Patents

Literature

205 results about "Nucleation growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

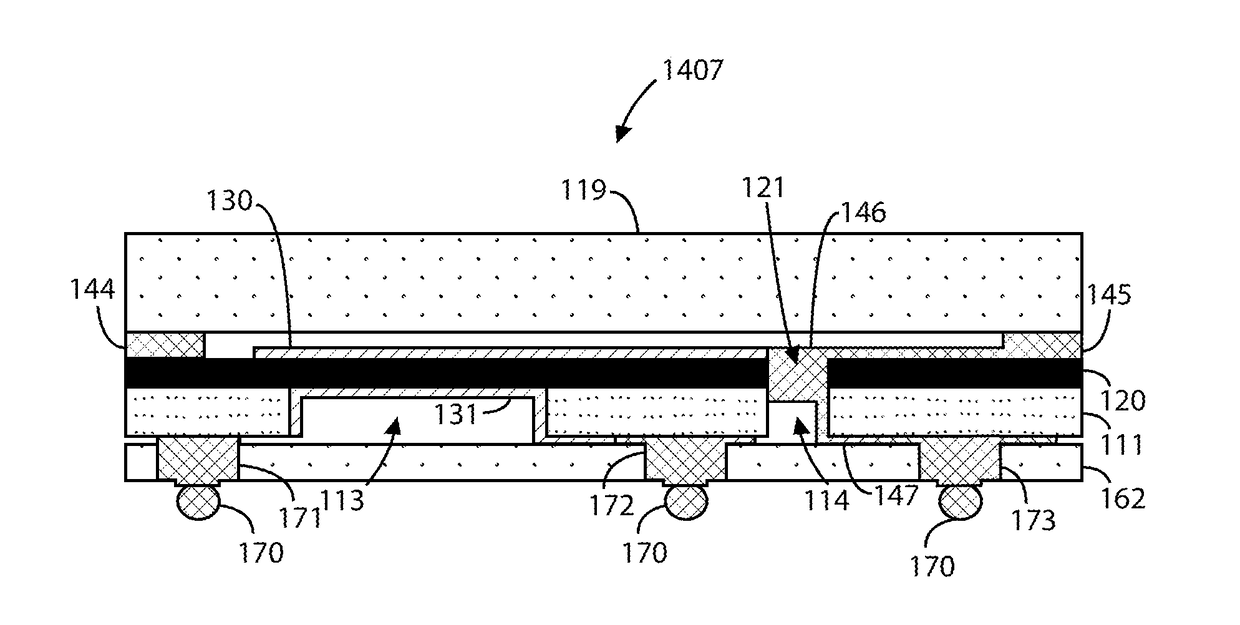

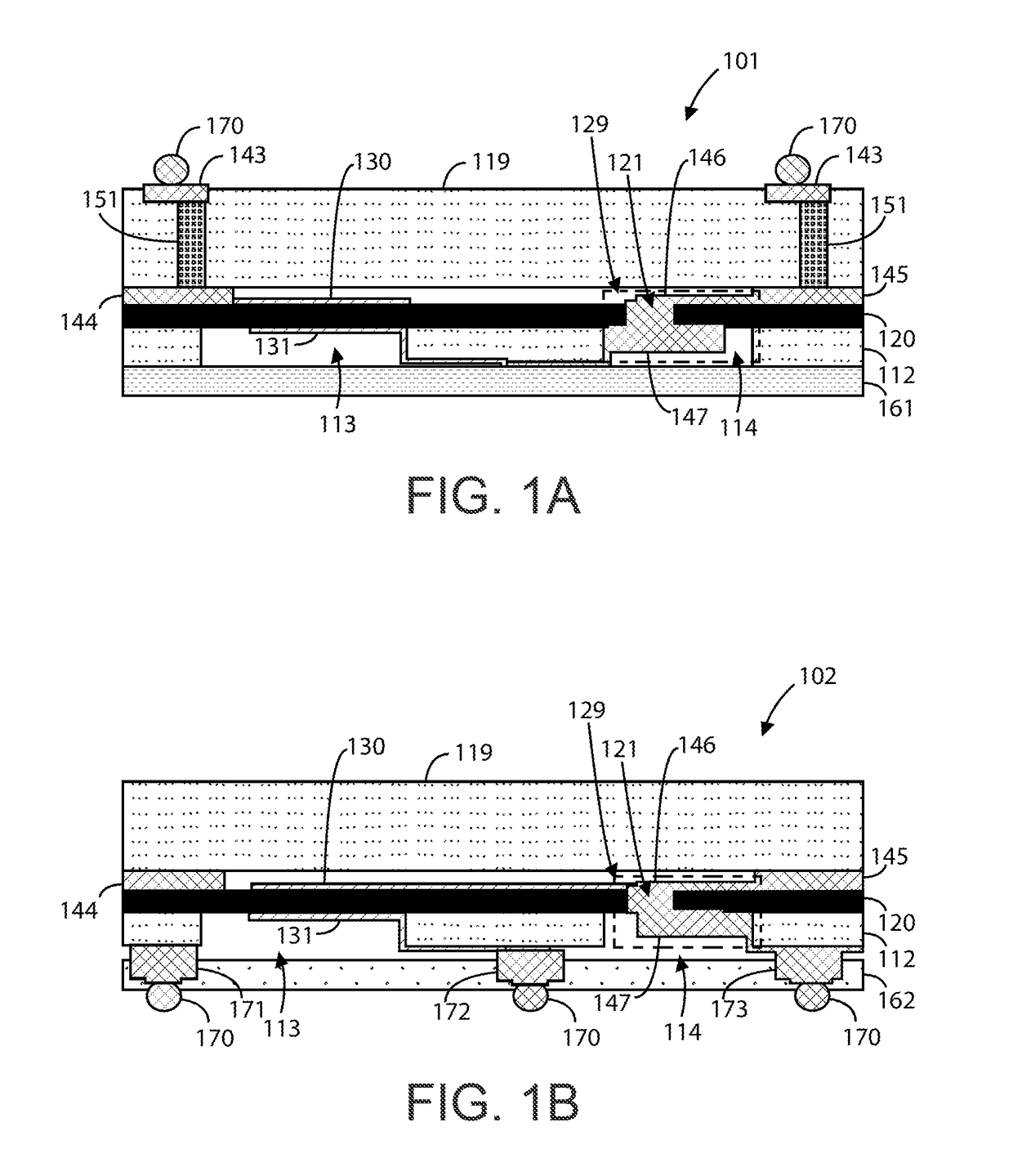

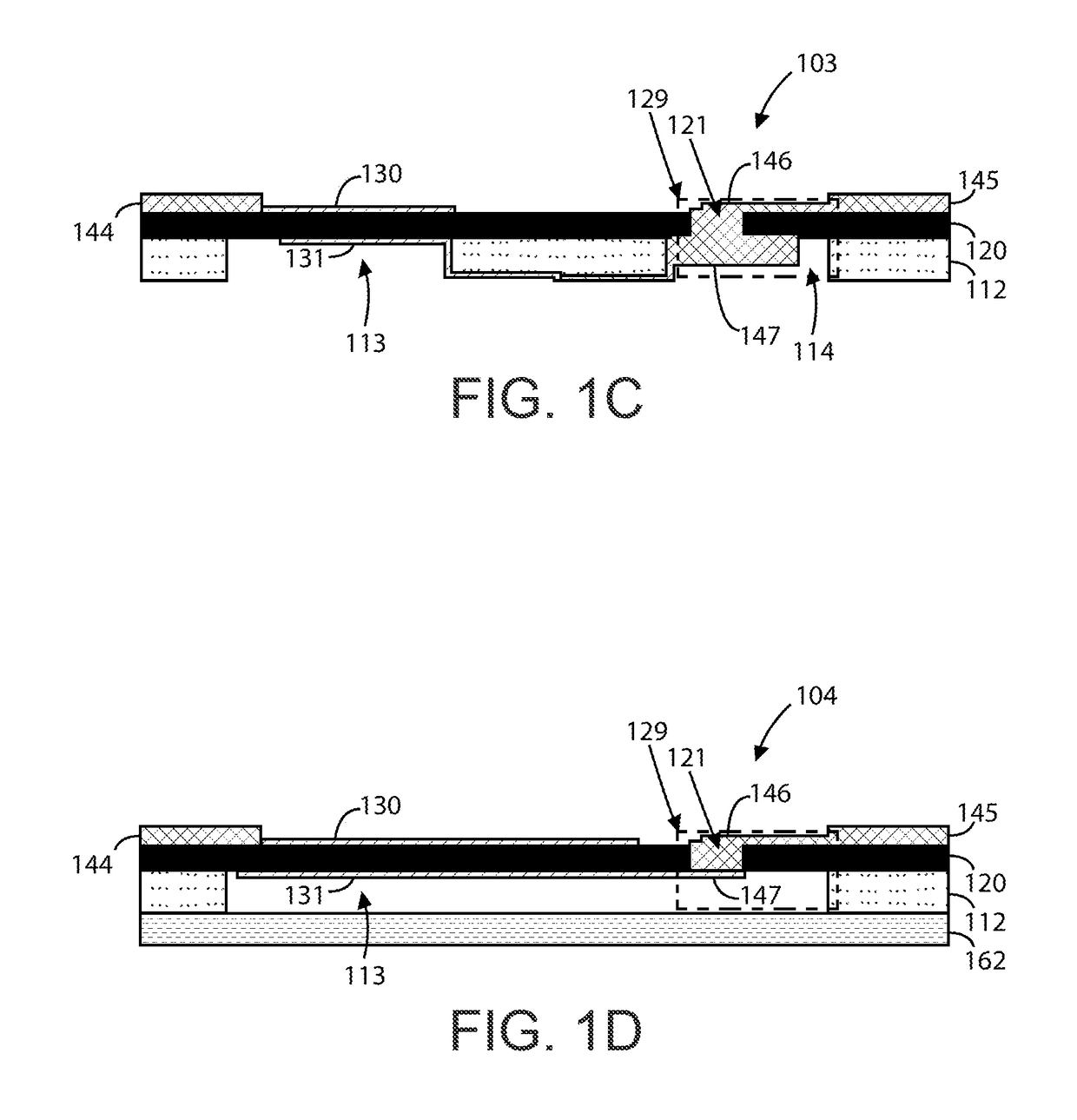

Method of manufacture for single crystal acoustic resonator devices using micro-vias

ActiveUS20170264256A1Simple and cost-effectiveImprove piezoelectric performanceImpedence networksSingle crystalNucleation growth

A method of manufacture for an acoustic resonator device. The method includes forming a nucleation layer characterized by nucleation growth parameters overlying a substrate and forming a strained piezoelectric layer overlying the nucleation layer. The strained piezoelectric layer is characterized by a strain condition and piezoelectric layer parameters. The process of forming the strained piezoelectric layer can include an epitaxial growth process configured by nucleation growth parameters and piezoelectric layer parameters to modulate the strain condition in the strained piezoelectric layer. By modulating the strain condition, the piezoelectric properties of the resulting piezoelectric layer can be adjusted and improved for specific applications.

Owner:AKOUSTIS INC

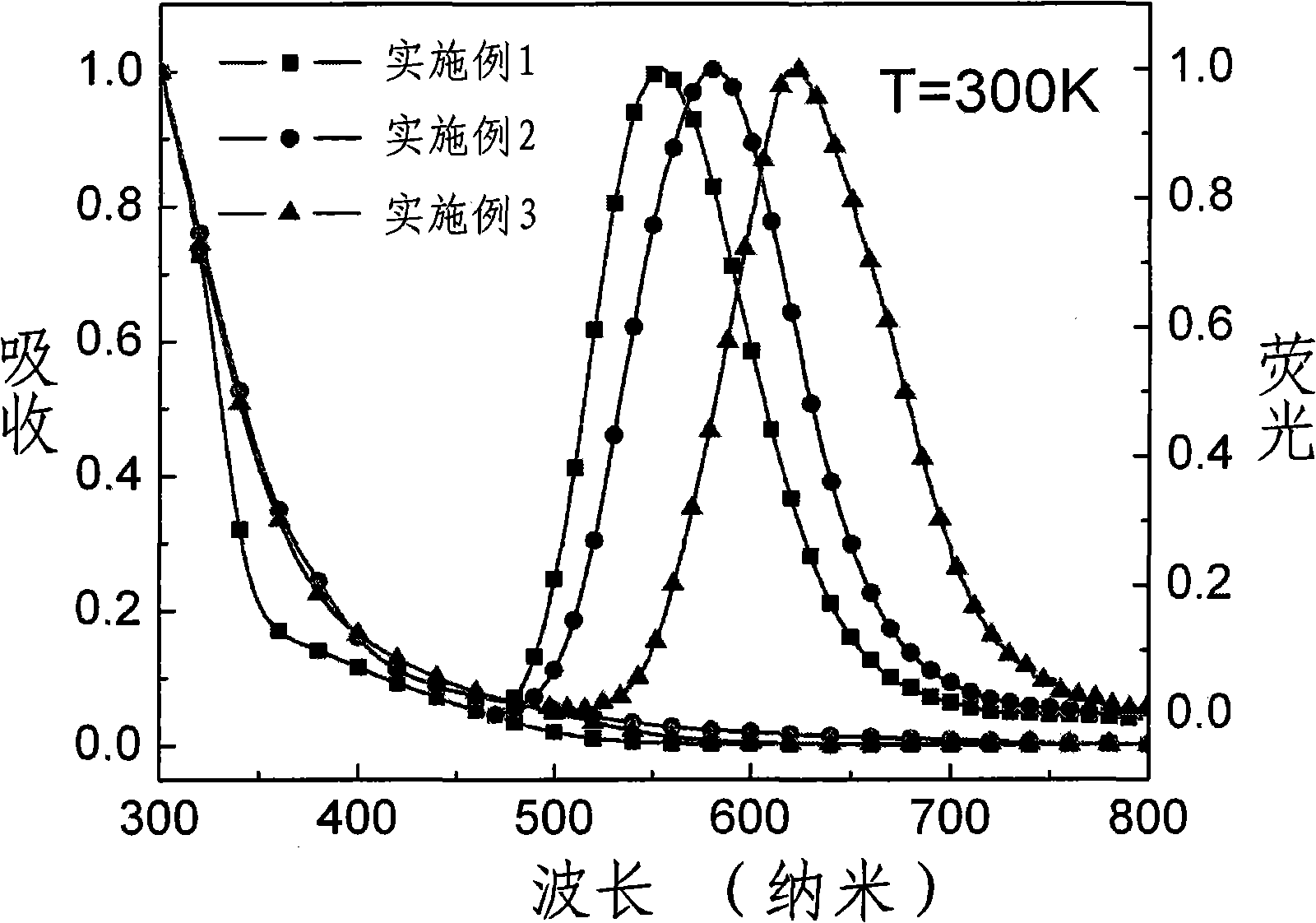

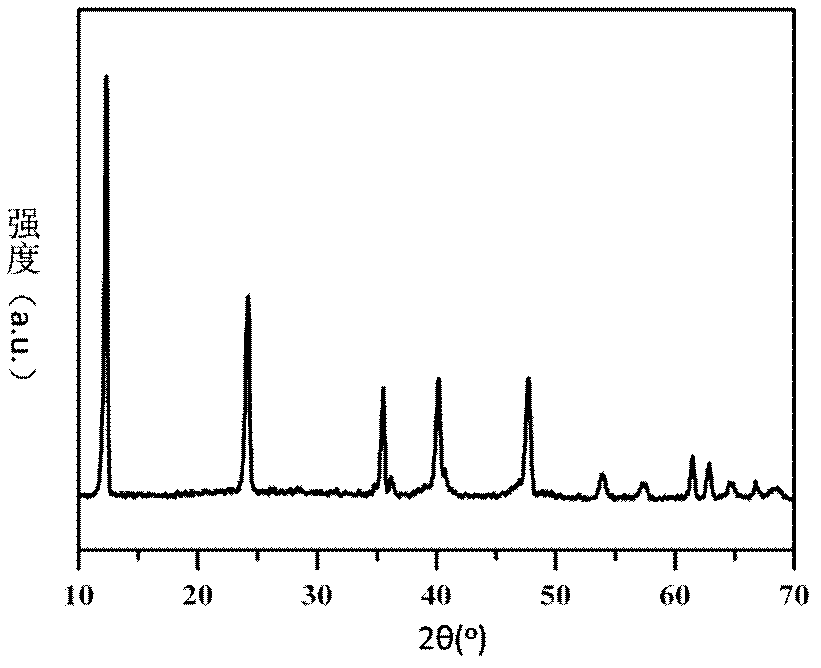

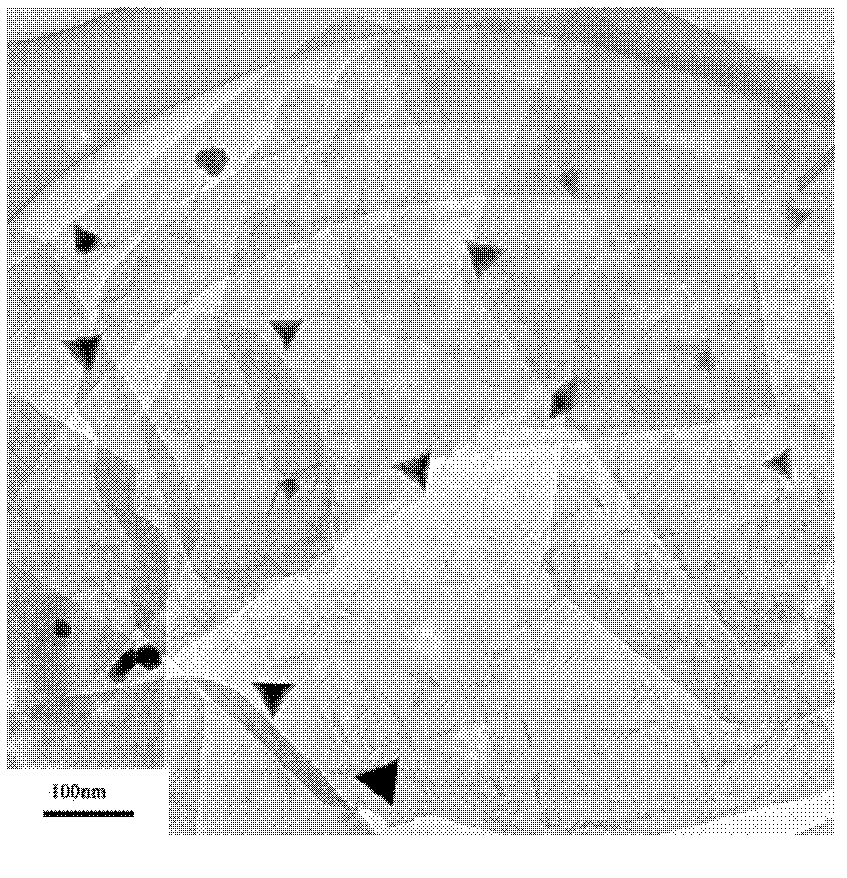

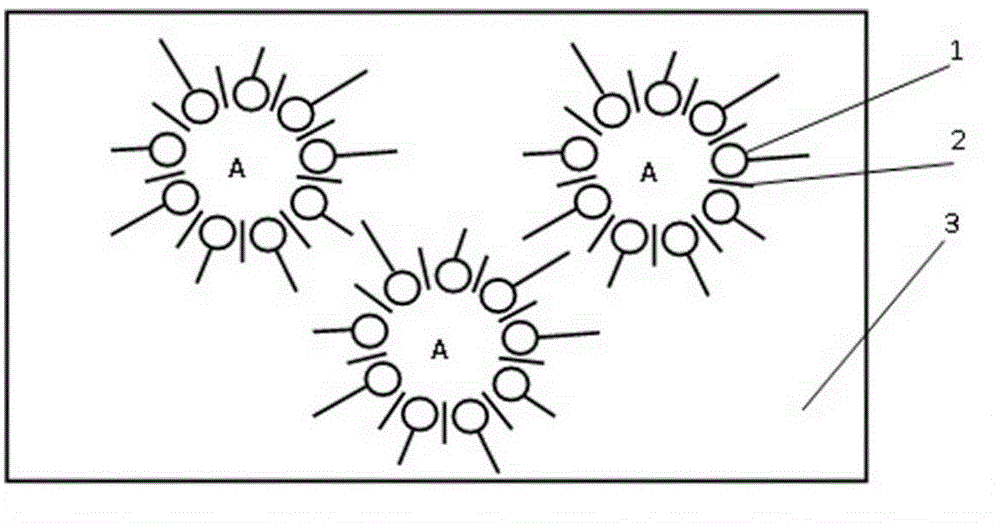

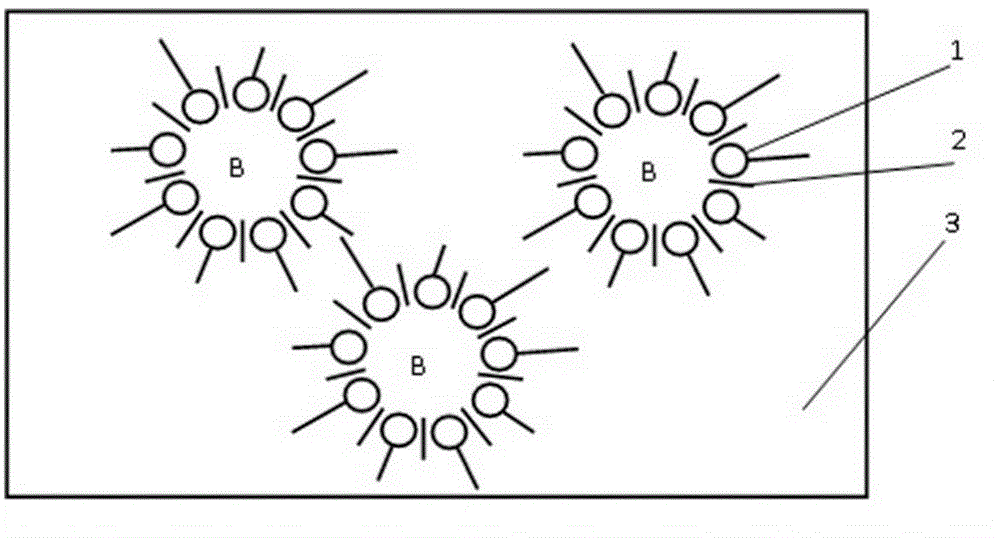

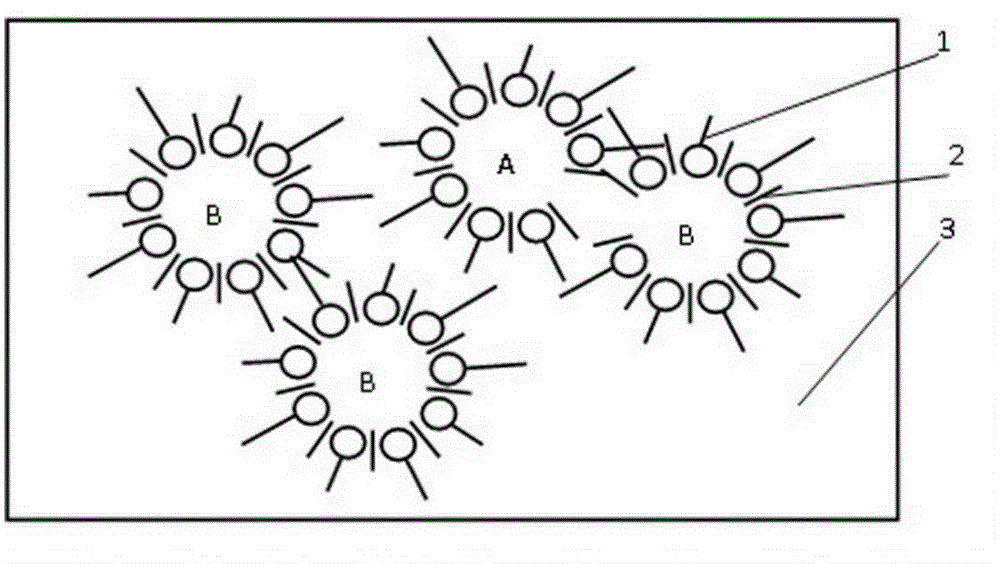

Preparation method and application in luminescent element thereof of CuInS2-ZnS/ZnSe/ZnS semiconductor quantum dots with core-shell structure

