Palladium nanocrystals and synthesis method thereof

A synthesis method and nanocrystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as large energy consumption, and achieve the effects of increased reaction rate, high yield, and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for synthesizing palladium nanocrystals, which comprises the following steps of mixing and reacting a palladium source compound, a ruthenium source compound and a surface modification reducing agent in a solvent to obtain palladium nanocrystals.

[0041] The palladium source compound in the present invention is preferably a compound containing chloropalladate; the ruthenium source compound is preferably a compound containing trivalent ruthenium. The present invention is not particularly limited to the compound containing chloropalladate group, and the compound containing chloropalladate group well known to those skilled in the art can be used. The present invention preferably includes potassium chloropalladate, sodium chloropalladate and chlorine One or more of ammonium palladium, more preferably potassium chloropalladate and / or sodium chloropalladate. The present invention is not particularly limited to the compound containing trivalent ...

Embodiment 1

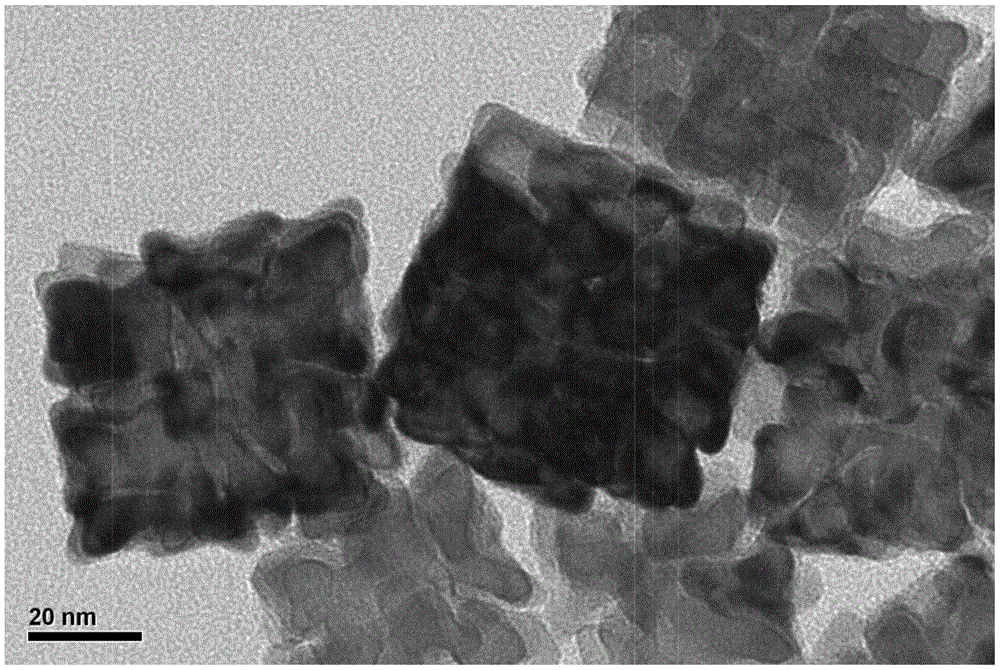

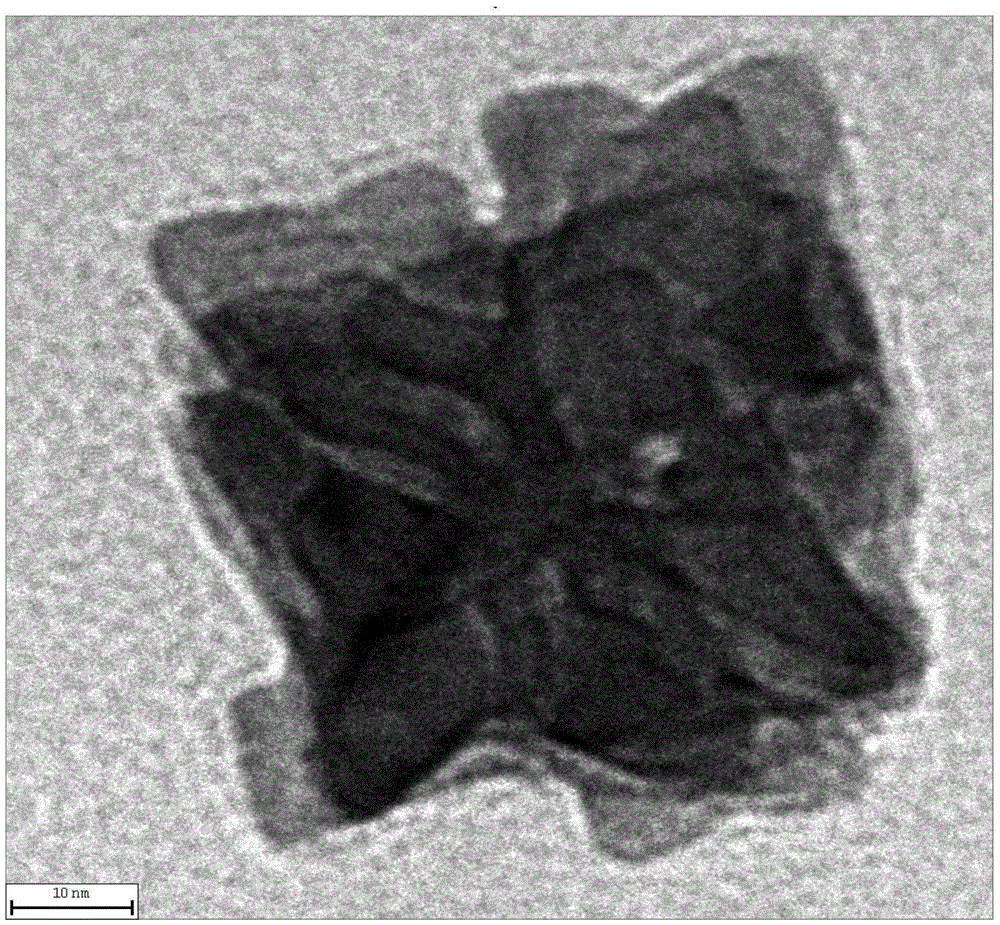

[0053] Irregular palladium nanocrystals with high-index facets

[0054] 210 mg of PVP (polyvinylpyrrolidone), 120 mg of AA (ascorbic acid) and 600 mg of KBr were dissolved in 16 ml of distilled water. Place in a three-necked flask with a volume of 50 ml, heat to 80° C., and keep the temperature constant for 5 minutes to obtain a mixed solution.

