Monoatomic dispersed MXene materials and applications in lithium battery negative electrodes

An atomic dispersion, negative electrode technology, applied in the direction of negative electrode, battery electrode, lithium battery, etc., can solve the problems of poor cycle performance, battery short circuit, low volume capacity, etc., to achieve long deep dissolution deposition performance, good cycle life, long The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

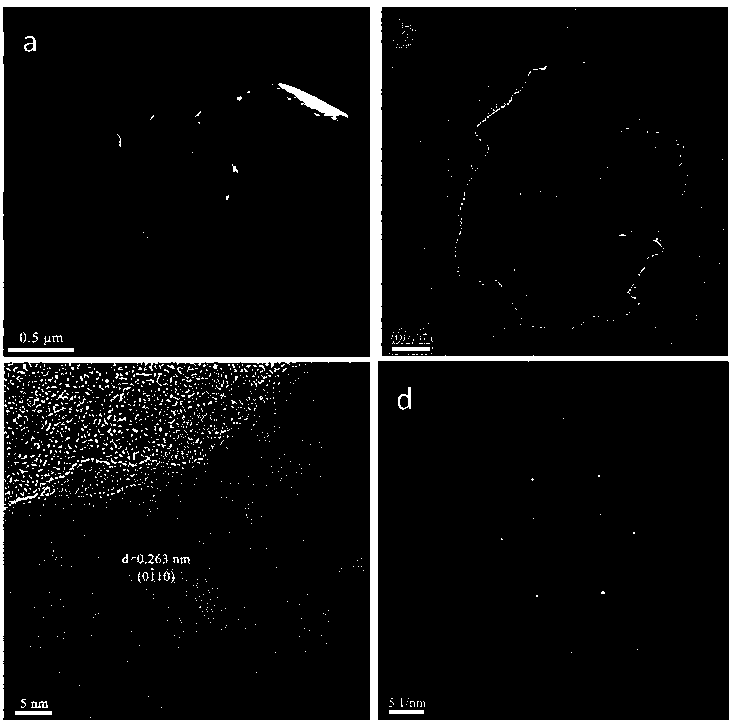

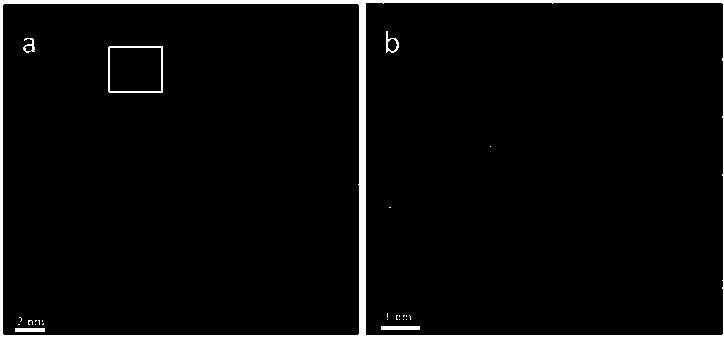

[0043] This embodiment provides a preparation method for preparing a single Zn atom dispersed MXene material, wherein the MXene material is based on Ti 3 C 2 Cl 2 Illustrate the present invention as an example, comprising the following steps:

[0044] Step 1): Add MAX-Ti with a mass ratio of 1:4 3 AlC 2 and ZnCl 2 The powders were evenly mixed, and ball milled for 6h under an argon atmosphere to make Ti 3 AlC 2 and ZnCl 2 Can be fully and uniformly mixed to obtain a mixture of the two;

[0045] Step 2): Put the mixture obtained in step 1) into a tube furnace filled with argon, heat up to 550°C and keep it warm for 10h. The purpose is to generate cation vacancies in the MXene plane, so that Zn atoms can replace Ti atoms, and the reaction After completion, drop to normal temperature and take out to obtain the reactant;

[0046] Step 3): Disperse the reactant obtained in step 2) in 2M hydrochloric acid and sonicate for 10 hours, then filter with suction and wash with arg...

Embodiment 2

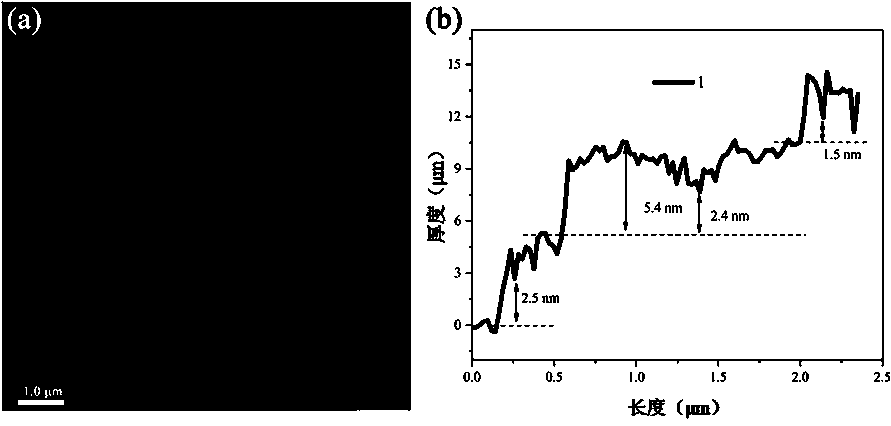

[0053] This embodiment provides a base material containing MXene material, including a dispersion layer and a matrix layer, the dispersion layer is on the surface of the matrix layer, the present embodiment contains the Zn-MXene prepared in Example 1 in the dispersion layer, and the matrix layer Taking copper foil as an example to illustrate, the schematic diagram of the preparation method of the substrate is as follows Figure 4 As shown in a, including steps: configure Zn-Mxene to a concentration of 1mg ml -1 The dispersion liquid is sprayed on the surface of the copper foil with a nozzle, and a heating platform with a constant temperature of 40°C is set under the copper foil to accelerate the evaporation of water on the surface of the copper foil, forming a Zn-MXene film as a dispersion layer, and finally obtained The substrate is a copper foil composite material containing Zn-MXene film (such as Figure 4 shown in b), the Zn-MXene film is a dispersed layer, and the compos...

Embodiment 3

[0056] This embodiment provides a metal lithium negative electrode, which is prepared by depositing metal lithium in a two-electrode system, wherein the metal lithium is the counter electrode, the Zn-MXene film prepared in Example 2 is used as the working electrode, and the electrolyte It is a solution of 1M LiTFSI, and the solvent is 1,3-dioxolane (DOL): ethylene glycol dimethyl ether (DME) = 1:1. Figure 7 gives a current density of 50 μA cm -2 Below, the voltage-capacity curves of deposited lithium on Zn-MXene film, MXene film and Cu foil, from which it can be seen that Zn-MXene film has the lowest overpotential (11.3 mV), compared with the overpotential of MXene film and Cu foil samples The potentials are 15.4 mV and 26.3 mV, respectively, indicating that the energy barrier for lithium deposition on the surface of the Zn-MXene film is the lowest, and metal lithium is more likely to form a uniformly dispersed deposited lithium layer on the Zn-MXene film.

[0057] The metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com