The invention discloses a preparation method and application in the luminescent element thereof of CuInS2-ZnS / ZnSe / ZnS semiconductor quantum dots with a core-shell structure, belonging to the technical field of the preparation method of the semiconductor quantum dot. The method comprises the following steps: dissolving the precursors of copper source, zinc source, indium source and sulfur source in nonpolar mixed solvent to perform nucleation and growth under a certain temperature and obtain a CuInS2-ZnS alloy core-ZCIS, then adding zinc source and selenium source alternately in the solution to perform epitaxial growth of ZnSe on the core, then perform epitaxial growth of ZnS to prepare the CuInS2-ZnS / ZnSe / ZnS quantum dots, finally adding polar solvent in the solution, settling, centrifuging, cleaning, and perform vacuum drying to obtain solid quantum dot powder. The prepared quantum dots are 2-8nm and have uniform particle size, controllable emission wavelength and high yield. The quantum dots are used as luminescent material to prepare red, yellow and green quantum dot luminescent elements and the luminescent elements have excellent luminescent property.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

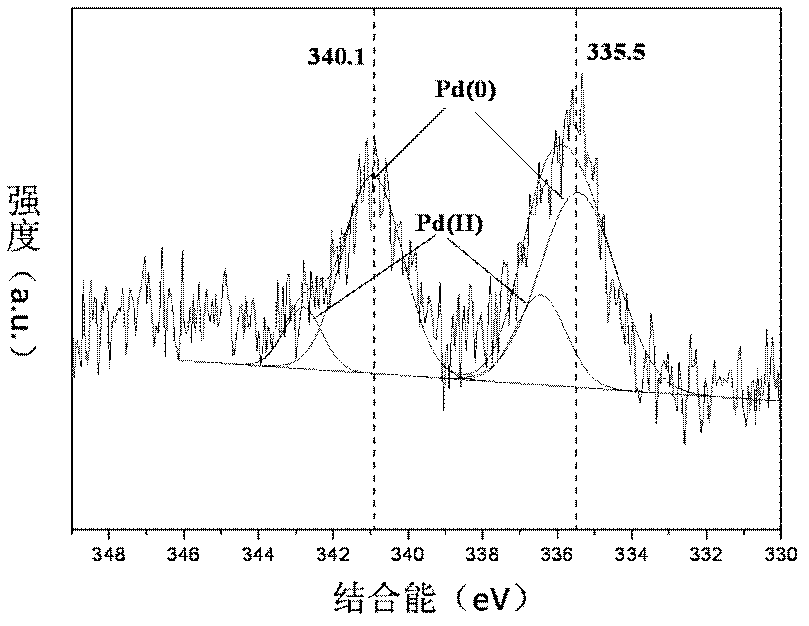

Active component morphology controllable loaded noble metal catalyst and preparation method thereof

InactiveCN102553581AHigh selectivityHigh activityMetal/metal-oxides/metal-hydroxide catalystsPtru catalystActive agent

The invention relates to an active component morphology controllable loaded noble metal catalyst which uses hydrotalcite as a carrier and is prepared by a precipitation-reduction method. A precipitating agent, a reducing agent, a surfactant, an etchant, a soluble salt solution of +2 and +3-valence metal ions forming the hydrotalcite, and an active component precursor solution are subjected to mixed crystallization, the +2 and +3-valence metal ions are nucleated and grown into the hydrotalcite in an alkaline environment provided by the precipitating agent, and meanwhile, the active component precursor is reduced to 0 valence, and the active component has specific uniform morphology, i.e., the active component morphology controllable loaded noble metal catalyst using the hydrotalcite as the carrier is obtained by one-step reaction. Since the kinetic rate is the key to control the morphology of the active component, and different reducing agents, surfactants and etchants can affect the dynamic process of reduction of the active component, the active component morphology controllable loaded noble metal catalyst of controllable preparation can be attained by controlling the reducing agents, the surfactants and the etchants.

Owner:BEIJING UNIV OF CHEM TECH

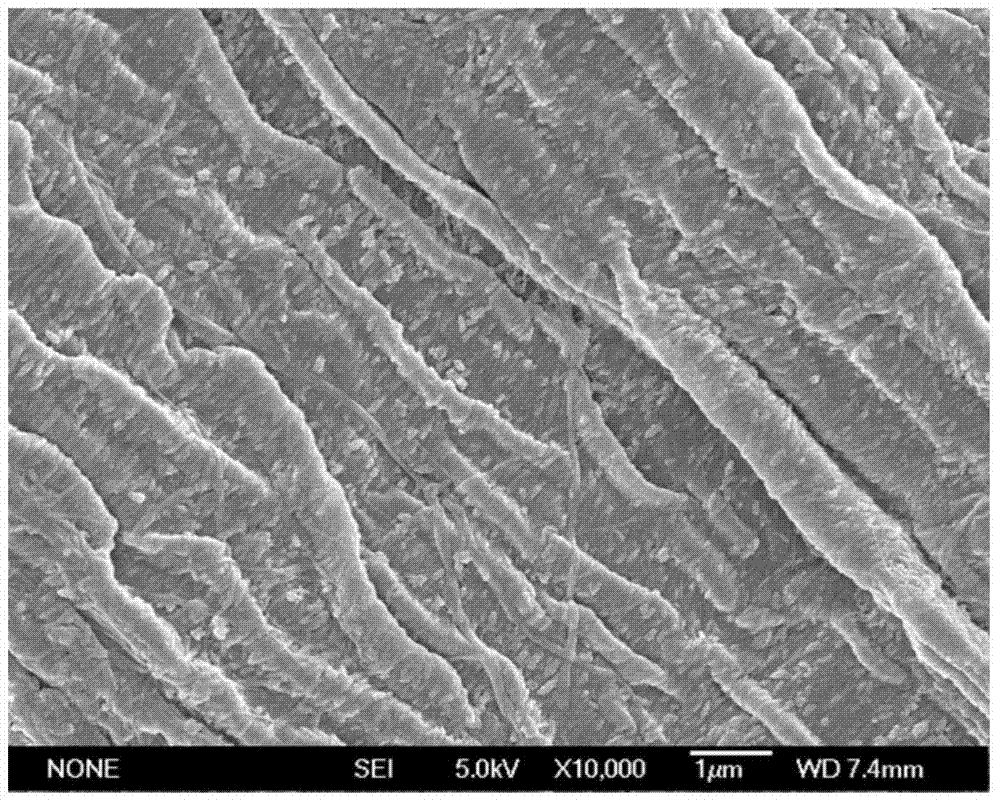

Preparation method of nano-fiber supported nano-titania mesoporous material

InactiveCN103172897APrevent nucleation and growthStrong mechanical propertiesOrganic-compounds/hydrides/coordination-complexes catalystsCelluloseFiber

The invention relates to a preparation method of a nano-fiber supported nano-titania mesoporous material. The preparation method adopts biomass cellulose nano-filaments having a large specific surface area and a high length-diameter ratio as a carrier, and allows nano-titania to be grafted to the surfaces of nano-fibers through a sol-gel reaction by means of a hydrogen bond. The nano-fibers interlace with each other in an aqueous solution to form a netted structure, so an effective reaction area can be provided, the rapid nucleation growth of gel titania particles can be prevented, and the full reaction of the gel titania particles with hydroxy groups on the surfaces of the fibers is promoted. The mesopore diameter can be adjusted through controlling the content of water in a mixed system, so the mesoporous composite aerogel material having the advantages of strong mechanical performances, good load effect and large specific surface area is obtained. The method has the advantages of simple operation, strong controllability, and wide raw material source, and is an efficient, environmentally-friendly and sustainable processing means.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

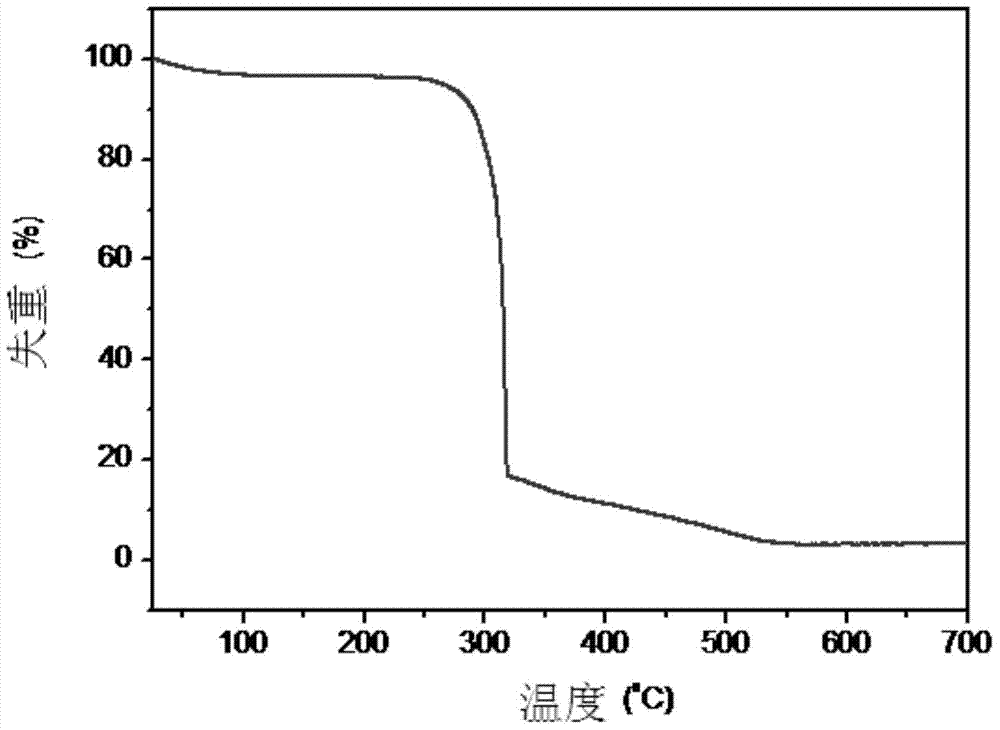

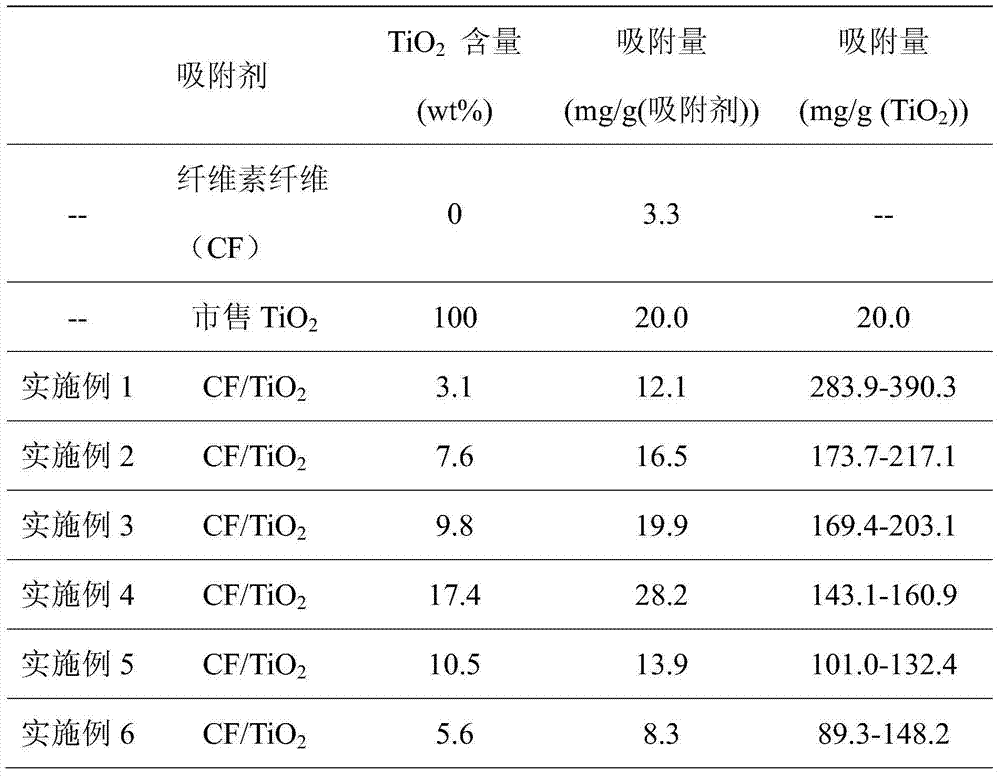

Titanium dioxide nanometer composite material, and preparation methods and use thereof

ActiveCN104759261AAvoid reunionAvoid churnOther chemical processesWater/sewage treatment by sorptionFiberHydrolysis

The invention relates to a titanium dioxide (TiO2) nanometer composite material used for adsorbing heavy metals, and preparation methods and a use thereof. The preparation methods comprise a hydrolysis method, a hydrothermal method and a self assembling method. The composite material is prepared through loading nanometer TiO2 to micrometer polymer fibers or particles, and the above polymer has nanometer particle immobilizing, nanometer particle aggregation preventing and nanometer particle nucleation growth controlling effects, so the problems of agglomeration and loss of nanometer particles in the application process and secondary pollution due to the agglomeration and loss are solved. The obtained composite material has strong adsorption ability to heavy metal ions in water, and can be used in purification and treatment of heavy metals in industrial and domestic wastewater. The preparation methods have the advantages of simplicity, easy operation, green, cheap and easily available raw materials, and low cost; and the material prepared in the invention can be easily engineered to form a blocky material in order to form devices which can be used, so the material has a wide application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

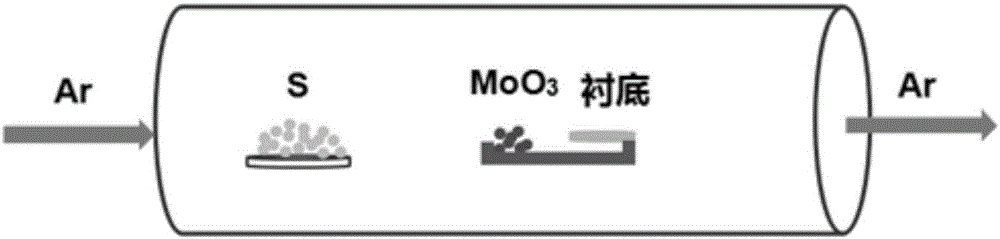

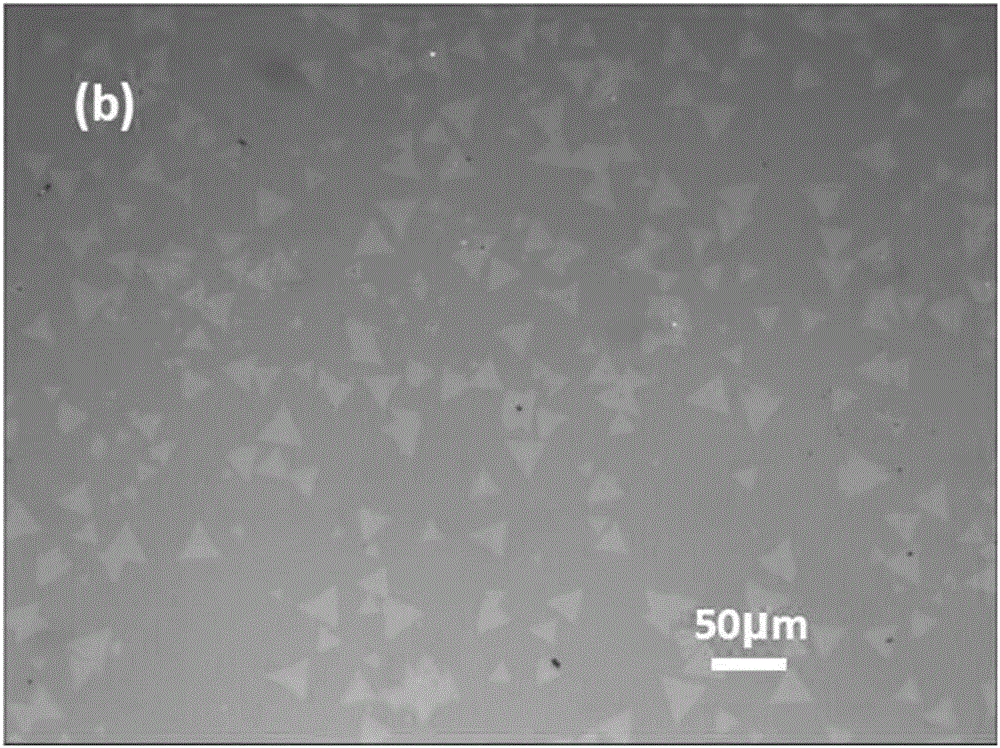

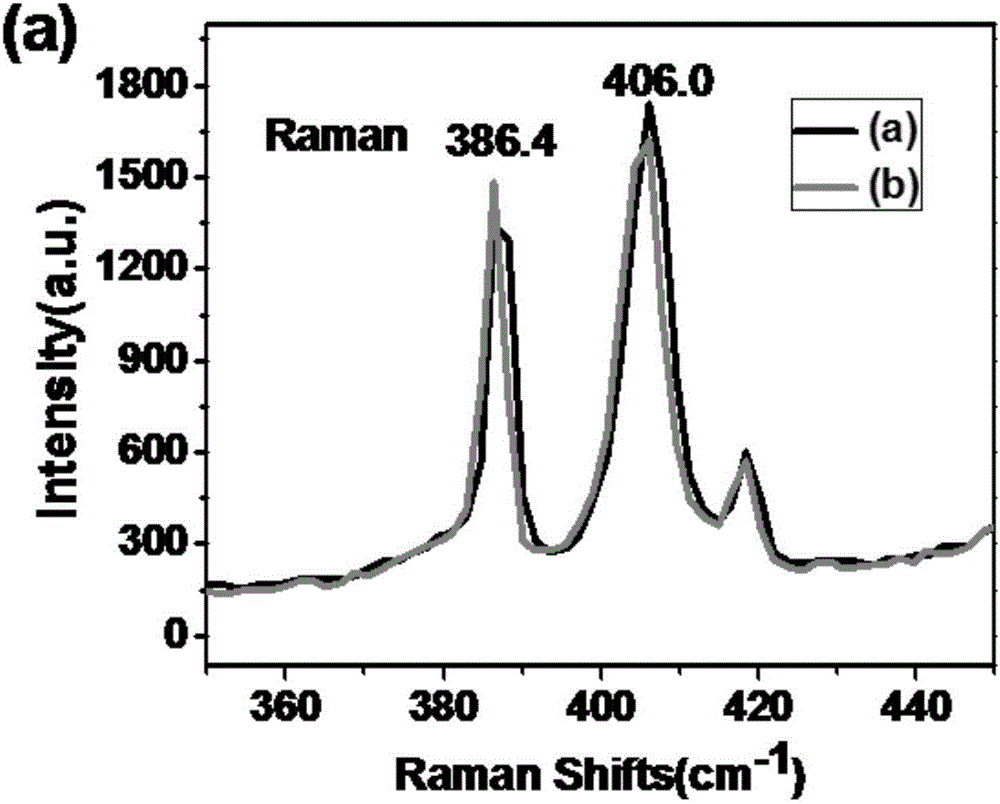

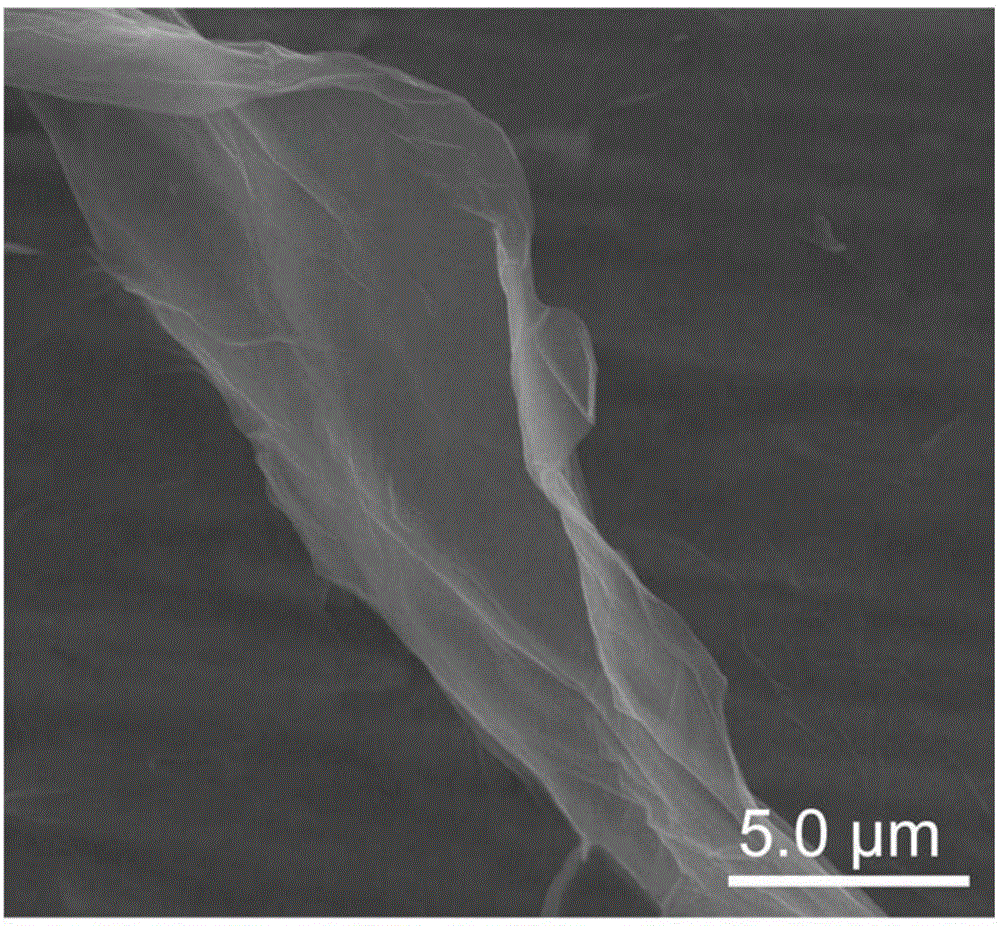

Method for preparing monolayer molybdenum disulfide

InactiveCN106835073AReduce stepsAvoid potential dangerChemical vapor deposition coatingHigh probabilityPiranha solution

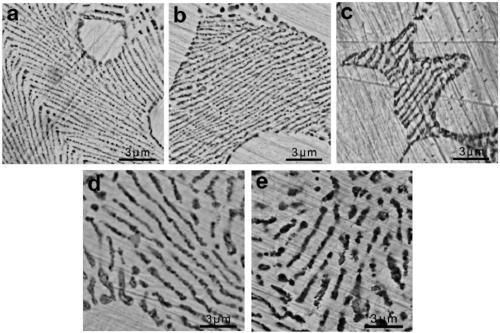

The current methods for preparing single-layer molybdenum disulfide include micromechanical exfoliation, liquid-phase ultrasonic exfoliation, lithium ion intercalation, laser method, annealing layer-by-layer thinning method, and chemical vapor deposition method. Molybdenum disulfide prepared by chemical vapor deposition method has large size, uniform surface and controllable layer number. When molybdenum disulfide is prepared by chemical vapor deposition, molybdenum disulfide is easy to nucleate and grow on defects such as impurities or scratches on the substrate. If the substrate is not cleaned cleanly, molybdenum disulfide will easily grow into multi-layer or solid materials. To clean the substrate thoroughly, toxic and dangerous drugs such as acetone and piranha solution will be used. These drugs are toxic to the human body, so the operation process is potentially dangerous. Based on the above problems, the object of the present invention is to provide a simplified chemical vapor deposition method for the preparation of single-layer molybdenum disulfide, which can produce high-quality single-layer molybdenum disulfide without using toxic hazards such as acetone and piranha solution. Drugs are used to clean the substrate, avoiding potential danger.

