Dual-flow centrifugal pump

a centrifugal pump and dual-flow technology, which is applied in the direction of motors, combination engines, working fluids for engines, etc., can solve the problems of significant impairment of the efficiency of the known centrifugal pumps and pump performance loss, and achieve the effect of smallest possible diameter and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

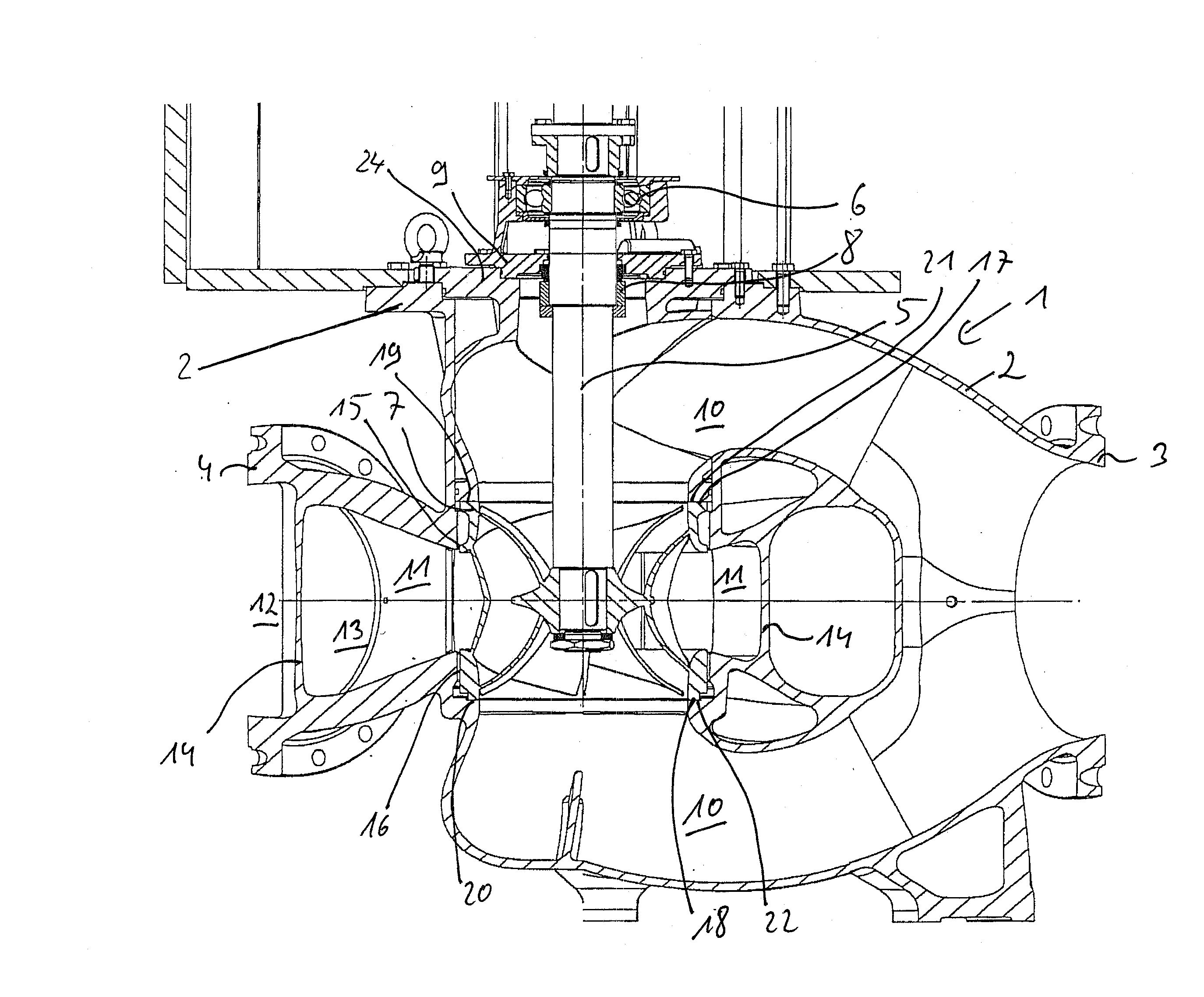

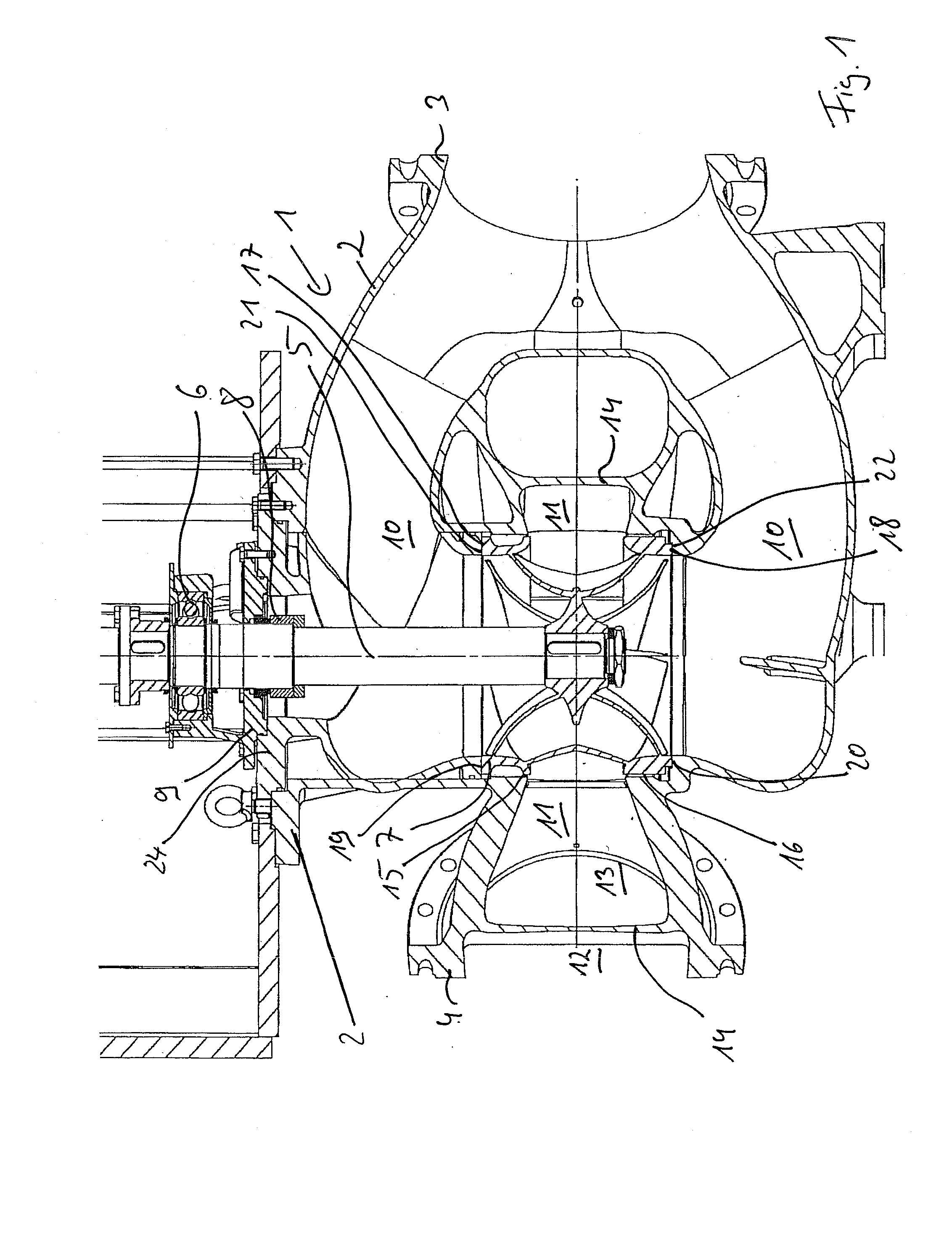

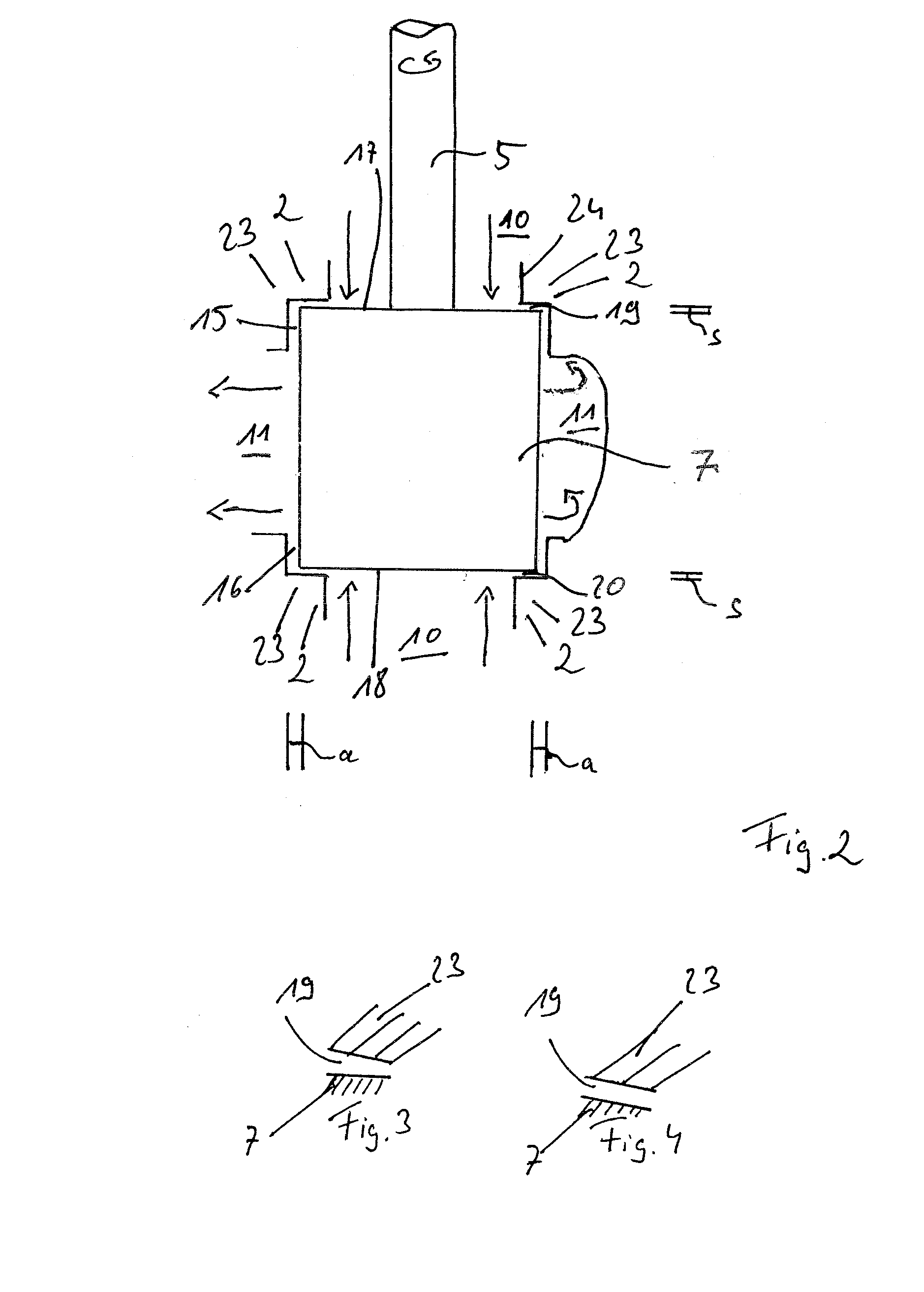

[0030]FIG. 1 shows a sectional view of a dual-flow centrifugal pump 1 in a vertical orientation (i.e., the impeller shaft is oriented vertically). The exemplary embodiment shown is a cooling water pump for a marine diesel engine designed for delivering a volume flow of 2300 m3 / h at a maximum delivery level of 30 m.

[0031]The centrifugal pump 1 comprises a pump housing 2 designed as a spiral housing and with a suction-side inlet 3 as well as a pressure-side outlet 4. A shaft 5 supported on one side extends into the pump housing 2 from above downward in a vertical direction and is supported by a bearing 6 constructed as a ball bearing. The shaft 5 carries on its inside a dual-flow impeller 7 with a substantially circularly cylindrical casing contour. The impeller 7 sits in a rotationally fixed manner on the shaft 5. A shaft seal 8 is located in an area axially between the support 6 and the impeller 7. As is apparent from FIG. 1 the shaft 5 extends in an area above the shaft seal 8 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com