Patents

Literature

62results about How to "Quick orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

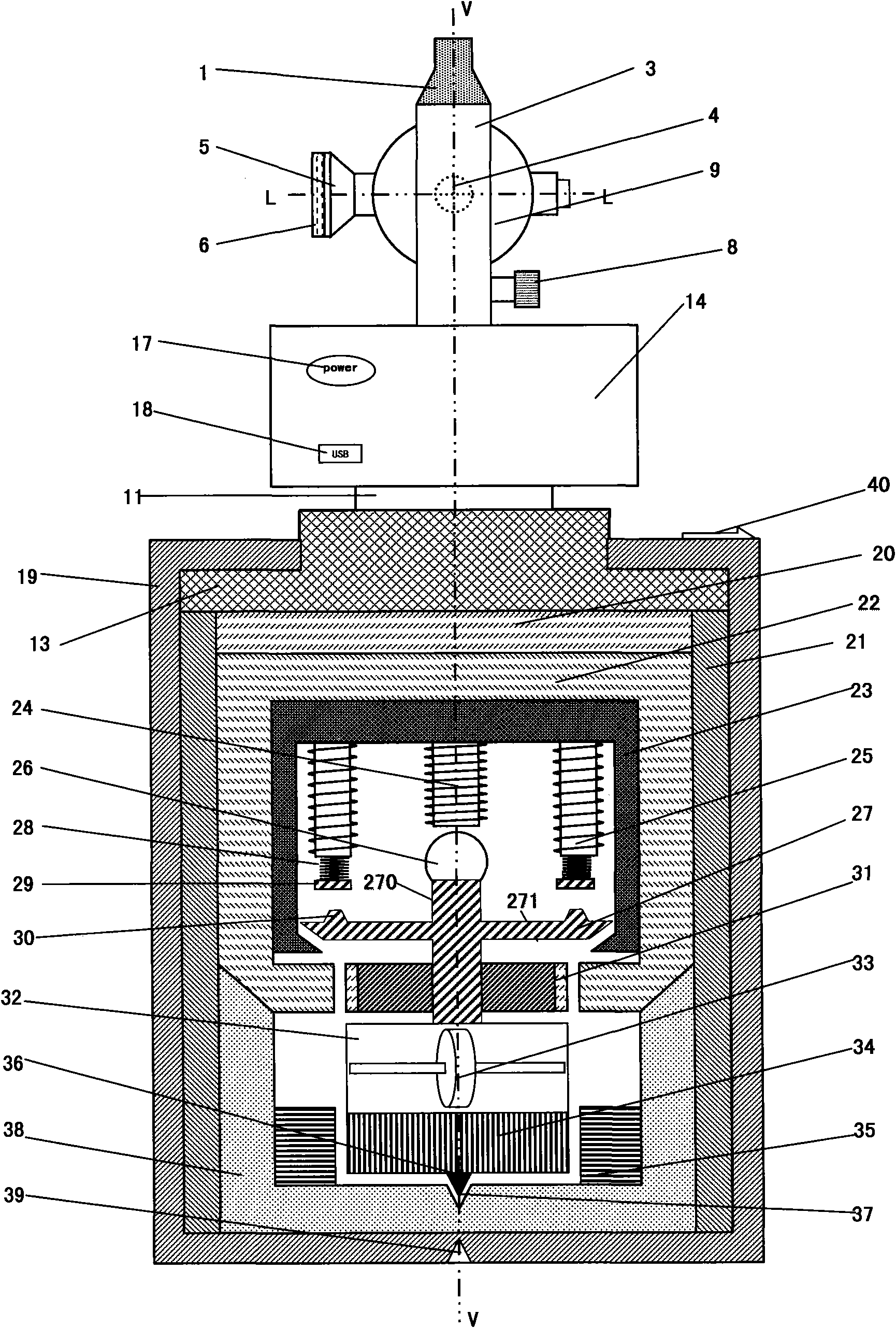

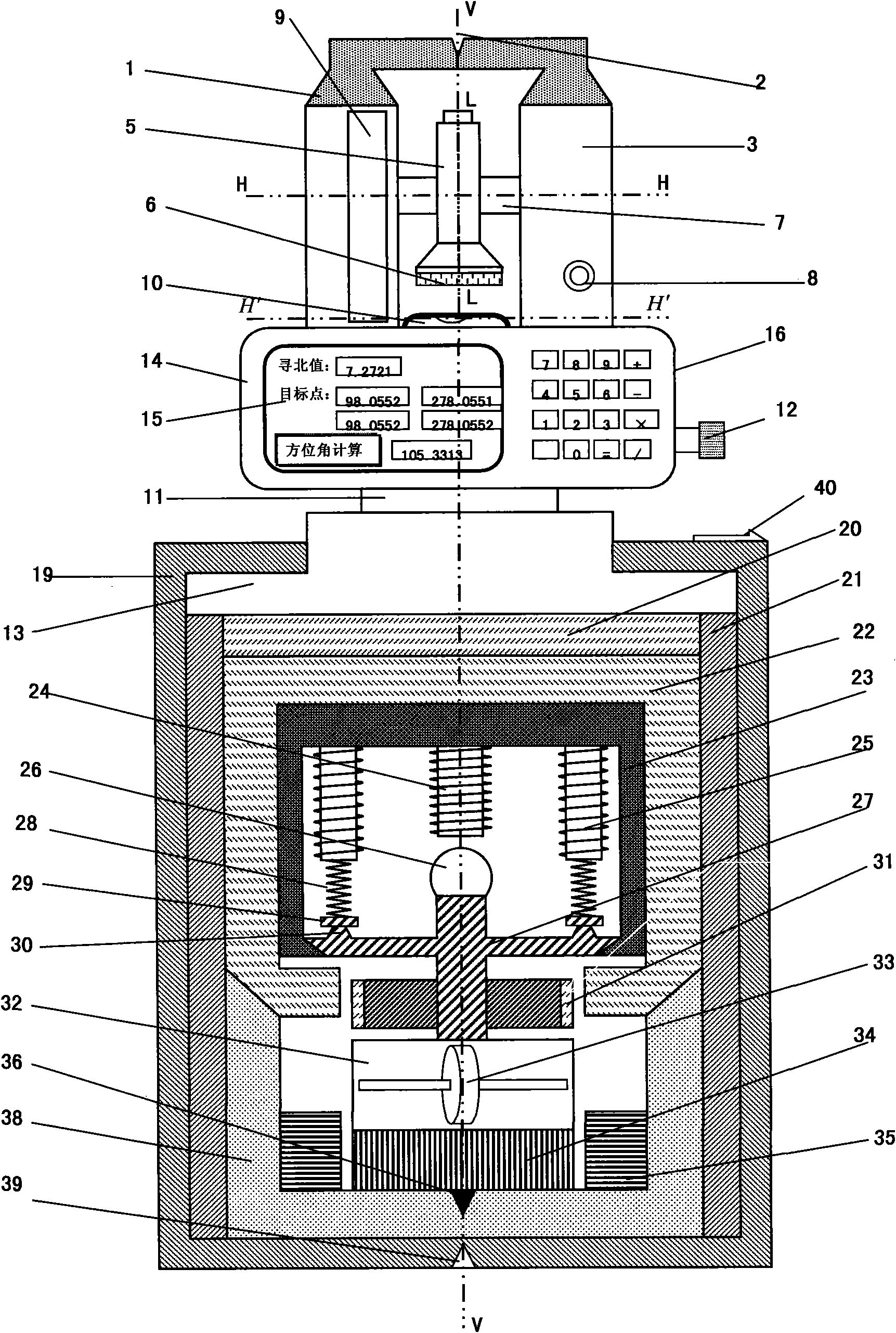

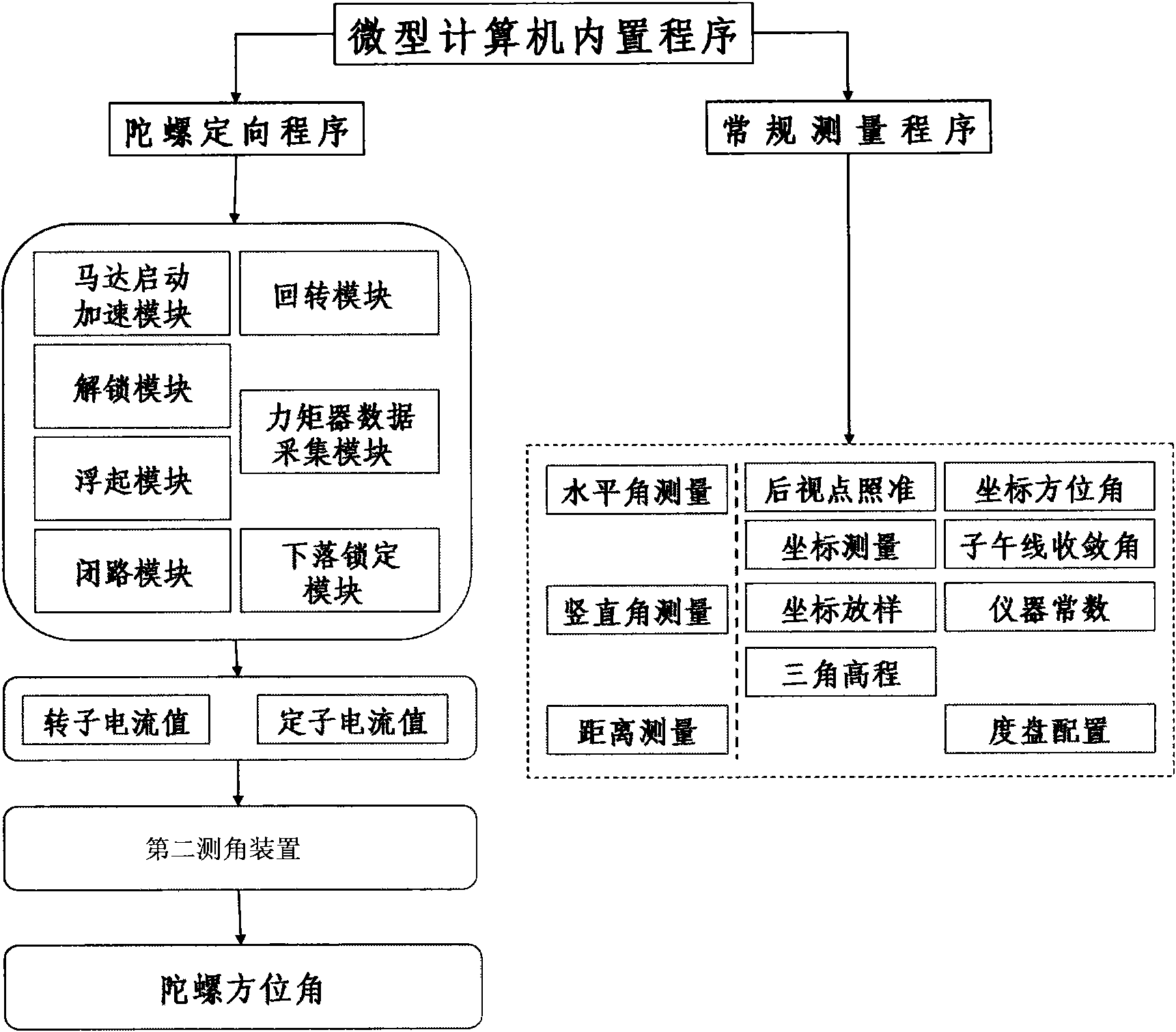

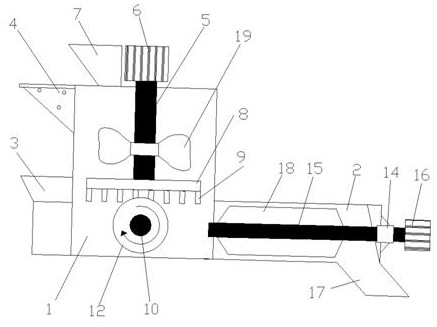

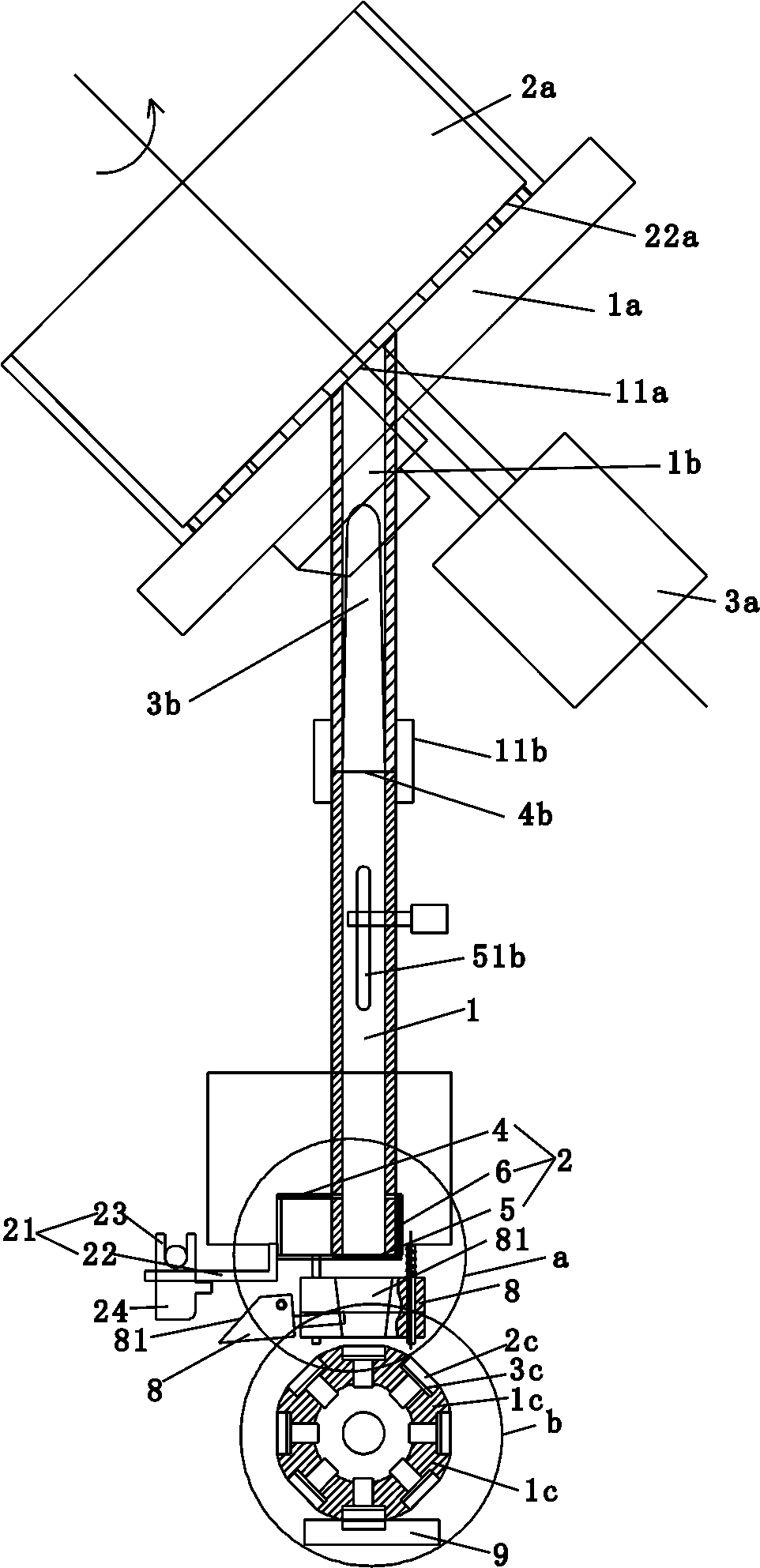

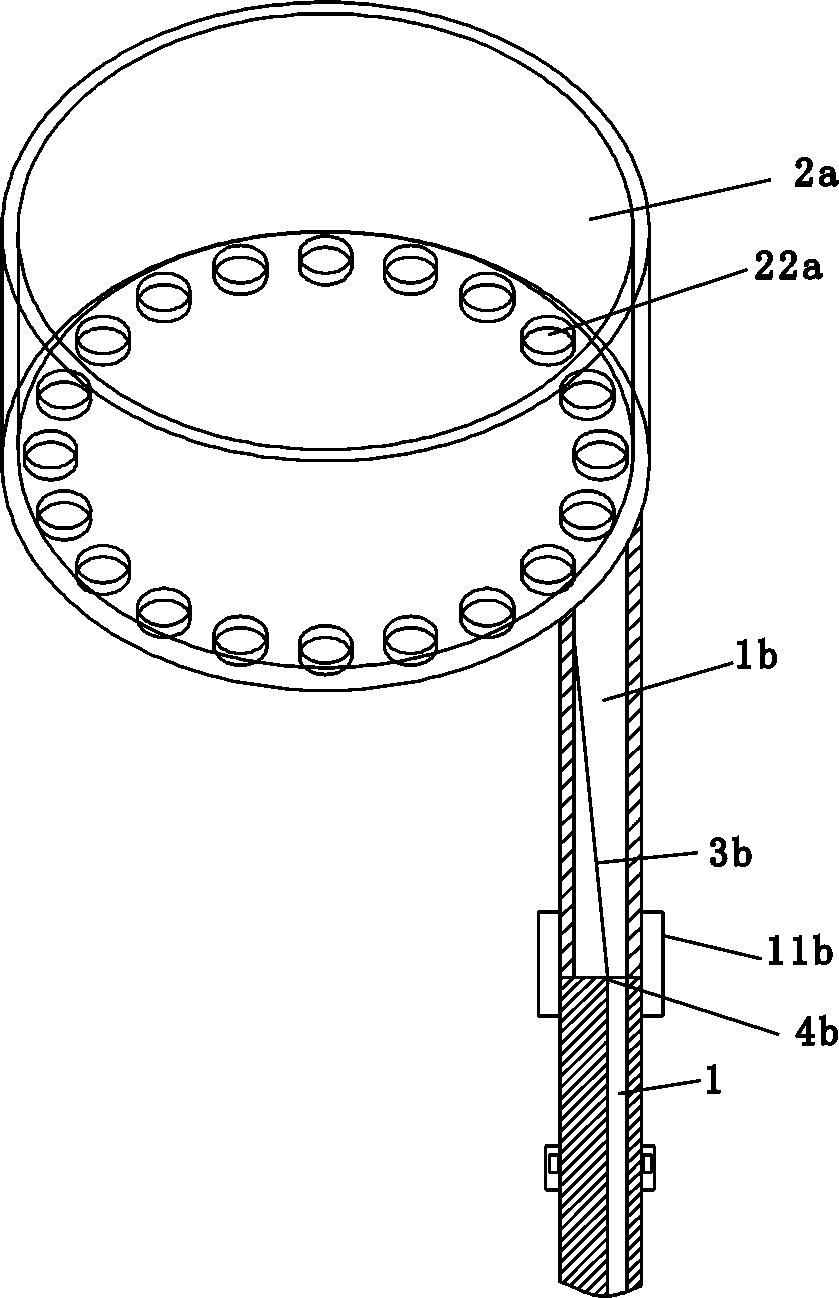

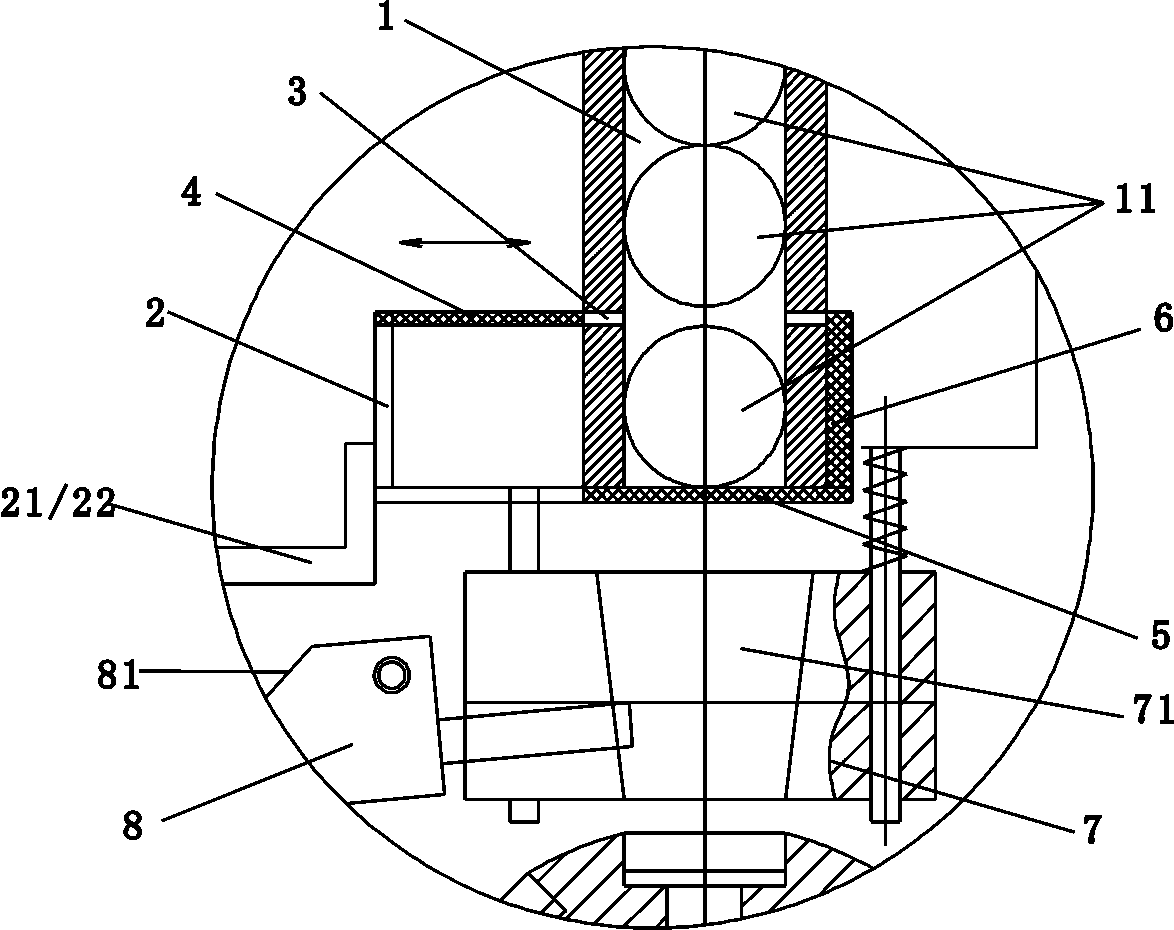

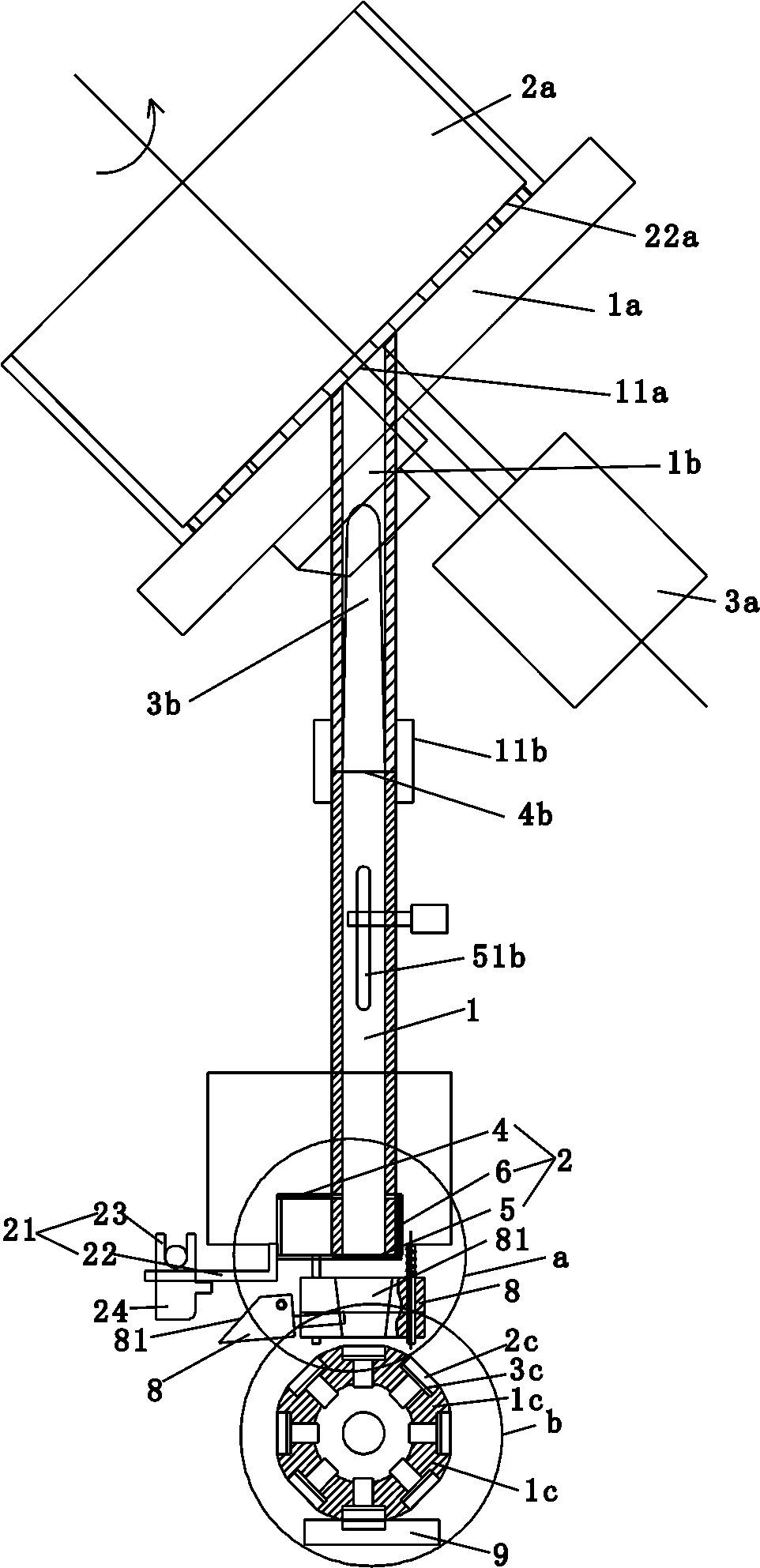

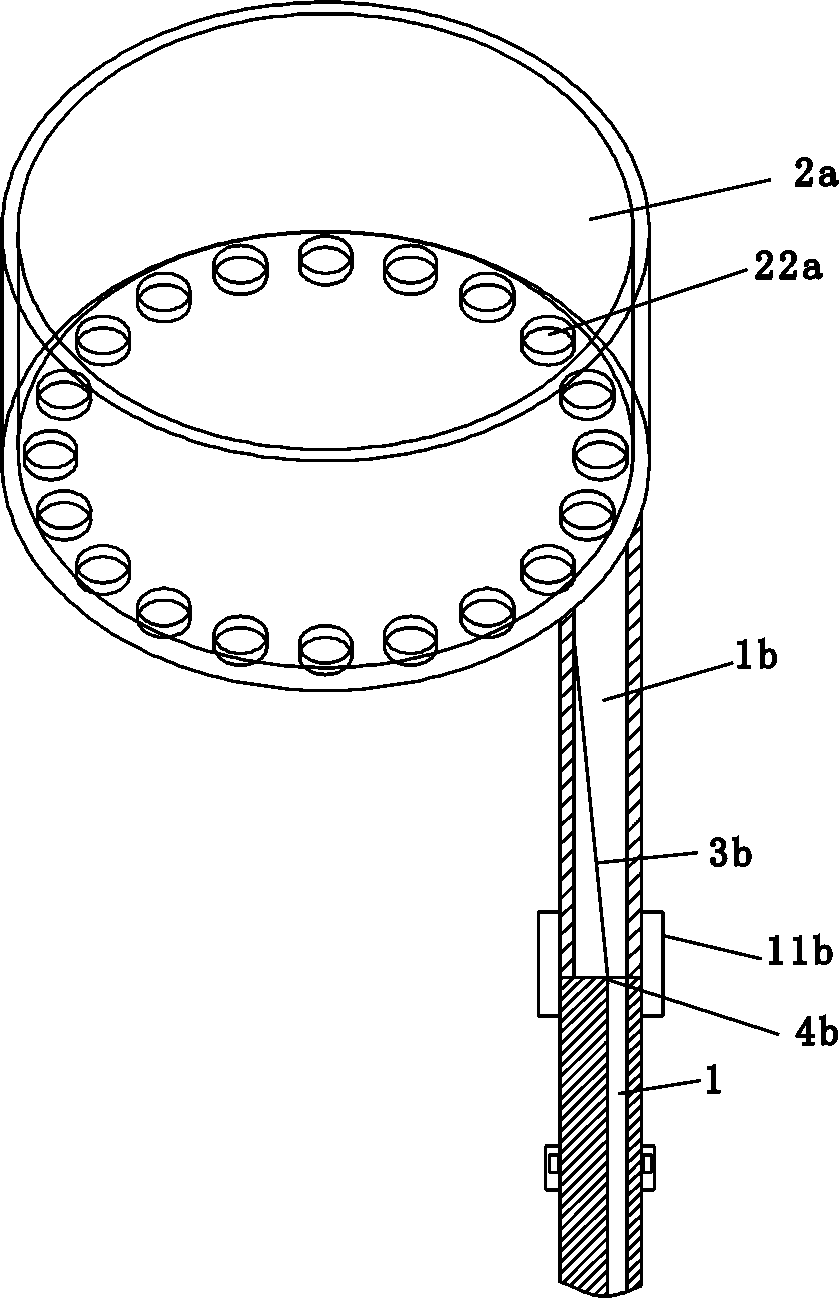

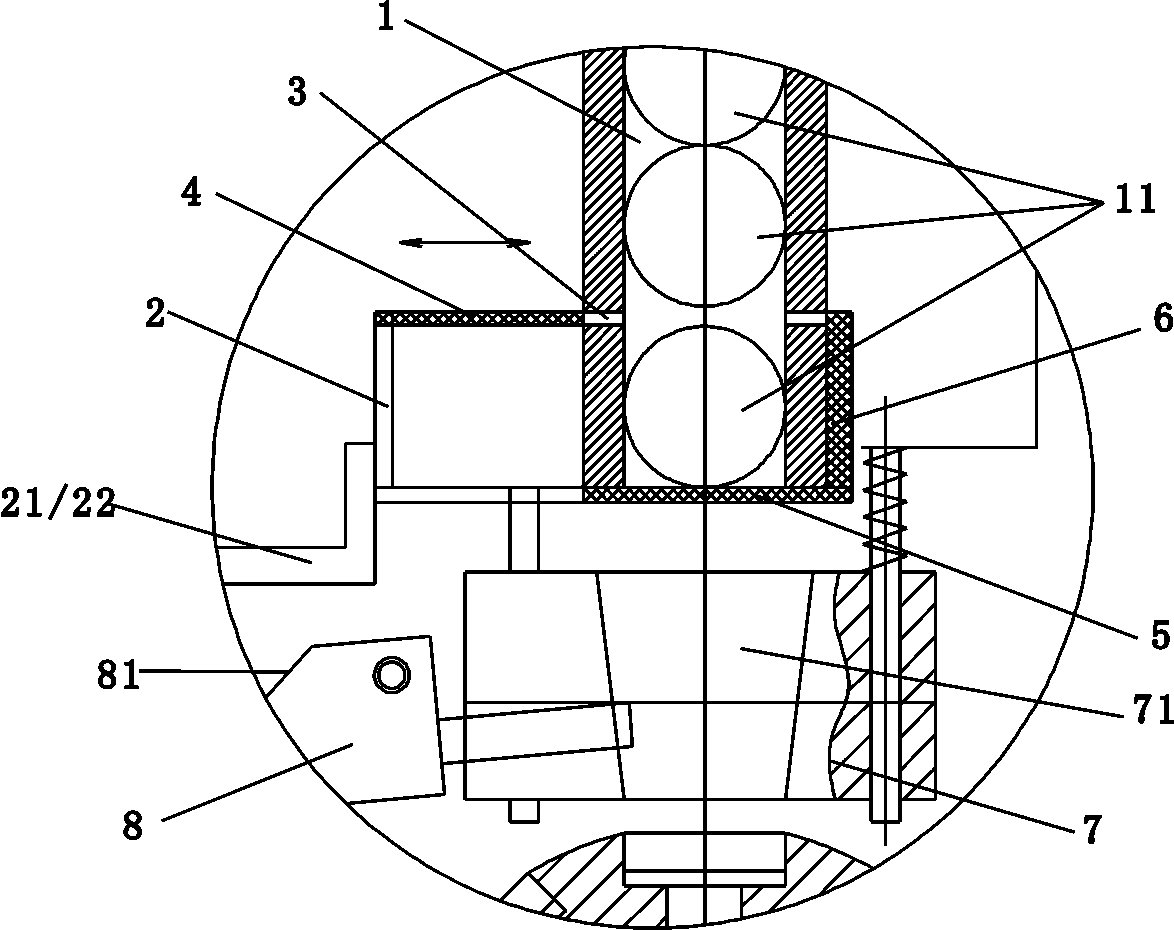

Magnetically suspended gyroscope total station

ActiveCN101776445AHigh degree of automationQuick orientationAngle measurementSurveying instrumentsGyroscopeTotal station

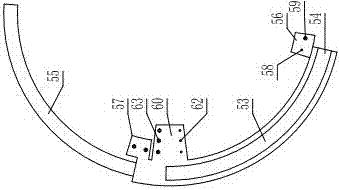

The invention relates to a magnetically suspended gyroscope total station, comprising a directional sighting system, a computer processing system, an angle measuring system, a gyroscopic slewing system, a light path auto-collimation system and a magnetic suspension system, wherein the gyroscopic slewing system, the light path auto-collimation system and the magnetic suspension system are arranged in a metal shell; the center position of the bottom part of the metal shell is provided with a lower centering identification hole; and the top of the metal shell is provided with a northward designator. When a linkage in the magnetic suspension system is in a suspending state, a spring is in a compressing state, and the upper surface of a photoelectric sensor is parallel and level with the receiving surface of the light path auto-collimation system; and when a rod meter shell falls back from the suspending state, a tabletting is contacted with a contact, and a dropping cone falls into a faller trough and is in a locked state. In the invention, the magnetic suspension technology is utilized to substitute the traditional hanging belt bearing technology, thus the problems of the traditional hanging belt type gyroscope hang spring such as easy damage, long orientation time, cockamamie operation and the like are solved. The magnetically suspended gyroscope total station has the advantages of high automaticity, rapid orientation, stable overall performance and the like.

Owner:CHANGAN UNIV

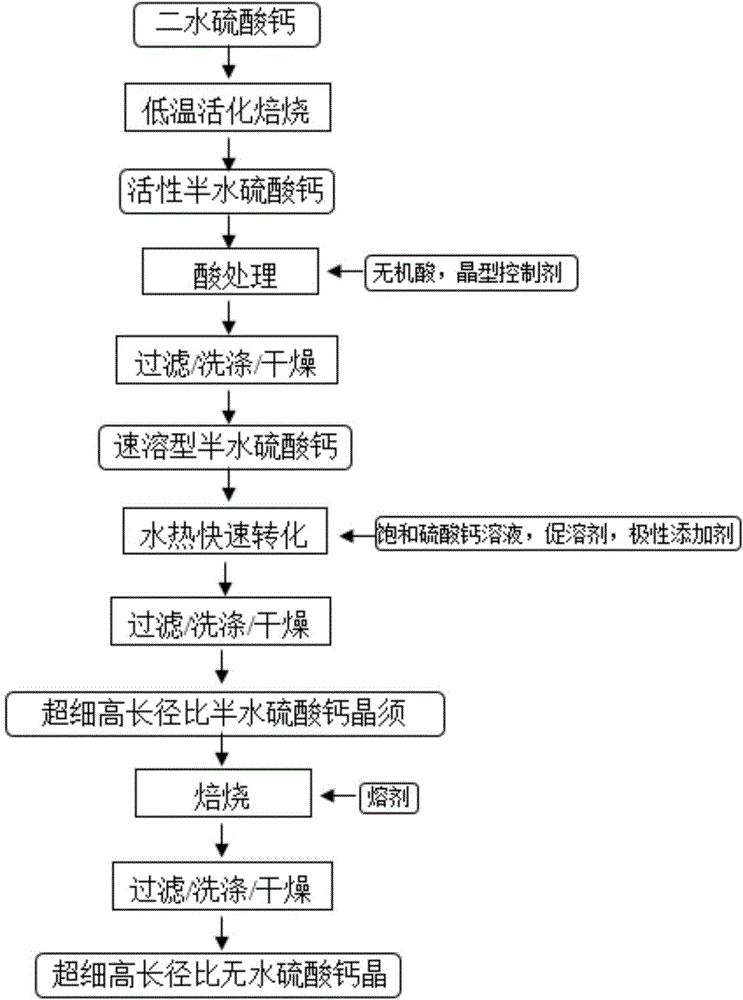