Owner:BEIJING JIAOTONG UNIV

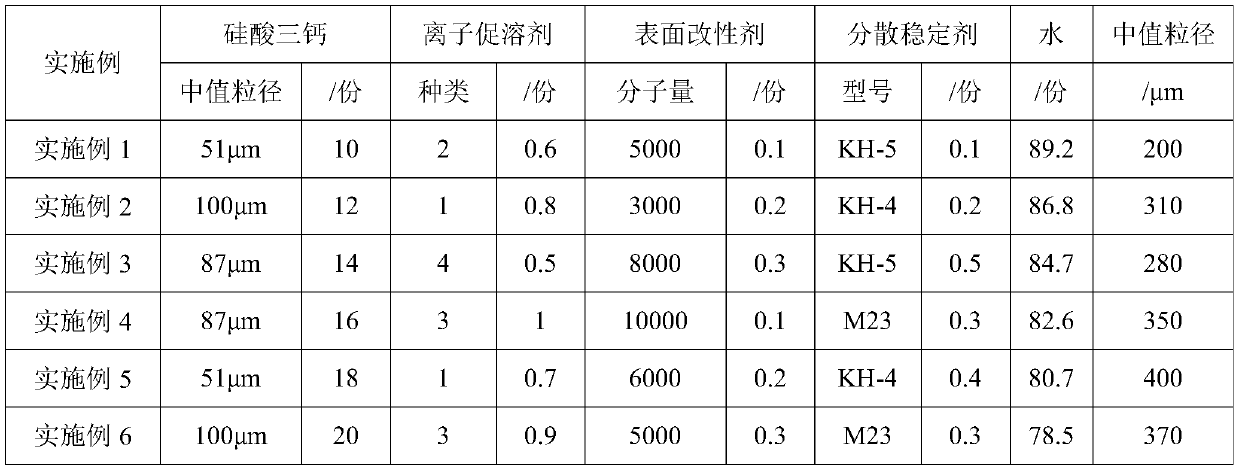

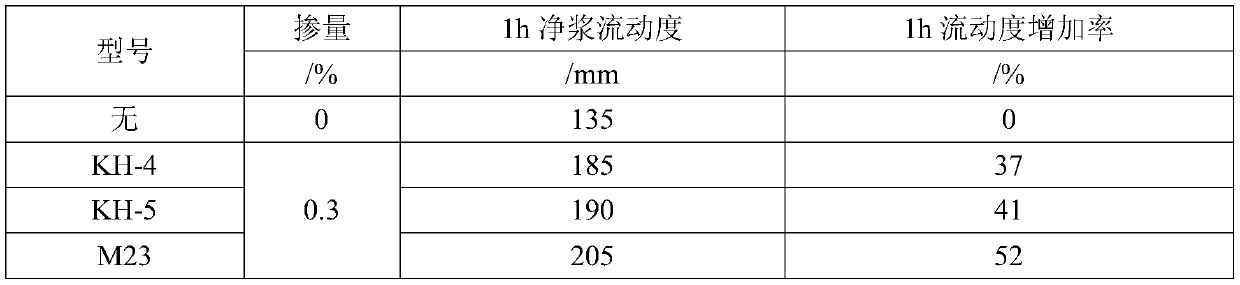

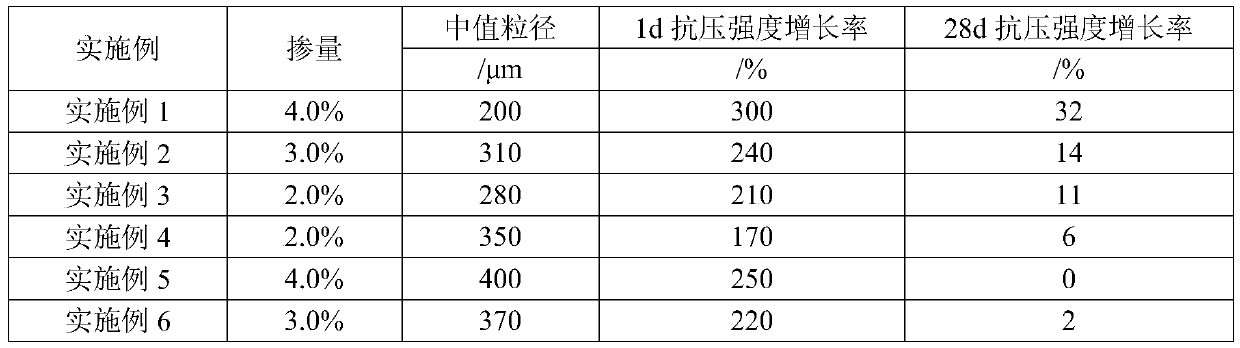

C-S-H gel nanocrystal nucleus early strength agent, preparation method and application thereof

ActiveCN110330257AAccelerated nucleation growthImprove pore structureIon acceleratorsNucleation growth

The invention provides a C-S-H gel nanocrystal nucleus early strength agent, a preparation method and application thereof. The C-S-H gel nanocrystal nucleus early strength agent is mainly prepared from the following components by weight through wet milling process: 10-20 parts of tricalcium silicate, 0.5-1 part of an ion promoter, 0.1-0.3 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and 78.5-89.2 parts of water. The C-S-H gel nanocrystal nucleus early strength agent provided by the invention utilizes the crystal nucleus induction effect of nano form C-S-H gel to accelerate the nucleation growth of hydration products at the early stage of hydration, and can achieve the early strength purpose from the two aspects of by improving the pore structure and inducing nucleation.

Owner:WUHAN UNIV OF TECH

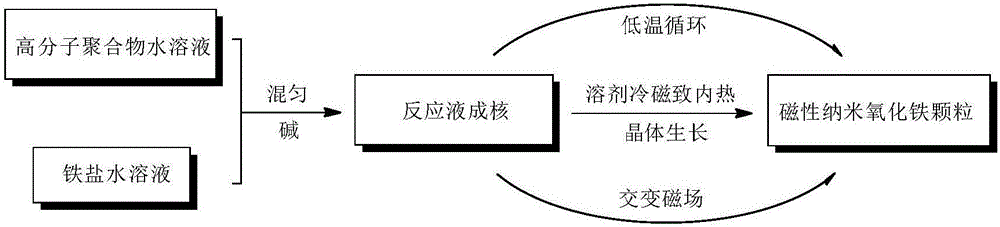

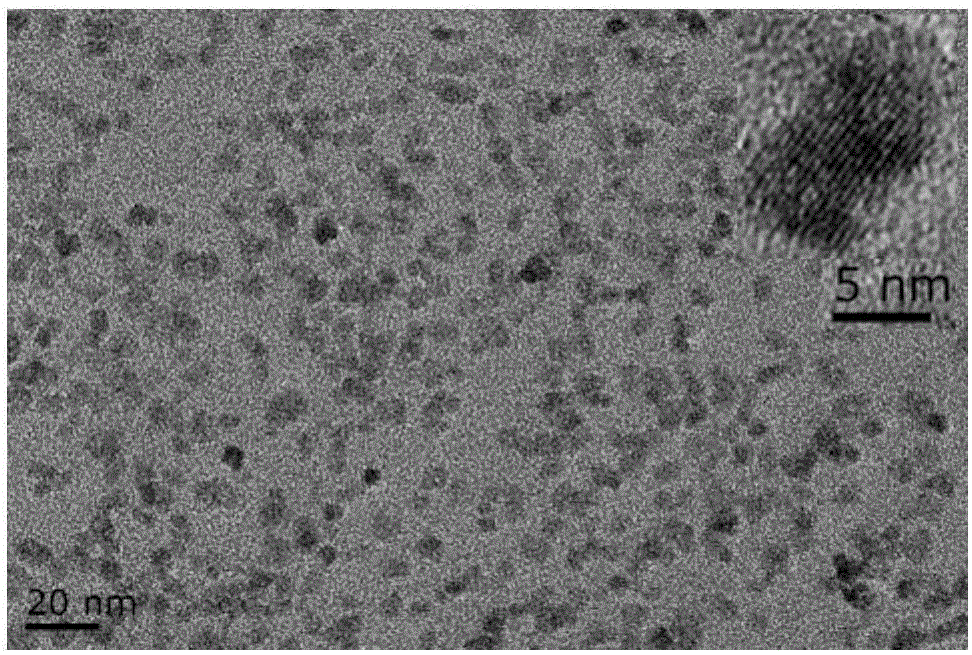

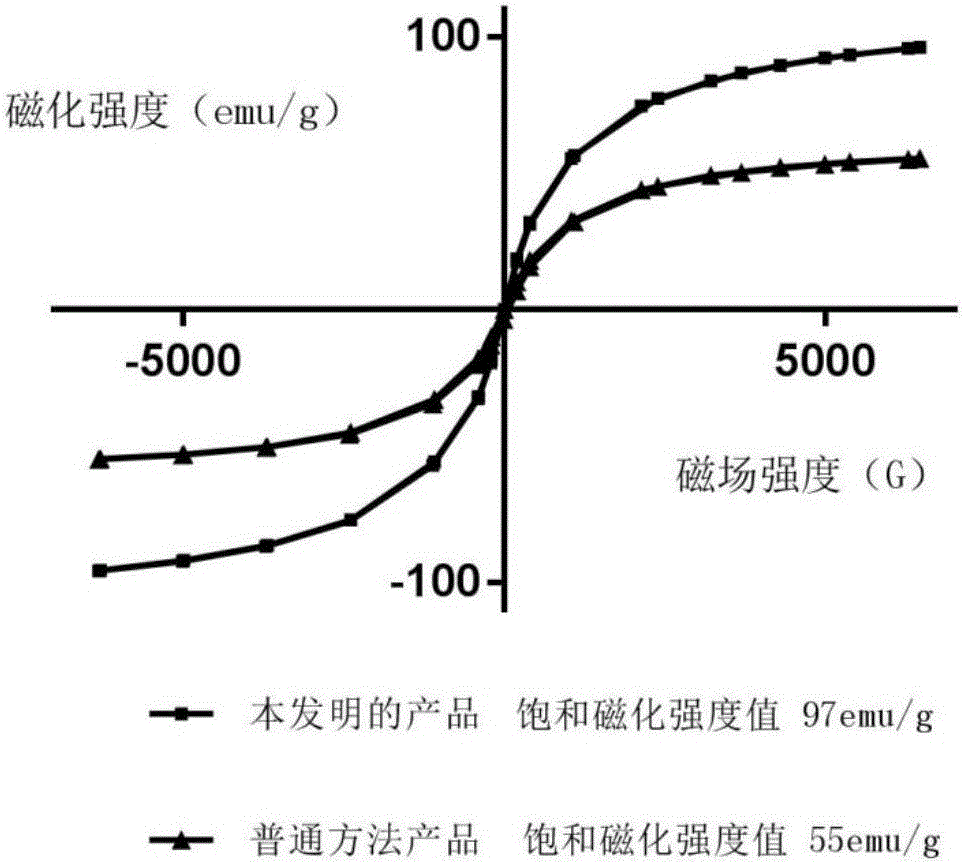

Preparation method of magnetic nano ferric oxide

The invention relates to a preparation method of magnetic nano ferric oxide, concretely comprising the step of synthesizing magnetic ferric oxide nanoparticles by adopting an alternating magnetic field solvent cold magnetic induced internal thermal mechanism. The preparation method is based on the traditional chemical co-precipitation principle, and the magnetic ferric oxide nanoparticles with a good crystal structure and good magnetic properties are obtained through internal thermal induction of an alternating magnetic field and external low temperature circulating cooling. Different from preparation of magnetic nanoparticles by adopting the traditional solvent thermal process, the preparation scheme utilizes the alternating magnetic field, and magnetic particles are synthesized through one solvent cold and slow nucleation growth process. Compared with the magnetic ferric oxide particles with the same size, saturation magnetization strength and relaxation rate of the product prepared by adopting the preparation method are improved by about twice, crystal defect is obviously reduced, and all the performance indexes of the product are also greatly improved.

Owner:SOUTHEAST UNIV

Decorative tile with diamond shining effect, colorful dry particles and preparation method of colorful dry particles

The invention discloses a decorative tile with a diamond shining effect, colorful dry particles and a preparation method of the colorful dry particles. A crystallization pre-treatment step is added for diamond shining frits, so that the frits contain crystals of a considerable quantity and the considerable sizes, a dry particle glaze mode is adopted to conduct glazing, the time required for crystal nucleation growth of crystal glaze is greatly shortened, and the temperature requirement of the crystal nucleation growth of the crystal glaze is reduced; the dry particle glaze mode is more suitable for the condition of the quick firing period for 50-90 minutes for an existing wall and floor tile roller kiln, and application occasions are added. The decorative tile utilizing the colorful dry particles is bright in color and specific in characteristics, and under irradiation of light, the decorative tile similar to a diamond is shiny and dazzling and achieves an ornamental function with finecrystal stripes of different shapes and sizes in a well-defined silver oil drop shape.

Owner:佛山市禅城区科捷陶瓷原料有限公司

Method for preparing TiO2-PS nucleocapsid structure nano powder by microwave assisted hydrothermal method

InactiveCN101322931AGrow fastShort reaction timeFrom normal temperature solutionsCatalyst activation/preparationHydrolysisNucleation growth

The invention provides a method for preparing nanometer beads of TiO2-PS core-shell structure by microwave hydrothermal which comprises the following steps: (1) a PS bead microemulsion is prepared or purchased with the diameter between 10nm and 999nm; (2) the PS bead micro-emulsion and tetrabutyl titanate are mixed according to certain ratio, ionic water or alcohol or organic acid is added to carry out hydrolysis, alcoholysis or acidolysis towards the tetrabutyl titanate; ammonia water is added during the hydrolysis process and deionized water is used for dilution; the microemulsion of TiO2-PS core-shell former body is obtained after 1 hour of ultrasonic vibration, heating, boiling and reflux; (3) the microemulsion of TiO2-PS core-shell former body prepared is transferred to a microwave hydrothermal reaction device to react, so as to obtain the nanometer microemulsion of TiO2-PS core-shell structure; (4) the nanometer microemulsion of TiO2-PS core-shell structure prepared is dried in an oven to obtain the nanometer beads of TiO2-PS core-shell structure. The method of the invention has the advantages of fast nucleation growth of the nano-crystalline, short reaction period, low energy consumption, etc.

Owner:SHANDONG UNIV

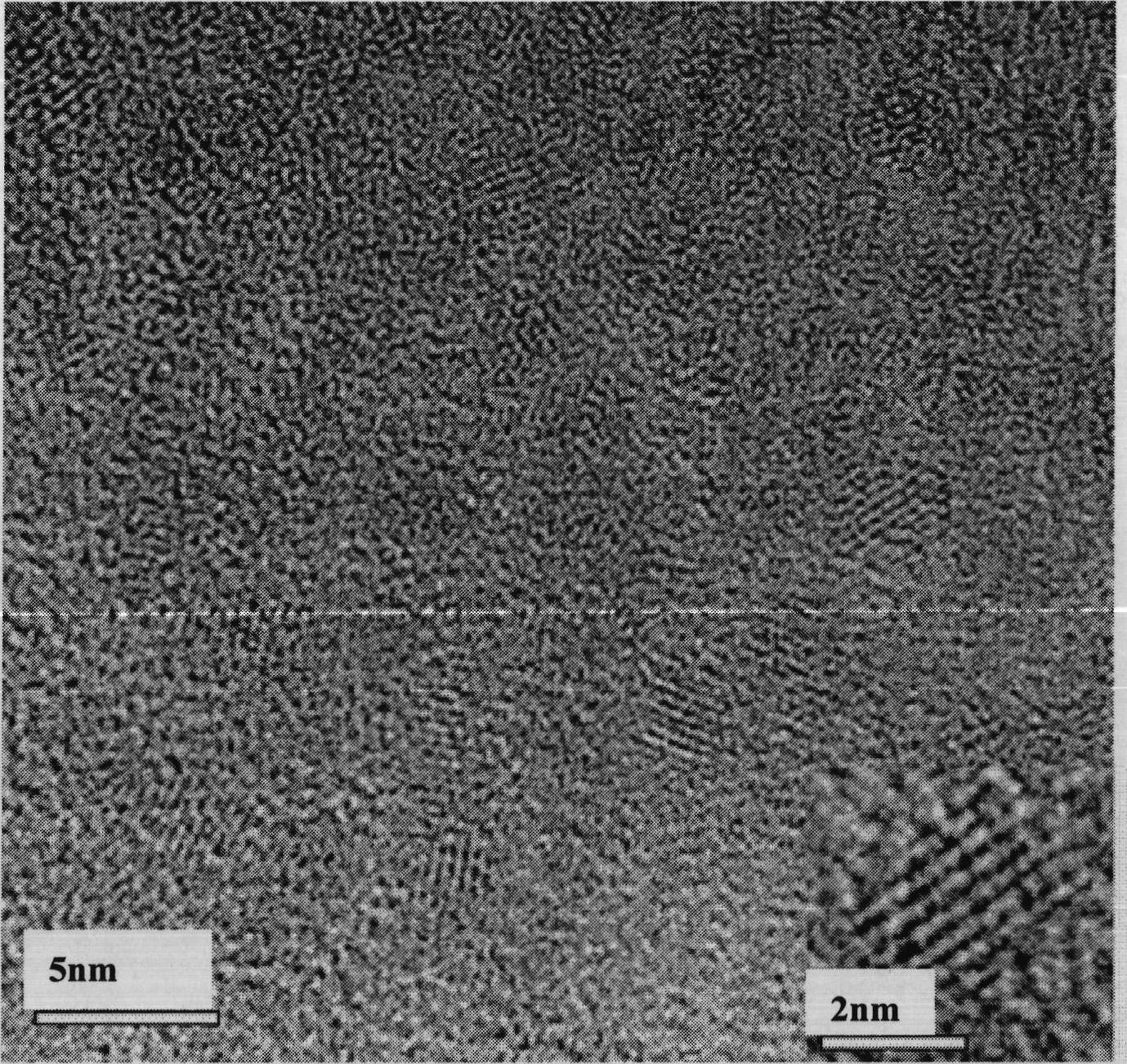

Scalable processing of nanocomposites using photon-based methods

InactiveUS20140302255A1Promote absorptionRadiation applicationsPretreated surfacesMetal oxide nanoparticlesOptical property

