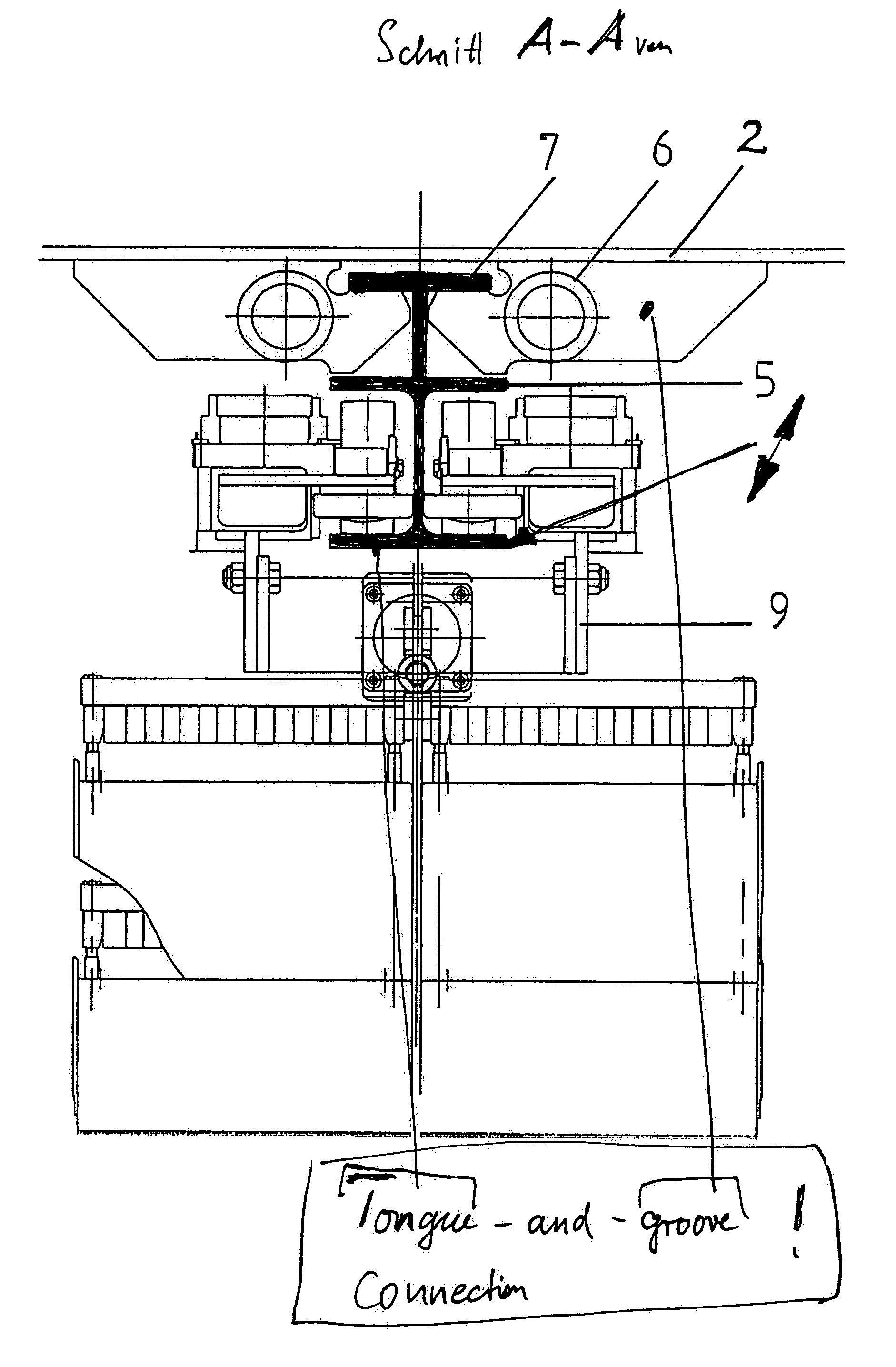

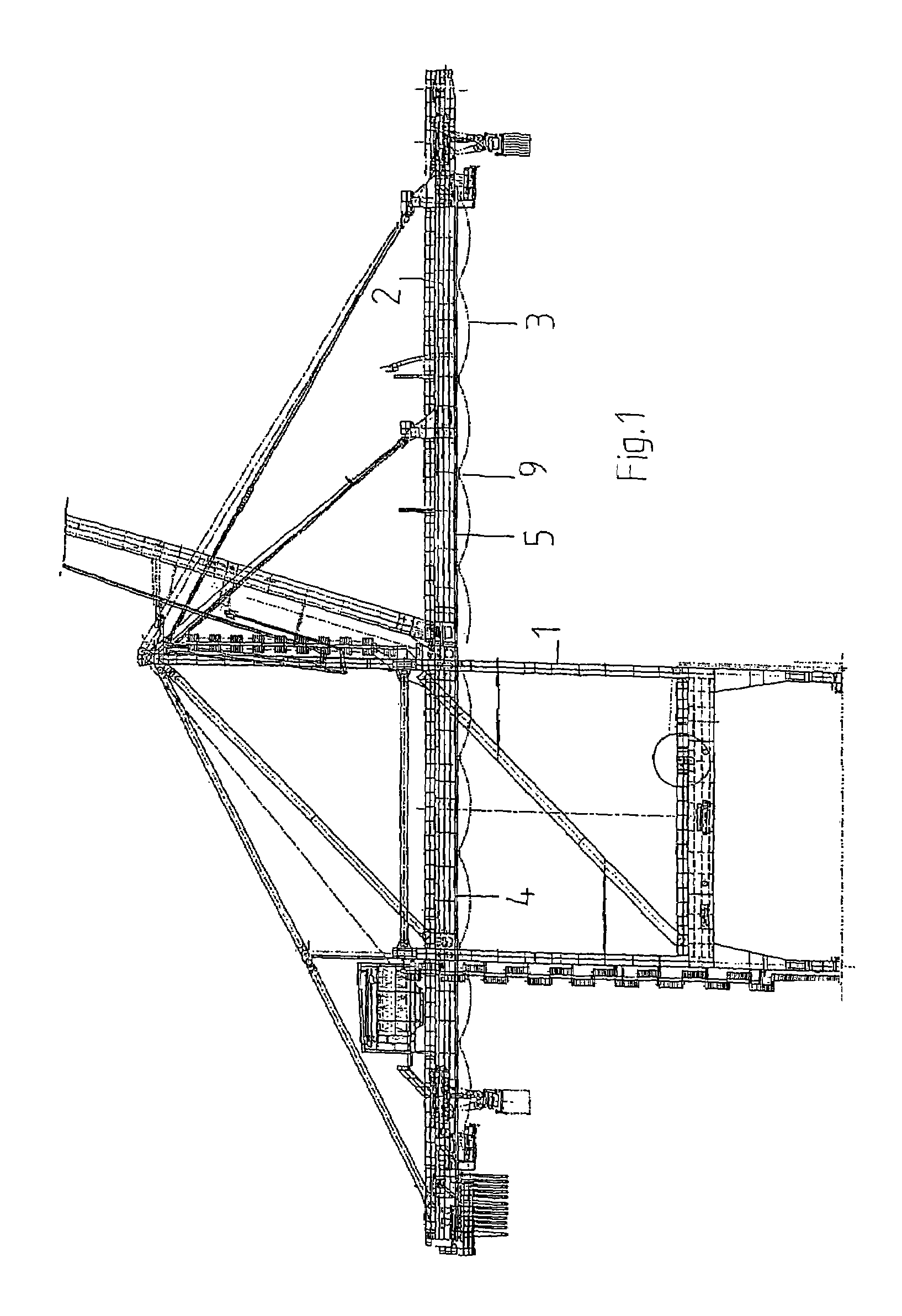

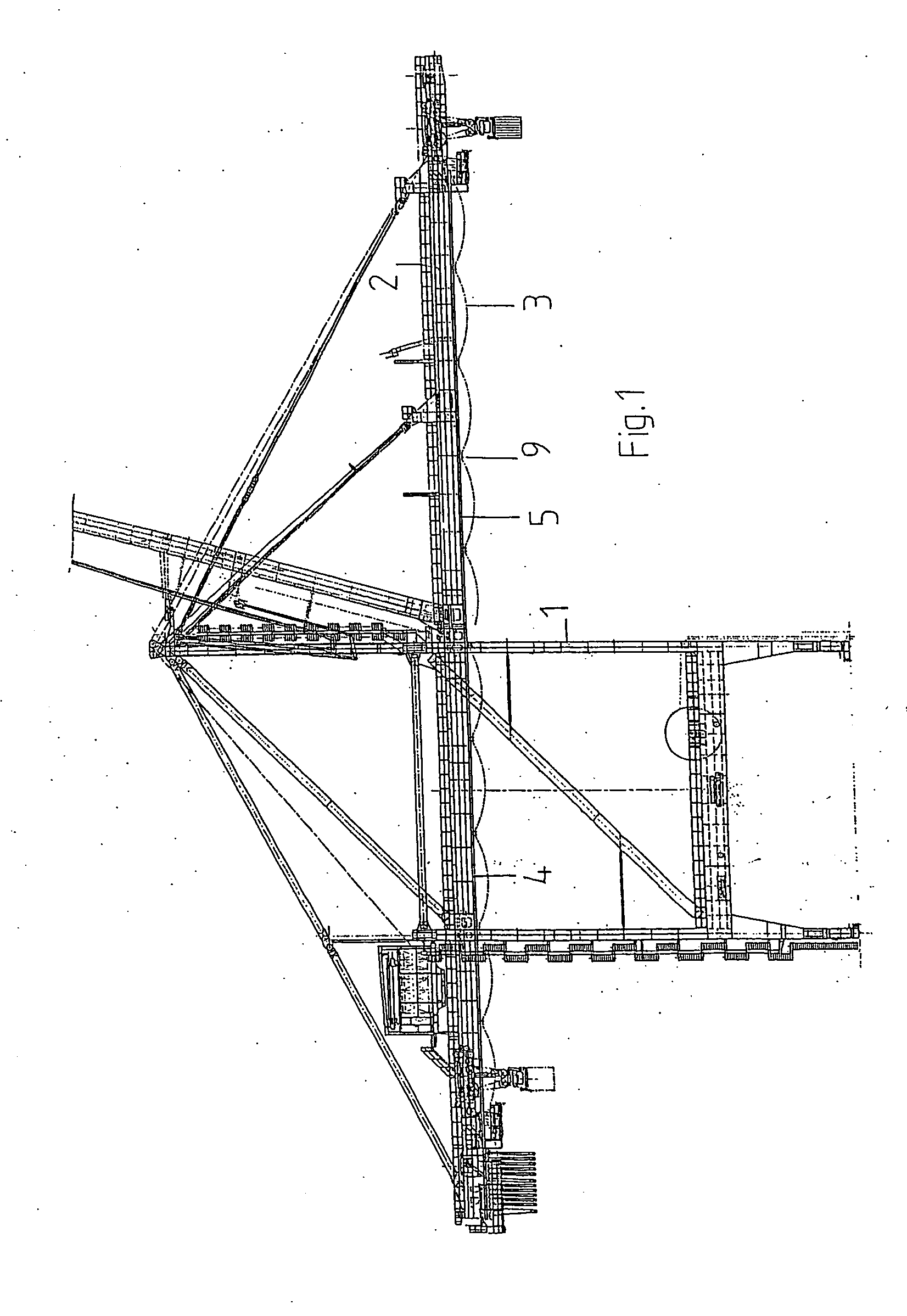

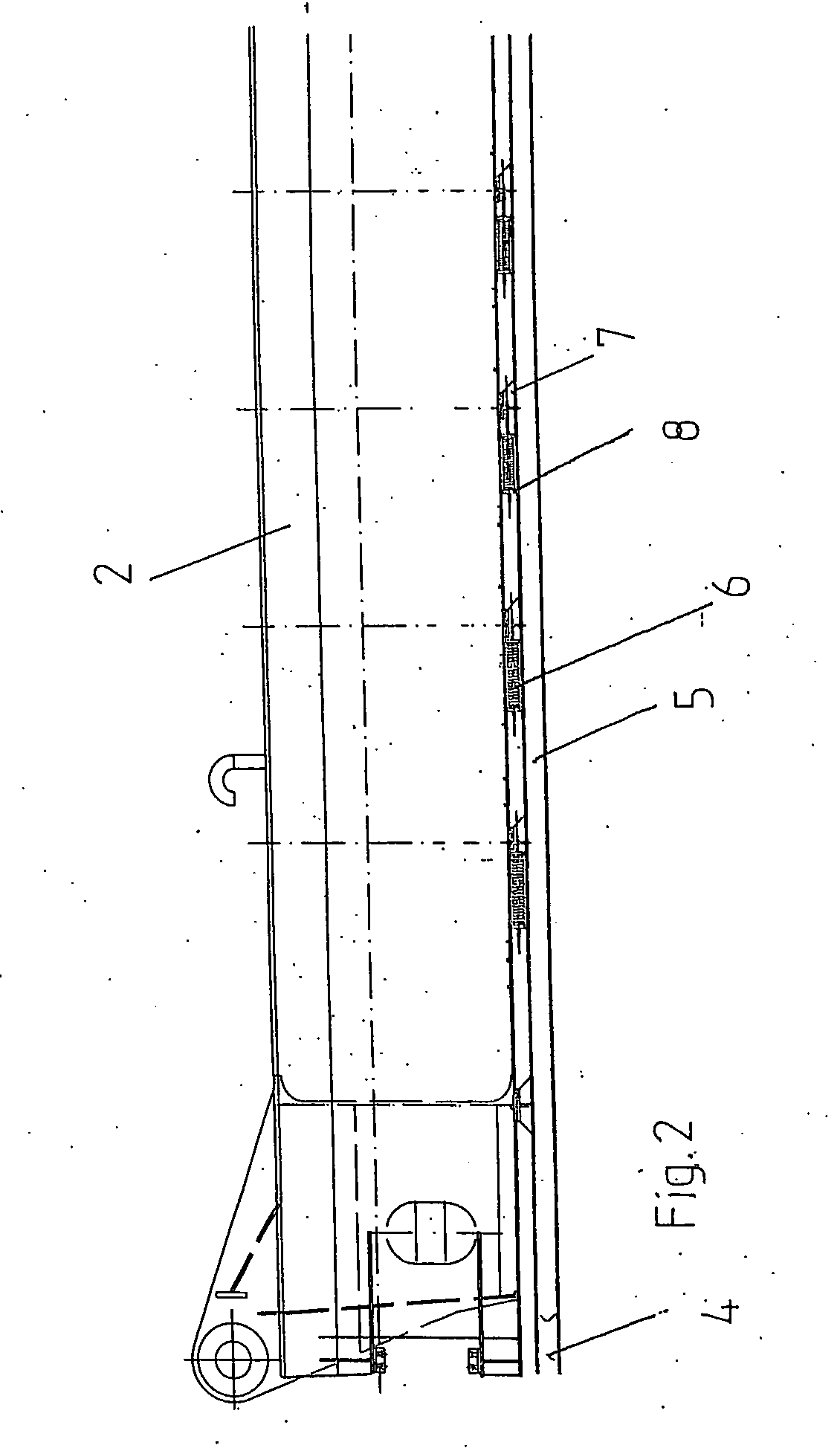

Crane with boom and running track for a cable carrier

InactiveUS7516857B2Small gap widthReduce gapBase supporting structuresBraking devices for hoisting equipmentsEngineeringCable carrier