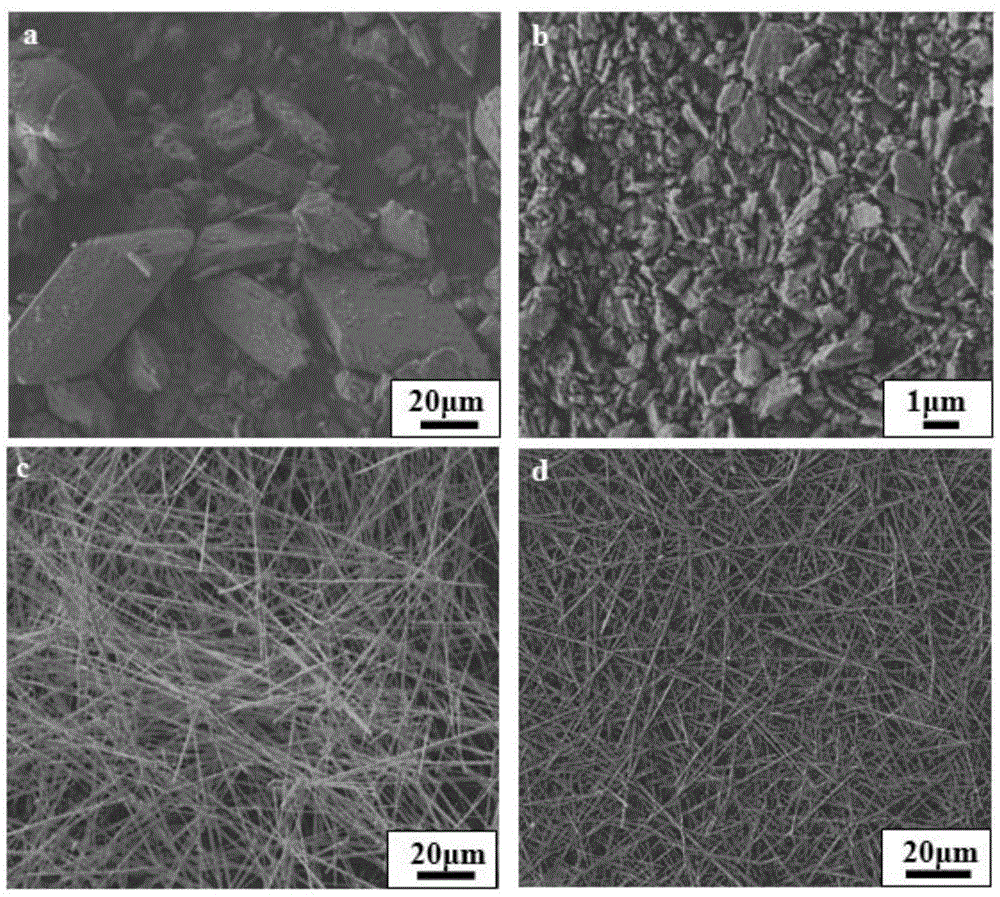

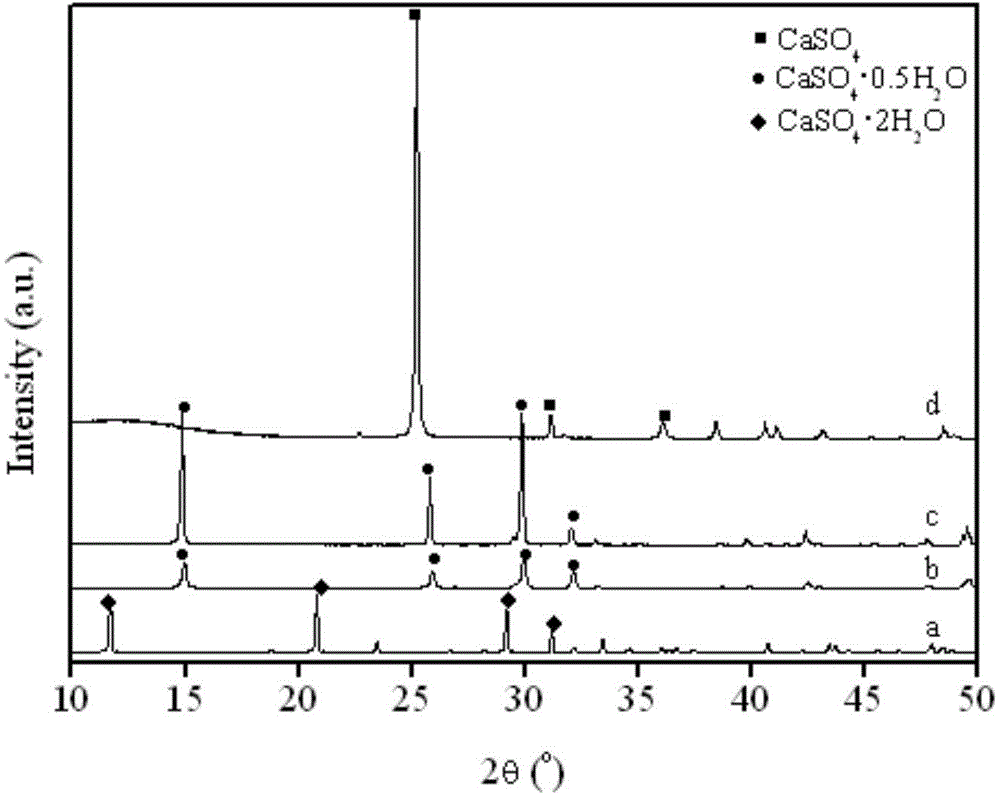

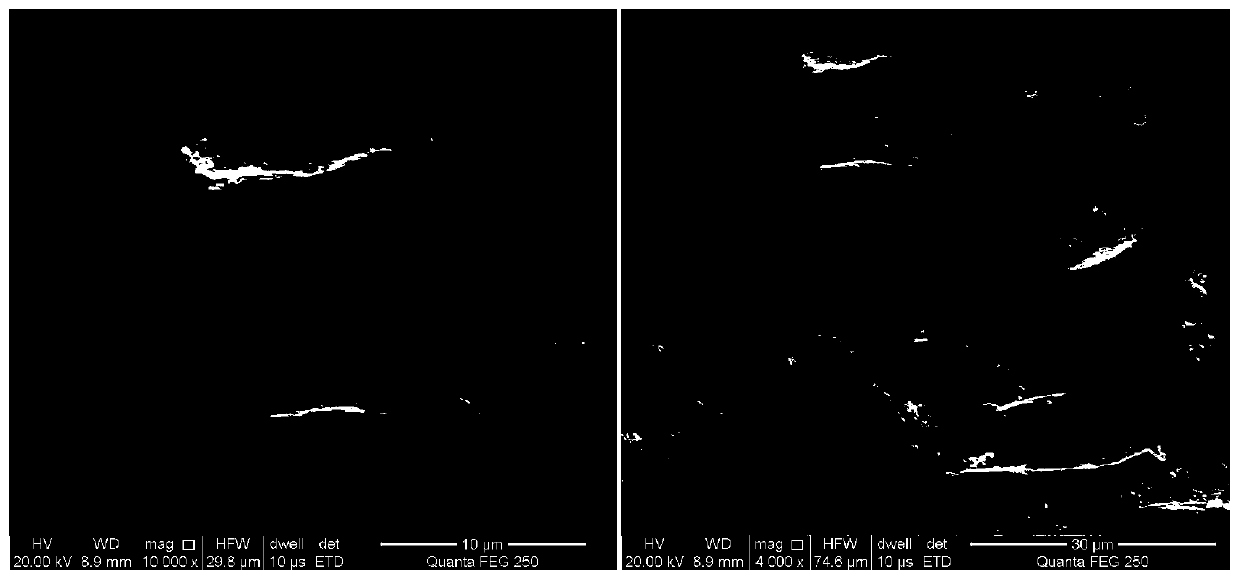

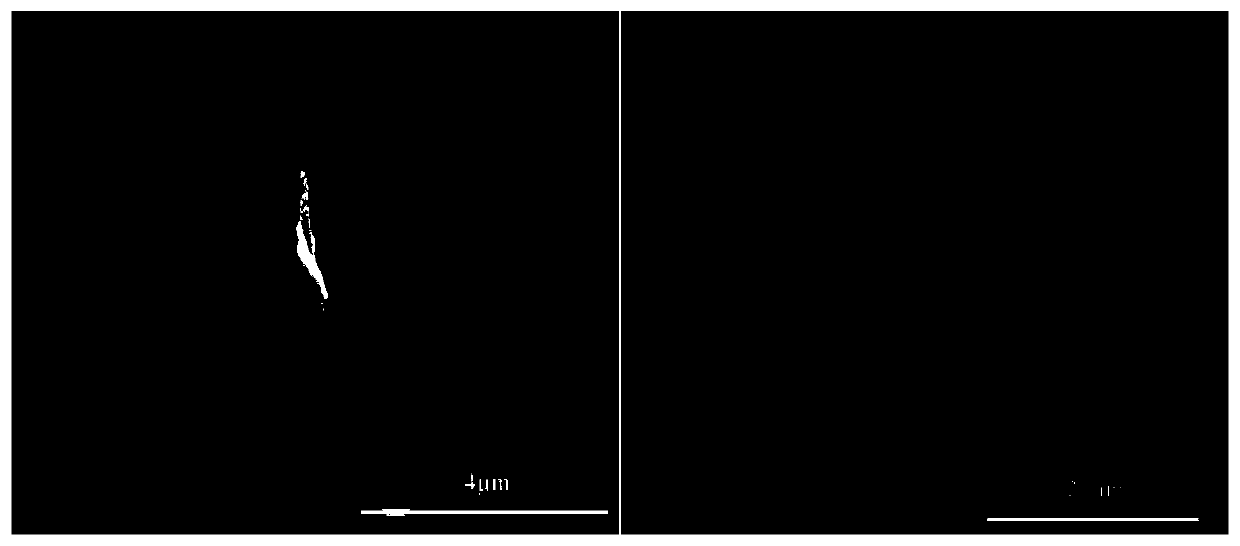

Improved method for preparing superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers by using hydrothermal process

InactiveCN104480523AMany structural defectsLarge specific surface areaPolycrystalline material growthFrom normal temperature solutionsSolventCrystal

The invention discloses an improved method for preparing superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers by using a hydrothermal process and belongs to the technical field of preparation of inorganic chemical materials. The improved method for preparing the superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers by using the hydrothermal process takes calcium sulphate dihydrate as the raw material and comprises the following steps: firstly activating and roasting at the low temperature to prepare active calcium sulfate hemihydrates, subsequently doping, acidizing, hydrating and drying to prepare a quick-soluble calcium sulfate hemihydrates precursor with the structure defects; then adding the precursor into a saturated calcium sulphate liquid containing a chaotropic agent and a polar solvent, carrying out hydrothermal reaction at 100-200 DEG C for 2-20 minutes, cooling, filtering, washing and drying to prepare superfine high length-diameter-ratio calcium sulfate hemihydrate crystal whiskers with diameter of 0.005-10 microns, length of 10-5000 microns, length-diameter-ratio of 100-10000, and main content of greater than 95%; then mixing the calcium sulfate hemihydrates crystal whiskers with a trace solvent, roasting at 600-800 DEG C for 1-6 hours, cooling, filtering, washing and drying to prepare the superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers with appearance which is as same as that of the calcium sulfate hemihydrates crystal whiskers and main content of greater than 95wt%. The improved method for preparing the superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers by using the hydrothermal process is rapid and simple in process and low in costs; and the prepared superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers can be used as reinforcement materials.