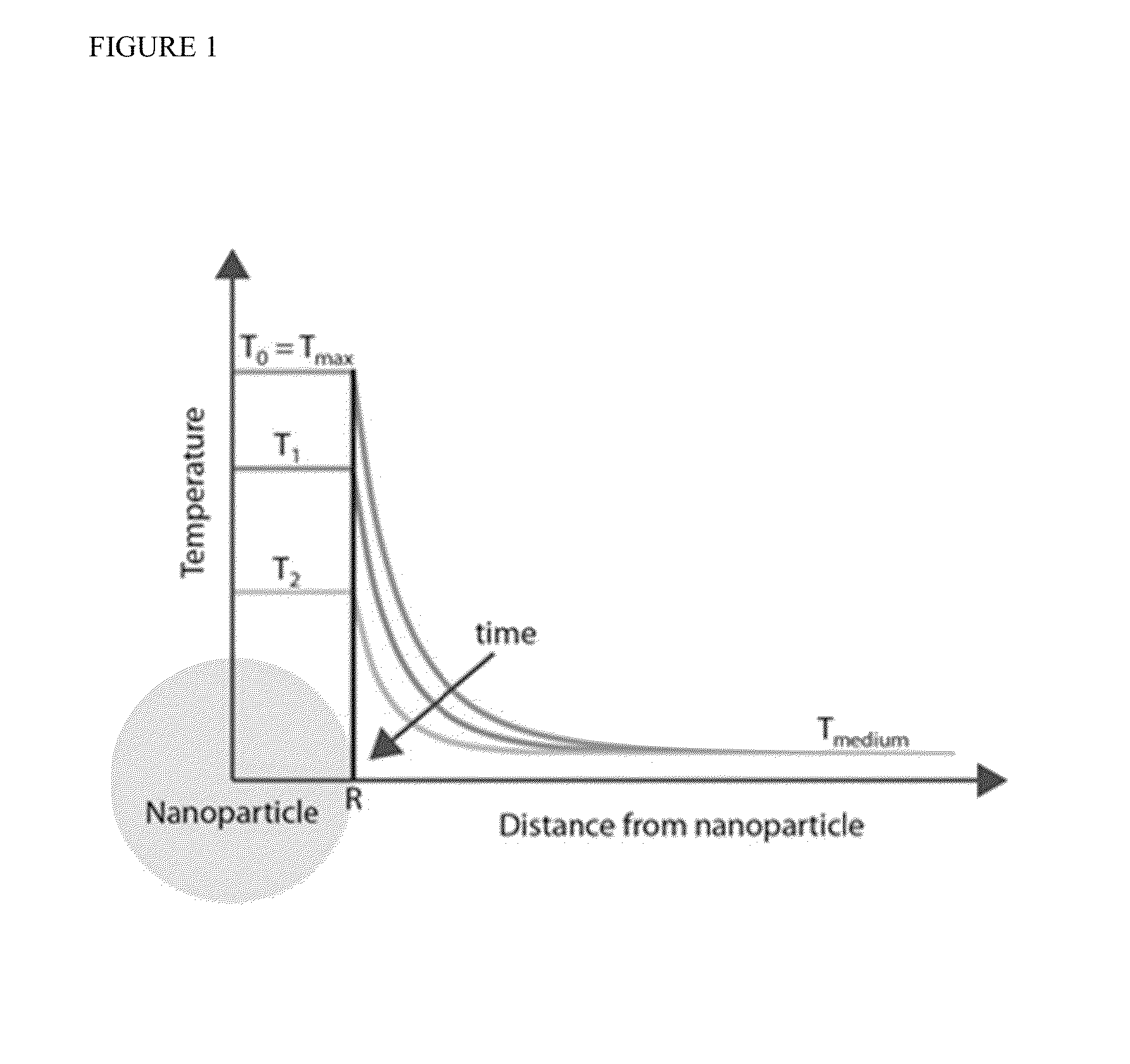

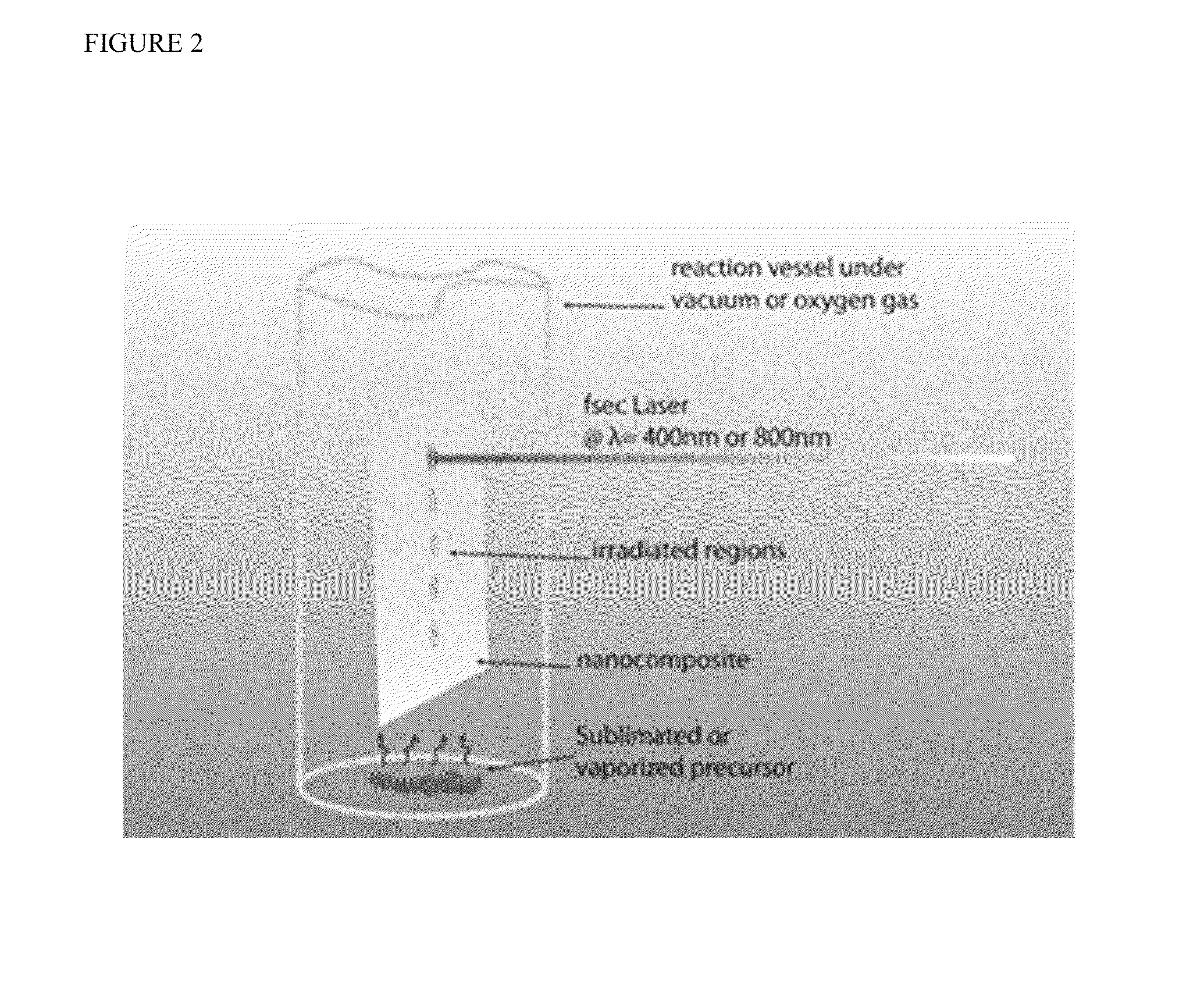

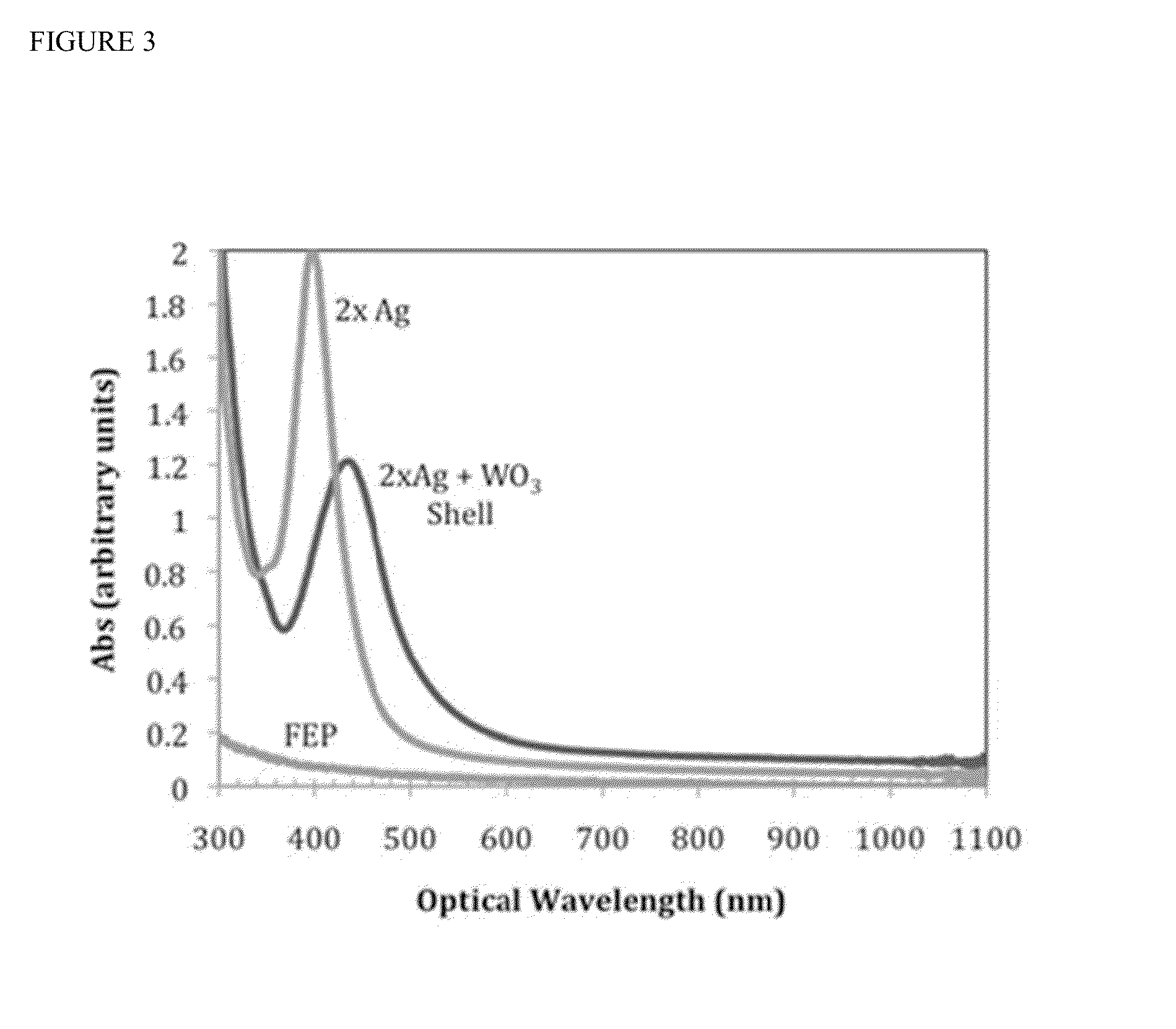

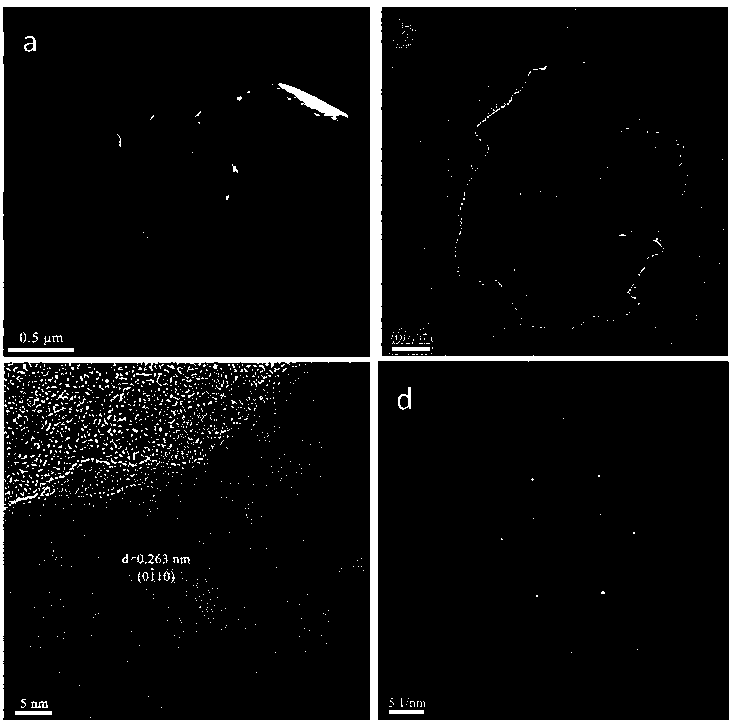

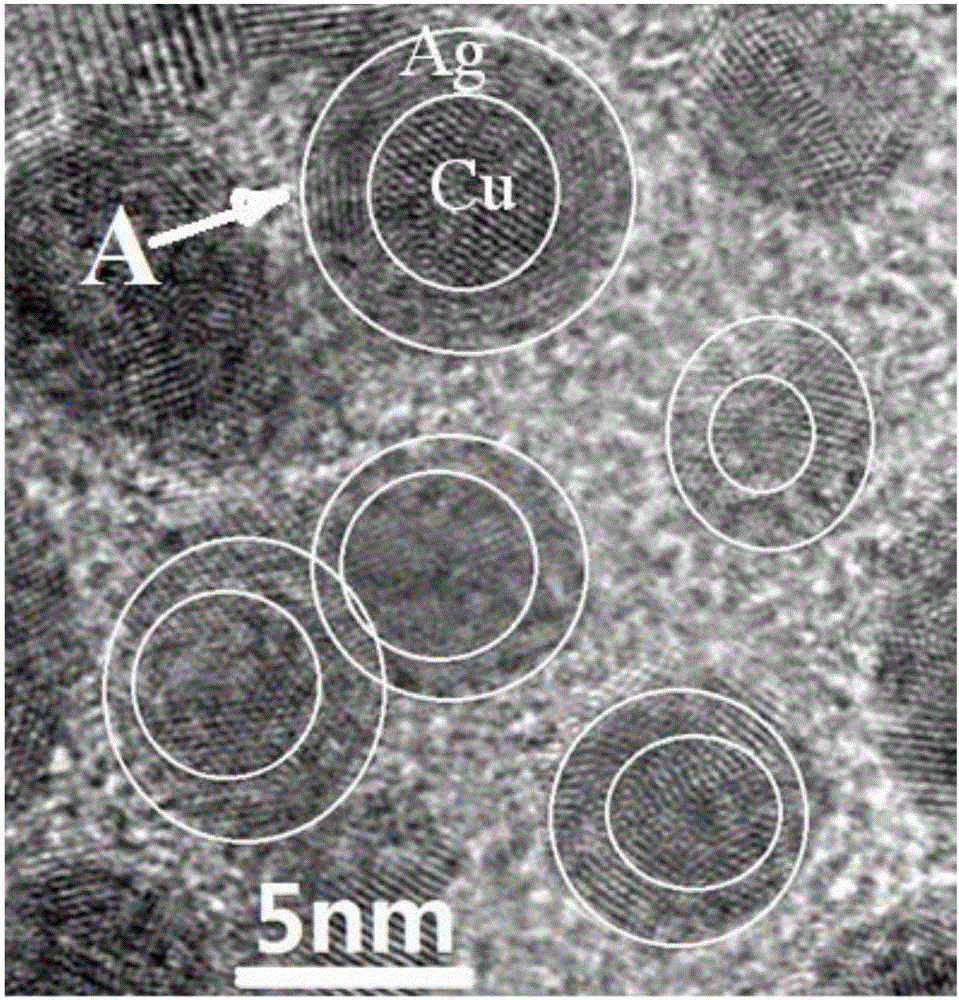

Using a modified CVD infusion process and femtosecond laser irradiation, the methods of the present invention demonstrate the ability to create core-shell nanoparticles of metal and metal oxide nanoparticles embedded within the bulk of an optically transparent substrate. Changes in the optical properties and changes in the structure, size, and shape of the nanoparticles were observed as a result of the methods. It was also observed that core-shell nanoparticles made using the inventive methods preferentially nucleated in the near surface region of the substrate, indicating a precursor-diffusion-dependent process for the nucleation growth of core-shell nanoparticles. With the use of optical masks and multiple precursor chemicals, the inventive methods make it possible to create nanoparticles or core-shell nanoparticles with drastically different compositions in close proximity to each other. Since the mechanism for precursor decomposition is limited to the surface of the nanoparticles within the substrate, it is possible to control the chemistry, size, and shape of nanoparticles within an optically transparent substrate on a nanoscale.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

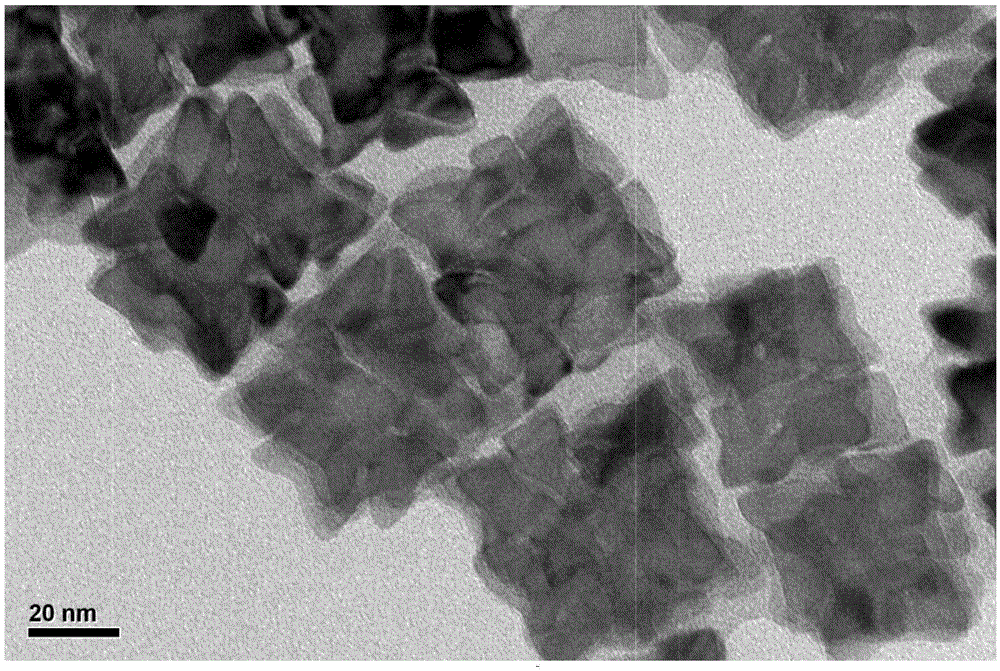

Monoatomic dispersed MXene materials and applications in lithium battery negative electrodes

ActiveCN111029531AControlled nucleation growthLower overpotentialNegative electrodesLi-accumulatorsMetallic lithiumNucleation growth

The invention discloses a monatomic dispersed MXene material and applications in lithium battery negative electrodes. The monatomic dispersed MXene material is characterized in that single doped metalatoms are dispersed on the surface of the sheet layer of the monoatomic dispersed MXene material, and can realize controllable nucleation growth of metal lithium in an initial metal lithium deposition stage; lithium tends to nucleate uniformly on the MXene layer containing single doped atoms, originates from a large number of doped metal atoms, and then grows vertically along the nucleation position due to a strong electric field at the edge so as to form bowl-shaped lithium and even blocky lithium, so that the growth of lithium dendrites is avoided; and when the monatomic dispersed MXene material is used as a metal lithium negative electrode, the monatomic dispersed MXene material is a dendrite-free metal lithium negative electrode, and the negative electrode has low overpotential, longcycle life and deep dissolution deposition plating performance. According to the invention, based on mature roll-to-roll and spraying technologies, the metal lithium negative electrode can be easily expanded in scale so as to substantially benefit the development of lithium batteries in the future.

Owner:BEIHANG UNIV

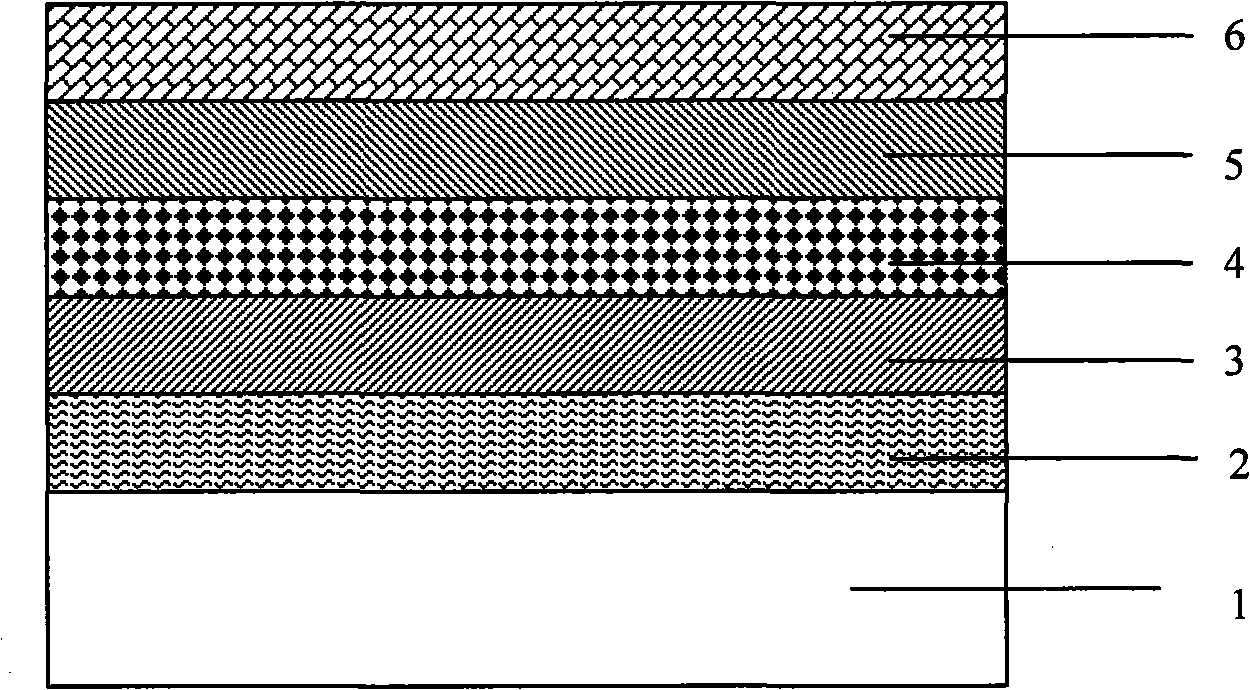

Method for preparing doped perovskite thin film battery by dissolving lead iodide at room temperature

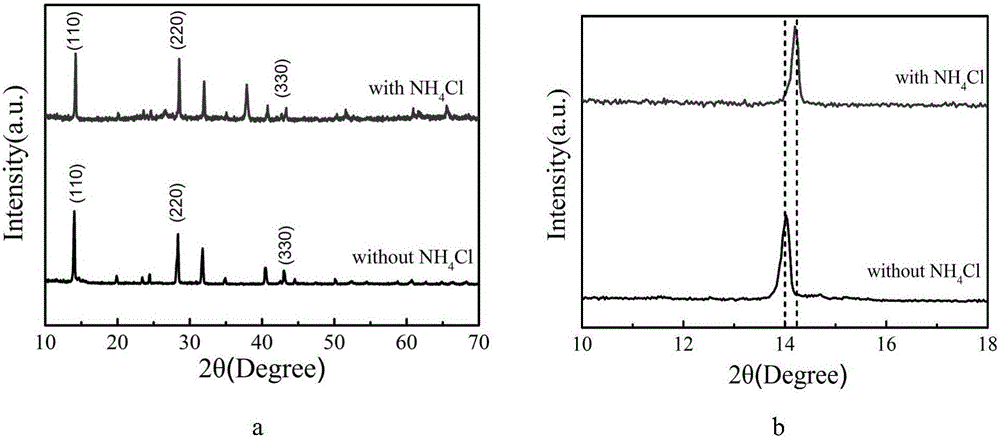

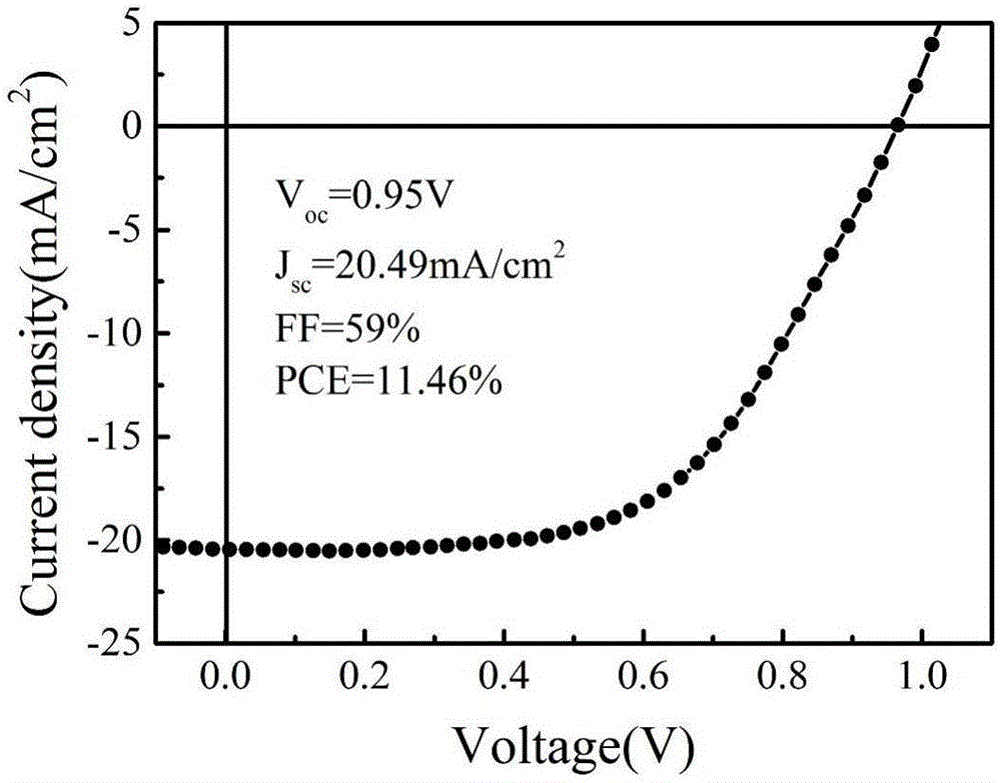

ActiveCN106299136AImprove solubilityImprove conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSolventHole transport layer

The invention discloses a method for preparing a doped perovskite thin film battery by dissolving lead iodide at a room temperature. A battery structure sequentially comprises a conductive substrate 1, an electron transport layer 2, a doped perovskite absorption layer 3, a hole transport layer 4 and a top electrode 5 from bottom to top, wherein the doped perovskite absorption layer is prepared by first dissolving ammonium chloride and lead iodide in a DMF solvent according to a certain mole ratio and performing vibration for 2-3 minutes at the room temperature, then spin-coating the mixture on a substrate, and finally depositing an organic halide (MAI, FAI or MAI / FAI mixture) by a CVD (Chemical Vapor Deposition) reaction or spin-coating the organic halide by a solution method. The perovskite thin film battery is prepared by using the ammonium chloride to help dissolve the lead iodide, thus, the lead iodide can be effectively prevented from being difficult to dissolve or a crystal can be effectively prevented from being easy to separate out in the spin-coating process, a metastable state in the preparation process of a polar solvent is prevented, the preparation of a thin film is facilitated, perovskite nucleation growth is facilitated, and the battery conversion efficiency is improved; and moreover, a large-area perovskite thin film battery can be prepared at the room temperature.

