Patents

Literature

245results about How to "Enable mass manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

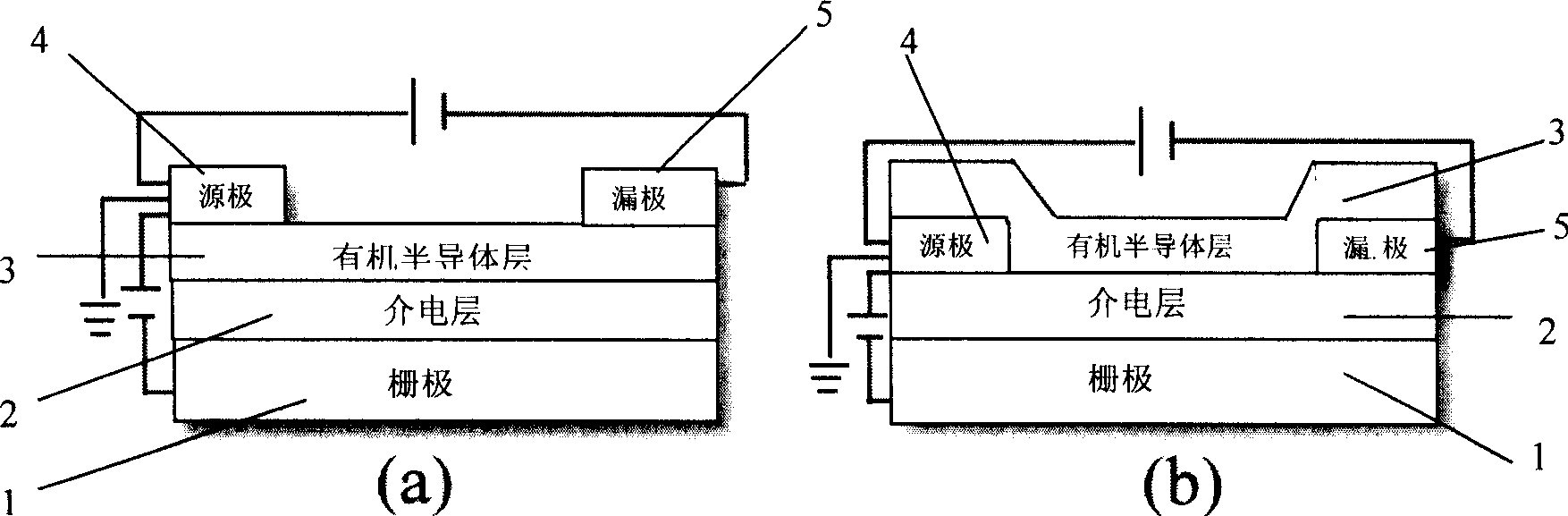

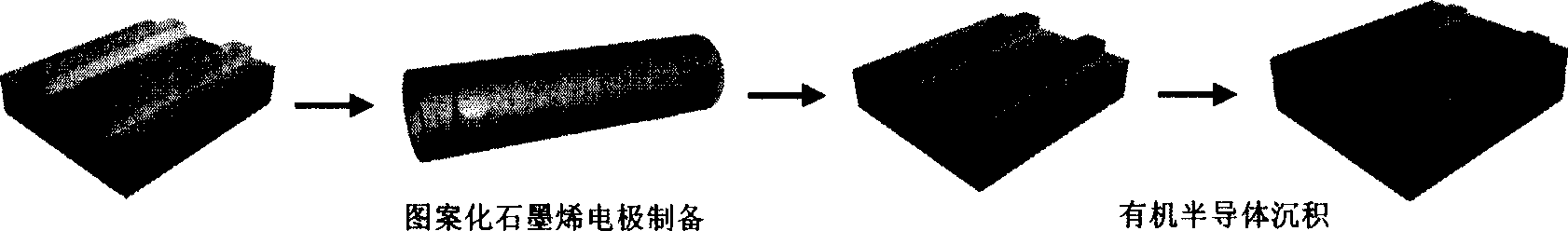

Organic field effect transistor and special source/drain electrode and preparation method thereof

InactiveCN101442105ALow costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorGas phase

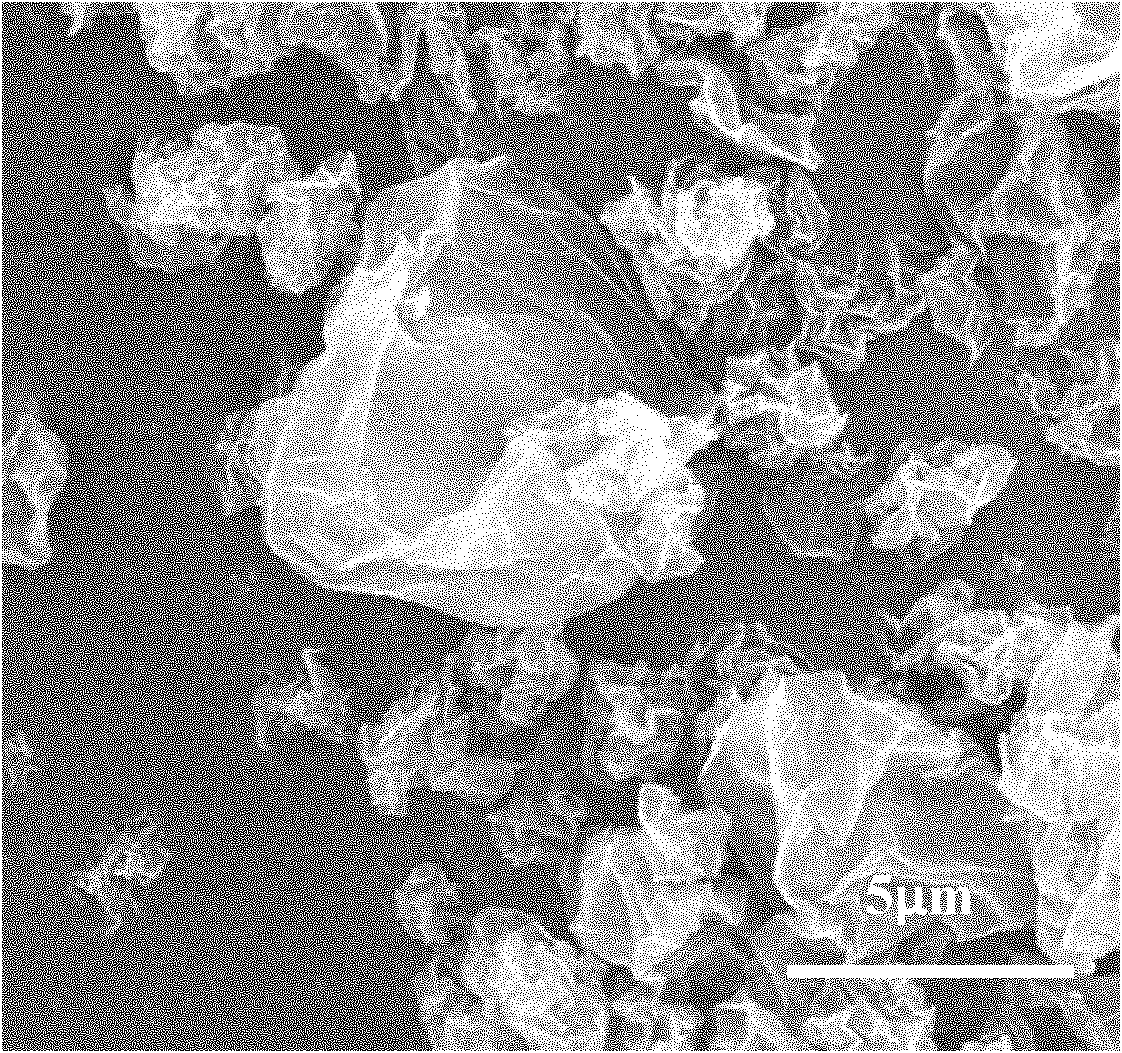

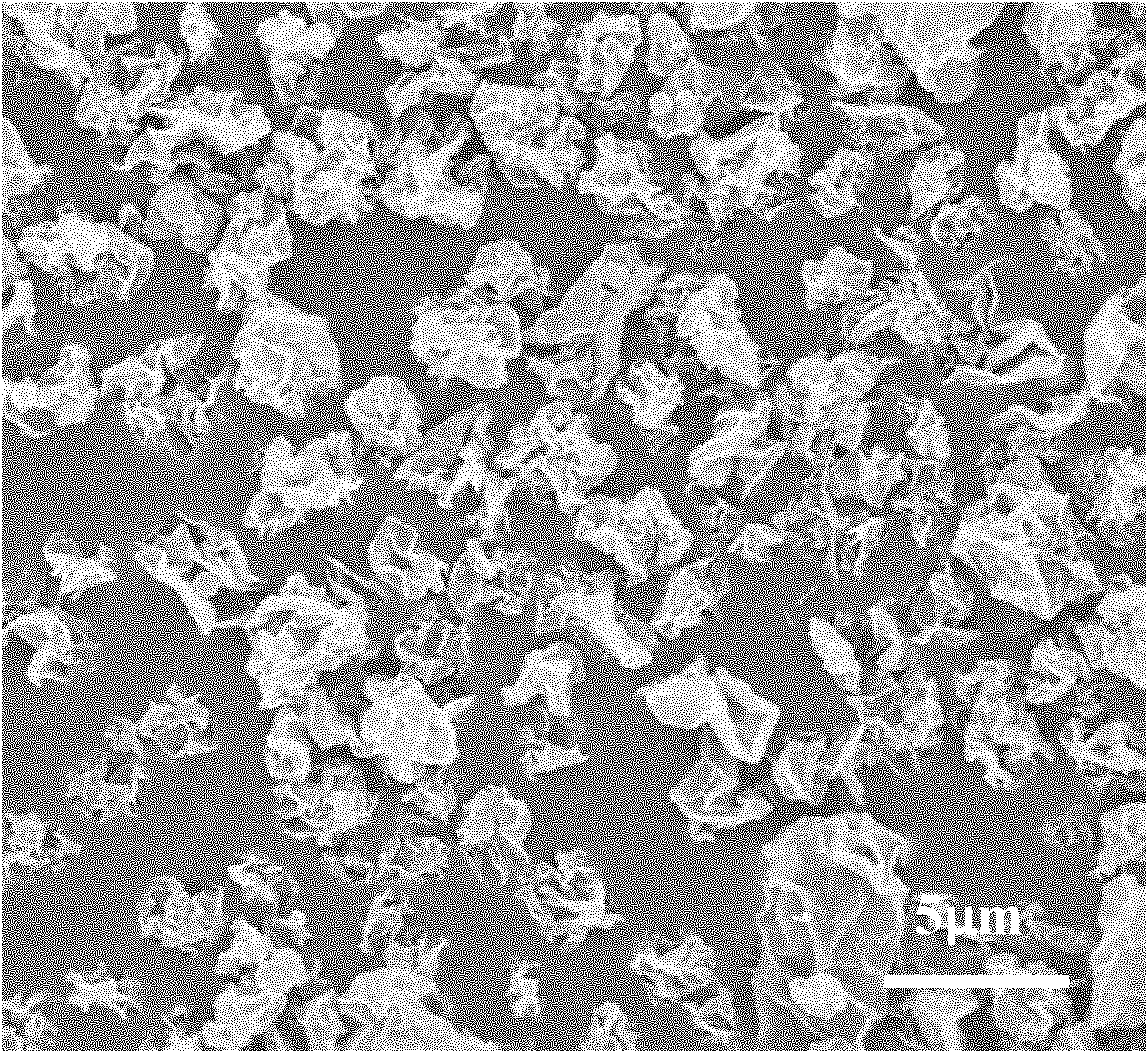

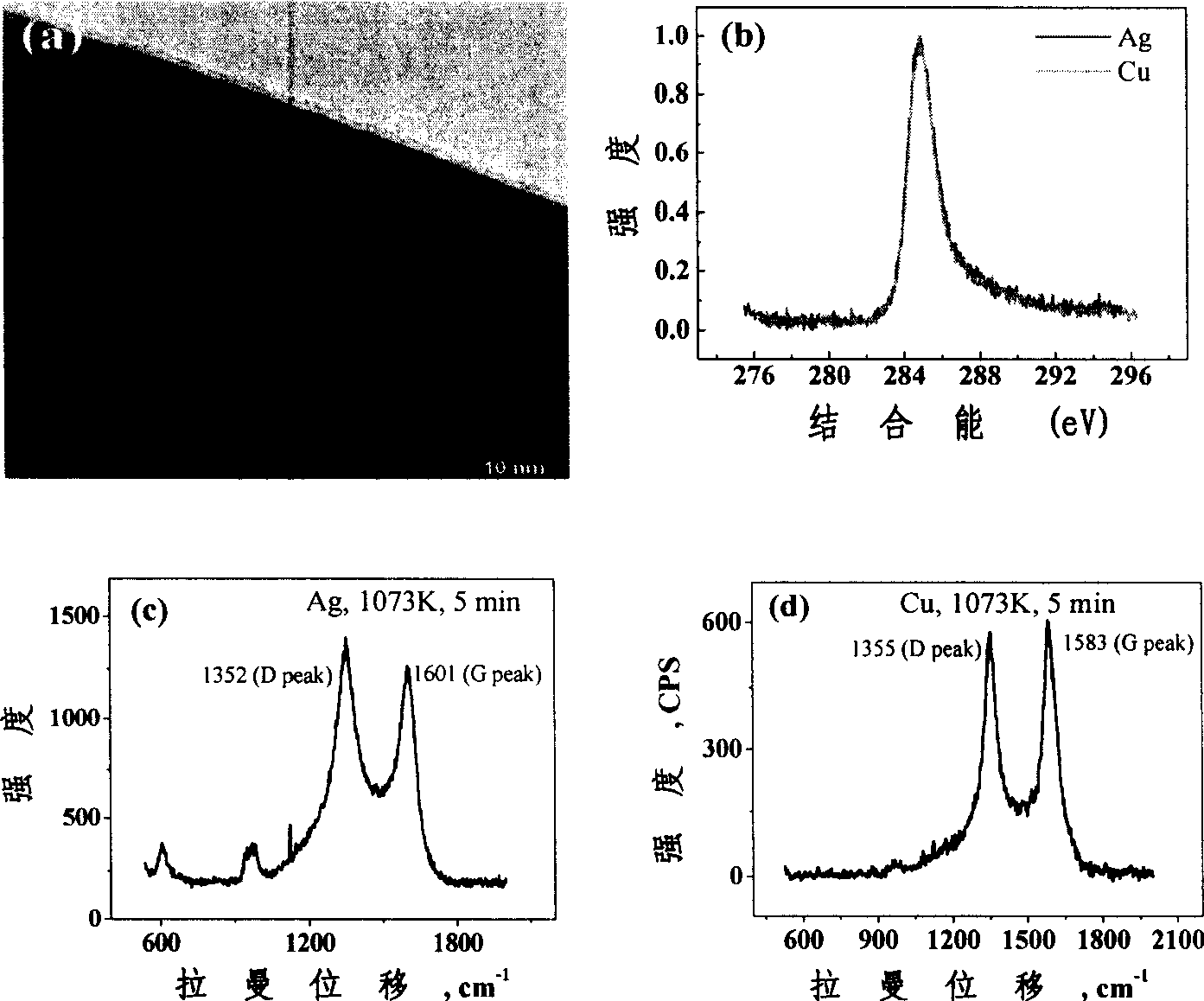

The invention discloses an organic field effect transistor (FET), as well as a special source-drain electrode and a preparation method thereof. The organic FET with an electrode structure comprises a gate electrode, a dielectric layer, an organic semiconductor layer, a source electrode and a drain electrode, wherein the source electrode and the drain electrode are patterned Graphene electrodes. The method for preparing the patterned Graphene electrodes comprises the following steps: 1) a metal film is deposited on a substrate and is patterned; and 2) the substrate on which the patterned metal film is deposited is placed in a chemical vapor deposition system, and chemical vapor Graphene deposition is performed on the surface of a patterned metal electrode material, so as to obtain the patterned Graphene electrodes, wherein a carbon source used in chemical vapor deposition is methanol, ethanol, propanol, pentanol, benzene, toluene, xylene, methane and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

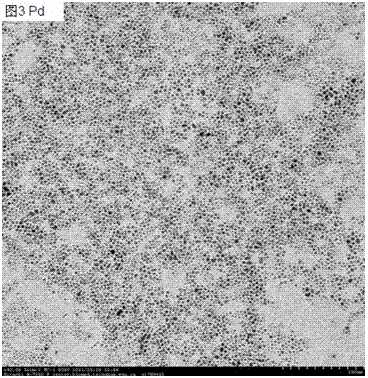

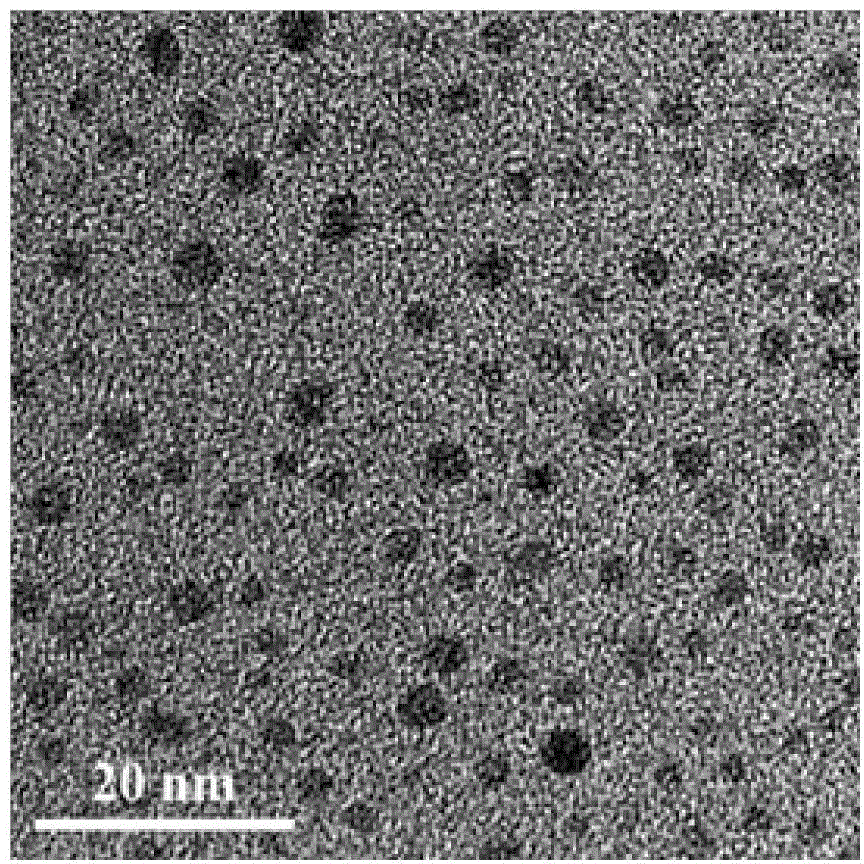

Synthesis method of noble metal nano particles

The invention discloses a synthesis method of noble metal nano particles, which comprises the following steps: dissolving soluble noble metal salt and surfactant polyvinyl pyrrolidone in ethanol at room temperature, wherein the mass ratio of the noble metal salt to the polyvinyl pyrrolidone is (1:5)-(1:20); adding a reductive amount of NaBH4, and then adding n-dodecanethiol; and carrying out centrifugal separation, precipitating, and washing to obtain the noble metal nano particles. By using ethanol as the solvent, the invention is safe, environment-friendly, green and non-poisonous, thereby reducing the environmental pollution and the harm to a human body, and being beneficial to environmental protection; the synthesis process is completed at room temperature without any heating step, thereby saving the energy and ensuring that the whole preparation process is very simple and convenient; and no special equipment is required, and the process is high in repeatability, thereby being beneficial to realizing large-scale production.

