Flexible strontium titanate nanofiber-based composite thermoelectric thin film and preparation method thereof

A thermoelectric thin film and fiber-based technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problems of flexible thermoelectric films that are not resistant to high temperatures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

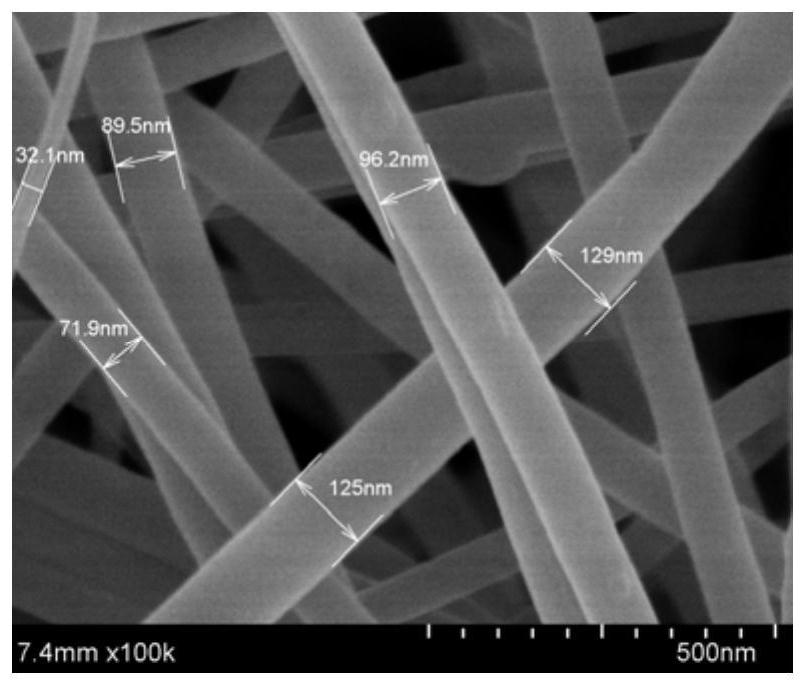

[0041] (1) Preparation of strontium titanate precursor gel fiber film: 1) Weigh 0.5g PVP (Anaiji, molecular weight 1300000), dissolve it in the mixed solution of water, ethanol and acetic acid (the volumes are 1, 6.35, 3.8ml, the addition of acetic acid is to control the subsequent hydrolysis of tetrabutyl titanate), magnetically stirred for 2 hours, added 286mg of strontium acetate (McLean, AR, 99%), stirred for 2 hours until completely dissolved, and finally added dropwise 473 μL of tetrabutyl titanate (Aladdin, CP, 98.0%) was reacted for 3 hours to prepare a spinning solution. 2) The spinning solution configured above was prepared by electrospinning into a strontium titanate precursor gel fiber film, and the spinning conditions were as follows: the applied voltage was 19kV, the feed rate was 0.2mL / h, and the fiber was coated with silicone oil The paper is received on a flat plate, the distance between the spinneret and the receiving plate is 15 cm, and the air humidity is a...