[0055] 63 mg K 2 PdCl 4 Dissolved in 3 ml of distilled water, and then 5 mg of ruthenium chloride (RuCl 3 ) was dissolved in 1 ml of distilled water. K 2 PdCl 4 solution and RuCl 3 The solution was quickly injected into the mixed solution for reaction, and after constant temperature reaction for 10 minutes, PVP, AA and KBr were removed by centrifugation and distilled water washing, and irregular palladium nanocrystals with high-index crystal planes were obtained.

[0056] The irregular palladium nanocrystals with high index crystal faces prepared by the above method are detected, and the detection results show that, see figur...

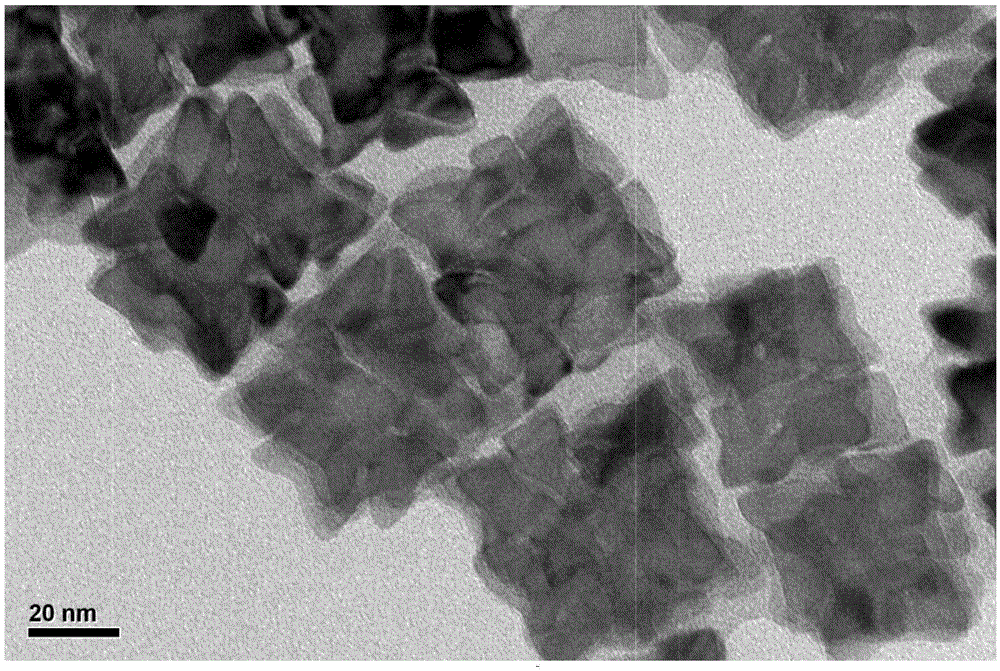

Embodiment 2

[0060] 210 mg of PVP (polyvinylpyrrolidone), 120 mg of AA (ascorbic acid) and 600 mg of KBr were dissolved in 16 ml of distilled water. Place in a three-neck flask with a volume of 50 ml, heat to (100)° C., and keep the temperature constant for 5 minutes to obtain a mixed solution.

[0061] 63 mg of K2PdCl4 was dissolved in 3 ml of distilled water, and 5 mg of ruthenium chloride (RuCl3) was dissolved in 1 ml of distilled water. The K2PdCl4 solution and the RuCl3 solution were quickly injected into the mixed solution for reaction. After 10 minutes of constant temperature reaction, PVP, AA and KBr were removed by centrifugation and distilled water washing, and irregular palladium nanocrystals with high-index crystal faces were obtained.

[0062] see Figure 8 , Figure 8It is a TEM photo of the palladium nanocrystal prepared in Example 2 of the present invention, and the scale bar is 20 nm. Depend on Figure 8 It can be seen that the palladium nanocrystals prepared by the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com