Owner:NORTHWEST UNIV

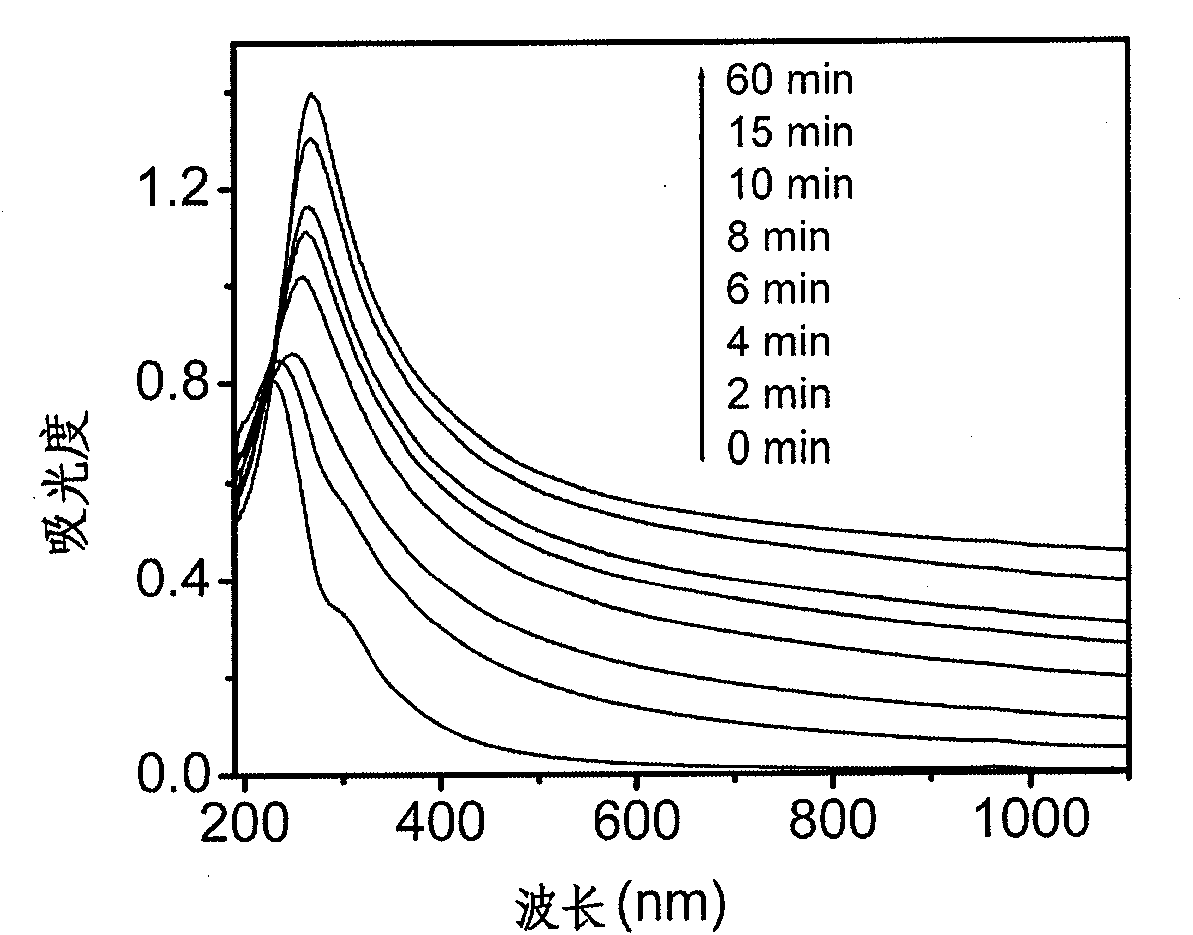

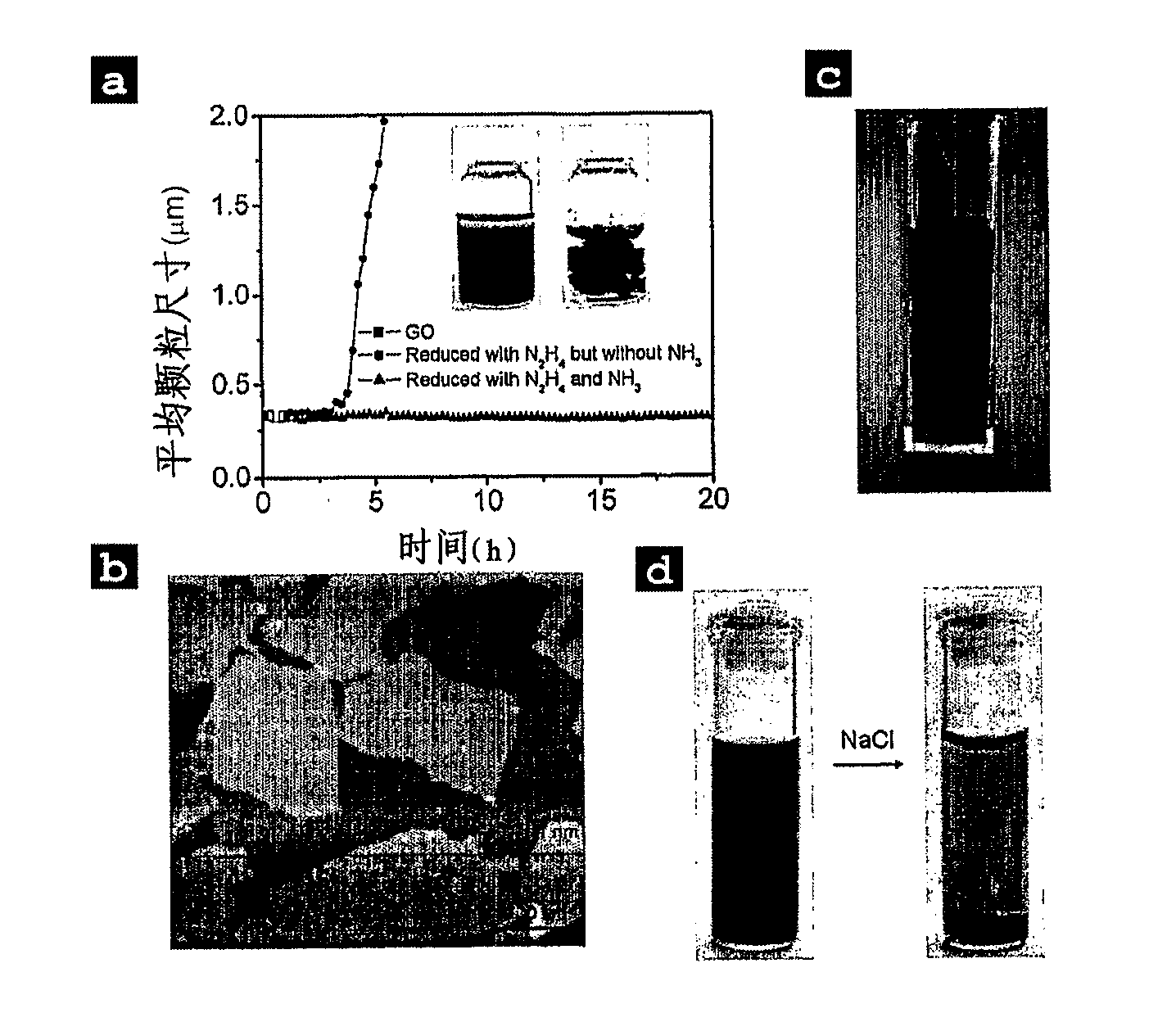

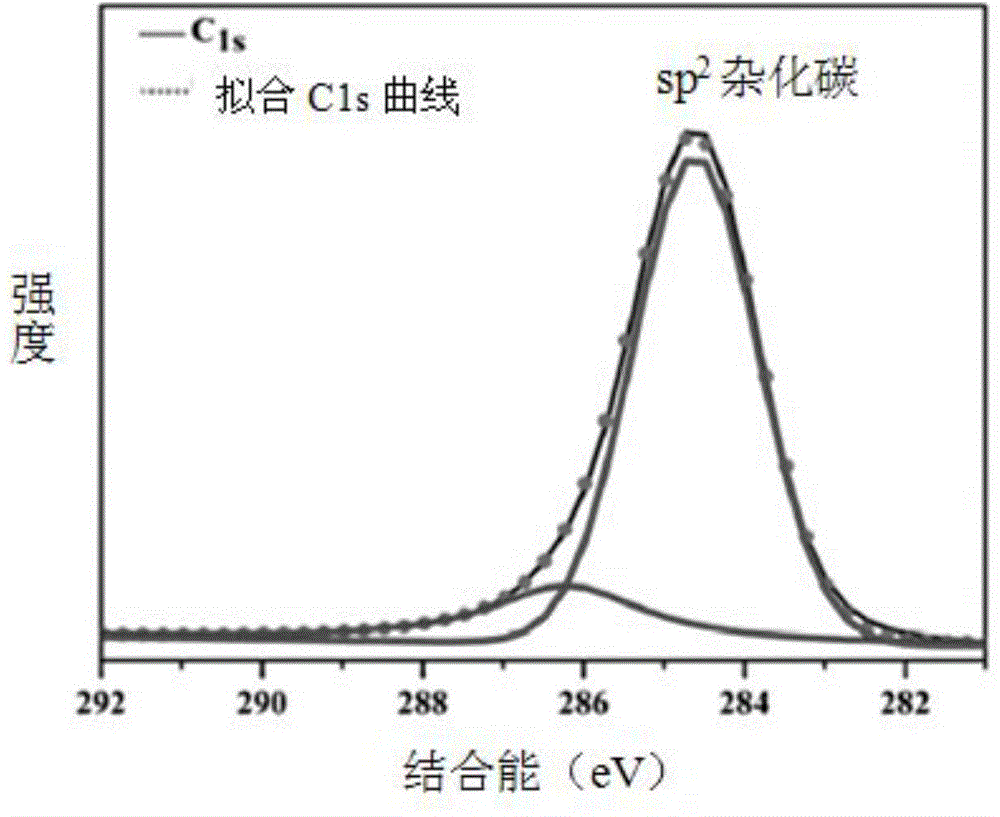

Process for the preparation of graphene

InactiveCN102066245AEnable mass manufacturingMaterial nanotechnologyIndividual molecule manipulationGraphite oxideNanocomposite

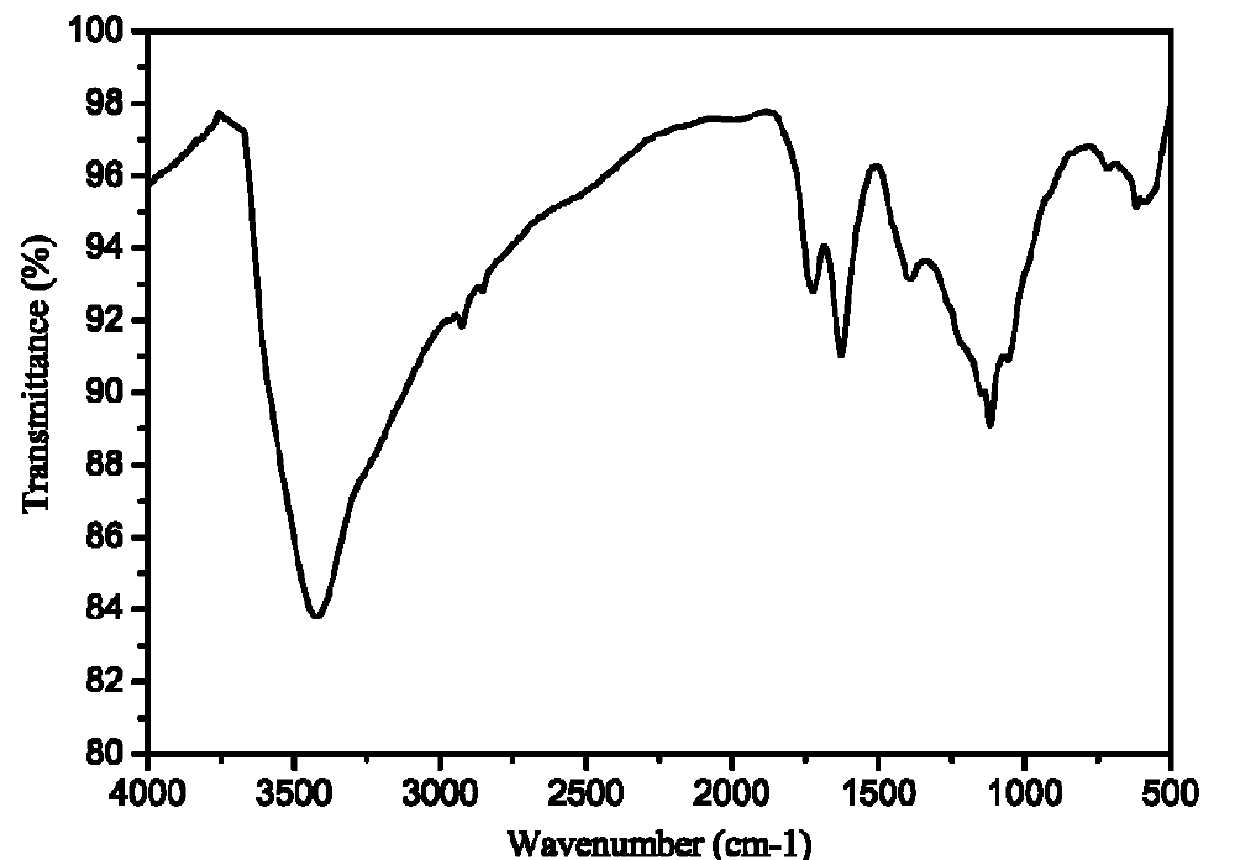

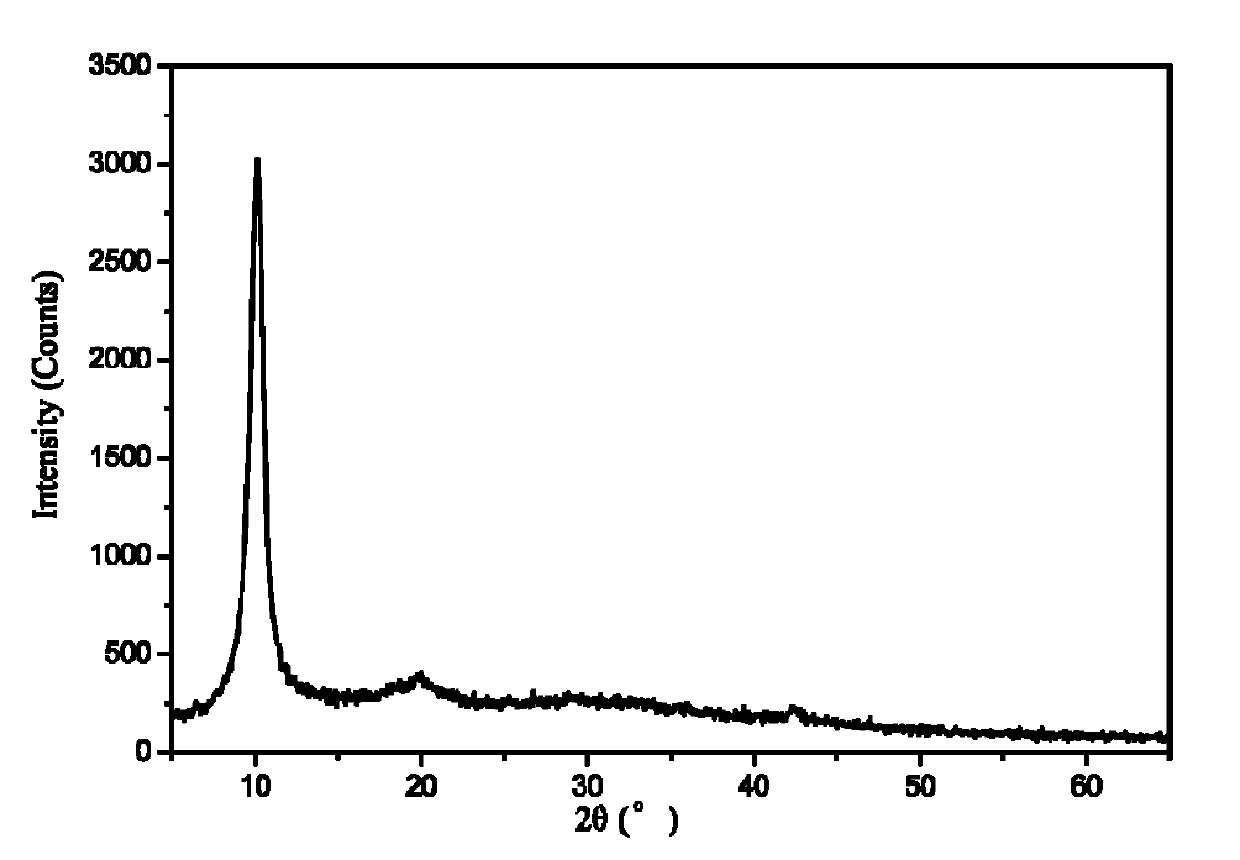

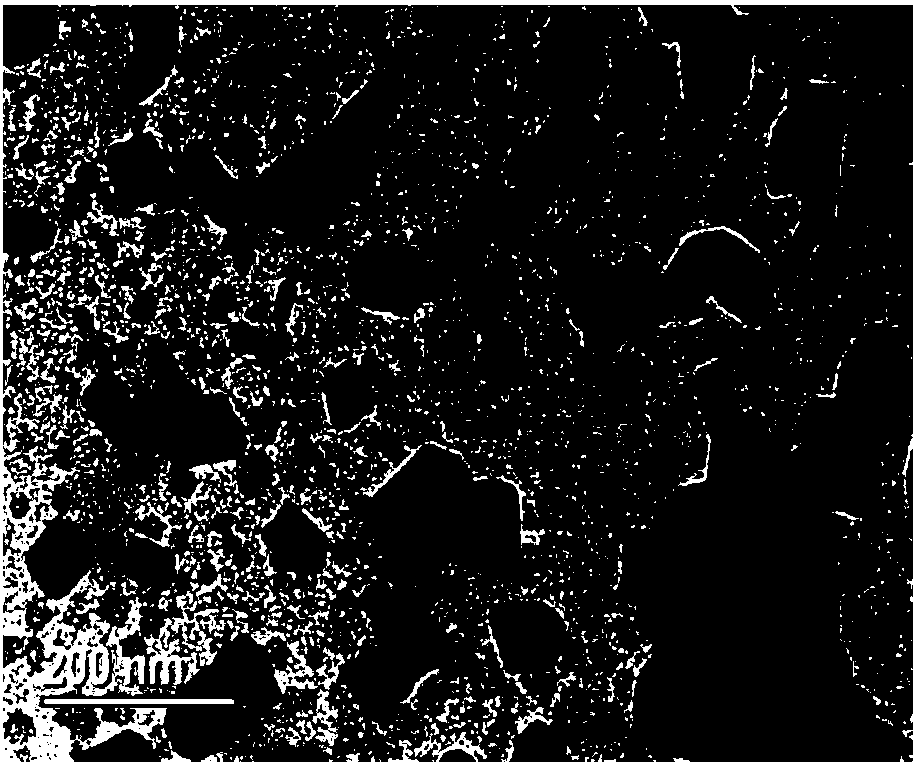

The present invention relates to a process for the preparation of graphene which can be used in the development of graphene paper or films, graphene-based composites and articles for nanoelectronics, nanocomposites, batteries, supercapacitors, hydrogen storage and bioapplications. This process comprises reducing purified exfoliated graphite oxide in the presence of a base.

Owner:UNIV OF WOLLONGONG

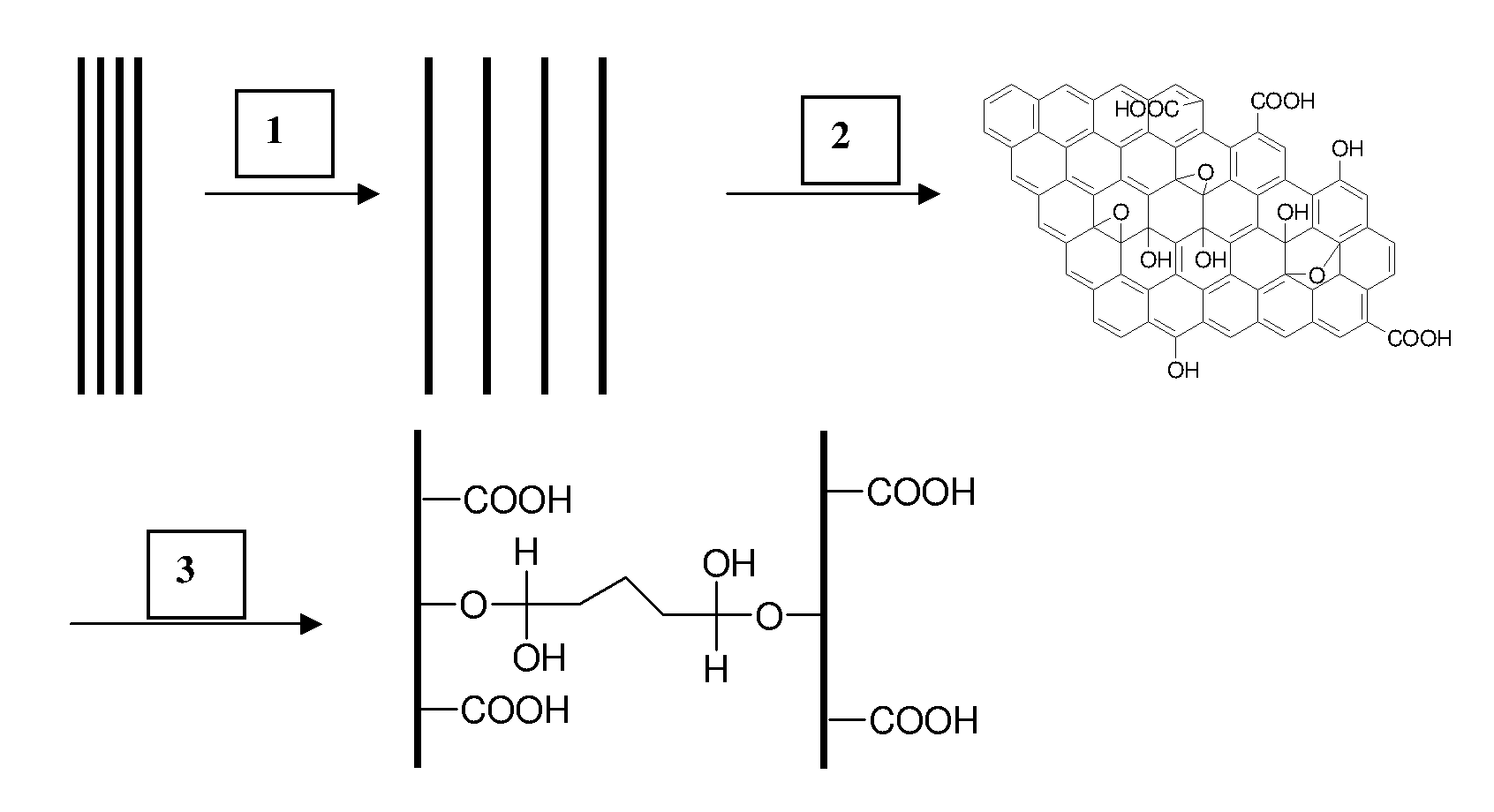

Optimized preparation method of oxidized graphite paper

InactiveCN101948108AEnable mass manufacturingImprove mechanical propertiesUltimate tensile strengthMechanical property

The invention relates to an optimized preparation method of oxidized graphite paper, belonging to the technical field of nanomaterials. The preparation method comprises the following steps: preparing graphene oxide by adopting hydrogen peroxide; then, adding a glutaric dialdehyde solution into the suspension of the graphene oxide; and casting and drying on a substrate after stirring to obtain the oxidized graphite paper with enhanced mechanical properties. The method of the invention is simple and easy, is suitable for large-scale preparation, and can realize large-scale preparation of the oxidized graphite paper. By adding a small amount of cross-linking agent, the obtained oxidized graphite paper with enhanced mechanical properties has regular structure, uniform height and enough mechanical strength.