Owner:TSINGHUA UNIV

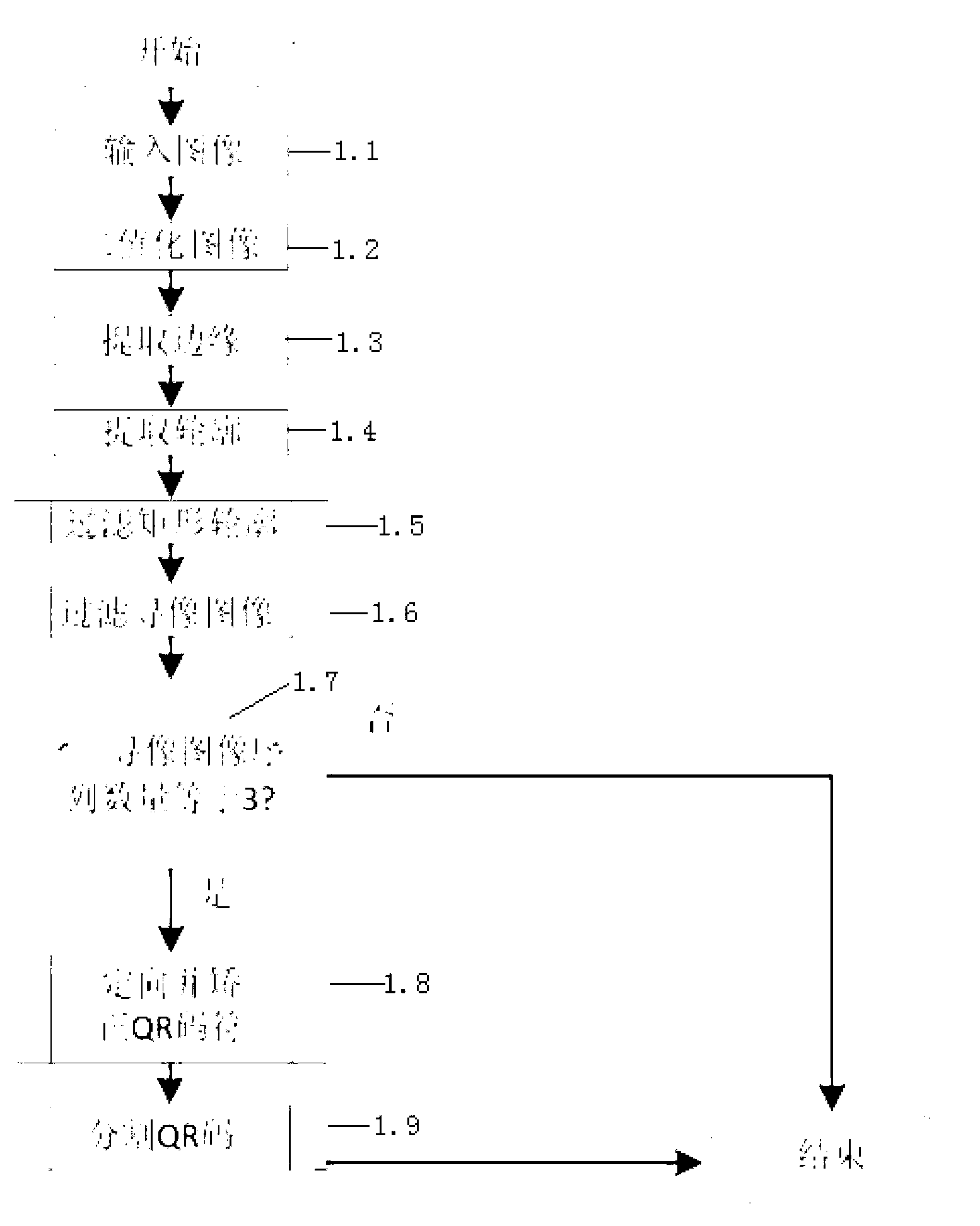

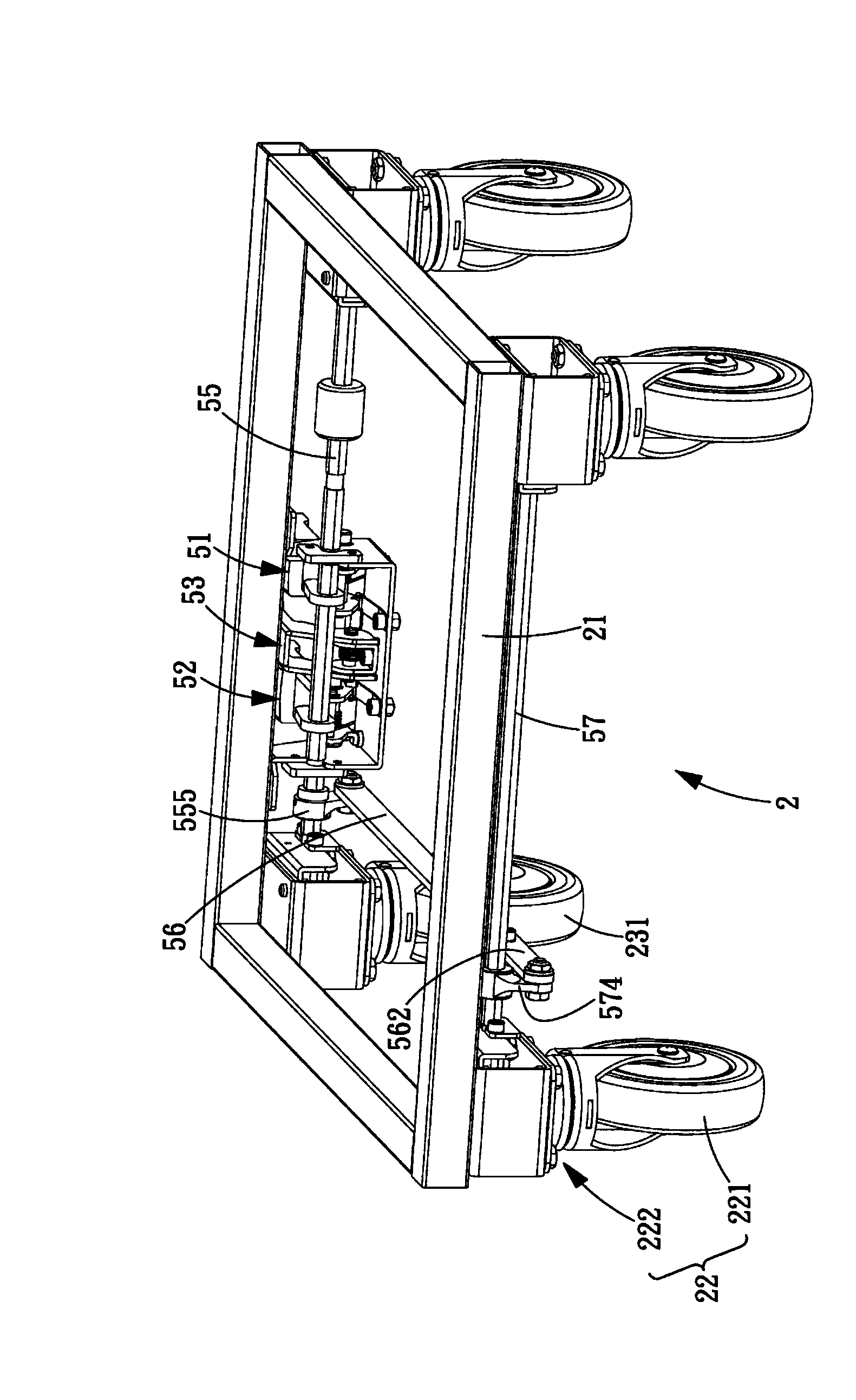

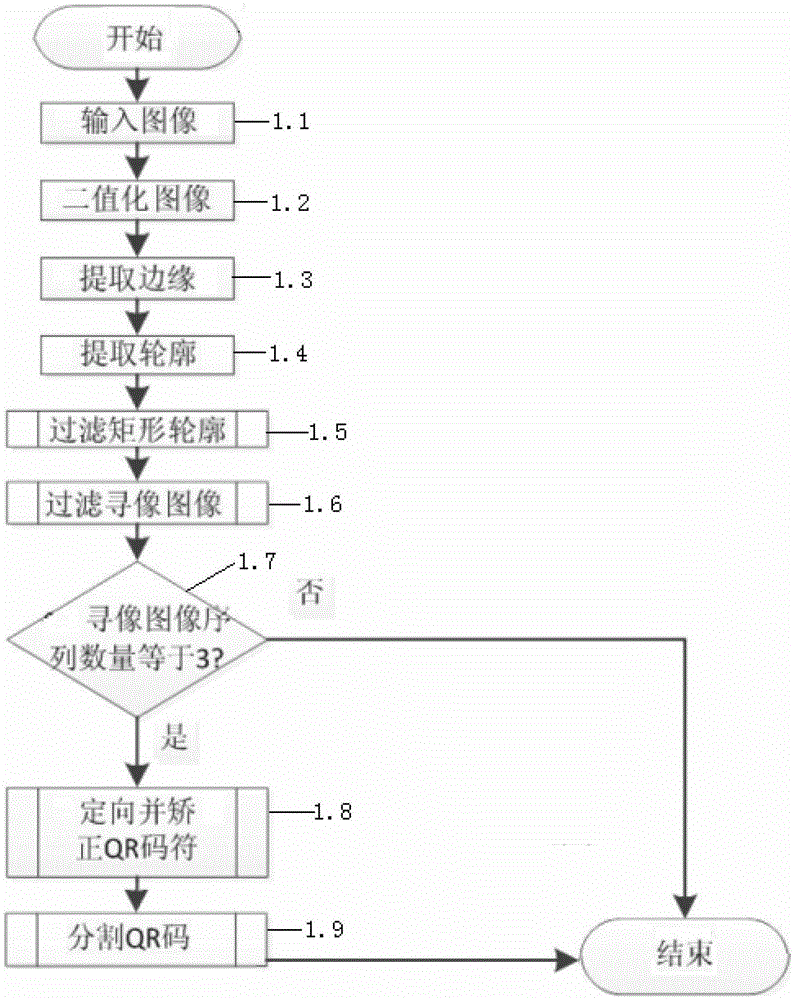

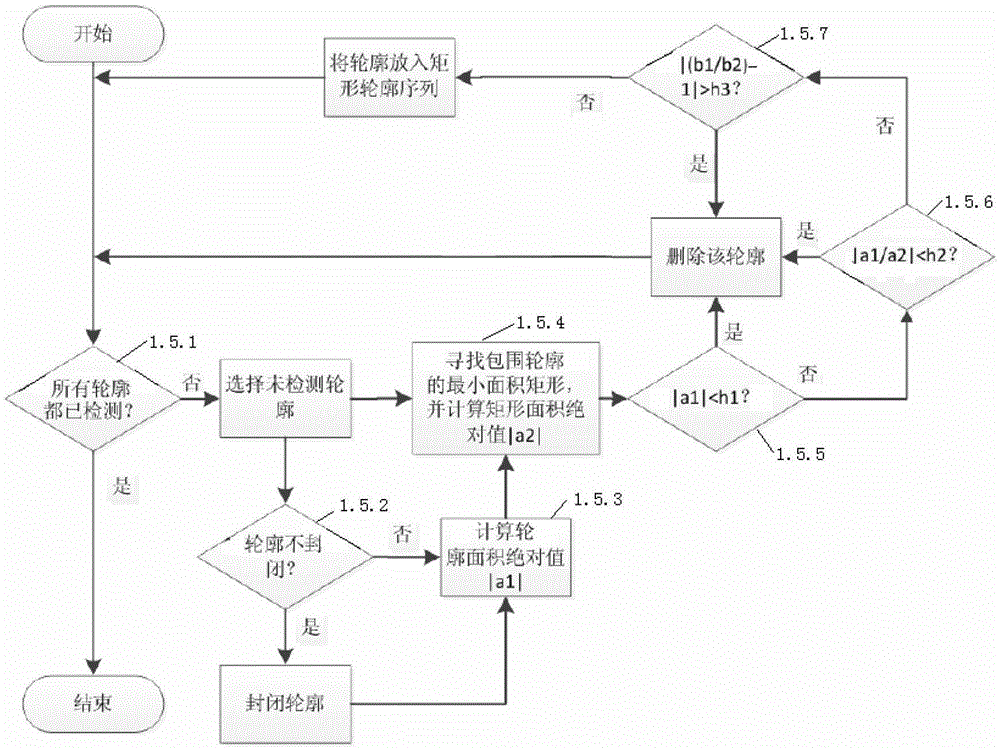

Automatic QR (quick response) code positioning and orientating method

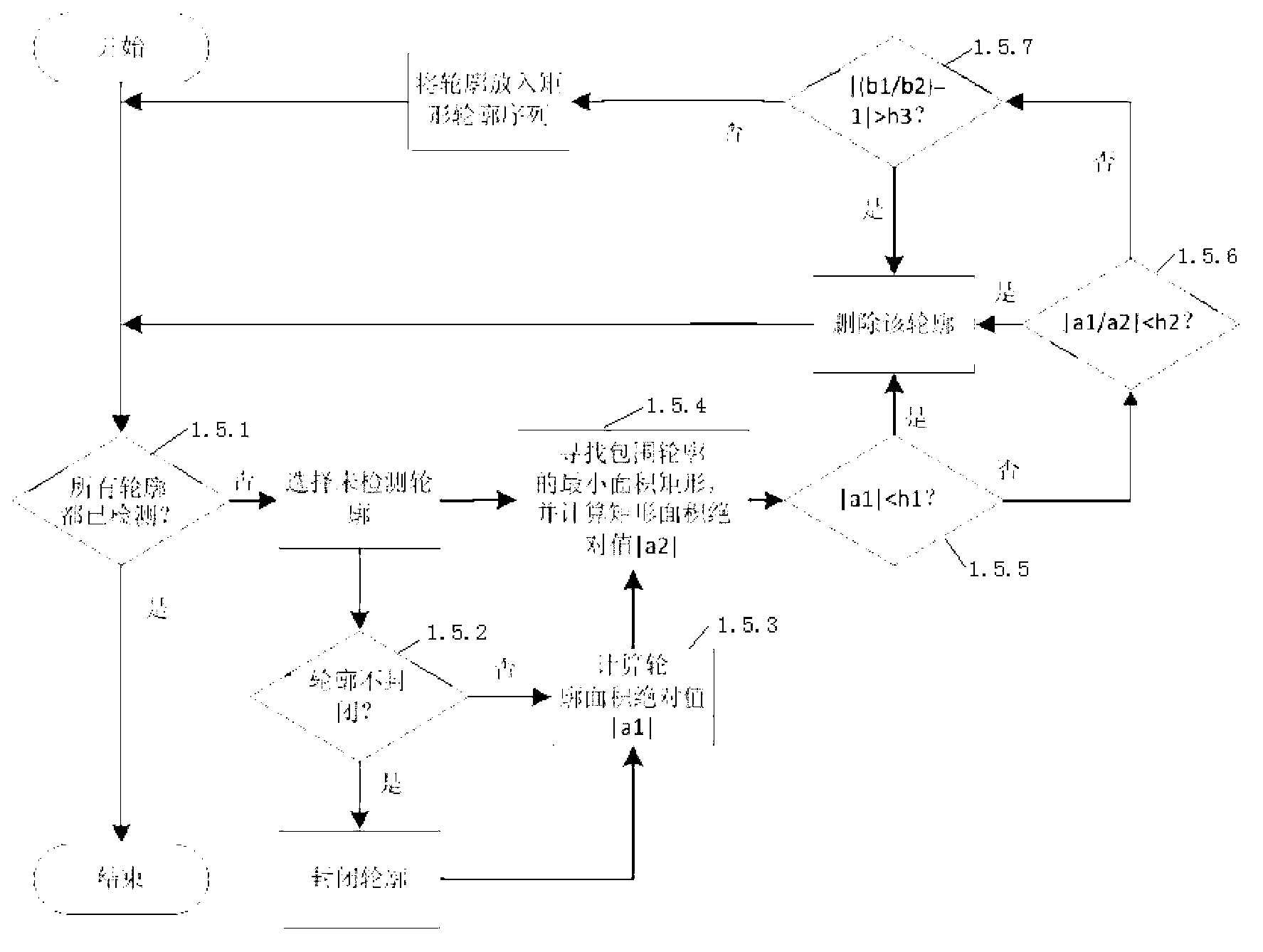

ActiveCN103177251ARapid positioningQuick orientationCharacter and pattern recognitionPattern recognitionSelf adaptive

The invention discloses an automatic QR (quick response) code positioning and orientating method. The method includes: converting an input image into a grayscale image; binarizing the grayscale image by the self-adaptive threshold algorithm to eliminate noise interference; extracting an grayscale image edge according to an Sobel operator; extracting a profile sequence from the edge by the chain code tracing algorithm; filtering a rectangular profile, filtering a view-finding image from the rectangular profile sequency, and judging whether the image has a QR code or not; and correcting and dividing the QR code. By the automatic QR code positioning and orientating method, QR code positioning and orientating can be realized quickly and accurately in a robustness manner, and QR codes can be extracted from images without manual operations, so that manpower cost and time are saved greatly. The automatic QR code positioning and orientating method is applicable to industrial informationization and automation and has wide application prospect.

Owner:南京无限物联科技有限公司

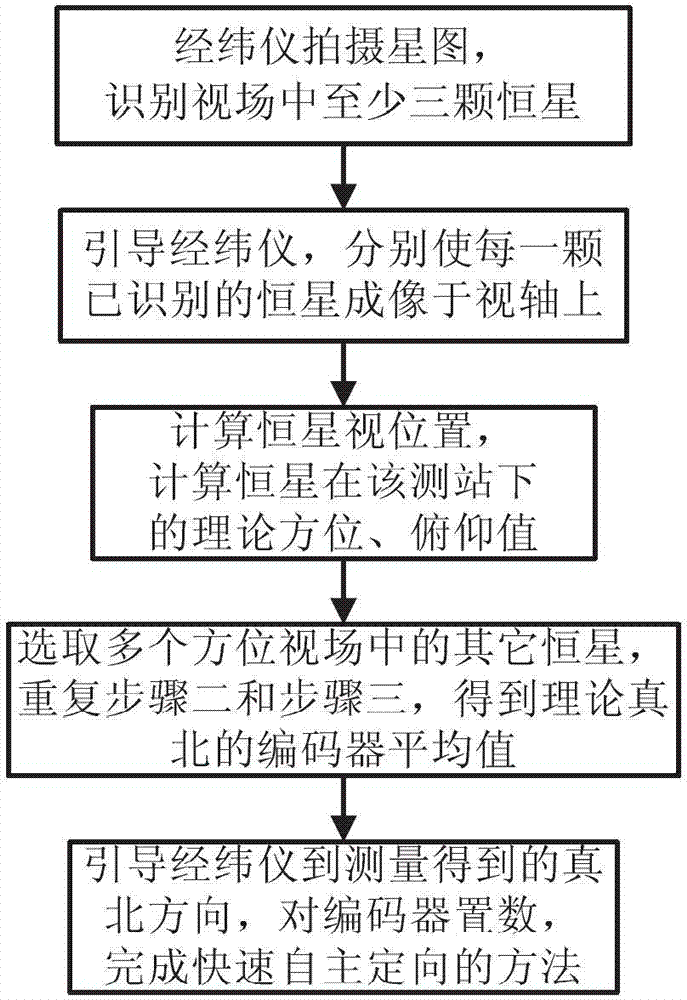

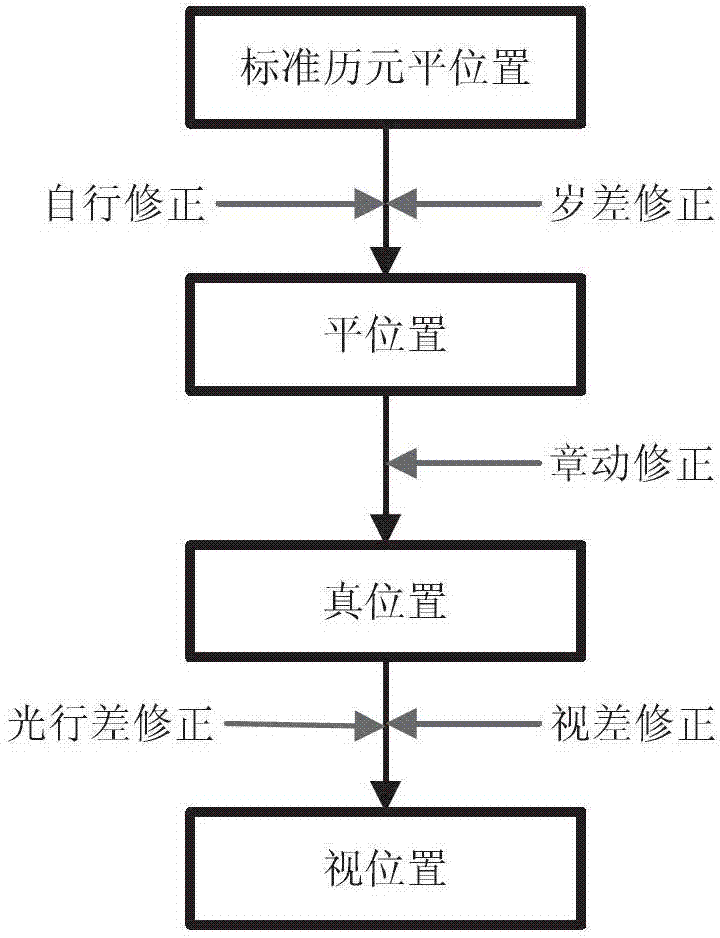

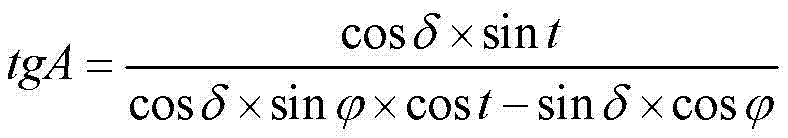

Quick and autonomous orientation method of photoelectric theodolite

The invention discloses a quick and autonomous orientation method of a photoelectric theodolite and belongs to the technical field of celestial navigation. The method comprises the following steps of: shooting a star map through the photoelectric theodolite, and identifying at least three fixed stars in a view field by using a star map identification algorithm; adjusting the photoelectric theodolite to ensure that the image of one identified fixed star is formed on a visual axis of the photoelectric theodolite, and computing the view position of the fixed star at this time; computing a theoretical azimuth angle and a theoretical angular altitude of the fixed star relative to the true north by combining an astronomical coordinate of the photoelectric theodolite; selecting other fixed stars to obtain a coder average value of the true north; and introducing the photoelectric theodolite to the measured true north direction, and clearing a direction encoder to finish quick and autonomous orientation of the photoelectric theodolite. The method is high in precision and high in speed, and the advantages of the photoelectric theodolite are realized. By the means of star map identification, the photoelectric theodolite can orient autonomously without initial direction, so that the limit of only observing the Polaris in the conventional astronomical orientation method is broken through, and the photoelectric theodolite can orient in any directions by virtue of any fixed stars.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

