Electrolyte system using pulse-electrodeposition method to prepare superfine magnetic metal powder

A technology of magnetic metal powder and electrodeposition method, which is applied in the field of electrolyte system for preparing ultra-fine magnetic metal powder by pulse-electrodeposition method, which can solve the problems of difficulty in the preparation of metal single substance, many impurities in ultra-fine powder, and slow reaction process, etc. , to achieve the effects of controlling nucleation growth, improving dispersion energy, yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) The present embodiment provides an electrolyte system for preparing ultrafine magnetic iron powder by a pulse-electrodeposition method, which specifically includes the following steps:

[0035] First, in the tank-type stirring equipment, use deionized water to configure ferrous sulfate solution, then add boric acid, and finally add povidone and thiourea;

[0036] (2) The electrolyte system composition that makes: ferrous ion concentration is 1mol / L, and the concentration of boric acid is 5g / L in the electrolyte system, and the concentration of povidone and thiourea is respectively 0.5g / L in the electrolyte system , 3g / L;

[0037] (3) The operation steps of preparing ultrafine magnetic iron powder by using the electrolyte system are as follows:

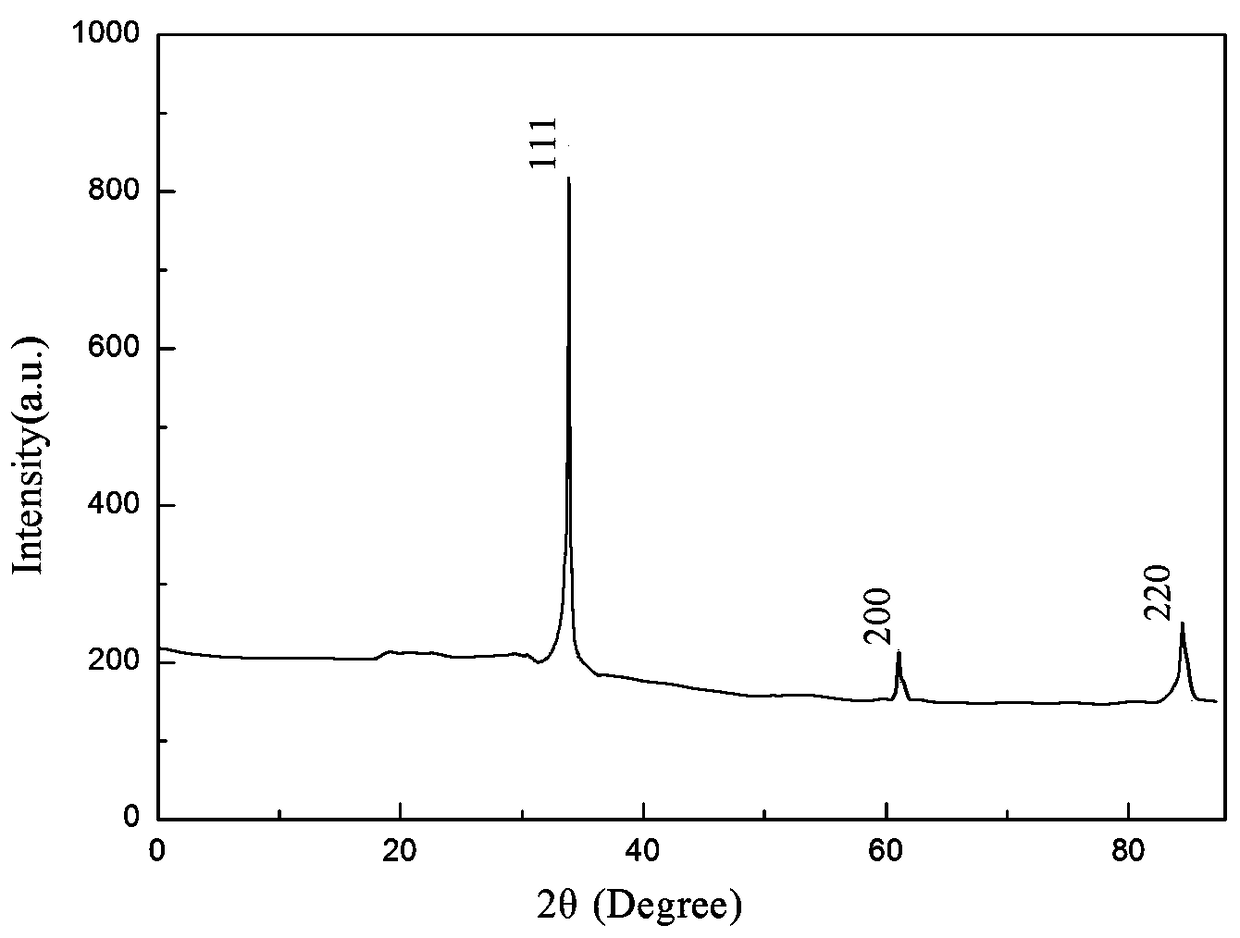

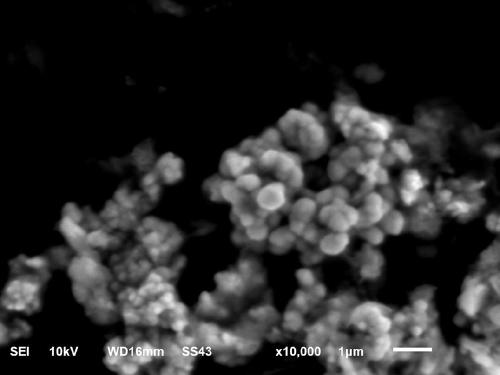

[0038] S1. Electrodeposition process: use an iron plate as the anode and stainless steel as the cathode, and the surface roughness of the cathode material is 9 μm. Place it in the above electrolyte system, and electrodeposi...