Owner:SHANGHAI JIAO TONG UNIV

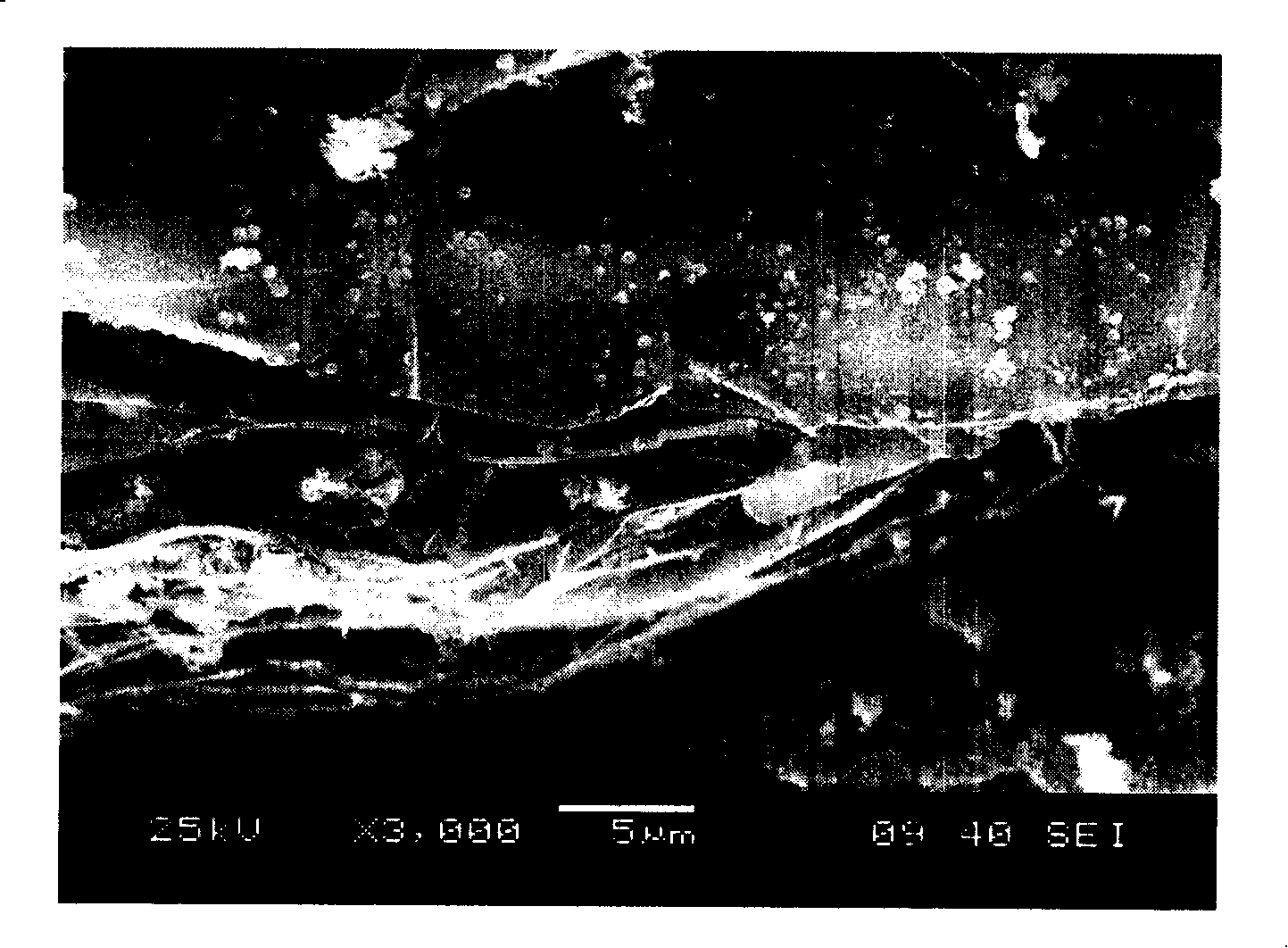

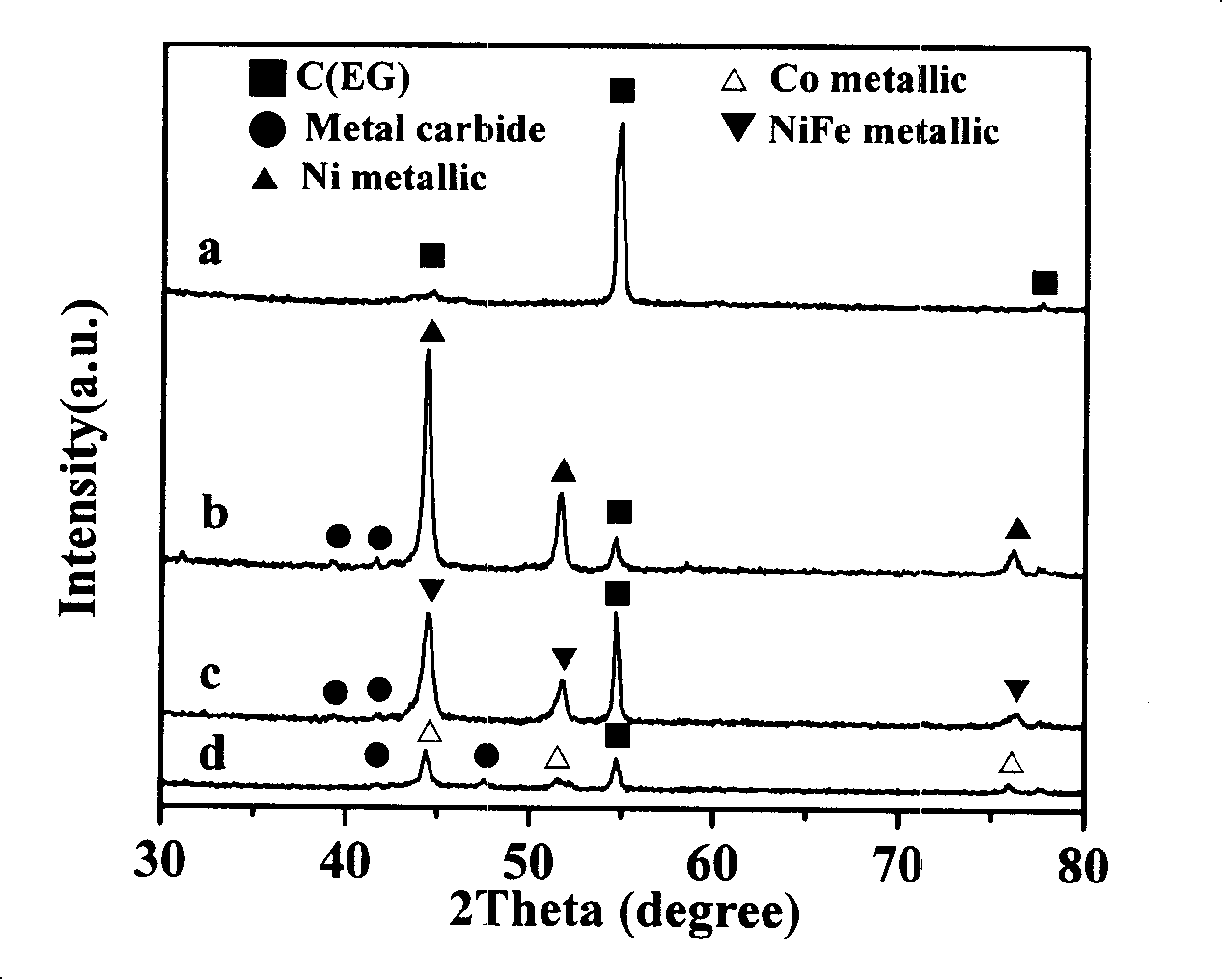

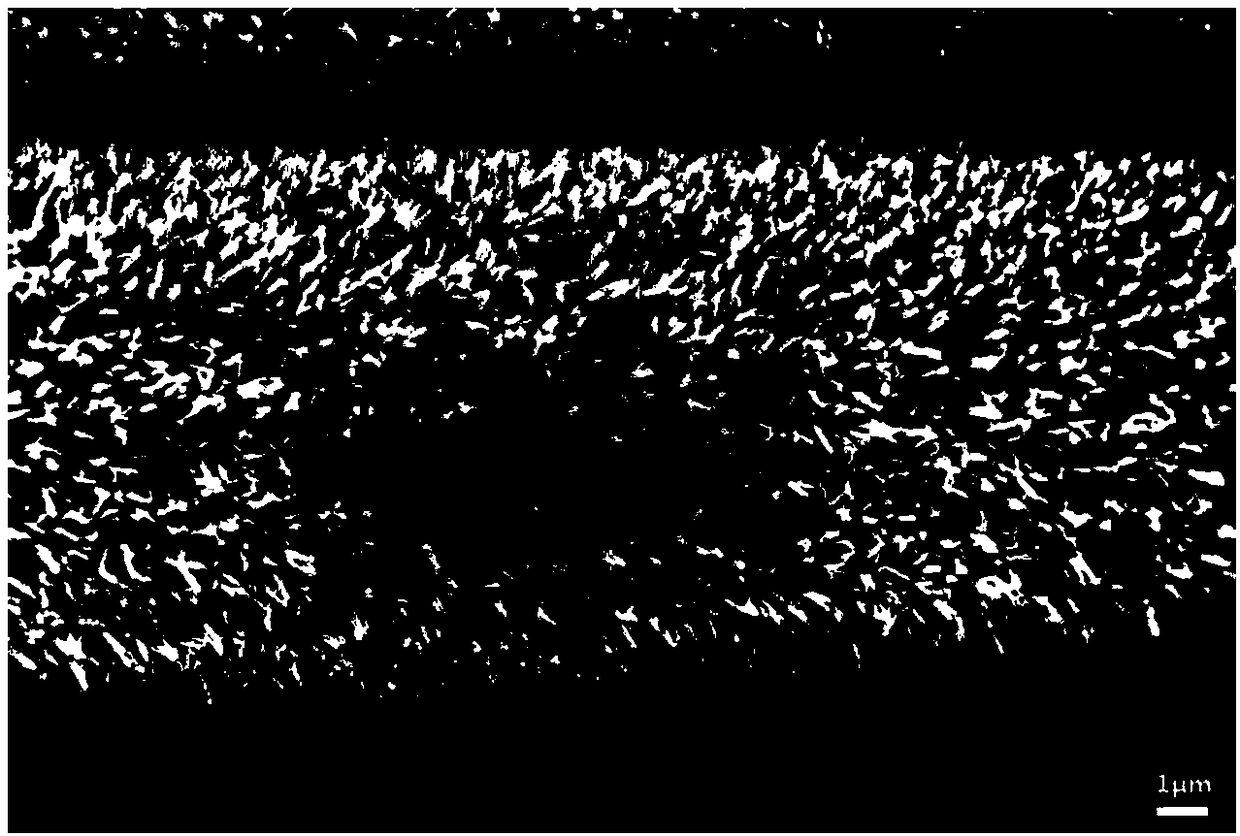

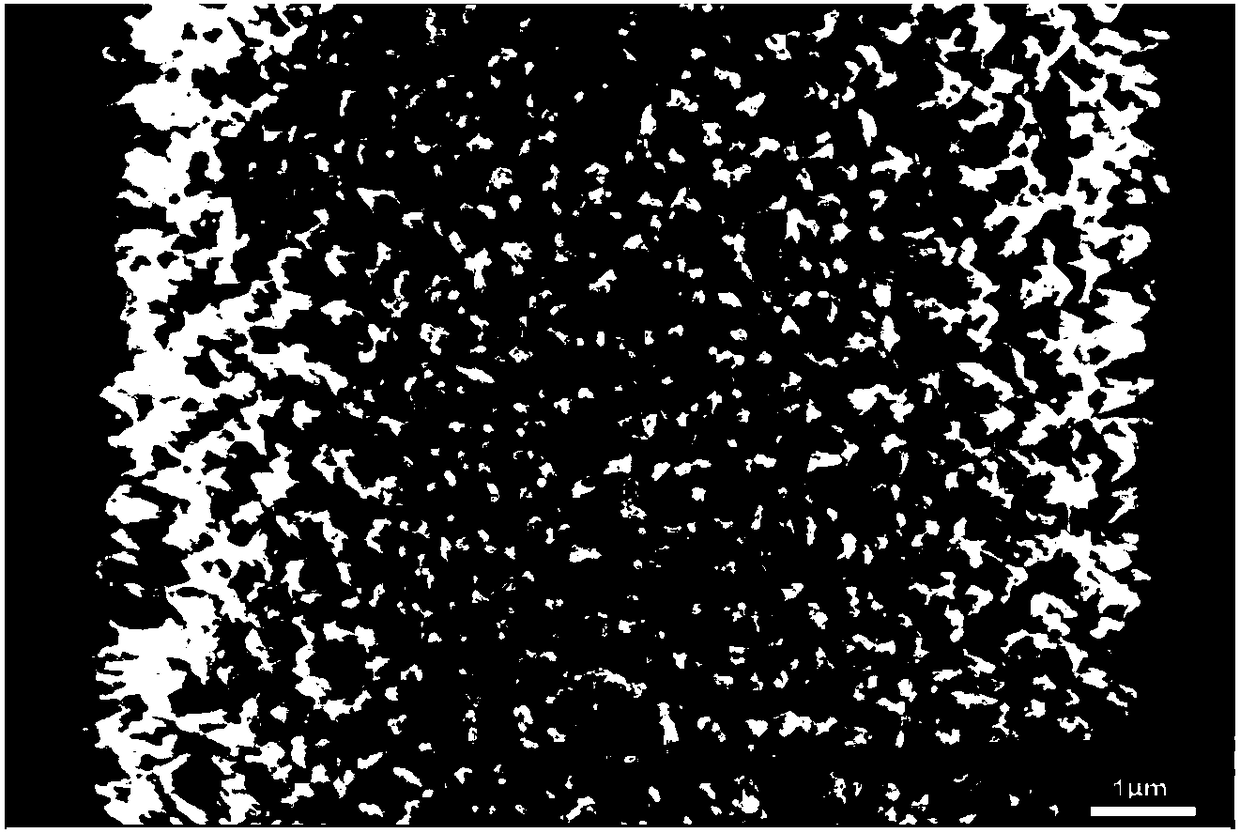

Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

InactiveCN101179921AStir and disperse evenlyEnable mass manufacturingMagnetic/electric field screeningScreening apparatusLow frequency bandElectromagnetic shielding

The invention relates to a preparation method of a lightweight graphite-based nano-magnetic metal composite material used for electromagnetic shielding, which belongs to the related field of electromagnetic shielding materials; the precursor solution of expanded graphite and magnetic metal is mixed and stirred evenly, and dried after evaporating the solvent. The obtained mixture is treated in a reducing atmosphere at 300°C-1000°C, passivated with ordinary nitrogen and cooled to room temperature to obtain a composite material of expanded graphite and magnetic nanometer metal, and the relative content of the two can be adjusted. The composite material is light in texture, has excellent electromagnetic properties, and can be pressed into various shapes required. The material has excellent electromagnetic shielding performance in the range of 300kHz-1.5GHz, reaching 70-105dB, and the addition of magnetic metal improves the electromagnetic shielding performance of the expanded graphite in the low-frequency band. The method is simple and efficient, suitable for mass preparation, and the obtained product is expected to be applied in aerospace, military, electronic and electrical products.

Owner:NANJING UNIV

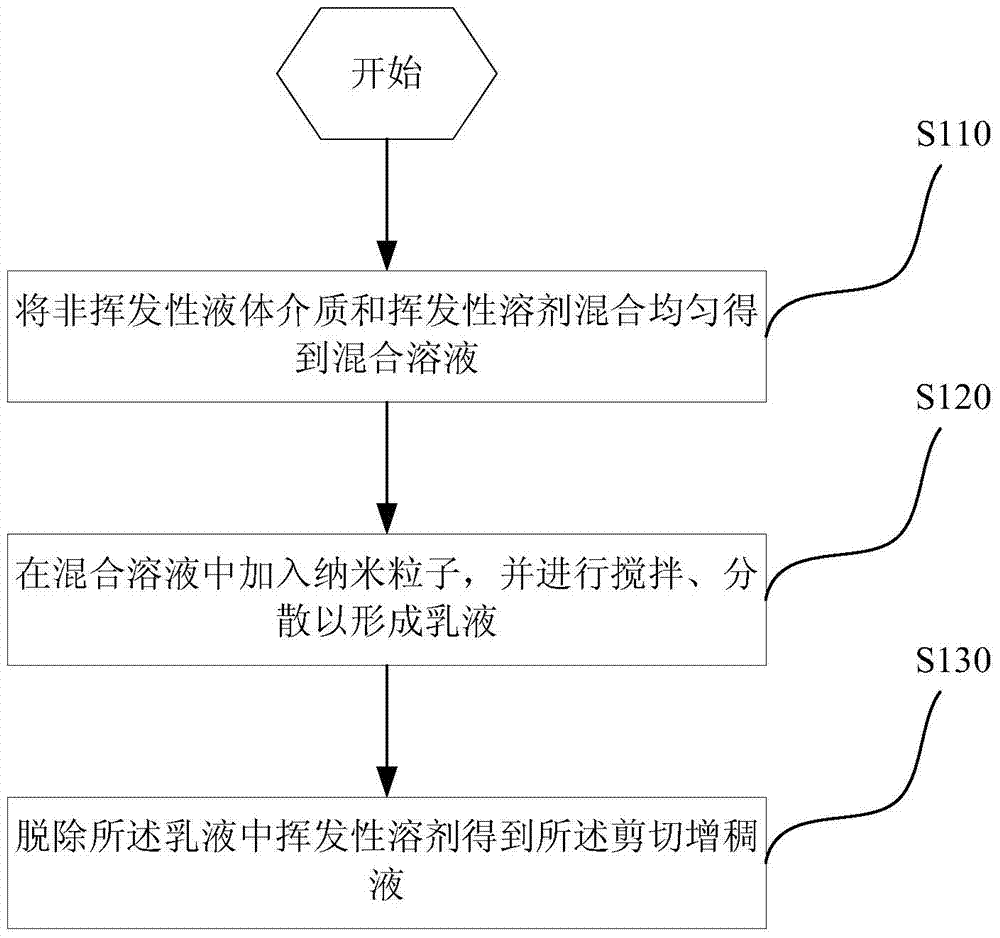

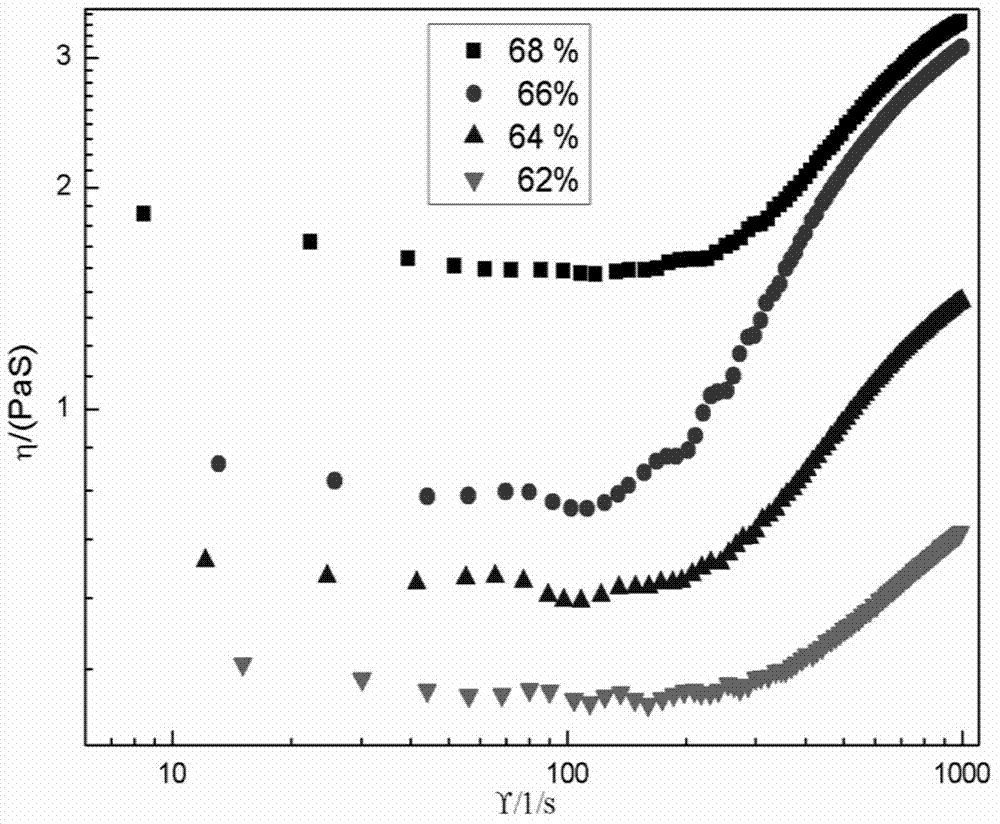

Preparation method of shear thickening liquid

ActiveCN104327795AEnable mass manufacturingEasy to manufactureOther chemical processesLiquid mediumEmulsion

The invention provides a preparation method of a shear thickening liquid. According to the preparation method, nanoparticles are used as a solid phase component of an STF liquid; a non-volatile liquid medium and volatile diluting solvent are prepared into a mixed solution; and the nanoparticles are dispersed in the mixed solution under the effects of stirring and ultrasound to form an emulsion; and then the diluting solvent is removed under a vacuum condition to obtain an uniform, transparent and stable STF liquid.

