Vapor phase preparation method of core-shell structure Cu / Ag nano alloy

A nano-alloy, core-shell structure technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy introduction of impurities, cumbersome process, difficult control, etc., and achieve good monodispersity , Simple operation, less error-prone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

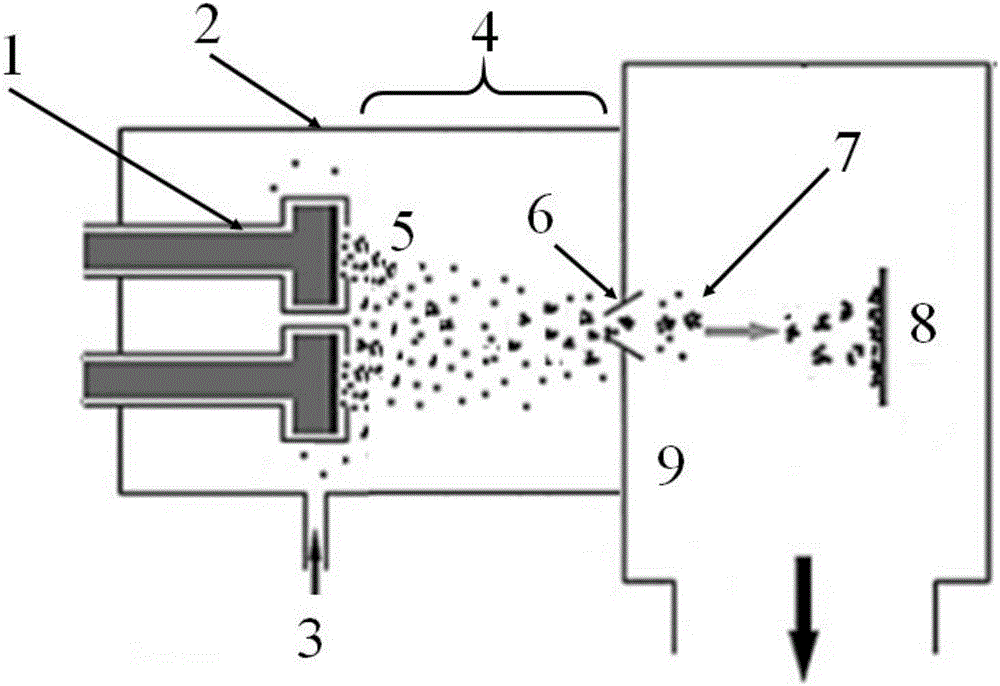

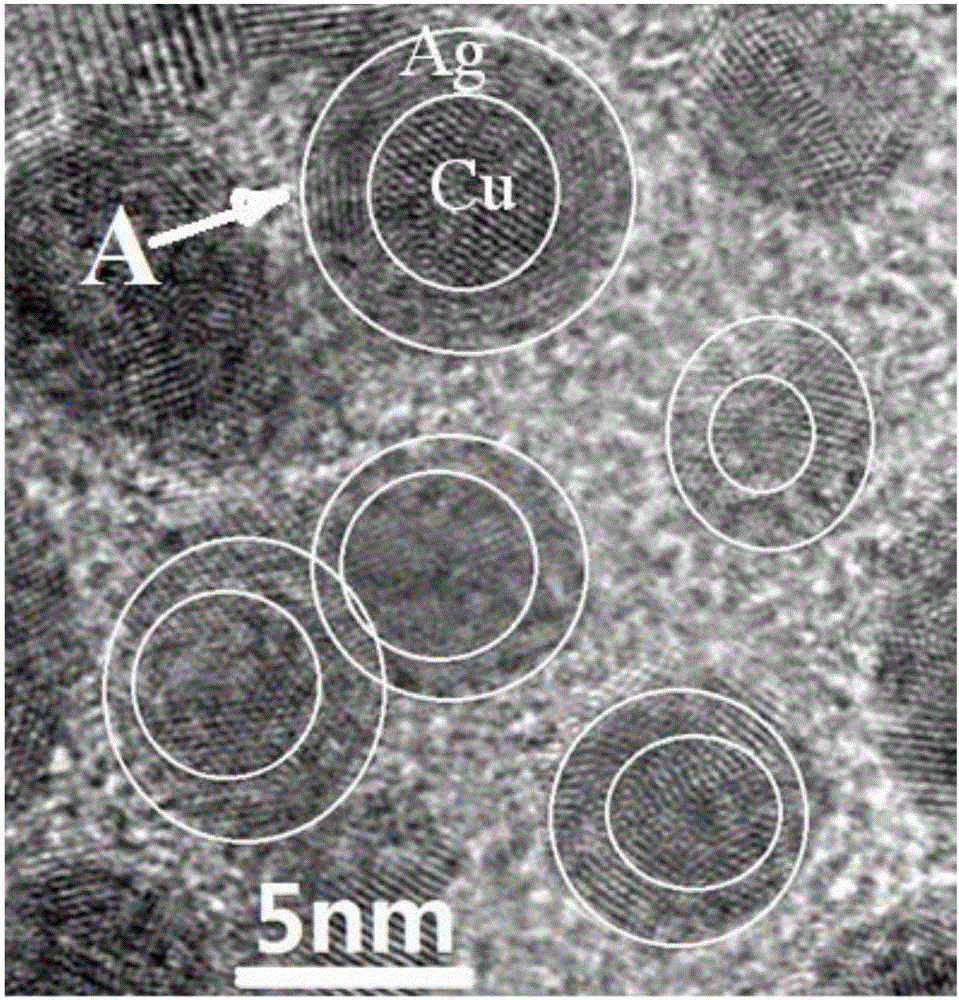

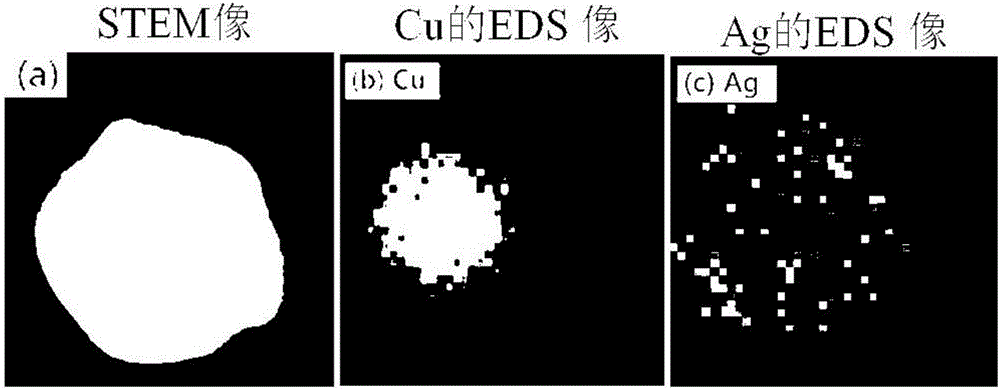

[0024] A preparation method of a core-shell structure nano-alloy, the core-shell structure Cu / Ag nano-alloy includes a Cu nano-core and an Ag nano-shell; the preparation method adopts such as figure 1 The shown dual-source gas cluster growth system includes the following steps:

[0025] A. Cluster growth of dual-source gas clusters: Inert buffer gas is introduced into the condensation chamber to maintain a constant pressure, and Cu and Ag single-substance targets are sputtered in the condensation chamber by magnetron sputtering, or Cu and Ag are simultaneously thermally evaporated through double crucibles powder to produce dense Cu and Ag atomic gas; Cu and Ag atoms nucleate and grow in the buffer gas atmosphere to form Cu and Ag clusters; Cu and Ag clusters flow with the buffer gas to the nozzle on the top of the condensation chamber and grow further. Formation of Cu / Ag nanoalloy clusters with core-shell structure;

[0026] B. Beam deposition: Cu / Ag clusters are ejected from...

Embodiment 1

[0031] Prepare Cu / Ag nano-alloy according to the above method, the inert gas adopts argon, and the metal atom gas is produced by double-target magnetron sputtering. The preparation method specifically includes the following steps:

[0032] A1. Double-target magnetron sputtering gas accumulation growth: Ar gas is introduced into the condensation chamber to maintain a constant pressure, and Cu and Ag single-substance targets are magnetron sputtered to generate dense Cu and Ag atomic gases; Cu and Ag atoms Nucleation and growth in the buffer gas atmosphere form Cu and Ag clusters; Cu and Ag clusters flow with the Ar buffer gas to the nozzle on the top of the condensation chamber and grow further to form Cu / Ag nano-alloy clusters with a core-shell structure.

[0033] B1. Beam deposition: the clusters are ejected from the nozzle to the high vacuum chamber with the Ar buffer gas to complete the growth, and form a directional cluster beam, which is deposited on the surface of the ultr...

Embodiment 2

[0036] The difference between this example and Example 1 is that the metal atom gas is produced by thermally evaporating Cu and Ag powders simultaneously in double crucibles, and the preparation method specifically includes the following steps:

[0037] A2. Dual-source thermal evaporation gas accumulation and growth: Ar gas is introduced into the condensation chamber to maintain a constant pressure, and the double crucible thermally evaporates Cu and Ag powder at the same time to produce dense Cu and Ag vapor; Cu and Ag atoms are in the buffer gas atmosphere Nucleation and growth form Cu and Ag clusters; Cu and Ag clusters flow with the Ar buffer gas to the nozzle on the top of the condensation chamber and grow further to form Cu / Ag nano-alloy clusters with a core-shell structure.

[0038] B2. Beam deposition: the clusters are ejected from the nozzle to the high vacuum chamber with the Ar buffer gas to complete the growth, and form a directional cluster beam, which is deposited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com