Preparation method of diamond grinding wheel with orderly-arranged crystal orientation abrasives

A diamond grinding wheel and crystal orientation technology, used in metal processing equipment, grinding/polishing equipment, grinding devices, etc., can solve the problem that the geometric size of diamond abrasive grains, the height of the cutting edge are difficult to keep consistent, and the diamond grinding wheel is difficult to meet the processing of precision grinding requirements, low efficiency of grinding wheel preparation, etc., to achieve the effect of improving cutting performance and service life, excellent crystal shape and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation method of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

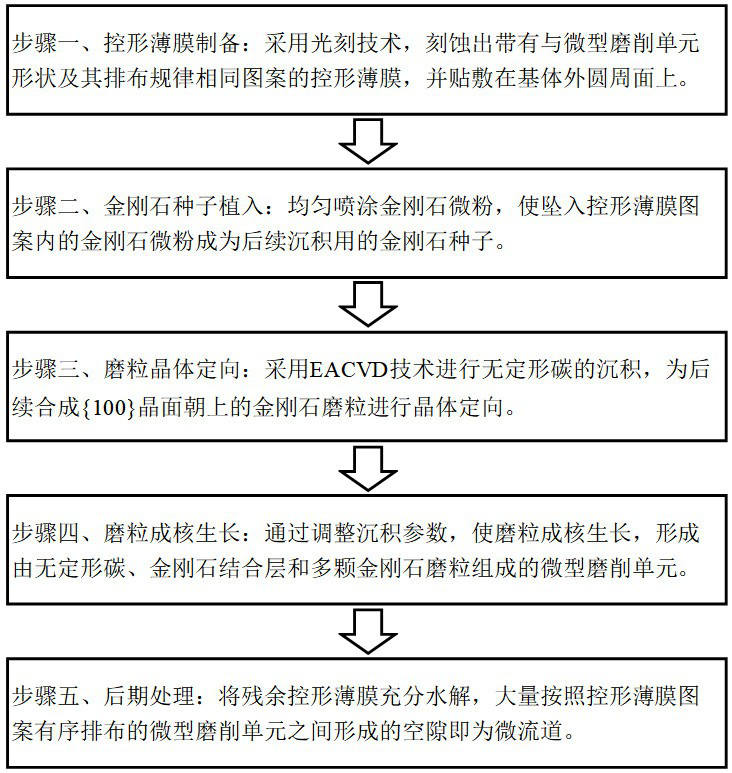

[0024] A method for preparing a diamond grinding wheel in which crystal oriented abrasives are arranged in order comprises the following steps.

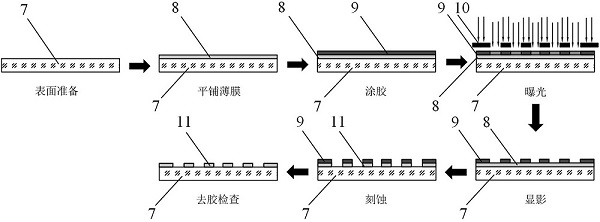

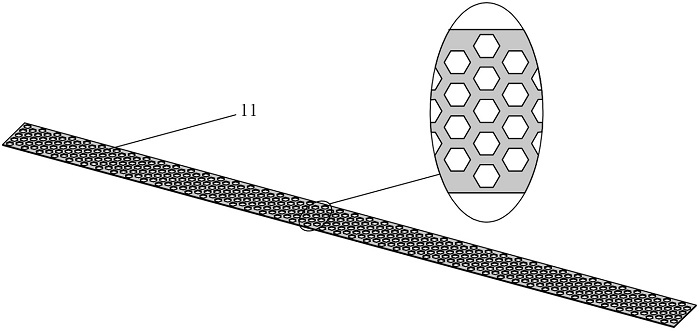

[0025] Step 1. Preparation of the shape-controlling film 11: the material of the substrate 1 is titanium alloy, the diameter is Φ 100 mm, and the thickness is 10 mm, and a film 8 matching the size of the substrate 1 is prepared according to the circumference and thickness of the substrate 1. The film 8 is made of polyimide with a thickness of 0.5 mm, has good thermal stability, and can be hydrolyzed by alkali. The cleaned and dried film 8 is evenly pasted on the glass substrate 7 , and a positive photoresist 9 is coated on the film 8 . The mask 10 with the same shape and pattern as the micro-grinding unit 3 is used for exposure and development, so that the pattern of the mask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com