Ultra-narrow gap welding device and method for pipe fitting welding

A welding device and pipe fitting welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as bed defects, and achieve the effects of simple installation, prevention of arc climbing, and low heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

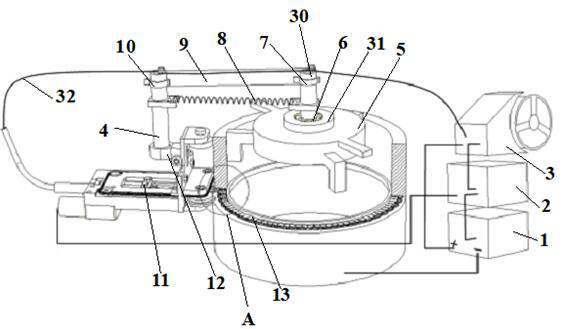

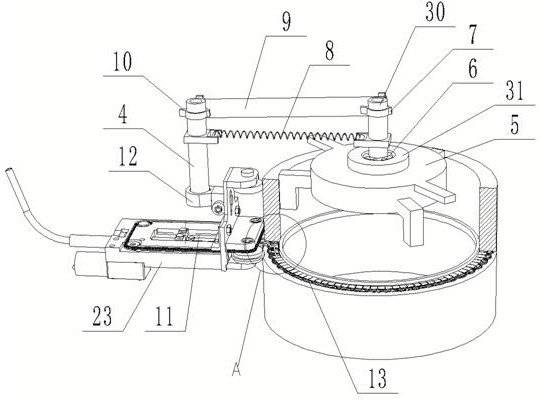

[0048] refer to Figure 1 to Figure 4 , an ultra-narrow gap welding device for welding pipe fittings. The welding device includes a welding mechanism, a rotating mechanism and a positioning mechanism; the welding mechanism rotates around the positioning mechanism through the rotating mechanism, and the positioning mechanism is arranged inside the pipe to be welded. The positioning mechanism is mainly The position of the welding mechanism in the groove is positioned, and the rotating mechanism is connected to the positioning mechanism in rotation;

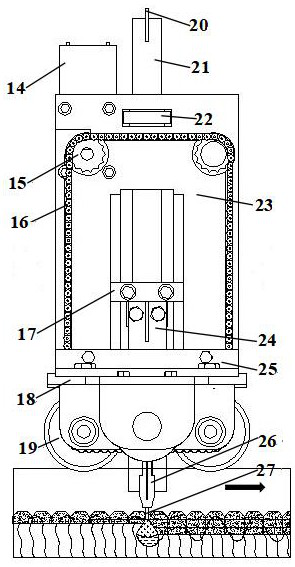

[0049] The welding mechanism comprises a motor 14, a first sprocket wheel 15, a chain 16, a support plate 18, a positioning wheel 19, a support frame 23, and a plate welding torch 11; The plate 25 is fixedly installed on the support frame 23, and the outer surface of the support plate 18 is evenly equipped with at least three positioning wheels 19 that match the pipe fittings to be welded, and a gap is provided between two adjacent ...

Embodiment 2

[0066]The present invention is mainly used for the welding of large pipe fittings and valve bodies. The groove gap used is between 4.5-5mm. Generally, the groove is assembled into an I-shaped groove of about 1.8°, and the thickness of each welding is 3-4mm. Left and right, in order to be able to weld in a narrow gap, the welding torch is a plate welding torch with a thickness of 3mm, and the flux is used to bring a restricted arc. The thickness is about 0.7mm, and its main components are limestone and fluorite. According to the composition of the weldment and welding quality It is required to properly add an appropriate amount of alloying elements, and the structure of the flux tape is a glass fiber net bonded with a flux sheet.

[0067] An ultra-narrow gap welding method for pipe fittings, comprising the steps of:

[0068] Before welding, derust and degrease the weldment, and clean the surface of the welding part of the pipe to be welded;

[0069] In order to effectively pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com