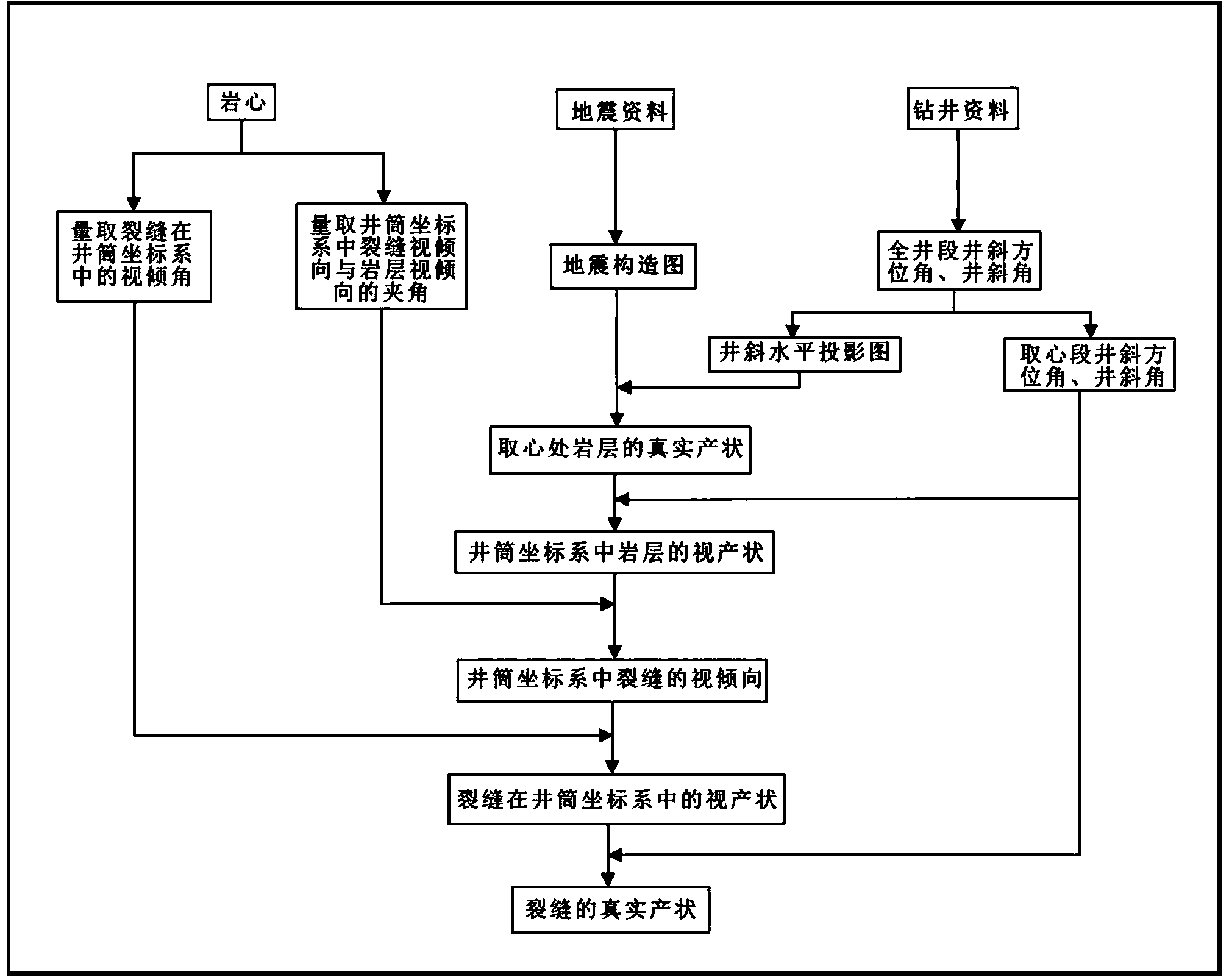

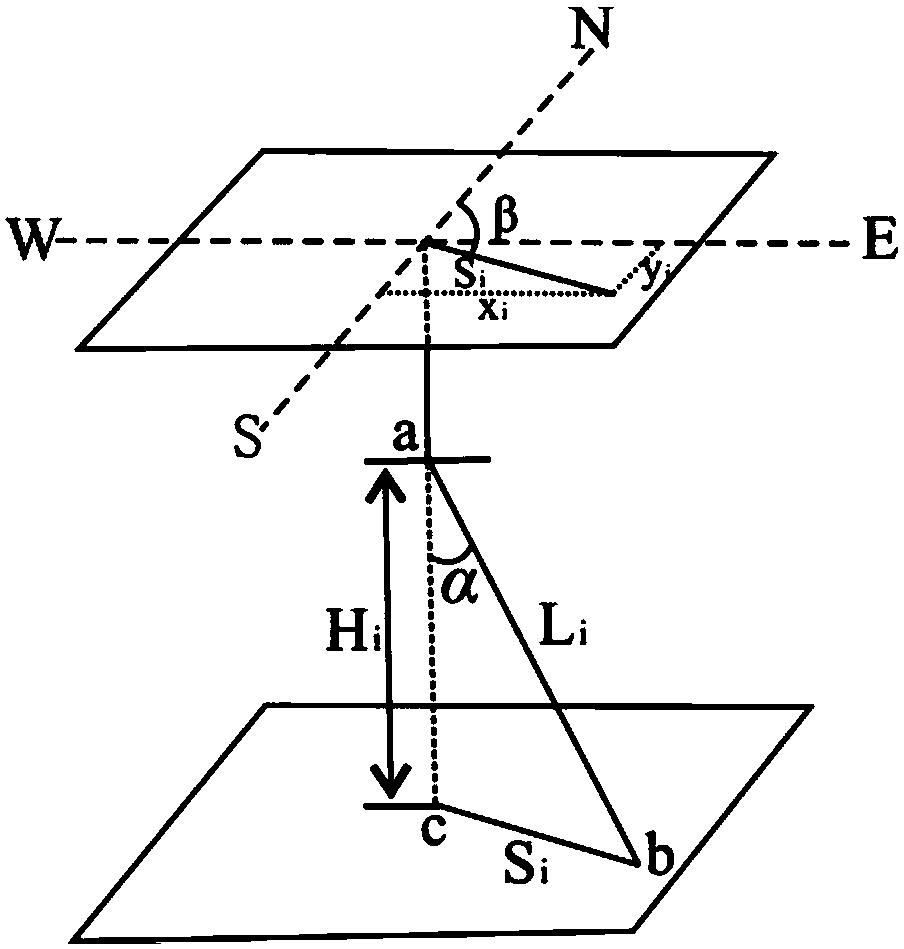

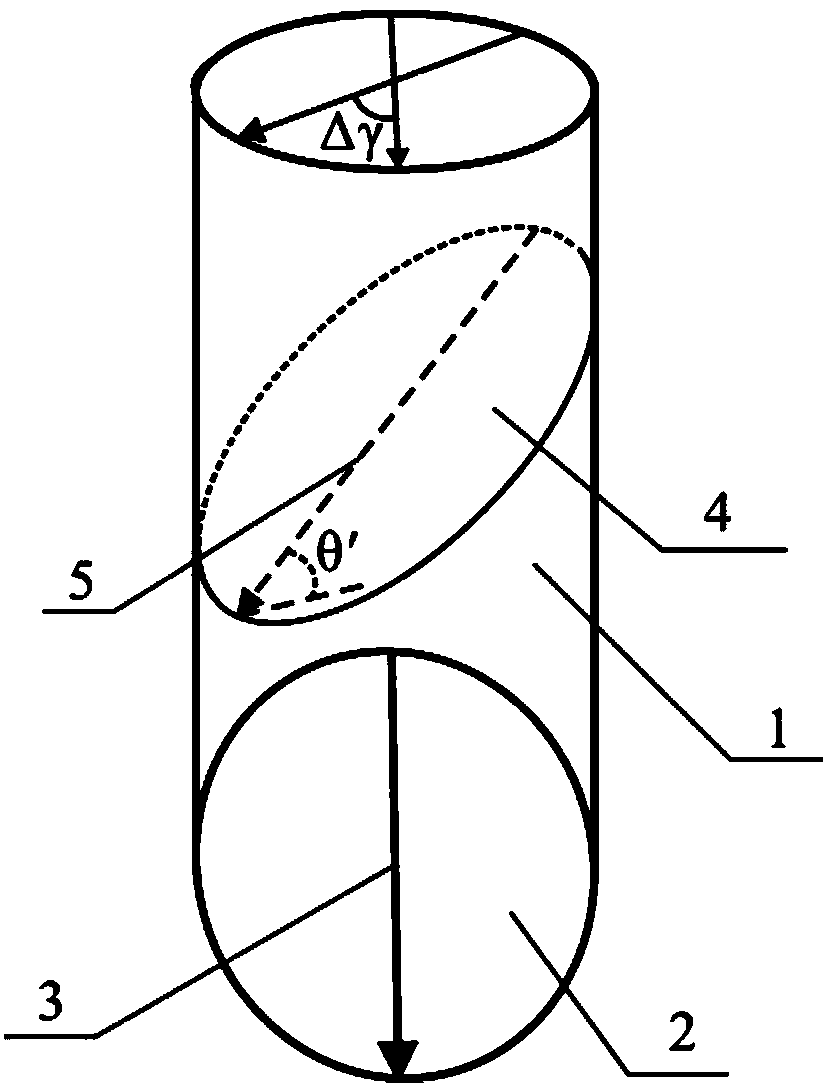

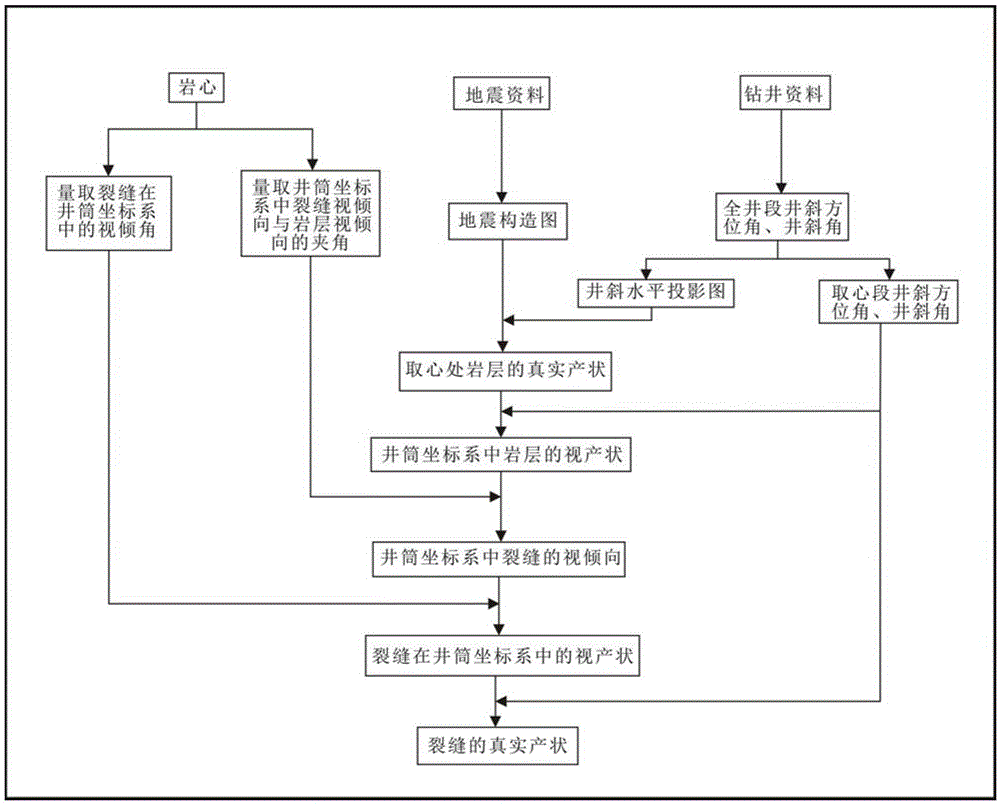

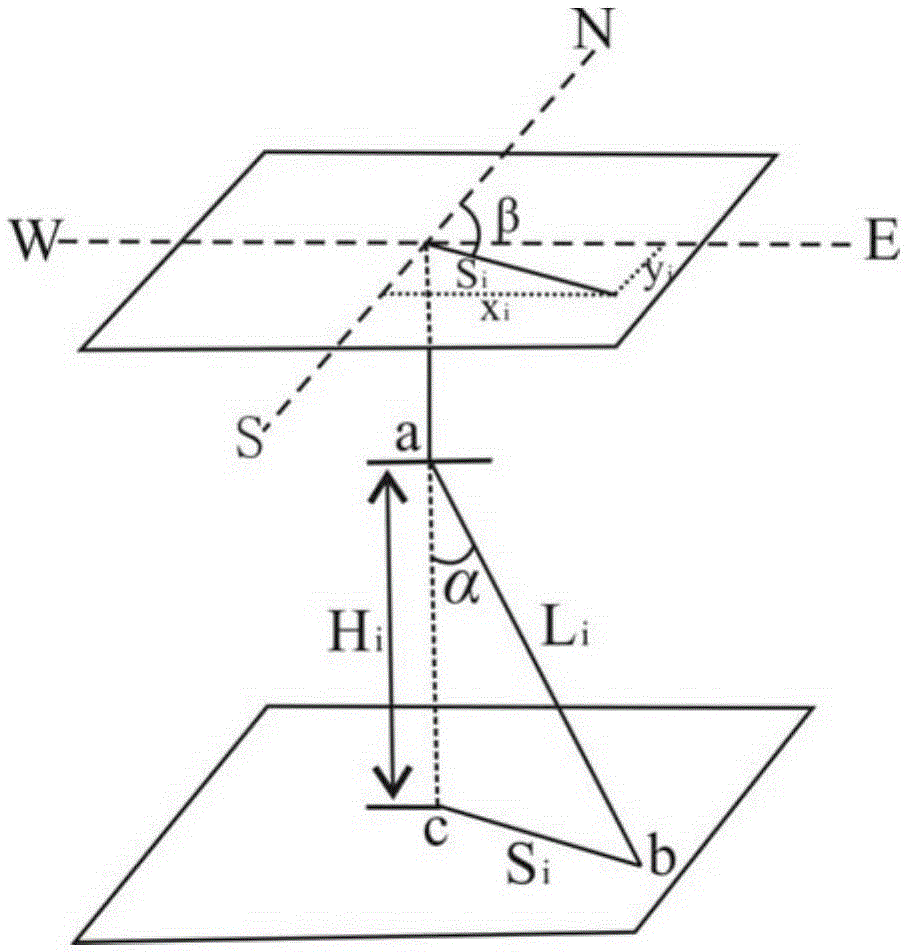

Inclined shaft core fissure orientation method

InactiveCN103983236AOrientation is accurateQuick orientationAngle measurementIncline measurementWell drillingFissure

The invention relates to the field of the exploitation and development of oil and gas fields, and in particular relates to an inclined shaft core fissure orientation method. The method is characterized by comprising the following steps: on the basis of drilling data, calculating well deviation information of a coring interval, calculating the real attitude of a rock stratum according to earthquake data, determining an apparent dip of the core fissure and an angle between the fissure apparent inclination and apparent inclination of the rock stratum according to the core data, designing an inclined shaft core fissure orientation concept on the basis, deriving a corresponding algorithm, and realizing the accurate orientation of the core fissure. By adopting the method, the problem that the inclined shaft core fissure cannot be orientated can be solved, the inclined shaft core fissure orientation accuracy is improved, and the practical value on multiple aspects such as accurately determining the permeation rate advantageous direction of a reservoir stratum of the oil and gas field, the relative position relation of a water filling well and an oil recovery well, direction of ancient stress field in the crack generation period, reasonable layout and development of well networks can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

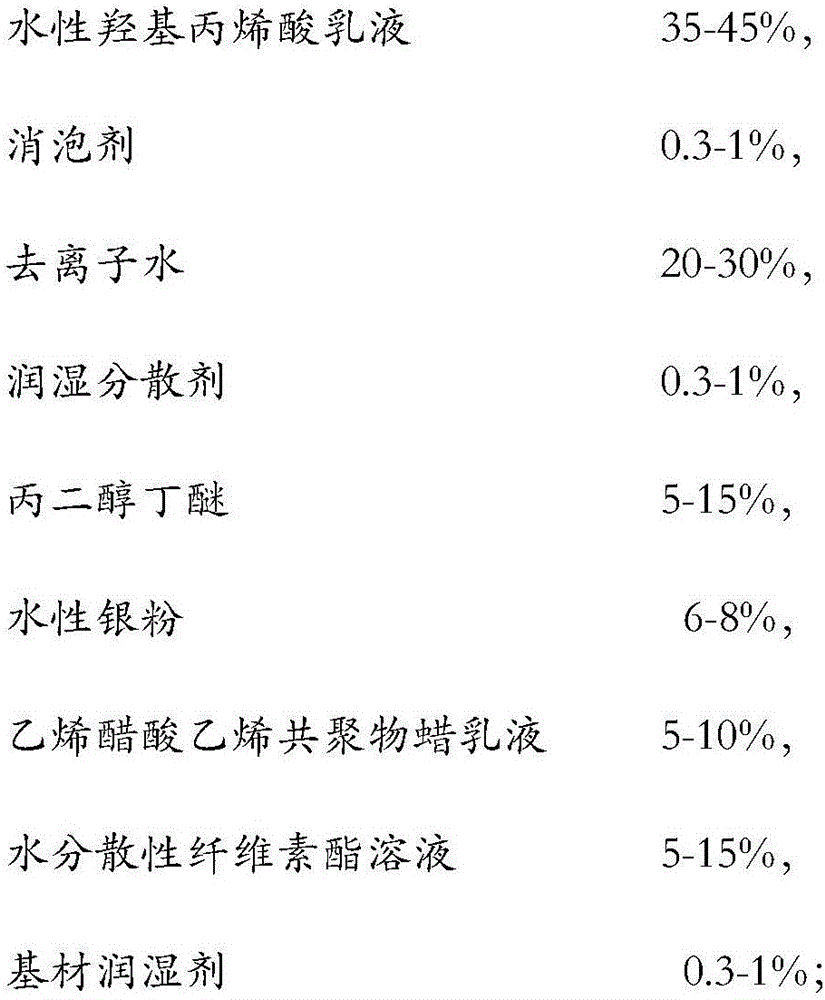

Aqueous acrylic polyurethane aluminum powder paint and preparation method thereof

InactiveCN106590379AReduce pollutionFast dryingPolyurea/polyurethane coatingsCellulosePROPYLENE GLYCOL BUTYL ETHER

The invention discloses an aqueous acrylic polyurethane aluminum powder paint, which is composed of a component A and a component B, wherein the component A is composed of, by weight, 35-45% of aqueous hydroxyl acrylic emulsion, 0.3-1% of a defoamer, 20-30% of deionized water, 0.3-1% of a wetting dispersant, 5-15% of a propylene glycol butyl ether, 6-8% of aqueous aluminum powder, 5-10% of an ethylene-vinyl acetate copolymer wax emulsion, 5-15% of water-dispersible cellulose ester solution, and 0.3-1% of a base material wetting agent; and the component B is an isocyanate curing agent. The weight ratio of the component A to the component B is 7-9:1. A paint film formed by the aqueous acrylic polyurethane aluminum powder paint is quick to dry, is glossy and has high brightness. Orientation of the aluminum powder is excellent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

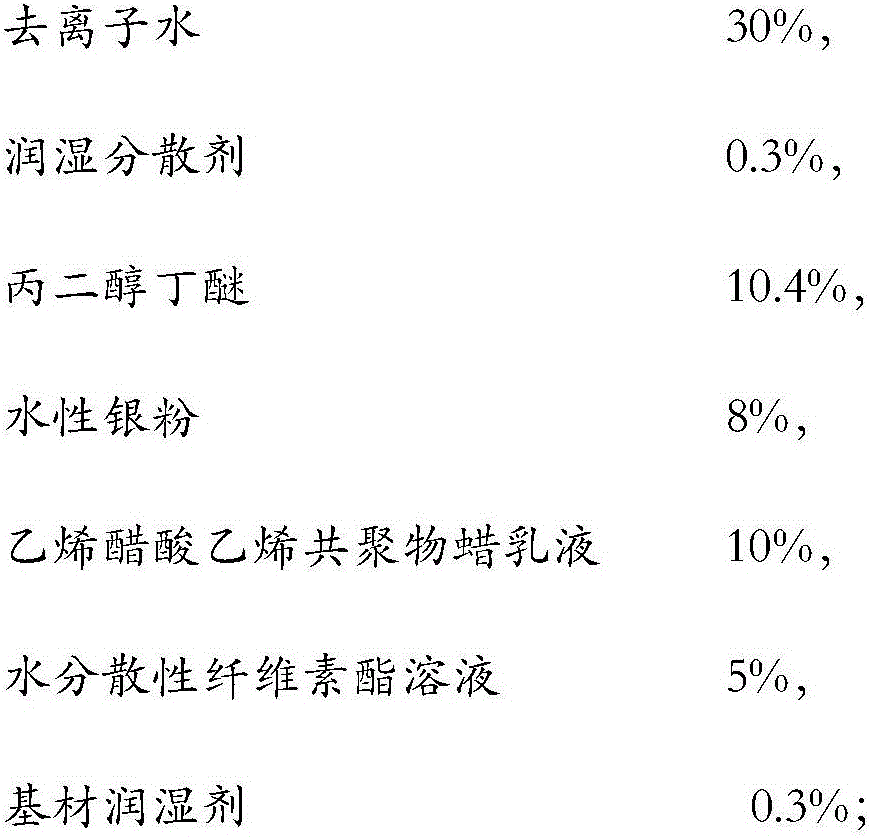

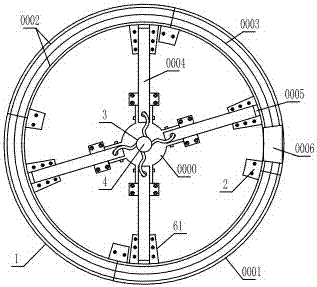

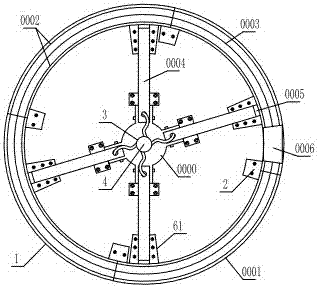

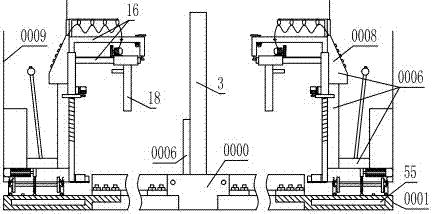

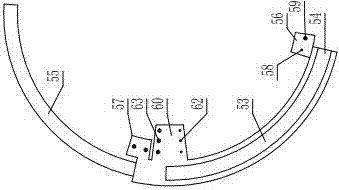

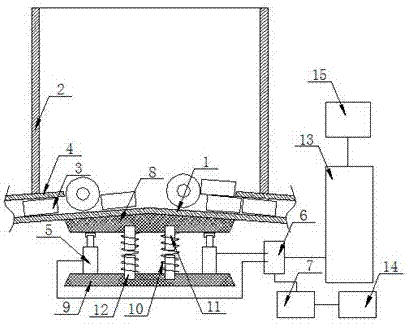

Device for field construction and fast positioning of electric power tower

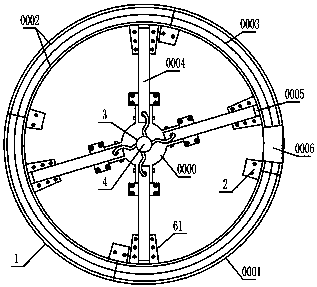

The invention discloses a device for field construction and fast positioning of electric power tower. The device includes a small round chassis, a large round chassis, an operation device, a central light set and an auxiliary positioning device, wherein the central light set is installed on the small round chassis, and the auxiliary positioning device is installed on the operation device. Quick assembly, quick orientation, rapid calibration and rapid positioning at a construction site can be achieved, the optical positioning accuracy is high, errors are small, the device is not affected by wind, rain and dust in the wild, the device is convenient to adjust, disassembly is simple, the occupation space is small after disassembly, the device is convenient to handle, labor and time are saved,and the whole positioning operation can be completed by only one person.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +2