Embodiment 2

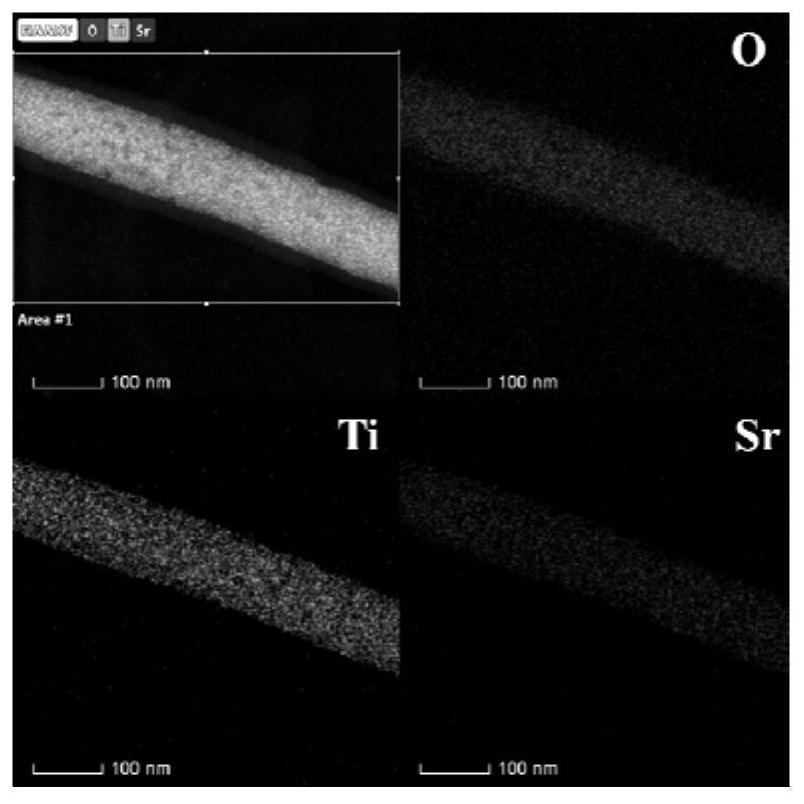

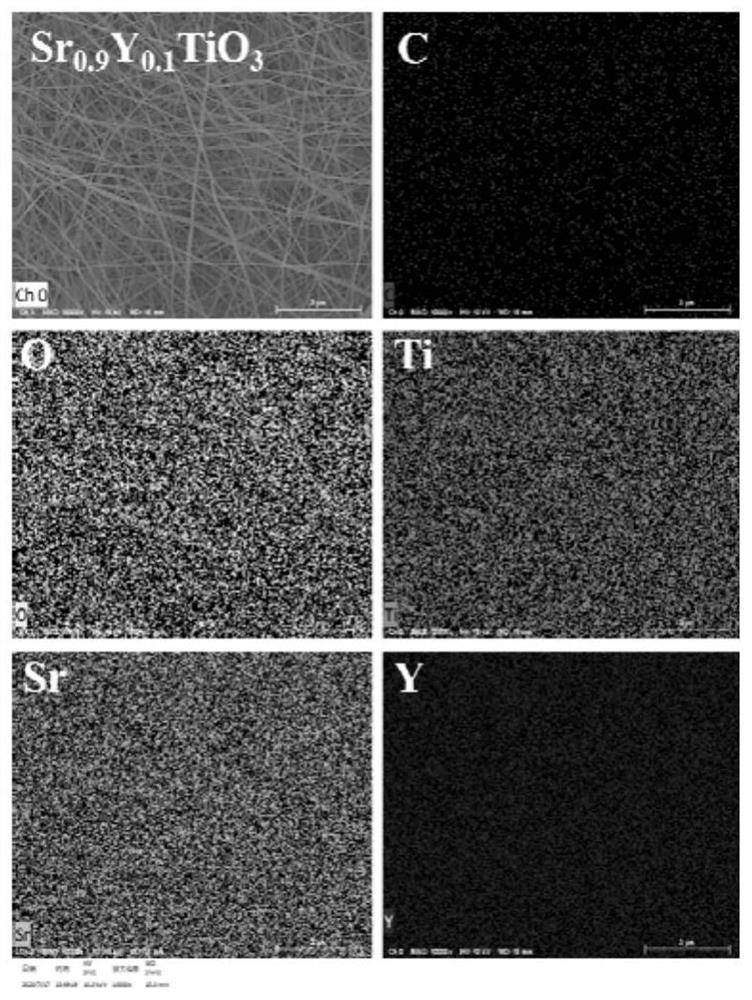

[0044] (1) Preparation of strontium titanate precursor gel fiber film doped with yttrium element: 1) Weigh 0.5g PVP (Anaiji, molecular weight 1300000), dissolve it in the mixed solution of water, ethanol and acetic acid (the volumes are respectively 1, 6.35, 3.8ml, the addition of acetic acid is to control the subsequent hydrolysis of tetrabutyl titanate), magnetic stirring for 2 hours, adding 257mg of strontium acetate (McLean, AR, 99%) and 47mg of yttrium acetate (Anaiji , REO, 99.99%), stirred for 2 hours until completely dissolved, and finally added dropwise 473 μL of tetrabutyl titanate (Aladdin, CP, 98.0%), and reacted for 3 hours to prepare a spinning solution. 2) The spinning solution configured above was prepared by electrospinning into a strontium titanate precursor gel fiber film, and the spinning conditions were as follows: the applied voltage was 17kV, the feed rate was 0.5mL / h, and the fiber was coated with silicone oil. The paper is received on a roll, the roll ...

Embodiment 3

[0047] (1) Preparation of strontium titanate precursor gel fiber film doped with lanthanum element: 1) Weigh 0.5g PVP (molecular weight 1300000), dissolve it in the mixed solution of water, ethanol and acetic acid (volumes are 1, 6.35, 3.8ml, the addition of acetic acid is in order to control the subsequent hydrolysis of tetrabutyl titanate), after magnetic stirring for 2 hours, add 257mg strontium acetate (McLean, AR, 99%) and 30mg lanthanum acetate (McLean, metals basis, 99.99 %), continue to stir for 2 hours until completely dissolved, and finally add 473 μL of tetrabutyl titanate (Aladdin, CP, 98.0%) dropwise, and react for 3 hours to form a spinning solution. 2) Electrospinning the above-mentioned spinning solution to prepare a strontium titanate precursor gel fiber film, the spinning conditions are as follows: the applied voltage is 20kV, the feed rate is 1mL / h, and the fiber is coated with silicone oil paper Receive on the drum, the rotating speed of the drum is 60rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power factor | aaaaa | aaaaa |

| Power factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com