Owner:KONECRANES GLOBAL

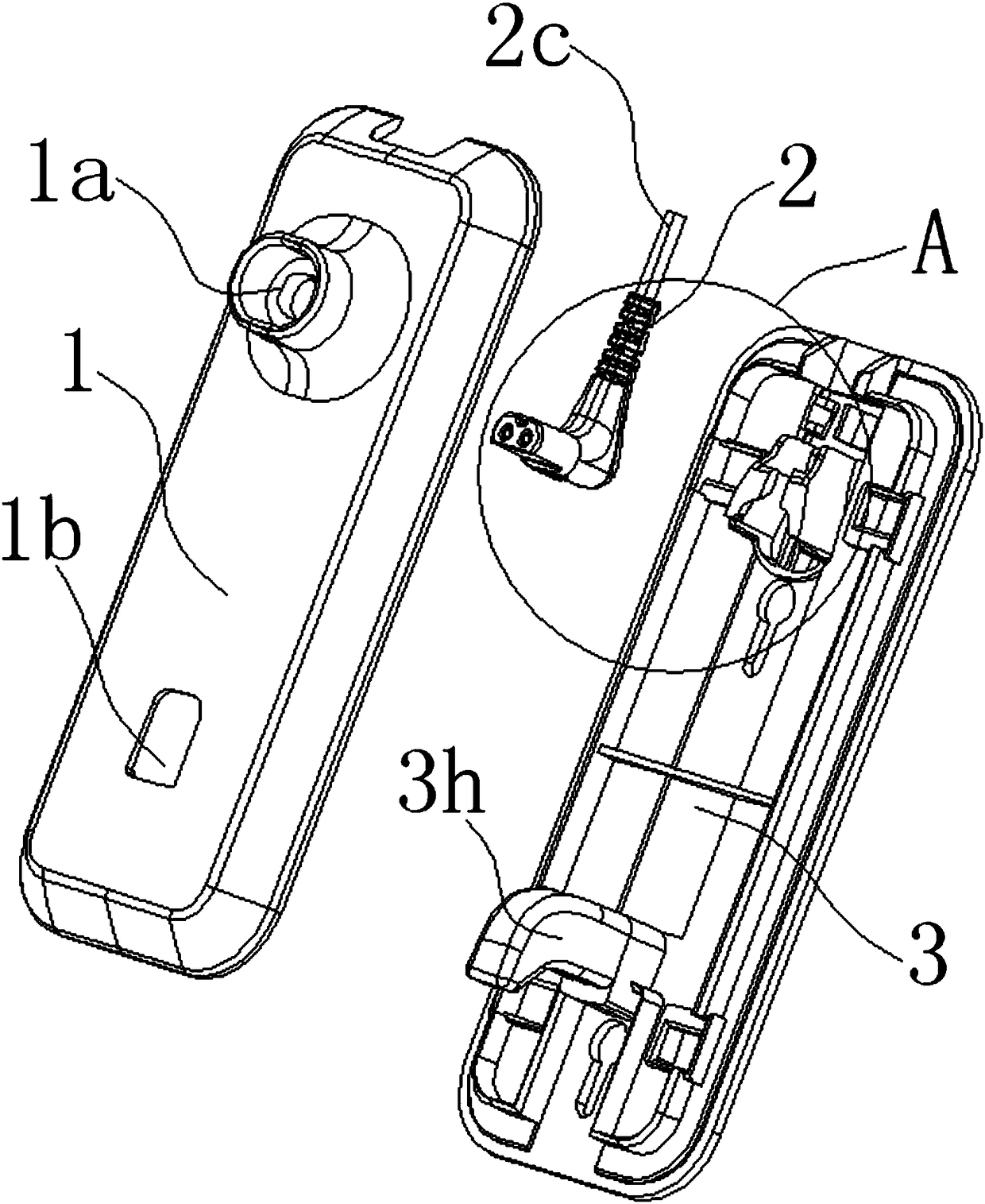

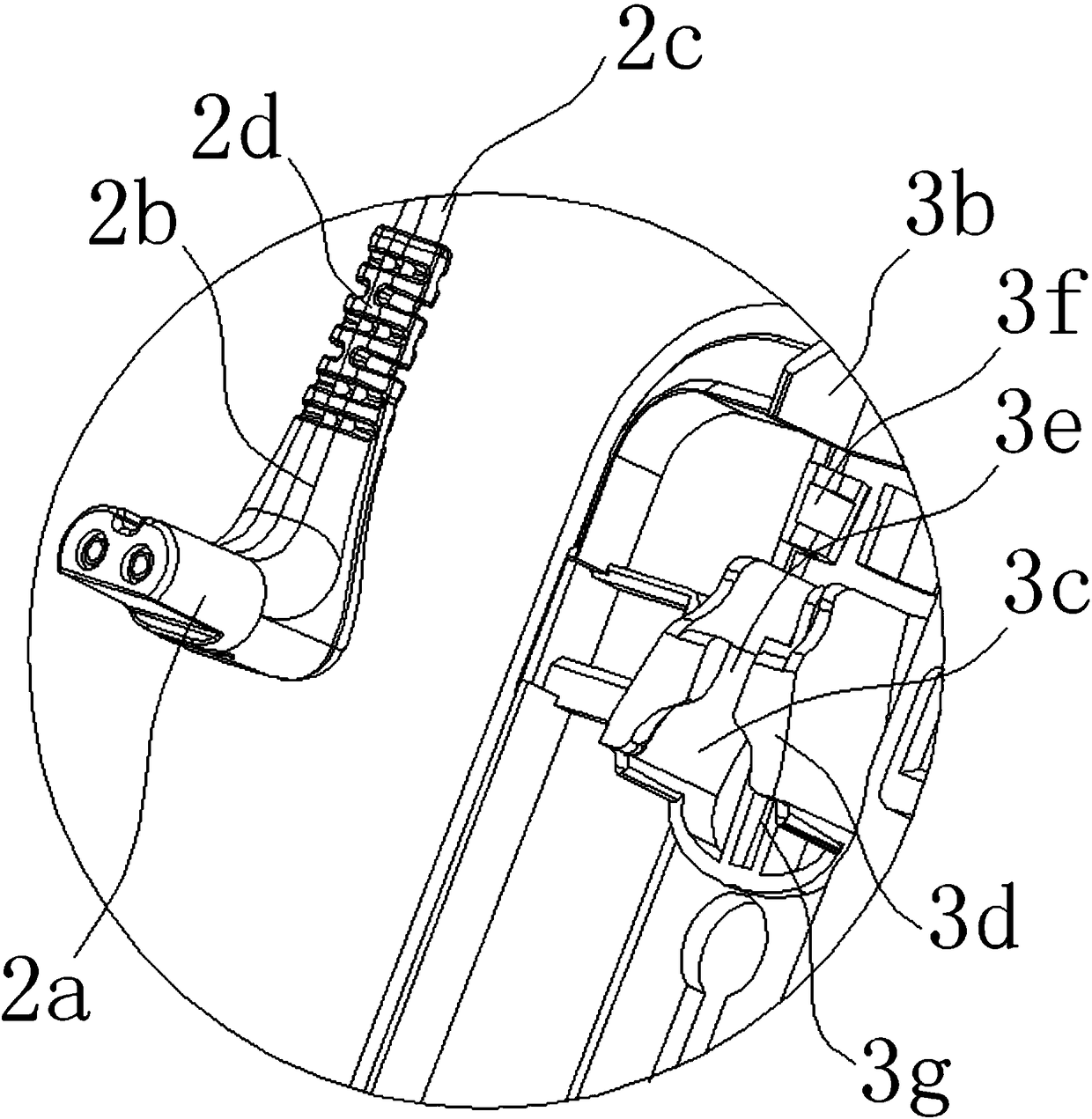

Stable charging terminal base and dust collector

PendingCN108493662AAvoid the problem of pulling outImprove experienceBatteries circuit arrangementsElectric discharge tubesDegrees of freedomEngineering

The invention discloses a stable charging terminal base and a dust collector. The stable charging terminal base comprises a charging terminal base, which has a plug and a connection portion which arein vertical connection mutually; a hanger cover plate, which has a hole for allowing the plug to pass; and a hanger base, which has a hook contacting and limiting the connection portion, wherein the hanger cover plate and the hanger base are matched up and down; the charging terminal base is arranged between the hanger cover plate and the hanger base; and the hook limits translational degree of freedom of the charging terminal base to the hanger cover plate. The hook has a vertical arm vertically protruding out of the hanger base and a horizontal hook vertically connected with the top end of the vertical arm, wherein the height of the vertical arm is equal to the vertical thickness of the connection portion, and the side end of the horizontal hook has a limit edge matched with the side profile of the plug. The hanger base limits the degree of freedom of vertical movement of the charging terminal base, thereby preventing the case that when the charging terminal base is under force, thehanger cover plate is pulled out.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

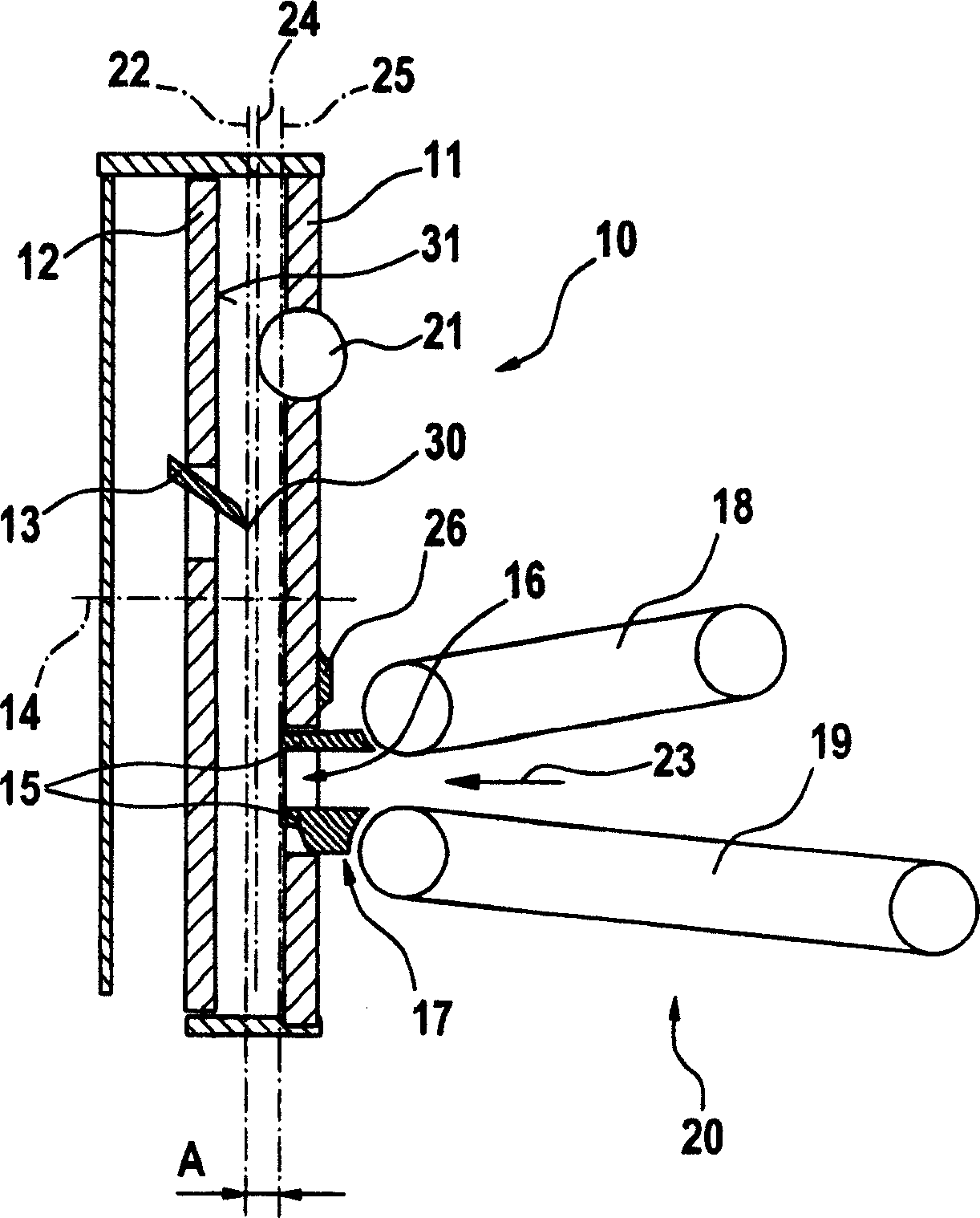

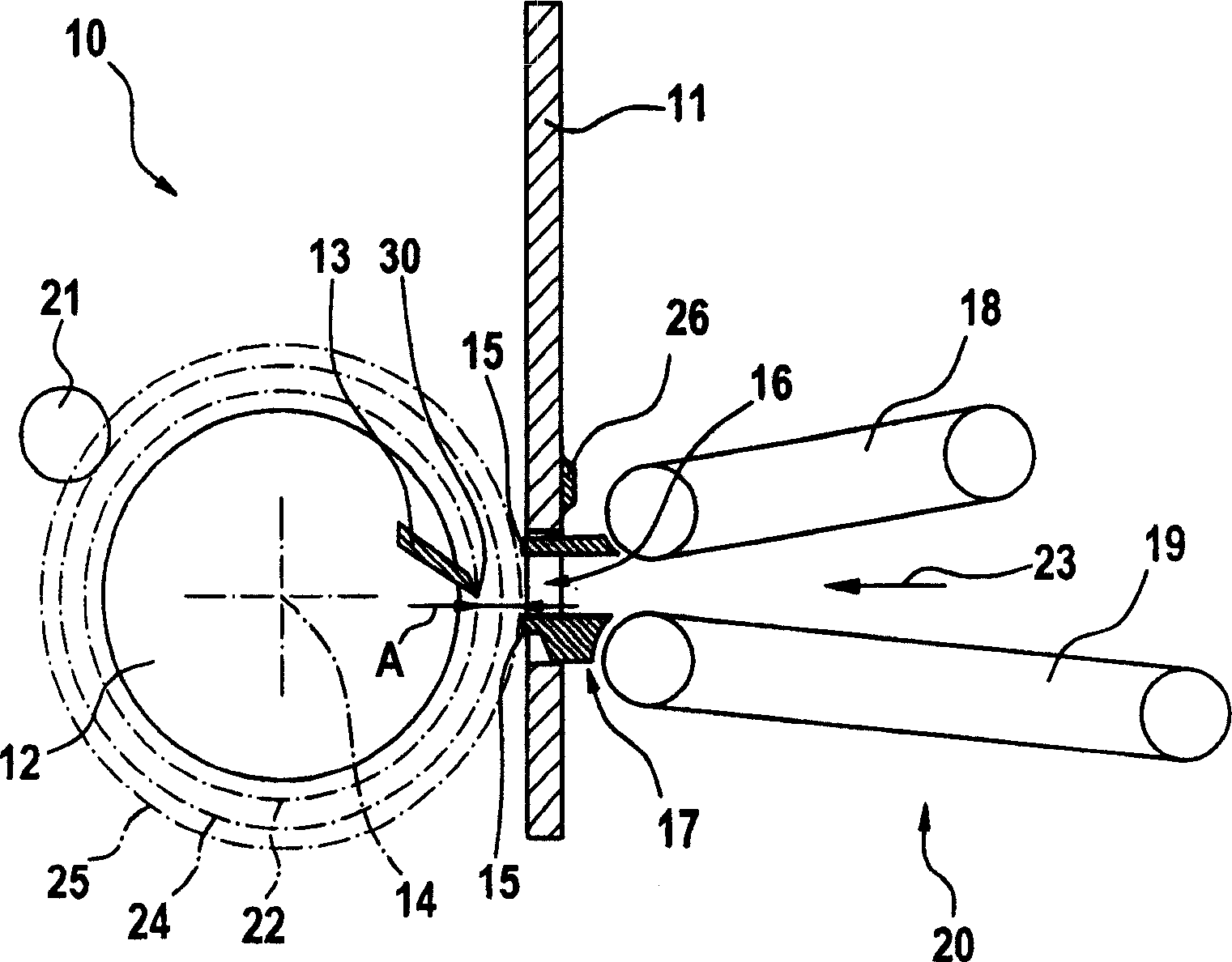

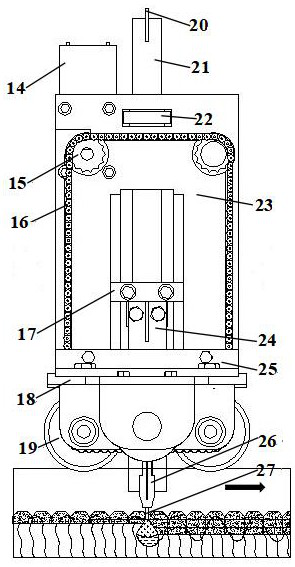

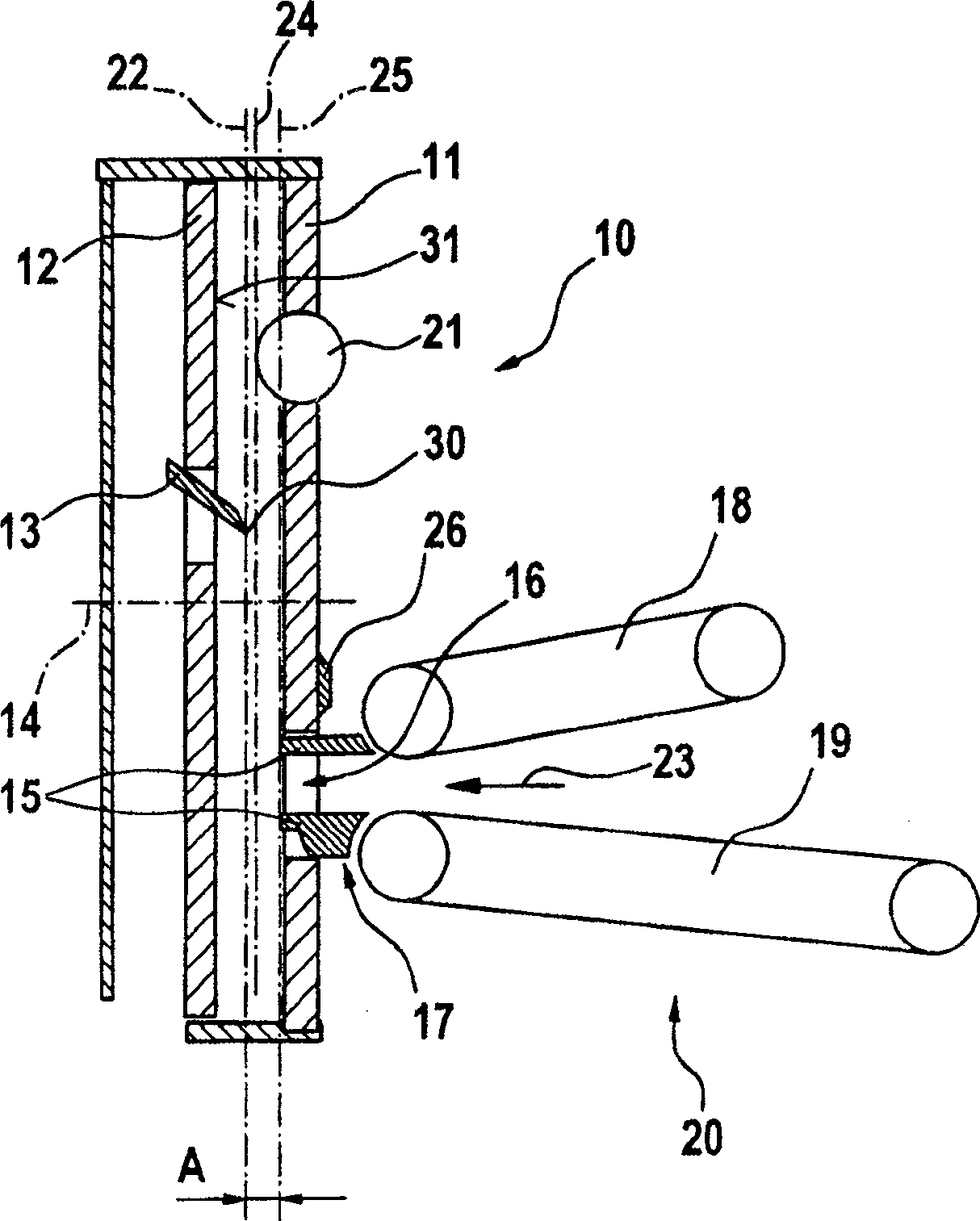

Device and method for cutting tobacco from a tobacco bale

InactiveCN1618348ASimple structureReduce maintenance costsTobacco preparationTobacco treatmentEngineeringBody sensors

The assembly to separate tobacco from a compressed tobacco cake has a housing frame (11) with a cutting unit (12) and a rotating cutting plate (13), fitted with a number of cutting blades and rotating around an axis (14). A grinder (21) sharpens the cutting plate with a common counter surface (15). The assembly has at least one sensor (26) near the grinder and / or the counter surface, which registers the sound of the cutting plate in contact with the counter surface as an acoustic body sensor working on the piezo principle, and is linked to the grinder.