Optical positioning apparatus of high-voltage pole tower base

ActiveCN109339467AReasonable structureHigh optical positioning accuracyTowersBuilding material handlingEngineeringHigh pressure

The invention discloses an optical positioning apparatus of a high-voltage pole tower base. The optical positioning apparatus comprises a small round chassis, a big round chassis, an operational device, a center light set installed on the small round chassis and an auxiliary positioning device installed on the operational device. The optical positioning apparatus of the high-voltage pole tower base can be quickly assembled, calibrated and positioned at a construction field, the optical positioning precision is high, errors are small, the optical positioning apparatus of the high-voltage pole tower base is not influenced by field wind, rain and dirt, easy to adjust, convenient to disassemble, and occupies little space after disassembly, carrying is convenient, time and labor are saved, anda people can complete entire positioning operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +2

Graphene reinforced ceramic matrix composite material and preparation method thereof

ActiveCN110698198AHigh densityImprove performanceCeramic shaping apparatusSilicon nitrideCeramic matrix composite

The invention discloses a graphene reinforced ceramic matrix composite material and a preparation method thereof, wherein the reinforcement body of the composite material comprises directionally arranged graphene, and the volume fraction of the graphene in the composite material is 0.125-1 vol%, the matrix of the composite material is at least one selected from zirconium oxide, silicon nitride andaluminum oxide, and the composite material is formed through 3D photocuring. According to the invention, the directionally arranged graphene reinforced ceramic matrix composite material formed by 3Dphotocuring is provided for the first time, the density of the obtained graphene-reinforced zirconium oxide ceramic reaches up to more than 99%, and the performance of the graphene-reinforced zirconium oxide ceramic is improved by more than 25% compared with the same process with no graphene adding.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

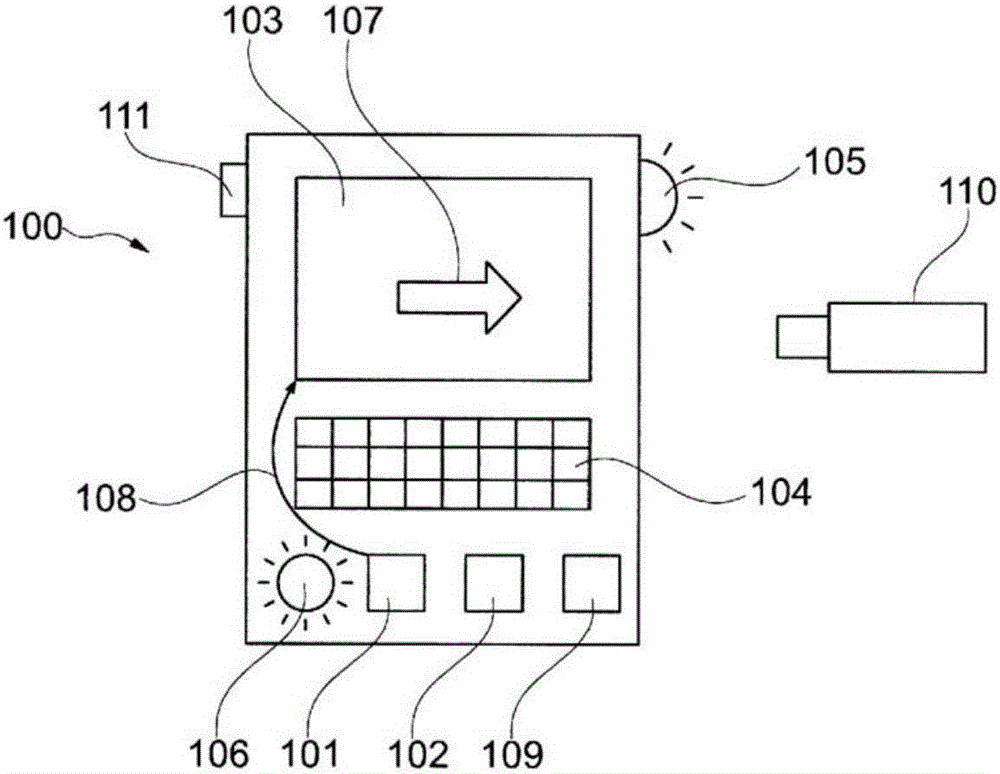

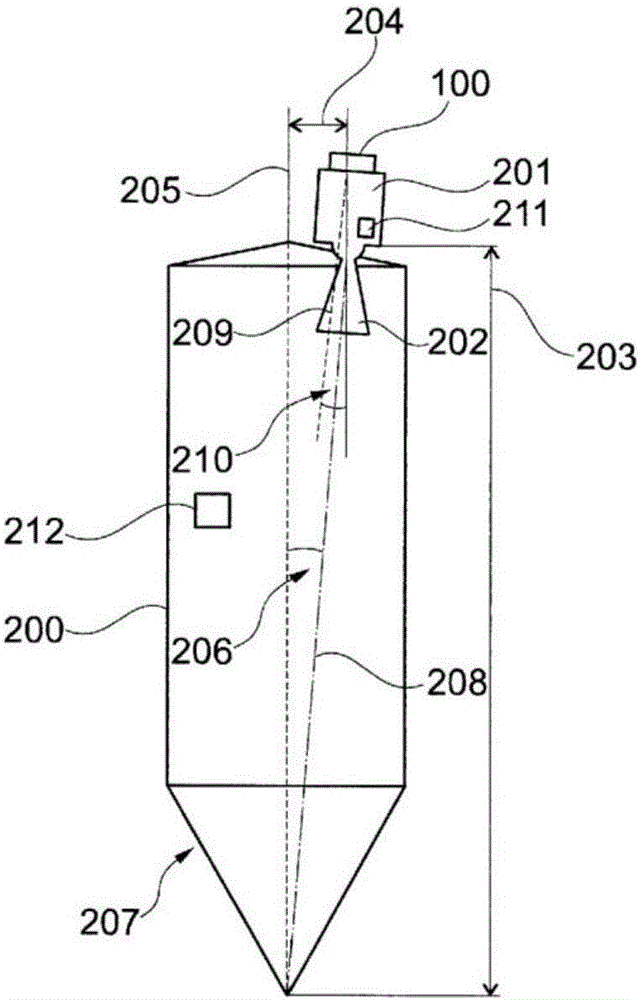

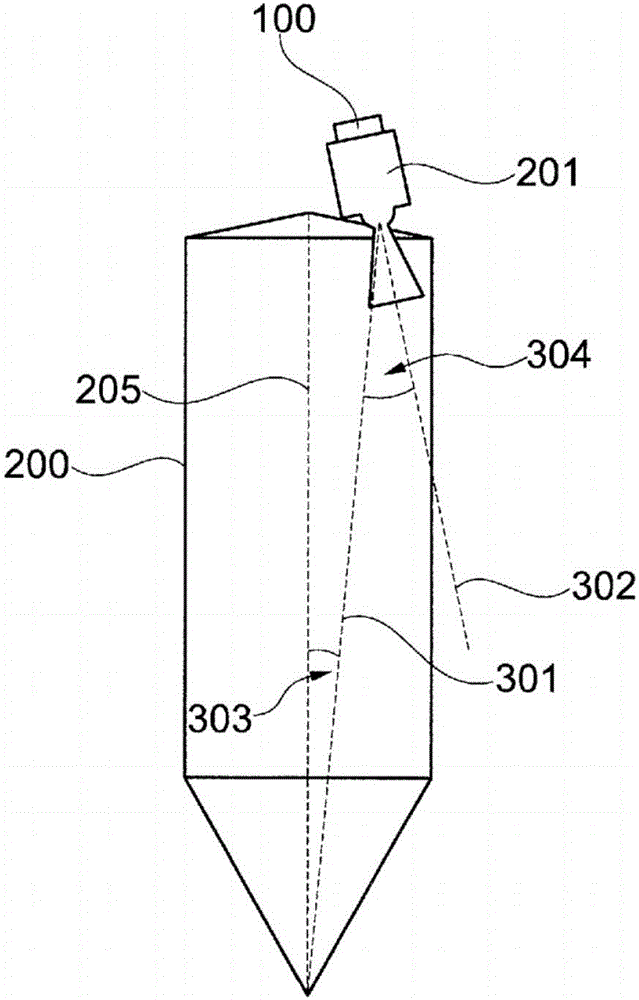

Portable device for orienting fill-level measuring device on container

ActiveCN106104224ASimplified orientationQuick orientationTesting/calibration apparatusMachines/enginesDisplay deviceEngineering

The invention relates to a portable device (100) for orienting a fill-level measuring device (201) on a container (200). For this purpose, the portable device (100) can be placed on a surface of the fill-level measuring device (201). By means of a tilt sensor of the portable device (100), the tilt of the portable device (100) and thus also the tilt of the fill-level measuring device (201) can be determined. On the basis of the tilt of the fill-level measuring device, a dimension of the container (200), and a position of the fill-level measuring device (201) in relation to the container (200) or on the basis of a tilt angle of the fill-level measuring device on the container that is to be set, a change of the orientation of the fill-level measuring device that is still required can be determined by a processor of the portable device. Said change of the orientation of the fill-level measuring device that is still required can be displayed on a display device of the portable device. The invention further relates to a fill-level measuring system, to a method, to a program element, to a computer-readable medium, and to the use of a mobile terminal.

Owner:VEGA GRIESHABER GMBH & CO

Electric tower construction auxiliary device

The invention discloses an electric tower construction auxiliary device. The electric tower construction auxiliary device comprises a small circular bottom plate, a large circular bottom ring, an operating device, a central optical set mounted on the small circular bottom plate and an auxiliary positioning device mounted on the operating device. Rapid assembling, rapid orientating, rapid rectifying and rapid positioning can be conducted ata construction site, optical positioning is high accuracy and small in error and is not affected by field wind, rain and dust, adjusting is convenient, dismounting is easy, the occupied space after dismounting is small, carrying is convenient, the time and labor are saved, and one person can complete whole positioning operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +2

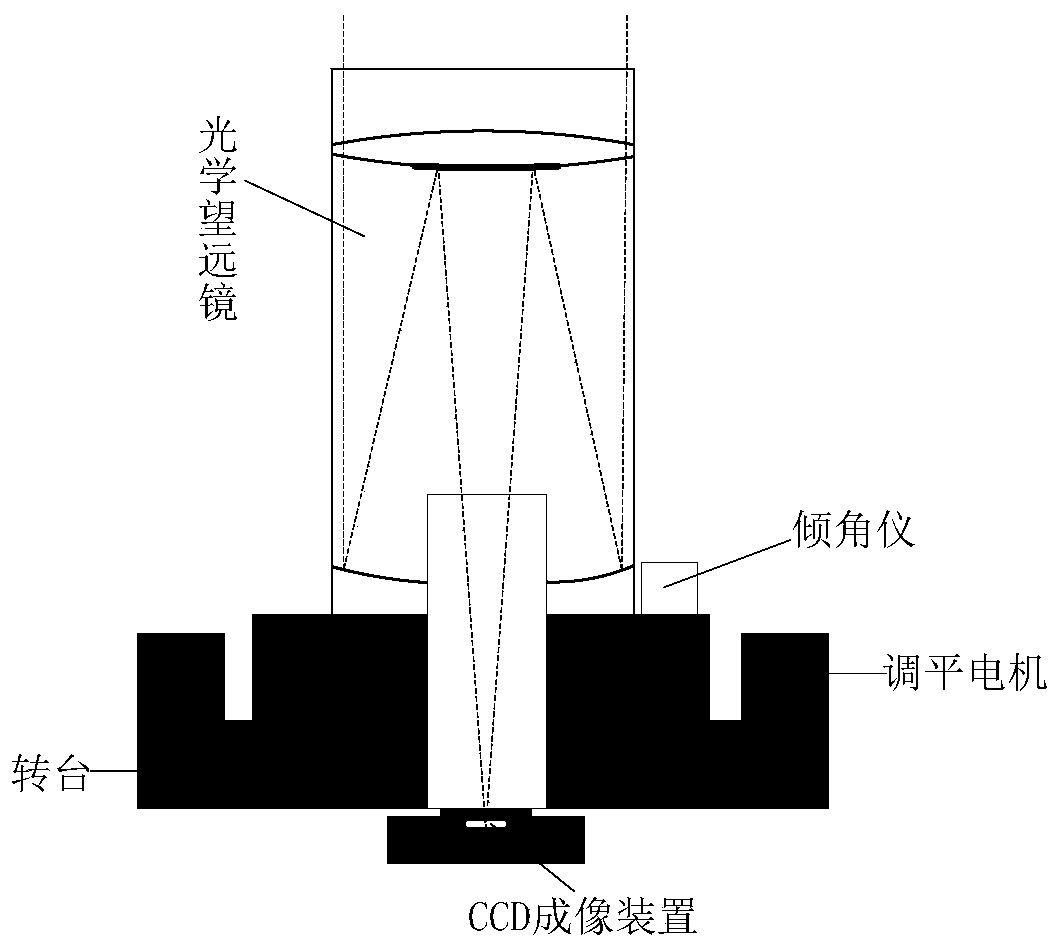

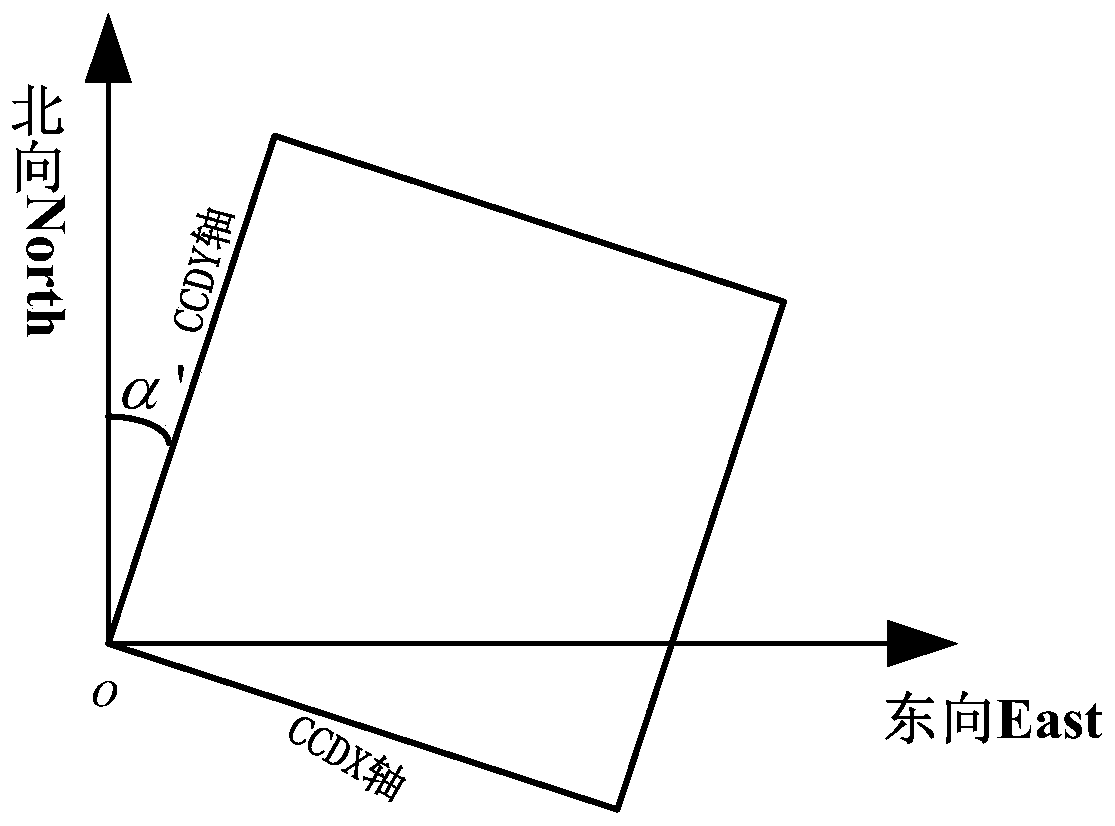

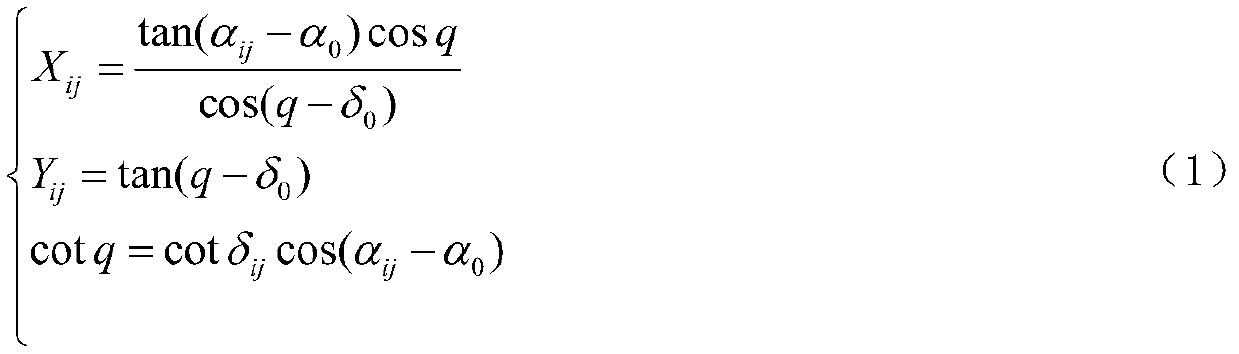

Digital zenith instrument orientation method based on projection transformation

ActiveCN110068313AQuick orientationImprove environmental adaptabilityNavigational calculation instrumentsSurveying instrumentsSoftware systemOptic system

The invention relates to a digital zenith instrument orientation method based on projection transformation. A universal digital zenith instrument having a star map and identification and positioning solution software system is adopted. The digital zenith instrument orientation method based on projection transformation is characterized by comprising the four steps of: measuring the astronomical coordinate of the position, where the zenith instrument is; constructing a projection model of a star coordinate; calculating an azimuth angle; and correcting the azimuth angle A. Compared with the priorart, influence by parameters of an optical system is low; the azimuth also can be accurately calculated even if the optical system is not calibrated; a process of calibrating the parameters of the optical system, such as the focal length and the distortion, very difficultly can be avoided; the problem that corresponding change occurs along with time due to influence by external factors also can be avoided; furthermore, the azimuth of the zenith instrument can be determined only through astro observation; furthermore, the azimuth is output; rapid orientation of a test site can be realized; theenironmental adaptation is relatively high; an experiment verifies that the orientation precision high precisely completed by the method in the invention is within 8''; and requirements of practicalwork on the orientation precision are completely satisfied.