Owner:HEFEI UNIV OF TECH

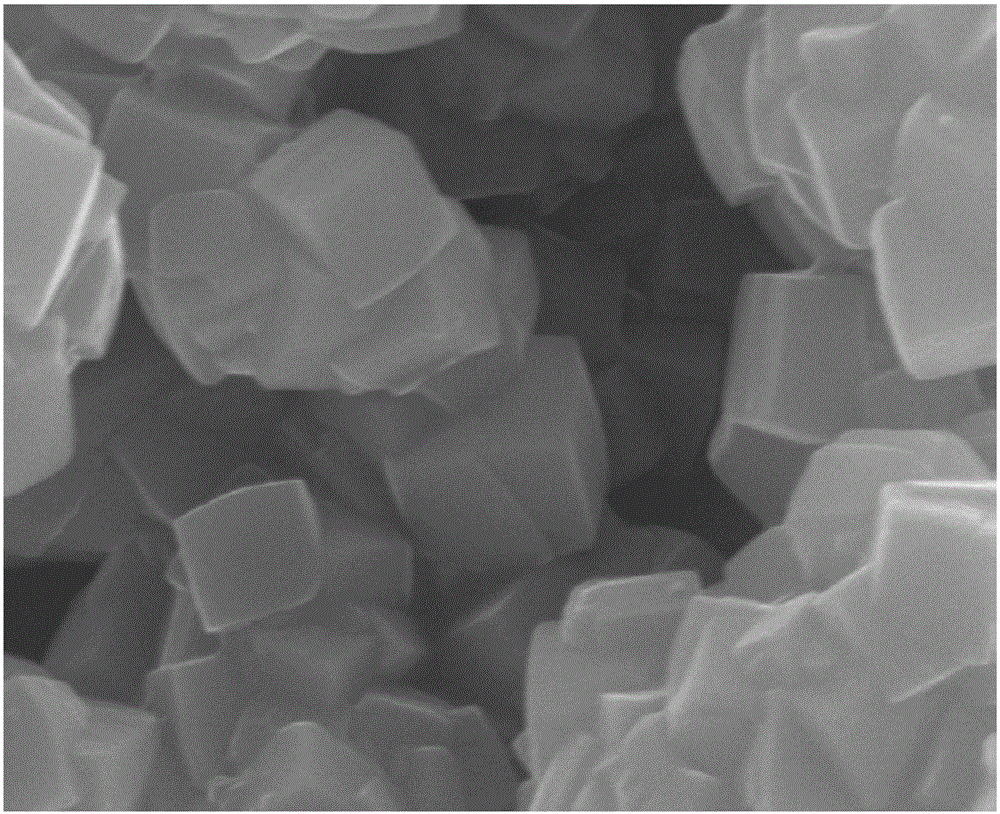

Solventing-out crystallization device and method through auxiliary control of films

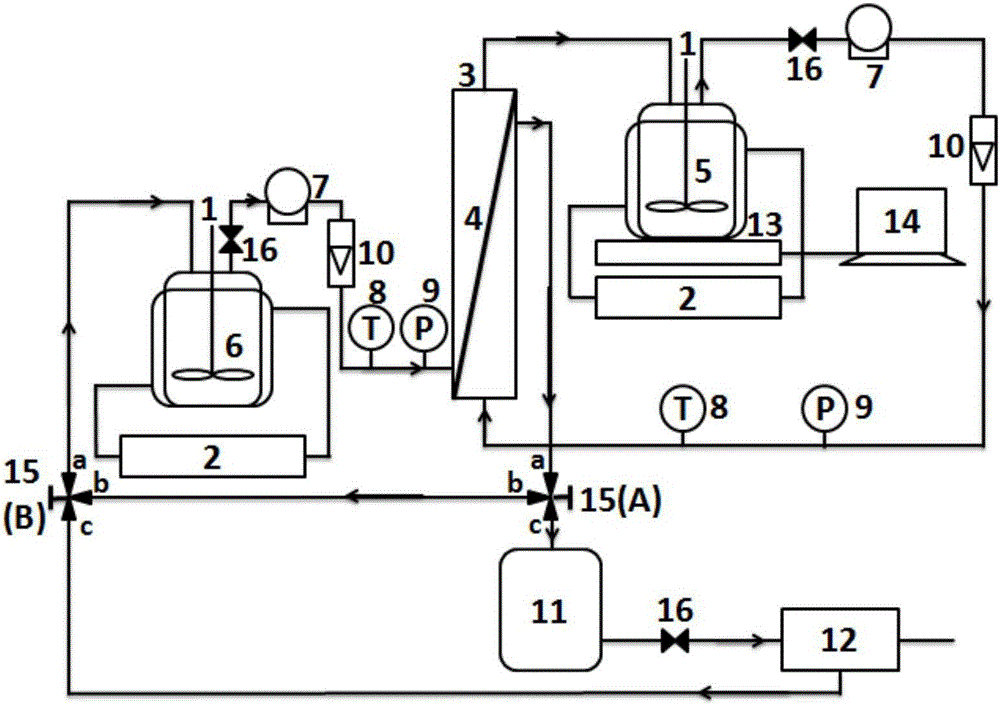

ActiveCN106166400AGood dispersionIncrease contact areaSemi-permeable membranesSolution crystallizationFiltrationOperant conditioning

The invention provides a solventing-out crystallization technique device and method through auxiliary control of films, and belongs to the technical field of crystallization engineering. When a crystallization solution is added to a raw material pot, a solventing-out agent is added to a material-liquid pot, electronic scales, a computer, a stirring device and temperature controlling devices are started, and after a system is stable, squirm pumps of the material-liquid pot are started, so that solventing-out agents can circulate between the material-liquid pot and a film assembly; and after the solventing-out agent is stable in circulation, the squirm pump connected to the raw material pot is started so that the crystallization solution enters the film assembly. The solventing-out agent and the crystallization solution which are in sufficient contact in the film assembly can perform nucleation growth in the film assembly, and then the solventing-out agent and the crystallization solution, after the nucleation growth, can flow into an external storing pot for filtration and post-treatment; and the solventing-out agent and the crystallization solution can also perform nucleation growth outside the film assembly, and after solutes are wholly dissolved, filtration is performed. The electronic scales record the addition quantity of the solventing-out agent in a real-time manner, and the addition quantity of the solventing-out agent is systematically controlled through controlling films and operation conditions, so that ideal crystal products are obtained.

Owner:DALIAN UNIV OF TECH

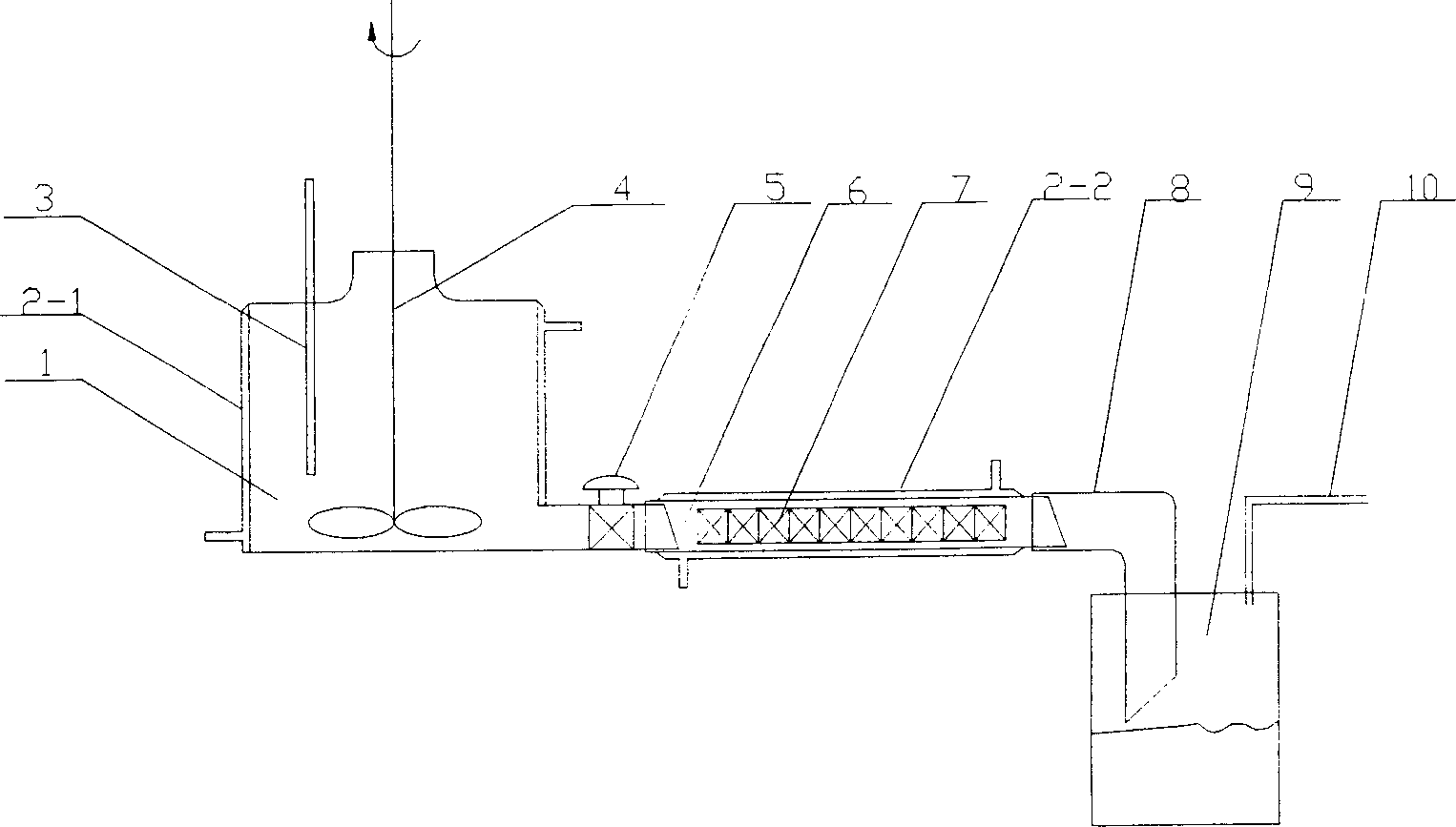

Technique for continuously preparing super fine nano powder by using precipitation method and its specialized equipment

ActiveCN1446654ASame sizeUniform particle sizeCalcium/strontium/barium oxides/hydroxidesCrystalliteNanometre

A process for continuously preparing nano powder by deposition method includes quantiatively and proportionally feeding raw materials in reactor at a certain speed, stirring while nucleating reaction, quickly coming in crystal nuclear growing tube, moving forward under the action of mixer, collecting suspension at tube end, and drying. Its advantages are controllable granularity, high dispersity and uniformity, and high productivity.

Owner:NANJING UNIV OF TECH

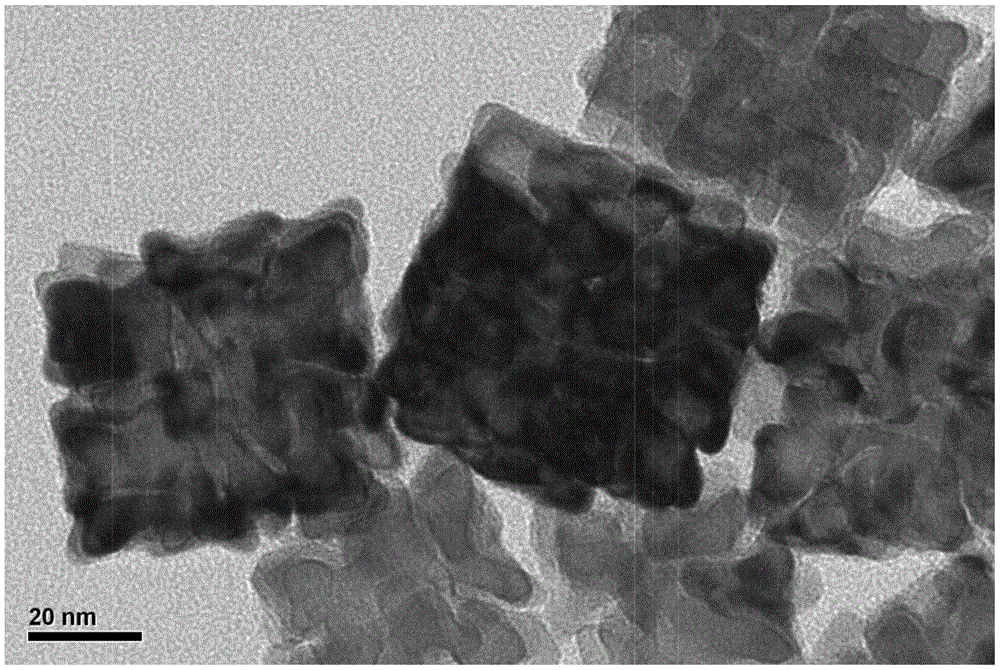

Palladium nanocrystals and synthesis method thereof

InactiveCN105332050AHigh yieldIncrease reaction ratePolycrystalline material growthFrom normal temperature solutionsSynthesis methodsReaction rate

The invention provides a synthesis method of palladium nanocrystals. A palladium source compound, a ruthenium source compound and a surface modification reducer perform mixed reaction in a solvent to obtain the palladium nanocrystals. Ruthenium atoms are reduced on the surfaces of the palladium nanocrystals in the nucleation growth process of the palladium nanocrystals in a reducing under-potential deposition mode, accordingly the surface energy of the ruthenium atoms is affected, and formation of high-index crystal faces is prompted. The synthesis method can remarkably improve the reaction rate, has the advantages of being simple in process, moderate in condition, high in yield, good in purity and the like and is suitable for large-scale production. The irregular nanocrystals with the high-index crystal faces are obtained, have rich edge and corner sites, can widely meet the requirements on the catalysis aspect, especially have excellent light absorption characteristics, accordingly achieve the application on the solar energy aspect, can drive a variety of organic reactions under the light condition and achieve conversion from solar energy to chemical energy.

Owner:UNIV OF SCI & TECH OF CHINA

Biological zinc alloy with fine lamellar eutectic structure and preparation method thereof

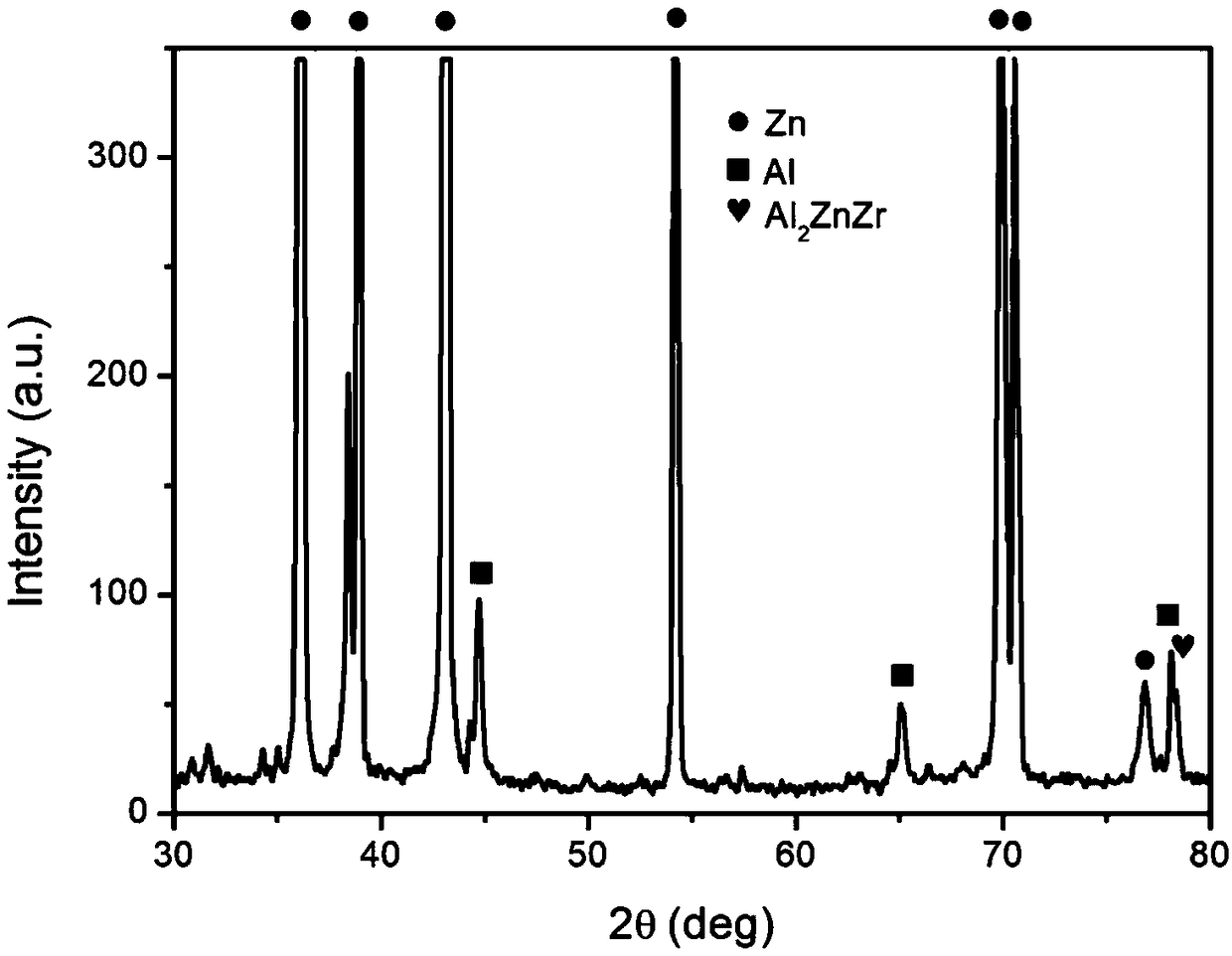

ActiveCN109112361AGood biocompatibilityProper degradation rateAdditive manufacturing apparatusIncreasing energy efficiencyZinc alloysMechanical property

The invention relates to a biological zinc alloy with a fine lamellar eutectic structure and a preparation method thereof, and belongs to the technical field of design and manufacturing of biologicalzinc alloys. The eutectic biological zinc alloy is prepared from the following components in percentage by mass: 98.9 to 99.1 percent of zinc, 0.8 percent of aluminum and 0.1 to 0.3 percent of zirconium. The preparation method comprises the following steps: taking zinc powder, aluminum powder and zirconium powder according to designed components; carrying out ball milling for 2 to 4h at the speedof 250 to 400r / min under a protection atmosphere to obtain mixed powder; preparing the zinc-aluminum-zirconium eutectic biological alloy by adopting an SLM technology under the protection atmosphere.According to the biological zinc alloy provided by the invention, an aluminum-rich phase and a zinc-rich phase in a base body are alternatively separated out and condensed, so that the lamellar eutectic structure is generated in a zinc-aluminum alloy, and the content of zirconium is increased and can further refine the lamellar eutectic structure; in addition, the characteristic of quick solidification rate of an SLM technology is applied and can inhibit nucleation growth, thus further refining the lamellar eutectic structure of the zinc alloy; the lamellar eutectic structure is formed and refined, so that the mechanical properties of the biological zinc alloy are improved, and the application of the biological zinc alloy to the field of tissue repairing is promoted.

Owner:JIANGXI UNIV OF SCI & TECH

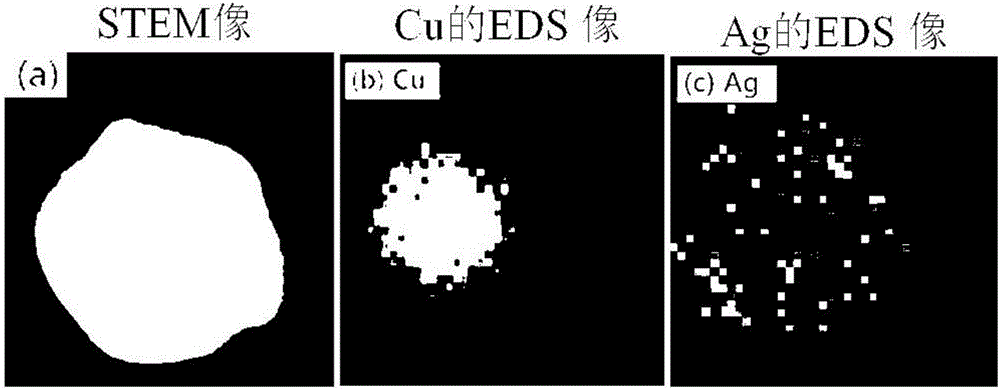

Vapor phase preparation method of core-shell structure Cu / Ag nano alloy

InactiveCN106835048AHigh crystallinityUniform sizeMaterial nanotechnologyVacuum evaporation coatingGas phaseAlloy

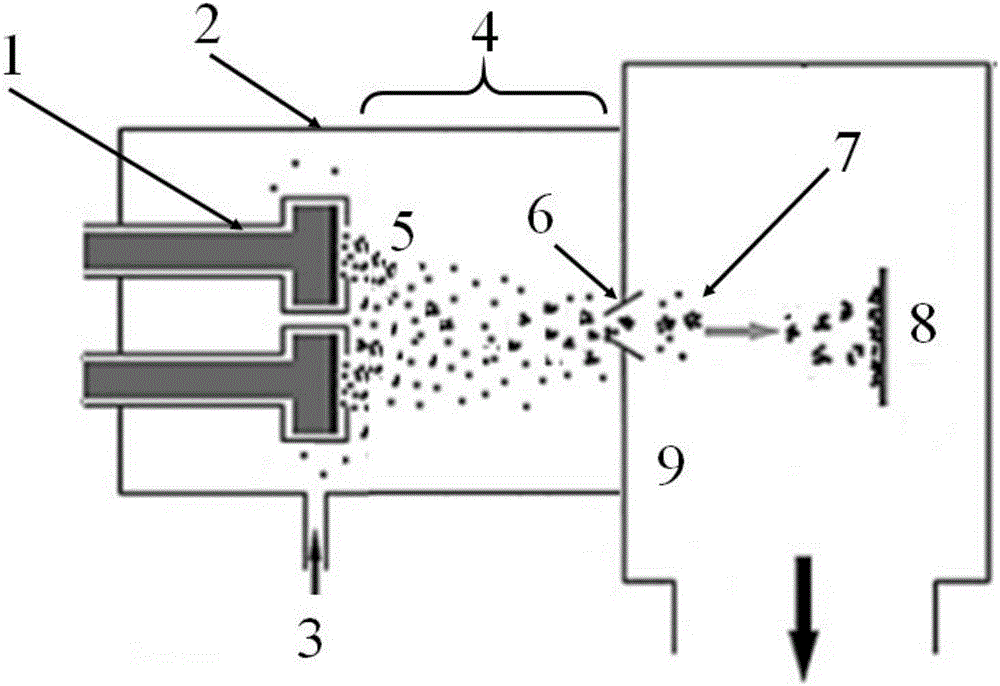

The invention discloses a vapor phase preparation method of a core-shell structure Cu / Ag nano alloy, and belongs to the technical field of nano materials, the preparation method is as follows: dual source gas aggregation clustering growth, to be more specific, an inert buffer gas is introduced into a condensation chamber, a constant air pressure is kept, Cu and Ag powder are simultaneously thermally evaporated by magnetron sputtering of Cu and Ag elemental target materials or by double crucibles to produce dense Cu and Ag atom gases, nucleation growth of Cu and Ag atoms is performed in a buffer gas atmosphere to form Cu and Ag clusters, the Cu and Ag clusters flow with the buffer gas to a nozzle at the top of the condensation chamber for further growth of core-shell structure Cu / Ag nano alloy clusters; and cluster beam deposition, to be more specific, Cu / Ag clusters are sprayed along with the buffer gas from the nozzle to a high vacuum chamber to complete growth and form a directional cluster beam to deposit on the surface of a substrate to obtain the Cu / Ag nano alloy. The vapor phase preparation method belongs to a physical preparation method, and has the advantages of simple operation, high versatility, good process control and no error making, and the prepared product has high purity, clean surface and good monodispersity.

