Method for preparing monolayer molybdenum disulfide

A single-layer molybdenum disulfide and silicon dioxide technology is applied in coatings, gaseous chemical plating, and metal material coating processes. Danger, effect of simplifying the heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

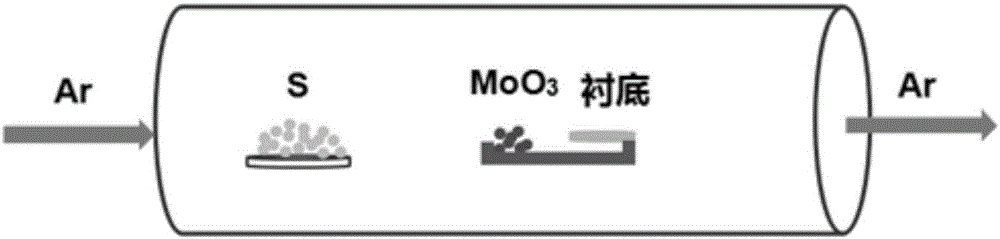

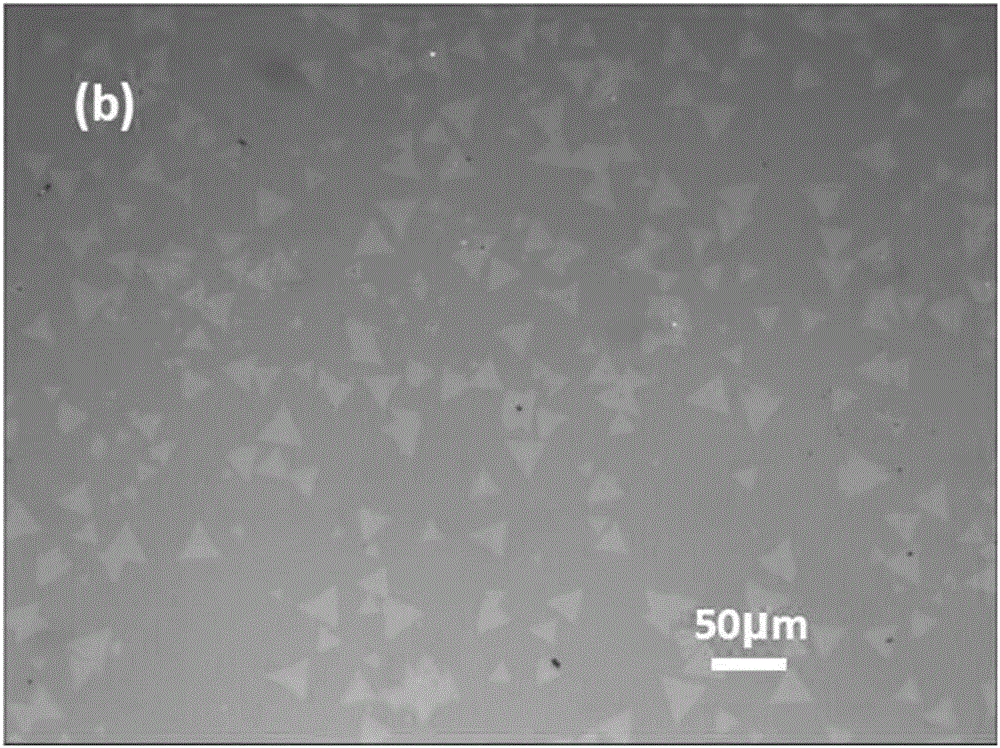

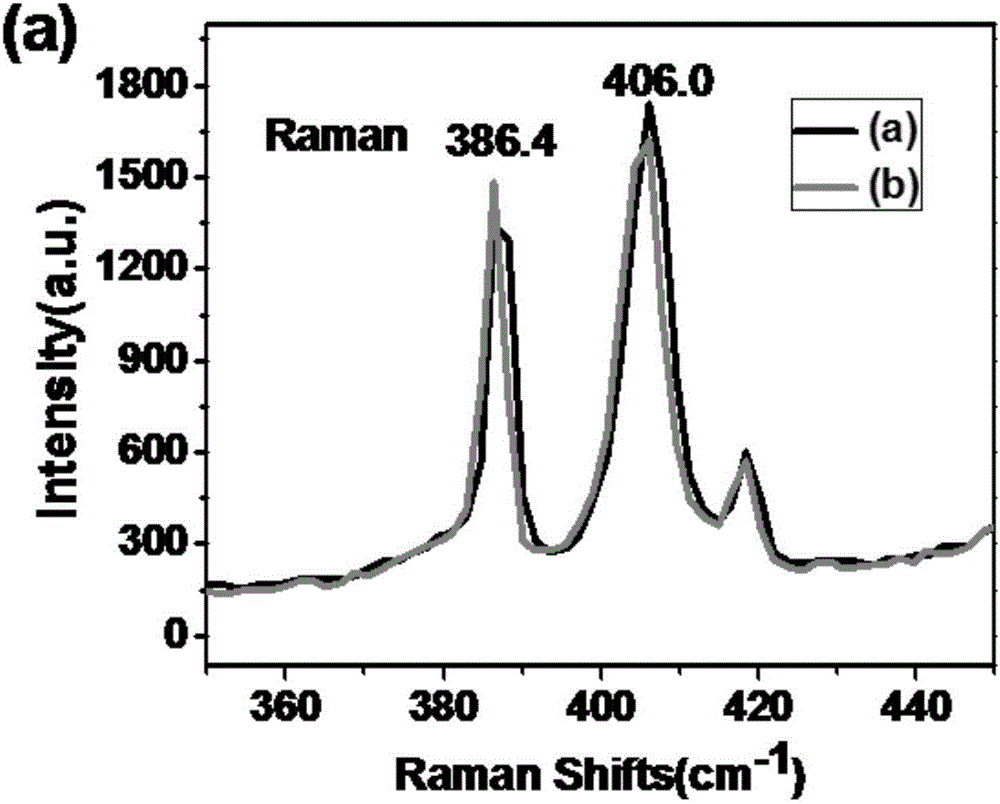

Embodiment 1

[0025] Atmospheric pressure chemical vapor deposition method is adopted; a certain mass of sulfur powder 0.2g and molybdenum trioxide powder 0.01g is weighed, and placed in two quartz boats; the cleaned silicon dioxide / silicon substrate is placed face down in three In the quartz boat of molybdenum oxide powder, 1cm downstream of the molybdenum source, and place it in the high temperature zone in the middle of the tube furnace, place the quartz boat containing the sulfur powder in the low temperature zone at the front of the tube furnace; before heating, First pass nitrogen gas for 15 minutes at a flow rate of 250 sccm to discharge the air in the tube furnace, then continue to feed nitrogen gas with a flow rate of 75 sccm as a protective atmosphere, start heating, heat the tube furnace to a temperature of 800°C within 25 minutes, and then maintain this temperature Molybdenum disulfide was grown for 40 minutes; after the growth was over, 50 sccm of nitrogen gas was continued to f...

Embodiment 2

[0027] Atmospheric pressure chemical vapor deposition method is adopted; a certain mass of sulfur powder 0.2g and molybdenum trioxide powder 0.01g is weighed, and placed in two quartz boats; the cleaned silicon dioxide / silicon substrate is placed face down in three In the quartz boat of molybdenum