Owner:ROCKET FORCE UNIV OF ENG

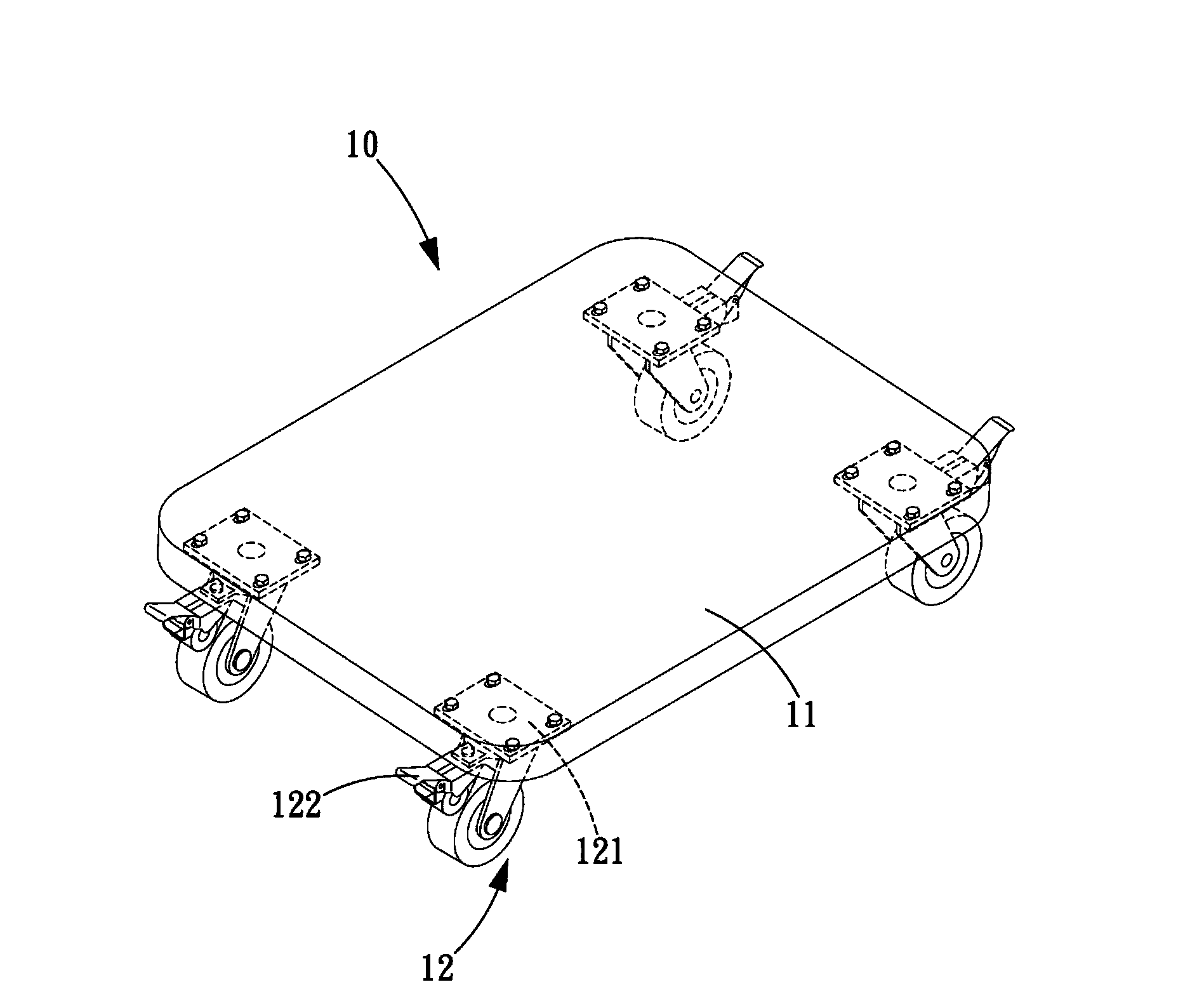

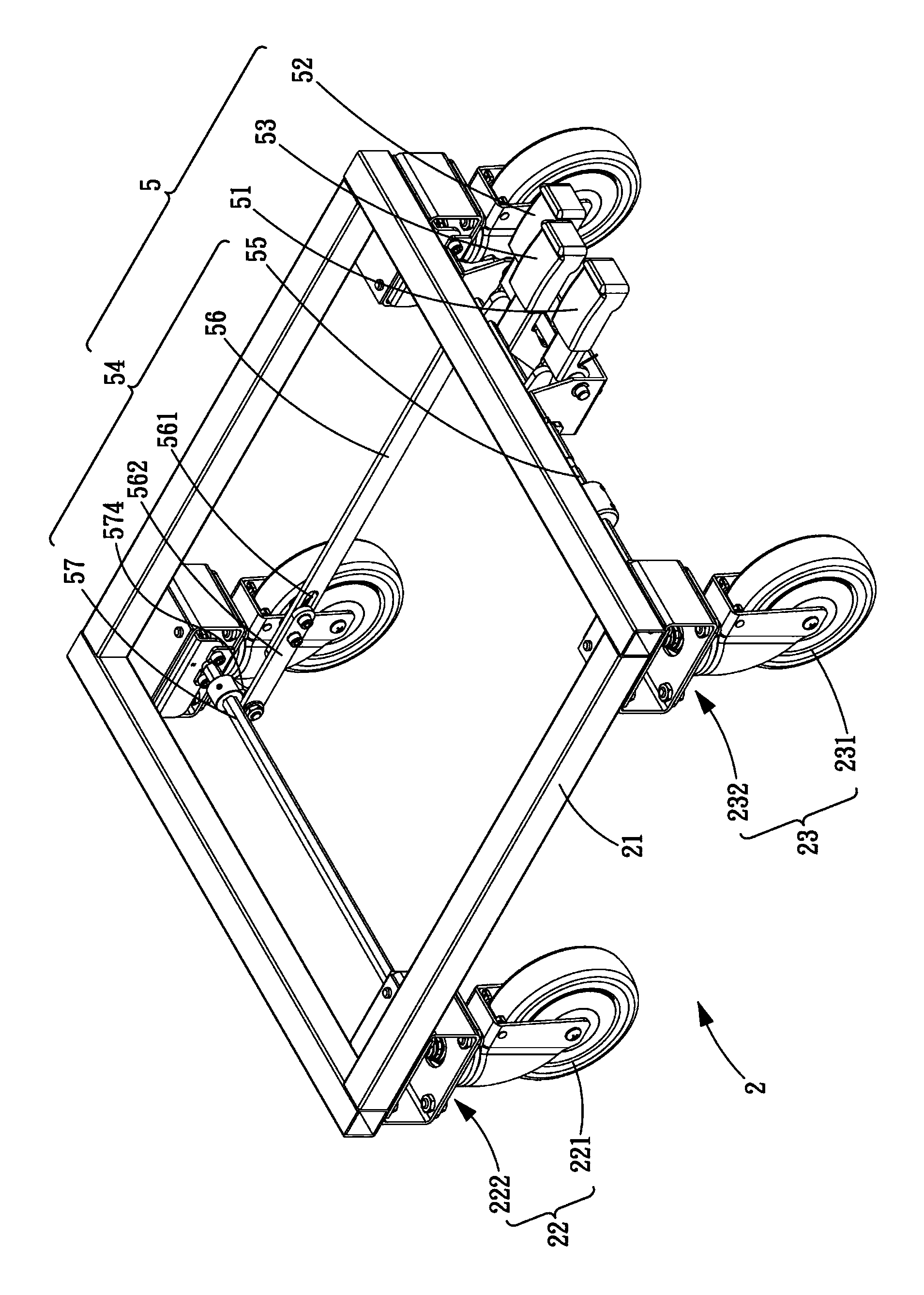

Orientating and positioning system of bogie

The invention discloses an orientating and positioning system of a bogie. The orientating and positioning system is mainly characterized in that a universally-known bogie is improved, and if direction fixing or brake positioning is needed, a user must tread down controllers mounted at the top ends of foot wheels respectively, so that inconvenience is caused due to the fact that the user must repeat actions. A linkage module is connected with a control unit and each of orientating units and positioning units, so that the user only needs to operate the control unit to actuate all of the orientating units and the positioning units, and the user can quickly orientate or position the bogie without repeatedly treading down brakes at the top ends of the foot wheels respectively.

Owner:CATIS PACIFIC MFG CORP

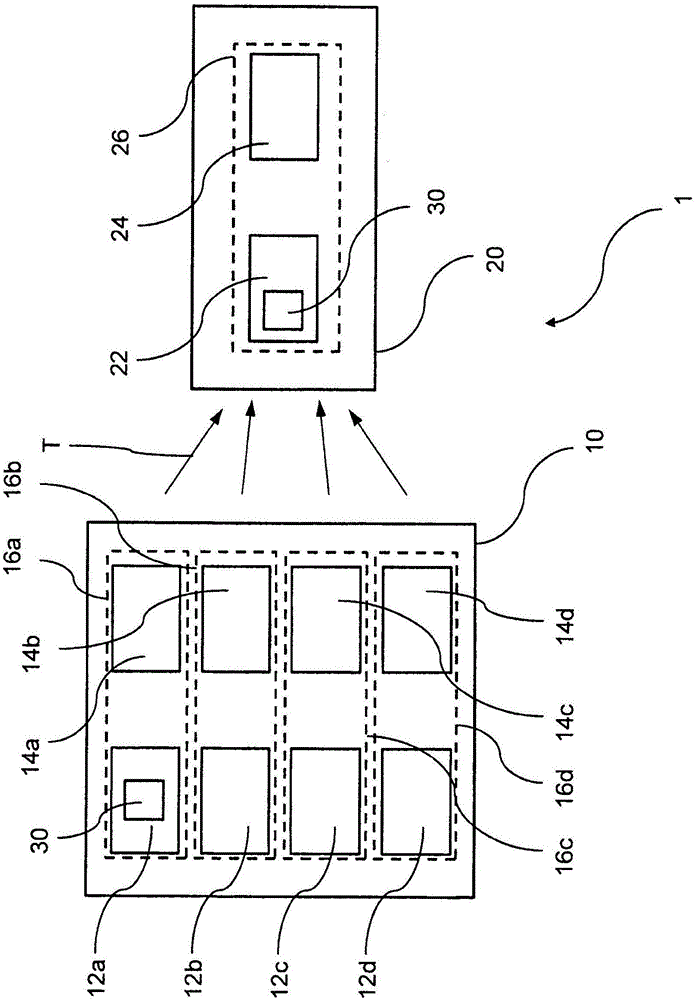

Methods and production system for laminating interior components in vehicles

ActiveCN105899345AImprove productivityIncrease production capacityLamination plant layoutLamination ancillary operationsIn vehicleMechanical engineering

Owner:BAYERISCHE MOTOREN WERKE AG

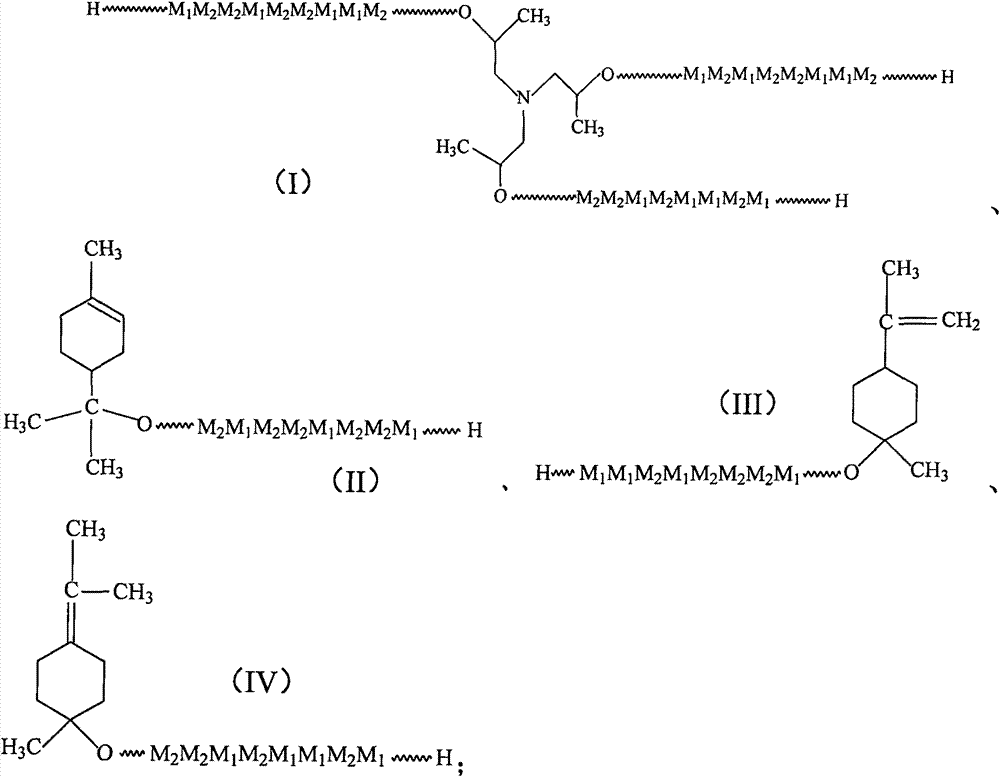

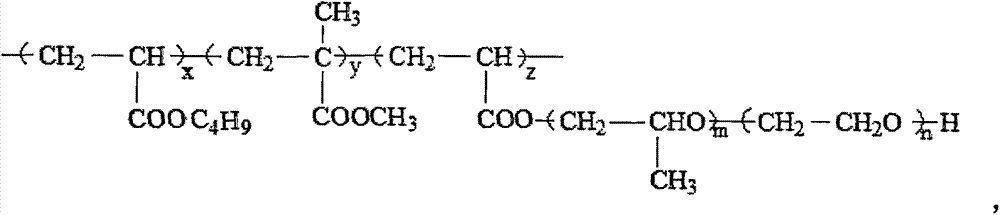

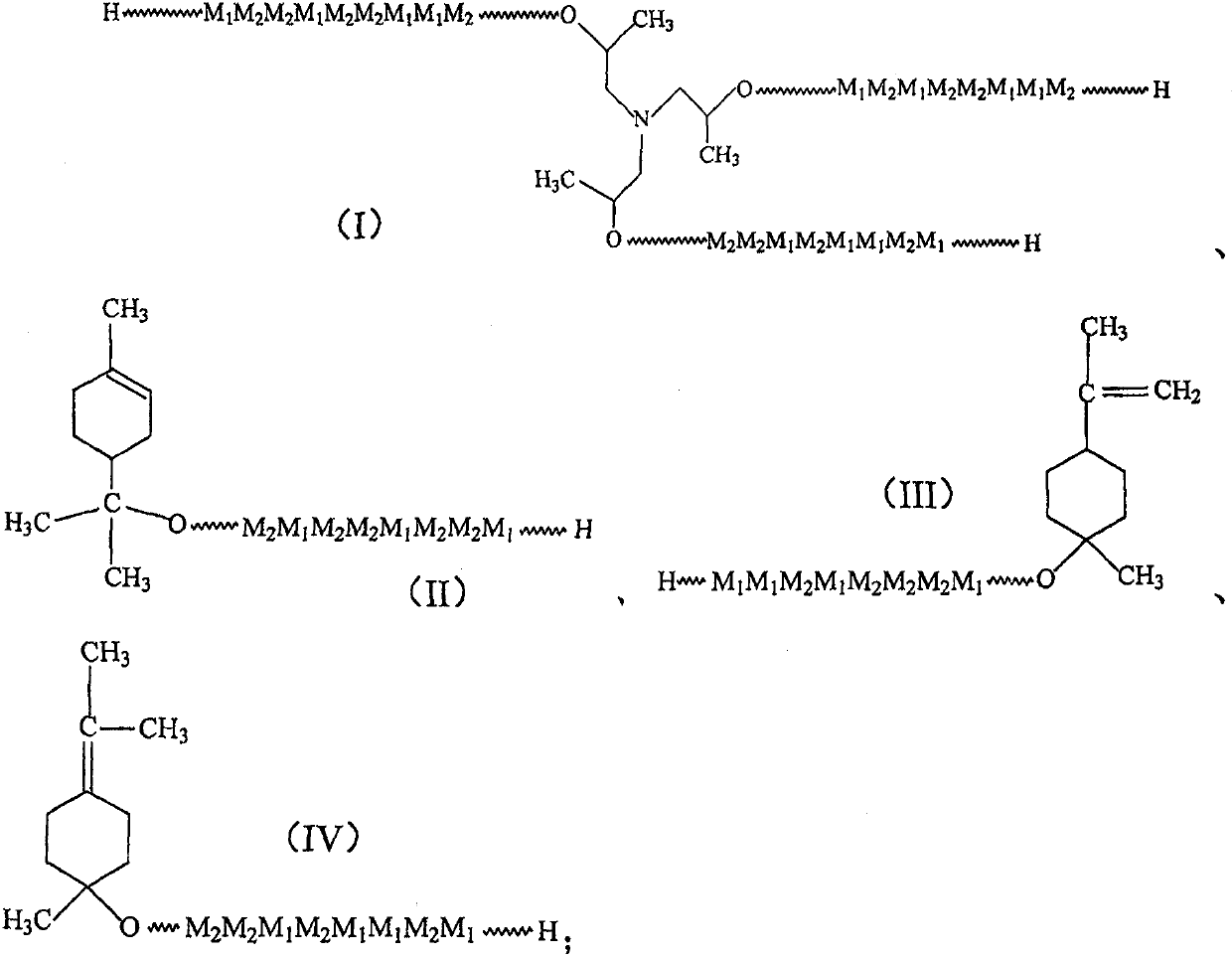

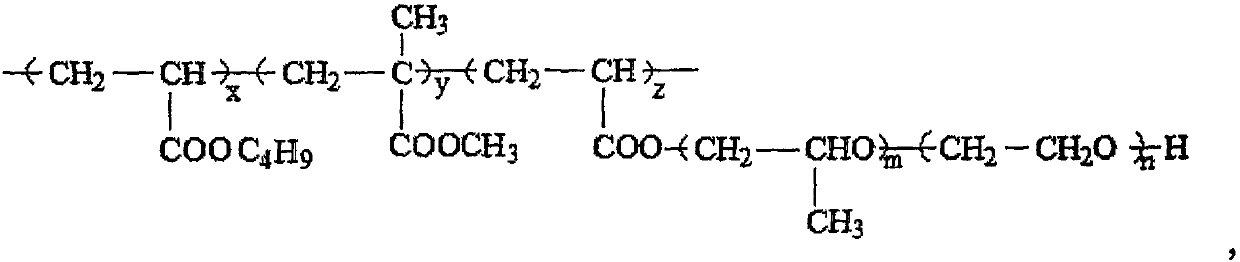

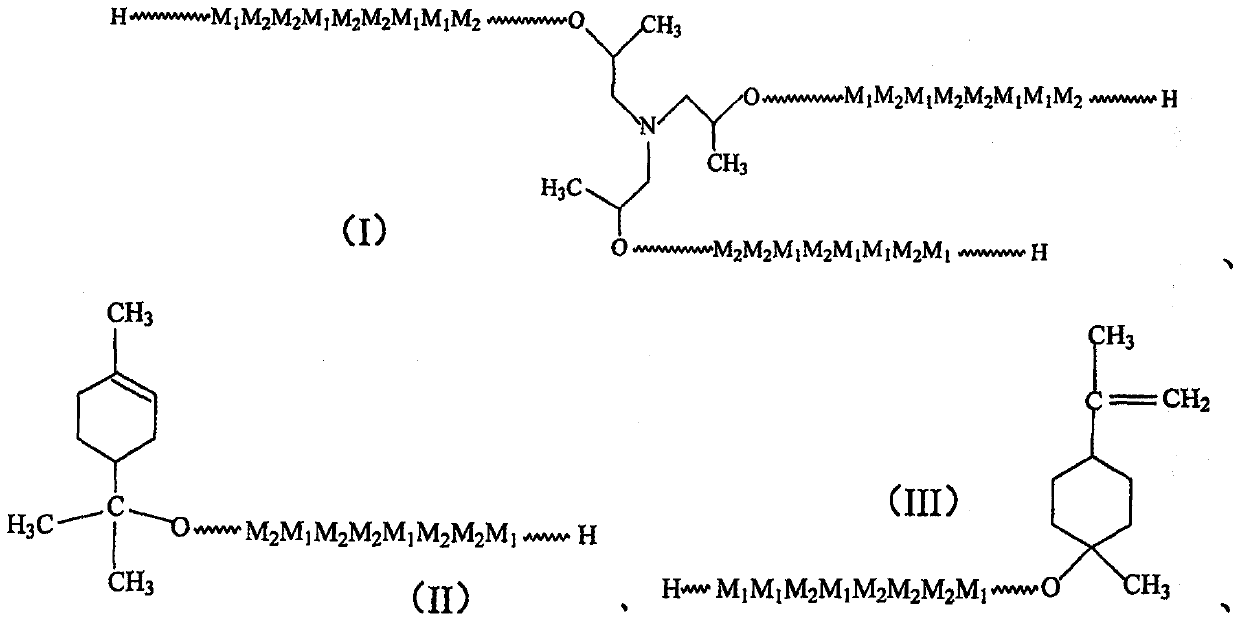

Broad-spectrum aged oil demulsifier and preparation method thereof

ActiveCN107418616AReduce intensityReduce interfacial tensionDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierEther

The invention discloses a broad-spectrum aged oil demulsifier. The broad-spectrum aged oil demulsifier is prepared from the components in percentage by weight: 3 percent to 15 percent of a super-high molecular weight crude oil demulsifier, 21 percent to 35 percent of ternary copolymerized ether, 16 percent to 30 percent of an auxiliary agent and 20 percent to 60 percent of a mixed solvent; the invention further discloses a preparation method. The demulsifier has a reasonable molecular structure, proper molecular weight and strong cooperativity, has the characteristics of deep dehydration on aged oil, rapid demulsifying speed, clear and smooth oil-water interface, wetting, penetration and water clearing and the like, and has broad-spectrum performance.

Owner:盘锦富隆化工有限公司

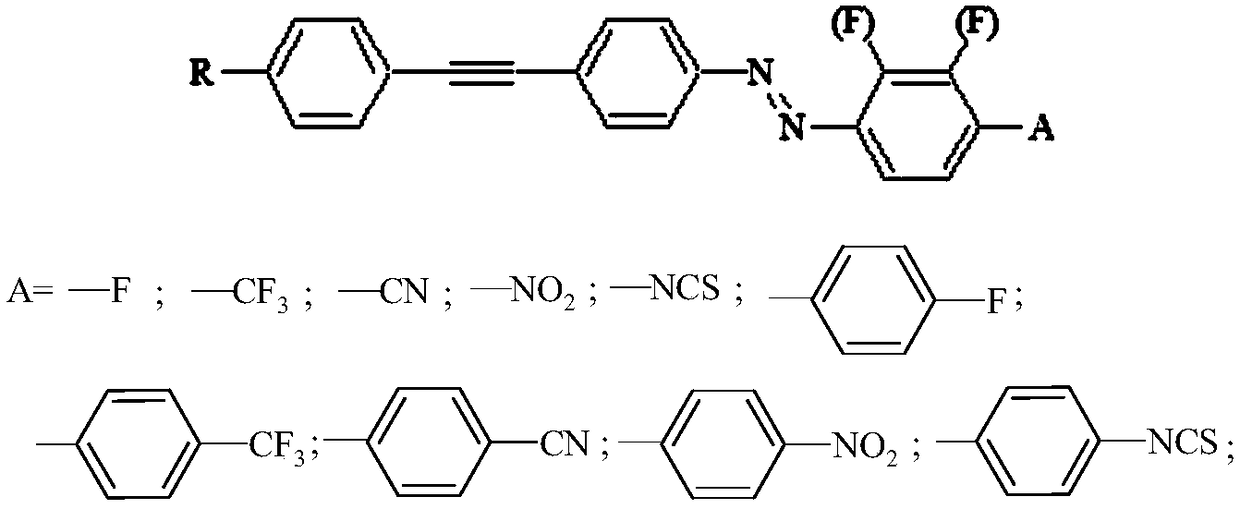

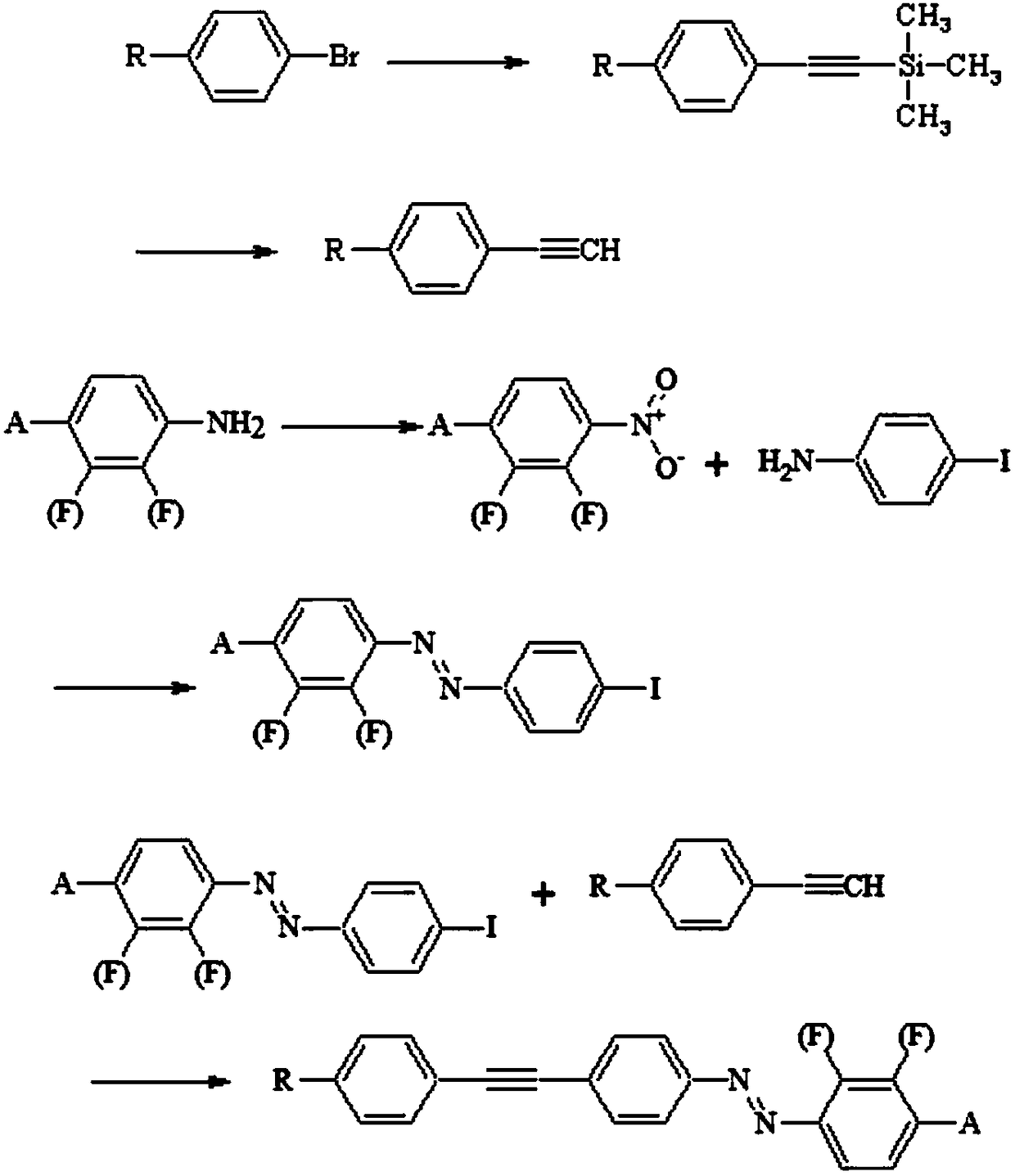

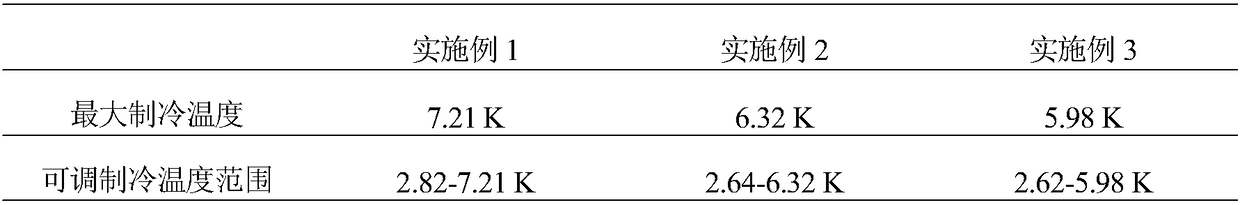

Mixed liquid crystal with huge electrothermal effect being controlled by light and preparation method of mixed liquid crystal

ActiveCN108191711ALarge dielectric anisotropyQuick orientationLiquid crystal compositionsSilicon organic compoundsCrystallographyElectrical field strength

The invention provides a mixed liquid crystal with a huge electrothermal effect being controlled by light and a preparation method of the mixed liquid crystal. Azobenzene liquid crystal molecules withgood compatibility are added in a liquid crystal mixture, the obtained mixed liquid crystal has large dielectric anisotropy, can orient rapidly under the effect of an electric field, and can recoverto the original orientation behavior under the condition that the electric field is revoked, meanwhile, cis-trans isomerisation can happen on the mixed liquid crystal when the mixed liquid crystal isshined by ultraviolet lights, influences of corresponding properties can be obtained under the effect of the electric field intensity on the electrothermal effect, energy can be saved, and the environment is protected.

