Biological zinc alloy with fine lamellar eutectic structure and preparation method thereof

A technology of crystal structure and biological zinc, applied in the field of biological zinc alloy and its preparation, can solve the problems of insufficient mechanical properties of biological zinc alloy, and achieve the effect of excellent biocompatibility and appropriate degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 0.02g zirconium powder, 0.08g aluminum powder and 9.9g zinc powder respectively according to the mass ratio of 0.2:0.8:99, add the three into the ball mill jar and use the mass ratio of ball to material of 20:1 to achieve a high temperature of 99.999%. Under the protective atmosphere of pure argon, the ball milled at a speed of 350r / min for 3h to obtain zinc-aluminum-zirconium mixed powder. Using the above mixed powder as raw material, under the process conditions of laser power 65W, scanning speed 14mm / s, spot diameter 50μm, scanning distance 0.01mm, powder coating thickness 0.1mm and 99.999% high-purity argon protective atmosphere, SLM Process to prepare biological zinc alloy.

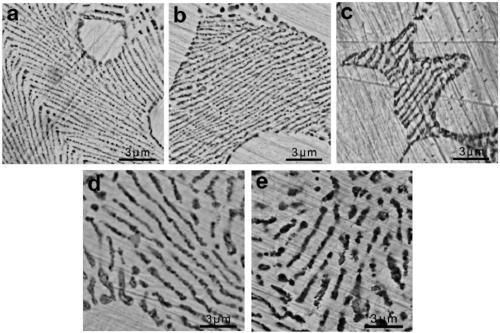

[0034] Microstructure tests found that a large number of fine and uniformly distributed lamellar zinc-aluminum eutectic structures were formed, such as figure 1 As shown in a, the lamellar spacing is 0.34 μm, and it is found through mechanical testing that the ultimate compressive stren...

Embodiment 2

[0036] Weigh 0.01g of zirconium powder, 0.08g of aluminum powder and 9.91g of zinc powder respectively according to the mass ratio of 0.1:0.8:99.1, add the three into the ball mill jar and use the mass ratio of ball to material of 20:1 to achieve a high temperature of 99.999%. Under the protective atmosphere of pure argon, the ball milled at a speed of 350r / min for 3h to obtain zinc-aluminum-zirconium mixed powder. Using the above mixed powder as raw material, under the process conditions of laser power 65W, scanning speed 14mm / s, spot diameter 50μm, scanning distance 0.01mm, powder coating thickness 0.1mm and 99.999% high-purity argon protective atmosphere, SLM Process to prepare biological zinc alloy.

[0037] The microstructure test found that after adding 0.1wt% zirconium and 0.8wt% aluminum to zinc, a small amount of fine and uniformly distributed lamellar eutectic structure was obtained, such as figure 1 As shown in b, the lamellar spacing is 0.37 μm. It is found throu...

Embodiment 3

[0039]Weigh 0.03g of zirconium powder, 0.08g of aluminum powder and 9.89g of zinc powder respectively according to the mass ratio of 0.3:0.8:98.9, add the three into the ball mill jar and use the mass ratio of ball to material of 20:1 to achieve a high temperature of 99.999%. Under the protective atmosphere of pure argon, the ball milled at a speed of 350r / min for 3h to obtain zinc-aluminum-zirconium mixed powder. Using the above mixed powder as raw material, under the process conditions of laser power 65W, scanning speed 14mm / s, spot diameter 50μm, scanning distance 0.01mm, powder coating thickness 0.1mm and 99.999% high-purity argon protective atmosphere, SLM Process to prepare biological zinc alloy.

[0040] Microstructure tests found that after adding 0.3wt% zirconium and 0.8wt% aluminum to zinc, a fine lamellar eutectic structure was obtained, such as figure 1 As shown in c, the lamellar spacing is 0.51 μm. It is found through mechanical testing that the ultimate compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com