Owner:HAUNI PRIMARY

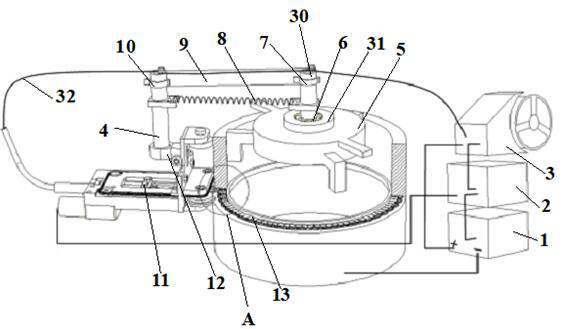

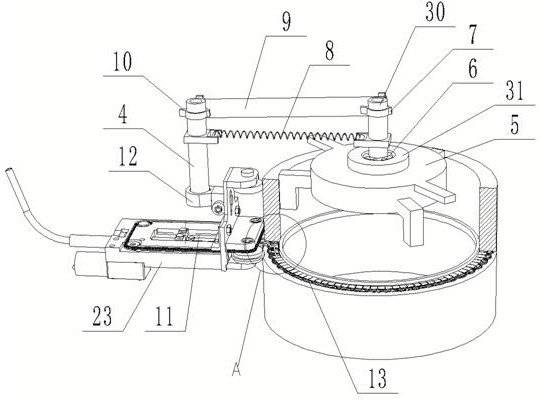

Ultra-narrow gap welding device and method for pipe fitting welding

ActiveCN111843128ASave energySmall energy is small, so the heat input in the welding processWelding accessoriesPipe fittingEngineering

The invention discloses an ultra-narrow gap welding device and method for pipe fitting welding, and relates to the technical field of welding. The ultra-narrow gap welding device for pipe fitting welding comprises a welding mechanism, a rotating mechanism and a positioning mechanism; and the welding mechanism rotates around the positioning mechanism through the rotating mechanism, the positioningmechanism is arranged inside a to-be-welded pipe fitting, and the rotating mechanism is rotationally connected with the positioning mechanism. Transverse welding can be carried out in a groove with the small gap width, due to the fact that the groove width is small, the welding line energy is low, the heat input amount in the welding process is low, growth of a molten pool is effectively inhibited, collapse of the molten pool is prevented, the collapse defect of the molten pool can be effectively overcome, and the welding production efficiency can be improved; and the device is convenient to operate and moves easily, and the problem that large equipment is difficult to operate and high in operation technical requirement in field welding is solved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