Embodiment 2

[0042] (1) The present embodiment provides an electrolyte system for preparing ultrafine magnetic iron powder by a pulse-electrodeposition method, which specifically includes the following steps:

[0043] Firstly, in the tubular mixing equipment, use deionized water to configure ferrous sulfate solution, then add sodium citrate, and finally add povidone and thiourea;

[0044] (2) The electrolyte system composition that makes: ferrous ion concentration is 1mol / L, and the concentration of sodium citrate in the electrolyte system is 5g / L, and the concentration of povidone and thiourea is respectively 8g / L in the electrolyte system L, 2g / L;

[0045] (3) Refer to Example 1 for the operation steps of preparing ultrafine magnetic iron powder using the electrolyte system.

Embodiment 3

[0047] (1) The present embodiment provides an electrolyte system for preparing ultrafine magnetic nickel powder by a pulse-electrodeposition method, which specifically includes the following steps:

[0048] First, in the tank-type stirring equipment, use deionized water to configure nickel sulfate solution, then add boric acid, and finally add sodium lauryl sulfate and γ-aminopropyltriethoxysilane;

[0049] (2) Composition of the prepared electrolyte system: the concentration of nickel ions is 0.5mol / L, the concentration of boric acid in the electrolyte system is 10g / L, sodium lauryl sulfate and γ-aminopropyl triethyl The concentrations of oxysilane are 5g / L and 12g / L respectively;

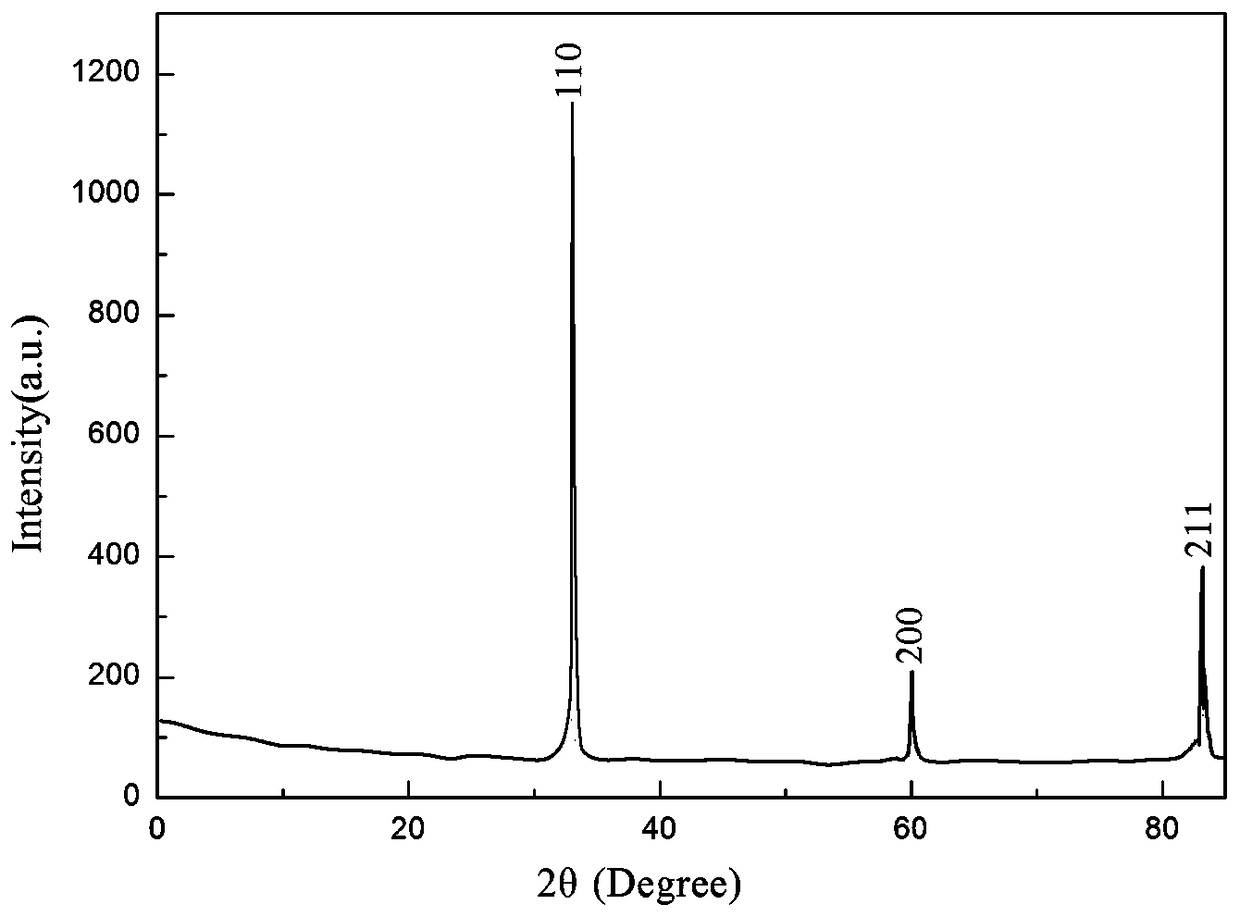

[0050] (3) The operation steps of preparing superfine magnetic nickel powder by adopting the electrolyte system are as follows:

[0051]S1. Electrodeposition process: use a nickel plate as the anode and a titanium plate as the cathode, and the surface roughness of the cathode material is 8 μm, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com