Preparation method of nano-cuprous oxide

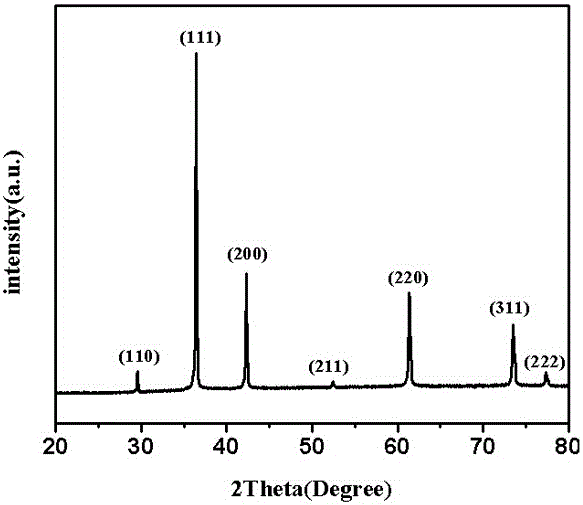

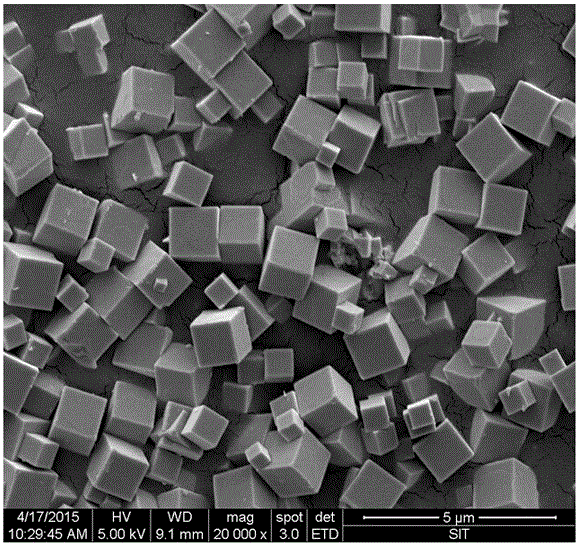

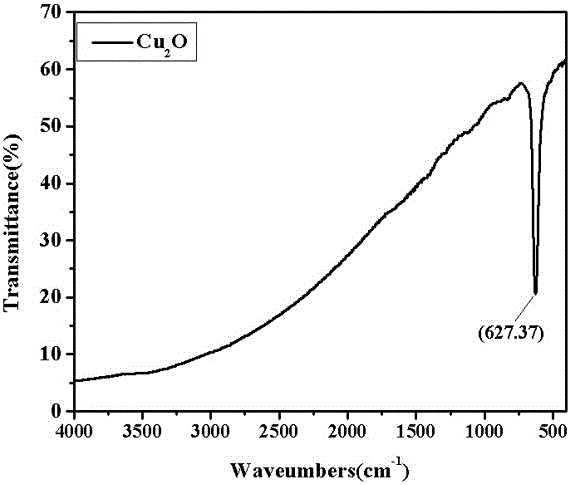

A nano-cuprous oxide solution technology, which is applied in the chemical industry, can solve the problems of uneven particle size and unstable performance of nano-cuprous oxide, and achieve the effects of good dispersion, uniform appearance, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of nano-cuprous oxide is completed according to the following steps:

[0023] (1) CuCl 2 Completely dissolved in deionized water to prepare CuCl 2 solution;

[0024] (2) Control a certain temperature, add additives, stir to make it evenly dispersed in CuCl 2 in solution;

[0025] (3) Add 1.0mol / L NaOH solution dropwise to adjust CuCl 2 Solution pH;

[0026] (4) Add 0.04 g / mL freshly prepared KBH dropwise to the above solution 4 solution, reacted for 4h;

[0027] (5) After the reaction is completed, leave it at room temperature for aging, centrifuge, wash, and dry to obtain dark red Cu 2 O powder.

[0028] CuCl in the present embodiment step (1) 2 The solution concentration is 0.02mol / L.

[0029] The temperature of the water bath in steps (2)(3)(4) of this embodiment is 50-90°C.

[0030] In the present embodiment step (2), the surfactant consumption is every milliliter of CuCl 2 The solution uses 0.0025-0.01 g of a self-made additive for ...

Embodiment 2

[0035] A kind of preparation method of nano cuprous oxide is carried out according to the following steps: (1) take by weighing 3.40gCuCl 2 ?H 2 O is completely dissolved in 200mL of deionized water and prepared as CuCl with a molar concentration of 0.02mol / L 2 solution; (2) under the condition of 70°C water bath, add 1.0 g of homemade additives for adjusting surface tension based on polyvinylpyrrolidone, and stir at a constant speed with a magnetic stirrer until the additives are completely dissolved in CuCl 2 solution, and then continue to stir for 20min; (3) dropwise add 1.0mol / L NaOH solution, adjust CuCl 2 Solution pH, make the solution pH in the range of 4.6-5.0, dropwise adding time 20min; (4) After adding NaOH dropwise, after stirring for 10min, add 0.04g / mL freshly prepared KBH dropwise 4 Solution 10mL, dripping time 20min; continuous 70℃ water bath, stirring at a constant speed for 4h; (5) after the reaction is completed, stand at room temperature and age for 0.5h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com