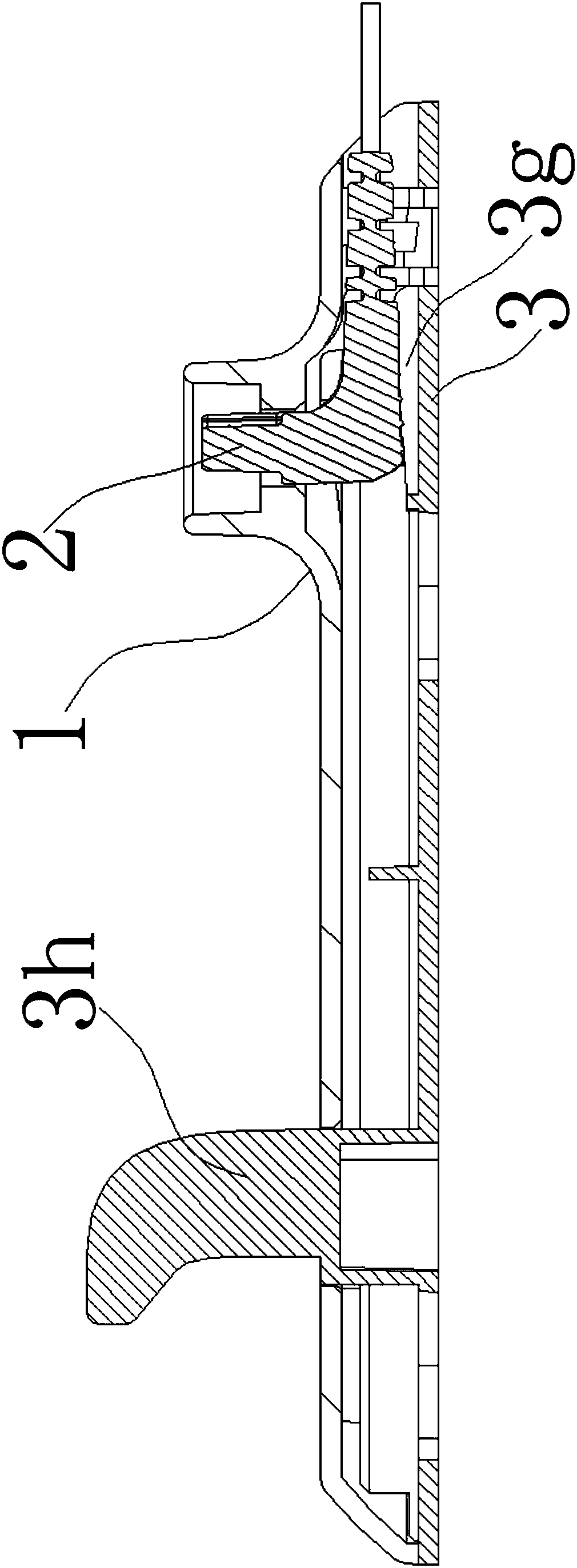

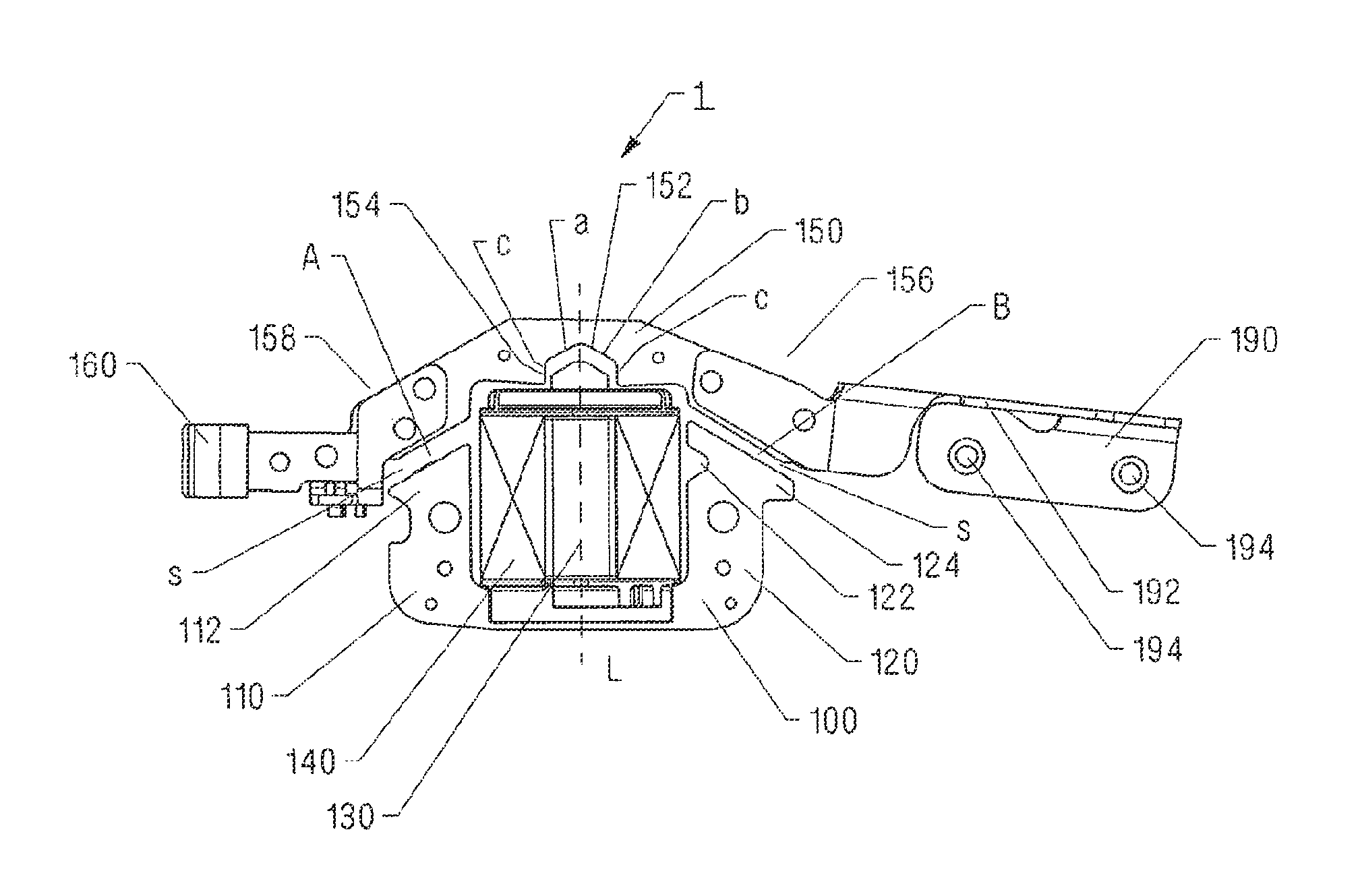

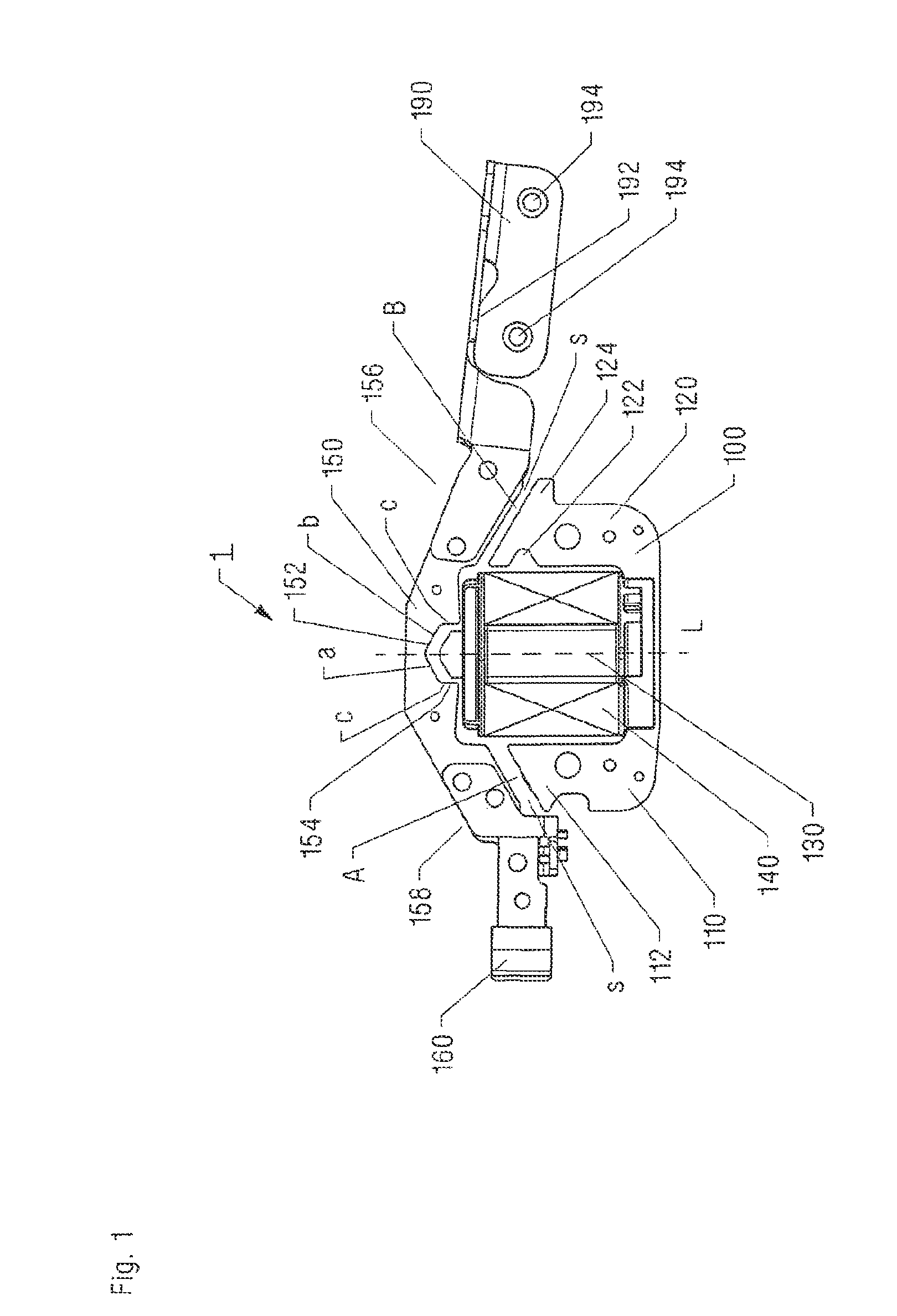

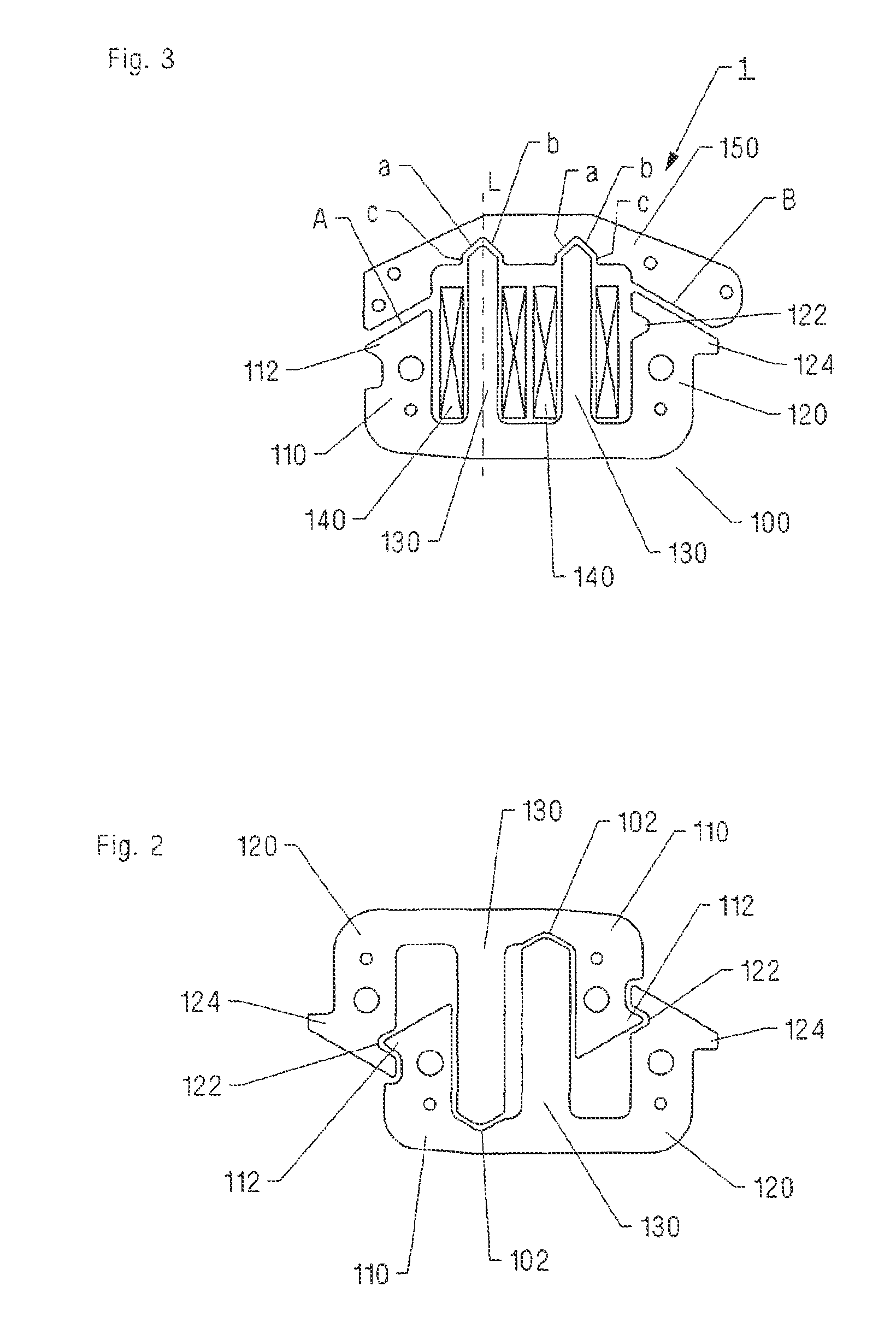

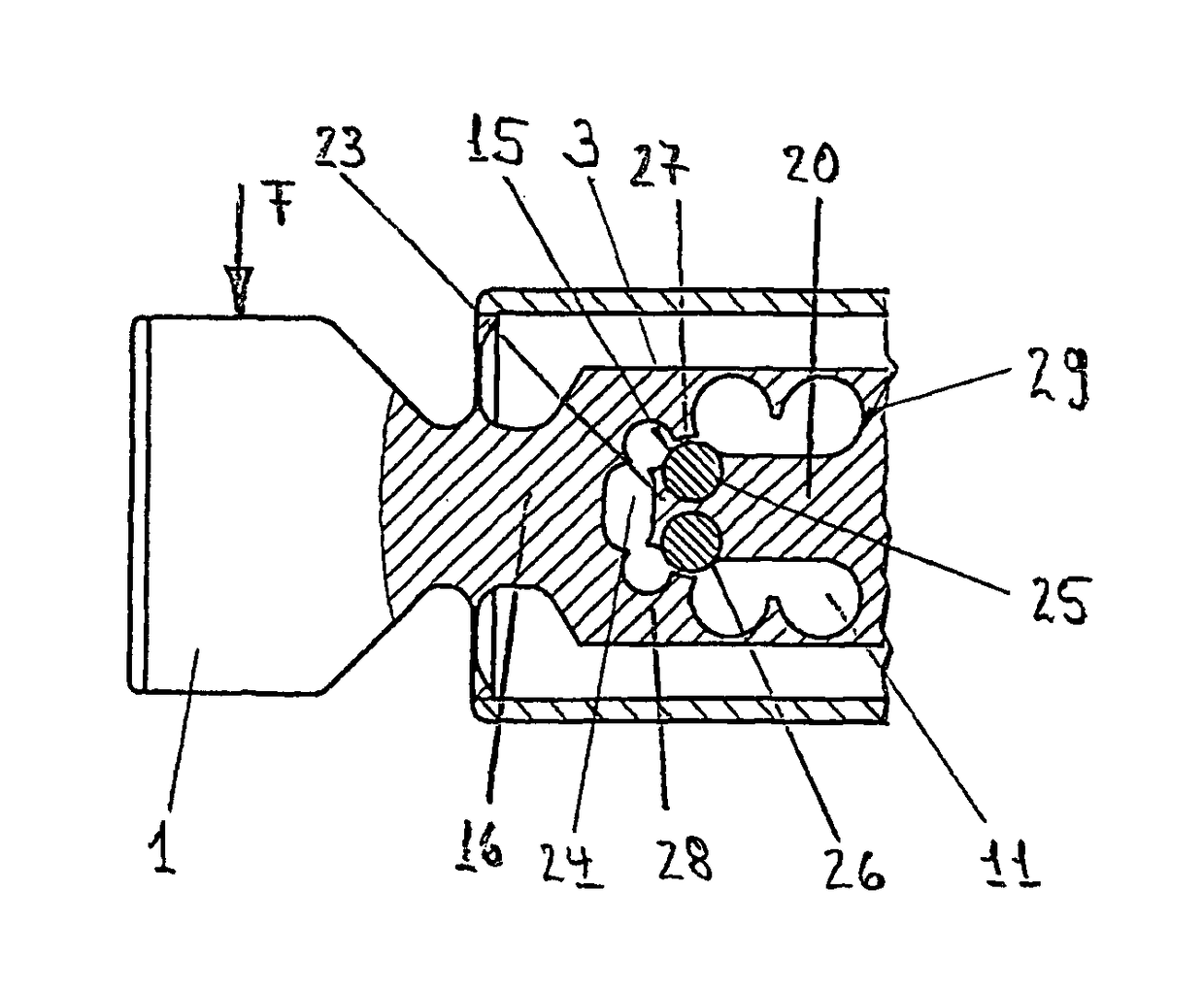

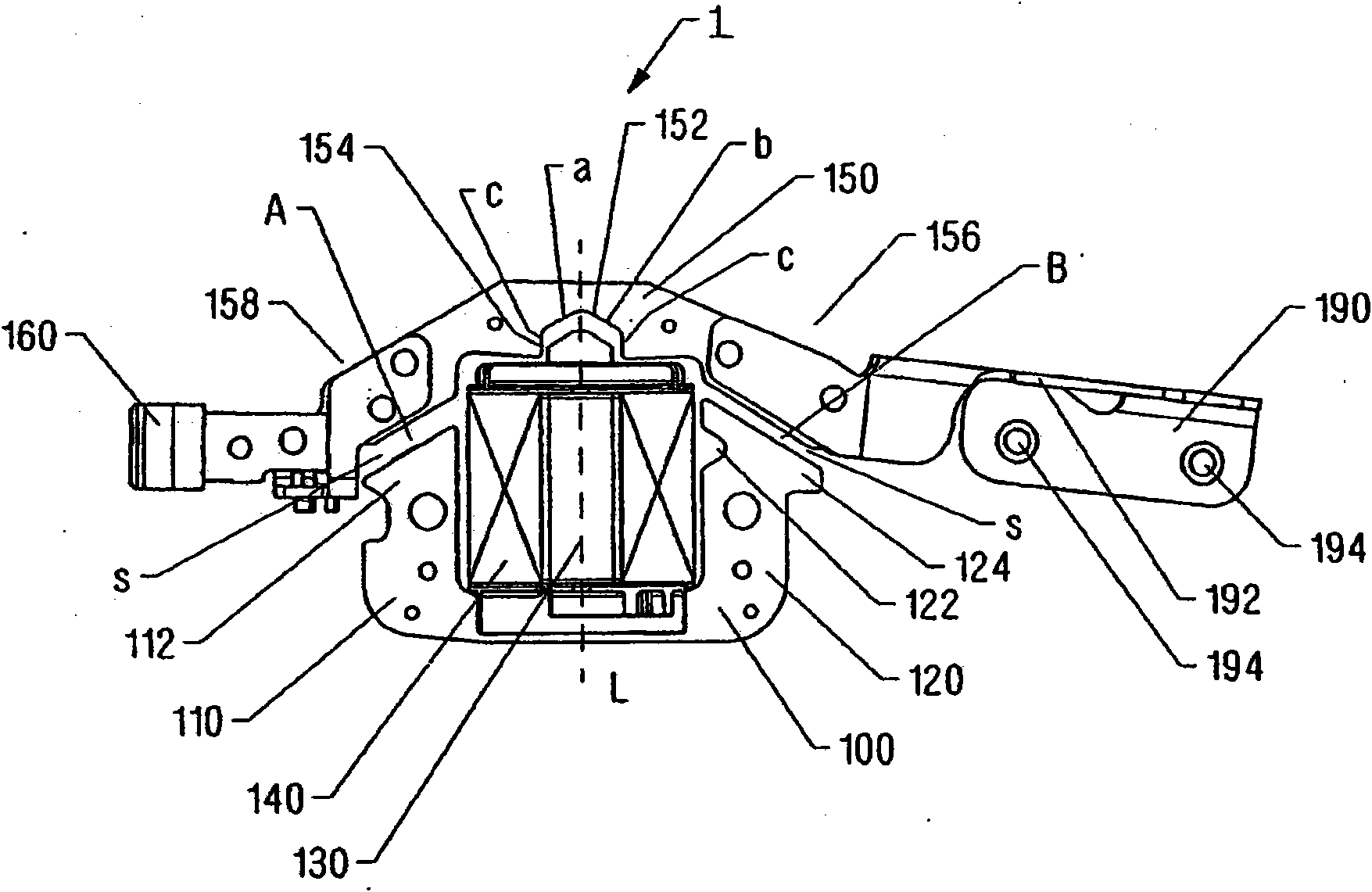

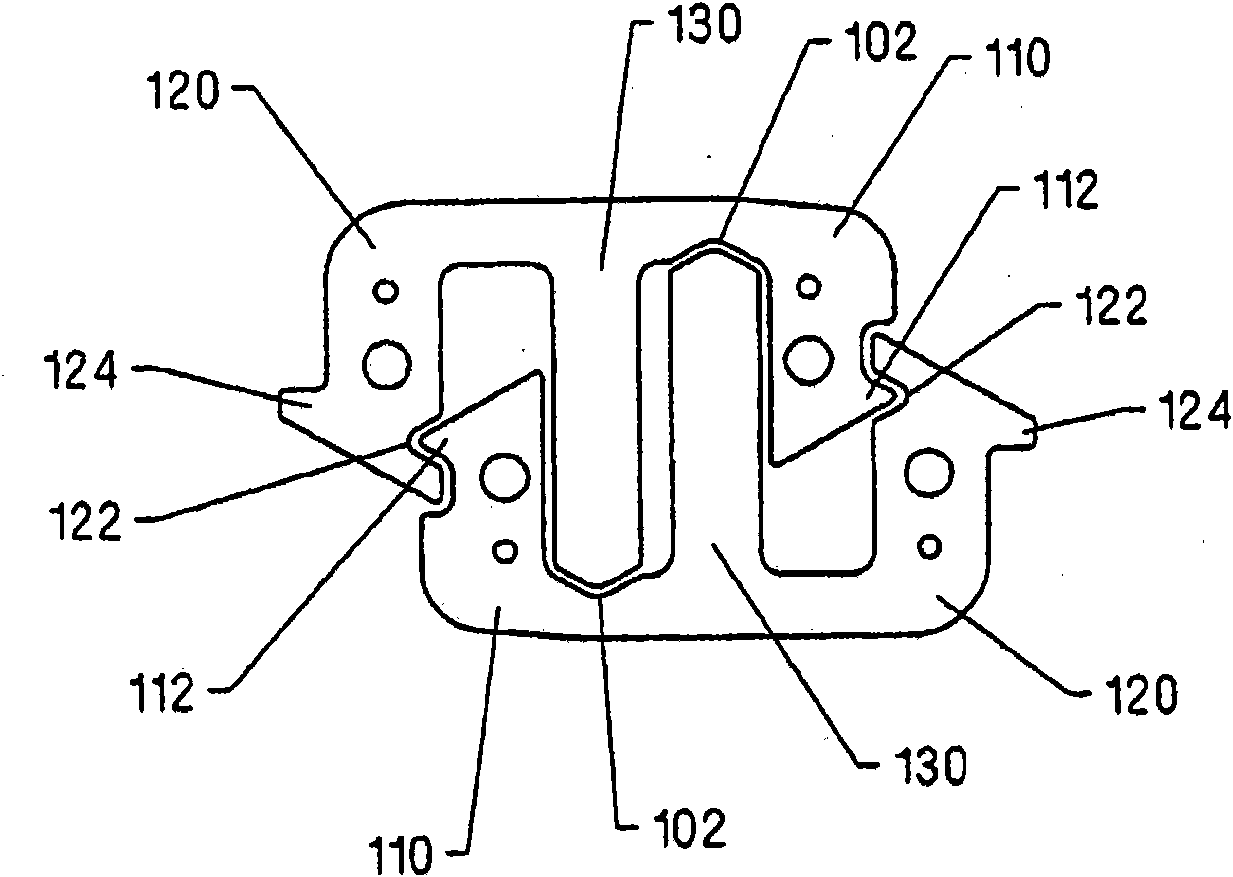

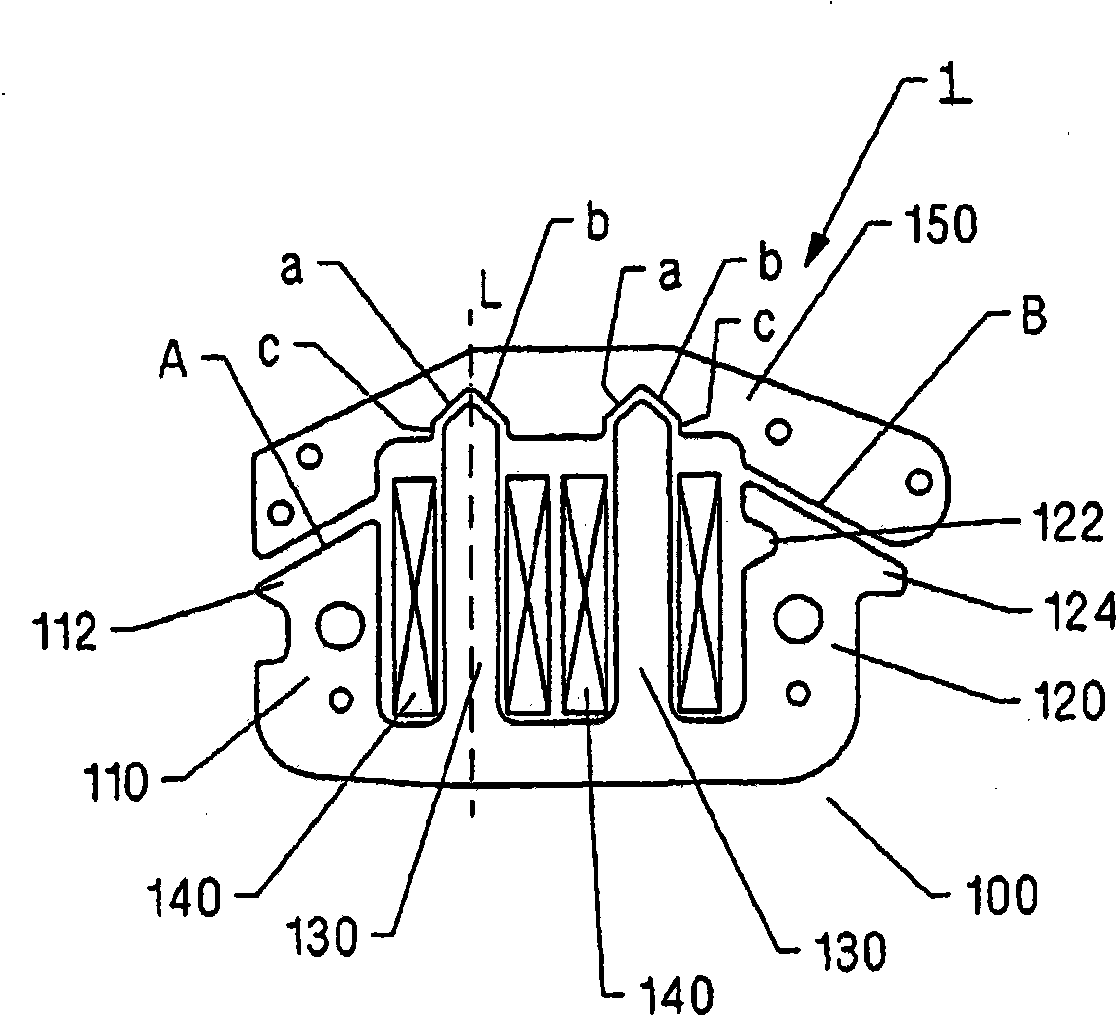

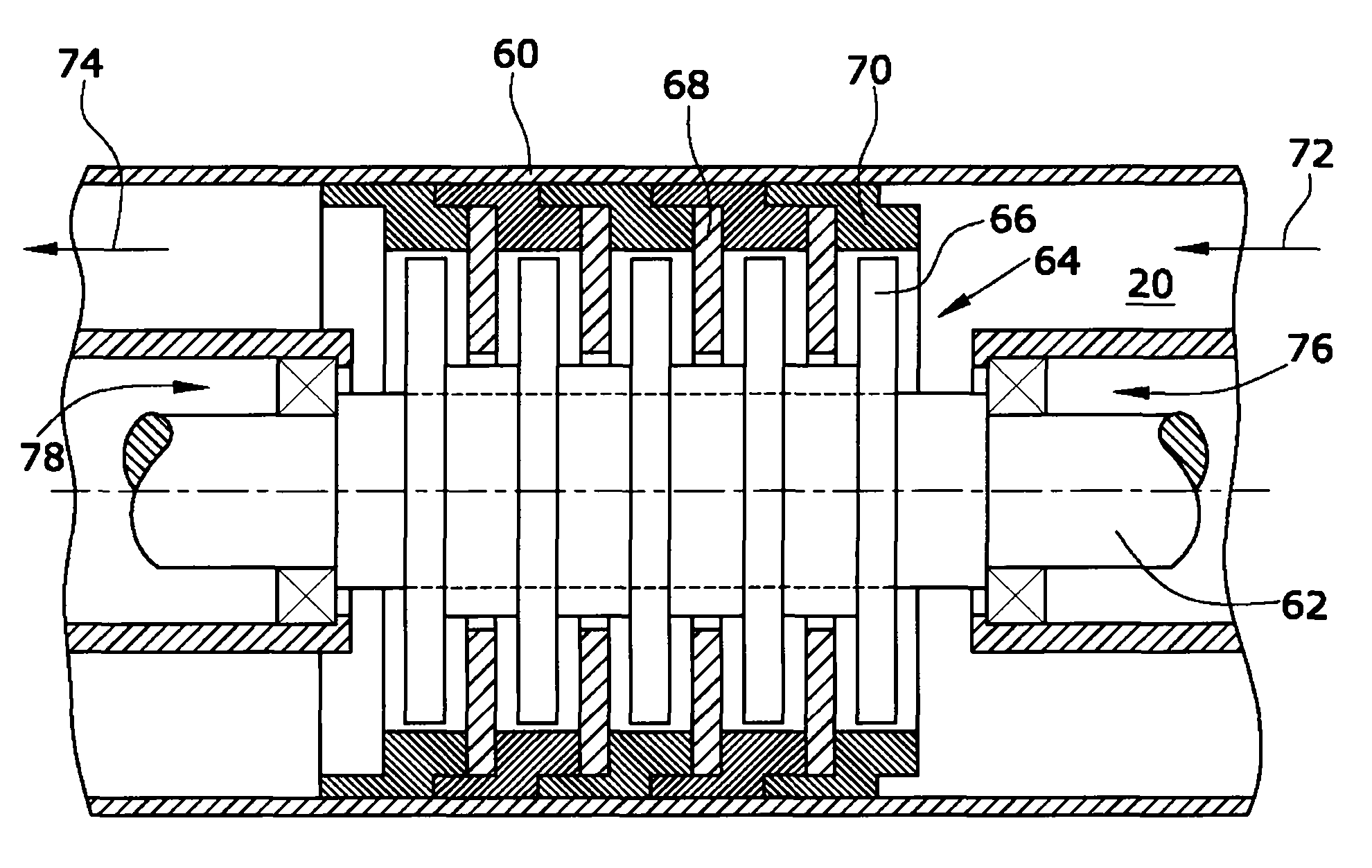

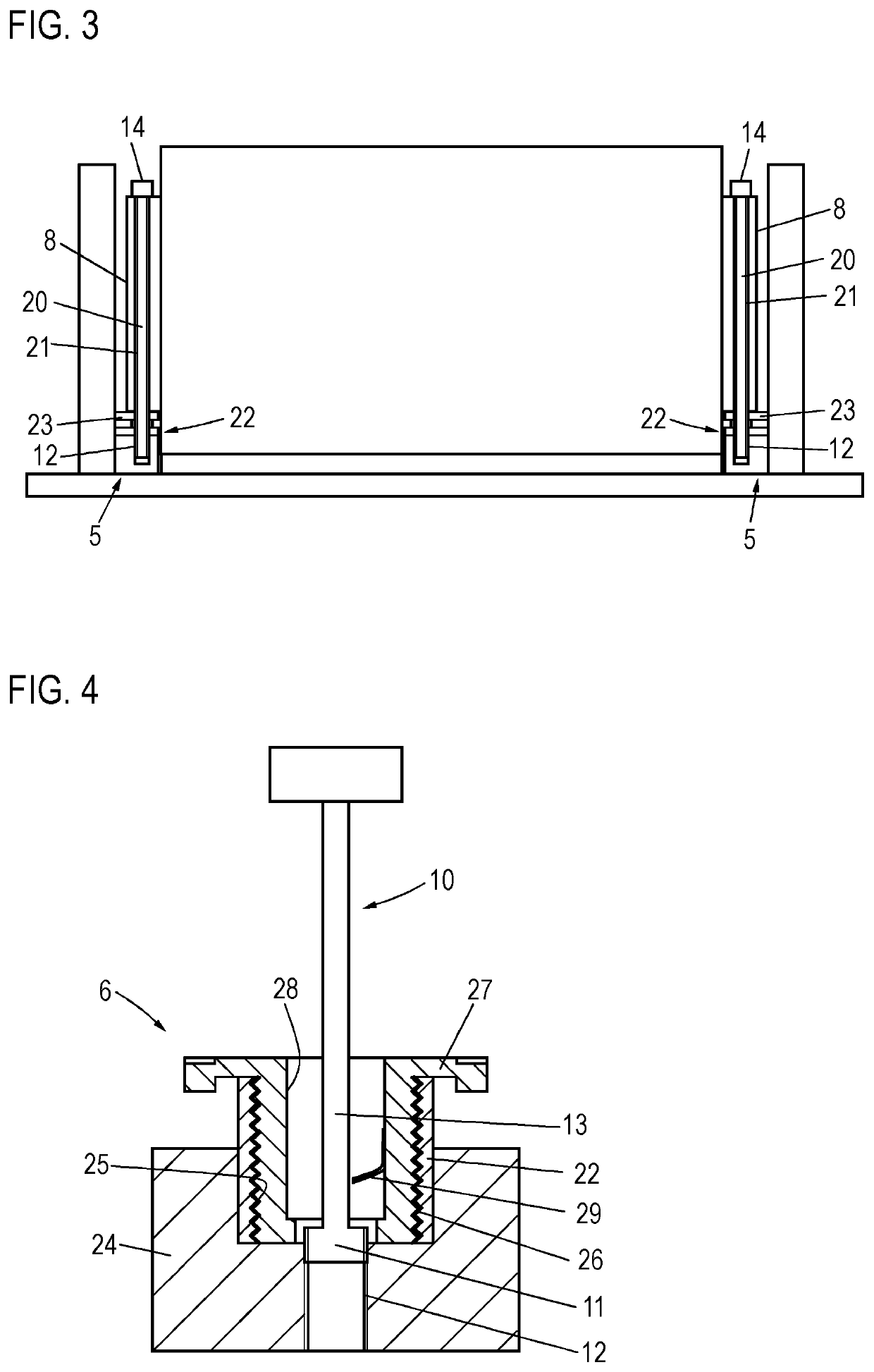

Drive unit for a hair cutting machine

ActiveUS8610329B2Save configuration spaceSmall gap widthMagnetic circuit shape/form/constructionMetal working apparatusDrive motorEngineering

A drive unit for a hair cutting machine comprises a driving motor that includes a substantially U-shaped stator which has a first leg, a second leg, and at least one additional leg located between the first leg and the second leg, at least one field coil which can be disposed on the at least one additional leg, and an armature. Lateral air gap sections are formed between the first and second leg and the armature while central air gap sections are formed between the additional leg and the armature. The central air gap sections and the lateral air gap sections extend at an angle from a longitudinal axis. A first nose, which faces away from the additional leg, is arranged at the end of the first leg, while a notch, which faces the additional leg and corresponds to the first nose, is arranged on the second leg.