Owner:XIJING UNIV

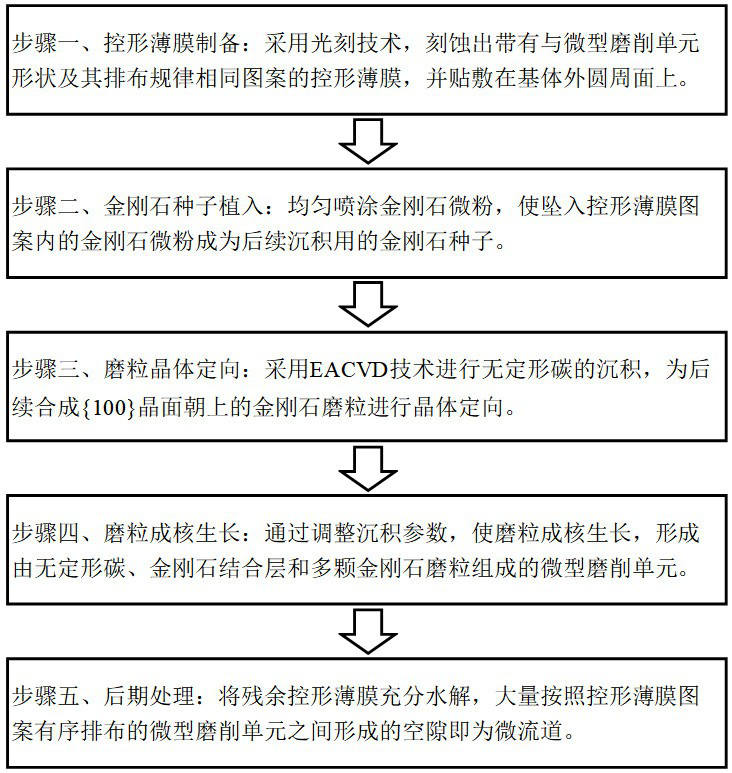

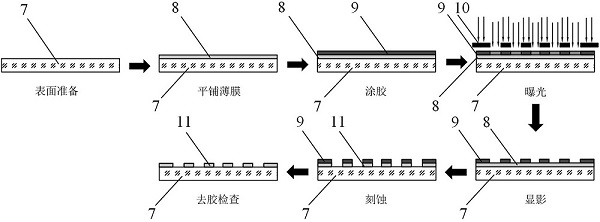

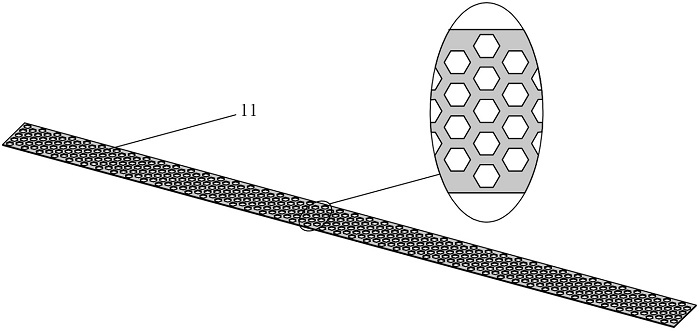

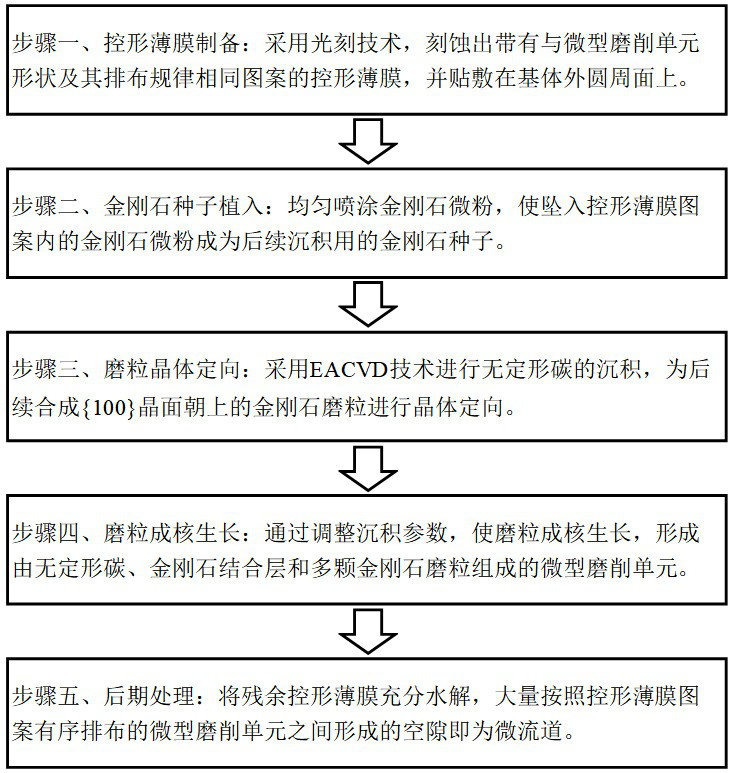

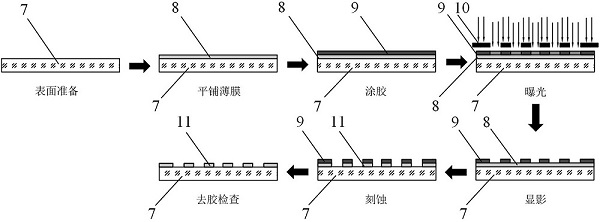

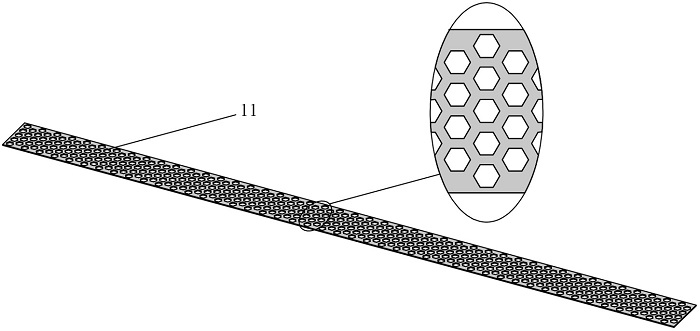

Preparation method of diamond grinding wheel with orderly-arranged crystal orientation abrasives

ActiveCN111941300ALow cost of preparationShort time consumptionGrinding devicesChemical vapor deposition coatingDiamond grindingNucleation growth

The invention discloses a preparation method of a diamond grinding wheel with orderly-arranged crystal orientation abrasives. The preparation method comprises the following steps that a shape controlfilm is prepared by adopting a photoetching technology and adhered to the outer circumferential surface of a substrate, and diamond micro-powder is uniformly sprayed as diamond seeds for subsequent deposition; a layer of amorphous carbon is deposited on the diamond seeds by adopting an EACVD technology, and crystal orientation is performed on subsequently synthesized diamond abrasive particles; deposition parameters are adjusted, nucleation growth is performed on the abrasive particles to form diamond abrasive particles with {100} crystal surfaces as the top surfaces, {111} crystal surfaces asthe side surfaces and larger exposure heights, a micro grinding unit is formed by the diamond abrasive particles, the amorphous carbon and a diamond bonding layer, and a plurality of micro grinding units are orderly arranged according to a photoetching pattern of the shape control film; and the shape control film is removed through ultrasonic cleaning, gaps between a large number of micro grinding units are micro flow channels, and a grinding wheel finished product is obtained through drying. According to the preparation method, crystal orientation can be performed on the diamond abrasive particles, the abrasives can be arranged orderly, and the grinding performance of the grinding wheel is remarkably improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Steel fiber reinforced concrete vibration leveling construction method for bridge deck reinforcement

PendingCN112832128AQuick OrientationHigh strengthPaving reinforcementsBridge structural detailsArchitectural engineeringBridge deck

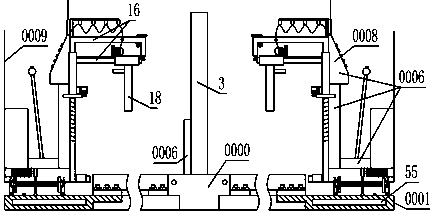

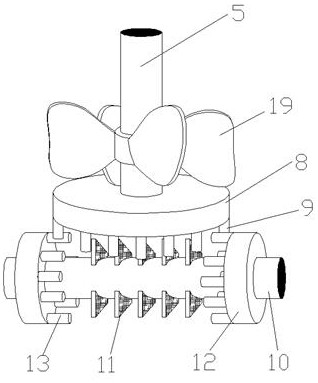

The invention discloses a steel fiber reinforced concrete vibration leveling construction method for bridge deck reinforcement. The construction method comprises the steps of bridge deck finishing, on-site mixing, paving, vibrating and compacting, scraper leveling, joint cutting, anti-sliding treatment, maintenance and the like. A special mixing machine is adopted for on-site mixing and comprises a mixing box and a stirring barrel, the mixing box is provided with a steel fiber feeding hopper, a triangular supporting plate, a concrete feeding hopper and a driving shaft, and the driving shaft is connected with a driving fluted disc and a plug-flow stirring paddle; the driving fluted disc is meshed with a driven fluted disc through a tooth column, the driven fluted disc is connected with a driven roller, and the driven roller is provided with wing plates. The stirring barrel is provided with a discharging pipe, a stirring shaft and a trapezoidal plate; the rotatable wing plates distributed at equal intervals are adopted to form a screening array, disordered steel fibers are rapidly arranged in an oriented mode, the trapezoidal plates basically parallel to the steel fibers are arranged for stirring after oriented arrangement, the contradiction between concrete stirring and steel fiber oriented arrangement is thoroughly solved. The obtained steel fiber reinforced concrete is high in strength.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

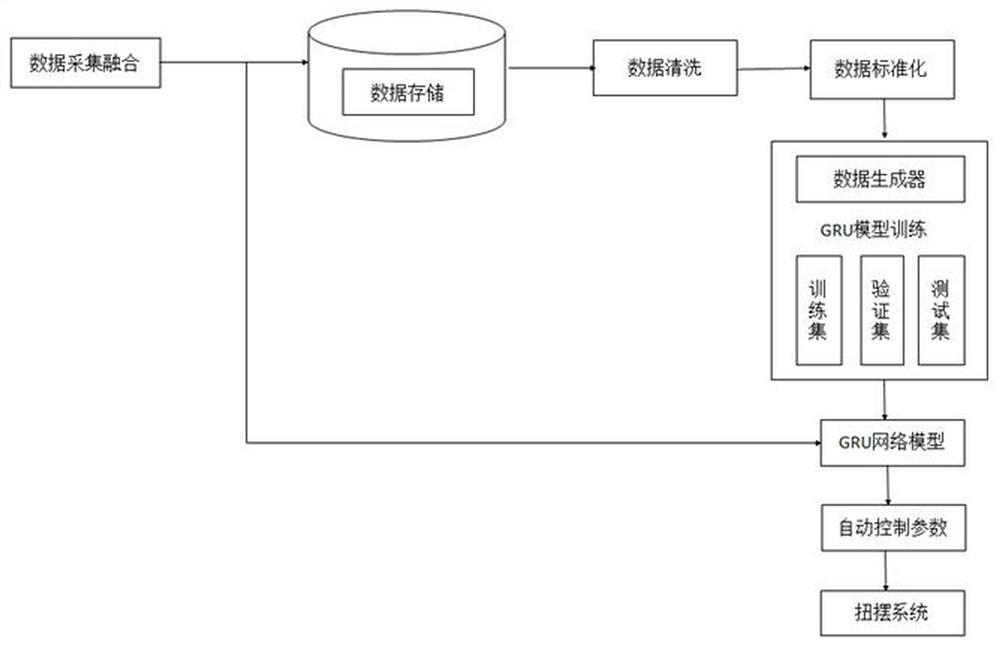

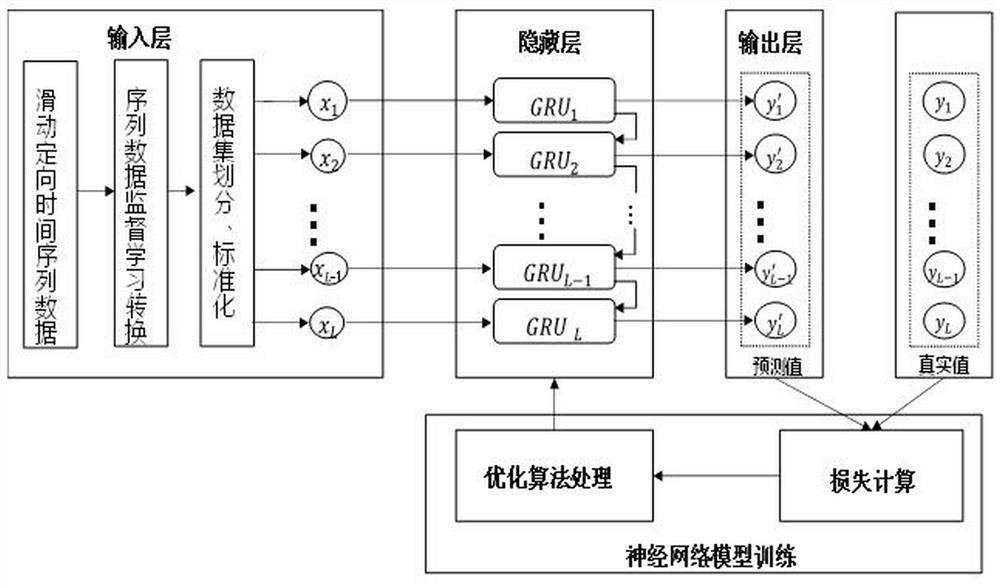

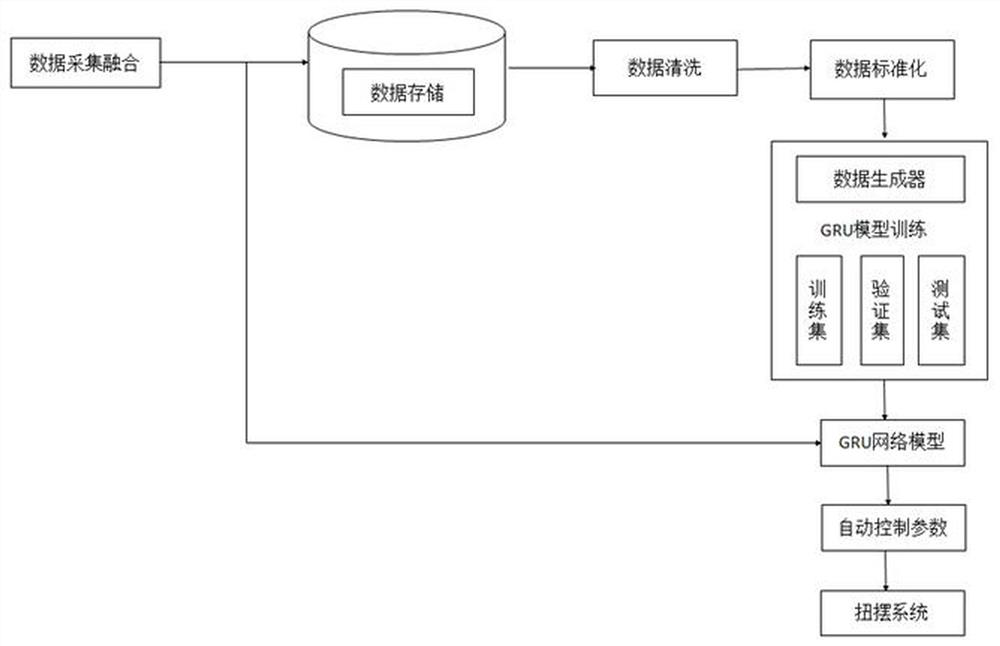

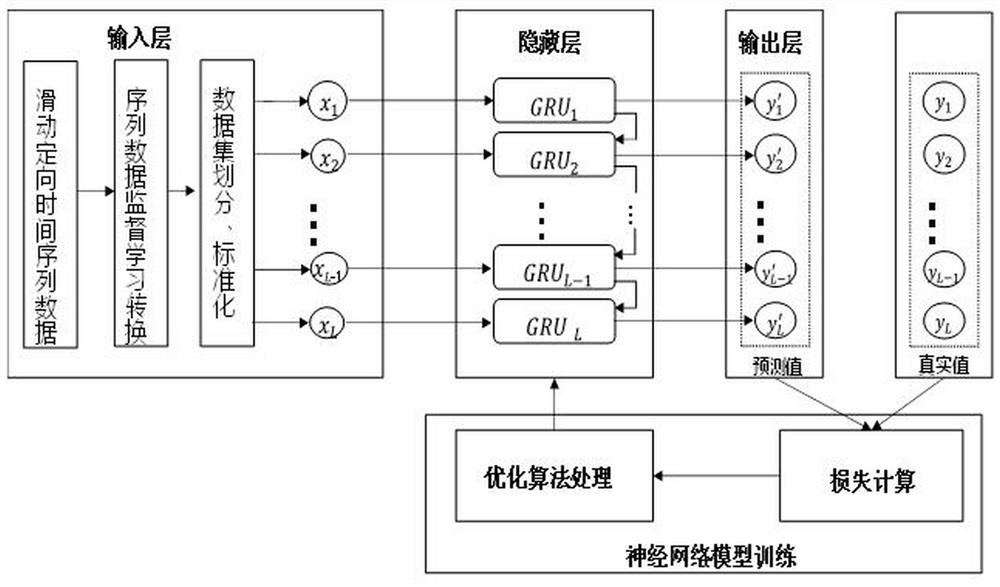

Sliding directional intelligent control method based on GRU

ActiveCN111946258AReduce the amount of parametersReduce riskDirectional drillingAdaptive controlAutomatic controlData cleansing

The invention discloses a sliding directional intelligent control method based on GRU. The sliding directional intelligent control method comprises the steps: 1, onsite initial sample data in slidingdrilling are obtained, classified and integrated, and stored in a database; 2, initial sample data in the database are subjected to data cleaning, the initial sample data after cleaning is subjected to standardization processing, and standardized sample data are obtained after processing; 3, a GRU network model is constructed; and 4, real-time data of sliding drilling is collected and input into the GRU network model, automatic control parameters are generated, and the automatic control parameters are input into a torsional pendulum system to achieve intelligent control. According to the sliding directional intelligent control method, effective and high-quality data are obtained by acquiring, fusing and storing the onsite data and cleaning and standardizing the data, a data generator is designed, GRU model training is performed by utilizing the onsite data to form the GRU network model, the automatic control parameters of sliding directional operation are generated based on the GRU network model, and intelligent decision and control of the torsional pendulum system are realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Orientation method of core fracture in inclined well

InactiveCN103983236BOrientation is accurateQuick orientationAngle measurementIncline measurementPermeationFissure

The invention relates to the field of the exploitation and development of oil and gas fields, and in particular relates to an inclined shaft core fissure orientation method. The method is characterized by comprising the following steps: on the basis of drilling data, calculating well deviation information of a coring interval, calculating the real attitude of a rock stratum according to earthquake data, determining an apparent dip of the core fissure and an angle between the fissure apparent inclination and apparent inclination of the rock stratum according to the core data, designing an inclined shaft core fissure orientation concept on the basis, deriving a corresponding algorithm, and realizing the accurate orientation of the core fissure. By adopting the method, the problem that the inclined shaft core fissure cannot be orientated can be solved, the inclined shaft core fissure orientation accuracy is improved, and the practical value on multiple aspects such as accurately determining the permeation rate advantageous direction of a reservoir stratum of the oil and gas field, the relative position relation of a water filling well and an oil recovery well, direction of ancient stress field in the crack generation period, reasonable layout and development of well networks can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

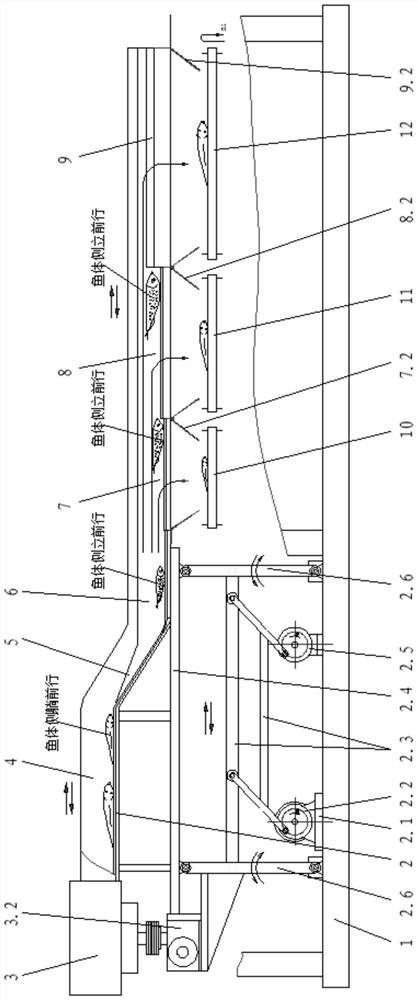

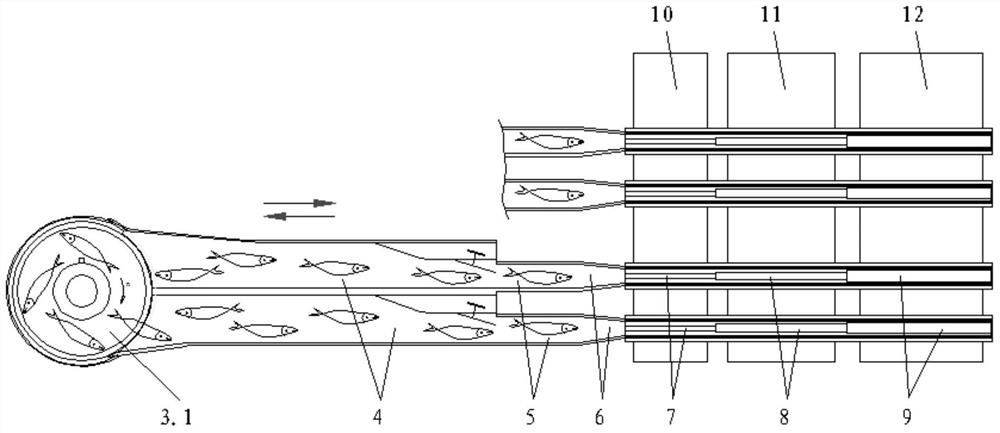

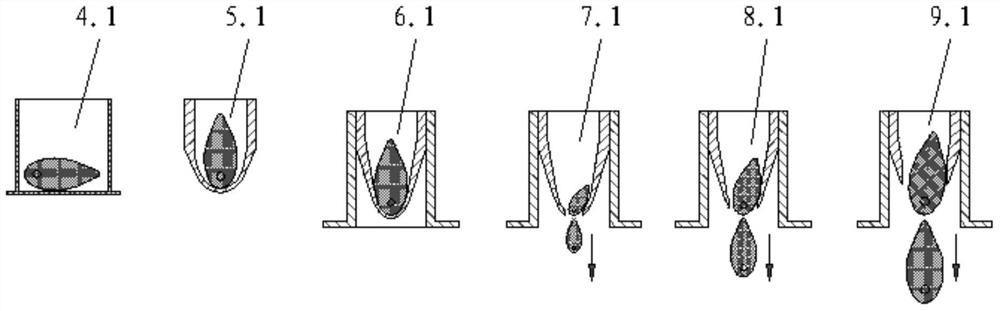

Vibration classifier for processing large yellow croaker and its classifying method

