Bearing arrangement with self-adjusting force elements which are resistant to malfunctioning

A bearing device and bearing ring technology, applied in the direction of shafts and bearings, bearings in rotary motion, bearings, etc., can solve problems such as inability to measure, and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

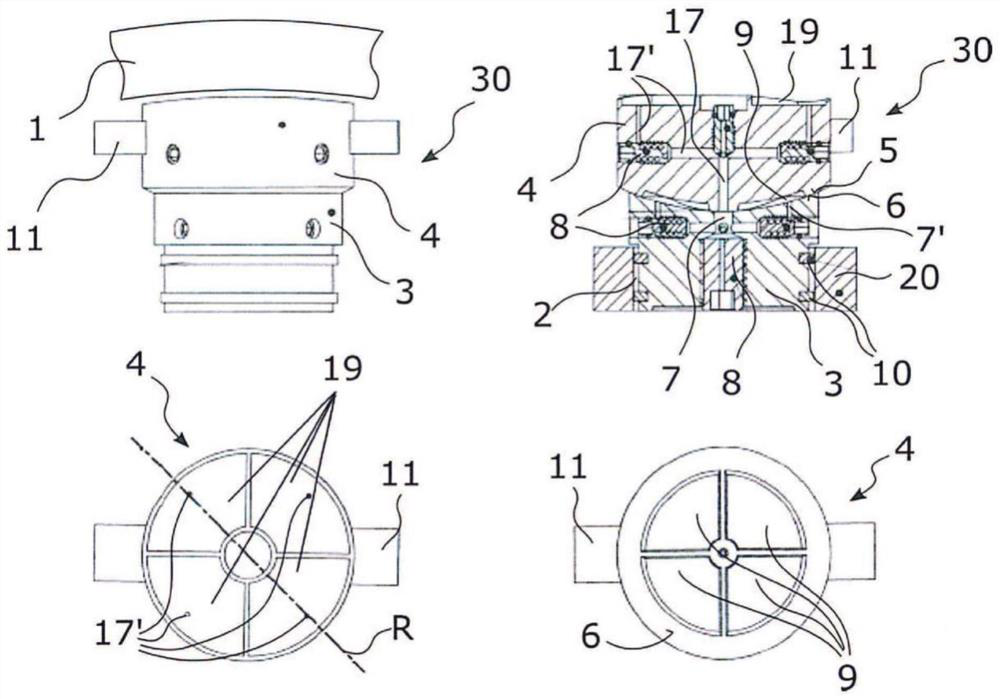

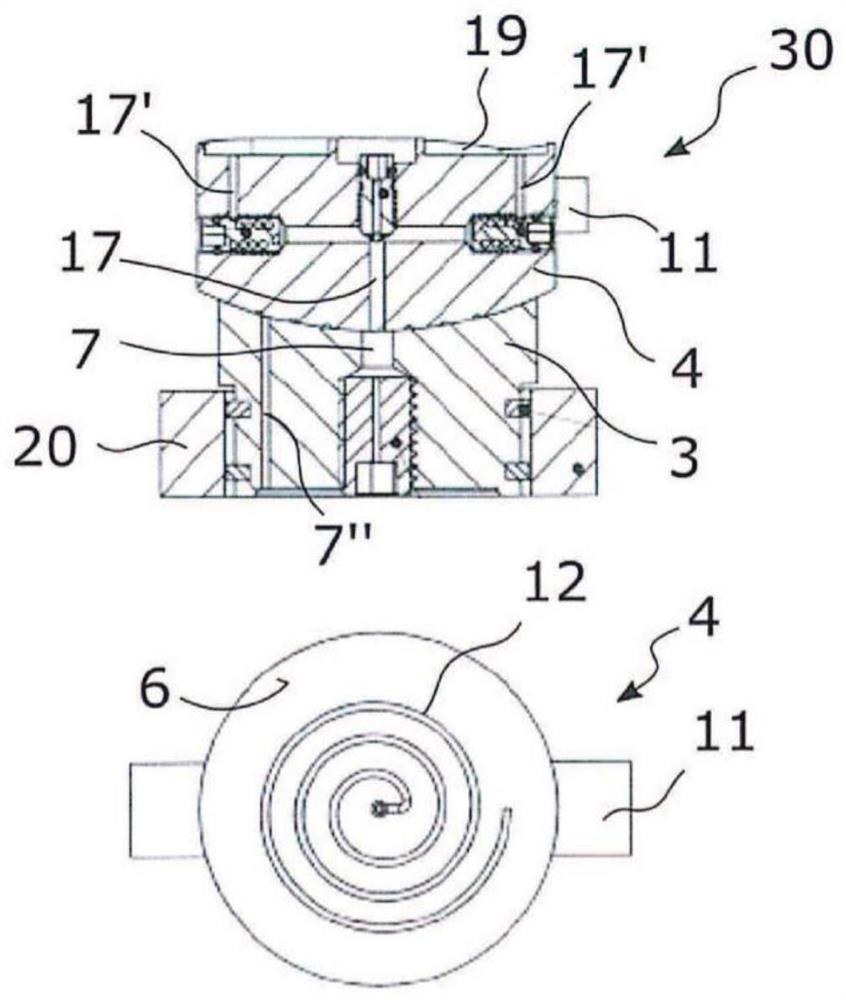

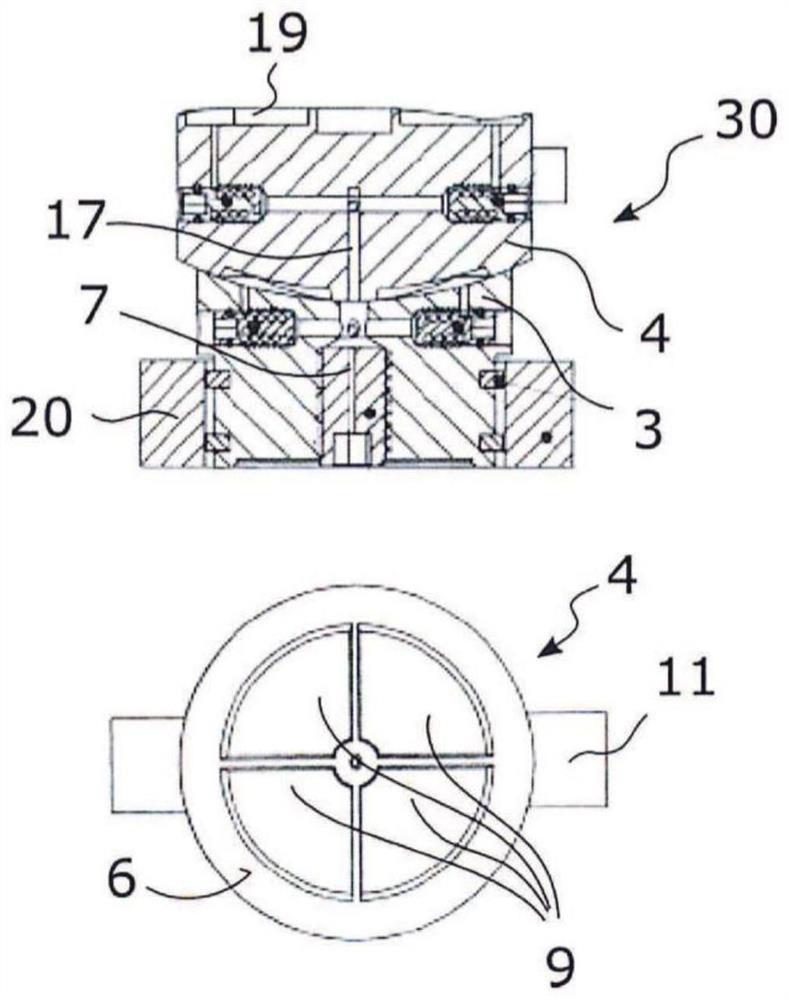

[0060] In the different figures, identical components are always provided with the same reference numerals and are therefore usually also named or mentioned only once in each case.

[0061] according to figure 1 The bearing arrangement of the first embodiment has a two-part shape according to the invention of the plain bearing segment 30 . As can be seen in the upper left side view, the plain bearing segment 30 is formed by the lower first sub-element 3 on which the second sub-element 4 is mounted in a hydrostatic bearing and upwardly, likewise Pressed against the rotating bearing ring 1 in a hydrostatic bearing. The lower sub-element 3 can move vertically here and can in this way compensate for changes in the distance between the lower, fixed bearing ring 20 and the upper, rotating ring 1 . In the following, vertical is also referred to as the adjustment direction and the first partial element 3 is correspondingly referred to as the adjustment punch 3 . The second subeleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com