Owner:WAHL +1

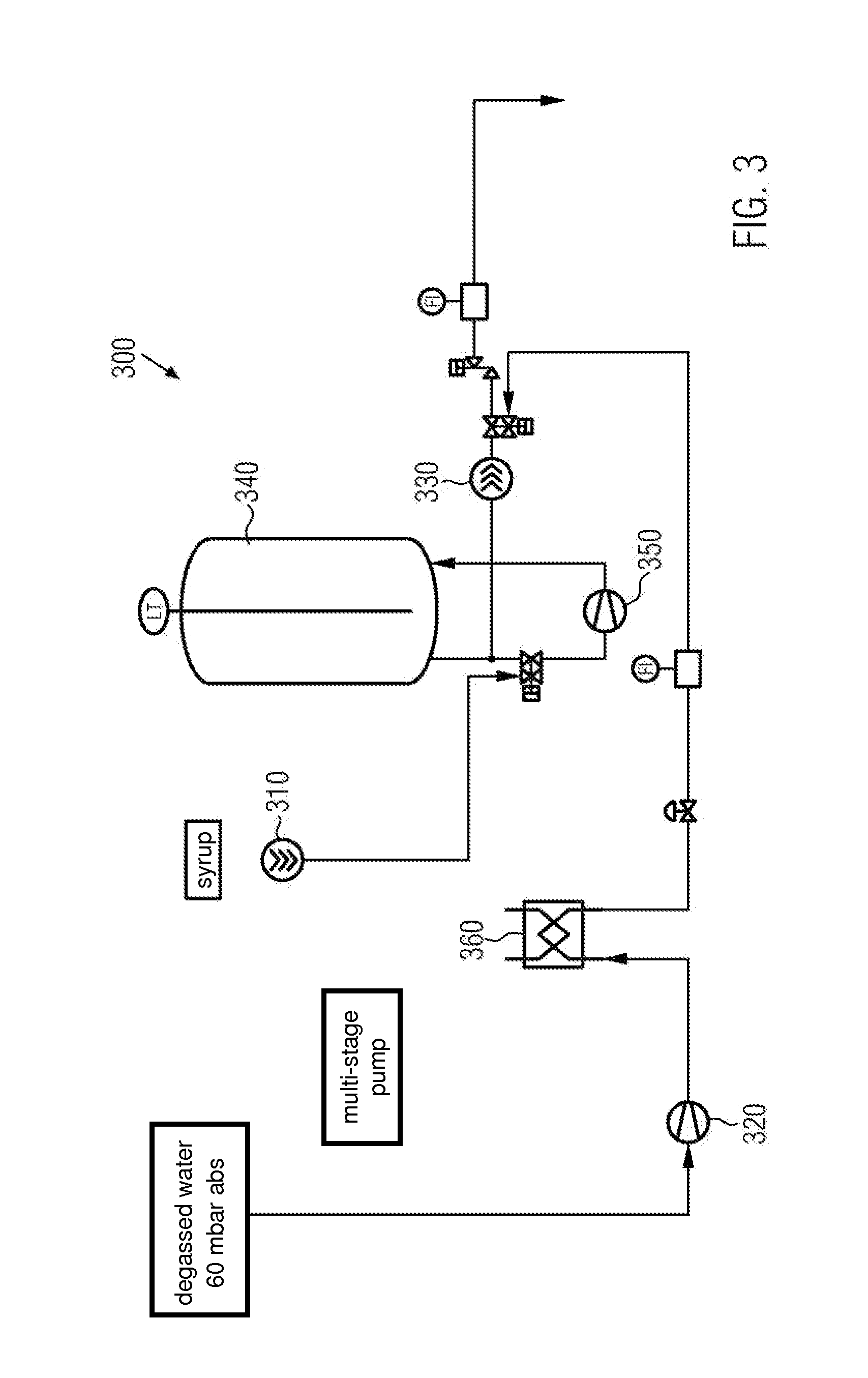

Mixer for pulp-and fiber-containing beverages

InactiveUS20130094323A1Efficient and gentle to productSmall gap widthFlow mixersTransportation and packagingFiberBiomedical engineering

A device for mixing a pulp- and / or fiber-containing fluid which comprises an apparatus for moving the fluid free from shearing, and a corresponding method.

Owner:KRONES AG

Hermetic weighing cell having overload protection

InactiveUS9903772B2Low costSmall gap widthWeighing apparatus using elastically-deformable membersForce measurementHermetic sealLoad cell

A load cell has a longitudinal body including a bending beam axially between a force input element and a force output element, strain gages applied on strainable measuring parts of the bending beam, a hermetically sealed enclosure outside around the strain gages and the strainable measuring parts, and an overload protection arrangement including an overload beam in a recess in the bending beam, a receiving hole partially in the overload beam, and a fitting pin received in the receiving hole so that a defined gap is formed between the fitting pin and an adjacent stop surface in the recess of the bending beam. In further embodiments, the enclosure includes a stiff pipe sleeve and ring elements with flexible membranes connecting the sleeve to the longitudinal body, and a mounting end face of the longitudinal body has centering pins in holes and an O-ring in a groove.

Owner:HOTTINGER BALDWIN MESSTECHNIK GMBH

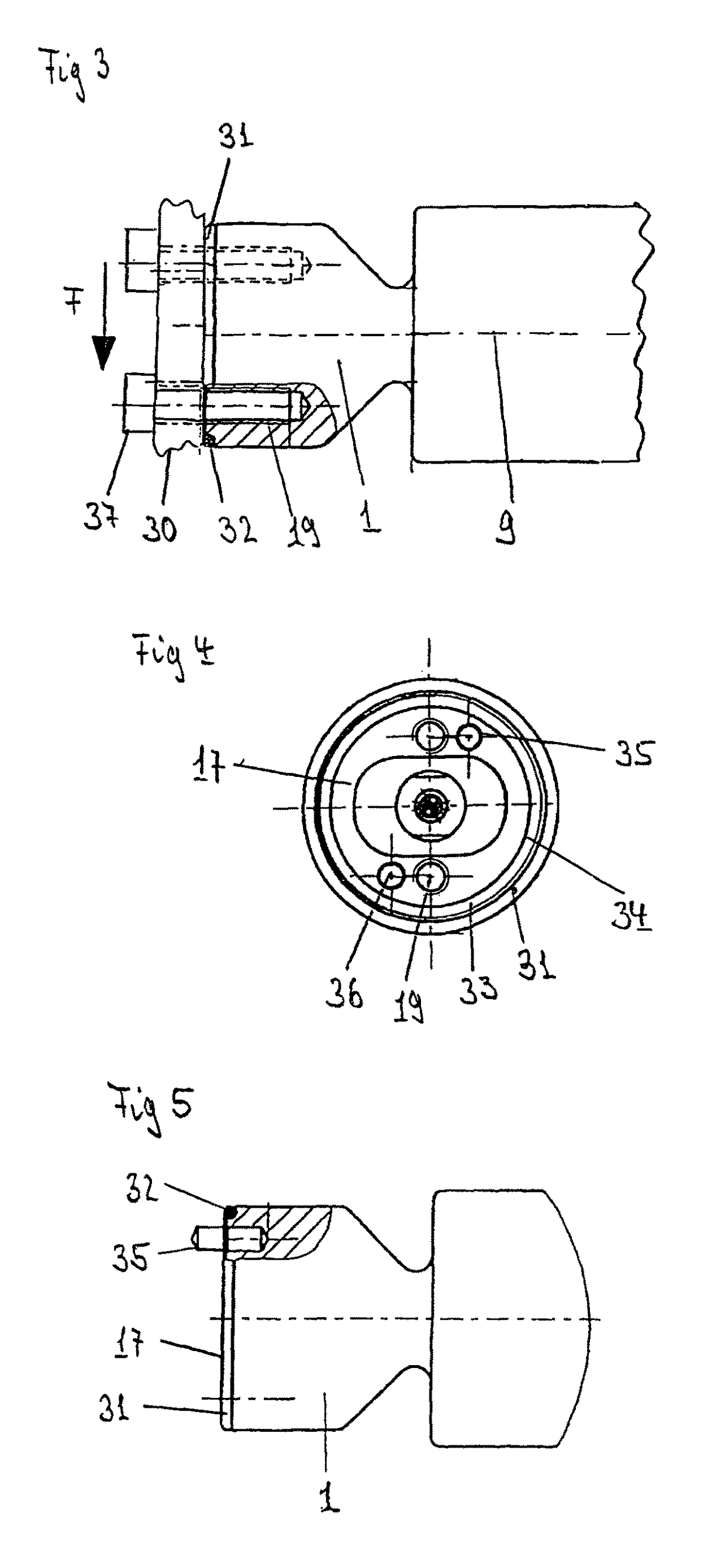

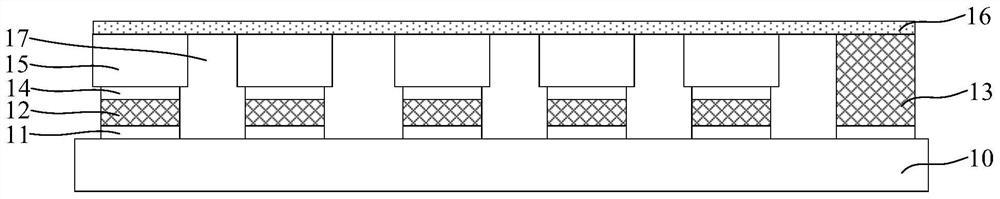

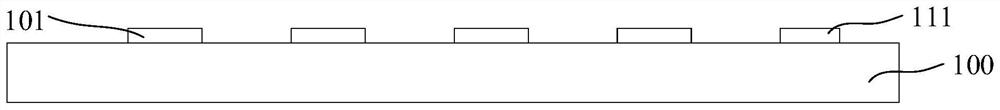

Display panel, manufacturing method thereof and electronic equipment

PendingCN111863832ASmall gap widthEnsure that signals do not interfere with each otherSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical connection

The invention provides a display panel, a manufacturing method thereof and electronic equipment. The manufacturing method comprises the steps of providing a driving backboard, wherein the driving backboard is provided with a plurality of discrete array electrodes; forming a spacing part on the driving backboard, a plurality of openings penetrating through the spacing part are formed in the spacingpart, and the array electrodes are exposed out of the openings; providing a plurality of light-emitting chips, wherein each light-emitting chip comprises a lower electrode and a functional layer located on the lower electrode; fixing a light-emitting chips on the array electrodes, wherein the array electrodes are electrically connected with the lower electrodes; and forming a common electrode layer, wherein the common electrode layer covers the top surfaces of the plurality of light-emitting chips and the top surface of the spacing part and is electrically connected with the functional layer.According to the invention, the common electrode layer with the whole continuous complete film layer can be formed, so that the quality of the display panel is improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Crane with boom and running track for a cable carrier

InactiveUS20070227996A1Less stressExtend instrument lifeBase supporting structuresBraking devices for hoisting equipmentsEngineeringCable carrier

Owner:KONECRANES GLOBAL

Device for treating human and/or animal tissue

InactiveCN1422138AImprove reliabilityLow reliabilityJoint implantsExcision instrumentsEngineeringAnimal body

Owner:亚历山大·约伊斯特

MEMS switch including an embedded metal contact

PendingUS20220328258A1Reliable switchingSmall gap widthContact surface shape/structureElectrostatic/electro-adhesion relaysEngineeringSilicon

A MEMS switch that includes a substrate with a first insulating layer and a silicon layer thereabove, a fixed portion and a movable switching portion being formed in the silicon layer.A first metal layer is situated in recesses in the silicon layer at a side of the silicon layer facing away from the substrate, the first metal layer forming at least one switchable electrical contact between the fixed portion and the switching portion.A method for manufacturing a MEMS switch including at least one embedded metal contact is also described.

Owner:ROBERT BOSCH GMBH

Dividing element for subdividing the interior of a wire basket

ActiveCN111051206ASmall gap widthReduce thicknessHand carts with multiple axesInternal fittingsInterior spaceClassical mechanics

The invention relates to a dividing element (1), by means of which the interior of a basket, particularly a shopping trolley basket, can be subdivided, comprising a plurality of connecting elements for fastening the dividing element (1) to the sides of the basket, wherein a first section (11) of a first connecting element (16) for fastening the dividing element (1) to one side of the basket is designed to be at least substantially U-shaped, and wherein one leg (11a, 11b) of the at least substantially U-shaped first section (11) adjoins a second section (17) of the first connecting element (16), which second section is retained in a first guide formed in the dividing element (1) by friction locking and / or by interlocking.

Owner:弗朗茨.维特 +1

Hermetic Weighing Cell Having Overload Protection

InactiveUS20160084720A1Low costSmall gap widthWeighing apparatus using elastically-deformable membersApparatus for force/torque/work measurementClassical mechanicsLoad cell

A load cell has a longitudinal body including a bending beam axially between a force input element and a force output element, strain gages applied on strainable measuring parts of the bending beam, a hermetically sealed enclosure outside around the strain gages and the strainable measuring parts, and an overload protection arrangement including an overload beam in a recess in the bending beam, a receiving hole partially in the overload beam, and a fitting pin received in the receiving hole so that a defined gap is formed between the fitting pin and an adjacent stop surface in the recess of the bending beam. In further embodiments, the enclosure includes a stiff pipe sleeve and ring elements with flexible membranes connecting the sleeve to the longitudinal body, and a mounting end face of the longitudinal body has centering pins in holes and an 0-ring in a groove.

