Decorative tile with diamond shining effect, colorful dry particles and preparation method of colorful dry particles

A technology for decorative bricks and diamonds, which is applied in the field of ceramics, can solve the problems of narrow application range, few research reports on crystallized art glaze, long firing cycle, etc., achieve shortening of time and temperature conditions, improve viewing effect, and distinctive color personality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

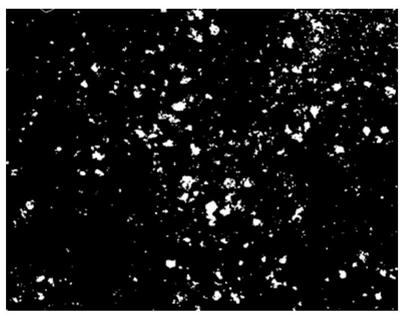

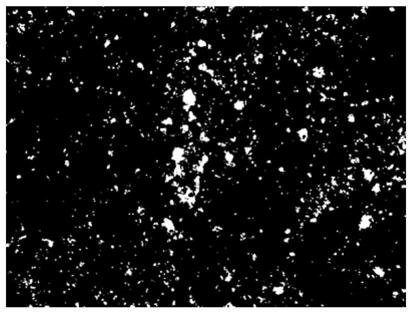

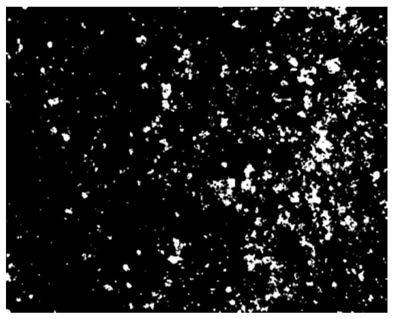

Image

Examples

preparation example Construction

[0021] Furthermore, the embodiment of the present invention provides a preparation method for preparing the above-mentioned diamond glitter effect colored dry particles, the preparation method mainly includes the following steps:

[0022] 1. Weigh the following raw materials: 0-15 parts of potassium sodium feldspar, 35-52 parts of quartz, 5-12 parts of calcite, 6-20 parts of dolomite, 0-6 parts of burnt talc, 4- 14 parts, 2-8 parts of borax, 0-5 parts of potassium nitrate, 6-12 parts of barium carbonate, 1-8 parts of soda ash, 1-5 parts of potassium dichromate, 2-5 parts of industrial copper oxide, 0- 4 parts, 0-6 parts of calcium phosphate, 0-3 parts of titanium dioxide, 0-4 parts of chromium oxide;

[0023] 2. Mix the above raw materials, melt and homogenize at 1450-1550°C, then heat-preserve and crystallize at 1350-1400°C, water quench, and dry to obtain frit;

[0024] 3. Pass the frit through different international sieves to obtain colored dry particles with diamond spar...

Embodiment 1

[0033] Implementation steps and process parameters of diamond flash effect colored dry glaze:

[0034] 1) The frit formula consists of: 47.5 parts of 325 mesh quartz, 8 parts of calcite, 8.5 parts of dolomite, 9 parts of industrial alumina, 5 parts of borax, 0.2 part of potassium nitrate, 10 parts of barium carbonate, 3.5 parts of soda ash, dichromic acid 3 parts of potassium, 2.5 parts of industrial copper oxide, 1.3 parts of fluorite, 1.5 parts of calcium phosphate;

[0035] 2) Melting homogenization temperature: 1500°C;

[0036] 3) Crystallization temperature: 1400°C;

[0037] 4) Range of dry granules and glaze amount: 12-40 mesh, 400g / 300×600 trays;

[0038] 5) Surface glaze slurry: The formulation of the surface glaze slurry used is: 30 parts of potassium feldspar, 15 parts of albite feldspar, 20 parts of quartz, 14 parts of kaolin 8 calcined alumina, 5 parts of calcite, 3 parts of wollastonite, silicon 12 parts of zirconium acid, appropriate amount of sodium carboxyme...

Embodiment 2

[0041] Implementation steps and process parameters of dry glaze with diamond glitter effect:

[0042] 1) The frit formula consists of: 48 parts of 325 mesh quartz, 10 parts of calcite, 10 parts of dolomite, 8.5 parts of industrial alumina, 4 parts of borax, 0.2 part of potassium nitrate, 8 parts of barium carbonate, 3.5 parts of soda ash, dichromic acid Potassium 3.5 parts, industrial copper oxide 3 parts, fluorite 0.5 parts, titanium dioxide 1 part;

[0043] 2) Melting homogenization temperature: 1530°C;

[0044] 3) Crystallization temperature: 1380°C;

[0045] 4) Dry granule range and glaze amount: 30-60 mesh, 265g / 300×600 trays;

[0046] 5) Surface glaze slurry: The composition of the surface glaze slurry used is: 25 parts of potassium feldspar, 20 parts of albite feldspar, 18 parts of quartz, 14 parts of kaolin 8 calcined alumina, 3 parts of calcite, 3 parts of wollastonite, dolomite Stone 2, 12 parts of zirconium silicate, appropriate amount of sodium carboxymethyl cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com