Owner:南通纳瑞纳米科技有限公司

Low-temperature sintering nano-silver paste and preparation process thereof

ActiveCN105127435AReduced impact on sintering propertiesImprove sintering performanceNanotechnologySilver pasteSlurry

The invention discloses a process for preparing low-temperature sintering nano-silver paste. The process comprises the following steps: 1) preparing blank reverse microemulsion and making a pseudoternary phase diagram; 2) preparing the reverse microemulsion containing nano-silver particles; 3) performing centrifugal separation: performing centrifugal separation on the reverse microemulsion containing the nano-silver particles 2-4 times, separating oil phase organic matter and aqueous phase solution, and obtaining the nano-silver particles adsorbed by mixed surfactants; 4) causing the nano-silver particles adsorbed by the mixed surfactants obtained in the step 3) to be mixed with organic carriers, adjusting the viscosity, and preparing the low-temperature sintering nano-silver paste. The process has the advantages that the nano-silver particles are wrapped with the surfactants from nucleation growth to the formation of final slurry, the hard aggregation of the nano-silver particles is greatly reduced, the nano-silver particles prepared through the process are controllable in size, and the preparation process is simplified.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method of three-dimensional self-assembled flower-like tungsten disulfide electrode material

A preparation method of a three-dimensional self-assembled flower-like tungsten disulfide electrode material comprises the steps that sodium tungstate dihydrate is added into a mixed solution of deionized water and ethanol, stirring is performed till the sodium tungstate dihydrate is dissolved to form a transparent solution A, then ammonium acetate is added and stirred evenly, then oleic acid is added and mixed evenly, a pH value is regulated to 1.3 to 1.7, hydrothermal reaction is performed at the temperature of 160-180 DEG C for 12-24 hours, centrifugation and drying are performed to obtainWO3.0.33H2O powder; WO3.0.33H2O powder and thioacetamide are mixed according to the mole ratio of 1:20, and then calcination is performed to obtain the three-dimensional self-assembled flower-like tungsten disulfide electrode material. The hydrothermal synthesis method is utilized to add the oleic acid and ammonium acetate in the mixed alcohol water system to control the nucleation growth of tungsten trioxide and to control the morphology, the synthesis method is simple, easy to control and good in product dispersivity, and finally the three-dimensional self-assembled flower-like tungsten disulfide electrode material is obtained through vulcanization, is uniform in morphology and high in purity and has better application in the field of electrochemistry.

Owner:SHAANXI UNIV OF SCI & TECH

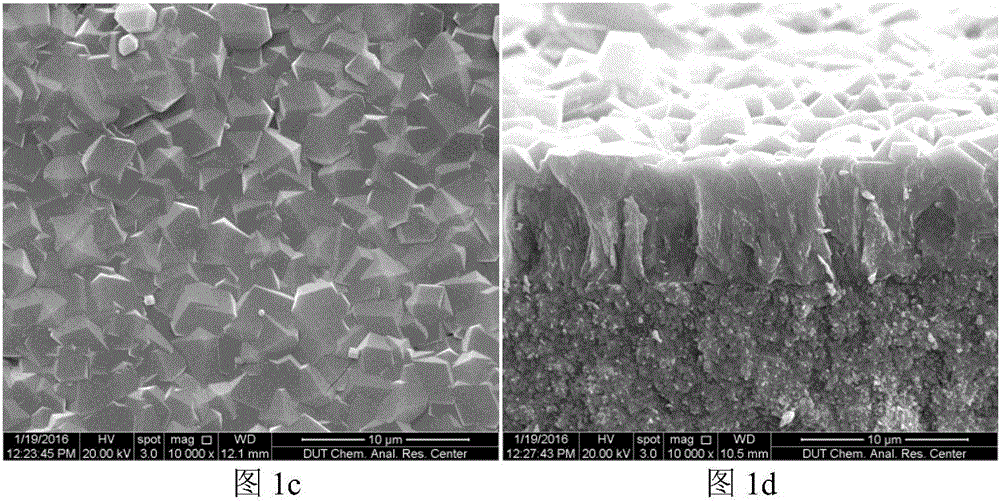

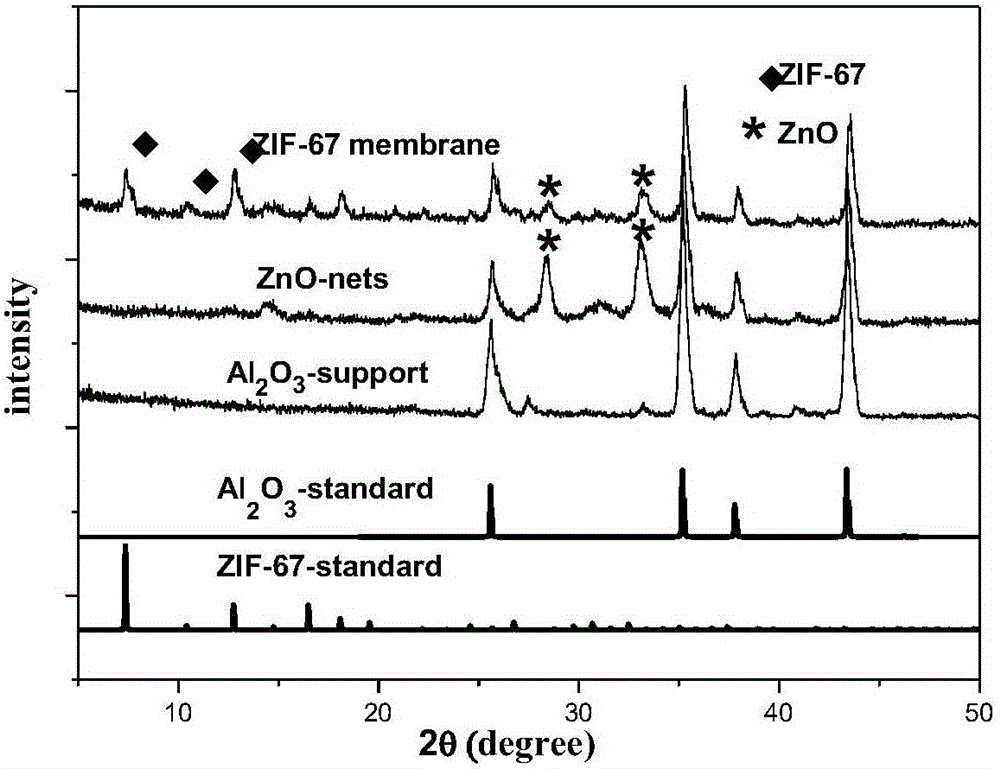

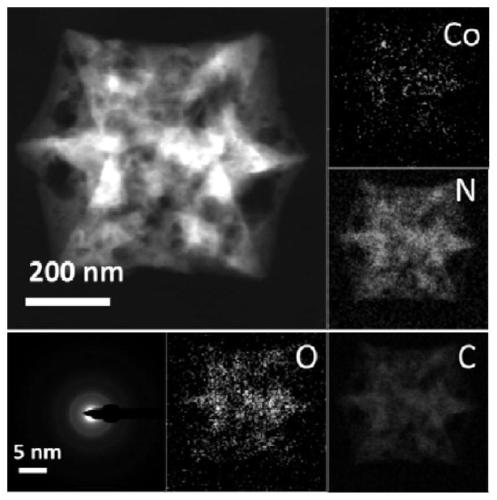

Method for inducing and preparing Co-ZIF-67 metal organic framework membrane by utilizing different-source zinc oxide layer

ActiveCN105879708AWell formedSolve the problem of weak bindingSemi-permeable membranesReactive siteMetal-organic framework

The invention provides a method for inducing and preparing a Co-ZIF-67 metal organic framework membrane by utilizing a different-source zinc oxide layer. Firstly, the zinc oxide layer different from Co-ZIF-67 in source pre-grows on a porous ceramic carrier, then Zn2+ on the carrier is firstly matched with an organic ligand in a solution and then is connected with Co2 in the Co-ZIF-67 synthesis solution, and a Co-ZIF-67 continuous membrane with metal ions different from metal irons of zinc oxide is induced and prepared. The zinc oxide layer provides growth active sites and connecting points of the Co-ZIF-67 membrane, and the obtained Co-ZIF-67 membrane is continuous and complete, has good preparation repeatability, stability, and a gas screening function and is superior to a Co-ZIF-The 67 membrane prepared by adopting a conventional seeding method and an in-situ method. By the adoption of the method, the problems of difficult nucleation growth and poor stability of the metal organic framework Co-ZIF-67 membrane are solved, and a new thought and method is provided for Co-ZIF-67 membrane preparation.

Owner:DALIAN UNIV OF TECH

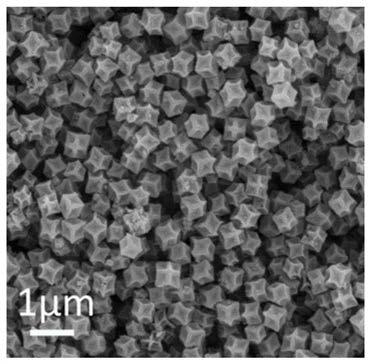

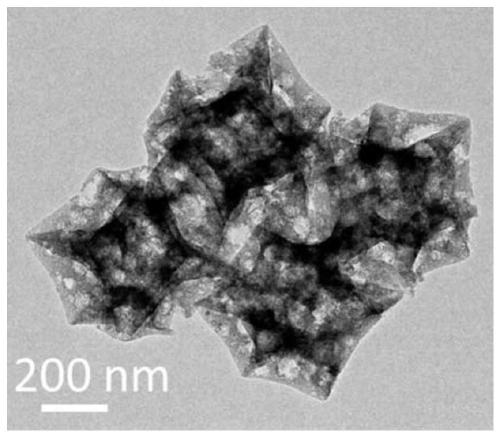

Nitrogen-doped graded porous carbon nano catalyst and preparation method thereof

InactiveCN110280286AExcellent advanced oxidation (AOPs) activityAvoid reunionPhysical/chemical process catalystsWater contaminantsNano catalystPtru catalyst

The invention discloses a nitrogen-doped graded porous carbon nano catalyst and a preparation method thereof. According to the method, a phenolic resin assisting strategy is adopted, a zeolite imidazole ester framework structure material is converted into nitrogen-doped graded porous carbon, and the nitrogen-doped graded porous carbon is applied to the advanced oxidation process. Through the coordination of the nucleation / growth rate and polymerization rate of a precursor, ZIF-67 / 8@PR composite carbon is obtained. The introduction of a phenolic resin polymer can prevent the agglomeration of cobalt and zinc nanoparticles, an evenly distributed graded porous structure is formed, and structural collapse during carbonization is prevented. The carbonized acid treatment can remove metal particles in NDHC, and the nitrogen-doped graded porous carbon is obtained. The nitrogen-doped graded porous carbon nano catalyst can effectively avoid secondary pollution caused by metal ions leached in the catalytic process, and has excellent AOPs catalytic performance.

Owner:NANJING UNIV OF SCI & TECH

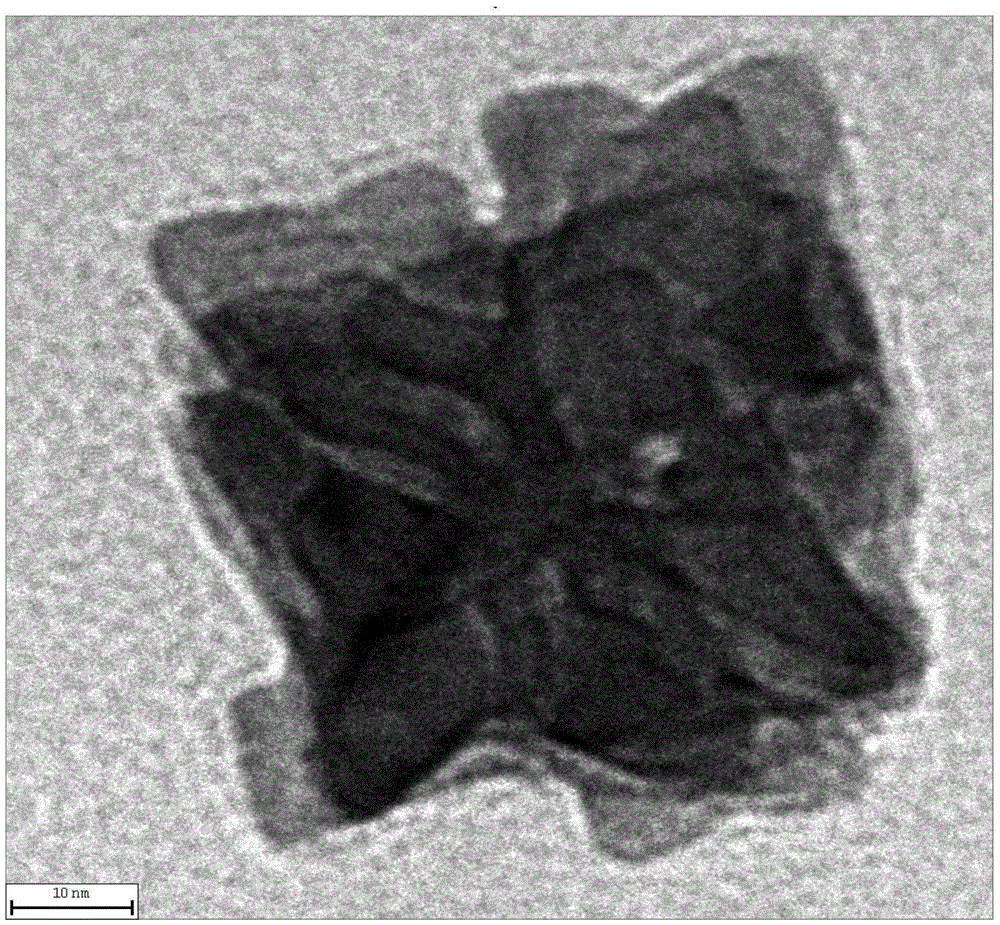

Iron disulfide/nitrogen-doped graphene nanocomposite, preparation and application

InactiveCN106702423AExcellent performance of electrocatalytic water splitting hydrogenEasy to operateElectrodesNitrogen doped grapheneHydrolysis

The invention belongs to the technical field of hydrogen evolution electrocatalysis and discloses an iron disulfide / nitrogen-doped graphene nanocomposite, preparation and application. A preparation method includes the following steps that an iron disulfide precursor solution is mixed with graphene oxide, a hydrothermal method reaction is carried out, and the iron disulfide / nitrogen-doped graphene nanocomposite is obtained. L-cysteine is adopted as a sulfur source and a reducing agent, ammonia water serves as a nitrogen source, ferric acetylacetonate serves as iron salt, a FeS2 nanocube is subjected to homogeneous nucleation growth on an NG surface through a hydrothermal method, and the FeS2 / NG nanocomposite is obtained, wherein the nitrogen content ranges from 0.38 wt% to 1.12 wt%; and by means of good hydrogen evolution electrocatalysis performance of iron disulfide and high specific surface area and high conductivity of nitrogen-doped grapheme, a good electrocatalysis hydrolysis hydrogen production effect is shown, and the nanocomposite can be applied to the field of hydrogen evolution electrocatalysis, especially preparation of hydrogen evolution electrocatalysis materials and can be directly used as an electrode material for electrocatalysis hydrolysis hydrogen production.

Owner:GUANGDONG IND TECHN COLLEGE

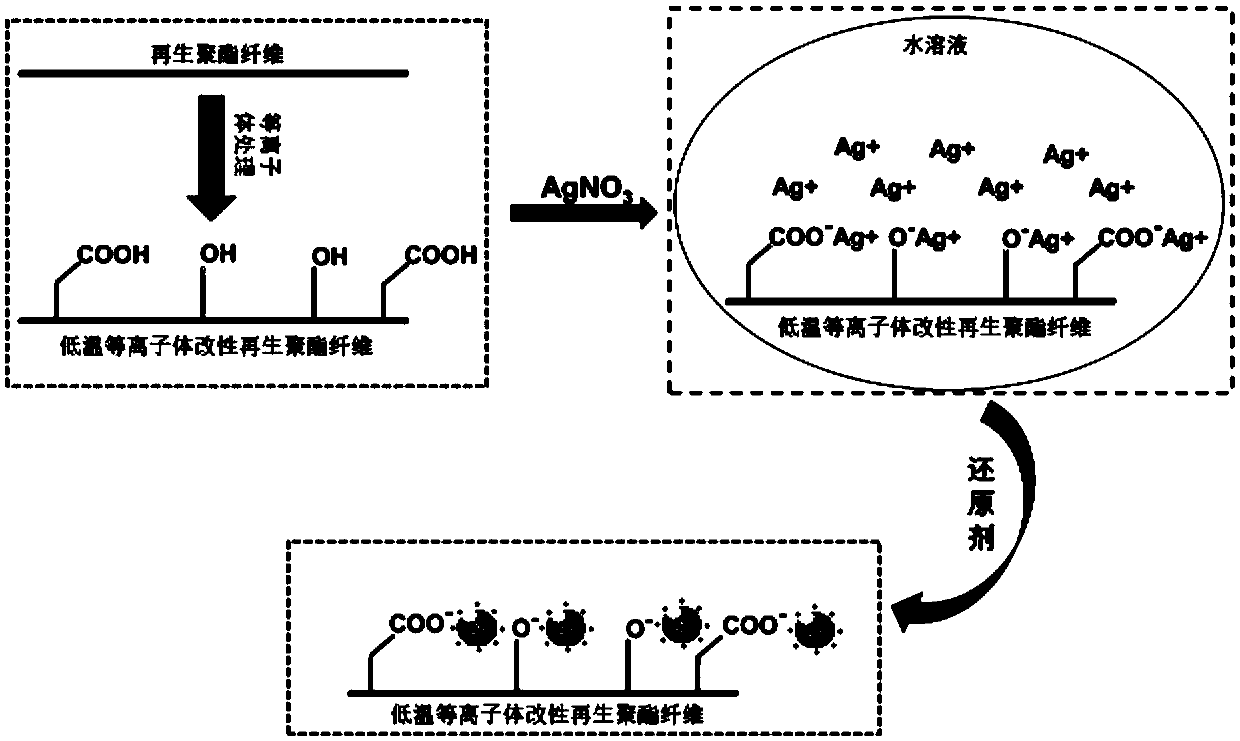

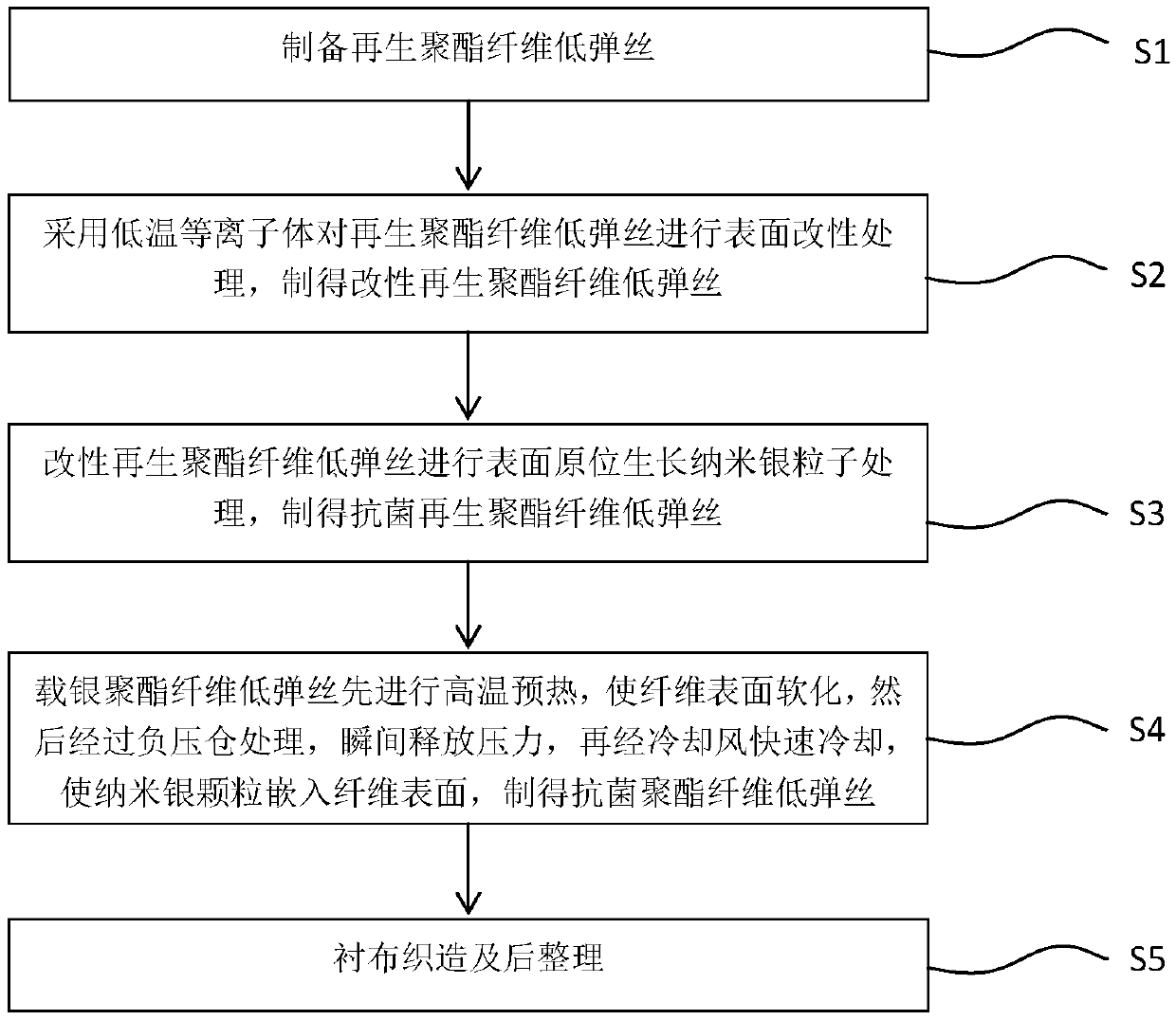

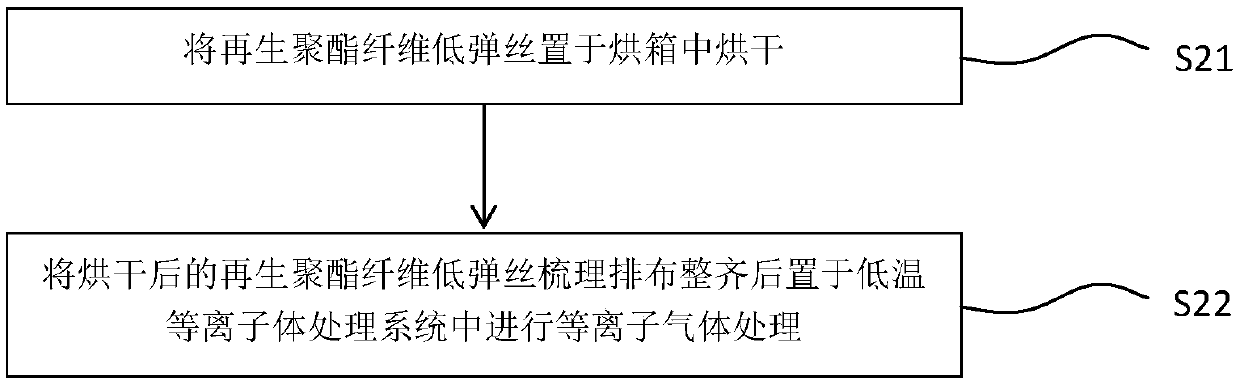

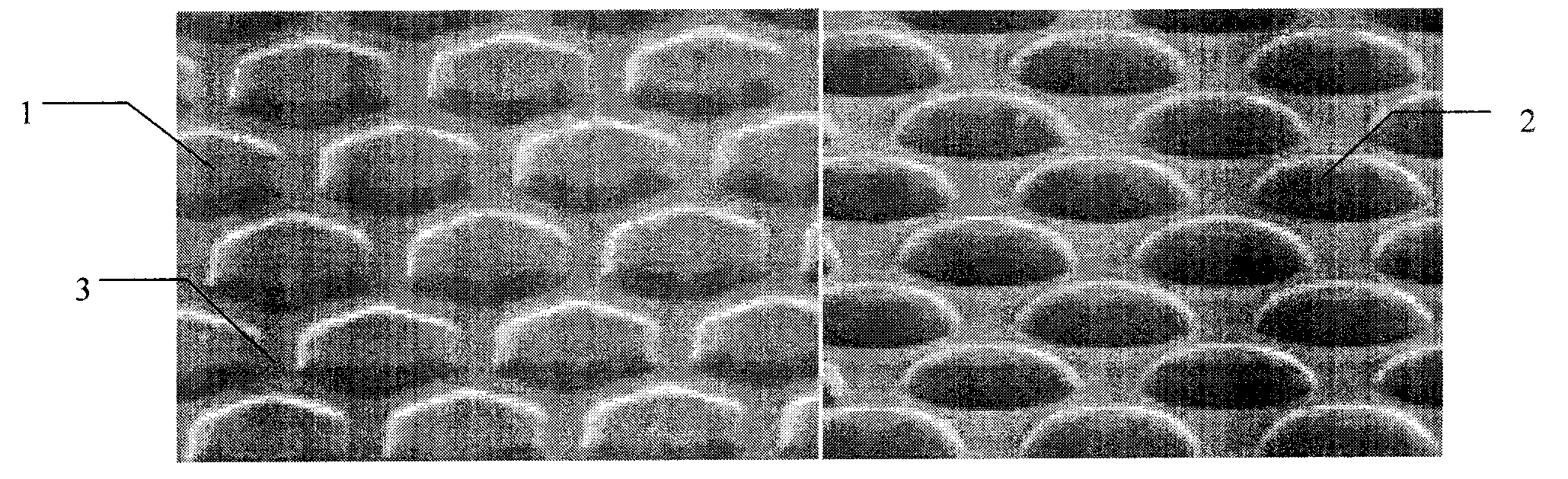

Antibacterial regenerated polyester fiber lining cloth and production process thereof