Owner:HOTTINGER BALDWIN MESSTECHNIK GMBH

Drive unit for a hair cutting machine

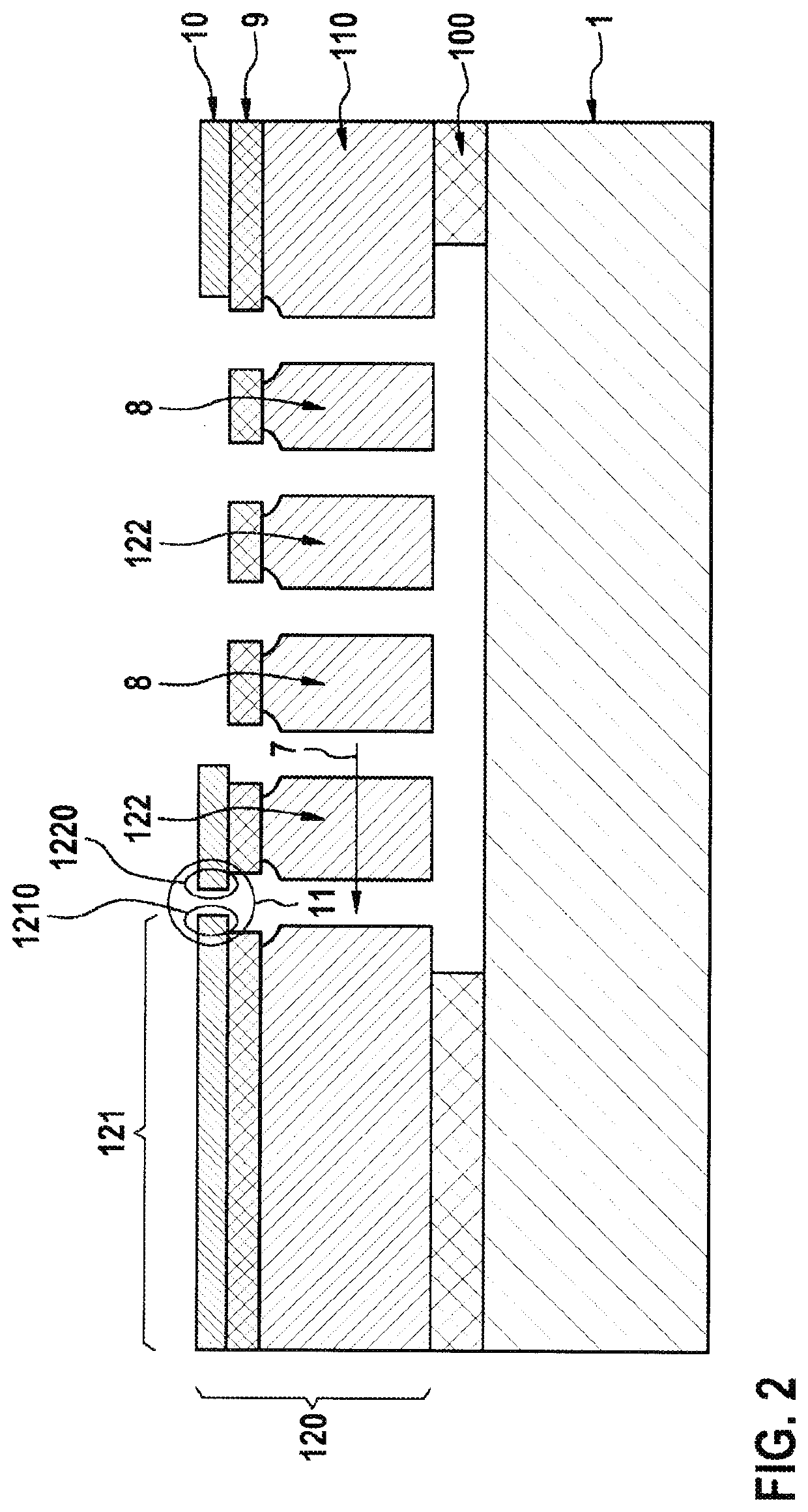

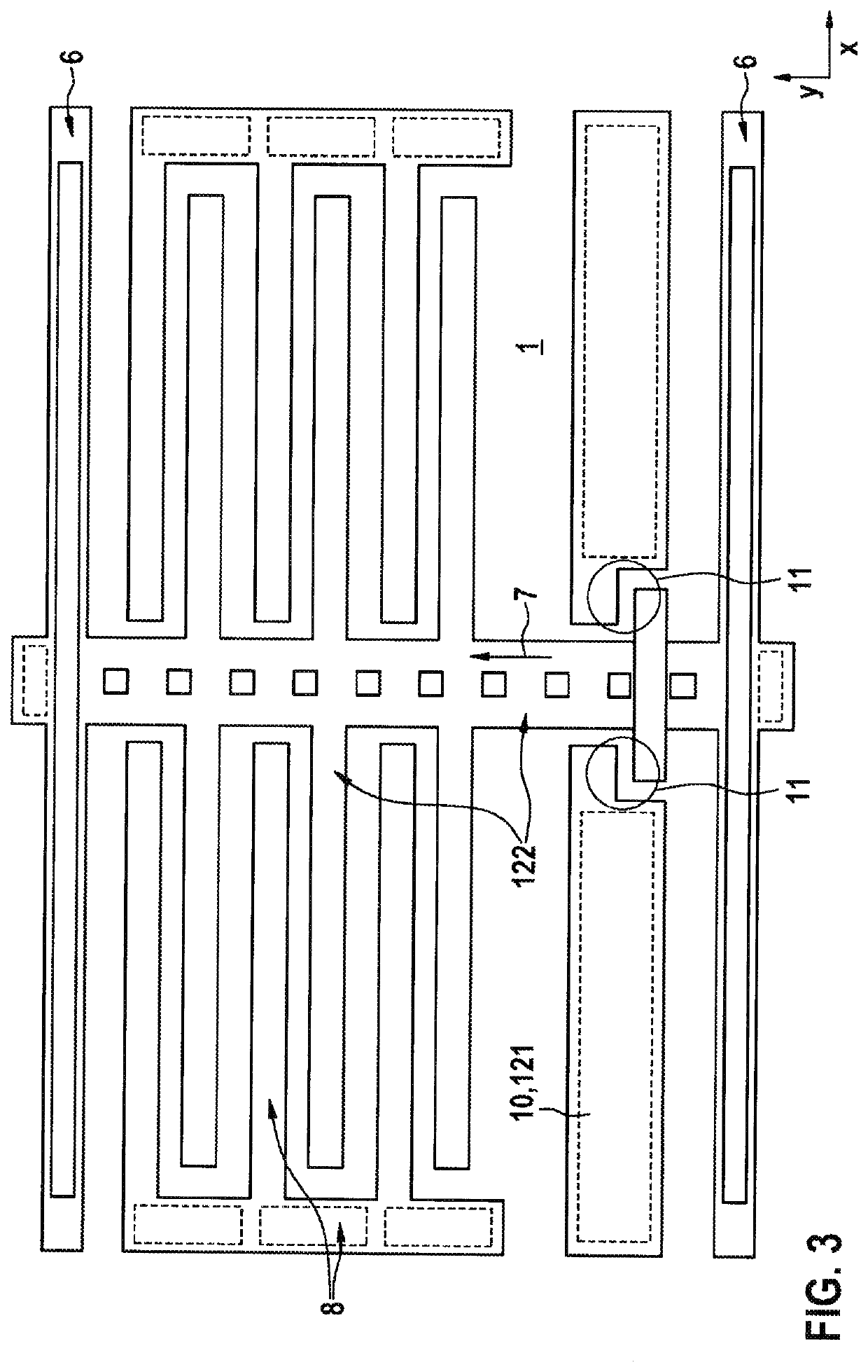

ActiveCN101868905ASmall gap widthOptimizing Magnetic FluxMagnetic circuit stationary partsMetal working apparatusEngineeringDrive motor

The invention relates to a drive unit for a hair cutting machine, comprising a driving motor (1) that consists of a substantially U-shaped stator (100) which has a first leg (110), a second leg (120), and at least one additional leg (130) located between the first leg (110) and the second leg (120), at least one field coil (140) which can be disposed on the at least one additional leg (130), and an armature (150). Lateral air gap sections (A, B) are formed between the first and second leg (110, 120) and the armature (150) while central air gap sections (a, b) are formed between the additionalleg (130) and the armature (150). The central air gap sections (a, b) and the lateral air gap sections (A, B) extend at an angle from a longitudinal axis (L). A first nose (112), which faces away from the additional leg (130), is arranged at the end of the first leg (110), while a notch (122), which faces the additional leg (130) and corresponds to the first nose (122), is arranged on the second leg (120).

Owner:WAHL

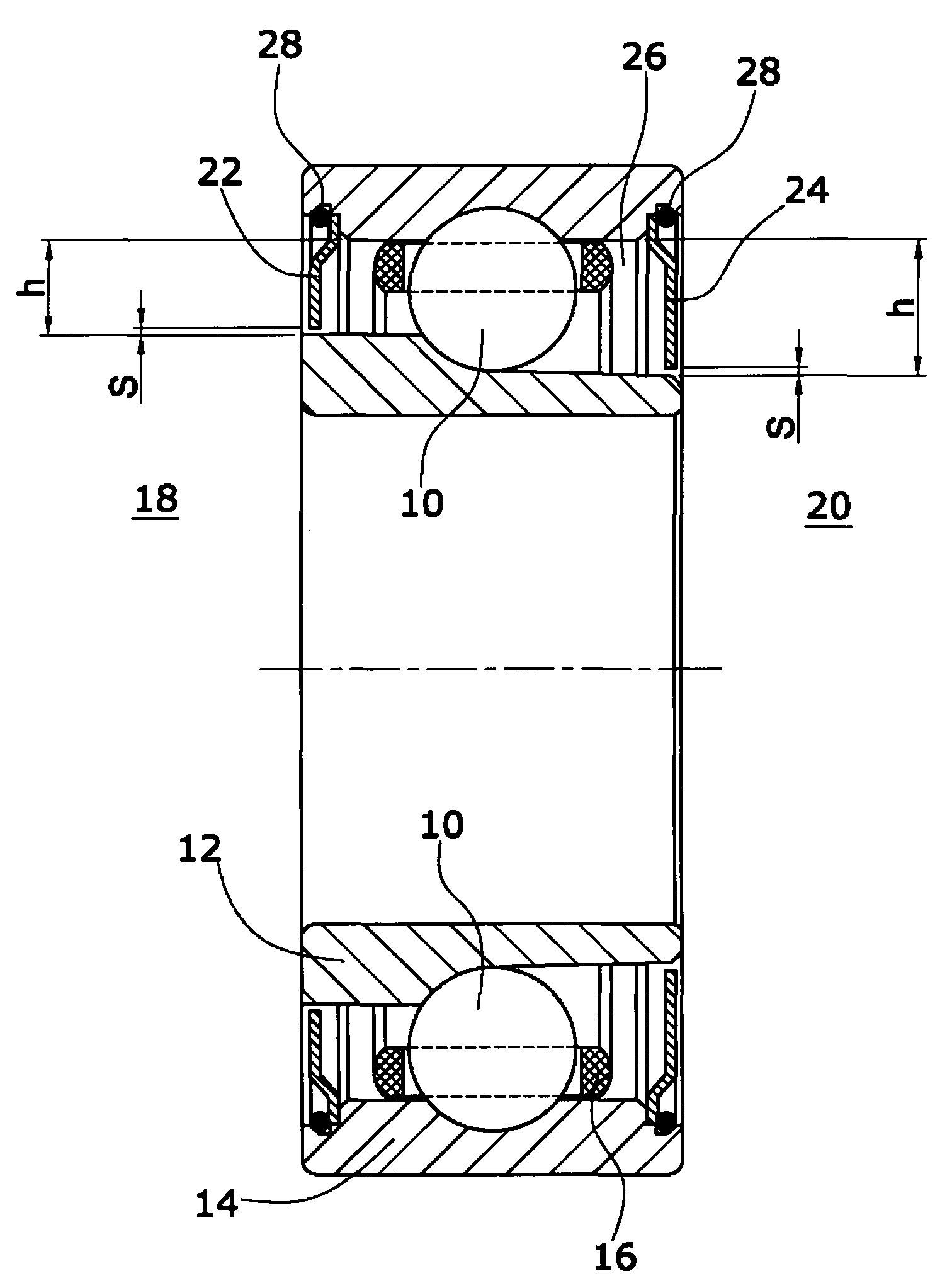

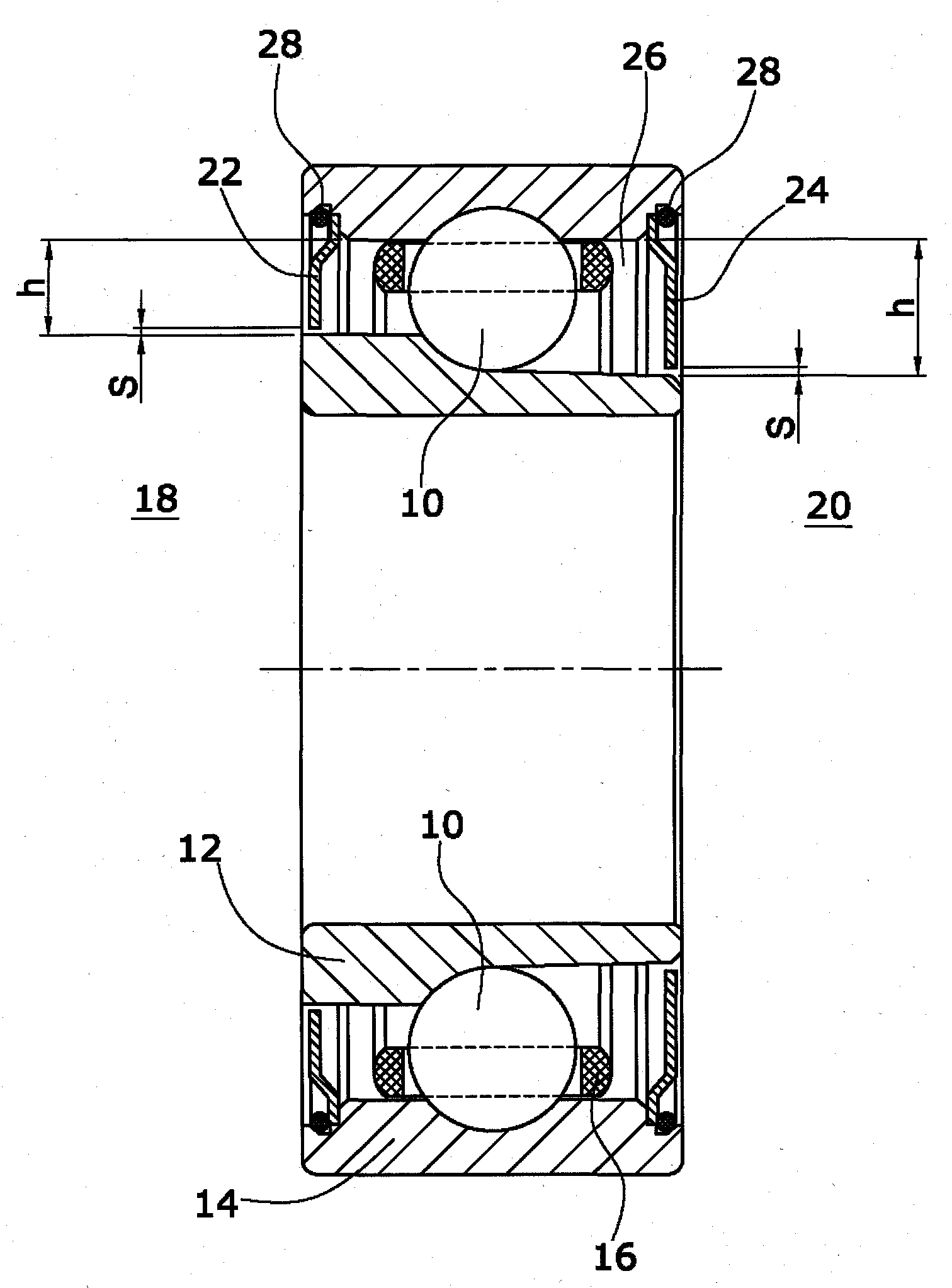

Use of a rolling-element bearing for bearing rotating components in vacuum devices and vacuum device

InactiveCN102105653APrevent or greatly reduce leaksSmall gap widthPump componentsShaftsRolling-element bearingEngineering

Owner:OERLIKON LEYBOLD VACUUM

Counterholder and method for supporting at least one of two boundary surfaces, between which a medium is arranged

PendingCN111193081AReduce deformationAvoid deformationFinal product manufactureSecondary cellsPhysicsThickened fluids

Owner:AUDI AG

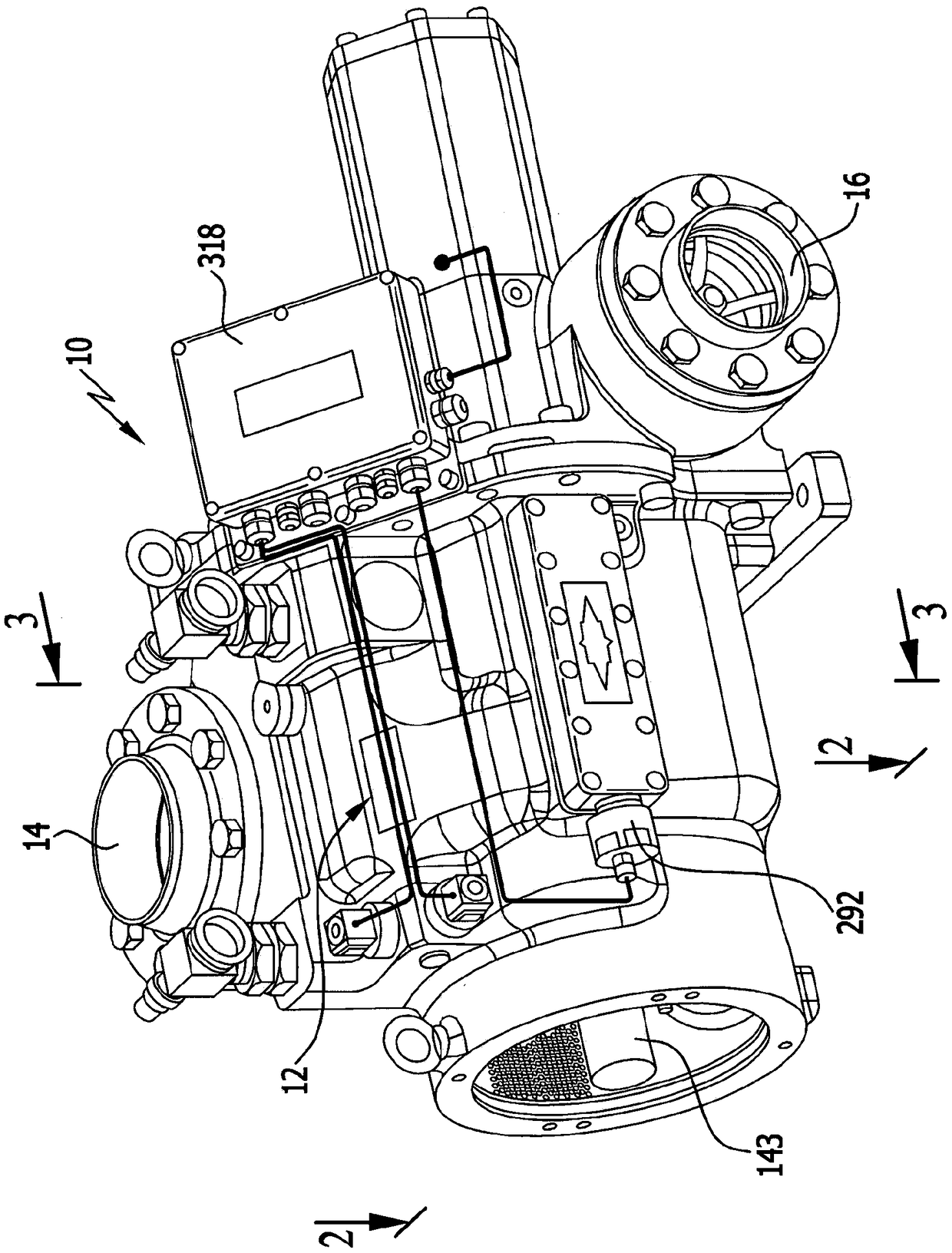

Screw compressor

ActiveCN109072919ASmall gap widthRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Screw compressor comprising a compressor housing (12) with a screw rotor chamber which is arranged therein, two screw rotors (26, 28) which are arranged in the screw rotor chamber, are mounted such that they can be rotated in each case about a screw rotor axis on the compressor housing (12), and engage into one another by way of the screw contours thereof, and two control slides (52, 54) which arearranged in a slide channel (56) of the compressor housing so as to lie behind one another in a displacement direction which runs parallel to the screw rotor axis, adjoin the two screw rotors with slide compression wall surfaces, and can be moved in the displacement direction, wherein the first control slide (52) and the second control slide (54) can be moved, in a composite position with end sides which face one another, in the displacement direction in a manner which is joint and terminates sealingly with one another, and can be positioned at a spacing from one another in a separated position with the formation of an intermediate space, wherein the control slides form an inflow chamber (198) at least in a transition position which lies between the composite position and the separated position, into which inflow chamber (198) the medium to be compressed flows from one of the compression chambers, by virtue of the fact that it passes between the end sides of the control slides which face one another, and wherein one of the control slides is provided with at least one outflow outlet (212) which adjoins the inflow chamber and through which the medium from the inflow chamber (198) enters into an outflow opening (144) on the slide channel (56), which outflow opening (144) overlaps with the outflow outlet in said transition position.