Owner:深圳市思创新材科技有限公司

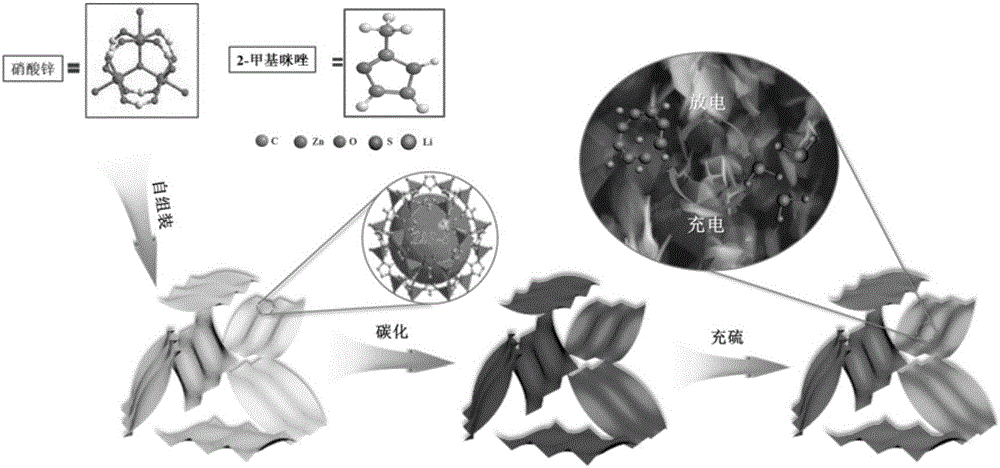

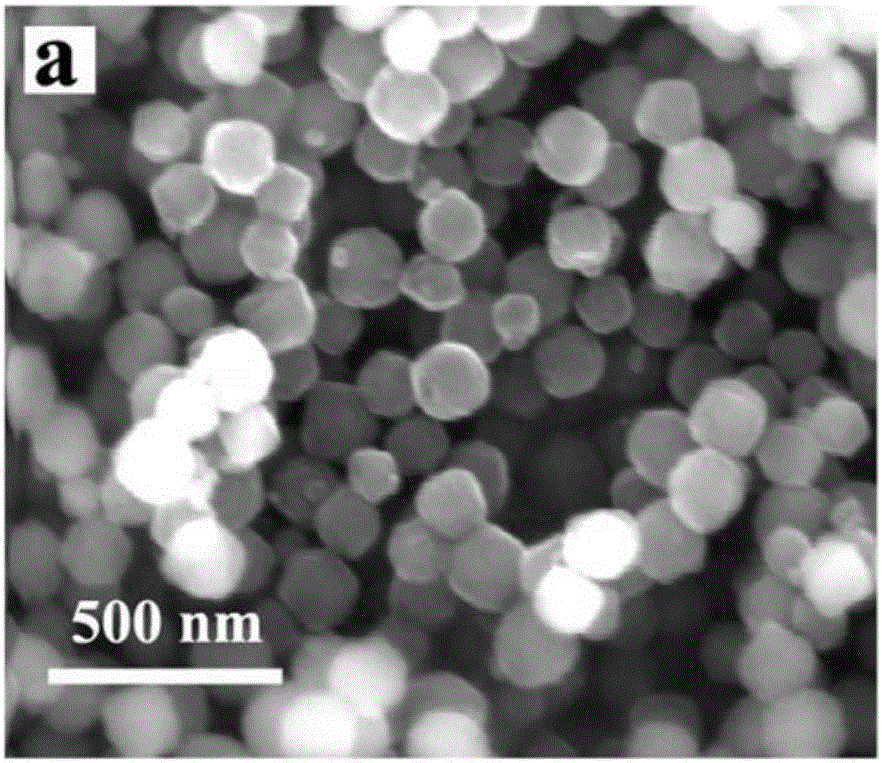

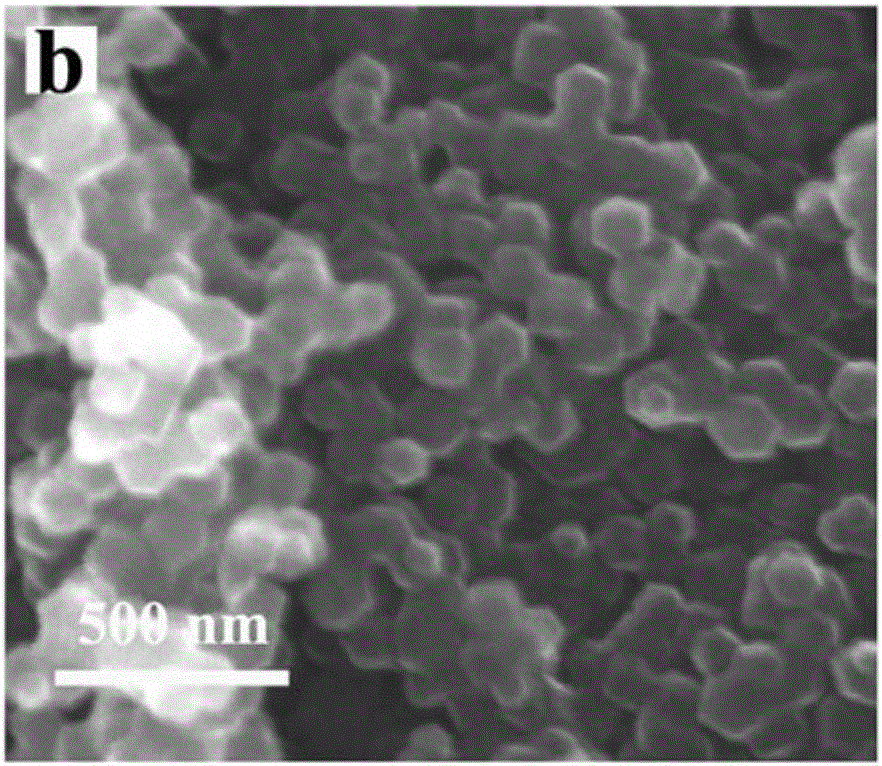

Two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet as well as preparation method and application thereof to lithium/sulfur battery

InactiveCN106025239AIncrease profitImprove performanceMaterial nanotechnologyCell electrodesLithium–sulfur batteryElectrical battery

The invention discloses a two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet as well as a preparation method and application thereof to a lithium / sulfur battery. The method takes zinc salt and a water-soluble nitrogen-containing organic ligand as raw materials and two-dimensional lamellar MOF is synthesized in a water solution in one step; the two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet is obtained through processes including carbonization, activation and the like. The carbon nano-sheet disclosed by the invention has micro-pores and also has micropores and macropores; the specific surface area is 200m<2>g / l to 5000m<2>g / l and the pore volume is 0.1cm<3>g / l to 4.5cm<3>g / l; the carbon nano-sheet disclosed by the invention is used as a positive electrode material of the lithium / sulfur battery, the sulfur fixing effect is obvious and the electron and ion conductivity is good, so that the obtained battery has very good circulating performance and rate performance; the first-turn discharge capacity at 0.2C can reach 1226mAh / g and the capacity rentention rate reaches 74.1 percent after 50 times of circulation. The preparation process is simple and has energy-saving and environment-friendly effects; large-scale preparation is easy to realize.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

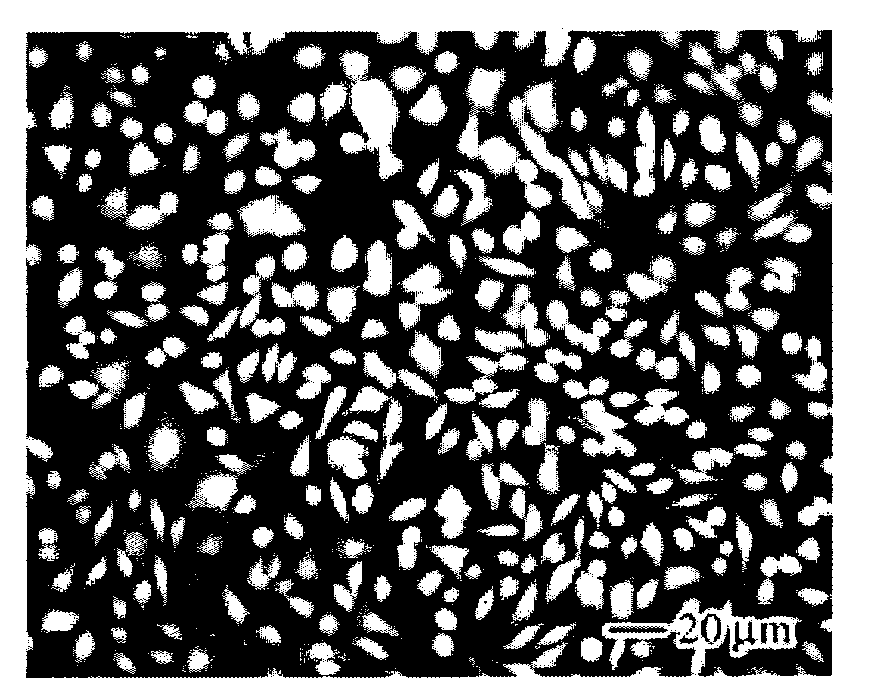

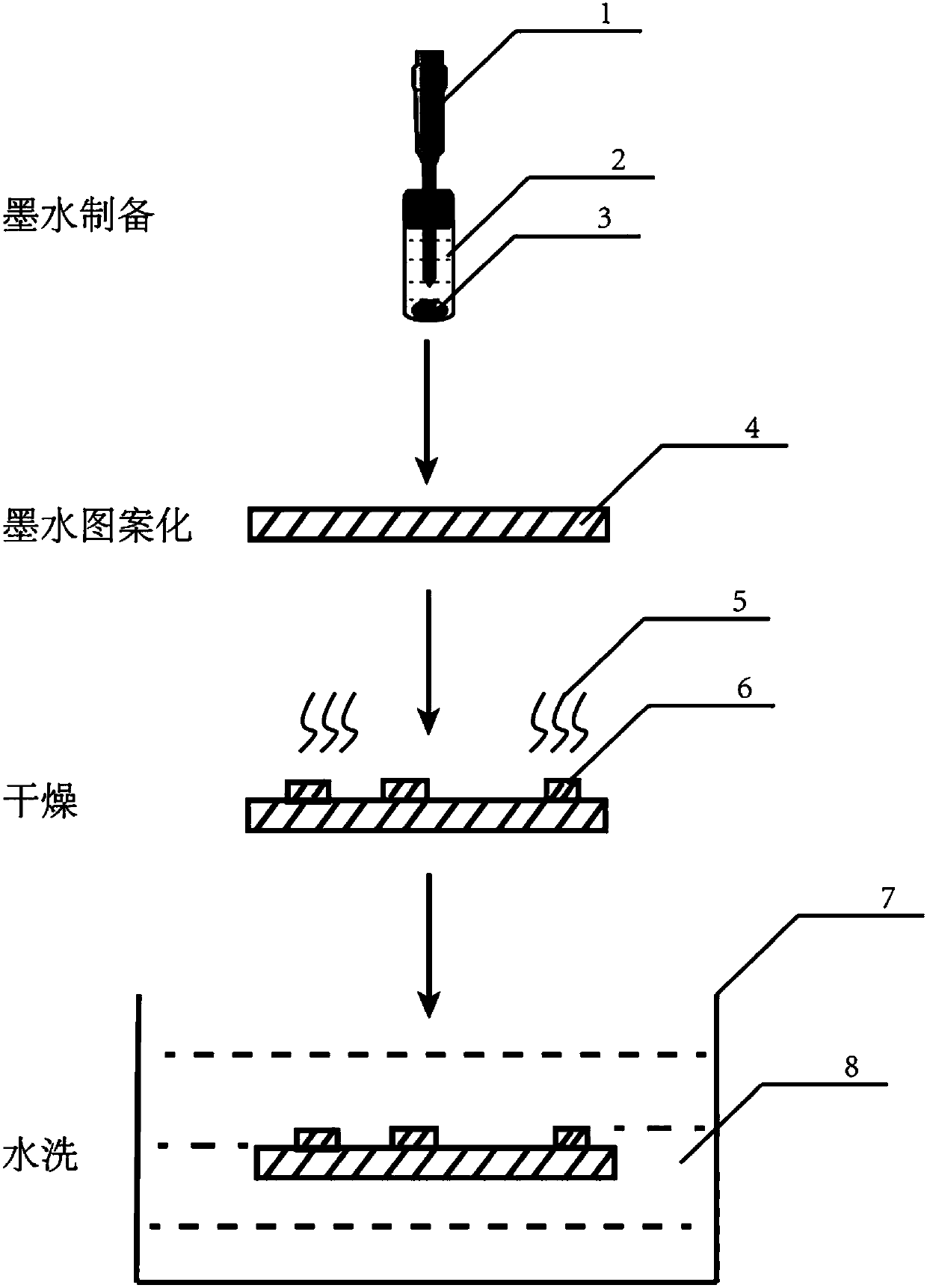

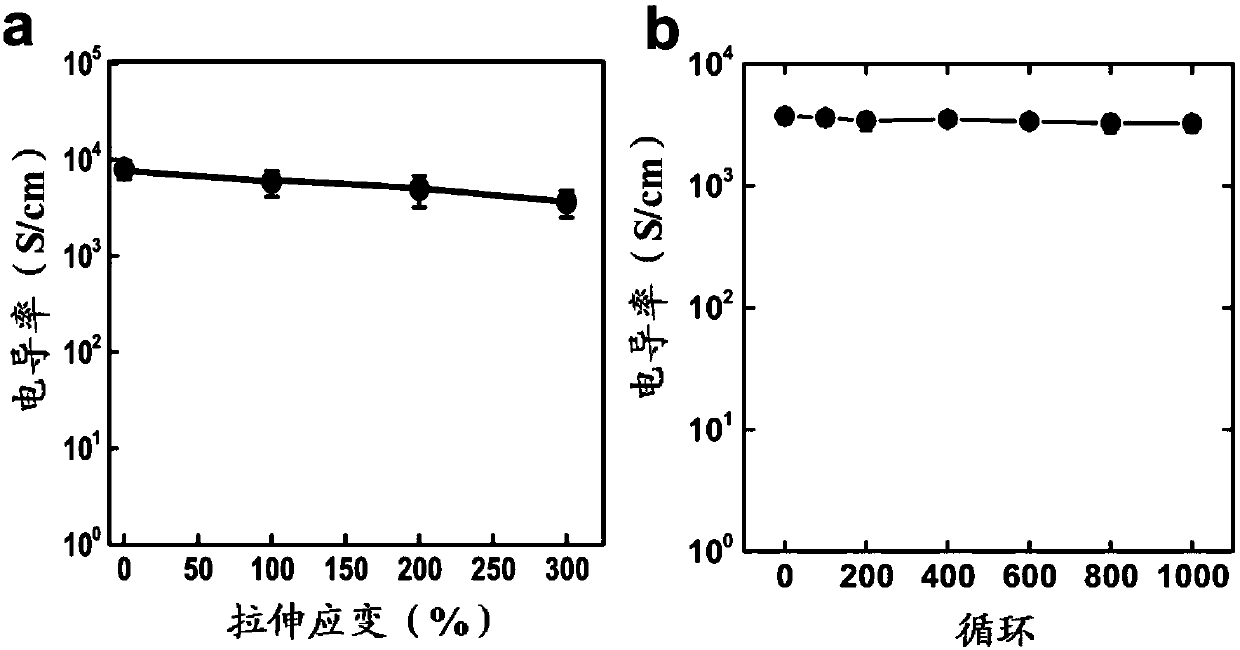

Self sintering conductive ink based on liquid-state metal particles as well as preparation method and application thereof

The invention provides self sintering conductive ink based on liquid-state metal particles as well as a preparation method and application thereof. The conductive ink has the main ingredients of liquid metal and water-soluble macromolecules; the preparation is simple; the cost is low; the patterning is easy; the ink can realize the automatic film breaking at the room temperature after the patterning; a conductive path is formed. The circuit manufactured by using the ink has very good flexibility and stretching performance; the line width is controllable; high resolution is realized; the ink is very suitable for large-scale production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Ceramic solid electrolyte and preparation method thereof

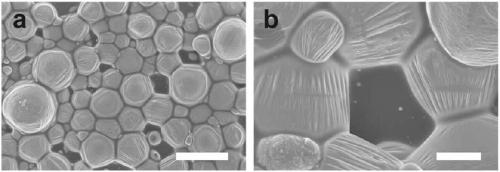

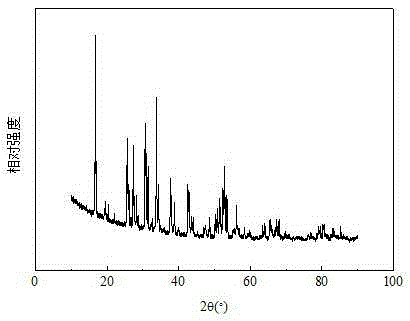

InactiveCN105406118AEnable mass manufacturingUniform size distributionSecondary cellsElectrolytesPerovskite (structure)Spray dried

The invention discloses a ceramic solid electrolyte and a preparation method thereof. The ceramic solid electrolyte comprises at least one of NASICON structure type (LiM<2>(PO<4>)<3>, M=Zr, Ge, Mg, Al), oxide (Li<3x>La<2 / 3-x>TiO<3>) of perovskite structure and oxide (Li<5>La<3>M<2>O<12>) of garnet structure. The preparation method of the ceramic solid electrolyte comprises the following steps of: a) weighing raw materials according to molar ratio of elements in chemical formula of the ceramic solid electrolyte, dissolving the raw materials in solvent, and obtaining mixed solution; b) preparing ceramic solid electrolyte precursor powder from the mixed solution through a spray drying process; c) sintering the precursor powder obtained by spray drying in the air, and finally obtaining the ceramic solid electrolyte with relatively high ionic conductivity and relatively low electronic conductivity. In the method provided by the invention, the spray drying process is used for preparing the ceramic solid electrolyte, spray drying has the advantages that the drying procedure is fast, the mixed solution is directly dried into powder and particle size distribution of the powder is uniform, and thus, large-scale preparation of the ceramic solid electrolyte is expected to be realized, and the method has practical value.

