Hinge with Anti-jamming mechanism and method for adjusting securing parts of a hinge

A technology of fixing parts and fixing elements, applied in the field of hinges, can solve problems such as damage, finger pinching, enlargement, etc., and achieve the effect of accurate and repeatable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

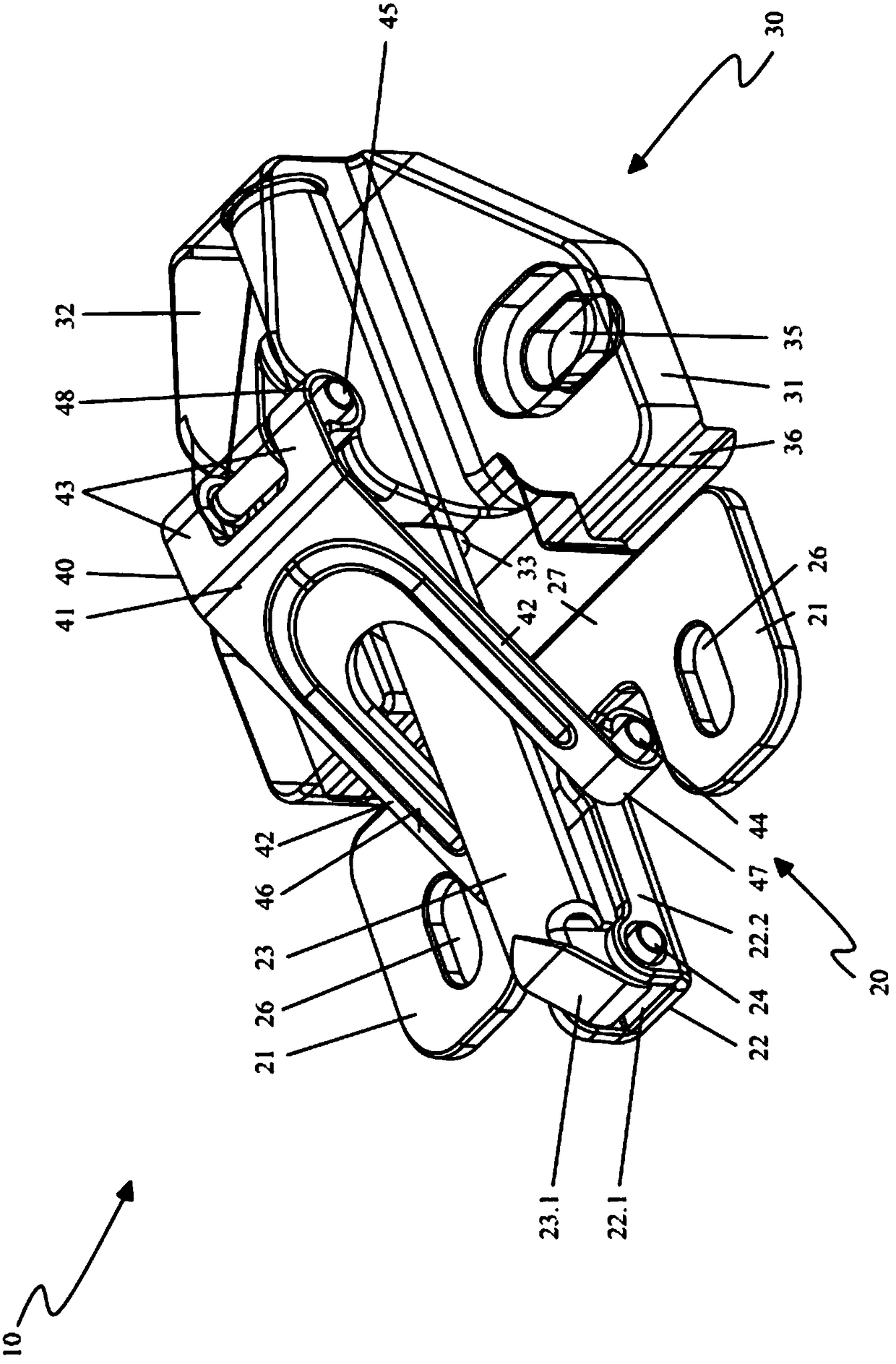

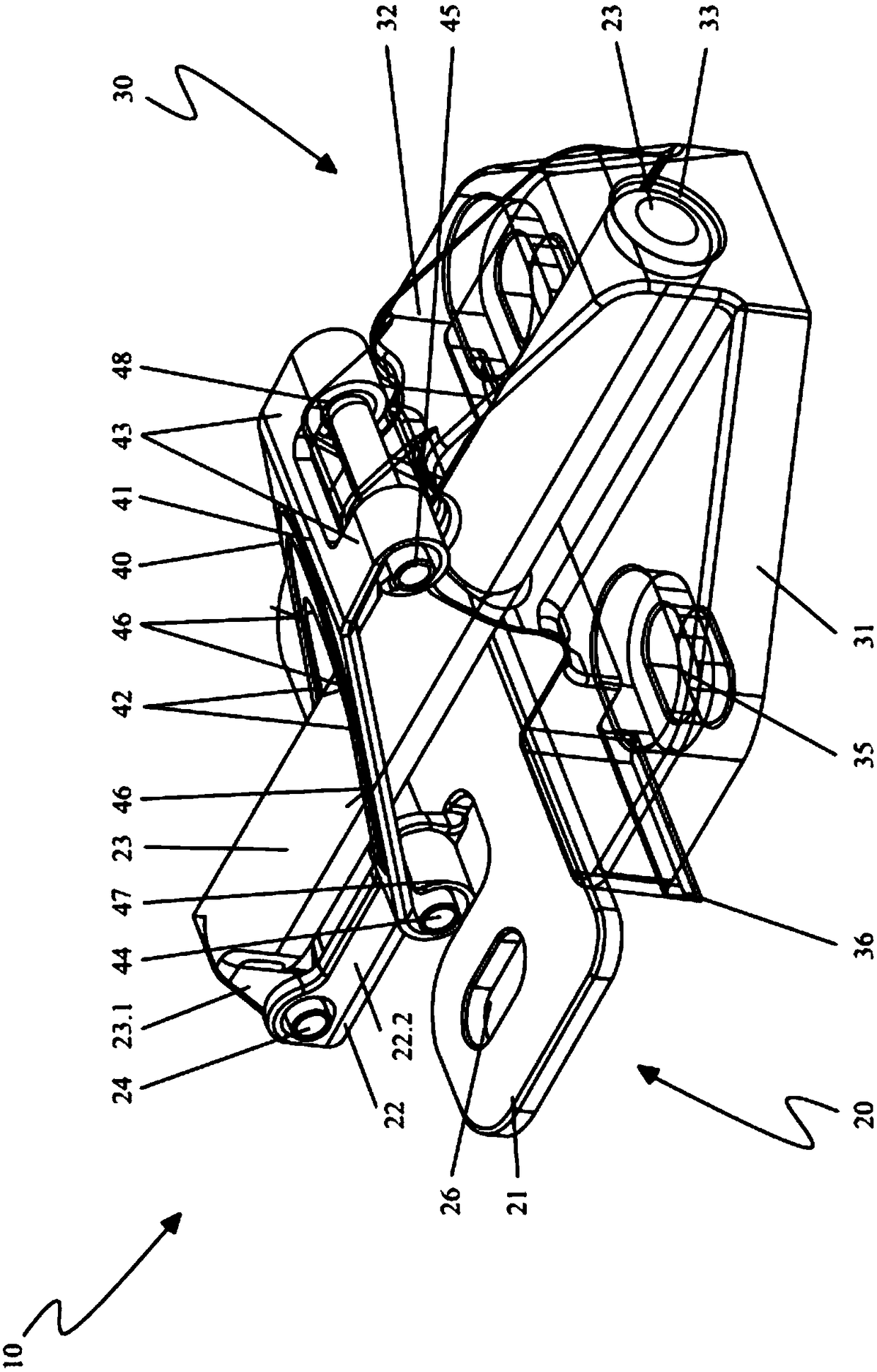

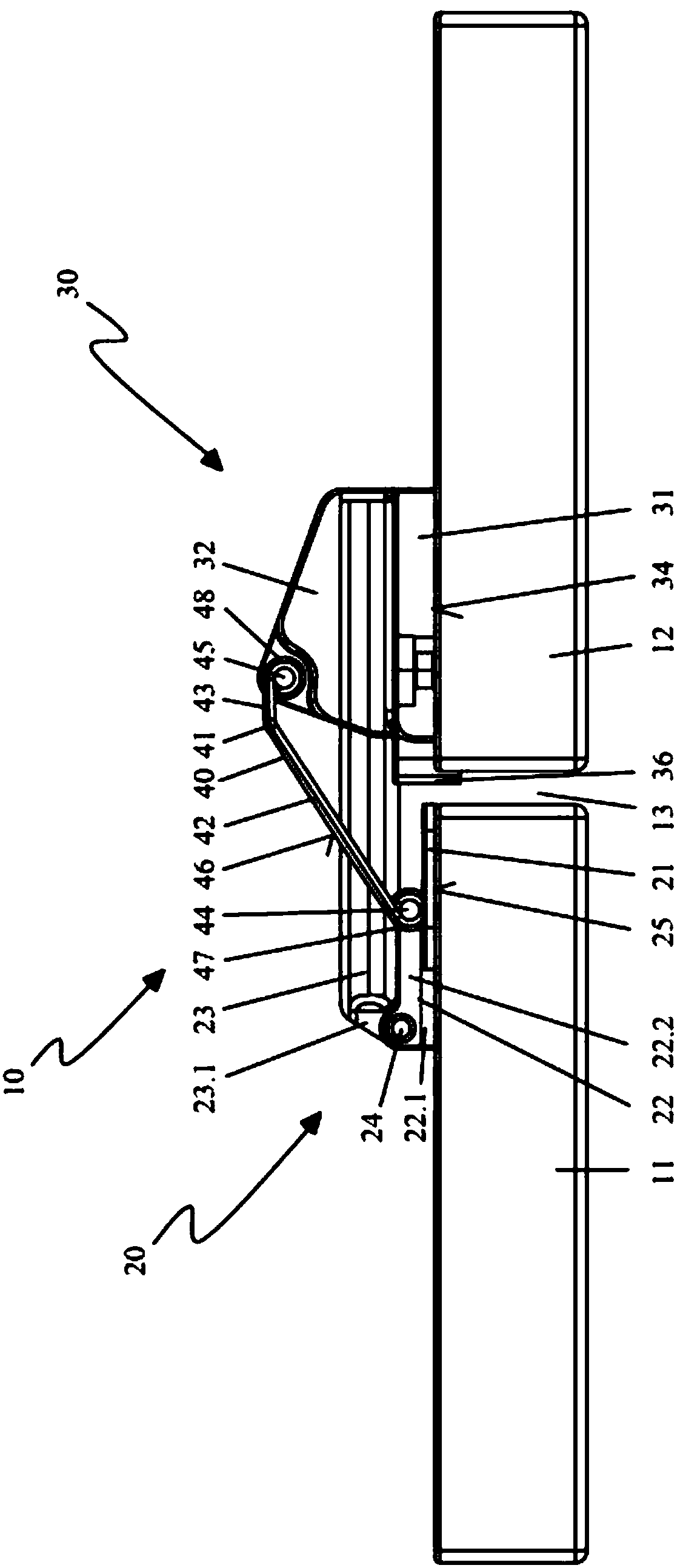

[0033] figure 1 A first perspective view of the hinge 10 with the linear guide in its extended position is shown.

[0034] A first fastening part 20 and a second fastening part 30 are assigned to the hinge 10 . The first fastening part 20 has a connecting section 27 on which the flange 21 is molded laterally. Furthermore, the boom 22 is preferably connected in one piece with the connection section 27 . The connecting section 27 and the lateral flange 21 are designed flat. Slotted holes 26 are respectively formed in the lateral flanges 21 . The elongated hole 26 is oriented in the direction of the second fastening part 30 . The boom 22 is configured U-shaped. The cantilever has a base 22.1 and side walls 22.2 molded at an angle on opposite edges of the base 22.1. Therefore, the side walls 22.2 lie opposite each other at a distance. The first fastening part 20 is designed here as a stamped sheet metal part. However, it is also conceivable for the first fastening part 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com