Owner:BITZER KUEHLMASCHINENBAU GMBH

Device and method for cutting tobacco from a tobacco bale

InactiveCN100521985CSmall gap widthEliminate contactTobacco preparationTobacco treatmentAgricultural engineeringStructural engineering

Owner:HAUNI PRIMARY

Method for connecting an energy storage module to a module support, in particular a cooling element

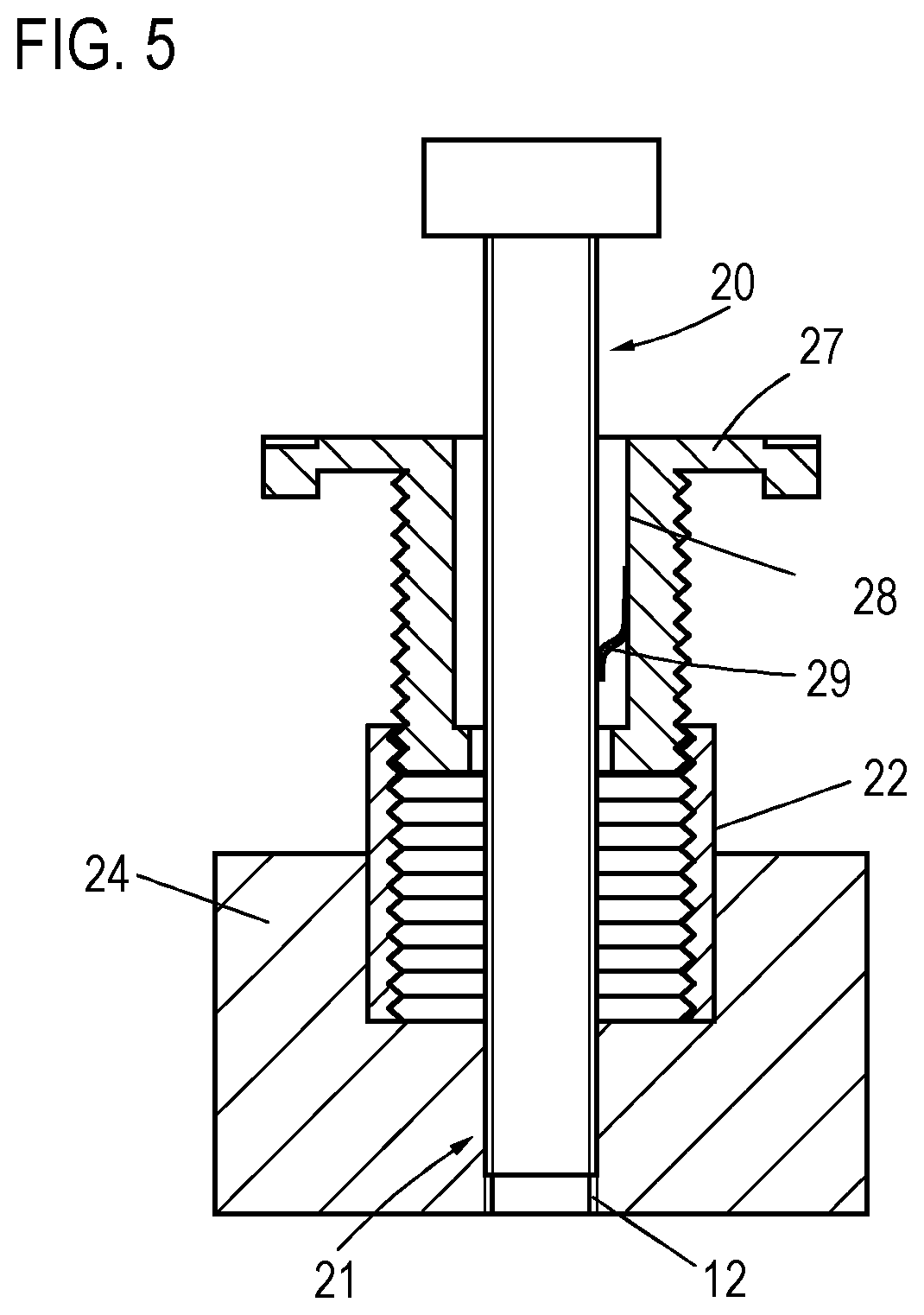

ActiveUS20210328249A1Small gap widthHigh strengthFinal product manufactureSecondary cells manufactureThermodynamicsScrew thread

A method for connecting an energy storage module to a module support, in particular a cooling element, The energy storage module is fastened on the module support by multiple connecting screws, which are each screwed into threaded bores provided on the module support. A gap is provided between the bottom of the energy storage module and the bottom of the module support, into which a thermally-conductive compound is introduced, which is distributed to fill the gap due to a reduction of the gap width when the energy storage module is screwed down.

Owner:AUDI AG

Centrifugal compressors for exhaust gas turbochargers

ActiveCN103671265BIncrease air flow rateSmall gap widthPump componentsEngine fuctionsPlastic materialsTurbocharger

The compressor (1) has a sleeve-like adapter element (10) sectionally including a surface contour (13) at an axial front side (12), which faces towards a compressor wheel (6) in an axial fixing position. The surface contour is formed complementary to an axial wheel-surface contour (9) so that a width (w) of a passage gap (14) is adjusted by axially moving an adapter element in a fastening section (11) in a non-fixed condition of the adapter element. The gap is axially formed between the adapter element and the compressor wheel along the surface contours facing towards each other. The adapter element is made of a plastic material. Independent claims are also included for the following: (1) a turbocharger (2) a method for manufacturing a radial compressor.

Owner:BMTS TECH SHANGHAI CO LTD

Use of a rolling-element bearing for bearing rotating components in vacuum devices and vacuum device

InactiveCN102105653BPrevent or greatly reduce leaksSmall gap widthPump componentsShaftsRolling-element bearingEngineering

Owner:OERLIKON LEYBOLD VACUUM

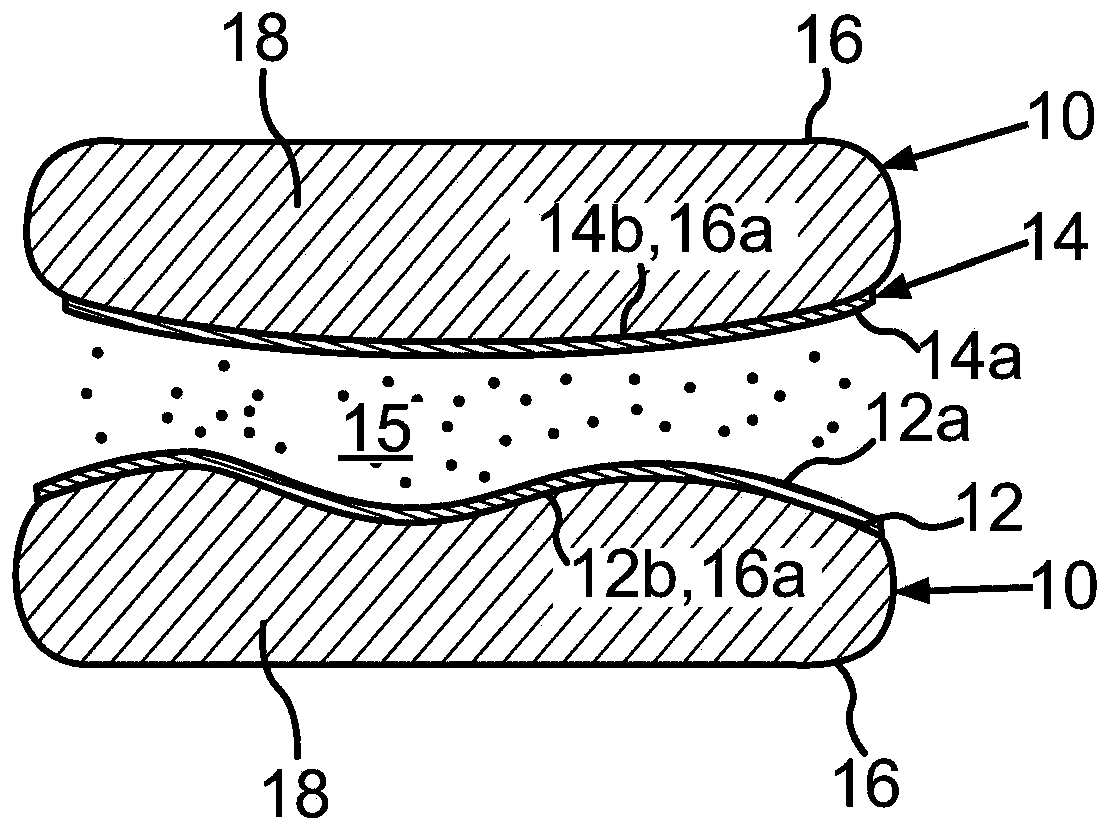

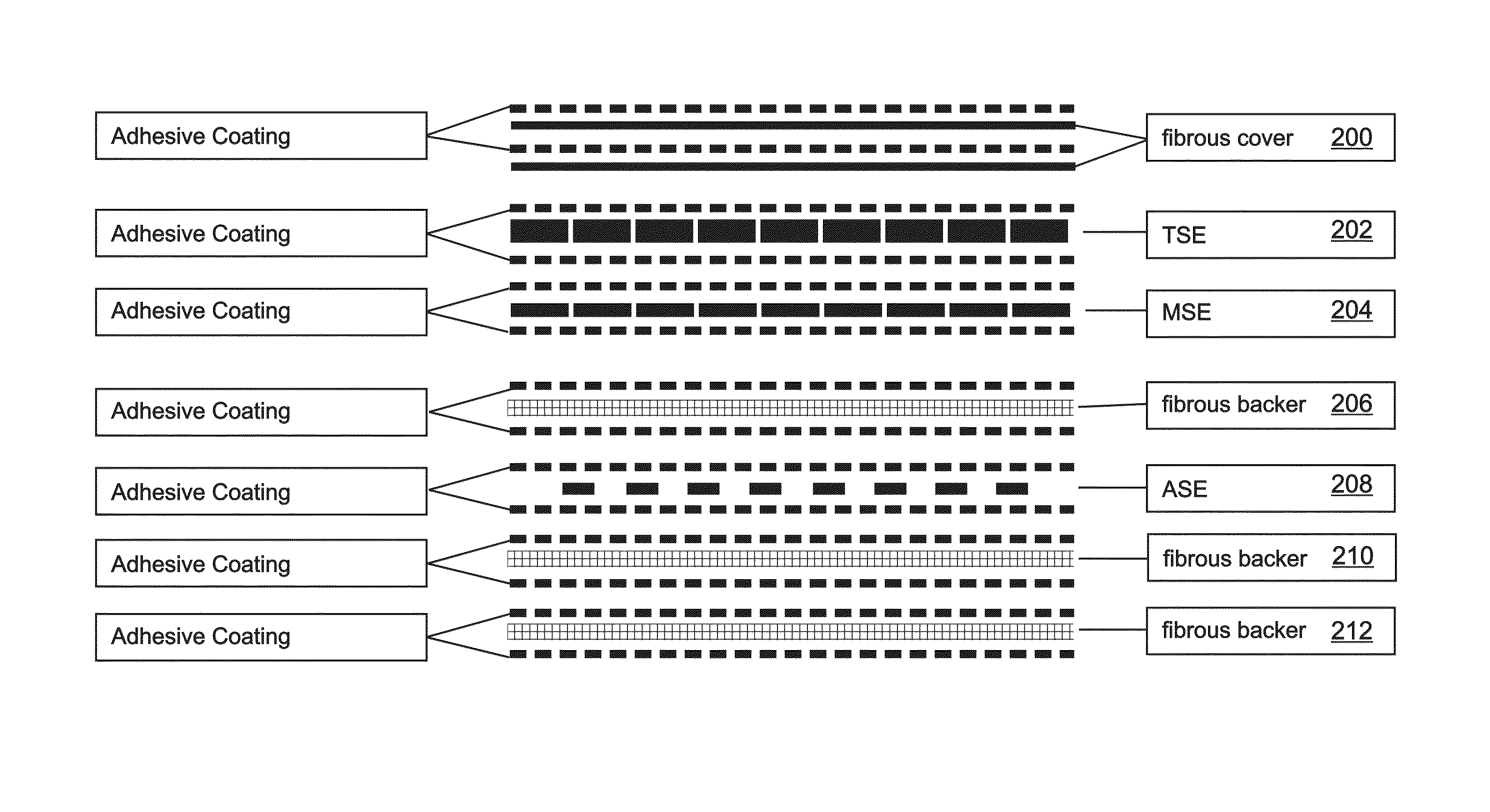

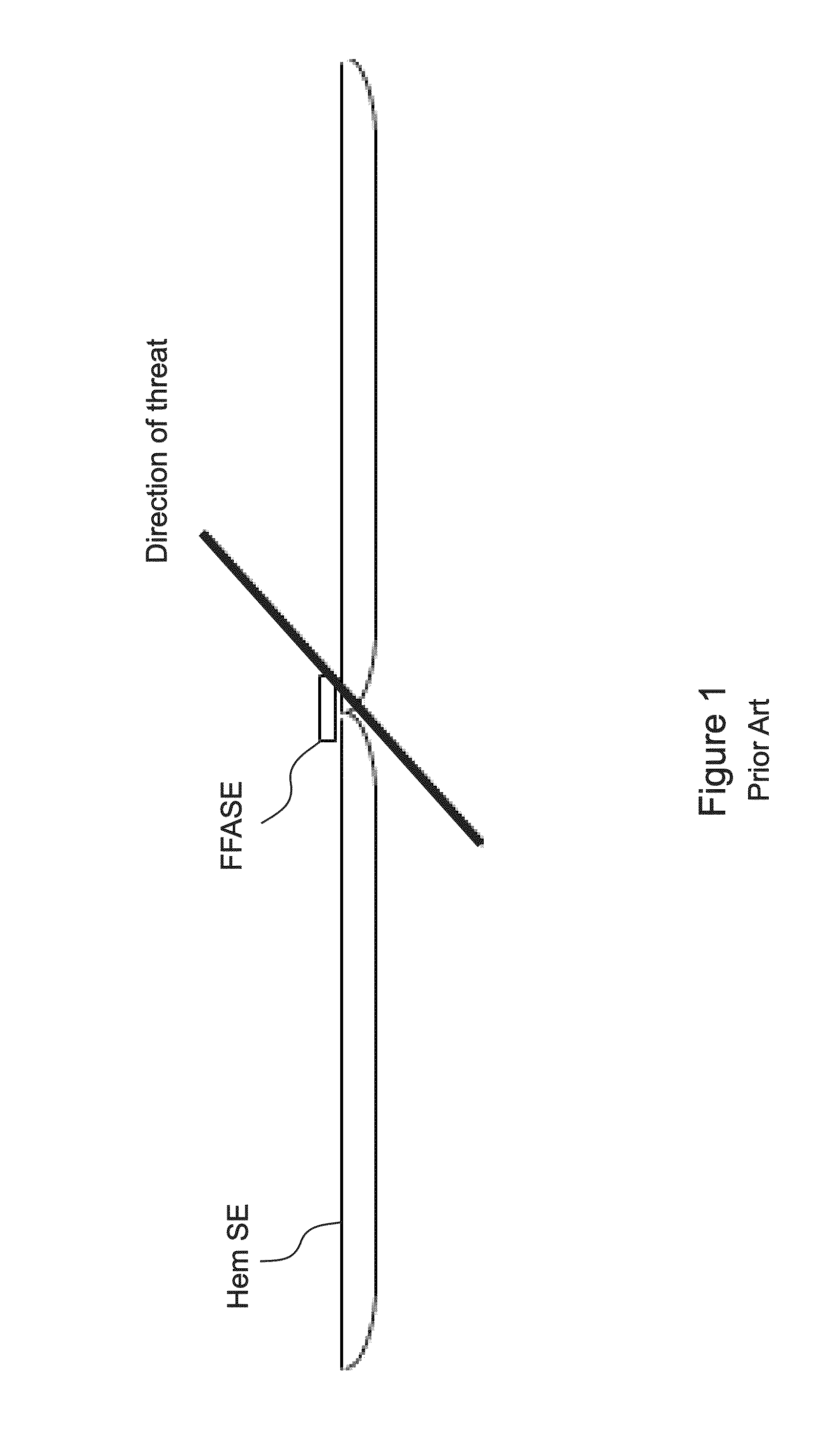

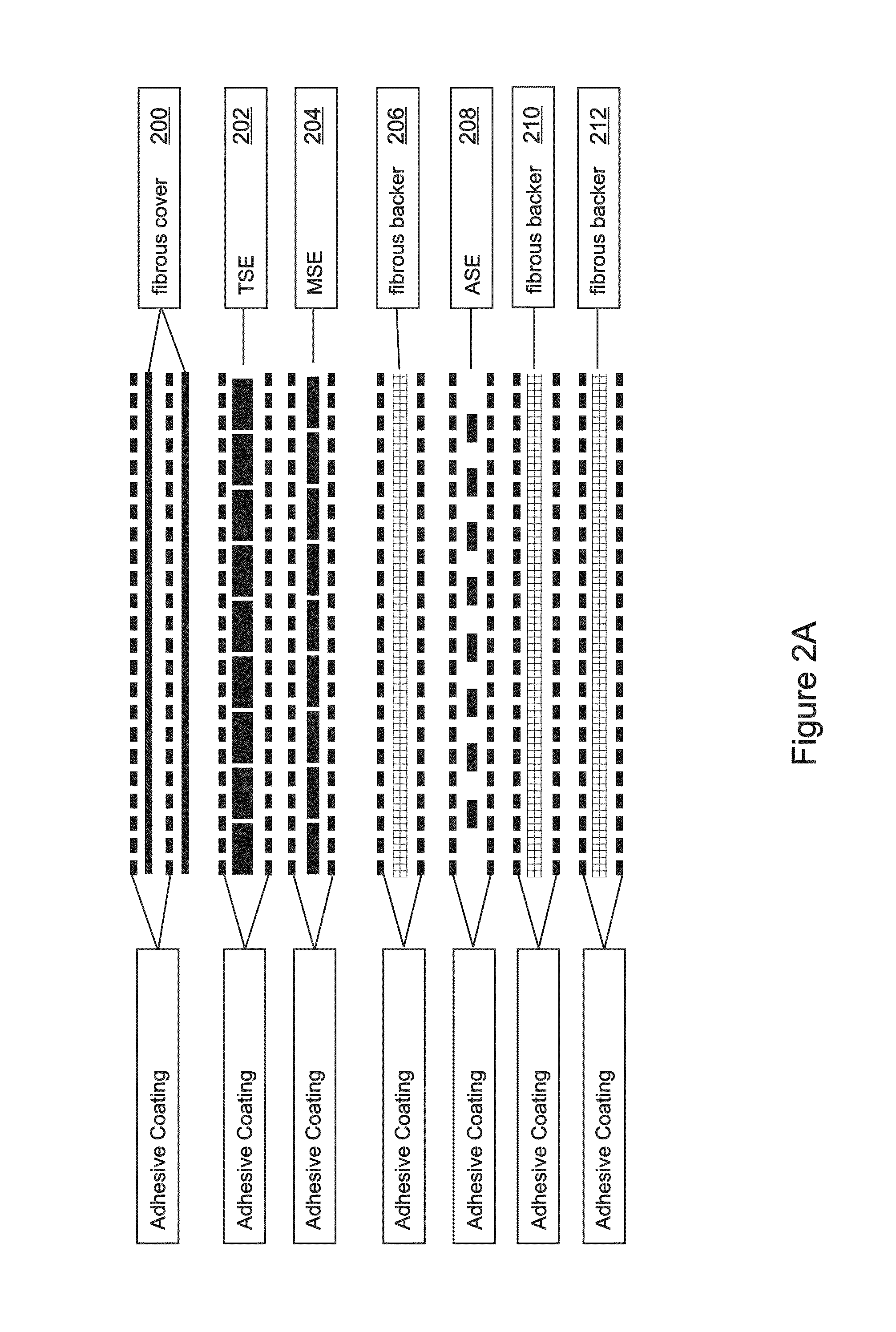

Multi-layer solid element mosaic body armor for on-axis and off-axis threats

ActiveUS9200873B2Small gap widthProtective equipmentSynthetic resin layered productsEngineeringBody armor

A flexible mosaic armor system that defeats threats at any attack angle includes top and middle solid elements layers separated by uniform gaps that intersect at apexes. The top elements can have a “hem” shape with raised edges. The middle elements can be flat, or can also have a hem shape. In embodiments, the edges of the top and middle layers are aligned and separated by an offset that is three or four times the gap width. Off-axis spike and needle strikes are thereby trapped between the two solid element layers, without added textile reinforcement. Embodiments include an apex layer of solid elements that overlap the first layer apexes, the apex layer being the second layer or a third layer beneath the 2 upper layers. The apex layer can be sandwiched between two textile backer layers that provide a full uninterrupted bonding surface to all of the solid element layers.