Owner:HARBIN INST OF TECH

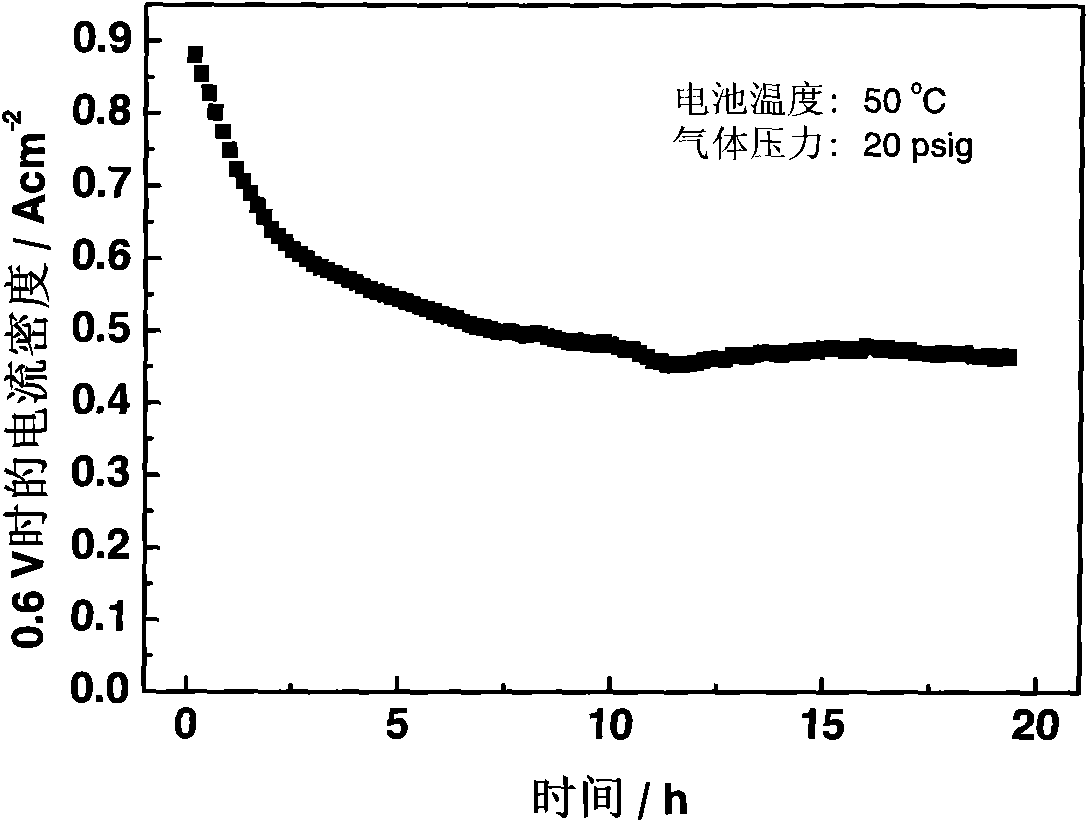

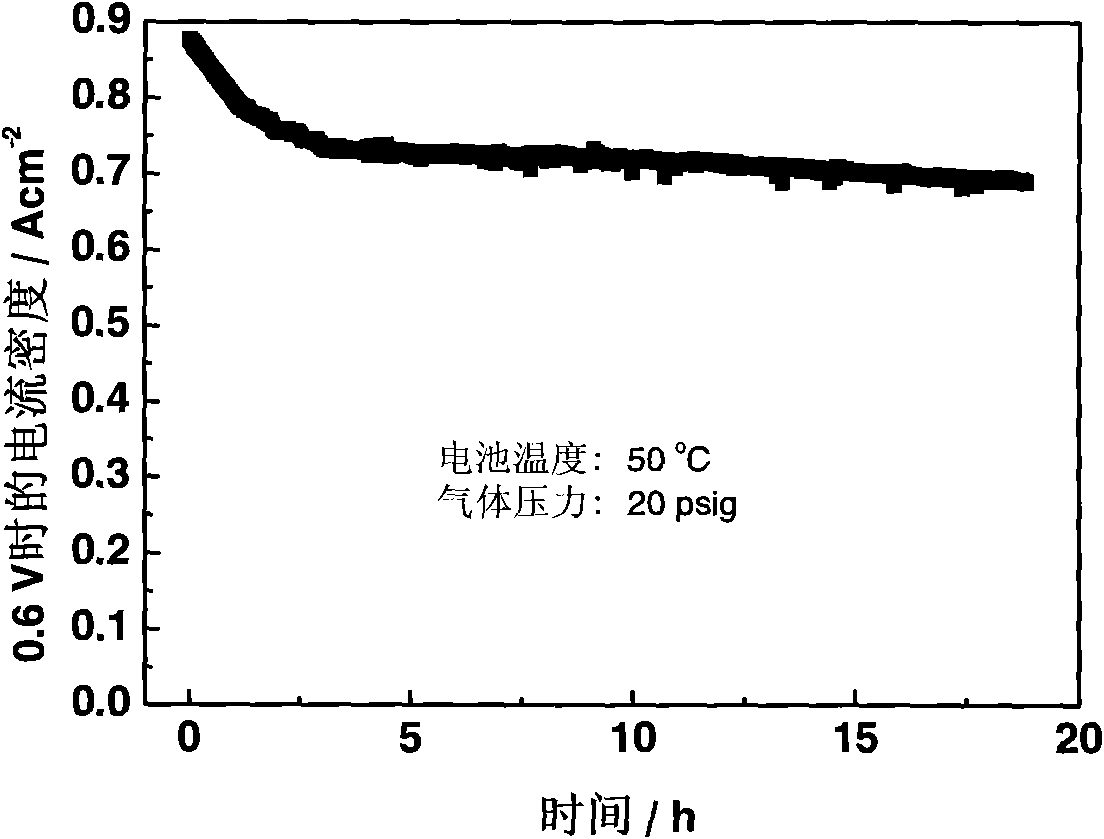

Electrocatalyst for fuel cell membrane electrode and preparation method thereof and fuel cell membrane electrode

InactiveCN101615677AImprove performanceGood moisturizing effectCell electrodesFuel cell detailsPtru catalystFuel cells

The invention relates to the fuel cell field and discloses an electrocatalyst for fuel cell membrane electrode and a preparation method thereof and a fuel cell membrane electrode; the electrocatalyst is characterized in that the electrocatalyst is prepared by loading precious metals on composite carrier and the composite carrier is carbon carrier deposited with water-retaining substance; in the electrocatalyst, the content of the water-retaining substance is 0.3-10wt% and the content of the precious metals is 10-60wt%. An electrode can be prepared by adopting the conventional method and using the electrocatalyst prepared by the method of the invention which is used as anode catalyst and the membrane electrode with good moisture-holding ability can be obtained; in the preparation method, a moisture-holding layer is needed to build and no moisture-holding substance is needed to add in the proton exchange membrane, thus avoiding the problems such as the increment of the internal resistance of cells which is caused by the addition of the moisture-holding substance in the moisture-holding layer and the proton exchange membrane, and providing a simple and efficient approach for preparing wetting-proof membrane electrode.

Owner:SOUTH CHINA UNIV OF TECH

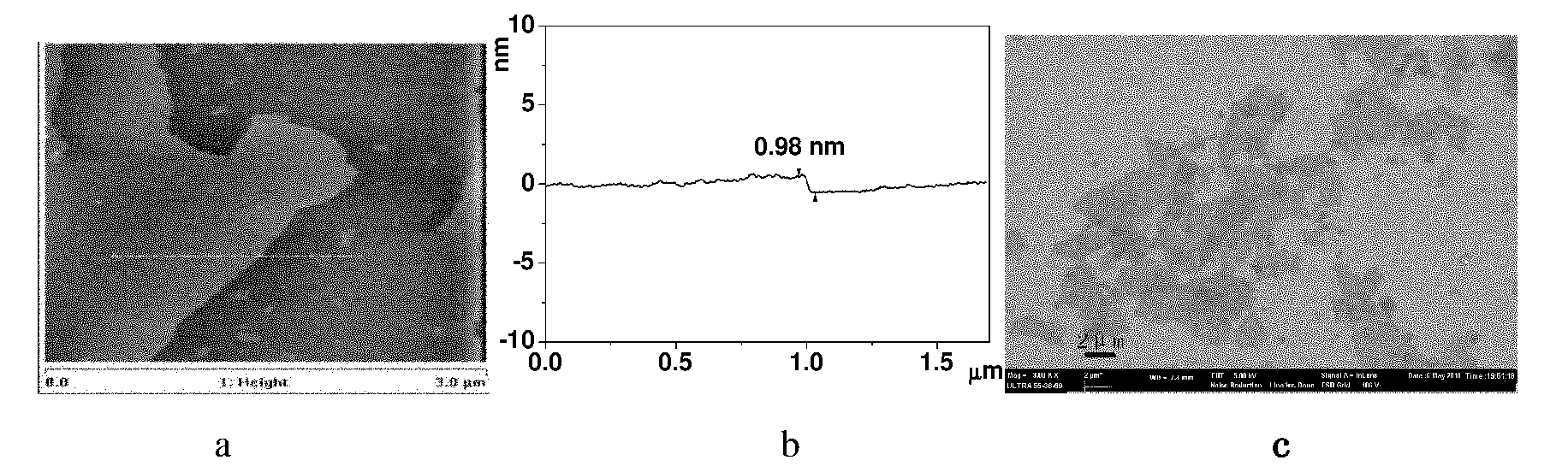

Method for large-scale preparation of oxidized graphene and selective adsorption of thorium in water

InactiveCN103130216ALow raw material costEasy to operateCarbon compoundsWater/sewage treatment by sorptionSingle layer grapheneSolid phases

The invention discloses a method for large-scale preparation of oxidized graphene and selective adsorption of thorium in water, belonging to the technical field of treatment of radioactive wastewater in nuclear wastes and environment protection. The method comprises the following specific steps of: oxidizing graphite by adopting an oxidant, adding water and concentrated hydrochloric acid, conglomerating, settling, pouring out, filtrating, washing and drying to obtain graphite oxide, and stripping by ultrasonic waves to obtain a single-layer graphene oxide aqueous dispersion. According to the method, an oxidative product of graphite, which is conglomerated and settled through the concentrated hydrochloric acid, can be very easily purified and separated to obtain graphite oxide, and the industrial large-scale preparation of single-layer graphite oxide is realized. The method has the characteristics of low cost, simple and convenient operation and good reproducibility; and simultaneously oxidized graphene can serve as a solid-phase adsorbent for adsorption of thorium in water and shows high adsorption capacity and selectivity (adsorption capacity qe is 529.6mgTh / g oxidized graphene, and the distribution coefficient Kd is 3047mL / g).

Owner:SICHUAN UNIV

Preparation method of metal-base ceramic composite filter membrane

ActiveCN102500245AThe preparation process is easy to operateReasonable designSemi-permeable membranesAnodic oxidationComposite filter

The invention discloses a preparation method of a metal-base ceramic composite filter membrane. The method includes steps: firstly, uniformly coating powder on the surface of a porous matrix, and obtaining a porous metal membrane layer by means of sintering; secondly, soaking the porous metal membrane layer into electrolyte to be anodized and obtaining a transition layer; thirdly, adding oxide powder into dispersing agent to obtain coating liquid; fourthly, coating the coating liquid onto the transition layer and sintering the transition layer after the transition layer is dried; and fifthly,repeating the fourth step for a product after being sintered until a porous ceramic filtering membrane with the thickness ranging from 2mum to 80mum is obtained, and obtaining the metal-base ceramic composite filtering membrane. The problem that bonding is not firm enough when metal and ceramic are compounded is resolved, the effective transition layer is formed on the metal matrix, so that a ceramic layer is firmly bonded with the metal matrix, processability of the prepared composite filter membrane is good, and the composite filter membrane can be used for preparing filtering devices in various shapes, simultaneously, has excellent chemical attack resistance, is high in pressure resistance and stable in repeatability, and can be used as a key component for micro-nano filtering and separating.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Two-dimensional tellurium nano-sheet as well as preparation method and application thereof

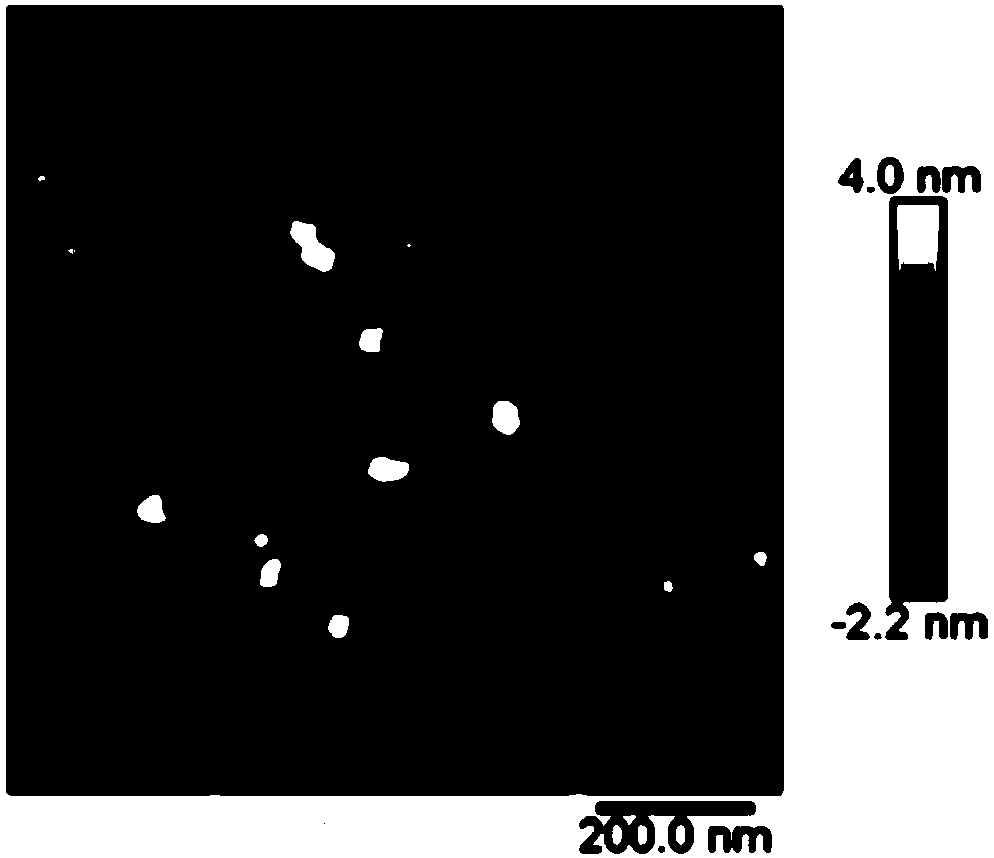

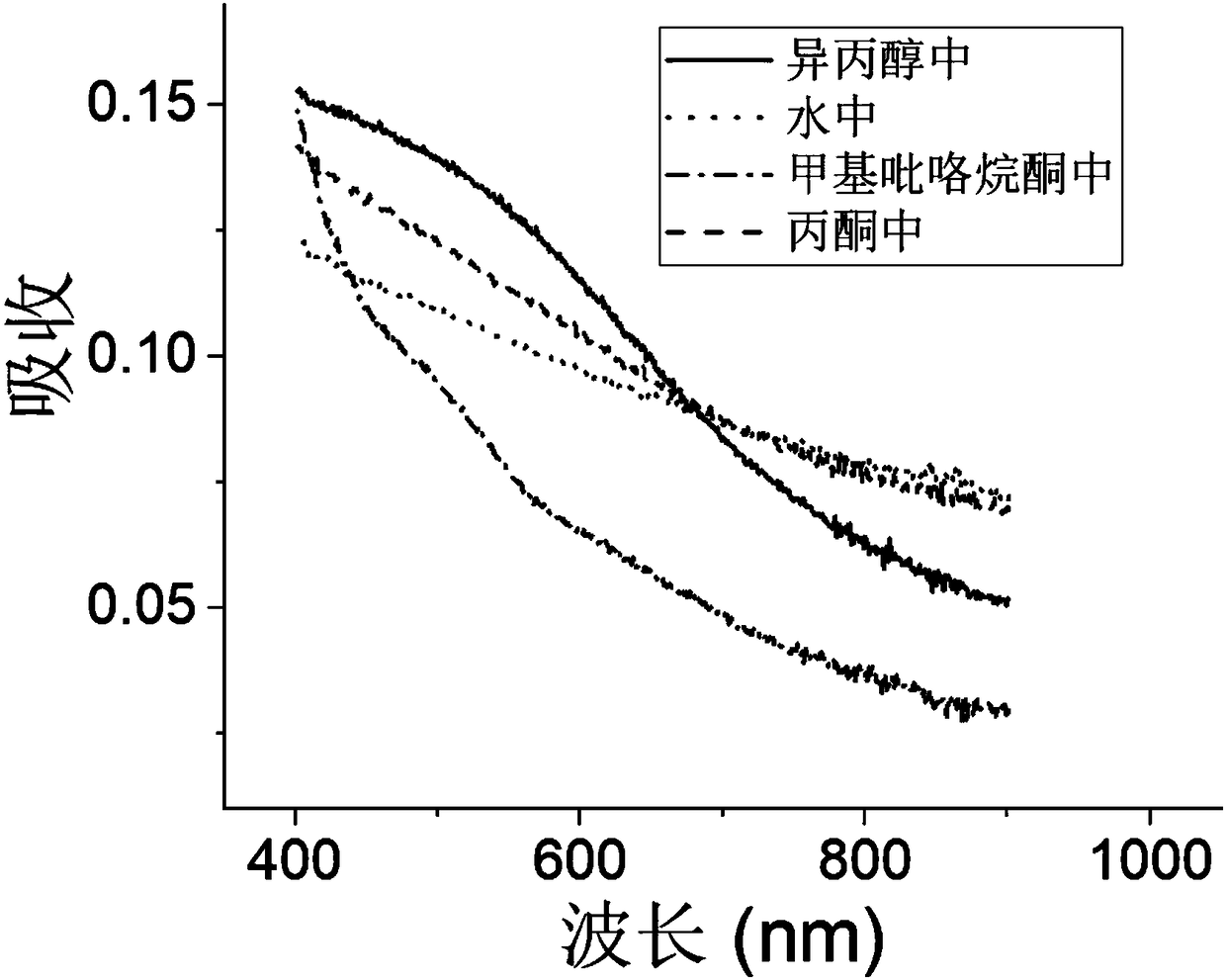

InactiveCN108313987AExcellent peelabilityEnable mass manufacturingMaterial nanotechnologySemiconductor devicesTe elementOptical detector

The invention provides a two-dimensional tellurium nano-sheet. The thickness of the two-dimensional tellurium nano-sheet is 1 to 50nm. The two-dimensional tellurium nano-sheet provided by the invention has good photoelectric detection performance. The invention further provides a preparation method of the two-dimensional tellurium nano-sheet; the preparation method comprises the following steps: providing a tellurium raw material; stripping the tellurium raw material by adopting a liquid-phase stripping method, so as to obtain the two-dimensional tellurium nano-sheet, wherein the thickness ofthe two-dimensional tellurium nano-sheet is 1 to 50nm. According to the two-dimensional tellurium nano-sheet and the preparation method, the two-dimensional tellurium nano-sheet is prepared from a non-laminar tellurium raw material by adopting a liquid-phase stripping method for the first time and the stripping effect is good; the two-dimensional tellurium nano-sheet can be prepared in a large scale and the cost is relatively low; the preparation method is simple and easy to operate. The invention further provides application of the two-dimensional tellurium nano-sheet to optical detectors.

