Preparation method of nitrogen doped super-large cavity carbon nanotube composite material

A carbon nanotube and composite material technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of uneven thickness of two-dimensional carbon nanosheet materials, low ion and electron transfer rate, and difficult to control the composition and structure. , to achieve the effects of good reactivity and catalytic activity, simple process, and enhanced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

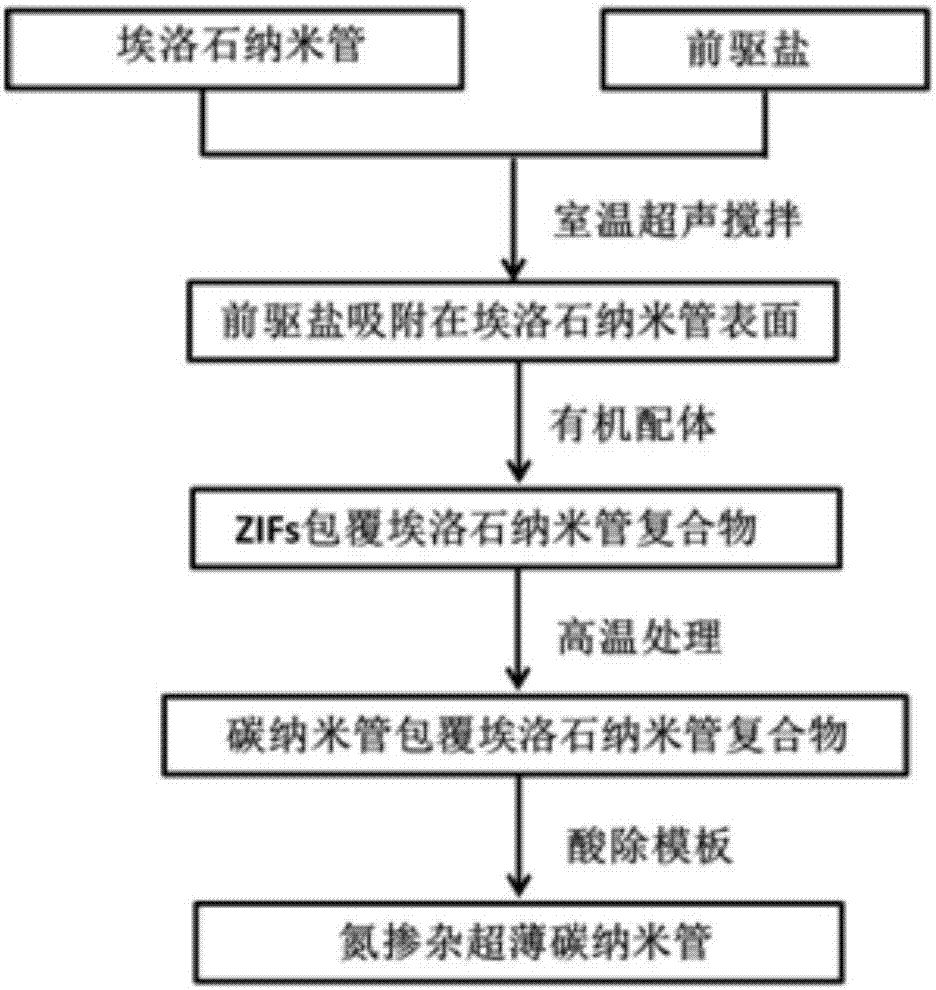

Method used

Image

Examples

Embodiment 1

[0039]Disperse 0.78g of halloysite nanotubes in 80mL cobalt nitrate ethanol solution (0.125M), first stir for 30 minutes and then sonicate for 30 minutes, then add 80mL dimethylimidazole methanol solution (0.5M), stir for 30 minutes and then static at room temperature After leaving for 24 hours, the reaction was completed, and the product was centrifuged and washed three times with ethanol, and dried at 60°C to obtain a ZIF-67-coated halloysite composite material. The composite material was heated to 800 °C in nitrogen flow, and the heating rate was controlled at 5 °C min -1 , and calcined for 2 hours to obtain a black solid powder. Finally, soak the material in hydrofluoric acid, filter and separate after reacting for 12 hours, wash with deionized water three times, and dry at 60°C to obtain ZIF-67 metal organic framework compound derived cobalt / nitrogen doped ultra-thin tube wall carbon nano tube (denoted as NCNT-1), its specific surface area is as high as 541m 2 g -1 , t...