Owner:WARWICK MILLS INC

Dual-flow centrifugal pump

InactiveUS20130156545A1Improve efficiencySmall diameterPump componentsWorking fluid for enginesPositive pressureEngineering

A double-flow centrifugal pump is disclosed, in which, using an impeller, a fluid can be suctioned from two axial sides from a negative pressure area and can be delivered in the radial direction into a positive pressure area. The negative pressure area is sealed off with respect to the positive pressure area by at least one stationary pump component, for example the pump housing and / or an insert part. According to the invention, sealing gaps are formed as axial gaps arranged axially between the impeller and the pump component and extending in the circumferential direction and in the radial direction, wherein the gap width(s) of said axial gaps is less than the radial spacing (a) of the impeller from all the components arranged with a radial spacing from the impeller.

Owner:ALLWEILER

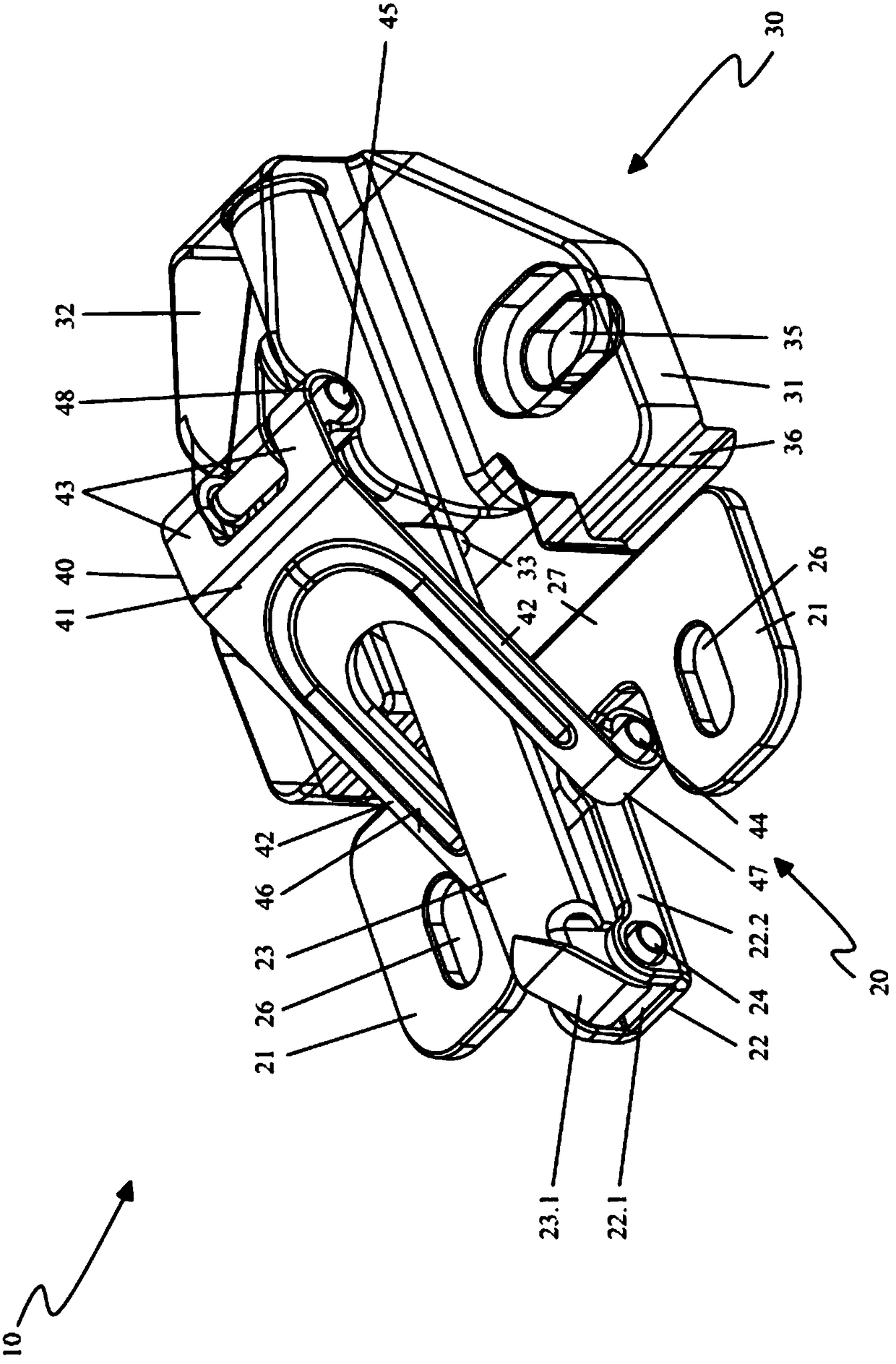

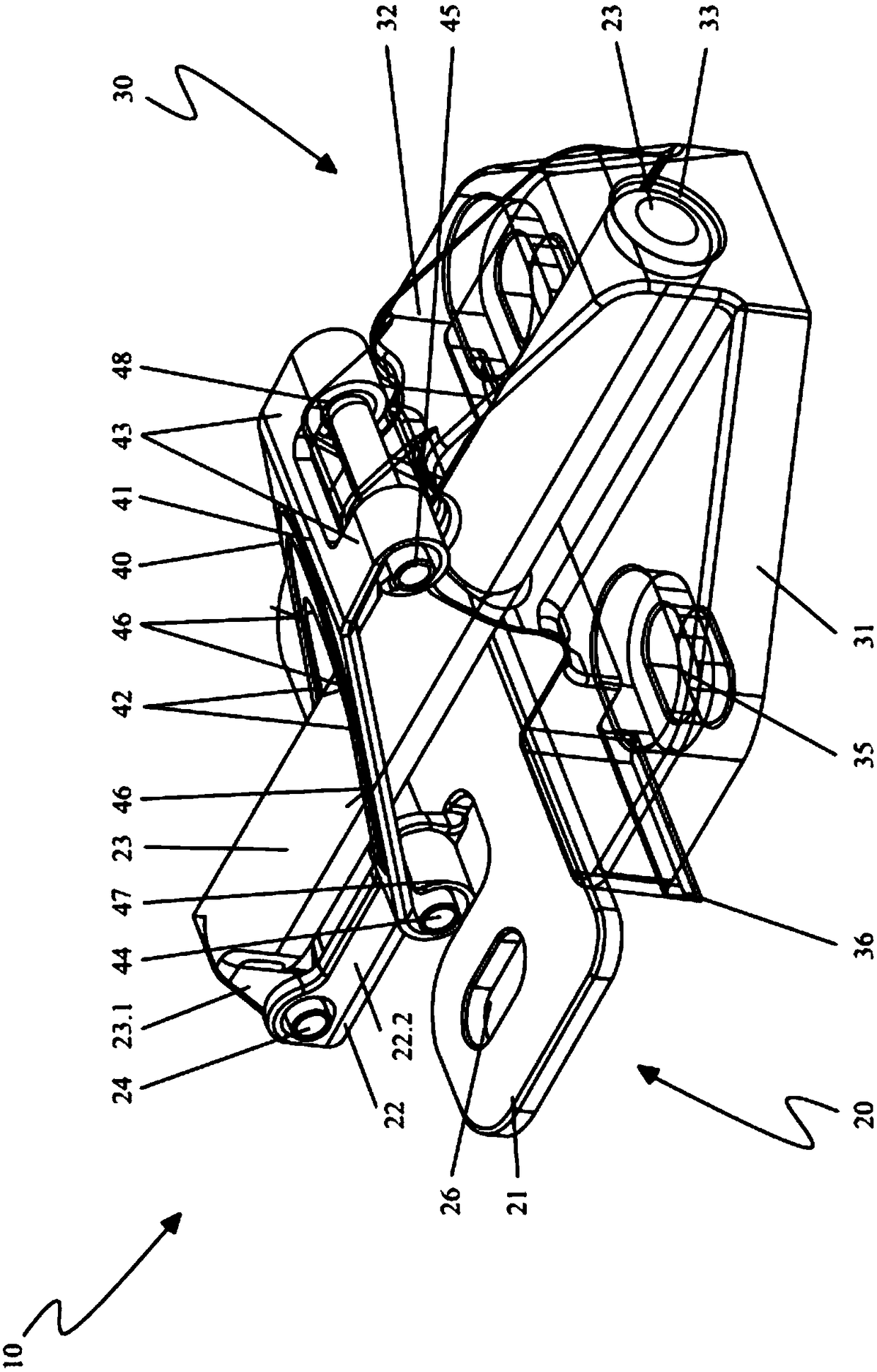

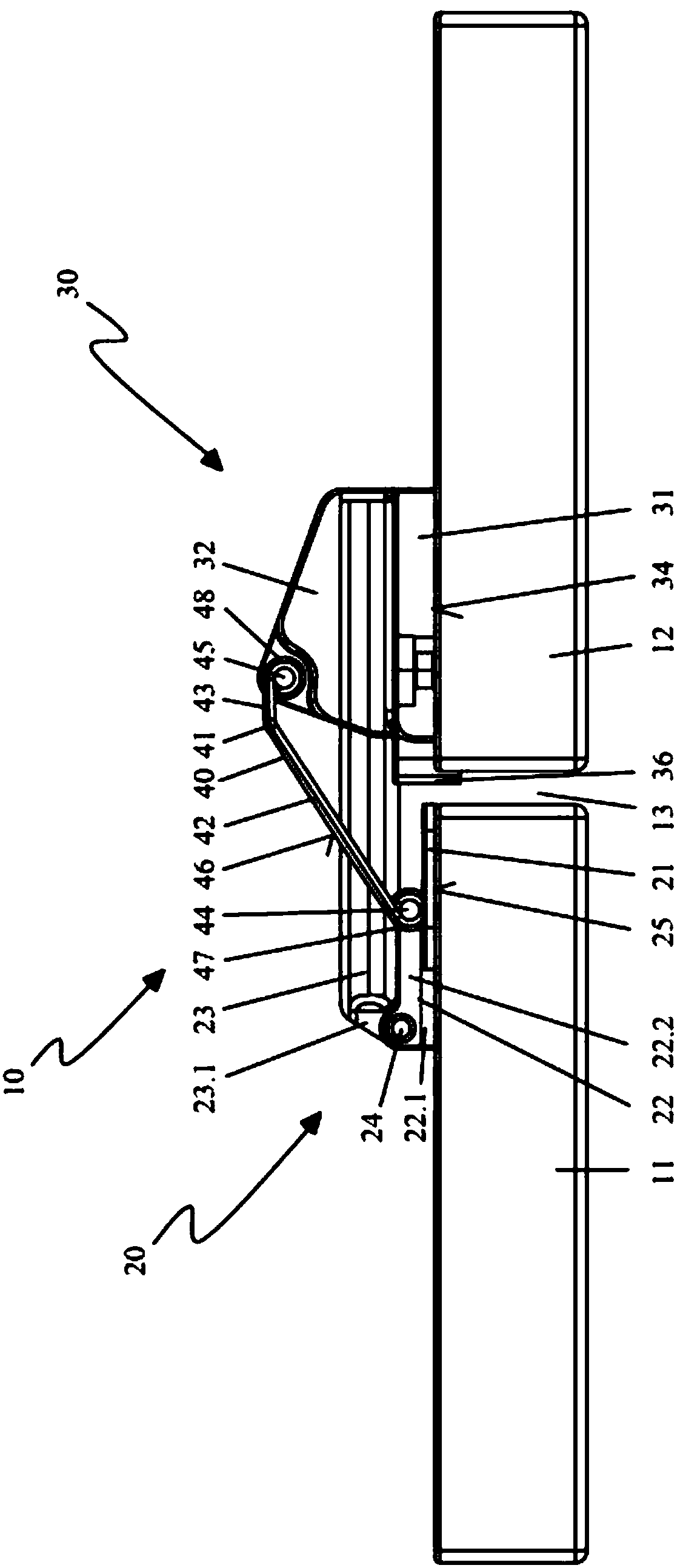

Hinge with Anti-jamming mechanism and method for adjusting securing parts of a hinge

ActiveCN108868409AAdjust pivot pointOrientation is accurateWing accessoriesPin hingesAnti jammingEngineering

The invention relates to a hinge with two securing parts for directly or indirectly securing to two furniture parts which can be pivoted relative to each other, wherein the securing parts are pivotally connected together via a connection assembly. A linear guide element is arranged on each of the two securing parts, said linear guide elements interacting in order to form a linear guide, and the hinge has a guide device which is designed to adjust the linear guide depending on the interrelated pivot positions of the securing parts. The invention further relates to a method for adjusting a firstsecuring part of such a hinge relative to a second securing part in an articulated manner. The hinge and the method allow a pivotal connection between furniture parts with an at least reduced risk ofinjury.

Owner:SAMET KALIP VE MADENI ESYA SAN TIC AS

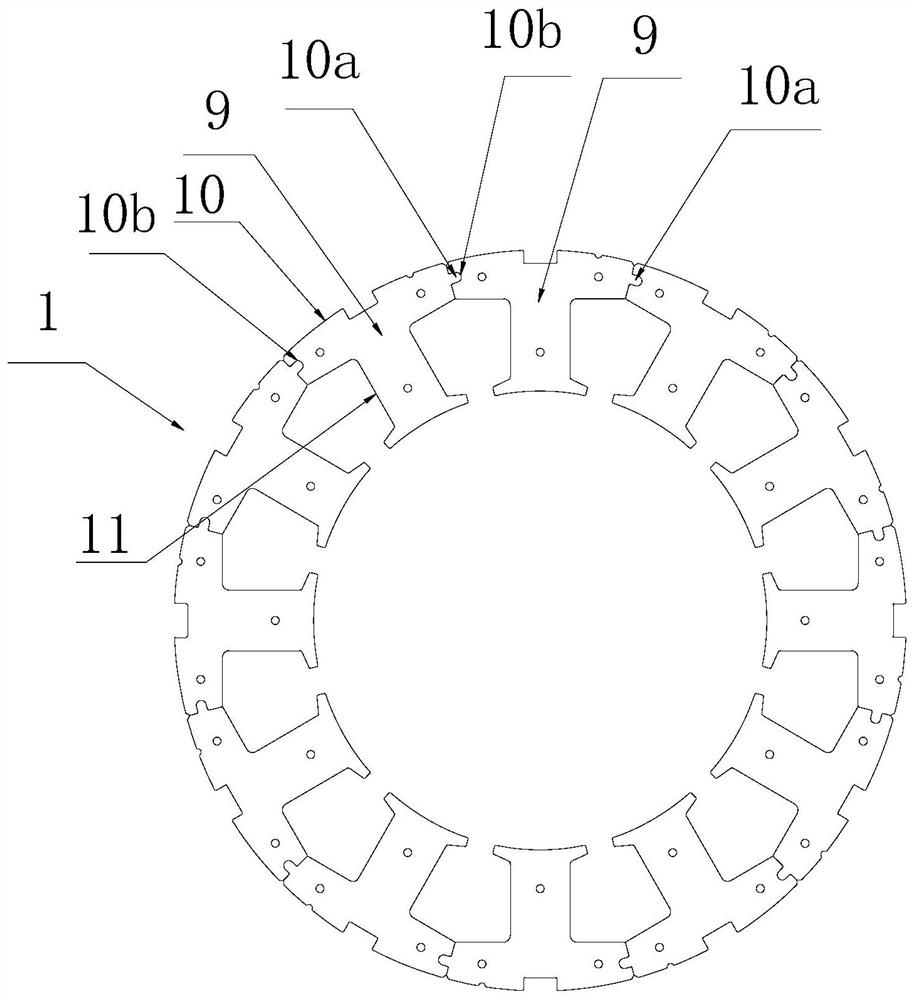

Permanent magnet motor stator

PendingCN112838686ALower positioning heightShorten the lengthWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machinePermanent magnet motor

The invention discloses a permanent magnet motor stator, which comprises a stator iron core, windings wound on tooth parts on the inner side of the stator iron core, and a wiring structure used for connecting winding outgoing lines with power lines, wherein the wiring structure comprises an upper insulating frame fixed at the top of the stator core, a wiring disc fixed on the upper insulating frame and provided with a central hole, and wiring terminals distributed on the wiring disc and used for being welded with winding outgoing lines one by one. The motor stator is characterized in that winding outgoing lines of the stator core are bent towards the surface of the patch board and then are welded and fixed with the wiring terminals arranged on the inner circumference of the patch board one by one. According to the wiring structure of the stator, the winding outgoing line and the wiring terminal are easier to weld, so that the whole stator is easier to manufacture, the production cost is lower, and the production efficiency is higher.

Owner:SUZHOU SHENGYI MOTOR

Bearing arrangement with self-adjusting force elements which are resistant to malfunctioning

ActiveCN111684164ASmall gap widthSimple replaceabilityRotary combination bearingsShaftsSlider bearingClassical mechanics

Owner:THYSSENKRUPP ROTHE ERDE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com