Owner:SHENZHEN UNIV

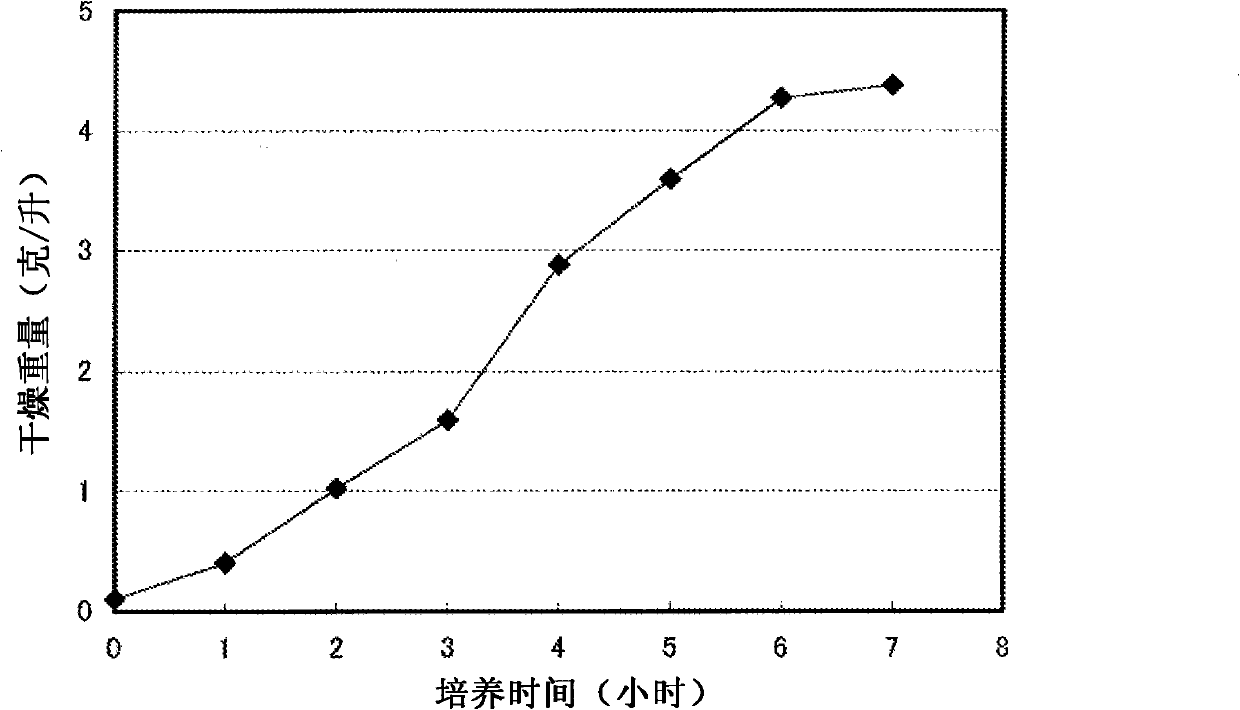

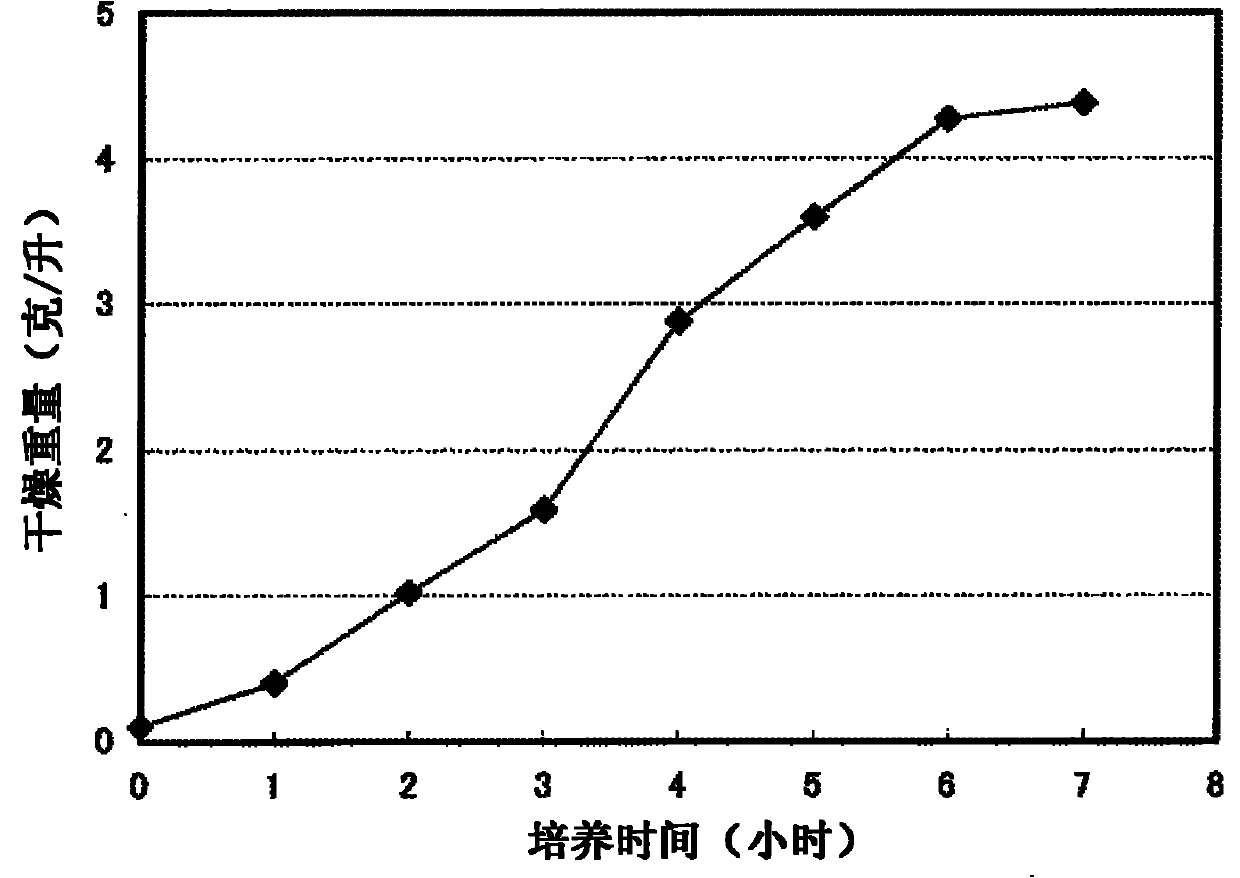

Process for production of fucoxanthin, and microalga for use in the process

Disclosed are: a process for producing fucoxanthin alone or fucoxanthin together with a highly unsaturated fatty acid efficiently, which enables the mass production of fucoxanthin; and a microalga for use in the process. Specifically disclosed are: a process for producing fucoxanthin alone or fucoxanthin together with a highly unsaturated fatty acid, which is characterized by culturing a microalga, more specifically a microalga belonging to the class Pinguiophyceae, Chrysophyceae, Bacillariophyceae or Haptophyceae, and extracting / isolating fucoxanthin alone or fucoxanthin together with the highly unsaturated fatty acid from the cultured microalga; and a microalga for use in the production of each of the above-mentioned fucoxanthin components.

Owner:NIPPON SUISAN KAISHA LTD +1

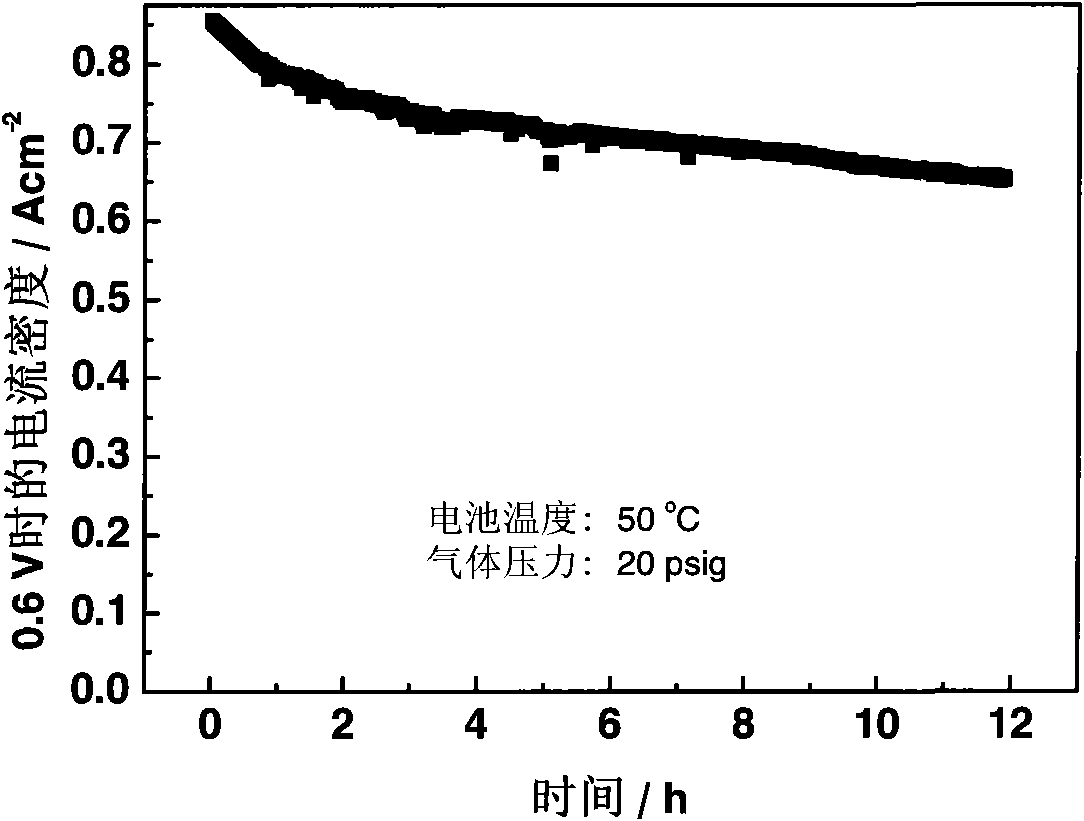

Preparing method of carbon-loaded monoatomic metal nitrogen-containing compound oxygen reduction catalyst and obtained catalyst

InactiveCN110201702ALow costSimple preparation processPhysical/chemical process catalystsCell electrodesOxygenPt element

The invention provides a preparing method of a carbon-loaded monoatomic metal nitrogen-containing compound oxygen reduction catalyst. The method comprises the steps of pre-oxidizing nitrogen-containing biomass at a first high temperature, after a pre-oxidized product is uniformly mixed with a transition metal source and a pore-forming agent, conducting first calcination at a second high temperature in an inert gas atmosphere, after a calcined product is subjected to acid pickling, washing and drying, conducting second calcination again at the second high temperature, and finally, obtaining thecarbon-loaded monoatomic metal nitrogen-containing compound oxygen reduction catalyst. The preparing method has the advantages of being low in raw material cost, simple in preparing technology and the like; the prepared catalyst has the advantages of being high in pH universality, atom utilization rate, catalytic performance and stability, excellent in methyl alcohol resistance and the like, is expected to replace expensive carbon-loaded platinum catalysts, and is about to have a wide application prospect in efficient and cheap large-scale commercialized fuel cells.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

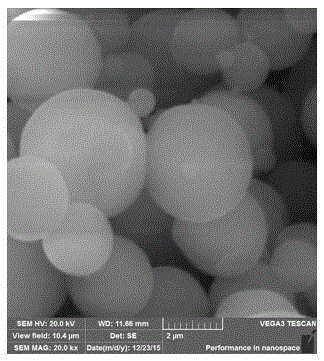

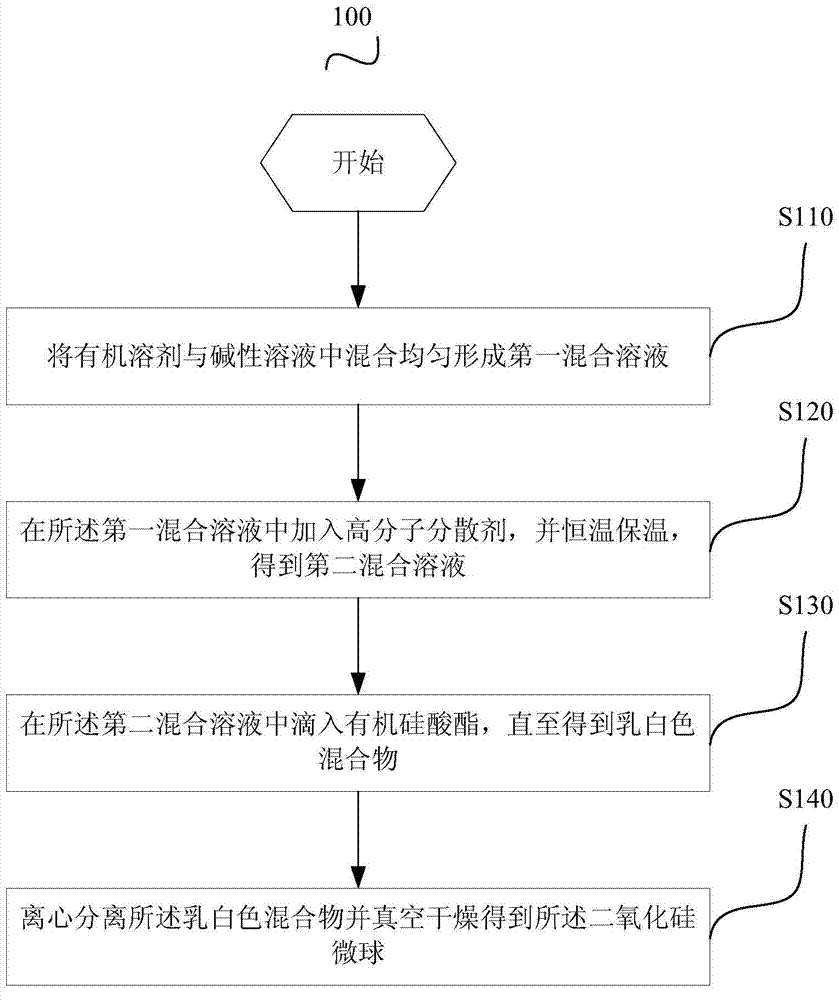

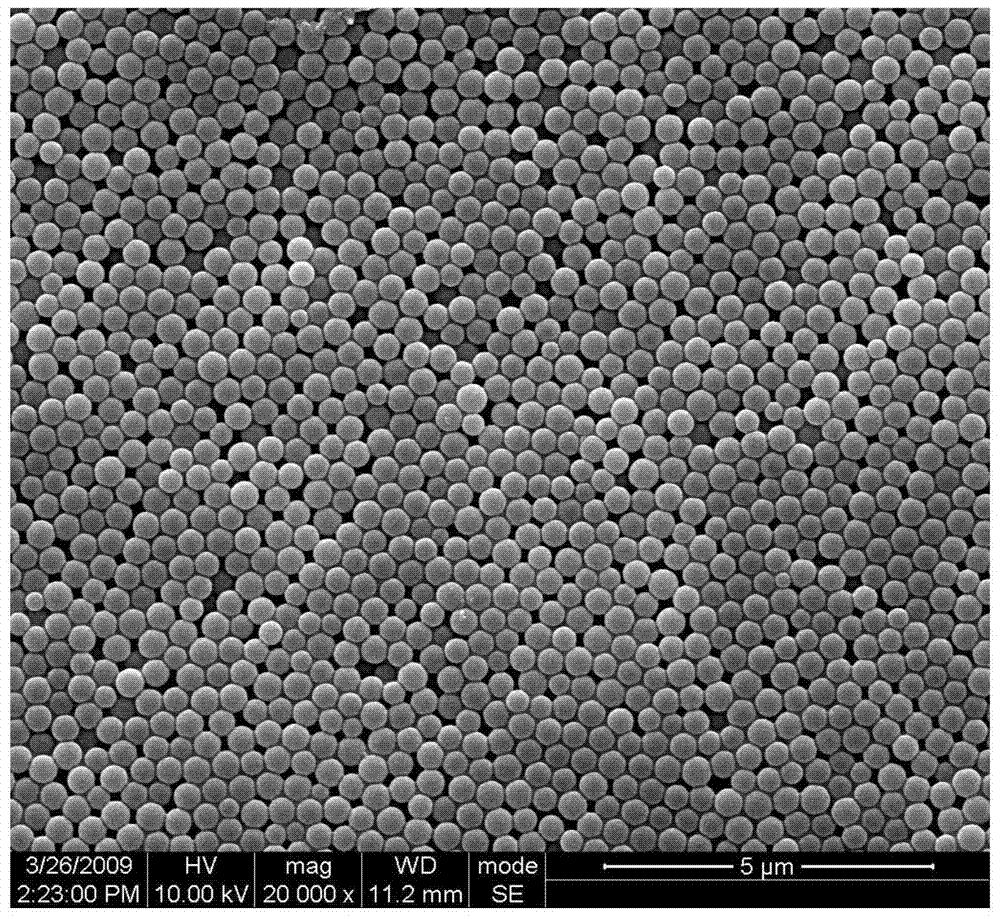

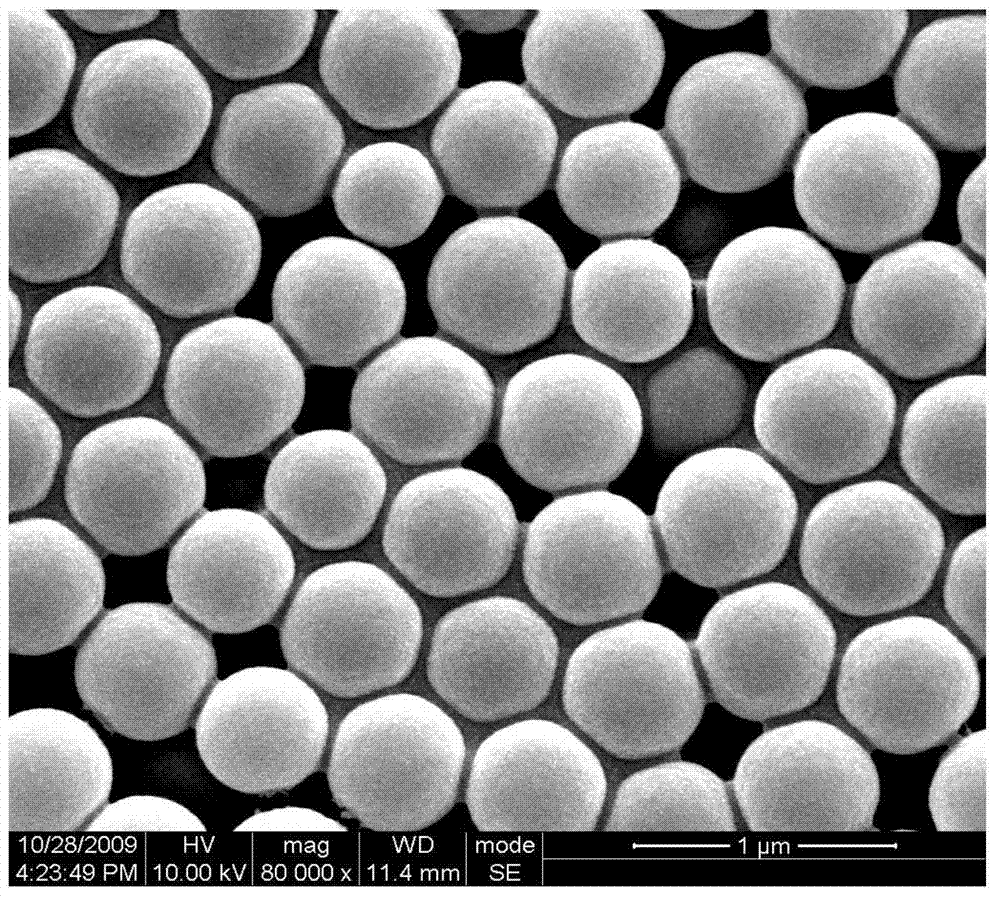

Preparation method of nano silica microspheres

The invention provides a preparation method of nano silica microspheres. Highly monodispersed nano silica microspheres can be obtained by using an organic silicate ester as a raw material and through the steps of hydrolyzation, centrifugal separation and vacuum drying in presence of a polymer dispersant and under an alkaline environment. The preparation process is simple and large-scale production of the nano silica microspheres can be realized.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