oxide powder, 1.5cm downstream of the molybdenum source, and place it in the high temperature zone in the middle of the tube furnace, and place the quartz boat containing the sulfur powder in the low temperature zone at the front of the tube furnace; before heating First pass nitrogen gas for 25 minutes at a flow rate of 200 sccm, discharge the air in the tube furnace, then continue to feed nitrogen gas with a flow rate of 65 sccm as a protective atmosphere, start heating, heat the tube furnace to a temperature of 820°C within 35 minutes, and then keep it Molybdenum disulfide was grown at a temperature of 35 minutes; after the growth was completed, 70 sccm of nitrogen was continued to...

Embodiment 3

[0029] Atmospheric pressure chemical vapor deposition method is adopted; 0.2g of sulfur powder and 0.02g of molybdenum trioxide powder are weighed and placed in two quartz boats; In the quartz boat of molybdenum oxide powder, 2.5cm downstream of the molybdenum source, and place it in the high temperature zone in the middle of the tube furnace, place the quartz boat containing the sulfur powder in the low temperature zone at the front of the tube furnace; before heating First pass nitrogen gas for 25 minutes at a flow rate of 200 sccm, discharge the air in the tube furnace, then continue to feed nitrogen gas with a flow rate of 65 sccm as a protective atmosphere, start heating, heat the tube furnace to a temperature of 790°C within 35 minutes, and then maintain this temperature Molybdenum disulfide was grown at a temperature of 35 minutes; after the growth was completed, 70 sccm of nitrogen was continued to be introduced, and the tube furnace was naturally lowered to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com