Embodiment 2

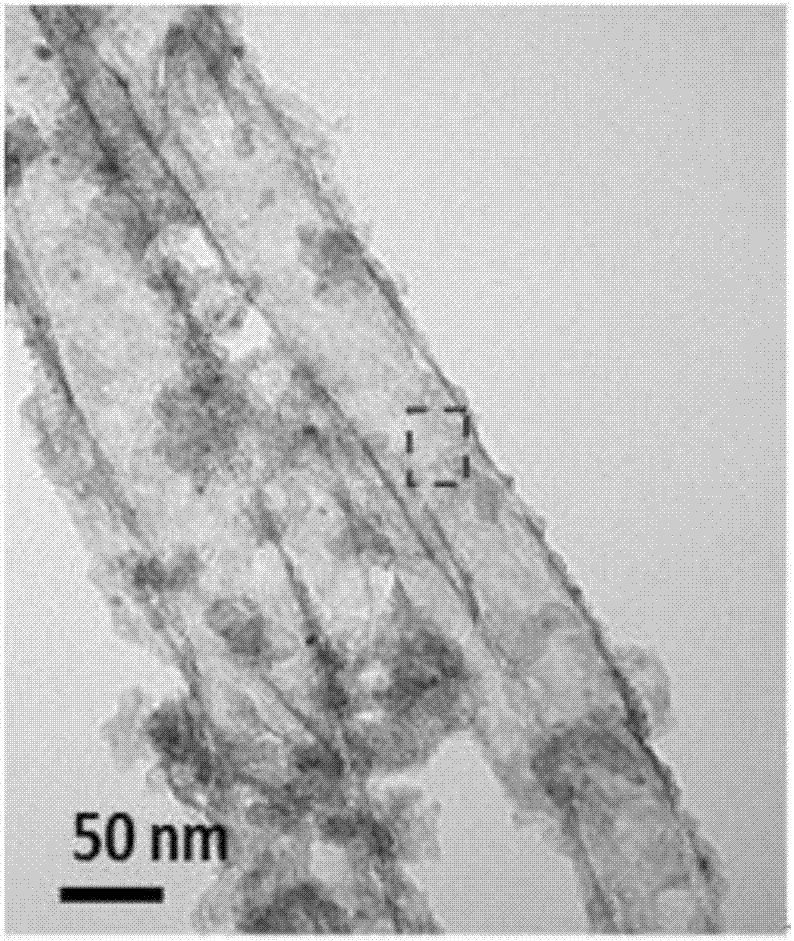

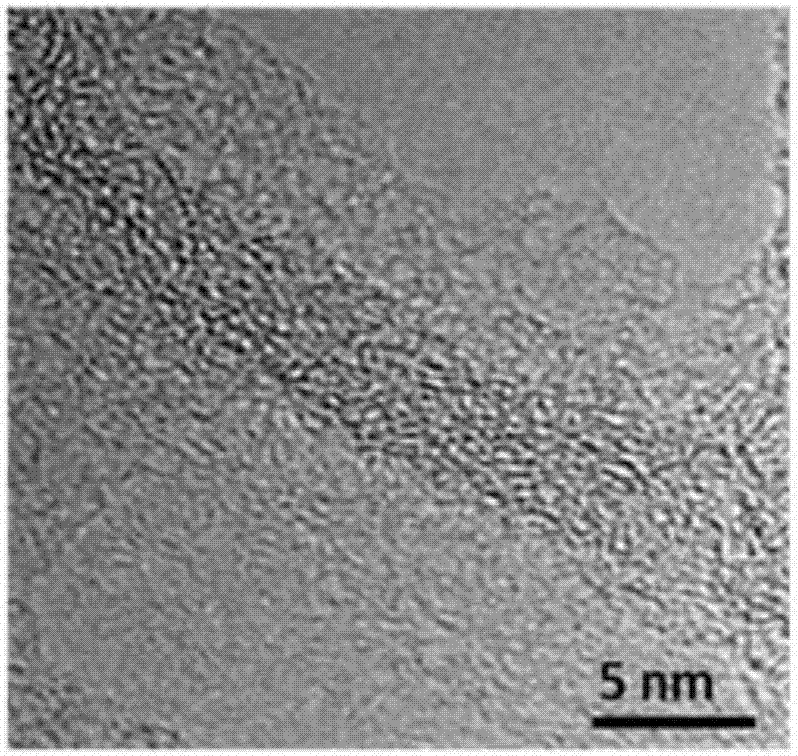

[0041] Disperse 0.78g of halloysite nanotubes in 80mL of zinc nitrate (0.125M) ethanol solution, first stir for 30 minutes and then sonicate for 30 minutes, then add 80mL of dimethylimidazole methanol solution (0.5M), stir for 30 minutes and then static at room temperature Set aside for 24 hours; after the reaction, the product was centrifuged and washed 3 times with ethanol, and dried at 60° C. to obtain ZIF-8 coated halloysite powder material. The powder material was heated to 800°C in a nitrogen stream, calcined for 2 hours, and the heating rate was controlled at 5°C min -1 , to obtain black solid powder. Finally, soak the powder in excess hydrofluoric acid, react for 12 hours, filter and separate, wash 3 times with deionized water, and dry at 60°C to obtain ZIF-8 metal-organic framework compound-derived nitrogen-doped ultra-thin tube-walled carbon nano Tube (marked as NCNT-2). Figure 4 Shown is the TEM photograph of NCNT-2. It can be seen from the figure that, compared...

Embodiment 3

[0043] Disperse 1.56g halloysite nanotubes in 80mL zinc nitrate (0.0625M) and cobalt nitrate (0.0625M) mixed ethanol solution, stir for 30 minutes, ultrasonic for 1 hour, then add 80mL dimethylimidazole methanol solution (0.5M), After stirring for 30 minutes, stand at room temperature for 24 hours; after the reaction, the product was centrifuged, washed with ethanol three times, and dried at 60°C to obtain a Zn / Co-ZIF-coated halloysite composite. The material was heated to 800°C in a nitrogen stream, calcined for 2 hours, and the heating rate was controlled at 5°C min -1 . Finally, soak the carbonized black solid powder in hydrofluoric acid, filter and separate after reacting for 12 hours, wash 3 times with deionized water, and dry at 60°C to obtain Zn / Co-ZIF metal organic framework compound derived cobalt / nitrogen doped Miscellaneous ultra-thin walled carbon nanotubes (referred to as NCNT-3). Figure 5 It is the TEM image of NCNT-3. It can be seen that the carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com