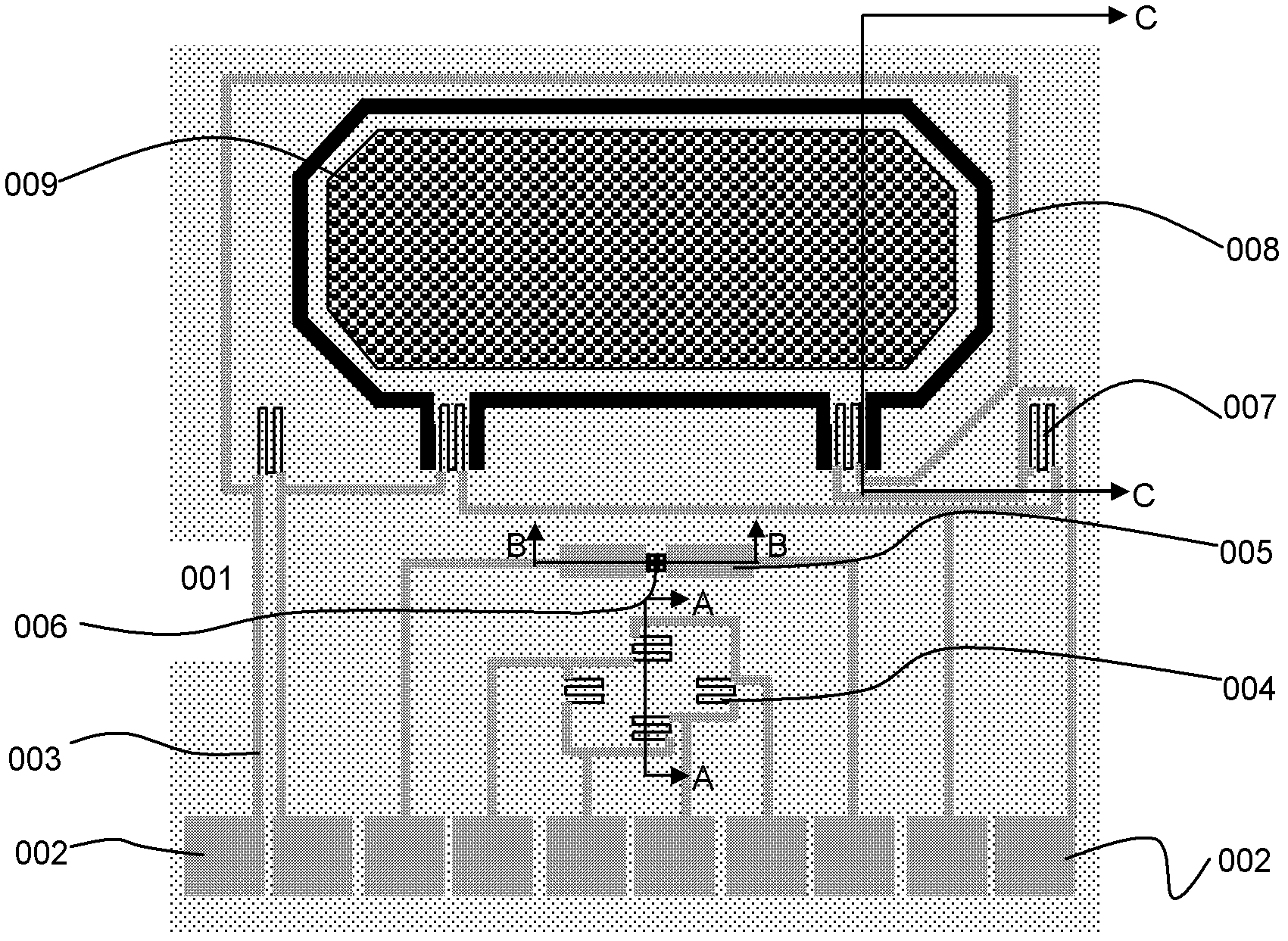

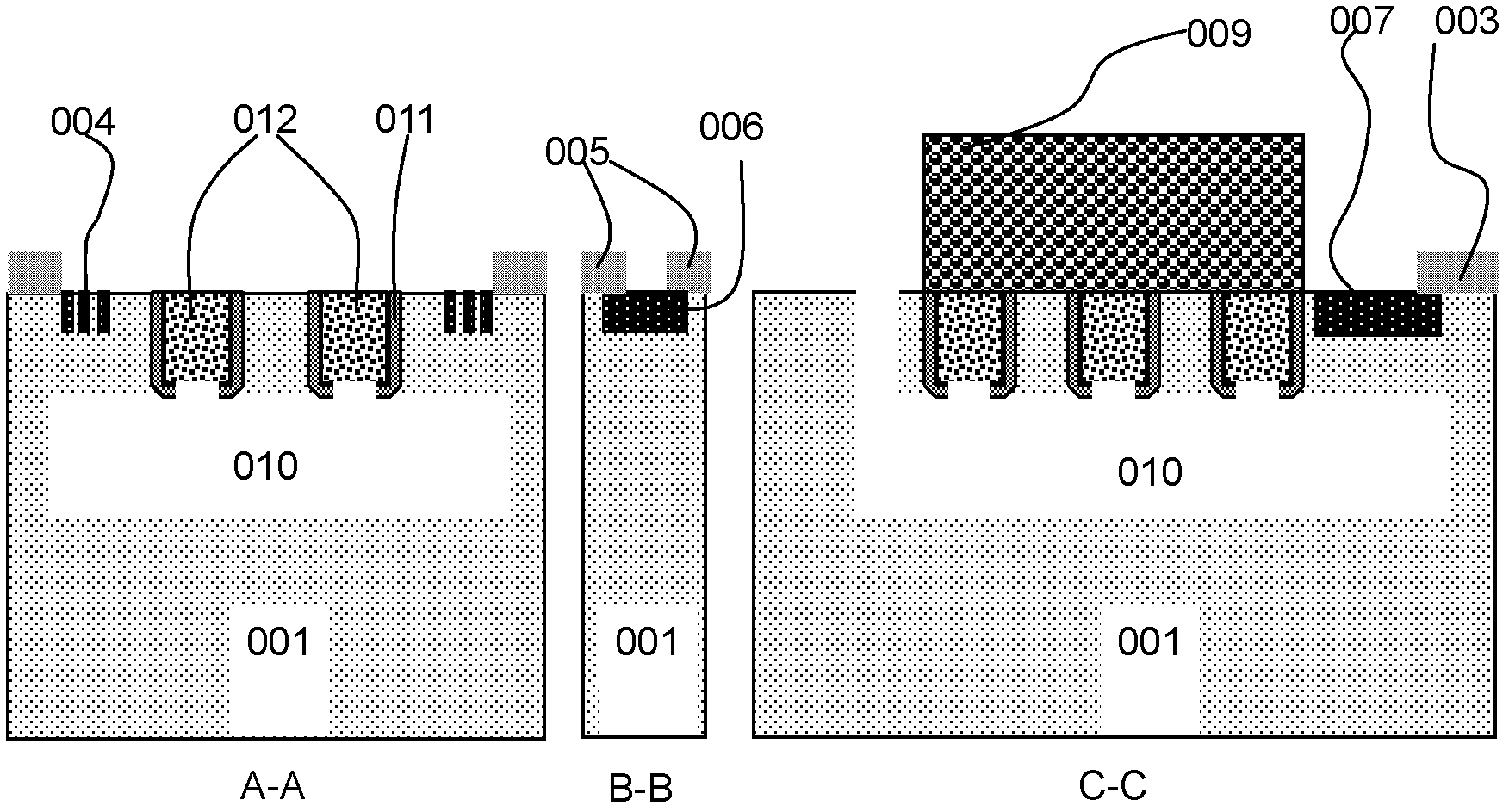

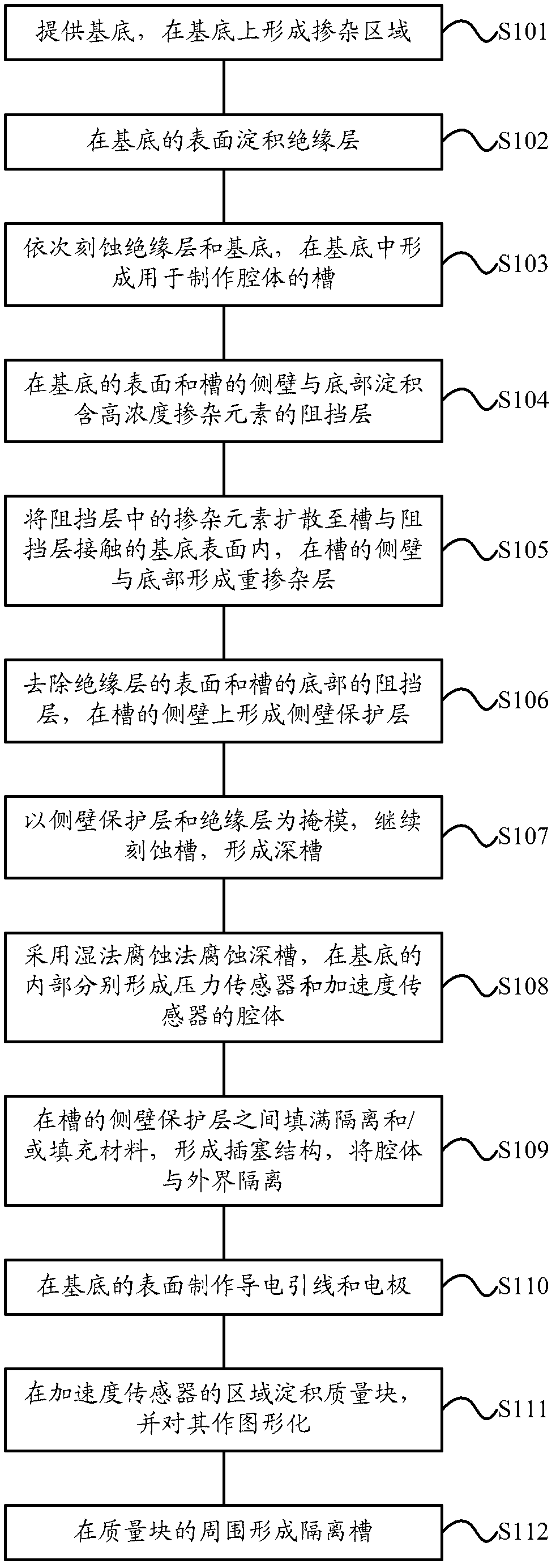

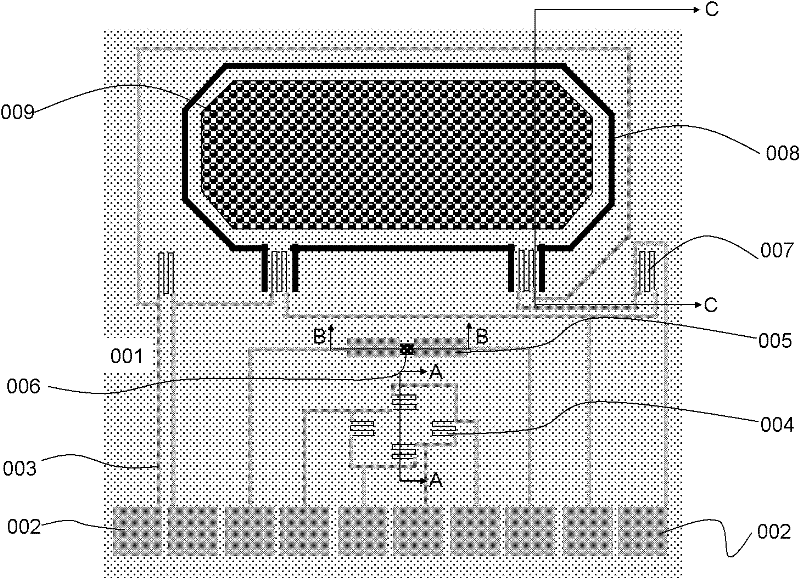

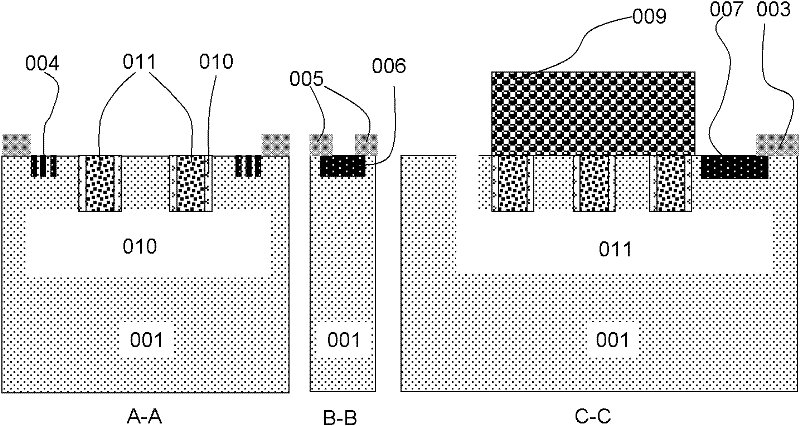

Composite integrated sensor structure and manufacture method thereof

ActiveCN102502479AEnable mass manufacturingPracticalMeasurement devicesDecorative surface effectsStructural engineeringProtection layer

The invention provides a composite integrated sensor structure and a manufacture method of the composite integrated sensor structure. The method comprises the following steps that: a substrate is provided, and a doping region is formed on the substrate; an insulating layer is deposited on the surface of the substrate; the insulating layer and the substrate are etched for forming grooves; a barrier layer with doped elements is deposited on the surface of the substrate and the bottom and the side wall of the grooves; the doped elements are diffused into the substrate to from a heavy doping layer; the barrier layer at the bottom of the grooves is removed, and a side wall protecting layer is formed on the side wall of the grooves; the grooves are continuously etched by using the side wall protecting layer and the insulating layer as masks, and deep grooves are formed; the deep grooves are corroded, a cavity is formed inside the substrate; isolation and / or filling materials are fully filled between side wall protecting layers; conducting leads and electrodes are manufactured on the surface of the substrate; a mass block is deposited in an acceleration sensor region and is graphical; and an isolation groove is formed on the periphery of the mass block, and the mass block is connected with the substrate in a cantilever mode. The composite integrated sensor structure and the manufacture method adopt a front-side process compatible with the conventional semiconductor process and have the advantages of practicability, economy, high performance and the like.

Owner:ADVANCED SEMICON MFG CO LTD

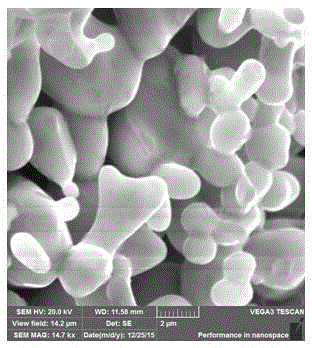

Method for preparing hollow zinc oxide microspheres

InactiveCN101880054AWide variety of sourcesLow priceZinc oxides/hydroxidesMicrosphereFlat panel display

The invention discloses a method for preparing zinc oxide with a hollow structure. Sodium citrate is introduced into a preparation process, and nucleation and growth behaviors of zinc oxide crystals are regulated and controlled by using coordination or adsorption action between the sodium citrate and a polar surface of the zinc oxide so as to obtain single uniform hollow zinc oxide microspheres. The method has mild conditions and simple synthesis, does not need to add any template during preparation, and can realize large-scale preparation. The hollow zinc oxide microspheres prepared by the method are expected to be used in many fields of catalysts, sensors, flat displays, solar cells, luminous diodes and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

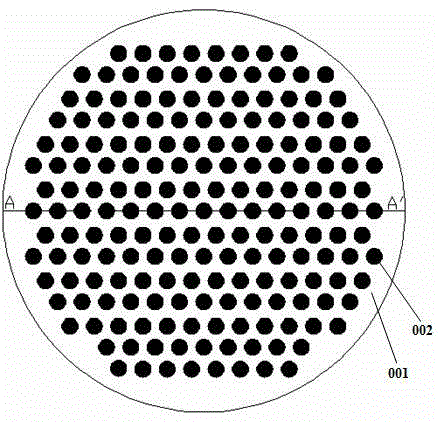

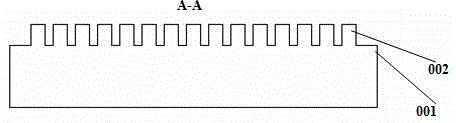

Patterned substrate manufacturing method

InactiveCN103337566AOutstanding FeaturesHighlight significant technological advancesSemiconductor devicesPatterned substrateLight-emitting diode

The invention relates to a patterned substrate manufacturing method. The method comprises the following steps: defining a pattern zone of a part of patterned substrate on the front surface of a substrate by using the photoetching technology; then depositing a barrier layer on the front surface of the substrate, and using the lift-off process to strip photoresist so as to leave the barrier layer on the surface of the substrate; performing the photoetching technology again to define a pattern zone of the remaining part of the patterned substrate; then depositing the other barrier layer on the front surface of the substrate, and using the lift-off process to strip the photoresist so as to leave the barrier layer on the surface of the substrate; finally performing the dry or wet etching process to form a patterned substrate. By the method provided by the invention, the problem that the luminous efficiency of an HBLED (High Brightness Light Emitting Diode) is affected by splicing errors among exposure fields and deformation of pattern splicing part is solved.

Owner:SHANGHAI UNIV

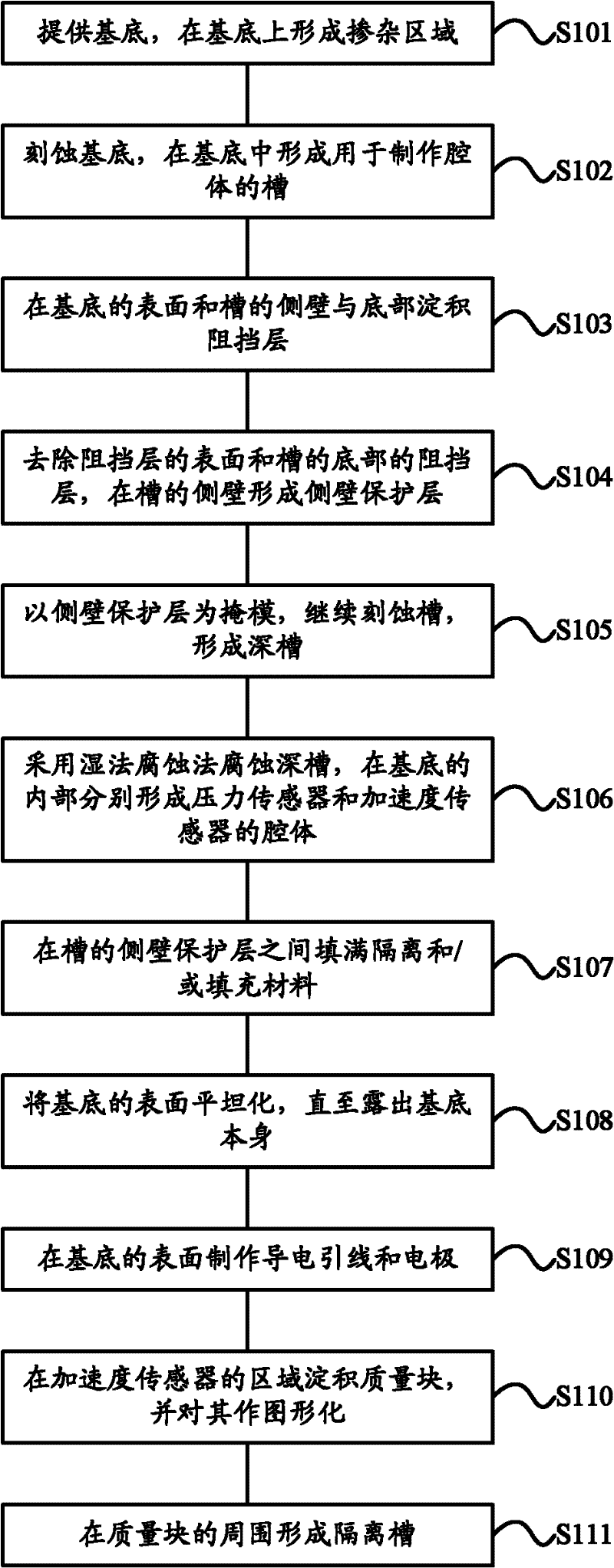

Composite integrated sensor structure and manufacturing method thereof

ActiveCN102285633AEnable mass manufacturingPracticalMeasurement devicesDecorative surface effectsEngineeringProtection layer

The invention provides a manufacturing method of a composite integrated sensor structure. The method comprises the following steps of: providing a substrate and forming a doped region on the substrate; etching the substrate to form a trench for manufacturing a cavity; depositing a barrier layer on the surface of the substrate and the side wall and the bottom of the trench; removing the barrier layers on the surface of the substrate and the bottom of the trench and forming a side wall protection layer on the side wall of the trench; continuously etching the trench under combined action of a hard mask on the substrate and the side wall protection layer to form a deep trench; corroding the deep trench and forming the cavity in the substrate; filling an isolating material and / or a filling material between the side wall protection layers of the trench to form a plug structure to isolate the cavity from the exterior; planarizing the surface of the substrate; manufacturing a conductive lead and an electrode on the surface of the substrate; depositing a mass block at the region of an acceleration sensor and patterning the mass block; and forming an isolating trench around the mass block and connecting the mass block with the substrate in a cantilever mode. In the invention, a front process which is compatible with the conventional semiconductor process is adopted; and the manufacturing method has the advantages of practicability, economy, high performance and the like.

Owner:ADVANCED SEMICON MFG CO LTD

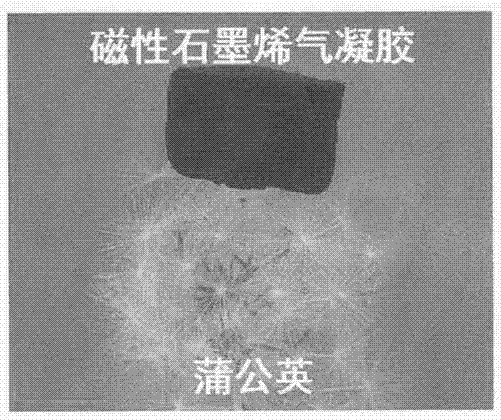

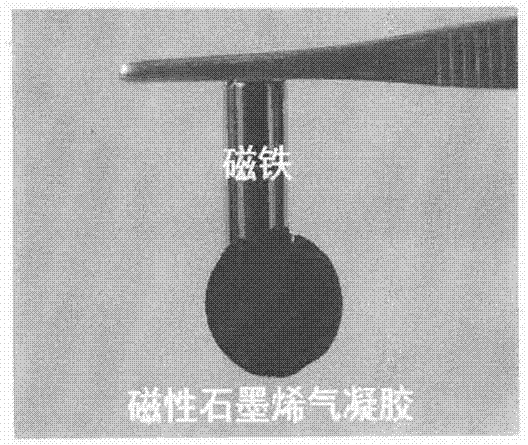

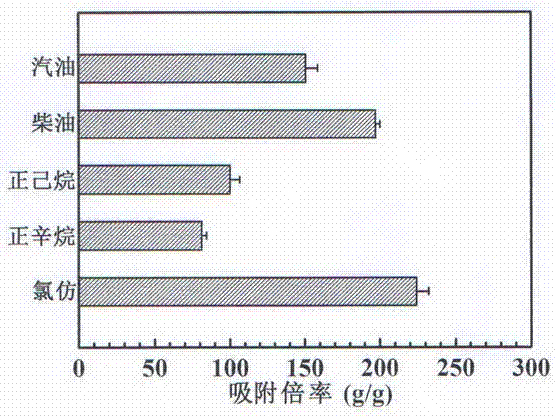

Preparation method of magnetic graphene aerogel

ActiveCN107140620ASimple and efficient operationLow costOther chemical processesGrapheneIonTemperature resistance

The invention relates to a preparation method of magnetic graphene aerogel. The preparation method comprises the steps of crosslinking dopamine modified graphene oxide with iron ions, carrying out heating reduction and self-assembling to form a three-dimensional graphene aerogel structure, and carrying out freeze drying and thermal treatment, so as to obtain a magnetic graphene aerogel material in situ. The preparation method which is simple in operation and preparation process and low in cost is utilized for preparing the magnetic graphene aerogel material with stable structure and good uniformity in situ and is a new technique for massively preparing the magnetic graphene aerogel material. The prepared material has good magnetic property, low density, good mechanical property, high temperature resistance, large specific surface area, super-strong adsorptive property, conductive property and wave absorbing property, is hopeful to be used as a novel functional magnetic material in the fields of water treatment, photoelectric materials, wave absorbing materials and the like and further has certain application values and market prospects.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +2