The invention relates to antibacterial regenerated polyester fiber lining cloth and a production process thereof. The lining cloth is weaving lining cloth, and warp yarns and weft yarns of the liningcloth contains antibacterial modified regenerated polyester fiber low stretch yarns. The production process comprises the following steps: preparing regenerated polyester fibers by virtue of a physical regeneration method or a chemical regeneration method, modifying the surfaces of the regenerated polyester fibers to generate functional groups capable of adsorbing silver ions on the surfaces of the regenerated polyester fibers, wherein the functional groups service as the nucleation growth foundation of reduced nano-silver particles, are continuously accumulated with a reducing agent to generate silver atoms, and the nano-silver particles are grown; and carrying out high-temperature preheating on silver-loaded regenerated polyester fibers so as to softening the surfaces of the regeneratedpolyester fibers, embedding the nano-silver particles into the surfaces of the regenerated polyester fibers under a negative pressure, and carrying out rapid cooling and formation, so as to embed thenano-silver particles into the surfaces of the regenerated polyester fibers. According to the production process, the problems that the antibacterial effect of the lining cloth is poor, the productioncost is high, and the antibacterial property is difficult to be guaranteed in the prior art are solved; and the antibacterial modified regenerated polyester fiber low stretch yarns have the antibacterial performance, and the antibacterial property is not degraded after the antibacterial modified regenerated polyester fiber low stretch yarns are washed for several times.

Owner:南通源佑纺织科技有限公司

Composite pyrophyllite material

ActiveCN101445357AReduce consumptionIncrease productivityUltra-high pressure processesClaywaresSuperhard materialPyrophyllite

The invention relates to a seal pressure-transmitting medium material used for synthesizing superhard material such as diamond, cubic boron nitride, composite slice, and the like, in particular to a composite pyrophyllite material The composite pyrophyllite material consists of the following raw materials by weight percentage: 50 percent to 60 percent of pyrophyllite, 12 percent to 20 percent of sericite, 8 percent to 15 percent of kaolinite, 5 percent to 10 percent of boehmite and 5 percent to 10 percent of cementing compound. The composite pyrophyllite powder briquette manufactured by the invention has good performances for sealing, pressure-transmitting, heat-preserving and insulating, provides a good environment for the nucleation growth of the superhard material, has stable flowing property and is easy for forming a sealing surface, thereby effectively reducing the phenomena of deflation and explosion during the superhard material synthesis, saving electrical energy due to the good heat preservation performance, improving the productivity due to the good pressure-transmitting performance and reducing the cost. Only South Africa owns the industrial pyrophyllite in the field of the superhard material in the world, and only Beijing Mentougou owns mineral resource in China which is insufficient. The composite pyrophyllite material is the substitute of the two and is better than the two.

Owner:李学增

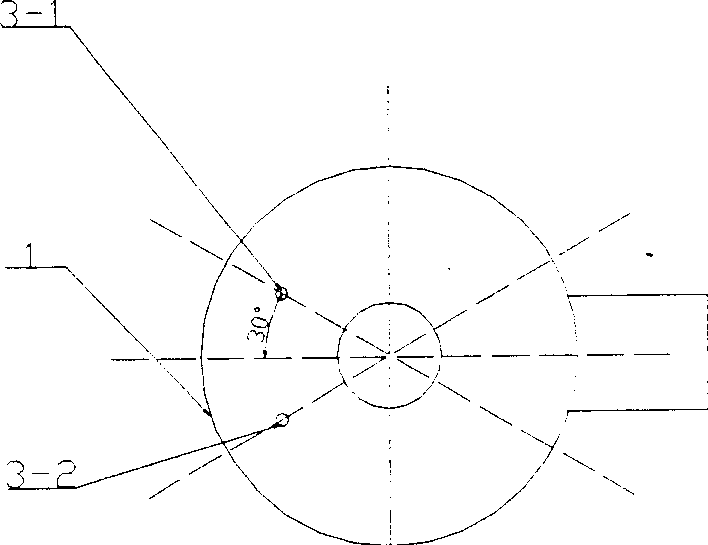

Growth technology for growing high-quality GaN crystal material on sapphire patterned substrate

InactiveCN102808221AQuality improvementReduce stressPolycrystalline material growthFrom chemically reactive gasesPatterned substrateRe crystallization

The invention discloses a growth technology for growing a high-quality GaN crystal material on a sapphire patterned substrate. The growth technology comprises the following step of: using MOCVD (metal organic chemical vapor deposition) equipment to grow a GaN crystal on the sapphire substrate. The growth technology is characterized in that a nucleating layer material of the GaN crystal is grown at a low temperature on the substrate, and the re-crystallization growth of the GaN crystal is carried out after the temperature of a substrate material is risen after the growth of a nucleating layer is completed. After a crystallization procedure is terminated, the temperature of the substrate material is reduced, and the nucleation growth of the GaN crystal, namely the three-dimensional growth of the GaN crystal, is carried out again. After a re-nucleation procedure is terminated, the temperature of the substrate material is risen again to carry out the re-crystallization growth of the GaN crystal. After the growth in each step above is completed, the temperature of a substrate slice is risen, and meanwhile, the pressure of a reaction chamber is reduced to carry out the growth of the GaN crystal material, so that a GaN material layer which has a flat surface and is further high in quality can be obtained. By using a process of combining two-time low-temperature nucleating layer growth with a high-temperature re-crystallization procedure, which is adopted in the growth technology, compared with a conventional single-time nucleating layer growth process, the GaN material with a lower defect concentration and lower material stress can be obtained.

Owner:姜涛

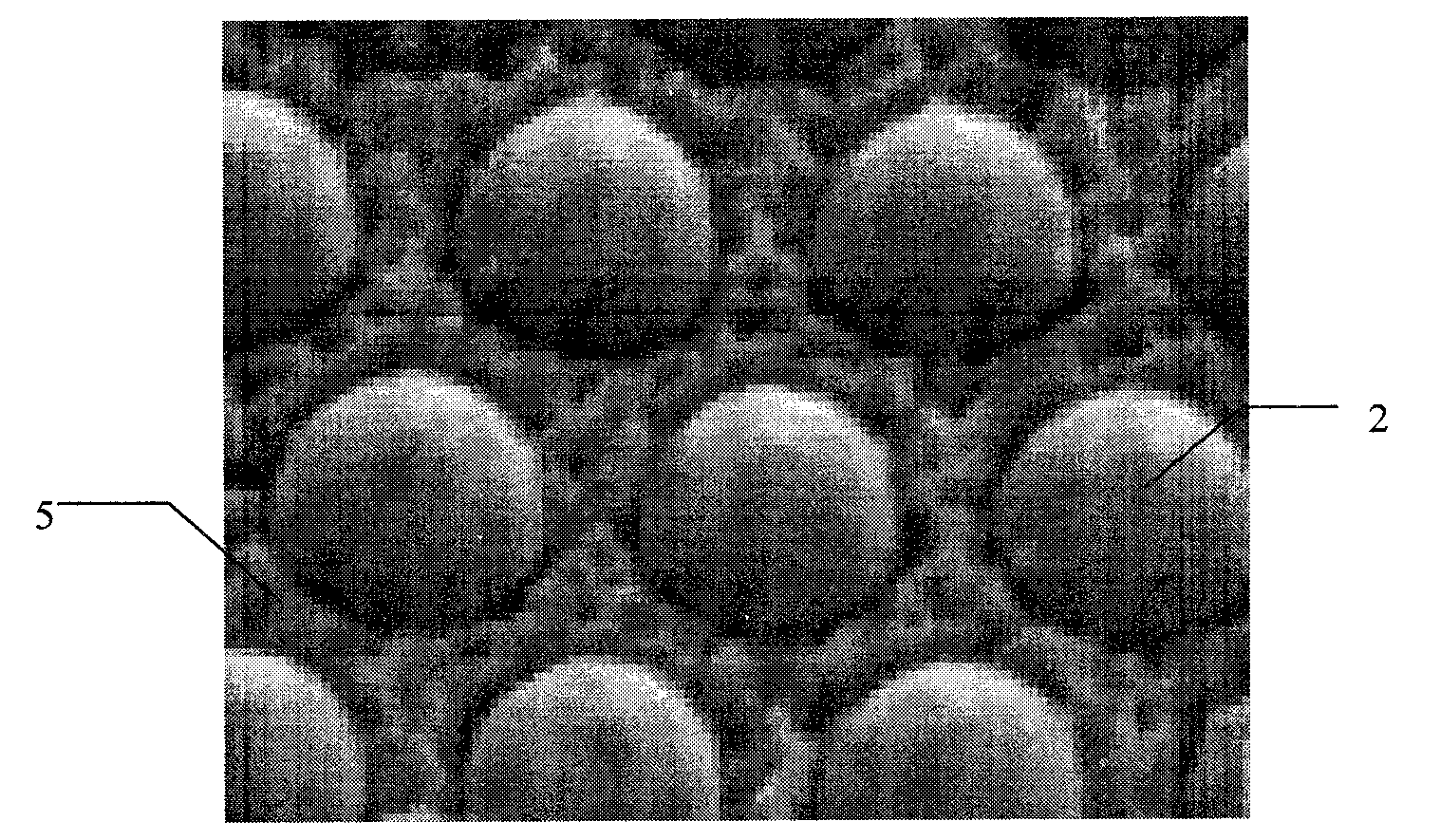

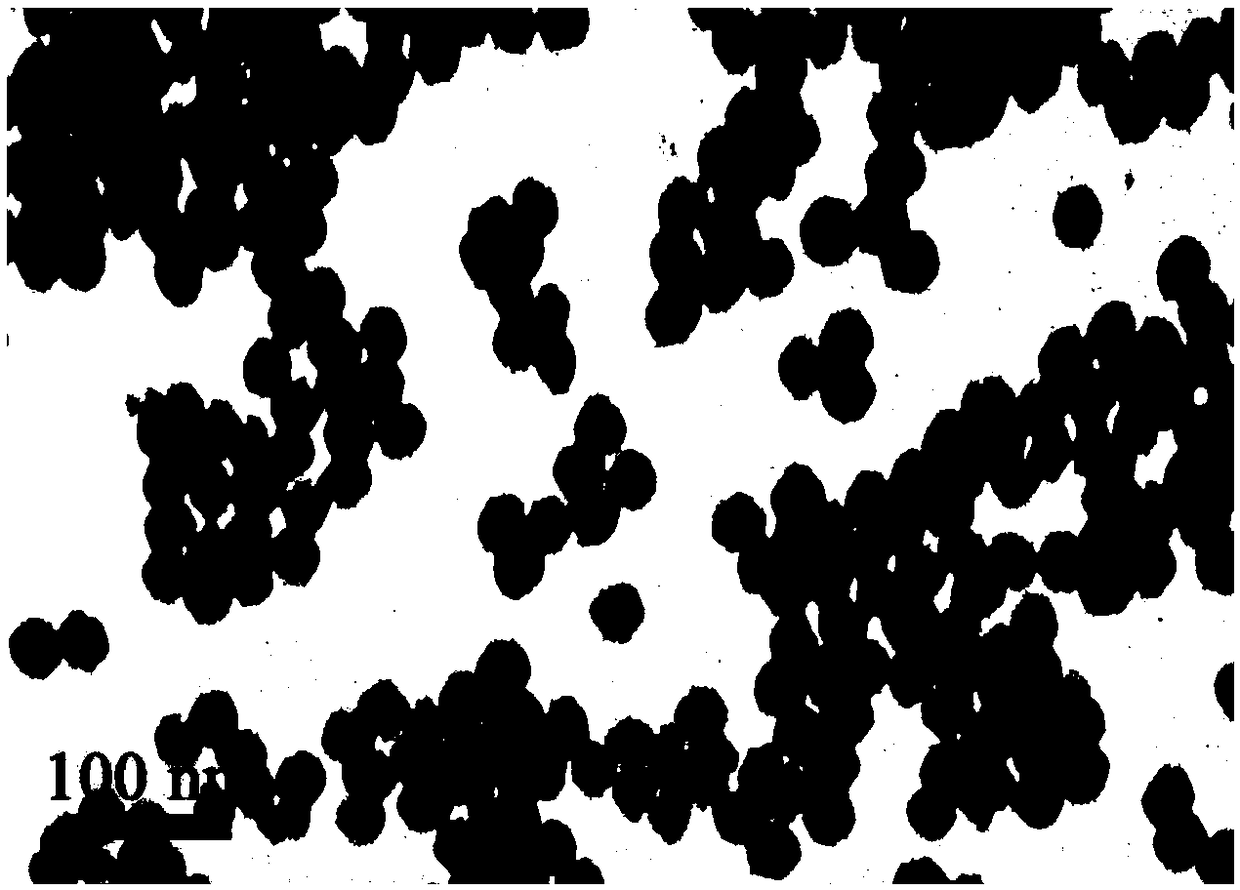

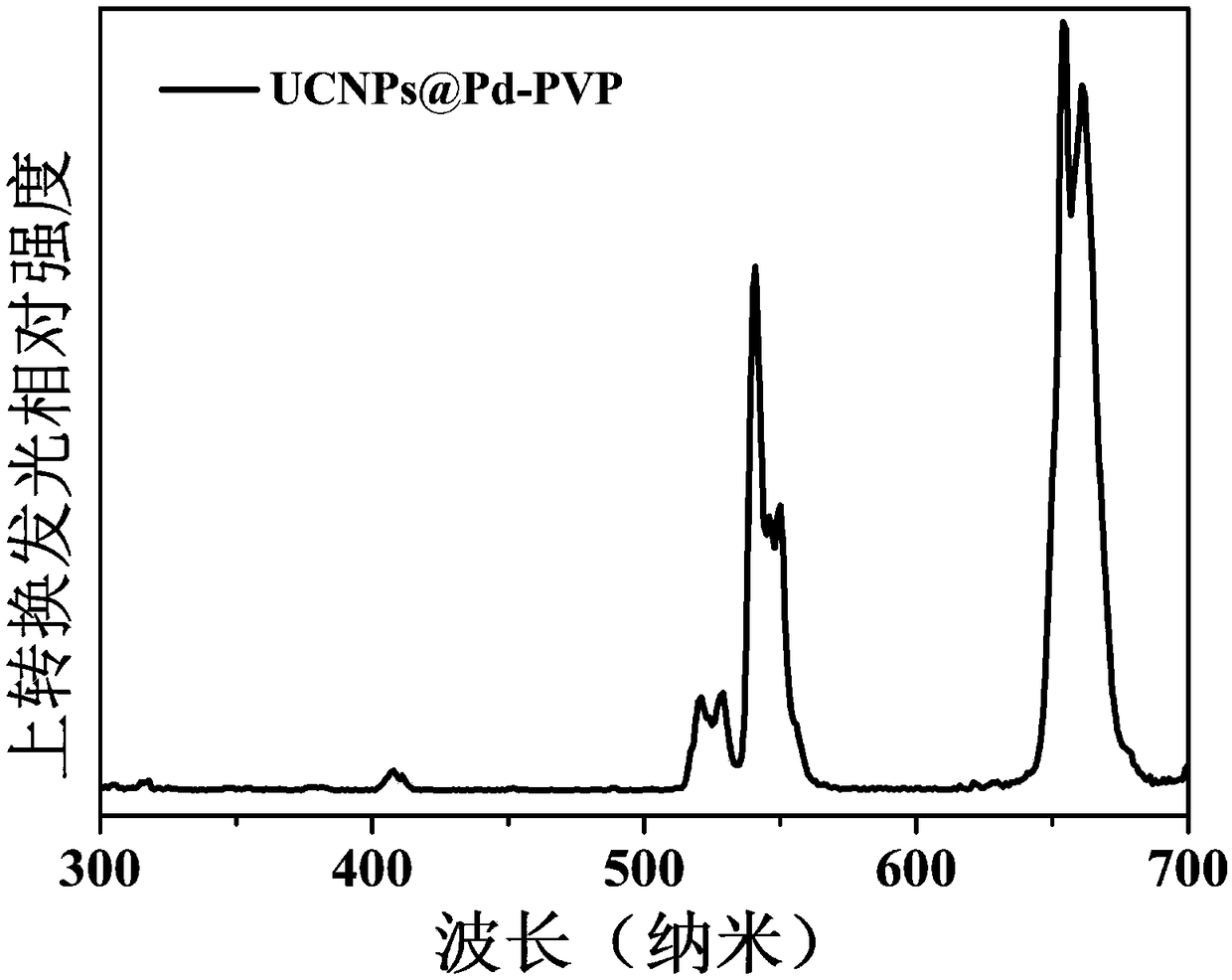

Preparation method of up-conversion nanometer hybrid system based on heterogeneous growth of nanometer palladium, preparation method and applications thereof

ActiveCN108904800AImprove uniformityImprove consistencyPowder deliveryEnergy modified materialsSolubilityFluorescence

The invention discloses a preparation method of an up-conversion nanometer hybrid system based on heterogeneous growth of nanometer palladium. According to the method, nanometer palladium is subjectedto heterogeneous nucleation growth on the surface of rare earth up-conversion luminescent nanoparticles to form the nanometer hybrid system; the surface of the rare earth up-conversion luminescent nanoparticles is coated with a layer of inert NaGdF4; the surface of the formed nanometer hybrid system is further modified with an organic ligand so as achieve good water solubility; and the final nanometer hybrid system is used for bimodal imaging diagnostic guided photothermal therapy. According to the present invention, the preparation method has advantages of simple process and high efficiency;and the nanometer hybrid system has advantages of good stability and good biocompatibility, has the photothermal conversion efficiency of 80-90%, is used for up-conversion fluorescence imaging and magnetic resonance imaging, can be used as the high conversion efficiency photothermal agent for photothermal therapy, and can meet the clinical diagnosis and treatment integration requirements.

