Display panel, manufacturing method thereof and electronic equipment

A technology of display panel and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., to achieve the effect of ensuring that signals do not interfere with each other and avoiding short-circuit problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

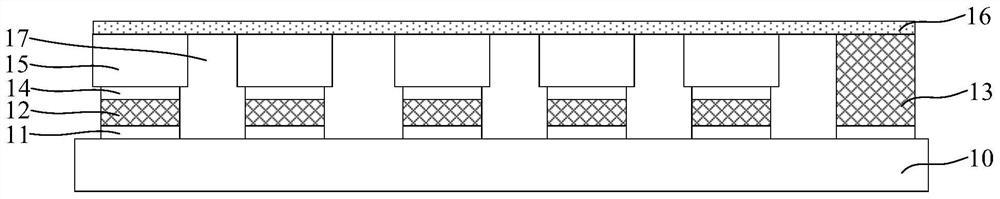

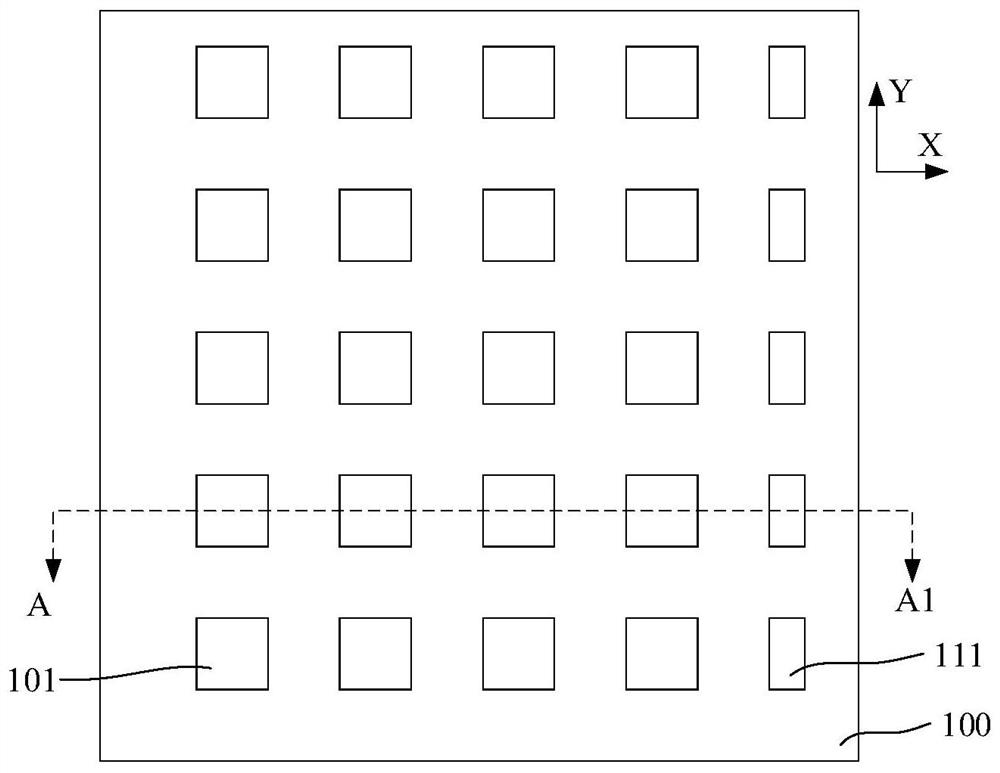

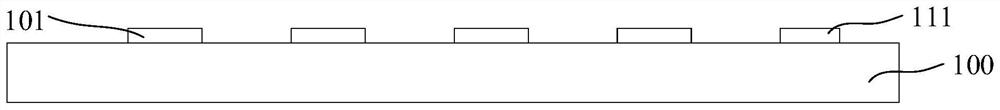

[0028] At present, the development of Micro-LED display panels based on vertical LED chips still has great technological difficulties. figure 1 It is a schematic cross-sectional structure diagram of a Micro-LED display panel, refer to figure 1 , the display panel includes: a driving backplane 10; a plurality of discrete array electrodes 11 positioned on the driving backplane 10; an LED chip, the LED chip including a lower electrode 14, an upper electrode, and a functional layer between the lower electrode 14 and the upper electrode 15, the lower electrode 14 is electrically connected to the array electrode 11 through the welding post 12; the common electrode post 13 located on the top surface of one of the array electrodes 11; a part of the common electrode layer 16 is used as the upper electrode, and the common electrode layer 16 also covers the common electrode post 13 top surface.

[0029] Wherein, the common electrode layer 16 needs to completely cover all the LED chips o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com