The invention relates to a vibrating classifier for processing large yellow croaker, comprising an eccentric mechanical vibration device, a cylindrical feeder, a classification tank for classifying small, medium and large fish bodies and a corresponding unloading conveyor; The tank body is sequentially provided with the fish body head and tail directional section tank body, the fish body turning side vertical downward slide section tank body, the fish body side vertical sliding section U-shaped tank body, the small size fish body grading section tank body, and the medium size fish body. Body grading section tank body and large-size fish body grading section tank body; the cylindrical feeder and the front end of the oriented and grading long groove are connected with a gap. Together with the vibration device, it slides into the directional and grading long trough, and in turn realizes the fish head in the front and the tail in the back, the fish body rotates and slides on the side, and the fish body moves on the side without overlapping. When arranging through the small, medium and large size fish grading troughs, they fall into the corresponding small, medium and large fish feeding conveyors below, thereby realizing the multi-specification grading treatment of batches of large yellow croaker.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Spar conveying method

InactiveCN108455224AContinuous and accurate deliveryFast screening and deliveryConveyor partsEngineeringMechanical engineering

The invention discloses a spar conveying method. The spar conveying method comprises the following steps that 1, spars are injected into a conveying pipe with an inclined surface to be oriented; 2, acarrying plate or a carrying belt is arranged at the outlet end of the conveying pipe, wherein the carrying plate or the carrying belt rotates intermittently, the outer periphery of the carrying plateor the carrying belt is provided with carrying holes for carrying the spars, and the oriented spars fall into the right-aligned carrying holes one by one from the outlet end of the conveying pipe; and 3, the carrying plate or carrying belt rotating intermittently is rotated to a discharging mechanism located at the lower portion and an appropriate position, and then the spars fall into or are driven to fall into the corresponding position of the discharging mechanism, and are clamped and conveyed to a corresponding position through a clamping opening of the discharging mechanism. According tothe method, the oriented spars fall into the right-aligned carrying holes one by one from the outlet end of the conveying pipe, further, the carrying plate or carrying belt rotating intermittently isrotated to the discharging mechanism located at the lower portion and the appropriate position, then the spars fall into or are driven to fall into the corresponding position of the discharging mechanism, and are clamped and conveyed to the corresponding position through the clamping opening of the discharging mechanism, finally, the spars are conveyed to the corresponding position through the discharging mechanism, so that the spars are continuously and accurately conveyed.

Owner:ZHEJIANG HEHE ELECTROMECHANICAL CO LTD

Spar feeding device

InactiveCN108177924AContinuous and accurate deliveryFast screening and deliveryConveyorsConveyor partsEngineeringMechanical engineering

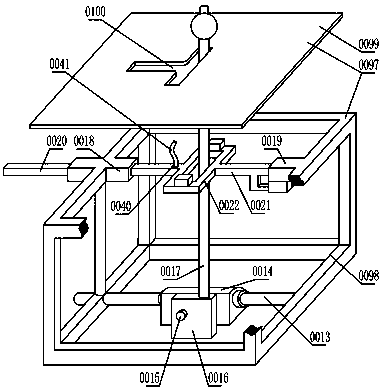

The invention discloses a spar feeding device which comprises a spar supply mechanism, a conveying mechanism and a delivery mechanism; the supply mechanism comprises a tray and a conveying pipe directed to spars; the conveying mechanism comprises a carrying disc or a carrying belt for carrying the spars; carrying holes used for carrying the spars are formed in the periphery of the carrying disc orthe carrying belt; the carrying disc or the carrying belt intermittently rotates and drives one carrying hole at the upper side to be aligned to an outlet of the conveying pipe in the intermittence period of the intermittently rotating carrying disc or carrying belt; and the delivery mechanism comprises a feeding structure which is arranged below the carrying disc or the carrying belt and is usedfor clamping the spar at a material taking work station and delivering the spar. For the spar feeding device provided by the invention, by arranging the supply mechanism, the conveying mechanism andthe delivery mechanism, the supply mechanism realizes continuous supply of directed spars, the conveying mechanism performs further conveying and gradually separates the spars with a special amount, and finally, the delivery mechanism conveys the spars to a corresponding position to finish continuous and accurate conveying of the spars.

Owner:ZHEJIANG HEHE ELECTROMECHANICAL CO LTD

Pneumatic pulse type electronic device feeding device

InactiveCN107472869AImprove processing efficiencyImprove transportation convenienceJigging conveyorsConveyor partsEngineeringSignal generator

The invention discloses a pneumatic pulse type electronic device feeding device. The pneumatic pulse type electronic device feeding device comprises a material vibrating barrel and a material vibrating base. The material vibrating barrel comprises a vibrating barrel bottom wall and a vibrating barrel side wall. The vibrating barrel bottom wall is arranged on the material vibrating base. A material arrangement outlet is formed in the lower end of the vibrating barrel side wall. A material arrangement baffle is arranged at the top of the material arrangement outlet and is parallel with the vibrating barrel bottom wall at the material arrangement outlet. The material vibrating base comprises material vibrating air cylinders, a multichannel solenoid valve and a pulse signal generator, wherein the multichannel solenoid valve is used for controlling the make and break states of an air channel of each material vibrating air cylinder; the pulse signal generator is used for transmitting a control signal to the multichannel solenoid valve; and the material vibrating air cylinders are vertically arranged. By means of the pneumatic pulse type electronic device feeding device, axial vertical placement of ringlike electronic devices can be achieved conveniently, rapidly and efficiently so that machining workers can improve operation efficiency.

Owner:安徽君华舜义恩佳非晶材料有限公司

A QR code automatic positioning and orientation method

ActiveCN103177251BRapid positioningQuick orientationCharacter and pattern recognitionSelf adaptiveImage edge

The invention discloses an automatic QR (quick response) code positioning and orientating method. The method includes: converting an input image into a grayscale image; binarizing the grayscale image by the self-adaptive threshold algorithm to eliminate noise interference; extracting an grayscale image edge according to an Sobel operator; extracting a profile sequence from the edge by the chain code tracing algorithm; filtering a rectangular profile, filtering a view-finding image from the rectangular profile sequency, and judging whether the image has a QR code or not; and correcting and dividing the QR code. By the automatic QR code positioning and orientating method, QR code positioning and orientating can be realized quickly and accurately in a robustness manner, and QR codes can be extracted from images without manual operations, so that manpower cost and time are saved greatly. The automatic QR code positioning and orientating method is applicable to industrial informationization and automation and has wide application prospect.

Owner:南京无限物联科技有限公司

Preparation method of diamond grinding wheel with orderly arrangement of crystal oriented abrasives

ActiveCN111941300BEfficient orientationQuick orientationGrinding devicesChemical vapor deposition coatingMetallurgyCrystal orientation

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

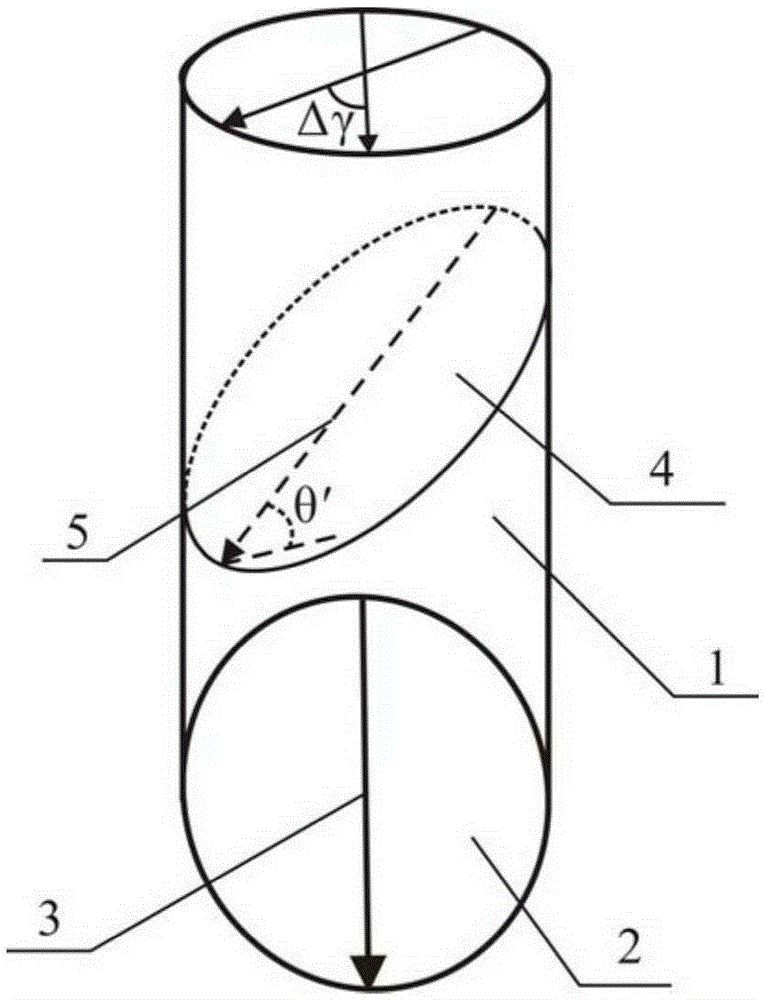

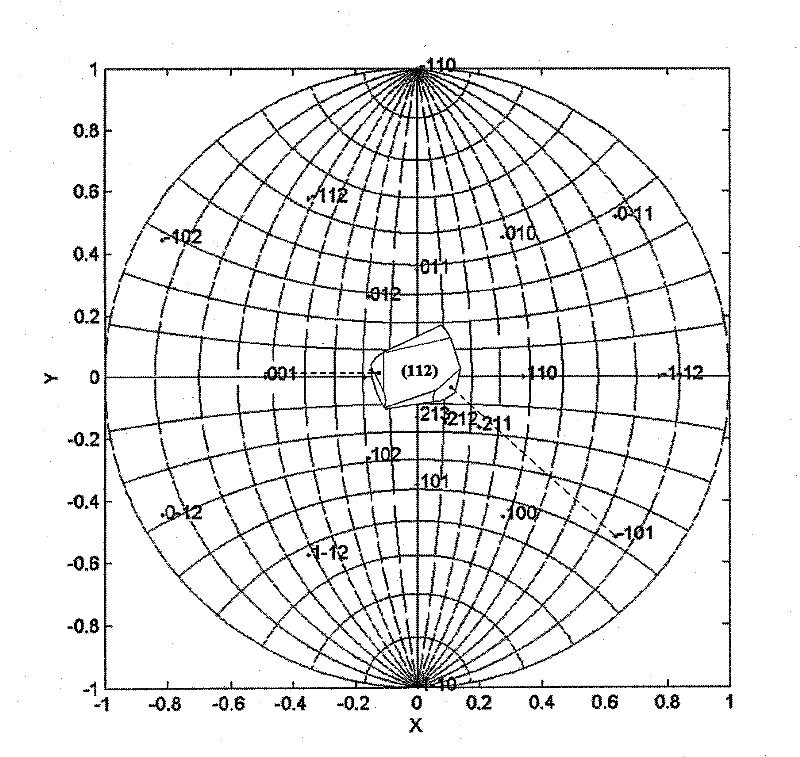

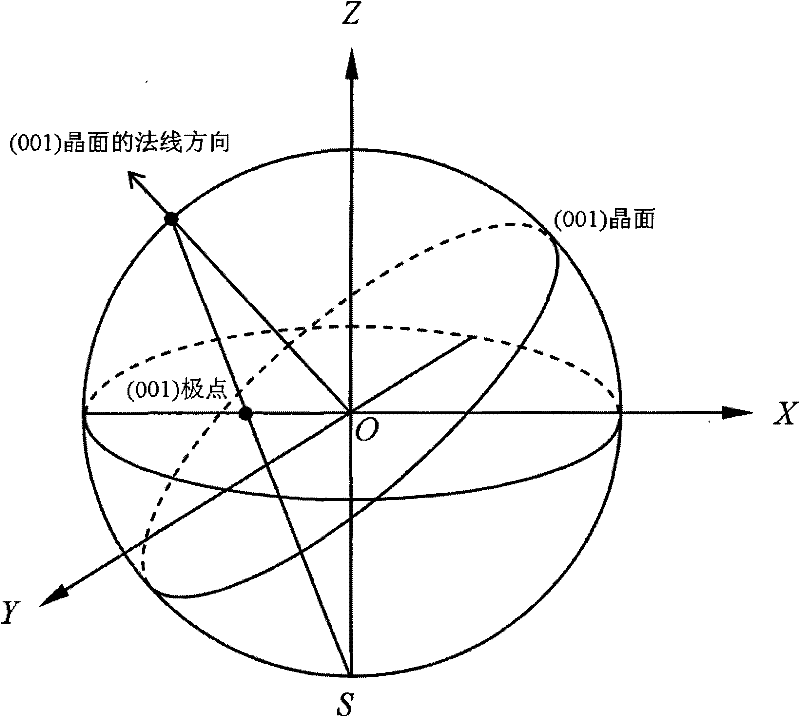

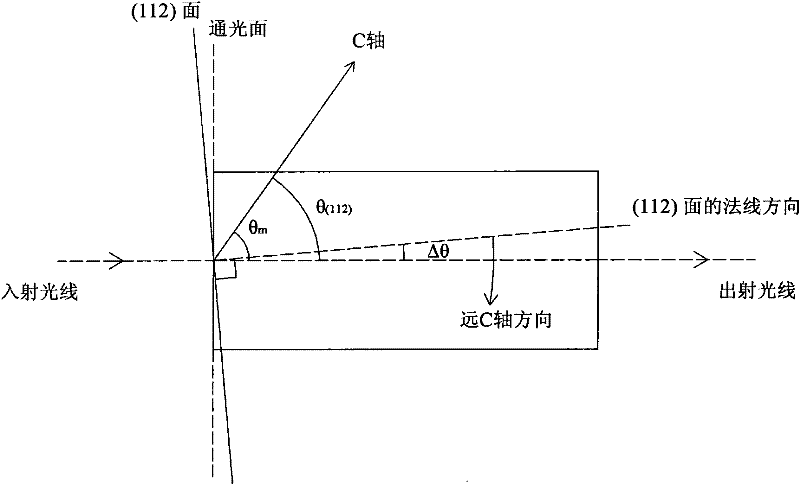

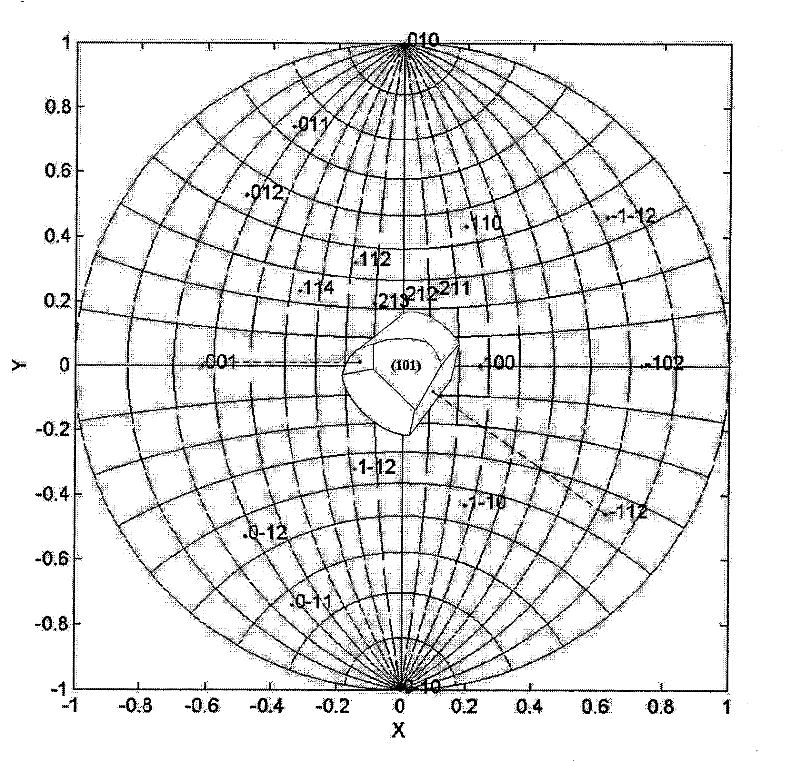

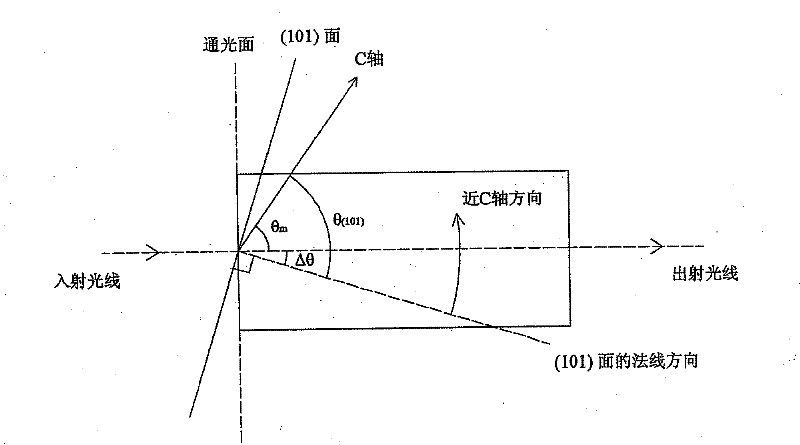

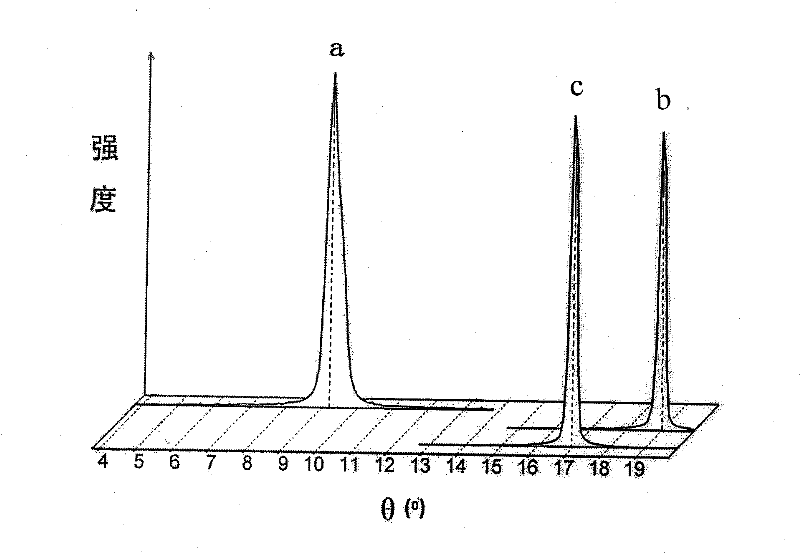

Directional Cutting Method for Infrared Nonlinear Optical Components Prepared by Chalcopyrite-like Negative Uniaxial Crystals

InactiveCN101486231BEasy to operateQuick orientationFine working devicesNonlinear opticsDiffractometer

A directional cutting method for preparing infrared nonlinear optical elements from chalcopyrite negative uniaxial crystals, the steps include: (1) according to the cleavage planes {112} and {101} of chalcopyrite negative uniaxial crystals, using The C-axis direction of the crystal is determined by the crystal standard pole figure of Wu's grid scale and the θ-2θ continuous scanning of the X-ray diffractometer; (2) The crystal with the determined C-axis direction is placed on the cutting machine, and according to the phase matching required by the optical element Rotate the sample stage Δθ toward the far C-axis at an angle θm and then cut to obtain the initial sample of the optical element, Δθ=θm-θ(112); (3) Place the initial sample of the optical element on the sample stage of the X-ray diffractometer, and measure the optical The swing-back spectrum of the cut surface of the original sample of the component, the diffraction peak value θ' and Δθ' are obtained, Δθ'=|θ'-θ'(112)|; (4) The finishing of the optical component, the cut surface Correction is performed until Δθ'=Δθ.

Owner:SICHUAN UNIV

A sliding orientation intelligent control method based on gru

ActiveCN111946258BSafe OrientationQuick orientationDirectional drillingAdaptive controlAutomatic controlNetwork model

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Broad-spectrum aging oil demulsifier and preparation method thereof

ActiveCN107418616BReduce intensityReduce interfacial tensionDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierPhysical chemistry

The invention discloses a broad-spectrum aged oil demulsifier. The broad-spectrum aged oil demulsifier is prepared from the components in percentage by weight: 3 percent to 15 percent of a super-high molecular weight crude oil demulsifier, 21 percent to 35 percent of ternary copolymerized ether, 16 percent to 30 percent of an auxiliary agent and 20 percent to 60 percent of a mixed solvent; the invention further discloses a preparation method. The demulsifier has a reasonable molecular structure, proper molecular weight and strong cooperativity, has the characteristics of deep dehydration on aged oil, rapid demulsifying speed, clear and smooth oil-water interface, wetting, penetration and water clearing and the like, and has broad-spectrum performance.

Owner:盘锦富隆化工有限公司

Oriented cutting method for preparing infrared non-linear optics element from yellow copper positive uni-axial crystal

InactiveCN101486232BEasy to operateQuick orientationFine working devicesContinuous scanningDiffractometer

The invention relates to a directional cutting method for preparing infrared nonlinear optical elements from a chalcopyrite uniaxial positive crystal, which comprises the following steps: (1) according to cleavage surfaces {112} and {101} of the chalcopyrite uniaxial positive crystal, utilizing a crystal standard pole figure with Wuwov's intersection ruler and an X-ray diffractometer to determinethe direction of a C axis of the crystal through theta-2theta continuous scanning; (2) putting the crystal of which the direction of the C axis is determined on a cutting machine, rotating a sample stage for delta theta toward the direction of the C axis according to a phase matching angle theta m required by an optical element, and cutting the crystal to obtain an original sample of the optical element, wherein the delta theta= theta (101) - the theta m; (3) putting the original sample of the optical element on the sample stage of the X-ray diffractometer, determining an oscillation photograph of a cutting surface of the original sample of the optical element, and obtaining a diffraction peak place value theta' and delta theta', wherein the delta theta'=absolute (theta'- theta'(101)); and (4) finishing the optical element, and correcting the cutting surface of the original sample of the optical element until the delta theta'=the delta theta.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com