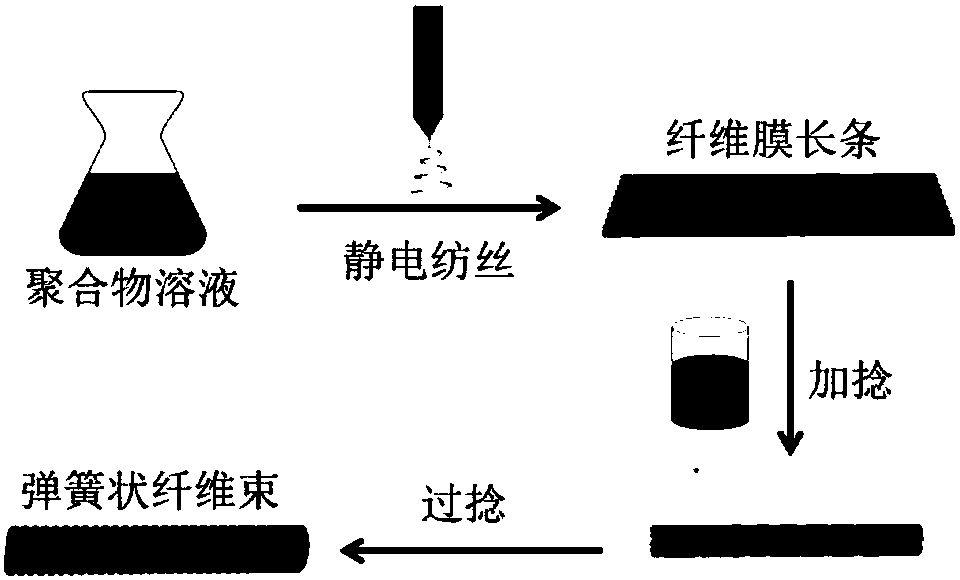

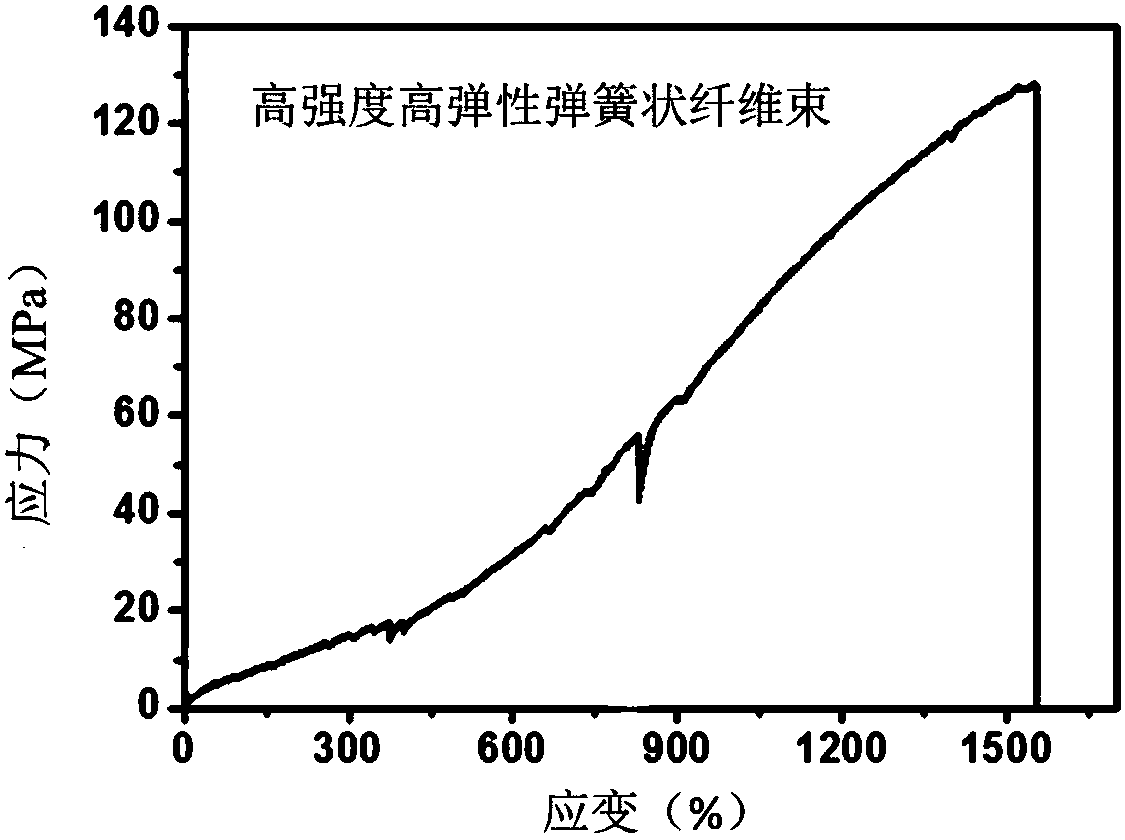

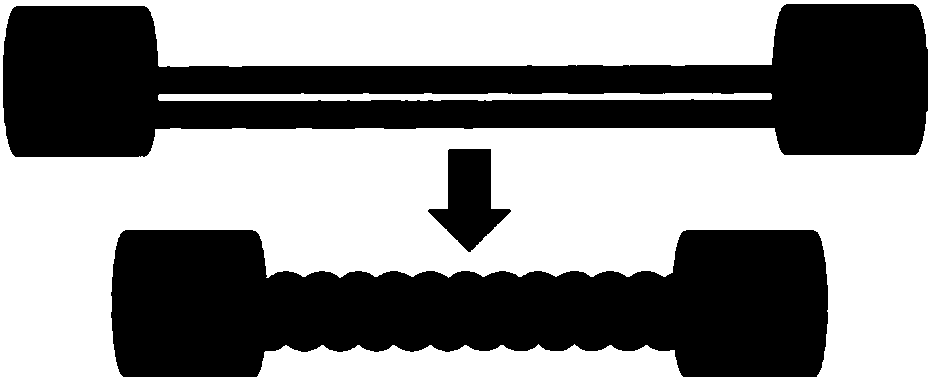

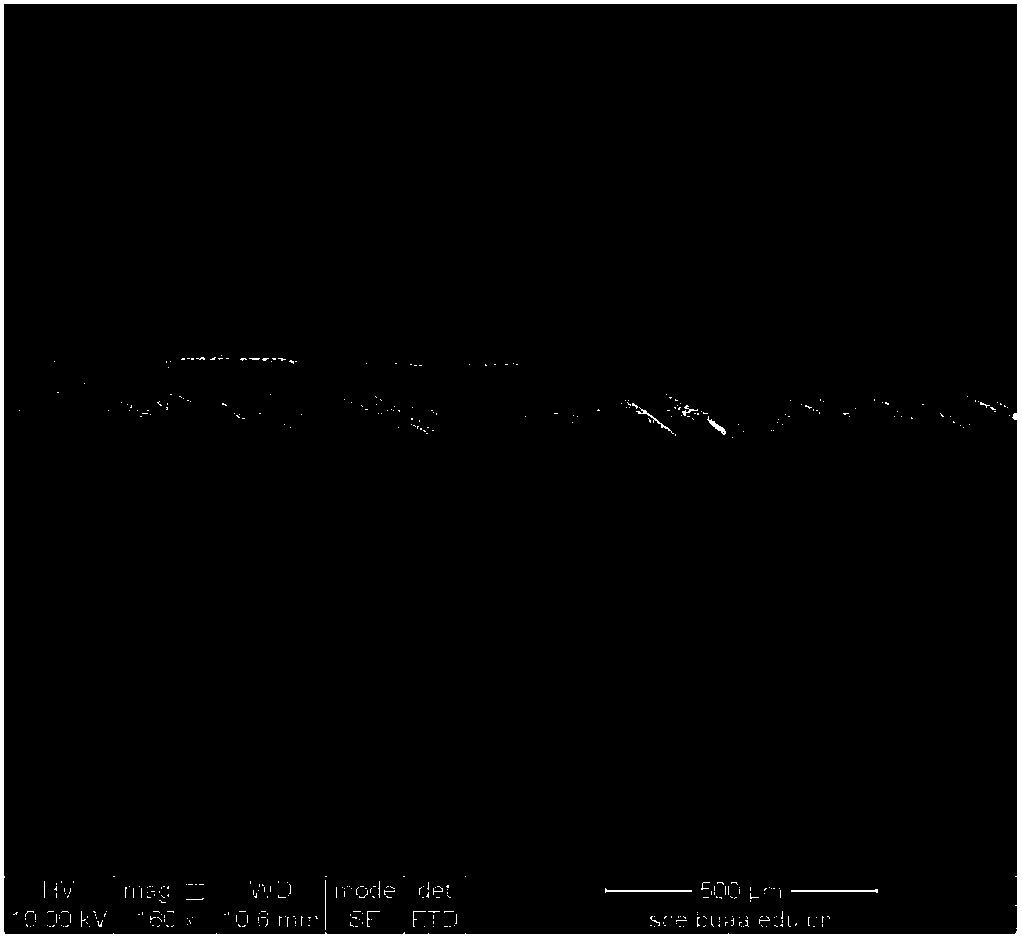

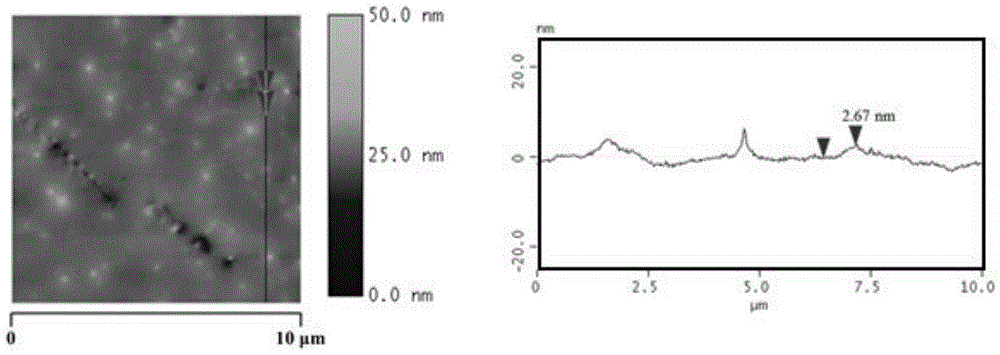

Preparation method for spring-like fiber bundle with high strength and high elasticity

InactiveCN107858780AHigh strengthStable structureFibre typesFilament/thread formingTensile strainPolymer science

The invention discloses a preparation method for a spring-like fiber bundle with high strength and high elasticity. Electrospinning and twisting technologies are adopted, and corresponding plasticizeris added in a preparation process. The fiber bundle is successfully prepared by the preparation method. The fiber bundle is of high mechanical strength, good flexibility and high tensile strain. Polymer is adopted as raw material of the fiber bundle, and by adding the corresponding plasticizer, the spring-like fiber bundle with high strength and high elasticity is acquired. The fiber bundle has astable structure and controllable dimensions and mechanical properties, and does not self-entangle and self-unwind, which is expected to be used in fields of woven conductive fabrics, stretchable sensors and flexible electronics.

Owner:BEIHANG UNIV

Multi-scale helical structure fiber bundle and preparation method thereof

ActiveCN107841808AAchieve compositeRealize large-scale mass productionElectro-spinningNon-woven fabricsFiber bundleElectrospinning

The invention discloses a multi-scale helical structure fiber bundle and a preparation method thereof. Through an electrospinning technique and a twisting and multistrand overtwist method, the preparation method of the multi-scale helical structure fiber bundle succeeds in preparing a series of multi-scale helical structure fiber bundles. The multi-scale helical structure fiber bundles can compound varied materials and integrate varied functions and have excellent intensity, flexibility, stretchability and resilience. Moreover, the diameter and length of the fiber bundles can be controlled, and the fiber bundles can be randomly bent and weaved and have broad application.

Owner:BEIHANG UNIV

Preparation method of high-crystallization graphene quantum dots capable of replacing fullerene

InactiveCN105692581AHigh carbon contentHigh crystalline structureMaterial nanotechnologySolventCvd graphene

The invention discloses a preparation method of high-crystallization graphene quantum dots capable of replacing fullerene. The preparation method comprises the steps: taking small-molecular carbohydrate as a carbon source, and synthesizing carbon quantum dots with the size of nanoscale by a one-step hydrothermal method; carrying out temperature controlled microwave reduction treatment on the carbon quantum dots, and removing oxygen-containing groups on the surface; mixing a chloroform solvent with a carbon quantum dot aqueous solution after the completion of treatment, carrying out extraction and separation operation on the mixed solution, collecting a lower-layer chloroform solution, and removing the lower-layer chloroform solvent by using a reduced pressure distillation method to obtain the final product. The preparation method has the advantages of easy operation, short time and high yield, and can realize large scale preparation; the graphene quantum dots soluble in an organic phase and uniform in size can be obtained through the one-step solvent selection separation action, and are expected to be applied in light detectors, solar cells and other organic photovoltaic fields.

Owner:TIANJIN UNIV

In-situ preparation method of multi-grade carbon based iron nickel hydroxide and product thereof and application

ActiveCN108295855AShape is easy to controlSimple equipmentCell electrodesCatalyst activation/preparationNanowirePolypyrrole

The invention relates to an in-situ preparation method of multi-grade carbon based iron nickel hydroxide and a product thereof and application. The method is characteirzed in that a polypyrrole nanowire / needle array grown in-situ on a carbon fabric by an electrochemical method and then is thermally processed to obtain the multi-grade carbon based needle shaped nanowire / needle array utilizing the carbon fabric as a substrate; and then the iron nickel hydroxide is loaded in situ. The method is simple, and low in cost; the prepared multi-grade carbon based nano needle / wire array is high in specific area controllable in appearance, high in oxygen evolution catalyzing performance, and widely applicable to the fields of energy storage and conversion.

Owner:CHONGQING UNIV

Preparation method for fluoride-free waterproof and moisture permeable fibrous membrane with photocatalytic self-cleaning function

InactiveCN109881490AFine fiber diameterSmall apertureFibre typesMonocomponent synthetic polymer artificial filamentFiberPolymer dissolution

The invention provides a preparation method for a fluoride-free waterproof and moisture permeable fibrous membrane with a photocatalytic self-cleaning function. The preparation method is characterizedby comprising the steps that step 1, an electrospun fiber membrane is prepared, wherein a hydrophilic polymer which cannot be dissolved in water is dissolved in a solvent to prepare an electrostaticspinning solution, and a fiber membrane base material is prepared through electrostatic spinning; step 2, the fiber membrane base material is dipped in an environmental-friendly fluoride-free waterproof agent solution or emulsion at the indoor temperature, then pre-dried and baked; step 3, nano-particles with the photocatalytic performance are utilized for conducting coating finish on the obtainedelectrospun fiber membrane, the obtained electrospun fiber membrane is subjected to high-temperature drying, and the fluoride-free waterproof and moisture permeable fibrous membrane with the photocatalytic self-cleaning function is obtained. The water resistance pressure of the prepared environmental-friendly fluoride-free waterproof and moisture permeable fibrous membrane is greater than or equal to 100 kPa, the water vapor transmission amount of the prepared environmental-friendly fluoride-free waterproof and moisture permeable fibrous membrane is greater than or equal to 15,000 g / m<2> / d, the strength of the prepared environmental-friendly fluoride-free waterproof and moisture permeable fibrous membrane is greater than or equal to 30 Mpa, and the fluoride-free waterproof and moisture permeable fibrous membrane can effectively degrade organic pollutants adhering to the surface of the fluoride-free waterproof and moisture permeable fibrous membrane.

Owner:DONGHUA UNIV

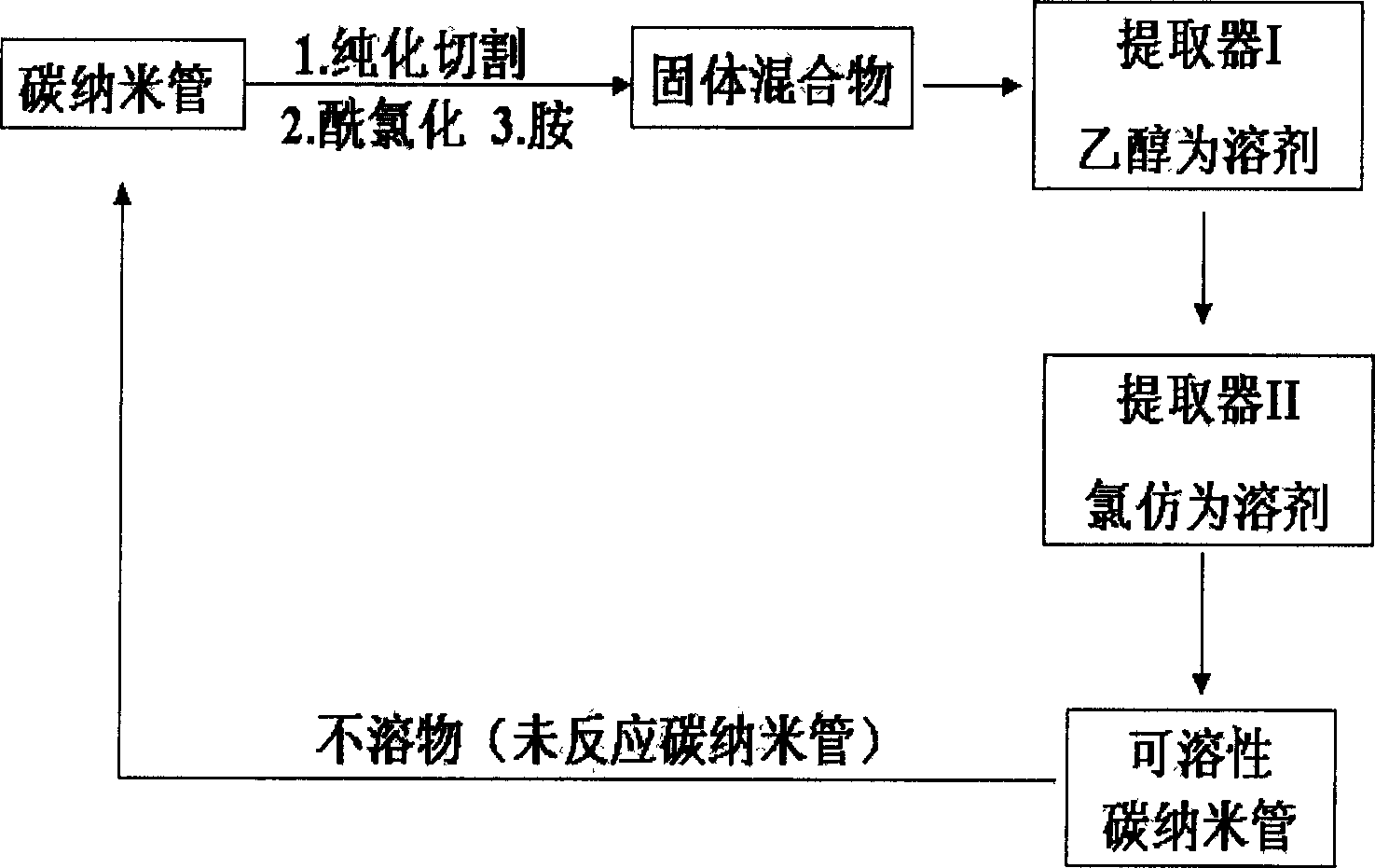

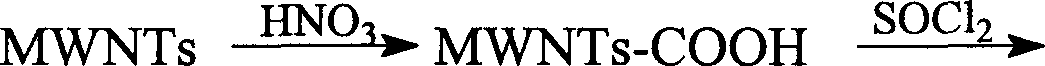

Method for preparing carbon nanometer tube in large-scale

InactiveCN1552620AEasy to manufactureEnable mass manufacturingCarbon nanotubeChemical vapor deposition

A process for preparing soluble carbon nanotubes in large scale includes such steps as using concentrated nitric acid to purify and cut the multi-wall carbon nanotubes (MWNTs) prepared by CVD to obtain carboxyl contained carbon nanotubes, reacting on sulfoxide chloride to obtain acyl chloride, and reacting on lipoamine.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Modified charcoal for adsorbing phosphorus in water body as well as preparation method and application thereof

InactiveCN111807453AImprove adsorption capacitySolve the problem of reduced adsorption functionWater treatment parameter controlOther chemical processesEnvironmental engineeringUltrasonic oscillation

The invention discloses modified biochar for adsorbing phosphorus in a water body as well as a preparation method and application of the modified biochar. The preparation method of the modified biochar comprises the following steps: carrying out acid treatment and alkali treatment on biochar; and placing the biochar in a modifying solution and performing ultrasonic oscillation. The modified biochar prepared by the preparation method disclosed by the invention has the advantages of high metal ion loading capacity, good adsorption performance and the like; the modified biochar can be widely usedfor adsorbing pollutants (such as phosphorus and lead) in the environment, efficient adsorption of the pollutants (such as phosphorus and lead) in water can be achieved, the modified biochar can be continuously used for adsorbing the pollutants after being simply activated, and the high use value and application prospects are achieved. Meanwhile, the preparation method disclosed by the inventionalso has the advantages of simple process, convenience in operation, easily available raw materials, low cost and the like, can realize large-scale preparation, is suitable for industrial production,and is beneficial to popularization and application of the modified charcoal.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of 3D (three-dimensional) porous nitrogen-sulfur doped anode carbon material based on short rod construction

InactiveCN108821258AEasy to operateLow costCell electrodesCarbon preparation/purificationHierarchical porousMaterials science

The invention discloses a 3D (three-dimensional) porous nitrogen-sulfur doped anode carbon material based on short rod construction. The material is prepared with a method comprising steps as follows:a uniform solution containing trithiocyanuric acid is slowly added to an aqueous graphene oxide solution containing dissolved melamine, and a mixed solution is sufficiently stirred at 50-120 DEG C; aproduct is calcined in inert atmosphere at 550-1150 DEG C, and the 3D porous nitrogen-sulfur doped anode carbon material based on the short rod construction is obtained. The 3D porous nitrogen-sulfurdoped anode carbon material based on the short rod construction has a short rod-like porous shell structure and comprises a framework formed by polymerization of melamine and trithiocyanuric acid supermolecules, a 3D structure formed by the framework and graphene and a doping structure of nitrogen-sulfur atoms in graphene. The carbon material as an anode of a lithium battery and a sodium batteryhas good rate capability, and by means of the larger specific surface area and hierarchical porous structure, sulfur loading is easy to realize. The preparation method is simple to operate and low incost, and large-scale preparation can be realized.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com