Technique for continuously preparing super fine nano powder by using precipitation method and its specialized equipment

A technology of ultra-fine nano and special equipment, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of difficult control of grain size and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

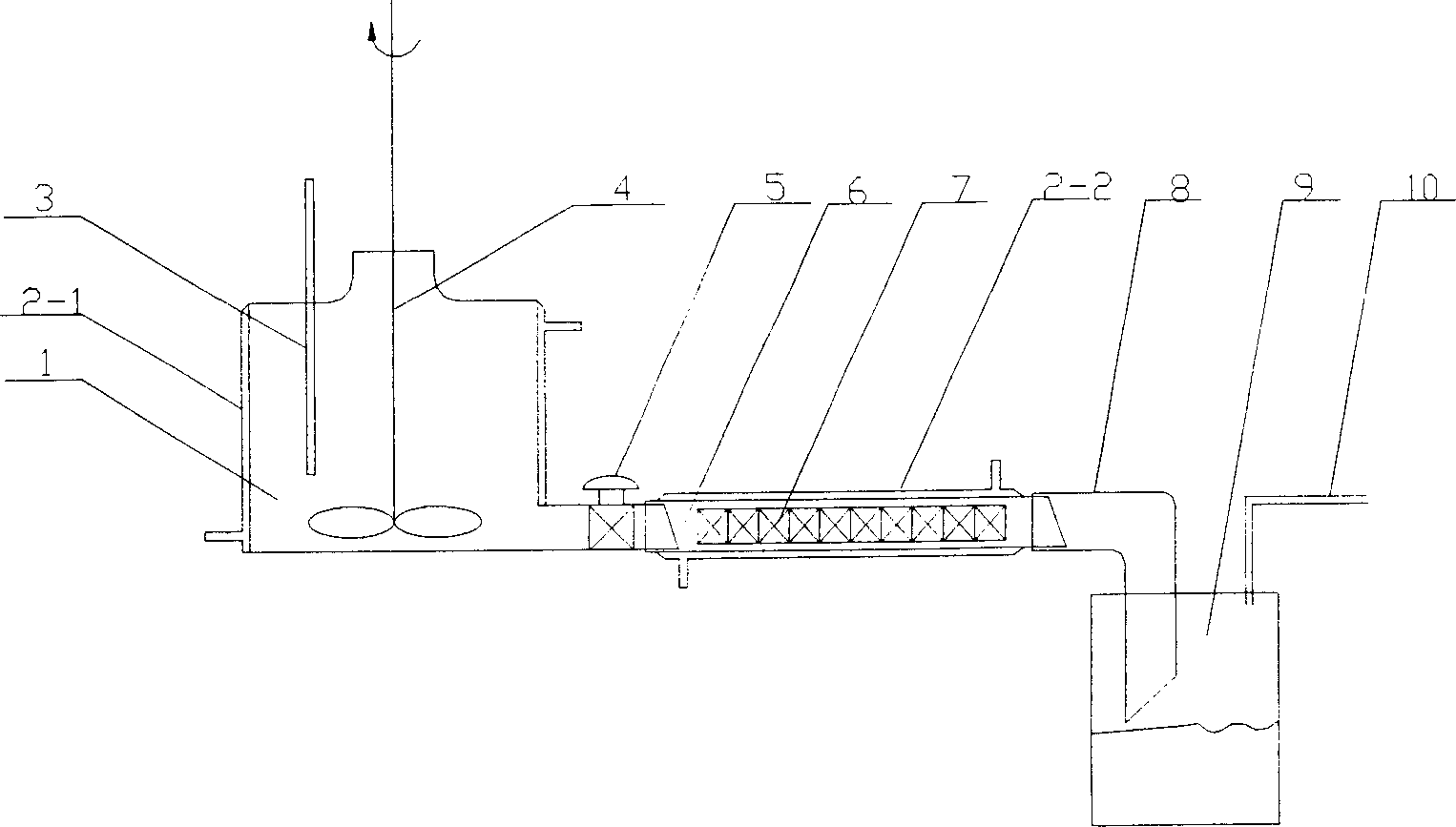

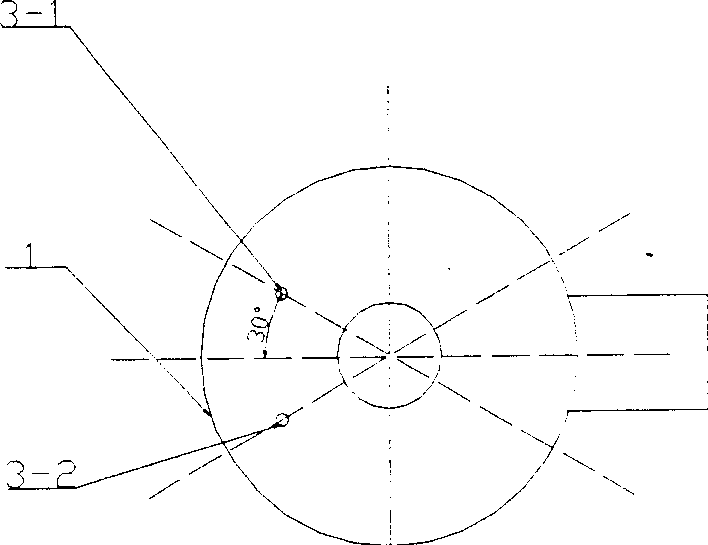

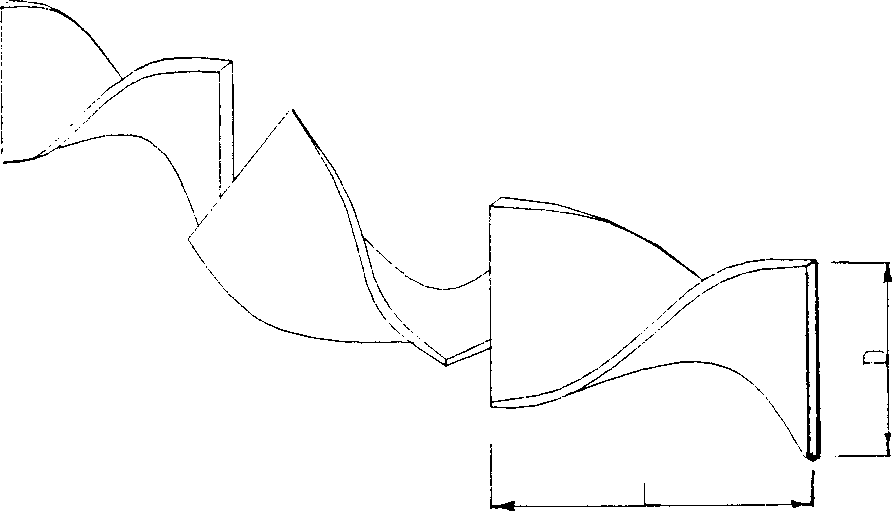

Method used

Image

Examples

specific Embodiment approach ) Embodiment 1

[0022] (specific implementation) the preparation of embodiment 1 superfine nickel powder

Embodiment 2

[0023] 20 kg nickel sulfate NiSO 4 ·6H 2 O was dissolved in deionized water to form a solution of 150 liters, which was heated to 80 °C and labeled as solution A. 9 kg of hydrazine and 4.8 kg of sodium hydroxide were dissolved in deionized water to form a solution of 150 liters, labeled as solution B. Solution A and solution B are added respectively in the reactor of the present invention with the flow rate of 1.25 liters / minute with metering pump. The temperature in the reactor was controlled to 80°C by passing constant temperature water through the jacket, and the stirring speed was 700 rpm. The temperature of the crystal growth tube is controlled at 60°C. The ammonia and nitrogen generated by the reaction are introduced into the ammonia absorption device through the vent tube, and the nitrogen is evacuated after the ammonia is absorbed. The nickel powder suspension flowing out of the feed pipe enters the product receiving tank, and is filtered, washed and dried to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com