Owner:SHANGHAI UNIV

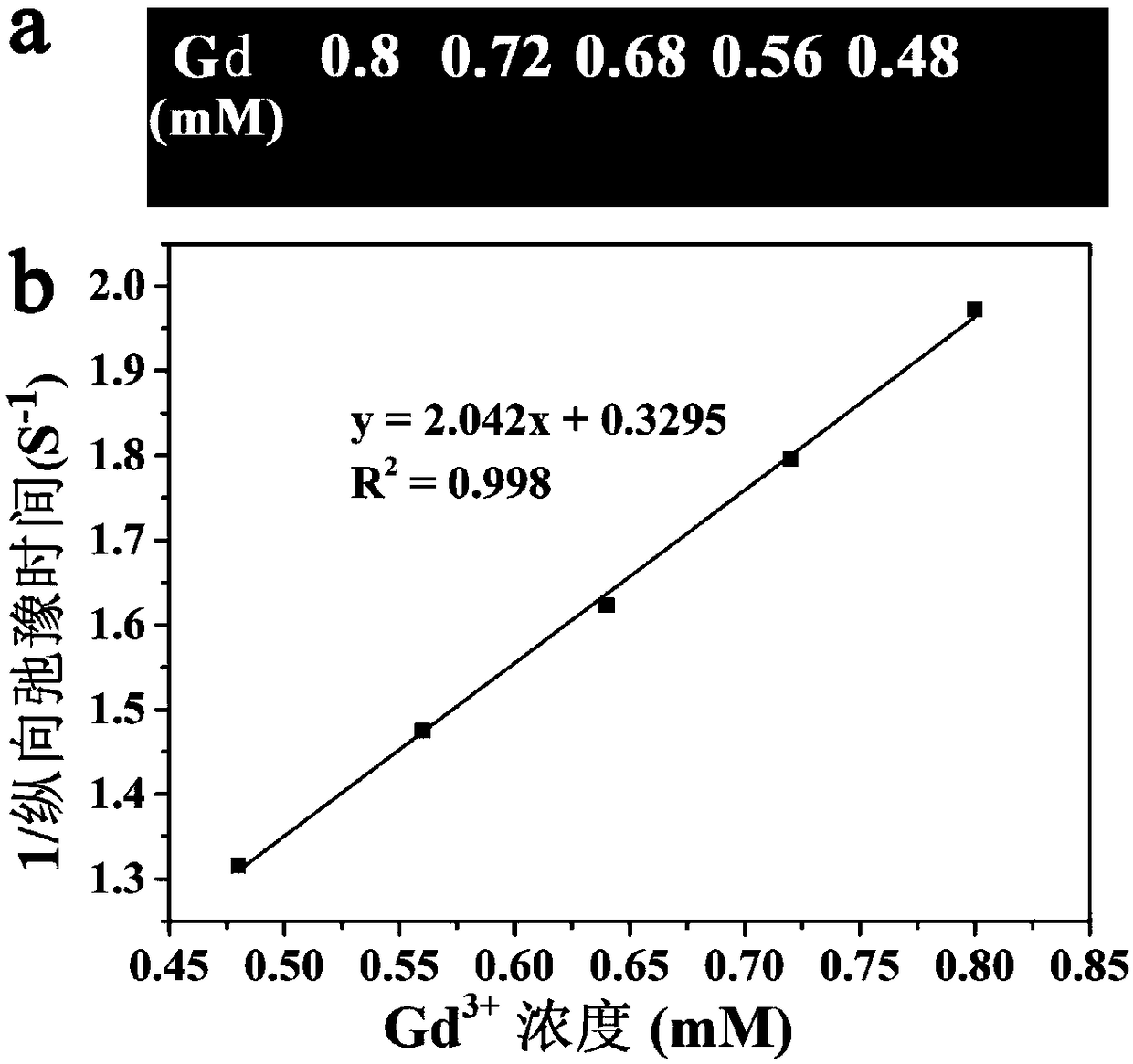

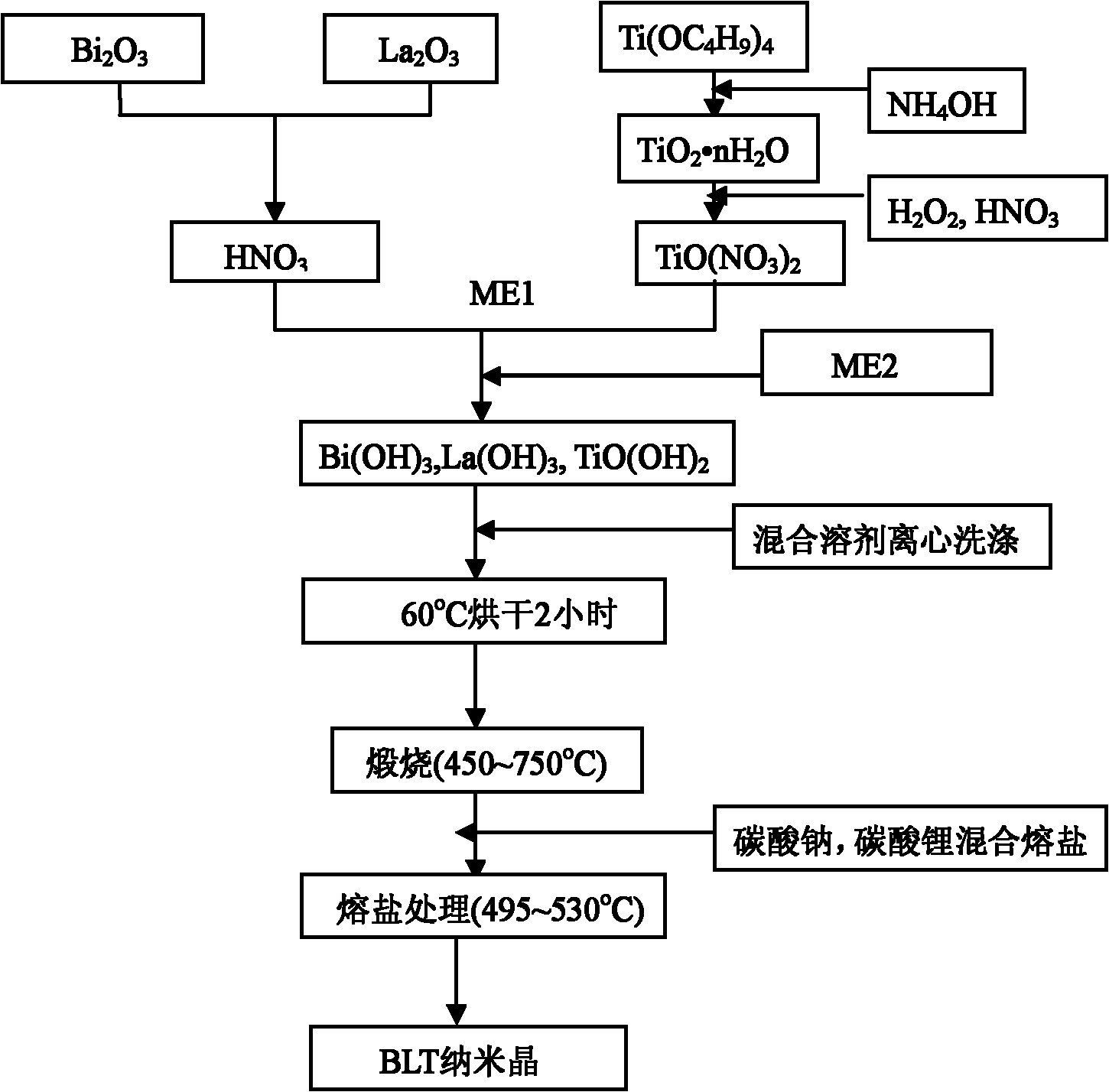

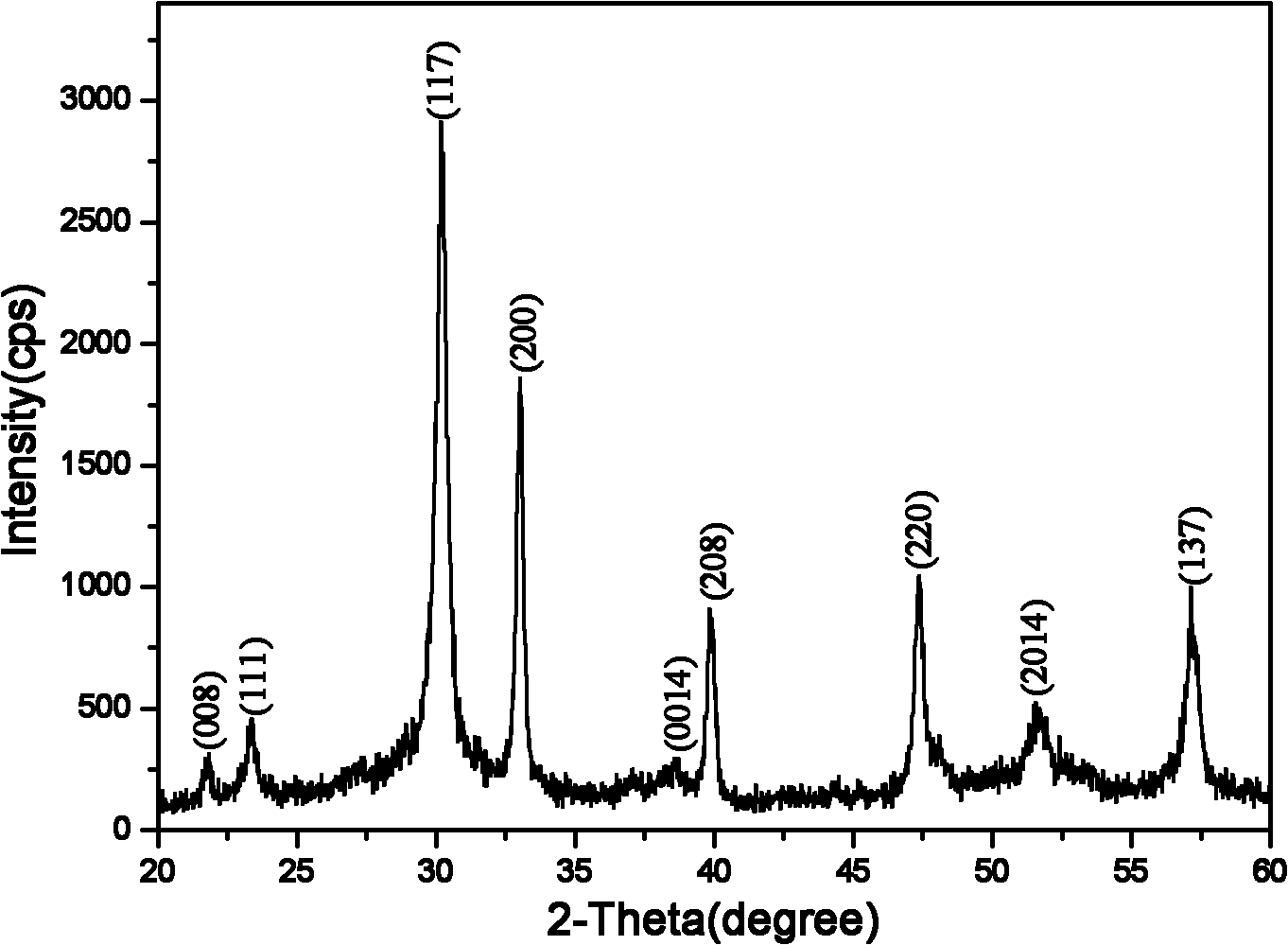

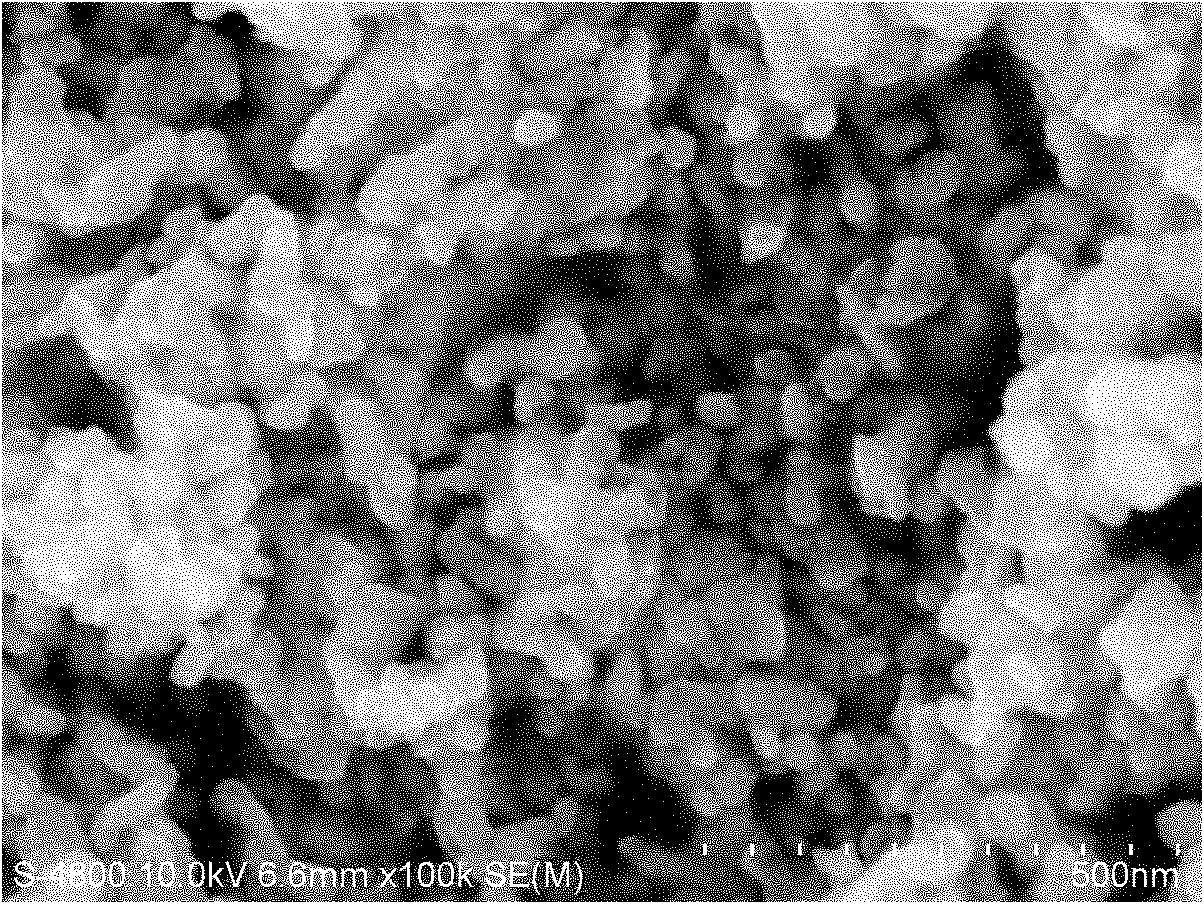

Quasi-cubic bismuth lanthanum titanate (BLT) nanoparticles and preparation method thereof

The invention discloses quasi-cubic bismuth lanthanum titanate (BLT) ferroelectric single crystal nanoparticles and a preparation method thereof. The nanoparticles and the preparation method have important application values for self-assembly of ferroelectric ordered nano-array structures. The technical scheme adopted by the invention is as follows: taking analytically pure Bi2O3, La2O3 and Cl6H36O4Ti as raw materials, cyclohexane as oil phase, Triton X-100 as a surfactant and n-butyl alcohol as a cosurfactant to form colloidal particles with chemical composition being Bi4-xLaxTi3O12 (x=0.5-1.0) through reverse microemulsion process, synthesizing BLT coarse nanocrystals through thermal treatment at the temperature of 450-750 DEG C, further putting the obtained BLT coarse nanocrystals intosodium carbonate / lithium carbonate mixed molten salt and obtaining the quasi-cubic BLT nanocrystals with uniform dimensions through melting-nucleation-growth. The microstructure characteristic of theBLT nanocrystals has not been publicly reported internationally so far.

Owner:NANJING TECH UNIV

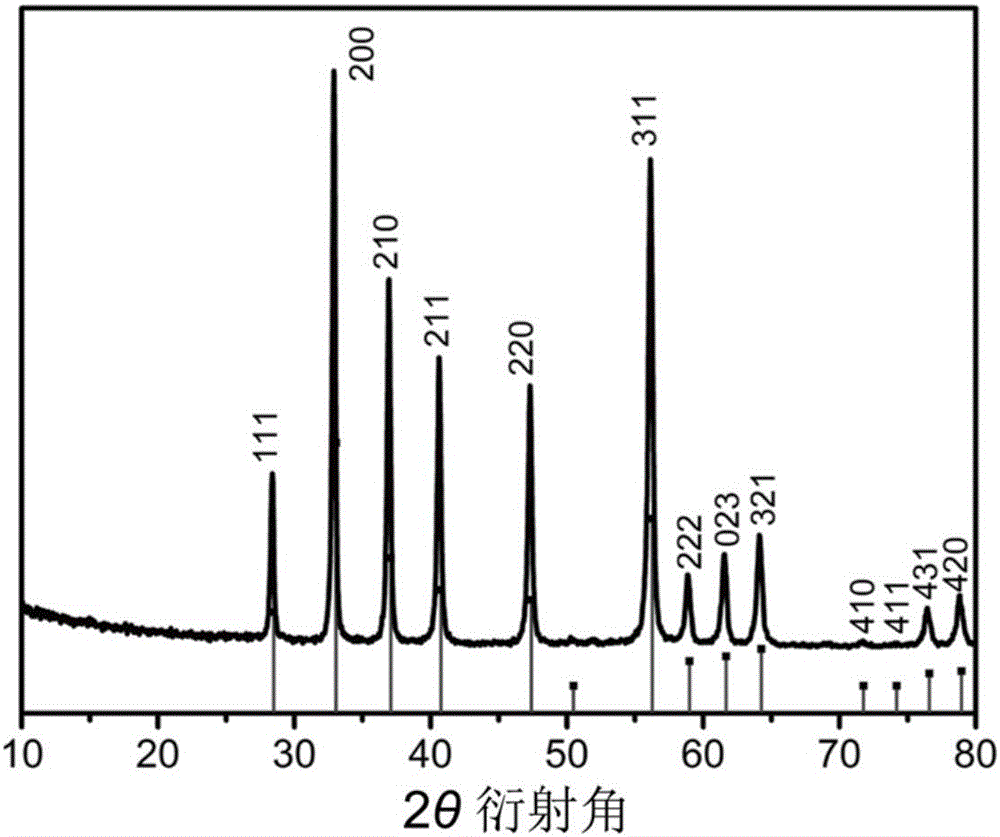

Positive electrode material precursor and preparation method and application thereof

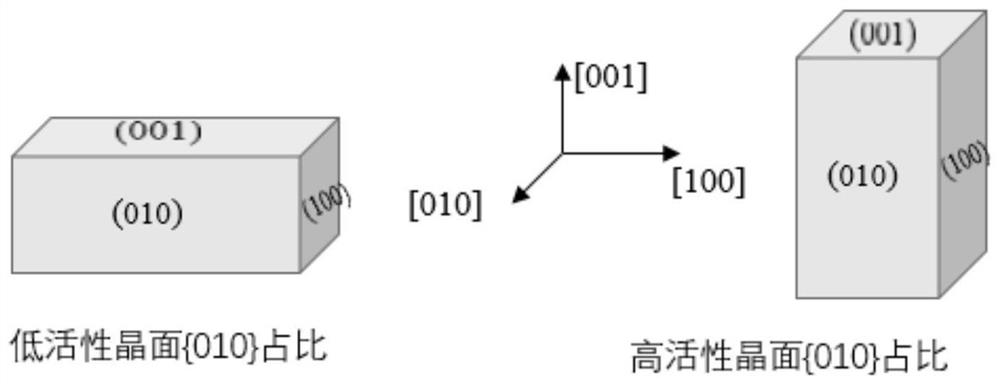

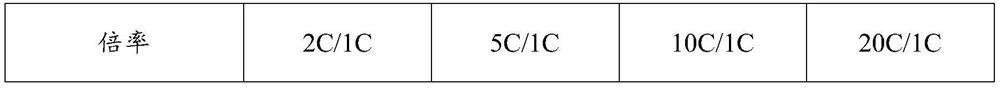

ActiveCN112919553AIncrease the proportionImprove power characteristicsSecondary cellsPositive electrodesElectrical batteryNucleation growth

The invention belongs to the technical field of battery materials, and discloses a positive electrode material precursor and a preparation method and application thereof, the chemical formula of the positive electrode material precursor is NixCoyMnz(OH)2, 0.2 < = x < = 1, 0 < = y < = 0.5, 0 < = z < = 0.6, 0.8 < = x + y + z < = 1. The positive electrode material precursor is in a sheet layer stacking shape, the particle size broadening coefficient of the positive electrode material precursor is K, and K is smaller than or equal to 0.85. The preparation process of the precursor is effectively controlled and adjusted by adopting a controlled crystallization method and combining a Lamer nucleation growth theoretical model, the prepared precursor has the morphological characteristics of concentrated particle size distribution and high proportion of active crystal face {010}, and the capacity retention rate can reach 91.33% under the multiplying power of 20C.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

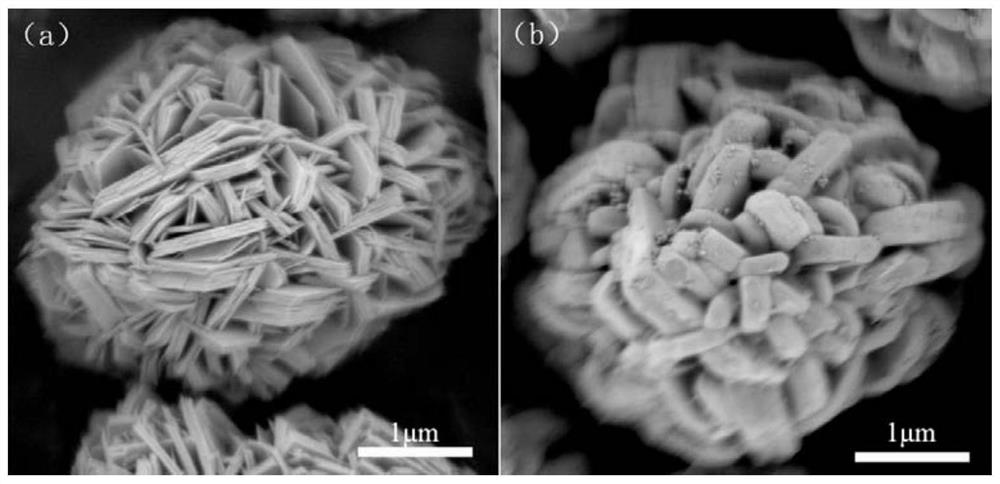

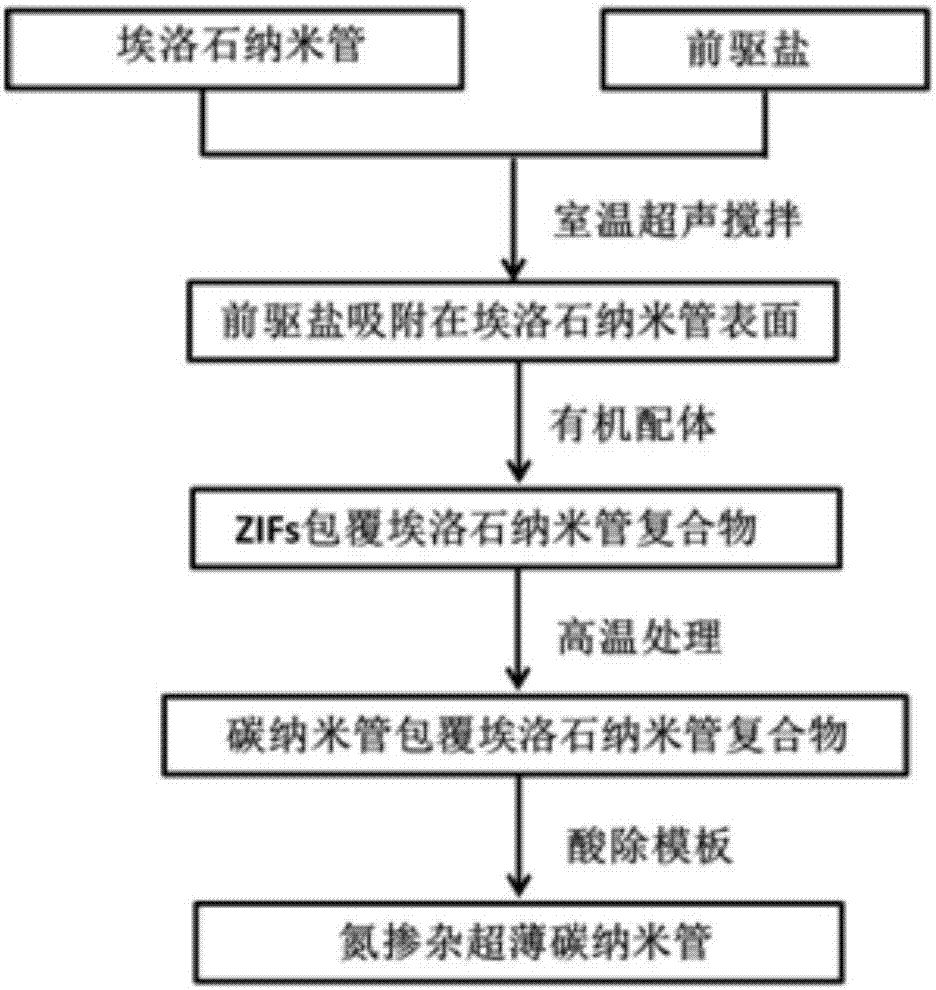

Preparation method of nitrogen doped super-large cavity carbon nanotube composite material

InactiveCN107413365ASimple processRaw materials are cheap and easy to getMaterial nanotechnologyPhysical/chemical process catalystsElectronic transmissionCarbonization

The invention provides a preparation method of a nitrogen doped super-large cavity carbon nanotube composite material, belonging to the technical field of preparation of nano composite catalysis materials. Based on a metal organic framework compound, electrostatic adsorption, directional nucleation growth, limited carbonization and acid corrosion for removing a template are performed on the surface of a tubular inorganic template one-dimensional nanotube, so as to obtain a metal-modified nitrogen doped carbon nanotube composite material. The prepared composite material has a large cavity and a thin wall, and has the characteristics of rich electrochemical activity sites and efficient electronic transmission. The preparation method has the characteristics of being easy to operate, being low-cost, and being easy for industrial production, and has a bright application prospect in energy storage and environment-friendly catalysis.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com